Vacuum cooling case

A vacuum and cold box technology, which is applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as radial vibration and impact, reduced strength and stiffness, and fracture, so as to reduce stress, reduce wall thickness, and reduce cooling loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail in conjunction with accompanying drawing now.

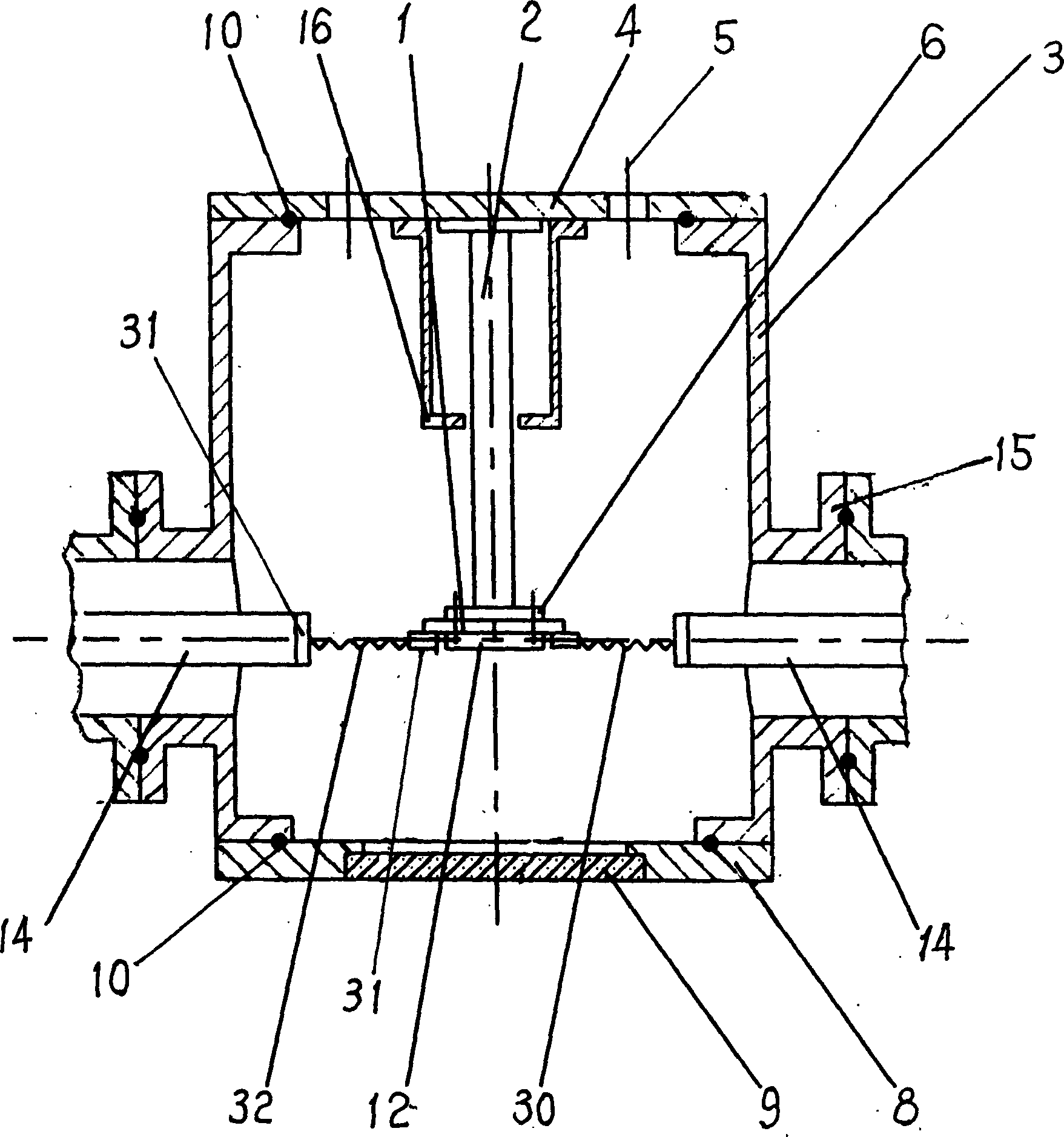

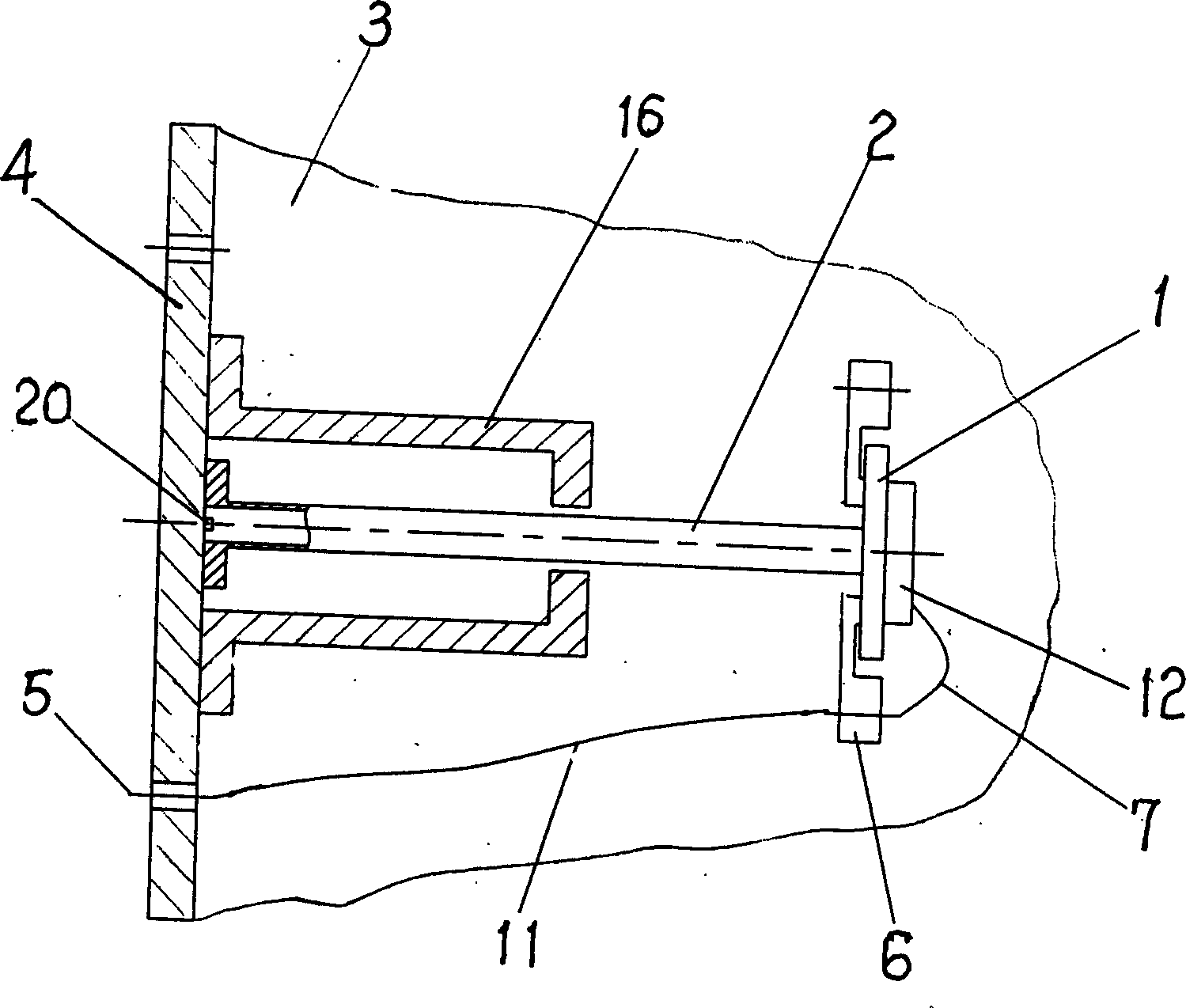

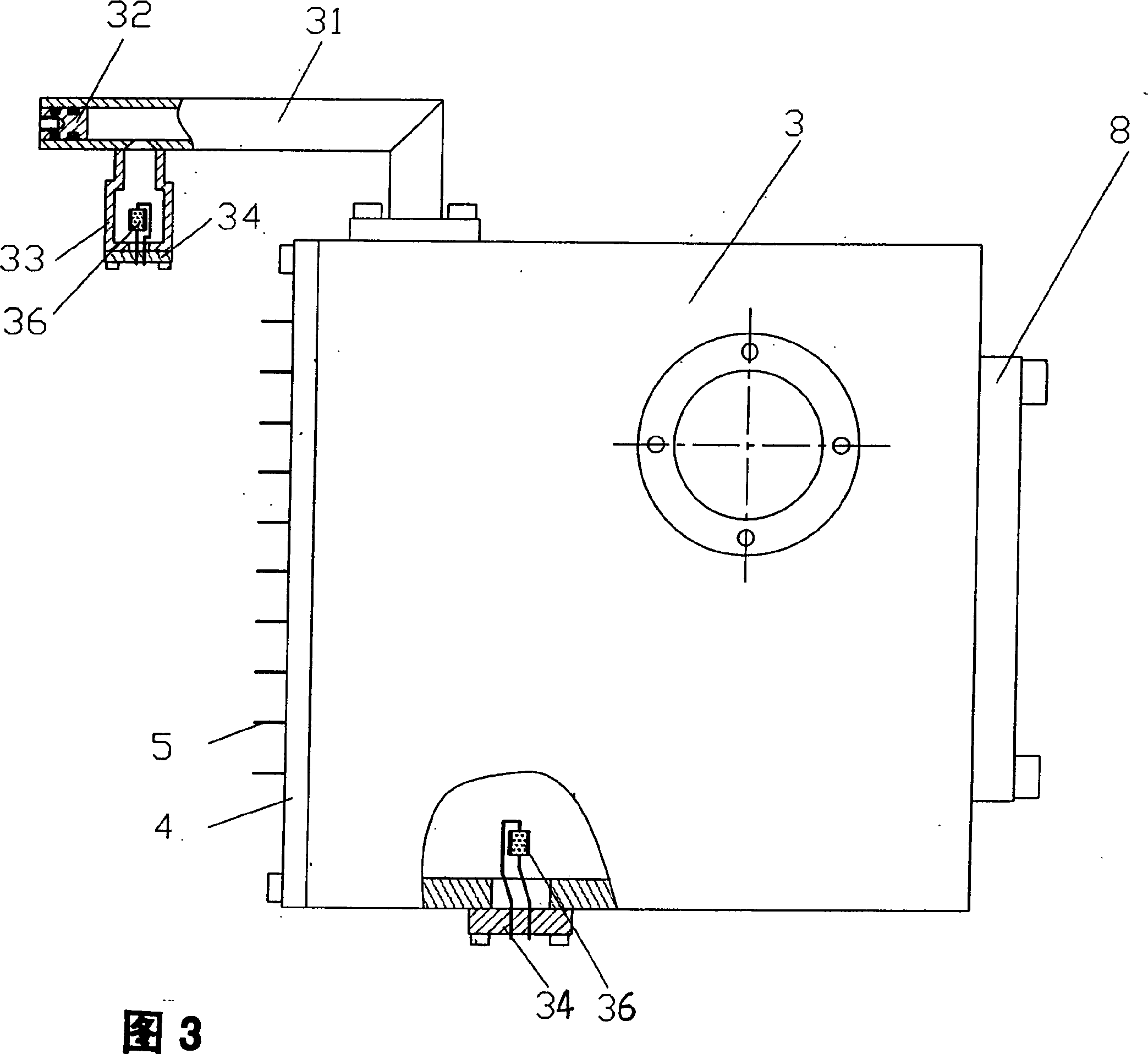

[0018] See figure 1 with figure 2 As shown, the vacuum cold box of the present invention includes a box body 3 , a cold platform 1 and a cantilever 2 . The front of the box body 1 is equipped with a light-through window composed of a window frame flange 8 and an infrared window 9, and a sealing ring 10 is arranged therebetween for vacuum sealing and fixed with screws. The light signal enters through the light-through window and is detected by the infrared detector 12 placed on the cold platform 1 . The rear wall of the box body 3 is a sealed cable plate 4 with output pins 5, which is fixed on the box body 3 by screws. The rear end of the cantilever 2 is fixed on the sealed cable plate 4, and the front end suspended in the box body 3 fixes the cold platform 1. The cantilever 2 is a thin-walled tube of low thermal conductivity material, its two ends are closed, and the inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com