Method for removing nitrogen monoxide gathering in large oxygen-making machine

A nitrous oxide and oxygen generator technology, applied in refrigeration and liquefaction, liquefaction, solidification and other directions, can solve the problems of waste of cooling capacity, non-recovery, and explosion of hydrocarbons in oxygen generators, so as to reduce and eliminate power costs. Potential safety hazards and small cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1 preliminary preparation

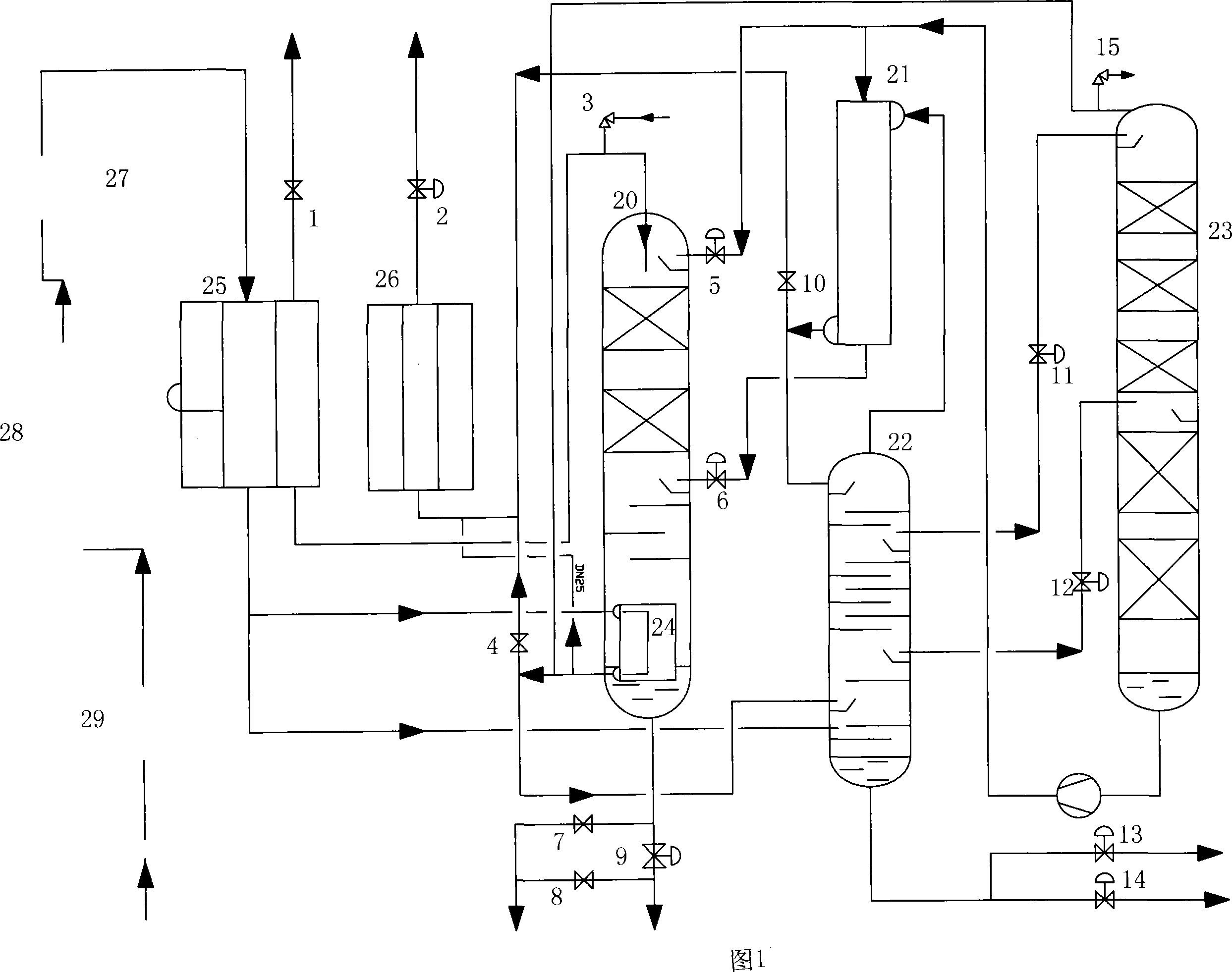

[0017] As shown in Figure 1, before the large-scale oxygen generator is ready to stop, the liquid oxygen at the bottom of the low-pressure tower 23 is sent into the tank to reduce the liquid oxygen level as much as possible; the liquid in the pressure tower 22 is sent to the low-pressure tower 23 to reduce the pressure as much as possible The liquid air liquid level of tower 22; Open the drain valve at the bottom of methane removal tower 20 to drain liquid, make the liquid oxygen liquid level at the bottom of methane removal tower 20 lower as far as possible; Air compressor 29 is unloaded; Stop the gas and liquid of large oxygen generator product output.

[0018] 2 switch valve

[0019] As shown in Figure 1, open the air outlet valve 2 of the argon plate heat exchanger 26, open the safety valve 3 on the top of the demethanizer 20, and open the air channel from the liquid oxygen evaporator 24 to the argon plate heat exchanger 26 in the demeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com