Inflating thermal-expansion forming method for titanium alloy panel

A titanium alloy and plate technology, applied in the field of parts forming, can solve the problems affecting the batch production quality of parts, the large difference in the gap between the tires, and the lack of detection devices, so as to save energy and labor costs, reduce the difference of parts, and unify the process method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

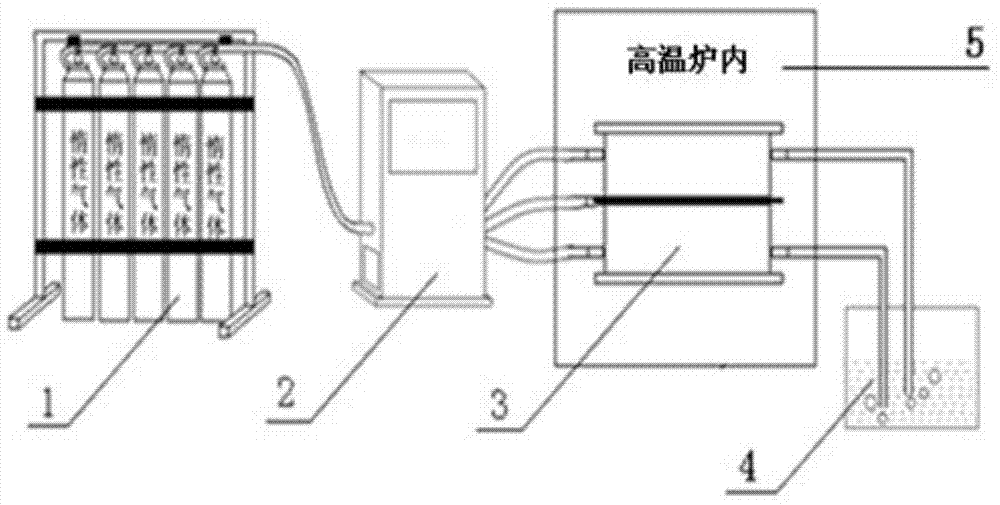

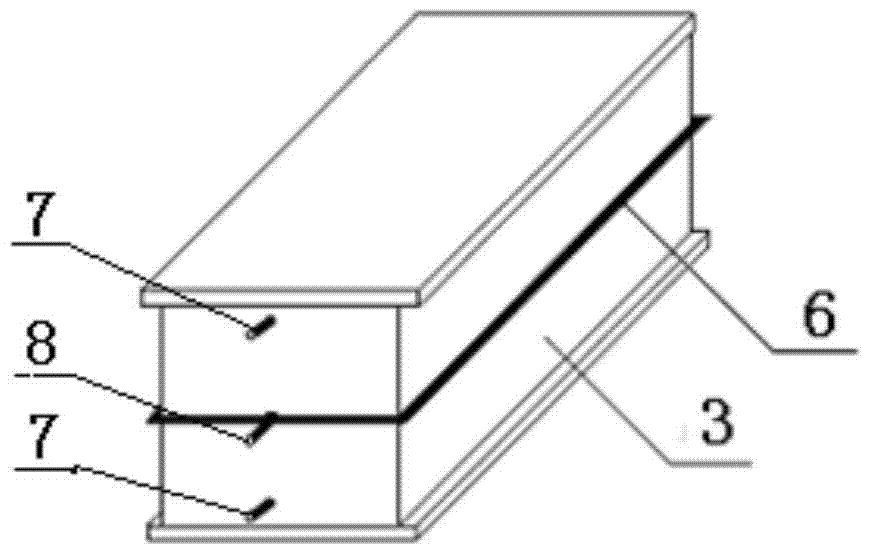

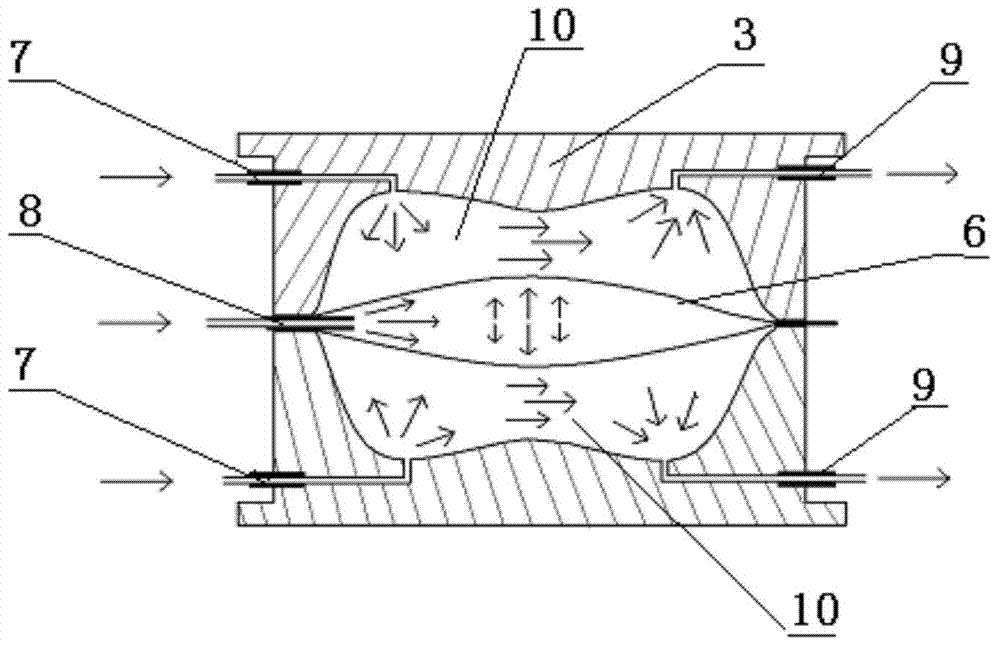

[0021] Referring to the accompanying drawings, the method for inflating and thermally expanding the titanium alloy plate of the present application is shown in the figure. The forming tooling 3 is composed of a group of thermoforming molds with the same notch size and can be buckled and sealed up and down. The forming cavity 10 of the forming mold is The bottom of the bottom is respectively provided with an air inlet 7 and an air outlet 9, and there are two titanium alloy sheet materials 6 that need to be formed. The gas source 1 is a set of inert gas bottles, and the gas source control cabinet 2 connects the gas source 1 to It communicates with the forming tool 3 and the detection container 4 , and the forming tool 3 is placed in the high temperature furnace 5 .

[0022] 1) Preparation of board wool

[0023] Coat the surfaces of the two titanium alloy sheet wools 6 that need to be formed with solder stopper except for the process periphery, and then buckle the surfaces of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com