Full-body high-strength damp-proof gypsum block and preparation method

A gypsum block and shape technology, which is applied in the field of building wall materials, can solve the problems of insufficient hanging bearing capacity, poor moisture-proof performance, and poor uniformity of the wall, and achieve the effects of eliminating mildew, increasing strength, and improving brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

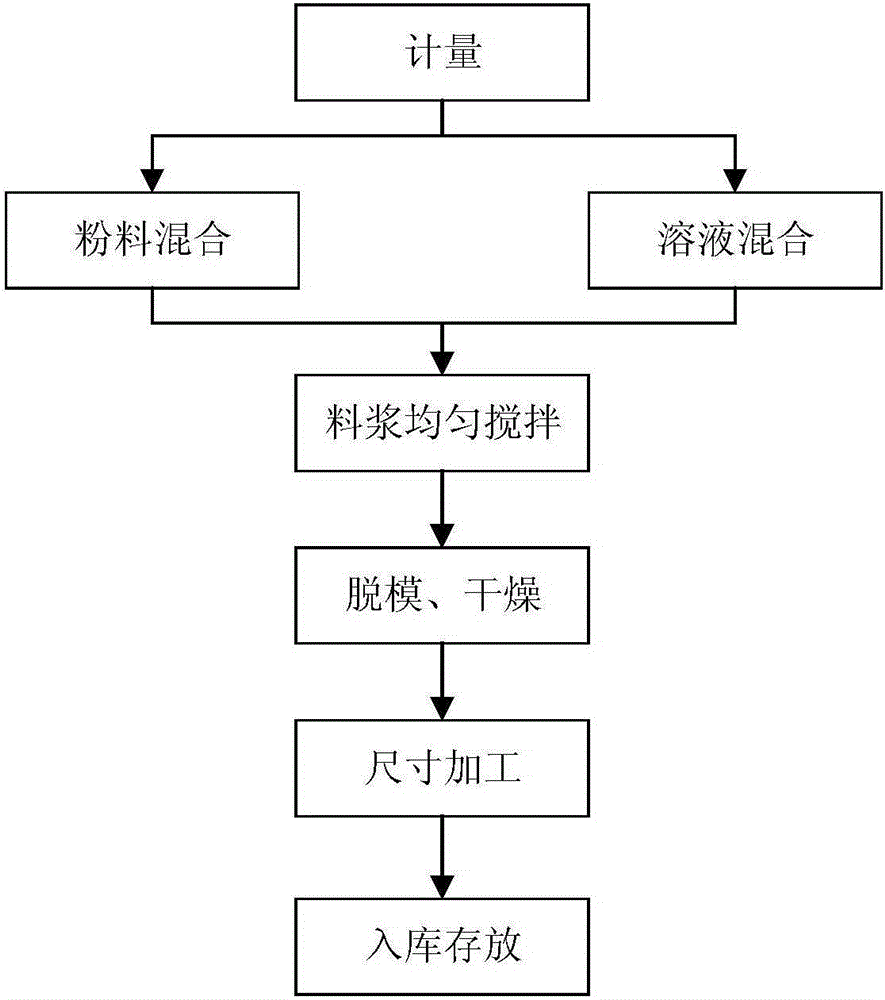

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation of gypsum block

[0039]Preparation of building gypsum: Gypsum powder with a purity of more than 90% is calcined. During the calcination process, according to the performance difference of gypsum powder and the performance sampling results of building gypsum products, the calcination temperature (145±10 degrees Celsius) is adjusted in time to ensure that the produced building gypsum The content of medium hemihydrate gypsum is high and the phase composition is stable; the performance parameters of the produced building gypsum reach 2 hours flexural strength ≥ 3.5MPa, compressive strength ≥ 10MPa, the initial setting time is about 5min, the final setting time is about 8min, and the standard thickness is 72± 2%.

[0040] Raw materials: see Table 1;

[0041] Table 1: Each composition and weight ratio table used in each embodiment 1

[0042] project

Example 1

Example 2

Example 3

plaster of construction

51.2%

...

Embodiment 2

[0047] Embodiment 2: the preparation of gypsum block

[0048] Raw materials: see Table 1; among them, the cement is P·O52.5R cement, the fiber is 10mm long glass fiber, the water reducing agent is naphthalene-based water reducing agent, the waterproofing agent is methyl silicone resin, and the pigment is iron oxide red.

[0049] Preparation method: with embodiment 1. Among them, the mold adopts a hollow block mold with a thickness specification of 150mm. Blocks are quickly dried at 45 degrees Celsius for two days.

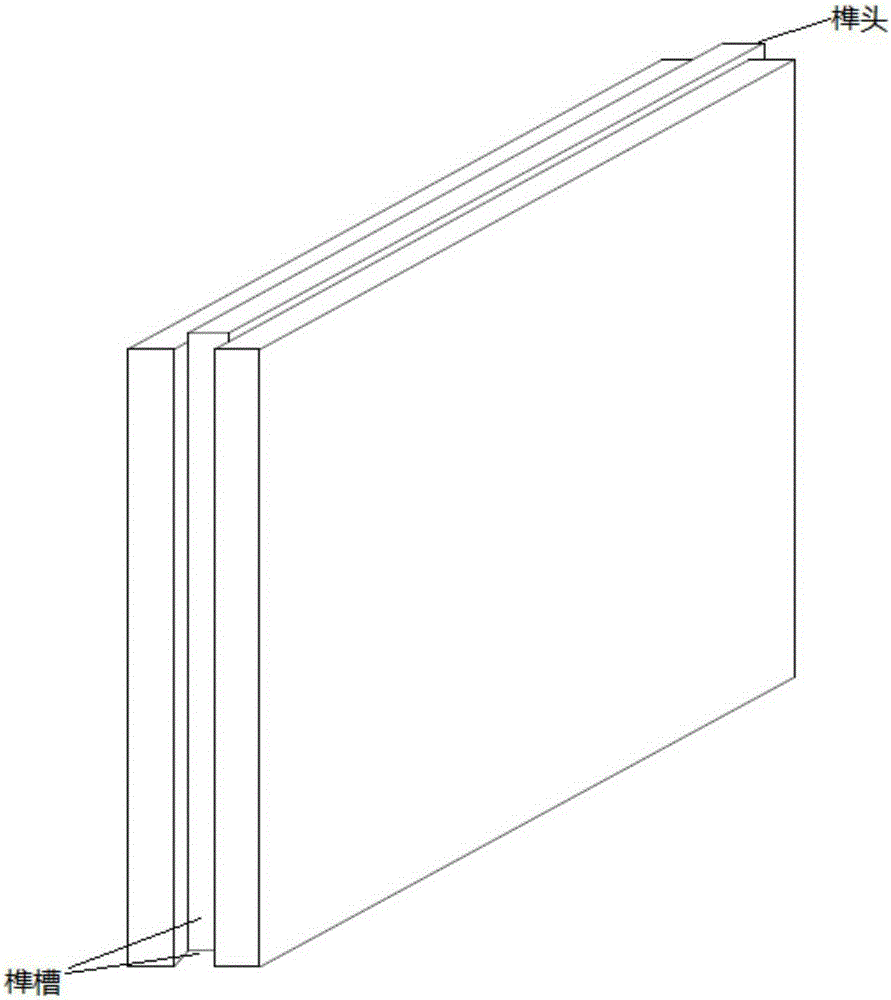

[0050] Structure: such as image 3 As shown, the block is a hollow block with a thickness of 150mm. The right and upper sides of the block are provided with tenons, and the left and lower sides are provided with a tenon and groove structure. environment.

[0051] Effect verification: The test results are shown in Table 2.

Embodiment 3

[0052] Embodiment 3: the preparation of gypsum block

[0053] Raw materials: see Table 1; among them, the cement is P·C42.5R cement, the fiber is paper pulp, the water reducing agent is naphthalene-based water reducing agent, the waterproofing agent is methyl hydrogen silicone oil emulsion, and the pigment is iron oxide red.

[0054] Preparation method: with embodiment 1. Among them, the mold adopts a hollow block mold with a thickness specification of 200mm. Blocks are quickly dried at 45 degrees Celsius for two days.

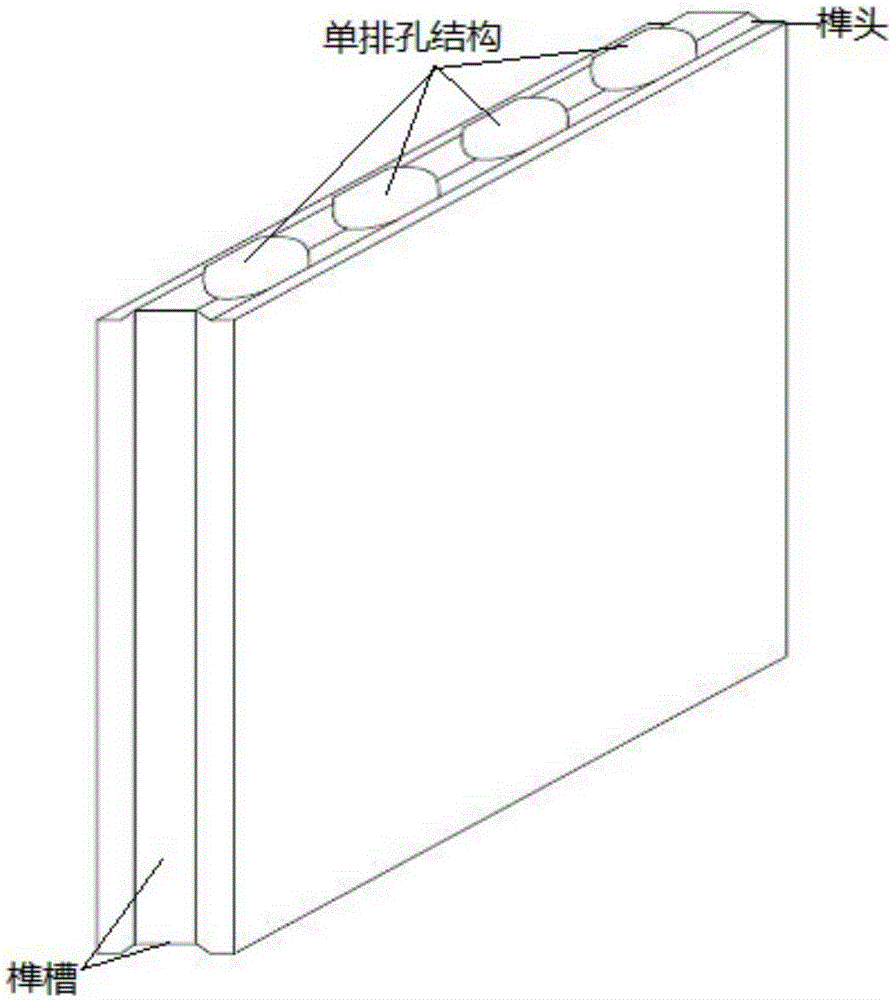

[0055] Structure: such as Figure 4 As shown, the block is a hollow block with a thickness of 200mm. The right and upper sides of the block are provided with tenons, and the left and lower sides are provided with tenon and groove structures. At the same time, there are double-row hole structures, which have excellent moisture-proof and heat-preserving effects. Can be used on exterior walls.

[0056] Effect verification: The test results are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com