Patents

Literature

265 results about "Gypsum block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gypsum block is a massive lightweight building material composed of solid gypsum, for building and erecting lightweight fire-resistant non-load bearing interior walls, partition walls, cavity walls, skin walls and pillar casing indoors. Gypsum blocks are composed of gypsum plaster, water and in some cases additives like vegetable or wood fiber for greater strength. Partition walls made from gypsum blocks require no sub-structure for erection and gypsum adhesive is used as bonding agent, not standard mortar. Because of this fundamental difference, gypsum blocks shouldn't be confused with the thinner plasterboard (also known as wallboard or gypsum board) used for paneling stud walls.

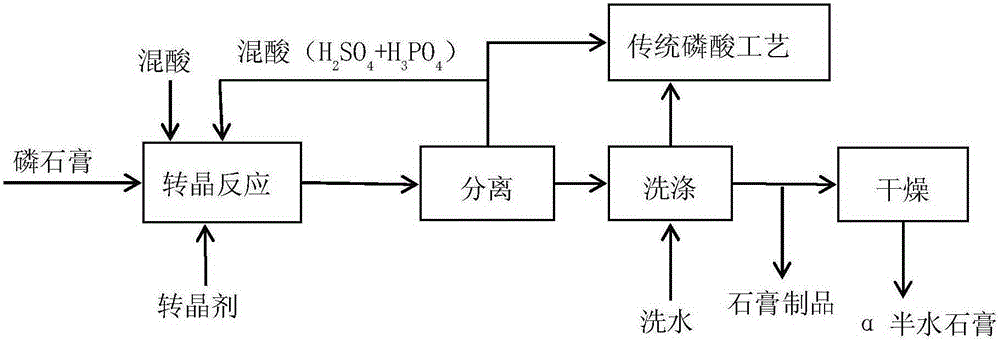

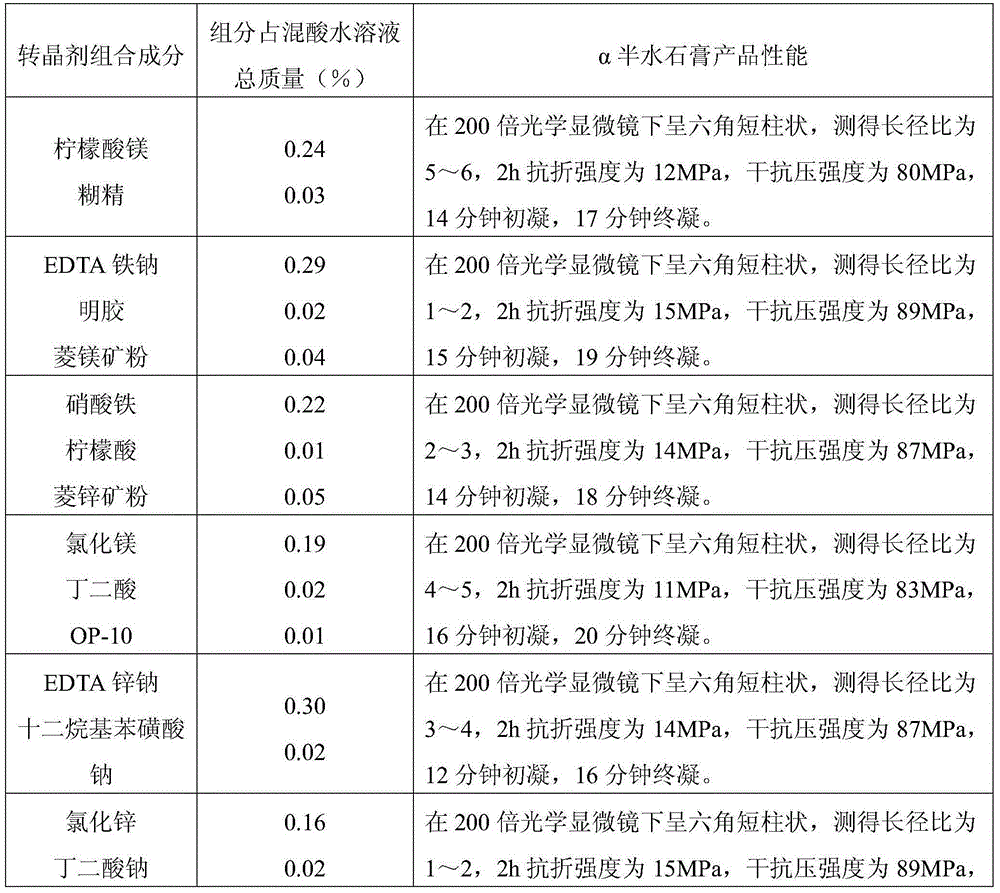

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

Processing method of Chinese bacon

The invention discloses a processing method of Chinese bacon. According to the invention, each ton of a raw material of pork sections is uniformly applied with 40 to 60kg of sea salt, 8 to 16kg of white granulated sugar, 10 to 20L of cooking wine, and 6 to 10kg of flavorings; the pork sections are then placed in a camphorwood bucket; the pork sections are pressed by using clean gypsum blocks on the surfaces; the pork sections are preserved for 9 days while protected from light; and the pork sections are baked under a temperature of 50 to 55 DEG C for approximately 20 days above a fire of charcoal or active carbon; the pork sections are cleaned by burning, sterilized through irradiation, and are processed through vacuum packaging. According to the invention, during a Chinese bacon preserving process, gypsum blocks are used for pressing, such that the Chinese bacon is naturally colored; no brushwood fire smoking is adopted, such that the Chinese bacon is not smoky, and basically no harmful substance is contained in the Chinese bacon. The Chinese bacon satisfies a national foodstuff security standard, and is a green foodstuff. The method is advantaged in simple processing, easy operation, shortened processing time, and saved production cost. The production is not restricted by seasons. With the method, scaled production can be realized.

Owner:镇巴县长兴实业有限责任公司

Water-tolerant gypsum hollow building block and production method thereof

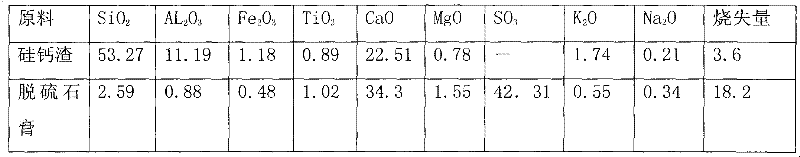

InactiveCN101614051ASolve the problem of land occupation for emissionsRealize recycling of resourcesMixing operation control apparatusCeramic shaping apparatusSlagGypsum block

The invention discloses a water-tolerant gypsum hollow building block which is produced by taking chemical gypsum, hydraulic cementing material, exciting agent and LY gelling agent as raw materials and adopting the processes of mixing, shaping and maintenance. The chemical gypsum is an industrial gypsum of ardealite, desulfurization gypsum or fluorine gypsum. The hydraulic cementing material is an industrial slag of yellow phosphorus slag, blast furnace slag or fly ash. The exciting agent is lime, propylene macromoleclar polymer or inorganic mineral concavo-convex stick earth binder. A production method of the water-tolerant gypsum hollow building block can effectively solve the problem that the discharge of the industrial slag occupies land, relieve the environment-protection pressure brought to enterprises and the society and realize the cyclic use of resources inside the enterprises. The water-tolerant gypsum building block provides an approach for comprehensively utilizing the industrial slag, is an energy-saving and environment-friendly building material product and conforms to state policies for recycling economy and sustainable development. The production method requires simple apparatuses and low cost, and the finished product rate of the production method is over 95 percent. The production method is suitable for the enterprises producing byproduct industrial gypsum.

Owner:GUIZHOU KAILIN GRP CO LTD

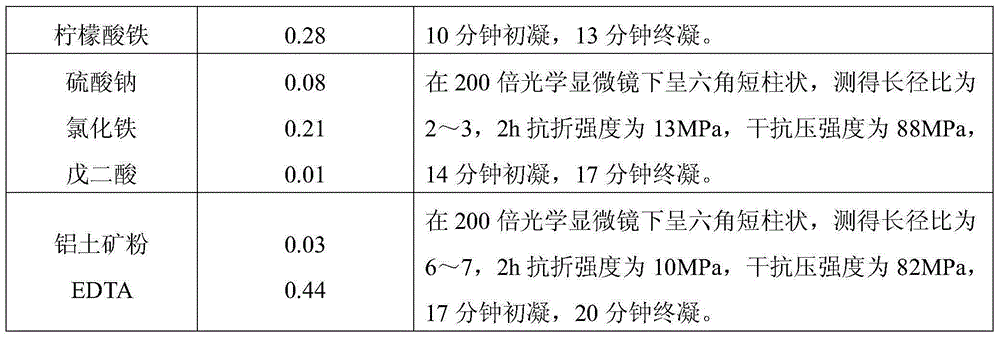

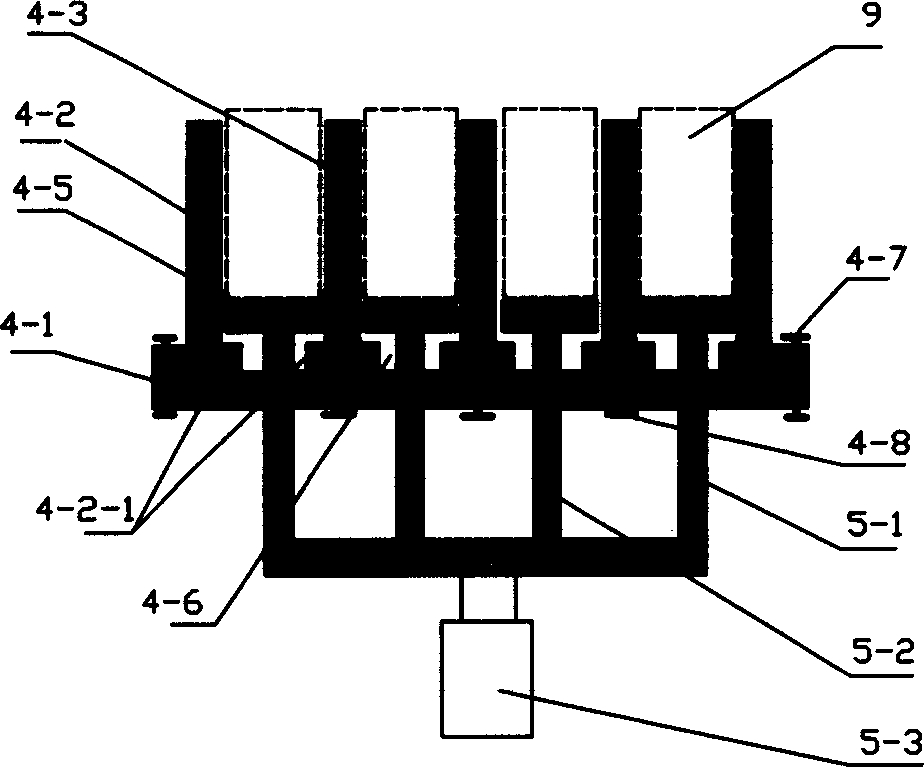

Multifunctional gypsum block die

InactiveCN101249668ALow priceReduce manufacturing costMould separation apparatusMouldsEngineeringGypsum block

The invention relates to a multi-functional gypsum block mold. A rail is provided with a mold box carriage, the base of which is connected via a first hinge with a front side mold plate and a back side mold plate parallel to each other. A cavity formed by the front side mold plate and back side mold plate is divided into small cavities by diaphragms arranged in parallel. The left and the right heads of the small cavities are sealed by an end mold plate, which is connected with an upper mold and a bottom mold through the concave and convex surfaces of the end mold plate. The upper end of the front side mold plate and the back side mold plate are connected by a locking device. The base is equipped symmetrically with a strip hole along the vertical center line of the base. The lower end of the hinge is fixed on the base through the bolt of the strip hole. The end mold plate is fixed with a positioning pin, which is inserted into the pin slot of the diaphragm or the front side mold plate or back side mold plate. The mold can produce the gypsum block with different types and specifications through replacing the end mold plate, the bottom mold and the upper mold, achieves multiple functions for one machine, and saves production cost.

Owner:胡云模

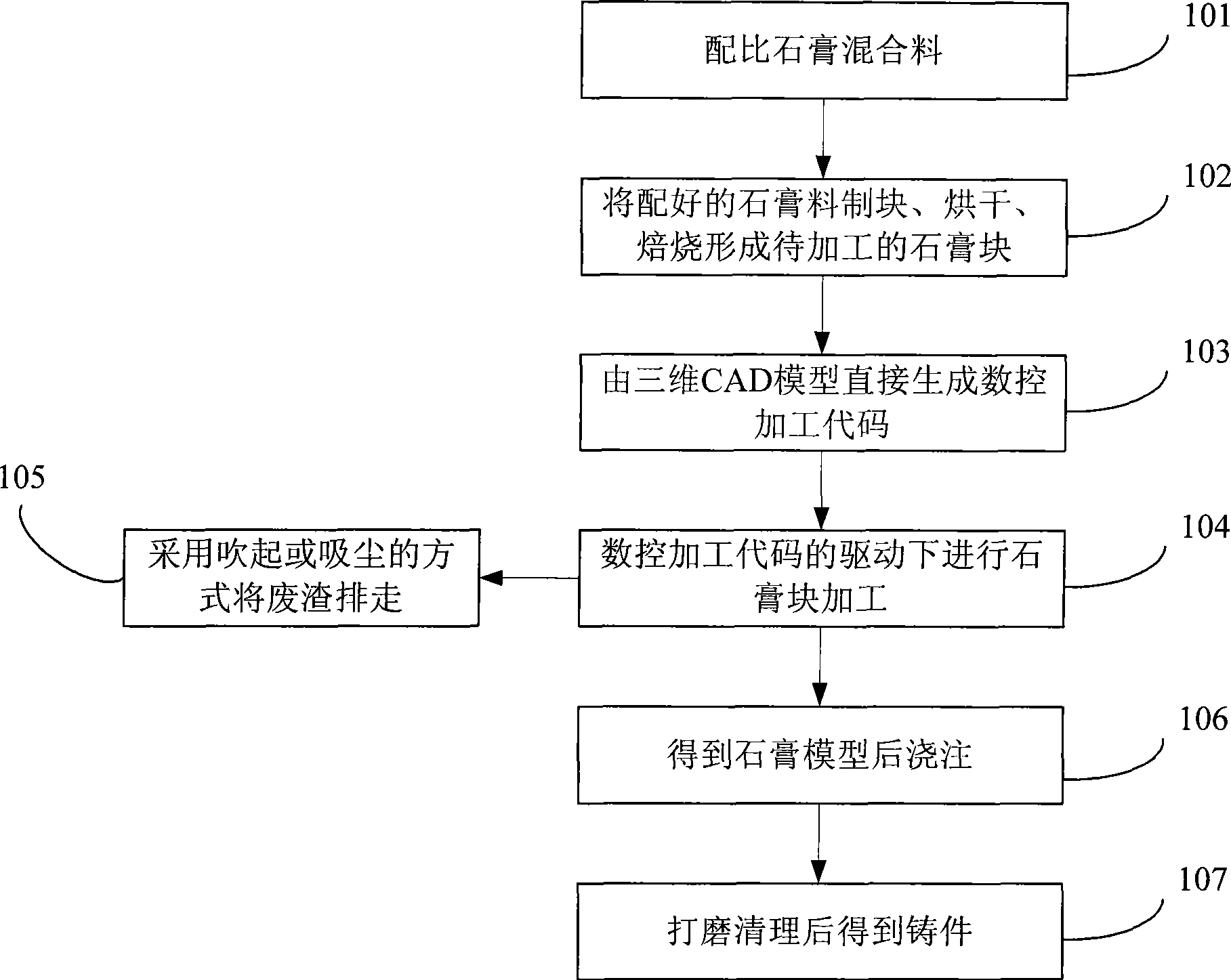

Digitalization processing method of gypsum mould

ActiveCN101439390AEfficient molding methodRapid prototyping methodFoundry mouldsFoundry coresDigital signal processingDigital control

The invention discloses a method for digital processing a gypsum mold, belonging to the crossed technical field of precision casing and digital control processing. The method comprises the steps as follows: a gypsum mixture is made into a block to be dried and calcined into a gypsum block to be processed firstly; a three-dimensional CAD model of the gypsum mold is transformed into digital control processing code directly; the gypsum block is arranged on a processing device and milling processing is carried out under the drive of the digital control processing code; waste residue produced during processing is taken away by blew-out air current or is absorbed by a dust collector; and finally, the well processed gypsum mold is cast to obtain a cast. Compared with the existing gypsum patternmaking method, the processing method has high processing precision, saves the step for manufacturing a mold, reduces the processing procedures, shortens the production period and reduces the production cost. The method is especially suitable for processing and manufacturing a single piece or a small batch of precise cast.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method for preparing alpha semi-hydrated gypsum at low cost and prepared alpha semi-hydrated gypsum and gypsum block

The invention provides a method for preparing alpha semi-hydrated gypsum at low cost. The method comprises the following steps: (1) pretreating ardealite; (2) pretreating a waste hydrochloric acid solution; (3) pretreating calcium carbide mud; (4) preparing an activity agent; and (5) preparing the alpha semi-hydrated gypsum through a normal pressure hydrothermal method. According to the method, three industrial wastes are used as main raw materials, the alpha semi-hydrated gypsum is prepared by adopting a simple process, emission of hazardous wastes is reduced, the industrial wastes are recycled, and the prepared alpha semi-hydrated gypsum is good in performance and low in cost and can be widely applied to the construction industry.

Owner:WUHAN UNIV OF TECH

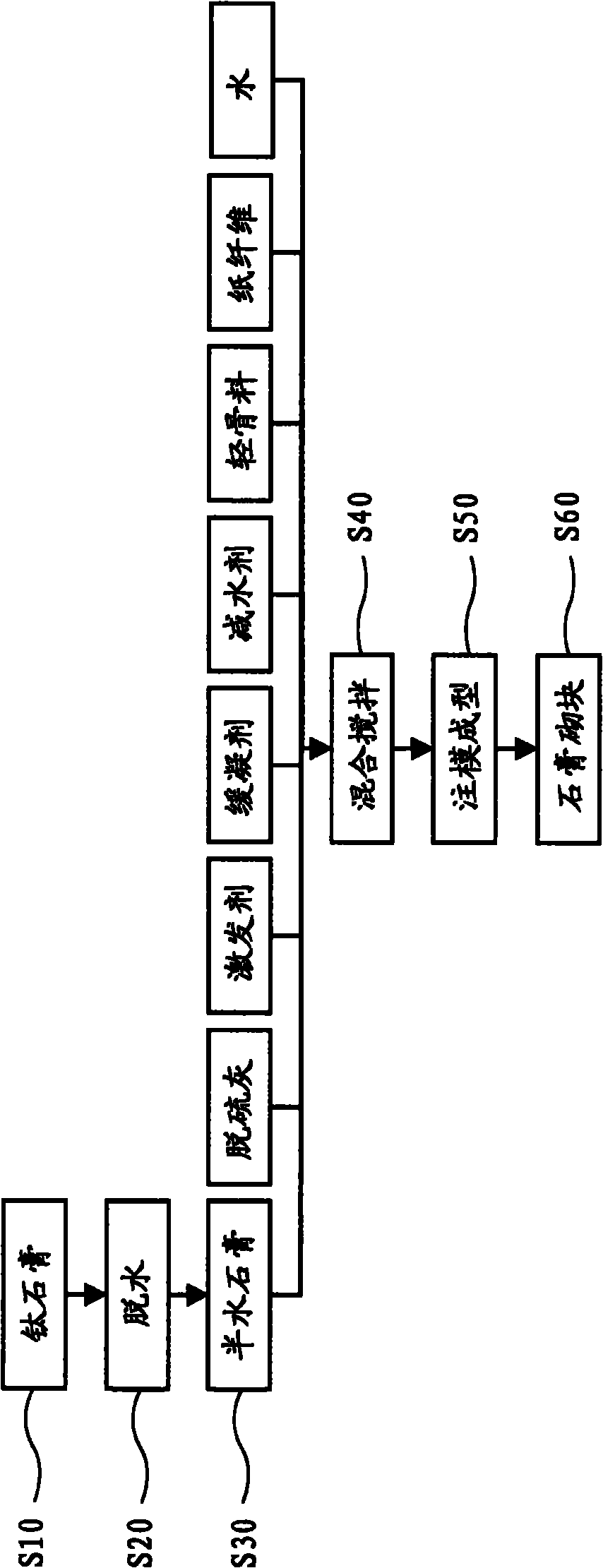

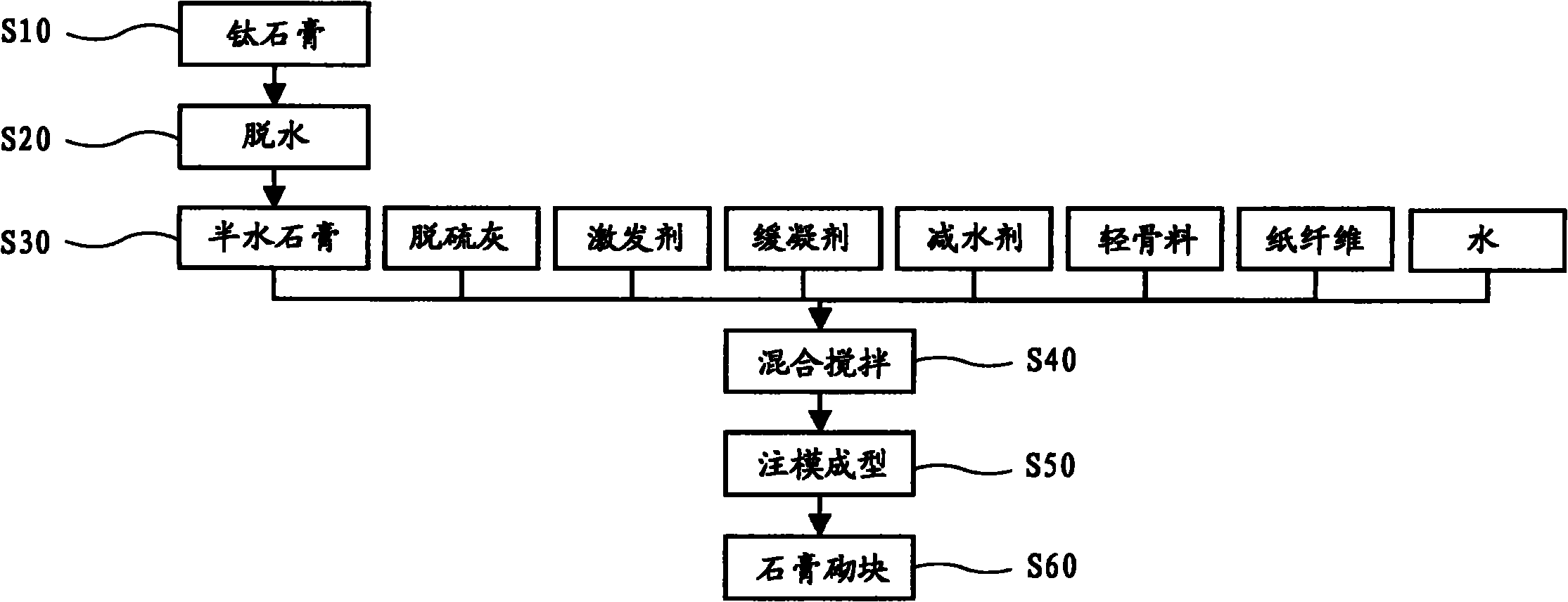

Method for preparing gypsum building block with titanium gypsum

InactiveCN101920520ASolve stacking problemsSolve pollutionSolid waste managementCeramic shaping apparatusSlurryWater reducer

The invention discloses a method for preparing a gypsum building block with titanium gypsum. The method comprises the following steps: crushing titanium gypsum to fine powder of which grain size is less than 80mu m, dewatering and drying at 180-220 DEG C; mixing the dried titanium gypsum powder, semidry FGD residues, light-weight aggregate, paper fibre, gypsum booster, retarder and water reducing agent evenly according to a certain ratio, then adding water to stir evenly; pouring the evenly mixed slurry in a standard mould, performing vibro-moulding; and performing natural curing for 2 hours, demoulding, and airing to obtain the gypsum building block. The gypsum building block prepared by the method of the invention is characterized by small volume, low density, high strength and softening coefficient and the like; and the physical performance of the prepared gypsum building block completely meets the national building material industry standard JC / T698-1998. The method for preparing the gypsum building block with titanium gypsum provided by the invention provides a new application way of titanium gypsum and solves the stacking problem of titanium gypsum and the environmental pollution problem.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Full-body high-strength damp-proof gypsum block and preparation method

The invention discloses a full-body high-strength damp-proof gypsum block and a preparation method. The full-body high-strength damp-proof gypsum block is prepared from the following materials in percentage by weight: 50-55% of building gypsum, 42-45% of water, 1-3% of cement, 0.2-1.5% of fiber, 0.2-1.0% of wood powder, 0.2-0.5% of a water reducing agent, 0.05-0.4% of a water proofing agent, and 0.005-0.02% of paint. According to the full-body high-strength damp-proof gypsum block prepared by adopting the uniform stirring technology, adding the waterproof component and strengthening the toughening component, the uniformity of the full body of a wall body material is improved, and the strength, the humidity resistance, the shock resistance, the permeation resistance, the crack resistance and the fireproof performance of the wall body material are improved; various performance indexes are superior to that of the conventional wall body material and the common gypsum block, cracking and permeation of the built wall body are avoided, and the engineering quality is ensured.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

Gypsum building block manufactured by chemical gypsum and industrial waste and manufacture method thereof

InactiveCN1919781AHigh strengthImprove water resistanceSolid waste managementMicro bubbleCrystal structure

The invention discloses a plaster block and preparing method through chemical plaster and industrial waste material, which is characterized by the following: the chemical plaster is allocated by anhydrous gypsum with different hydrating speeds and hydrated crystal structures at 2: 1-3: 1 into semi-plaster through frying; the rate of cement in the hydrating course and anhydrous gypsum rate in the micro-bulking course is 1:12-1:3; the air-entrainer is added in the raw material, which generates dispersing micro-bubble without light-weight aggregate.

Owner:武汉冶金建筑研究院

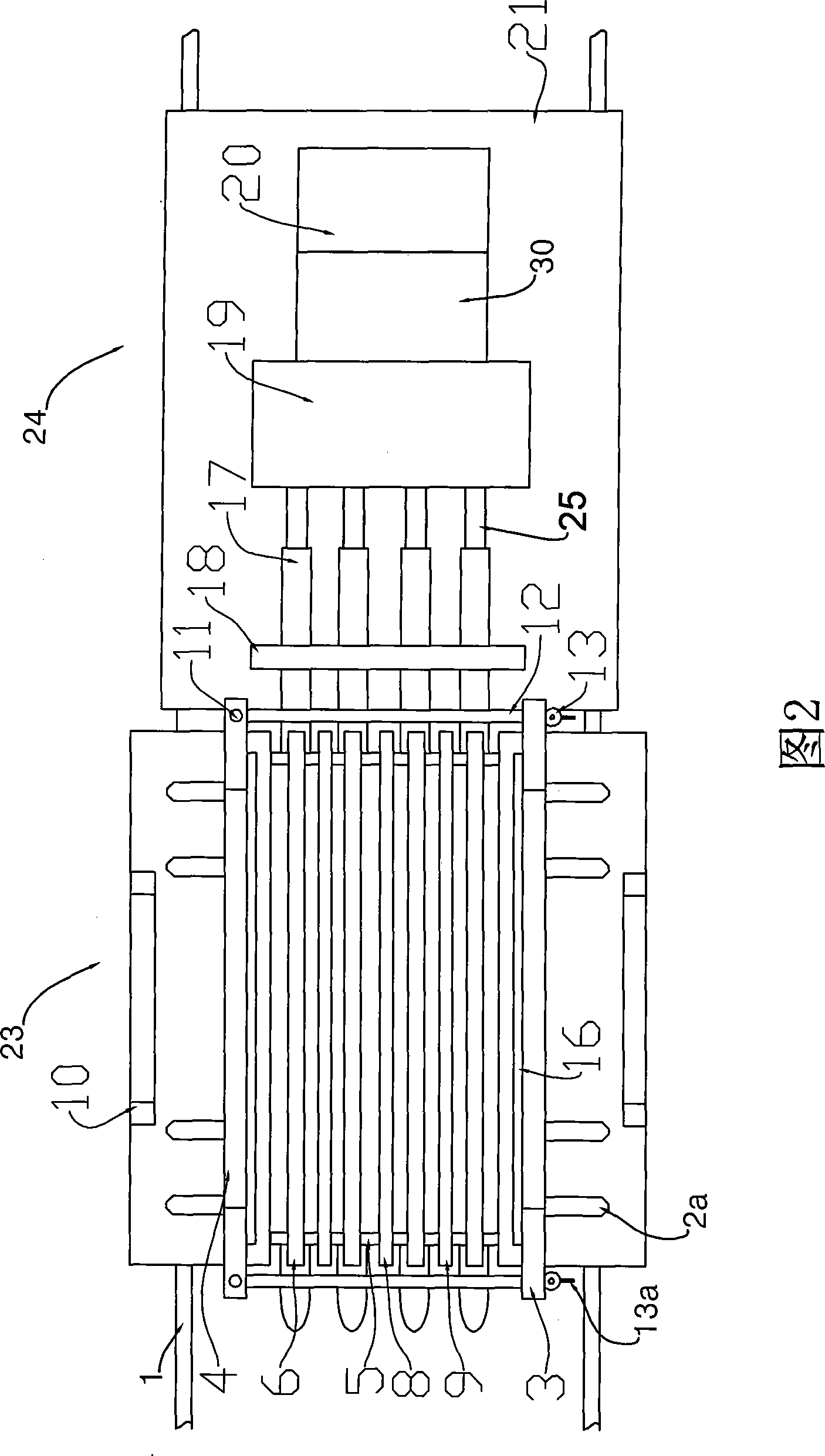

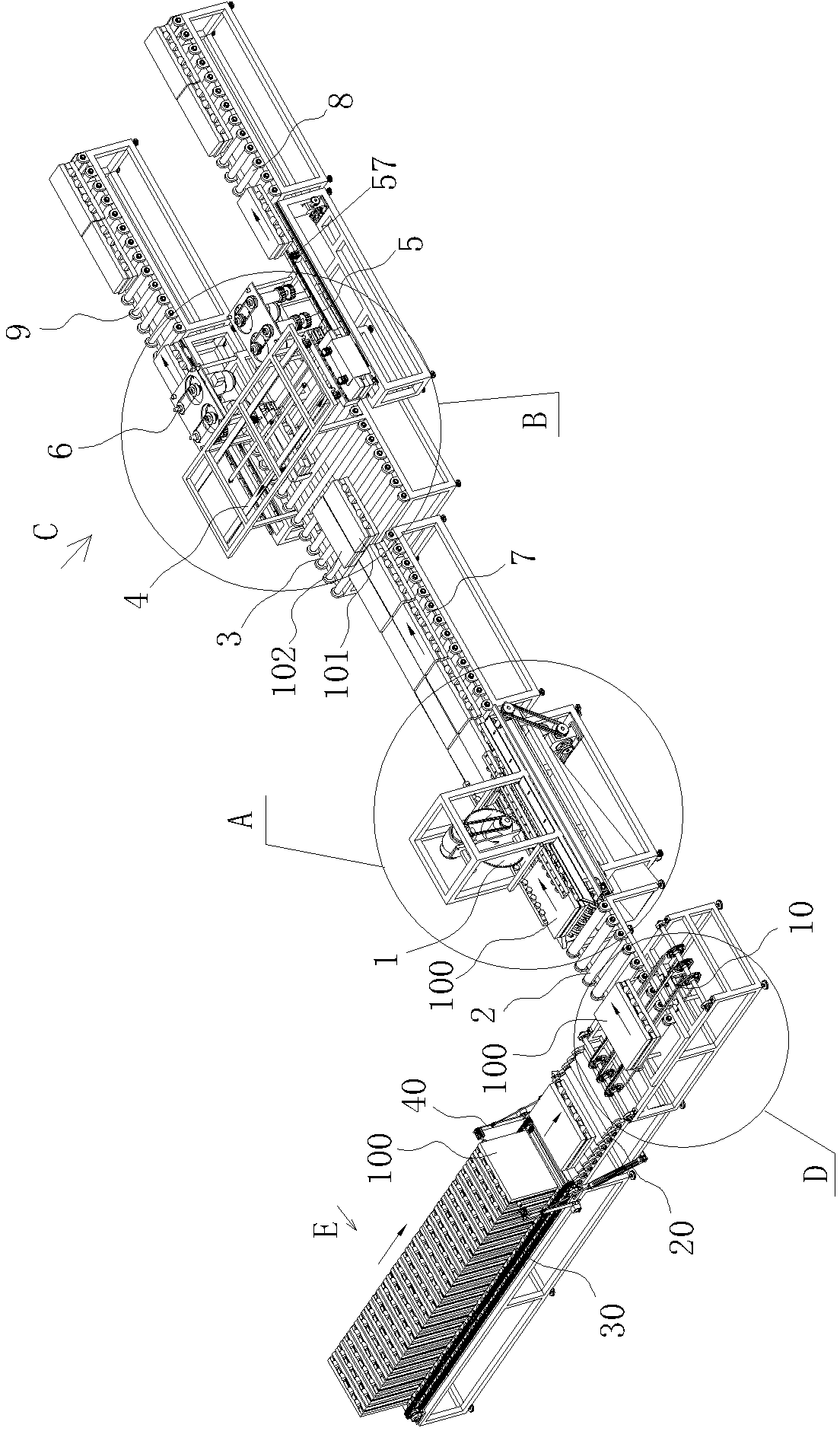

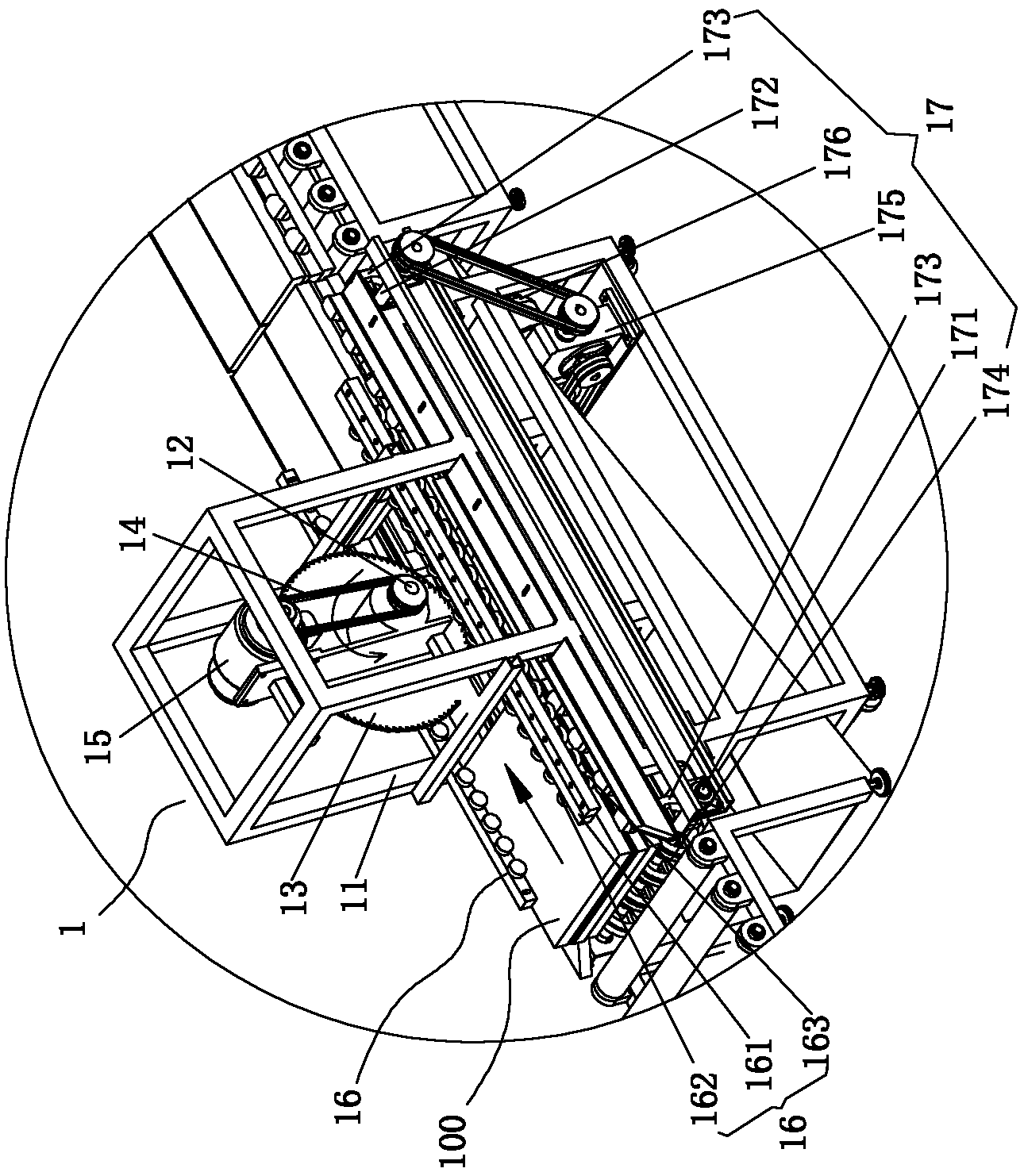

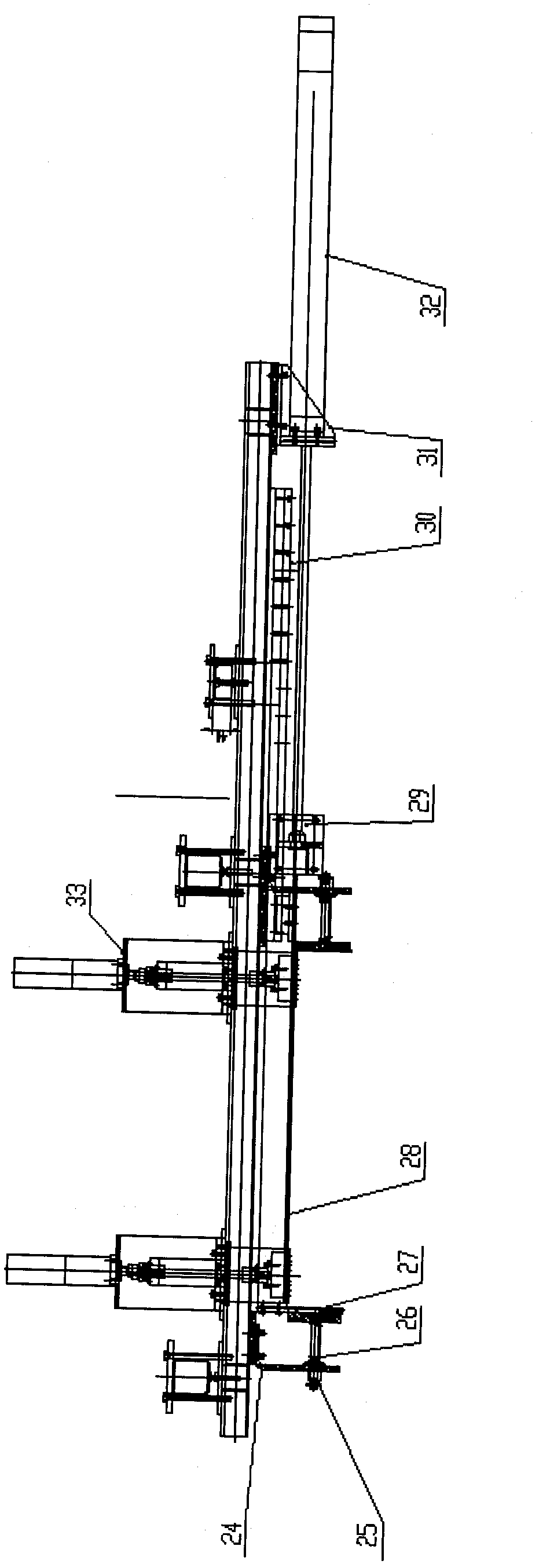

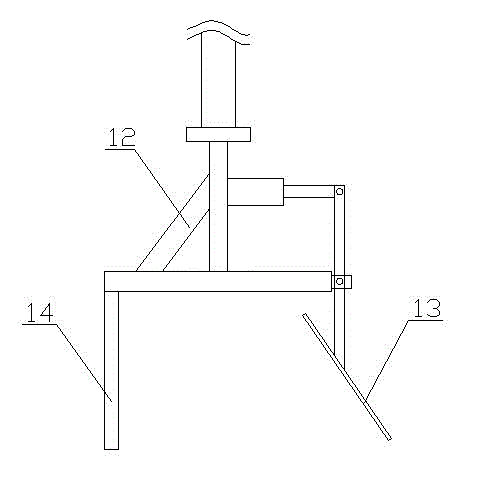

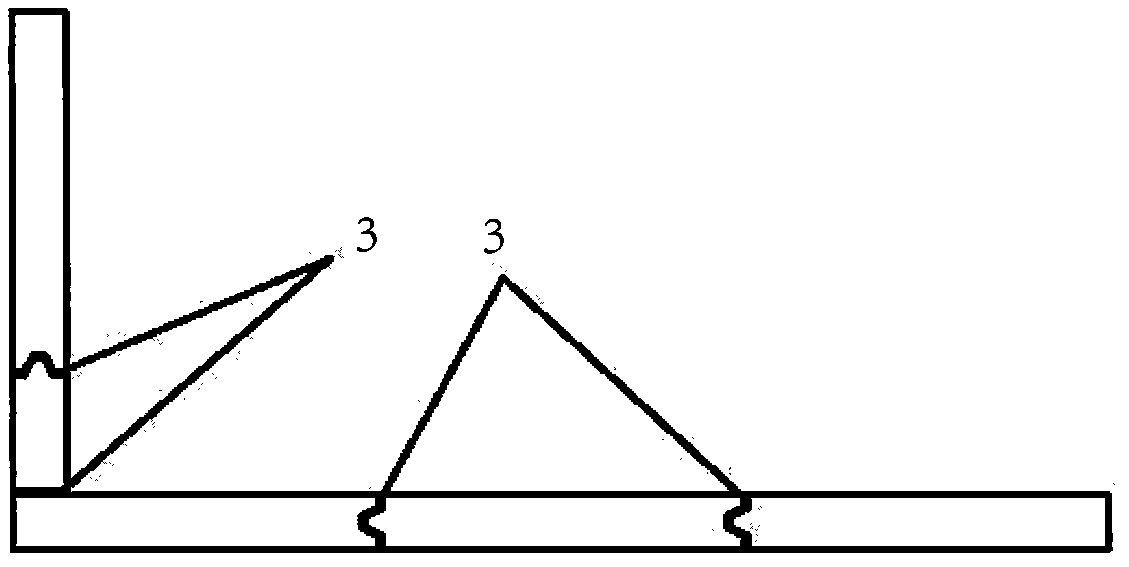

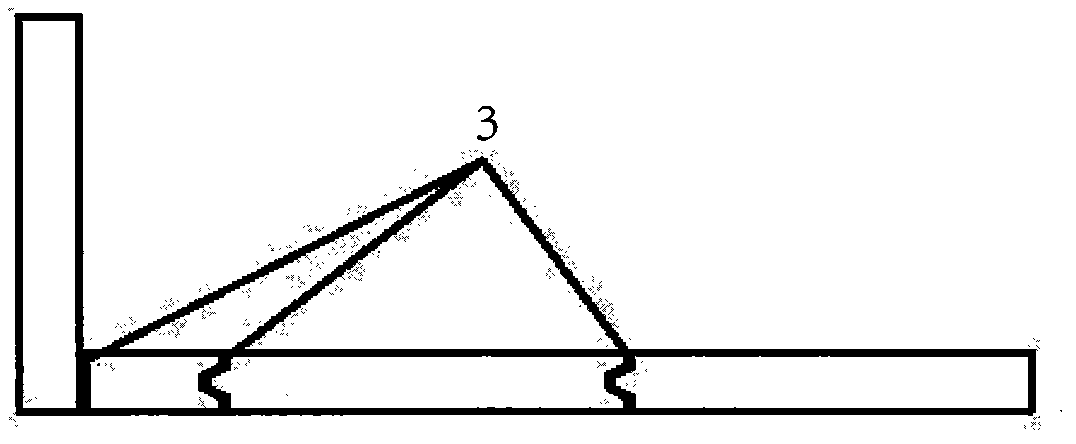

Production line of cut milling groove of gypsum block

ActiveCN102700007ARealize automatic cuttingReduce reprocessing costsWorking accessoriesStone-like material working toolsProduction lineControl system

The invention discloses a production line of a cut milling groove of a gypsum block. The production line comprises a cutting mechanism, a first conveying mechanism, a second conveying mechanism, a shunt conveying mechanism, a block tenon milling mechanism, a block mortise milling mechanism and a PLC (programmable logic controller) control system, wherein the first conveying mechanism is joined in the front of the cutting mechanism; the first conveying mechanism horizontally conveys blocks to the cutting mechanism; the second conveying mechanism is joined behind the cutting mechanism; the shunt conveying mechanism is arranged on the rear part of the second conveying mechanism; the block tenon milling mechanism and the block mortise milling mechanism are arranged on two sides of the shunt conveying mechanism; the PLC system coordinates each mechanism to act; and the second conveying mechanism conveys the blocks cut by the cutting mechanism below the shunt conveying mechanism, and the shunt conveying mechanism respectively transmits two cut blocks to the block tenon milling mechanism and the block mortise milling mechanism to respectively process tenons and mortises on the sides of the blocks. According to the production line, automatic cutting of the gypsum block and automatic processing of the tenons and mortises on the sides of the blocks are achieved, the production efficiency is high, and the reprocessing cost of the gypsum block is effectively reduced.

Owner:ZHANGZHOU ZHENGBA BUILDING MATERIAL TECH

Moistureproof titanium gypsum hollow building block and preparation method thereof

The invention discloses a moistureproof titanium gypsum hollow building block, comprising the following raw materials in parts by weight: 50-70 parts of titanium gypsum powder (type beta), 15-35 parts of building gypsum powder (beta type), 1-5 parts of excitant, 1-5 parts of neutralizing agent, 0.1-1 part of retarder, 0.2-0.5 part of water reducer, 0.1-0.3 part of waterproofing agent and 25-40 parts of water. The invention also discloses a preparation method of the hollowing building block. The invention has the advantages that a production process flow is simple and direct, cost is low, appearant density is low (800kg / m<3>), softening coefficient of the gypsum hollow building block is more than 0.60, each index completely meets requirements in JC / T698-2010 gypsum block; as the production efficiency is high, one movable pouring gypsum hollow building block production line consumes about 0.3 million tons of titanium gypsum waste slag; industrial policy supported by China can be met, and the requirements on low carbon, environmental protection, energy conservation, consumption reduction and recycling economy can be met; and important significance to ecological environment protection can be achieved.

Owner:ANHUI SENKE NEW MATERIAL

Method for preparing alpha-type high-strength gypsum powder

The invention discloses a method for preparing alpha-type high-strength gypsum powder. The method comprises the steps: A, preparing a base material, cleaning, drying and classifying natural gypsum ore to be placed into a storage, and breaking gypsum blocks, wherein the content of crystal water >=19%, and the grade of dihydrate gypsum >=96%; B, stacking the gypsum blocks into charging baskets in a layering mode, using a travelling crane for lifting the charging baskets into still kettles, fixing the charging baskets, and closing kettle covers, wherein two charging baskets are arranged in each kettle; adjusting intake pressure of the still kettles, heating materials inside the kettles, exhausting cold air inside the kettles, and starting to conduct steam pressing; C, after the steam pressing is completed, drying the materials inside the same kettle, conducting steaming into heating pipes, and conducting drying; D, conducting slot-type discharging, conducting grinding, and conducting packaging to obtain the alpha-type high-strength gypsum powder. The method is easy to implement and convenient to operate, the labor intensity of workers is greatly reduced, and the production cost is reduced. The alpha-type high-strength gypsum powder produced by the process is high in strength, high in hydration speed, beneficial to saving the stripping time, and capable of being produced in a large-scale mode.

Owner:湖北龙源石膏有限公司

Composite flyash-gypsum block (brick) and its production process

The composite flyash-gypsum block (brick) is produced with building gypsum powder 30-40 wt%, flyash 30-40 wt%, lime 10-14 wt%, perlite 13-18 wt%, gypsum water reducing agent 0.6-1.4 wt% and flyash activator 0.8-1.2 wt% and through the following processes: mixing the mixture of ground lime and flyash with water solution of gypsum water reducing agent and flyash activator; adding gypsum powder and alkali resisting glass fiber or produce slurry through stirring; molding the slurry inside mold through vibration to produce block or brick; demolding and curing to obtain product with water content less than 5 %. The composite block or brick of the present invention has high softening coefficient, simple production process and low cost and may be used in moist environment.

Owner:季东波

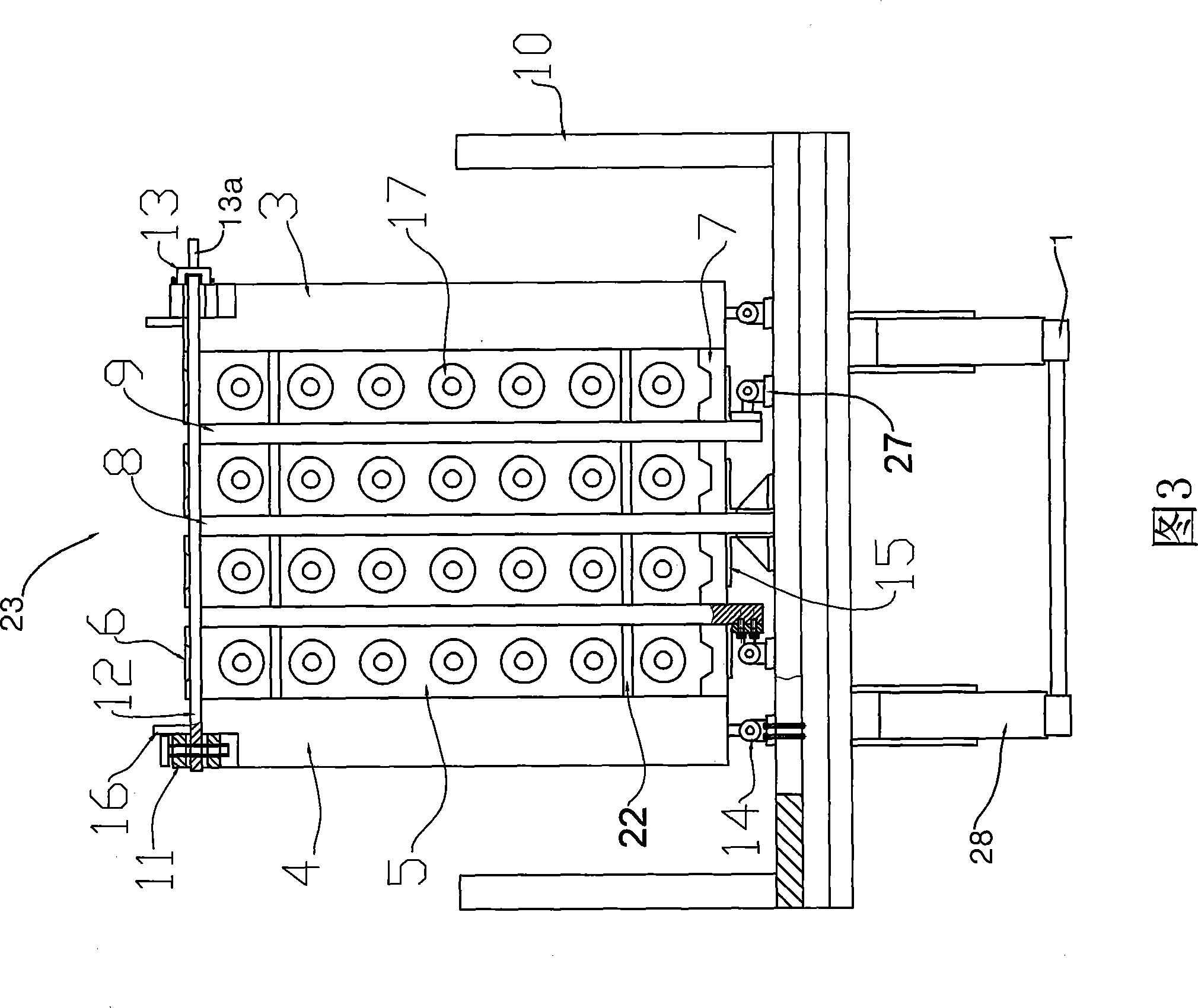

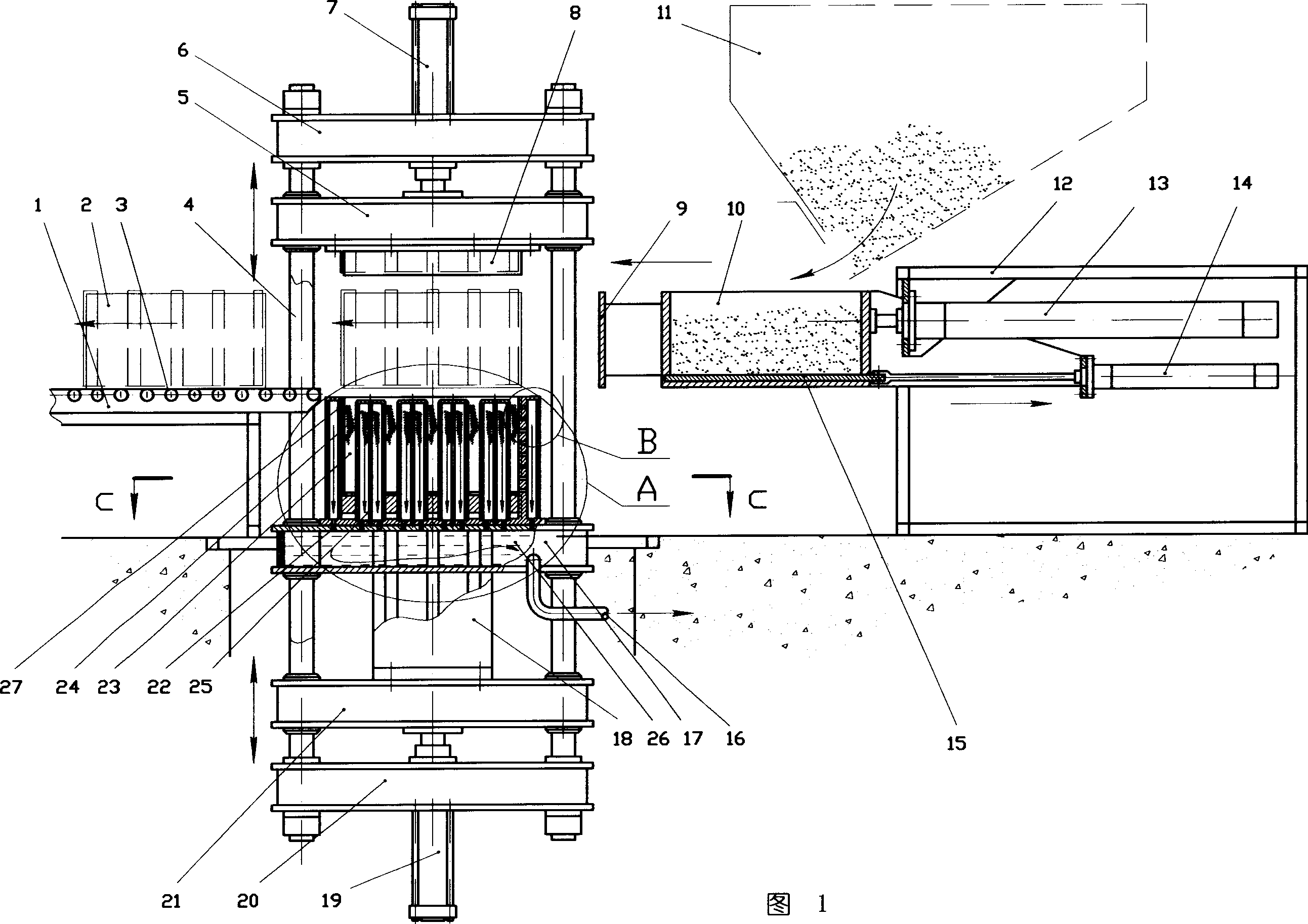

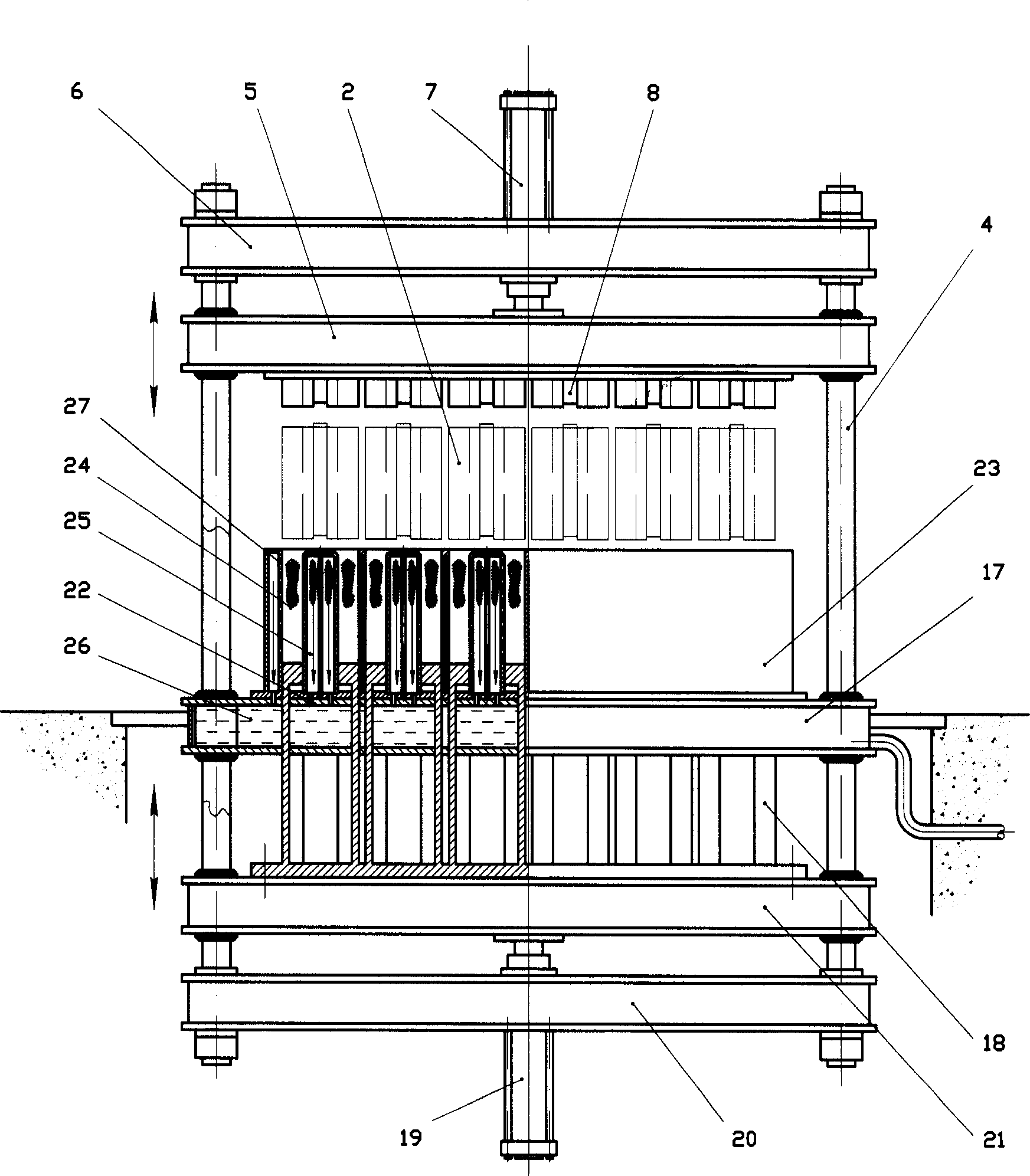

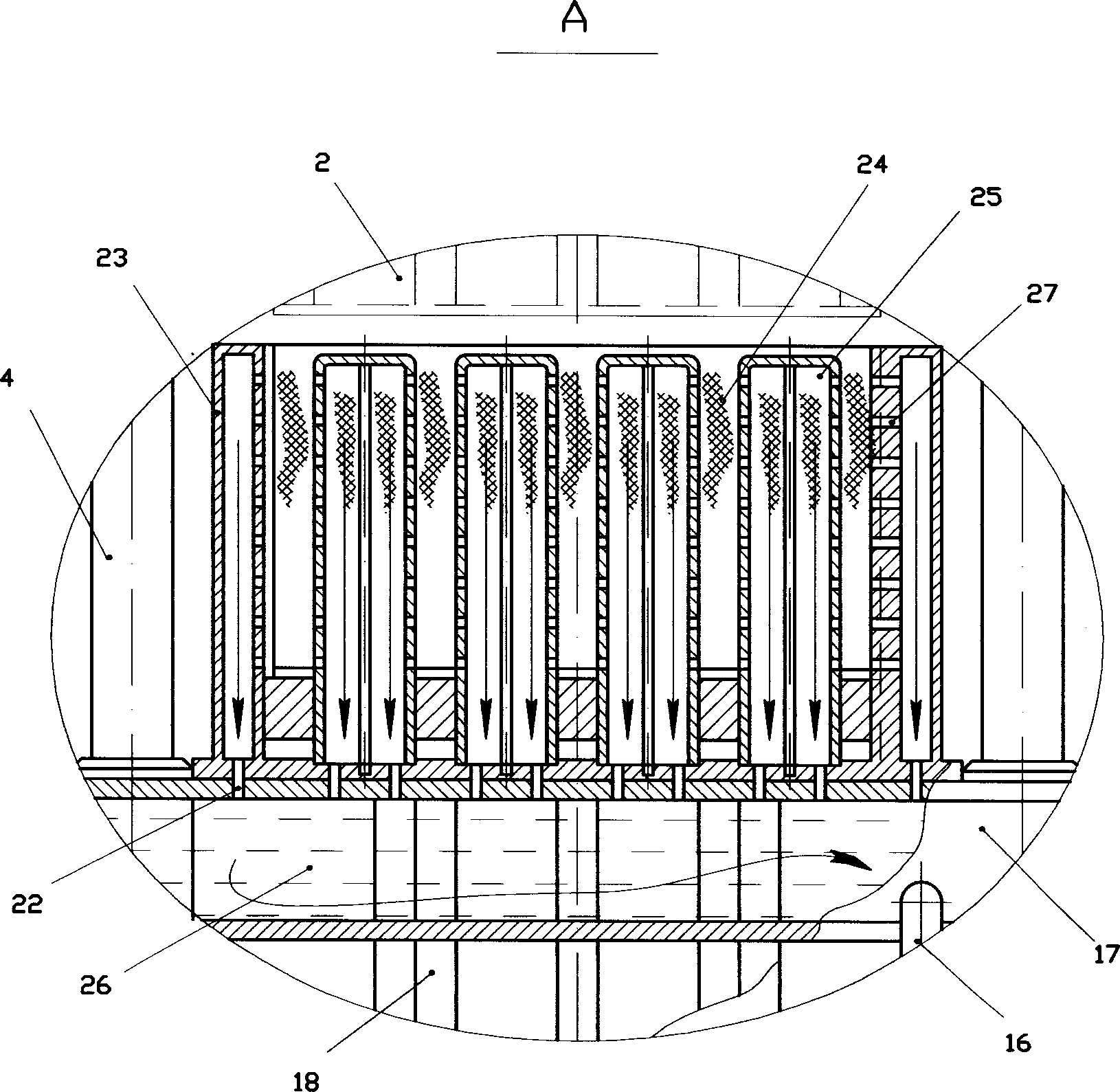

Hight-pressure gypsum block and its continuously-forming machine

InactiveCN1394729AGuarantee molding qualityImprove work efficiencyCeramic shaping apparatusHydraulic cylinderWater channel

The present invention provides a high-pressure high-strength gypsum block and its automatic water-filtering continuously-forming machine used in the course of press-forming process. Said ivnention is aimed at raising working efficiency and improving quality and property of the gypsum block. Its forming pressure is 8-10 kg / sq.cm, and its composition includes 5-30% of fibre including paper pulp, wood pulp, straw powder and other plant fibre, and the rest is gypsum. Said high-pressure gypbum block continuous forming machine includes machine frame, hydraulic cylinder, distributing device, upper, middle and lower press dies and conveying rollers. Its middle die is equipped with micropore for filtering water and its lower portion is equipped with water channel and water outlet.

Owner:张晶廷

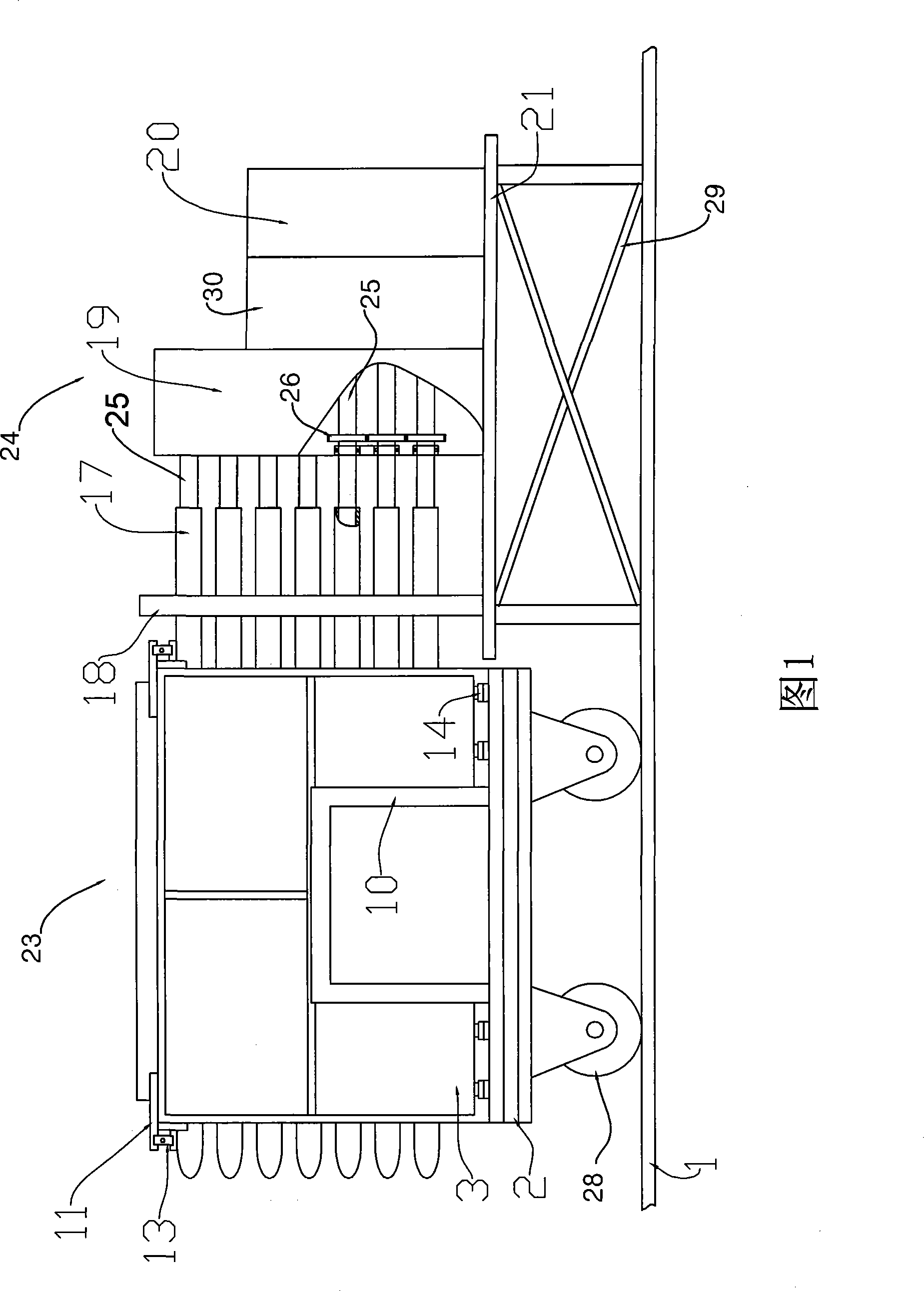

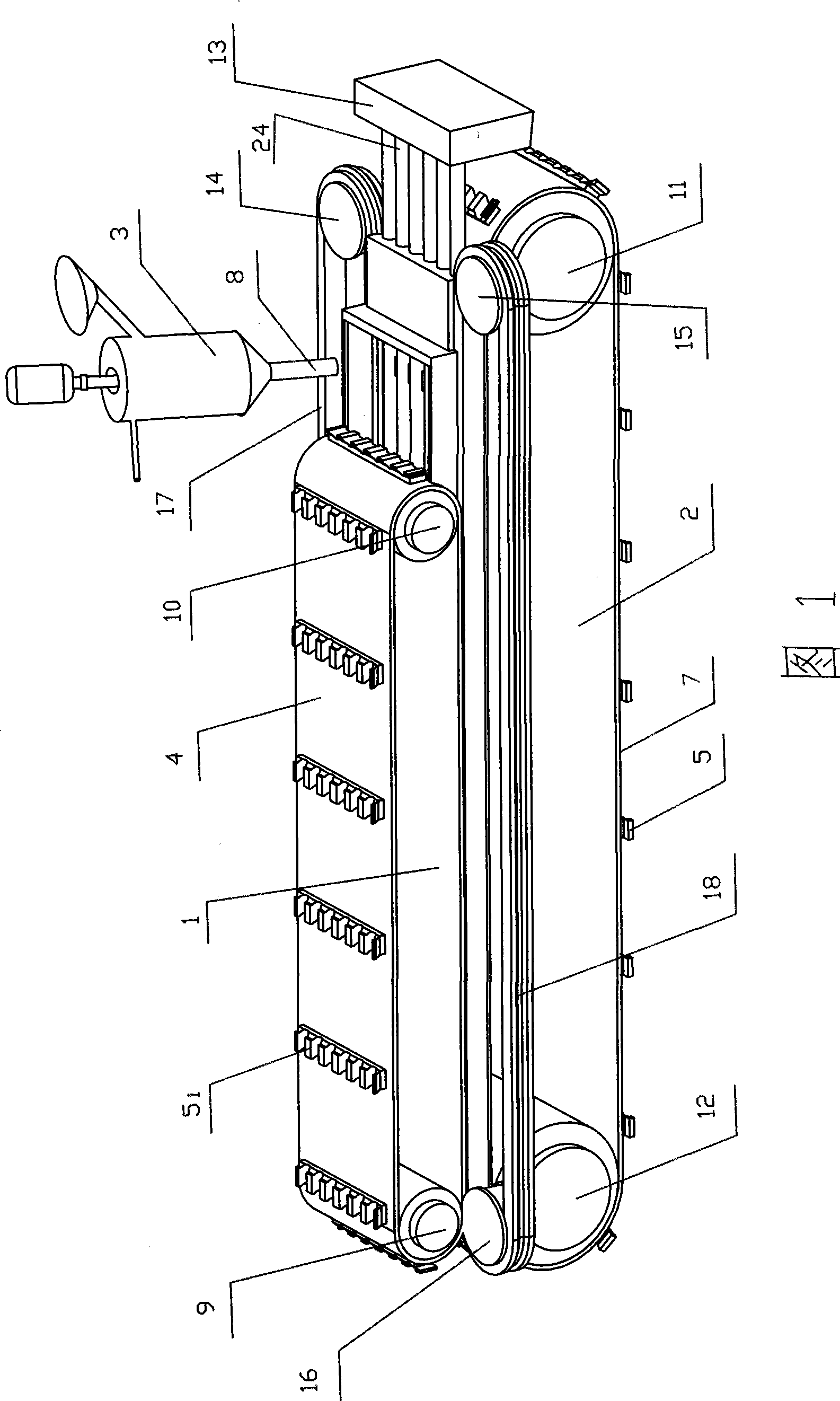

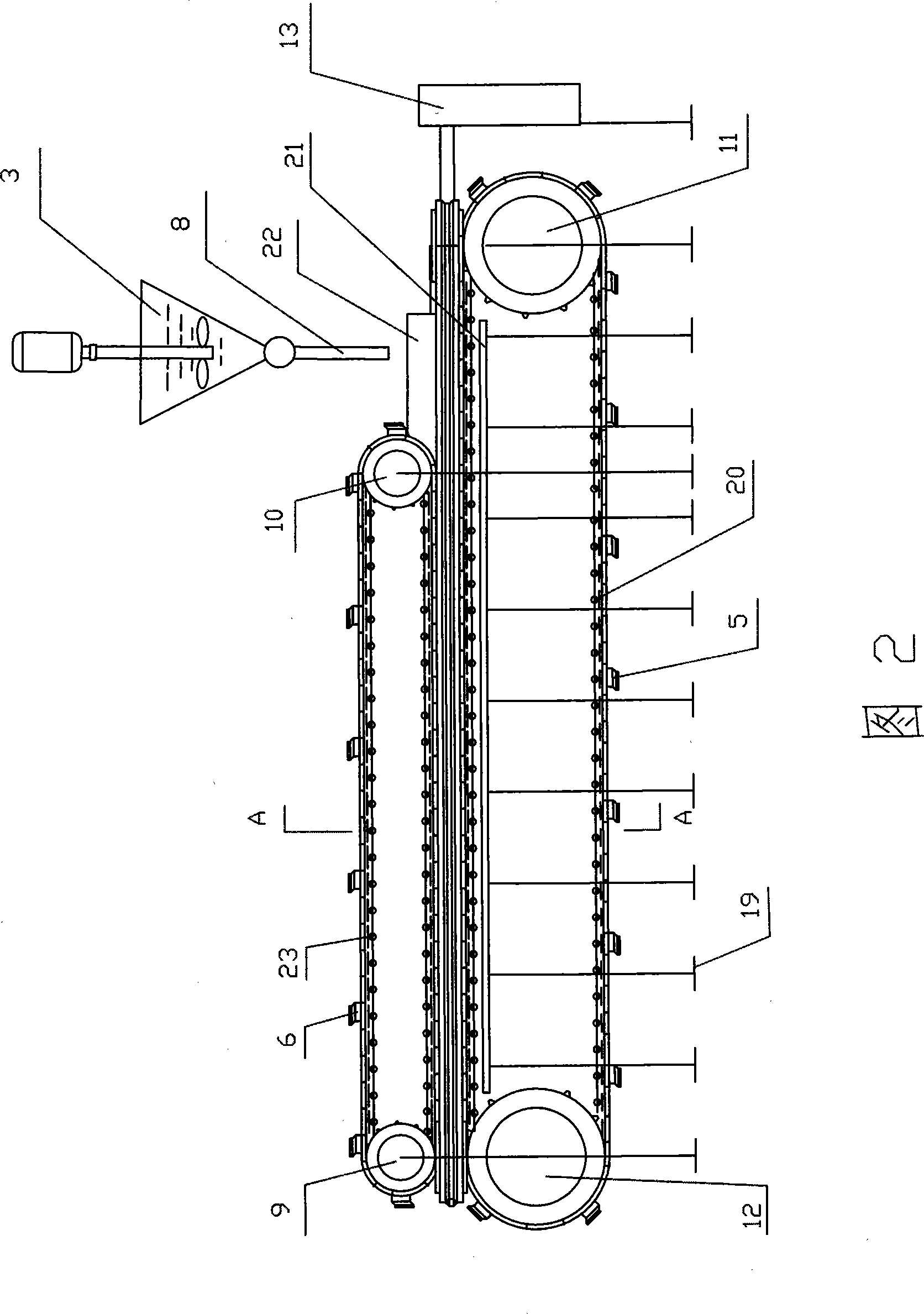

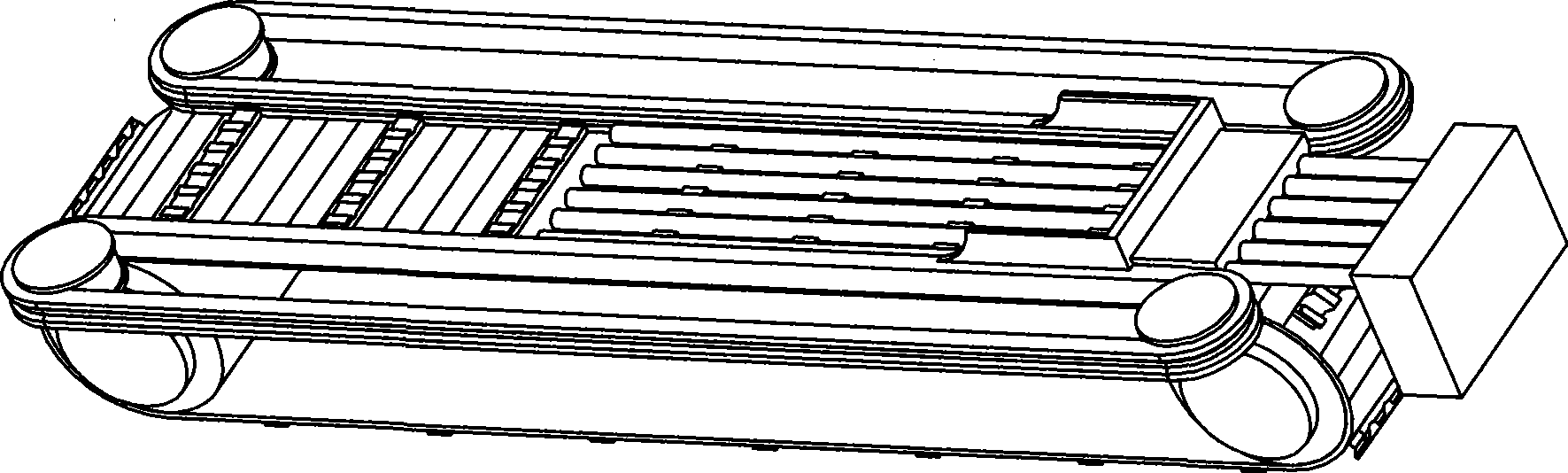

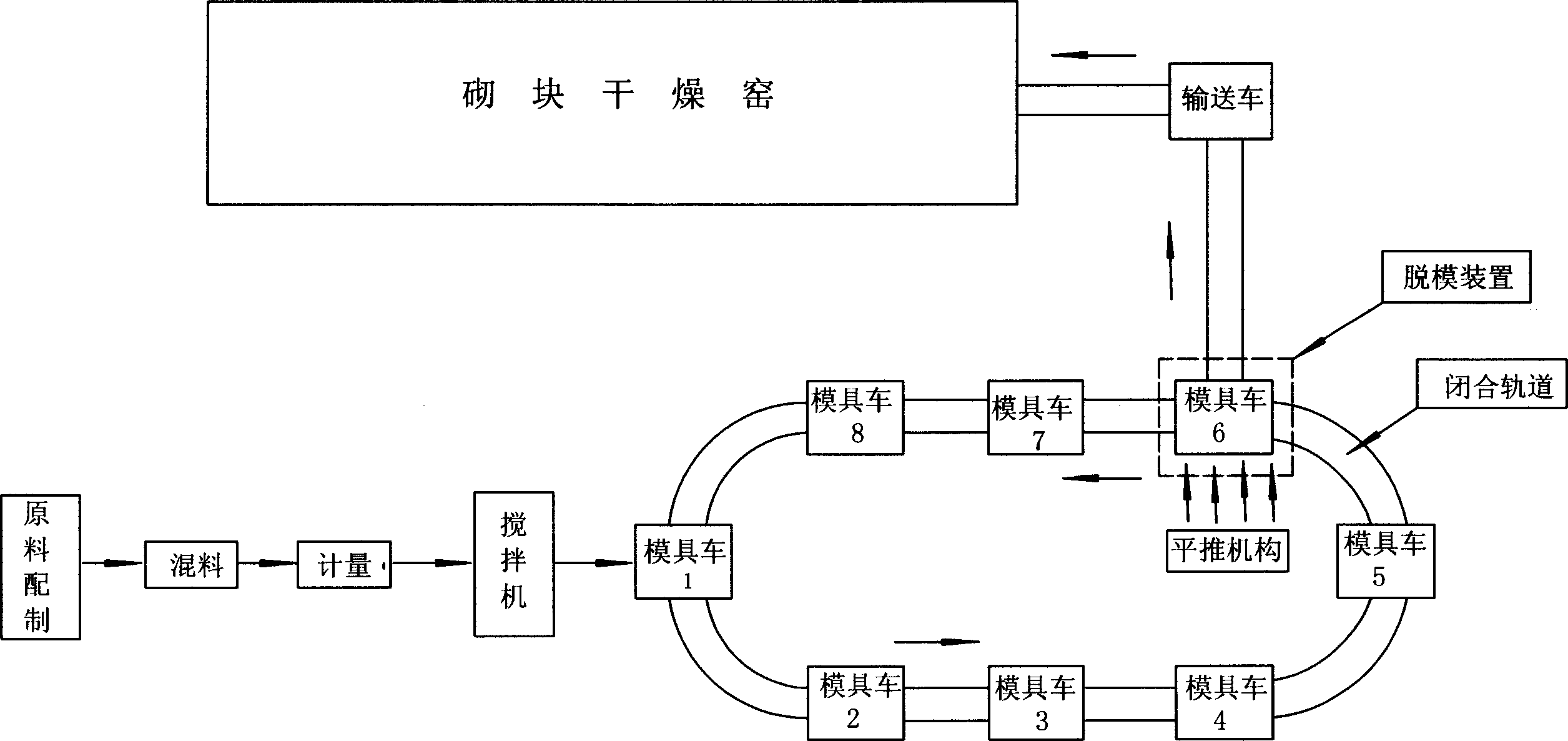

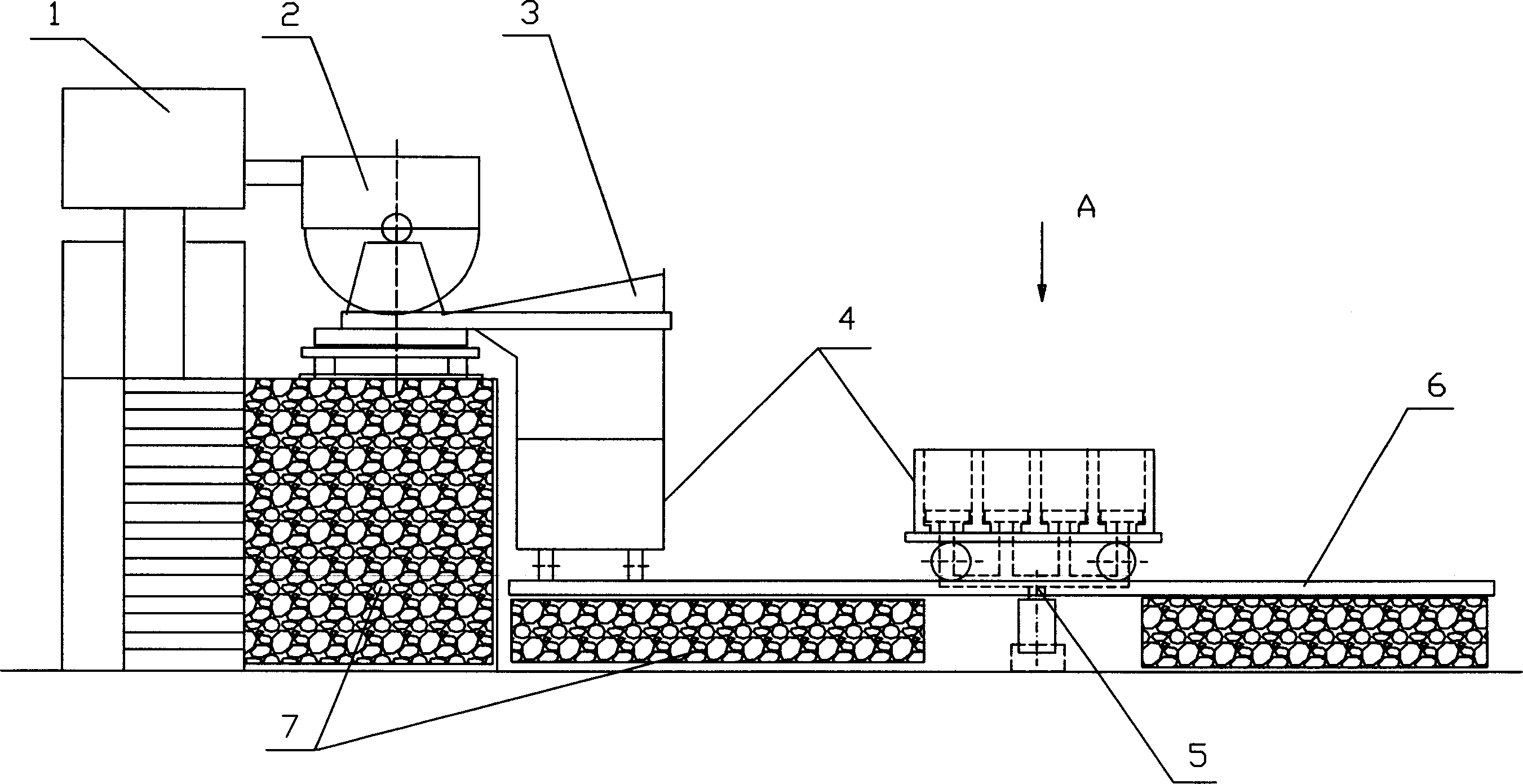

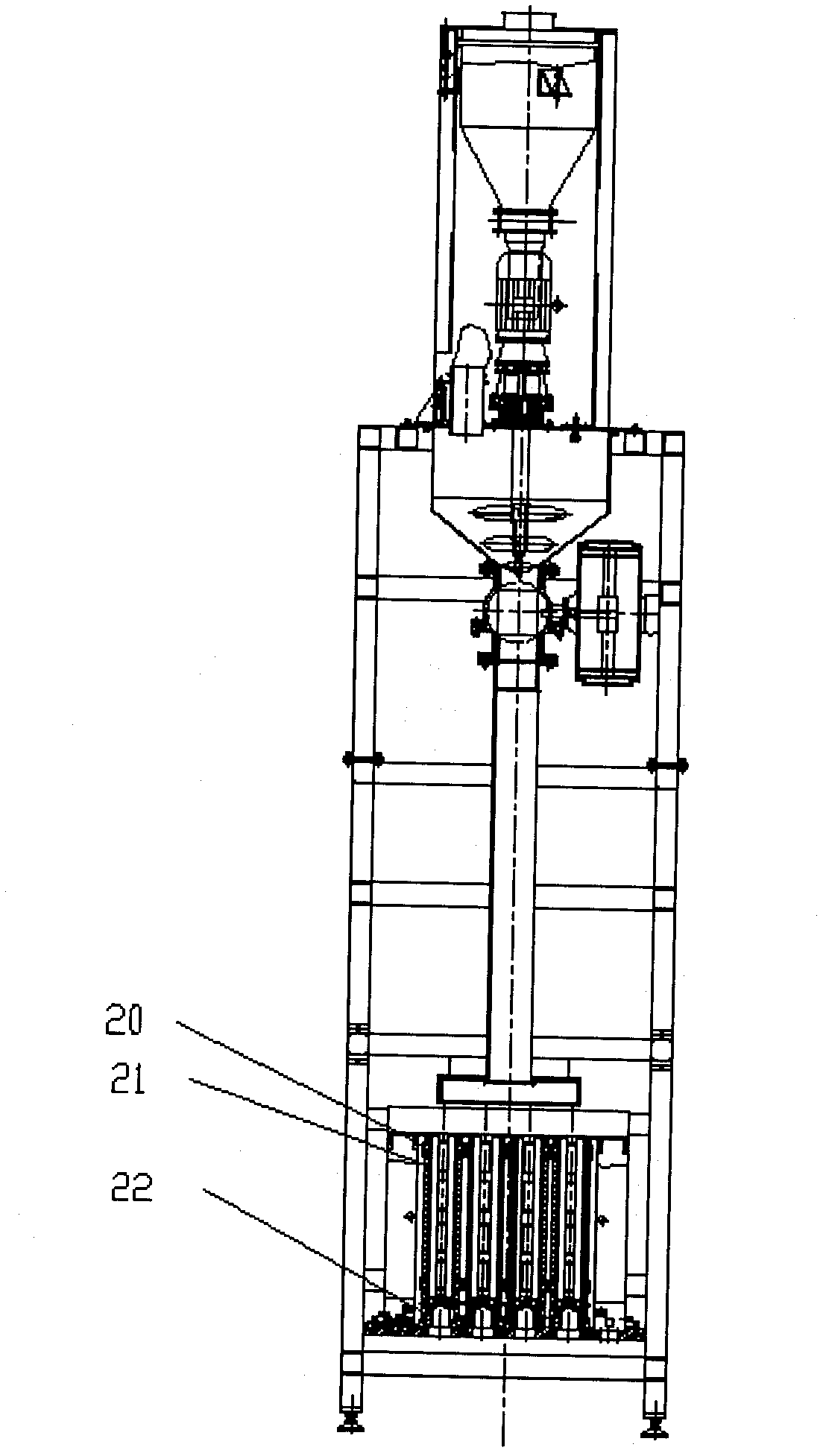

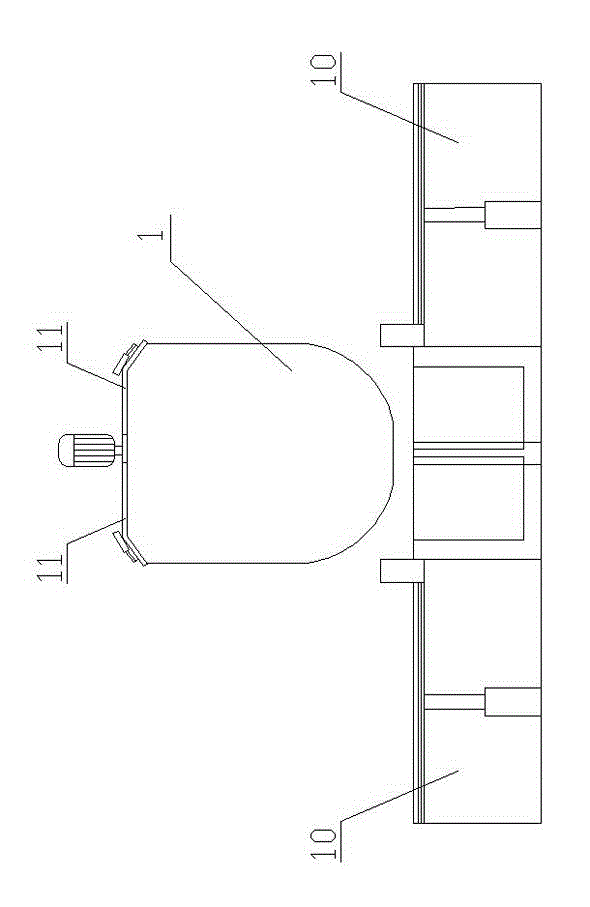

Conveyer-belt type block molding device for continuous producing gypsum block

ActiveCN101456209AResolve continuitySolve productivityCeramic shaping plantsShaping conveyorsSocial benefitsHigh volume manufacturing

The invention discloses a conveyer belt type block mould machine for continuously producing gypsum blocks, which consists of 2 to 4 mould conveyers, an additionally forming mould, and a continuous stirring and feeding machine. The conveyer belt type block mould machine can be fastened with a replaceable block mould together during rotating contact, combines a row of gypsum block moulds to be cast with the additionally forming mould, and can continuously produce the gypsum blocks through casting; the mould machine solves the contradiction that the prior production equipment can not continuously produce the gypsum blocks on a large scale, and solve the problem of high cost of the equipment; and during operation, slurry is injected by continuous stirring, the discharged substances are the solidified gypsum blocks, and then the solidified gypsum blocks are conveyed to a stacking position and dried to obtain products. The mould machine can lower production cost of products greatly, form large-scale production, save energy, has single consumption, and has good social benefit and economic benefit.

Owner:绿建科技集团新型建材高技术有限公司

Citric acid gypsum hollow block and preparation method thereof

The invention discloses a citric acid gypsum hollow block and its preparation method. The citric acid gypsum hollow block comprises the following raw materials by weight: 59-69.95 parts of citric acid gypsum powder (beta type); 20-25 parts of desulfurized gypsum powder (beta type); 2-3 parts of a reinforcing agent; 8-12 parts of a neutralizer; and 0.05-1 part of a water reducer. The hollow block provided in the invention has an excellent color better (whiter than ordinary gypsum hollow blocks), is more conducive to wall decoration, and has the effects of light weight, waterproofness as well as thermal insulation. With all indexes meeting the JC / T698-2010 and GB6566-2001 building materials radionuclide limited standards of gypsum blocks, the hollow block is also in line with the requirements of low carbon, environmental protection, energy saving and consumption reduction, and recycling economy, and alleviates the environmental pollution problem to certain extent.

Owner:ANHUI SENKE NEW MATERIAL

Desulfurized gypsum.phosphorous gypsum without roasting, extruding gypsum block and production method thereof

InactiveCN101830678ACompact structureImprove water resistanceSolid waste managementCeramic shaping apparatusResource utilizationHigh intensity

The invention provides dihydrate desulfurized gypsum.phosphorous gypsum without roasting, which is applied to the technical filed of solid waste resource utilization of generating plants and phosphate fertilizer plants and used for preparing water extrusion-resistant gypsum blocks with high strength. The dihydrate desulfurized gypsum.phosphorous gypsum without roasting comprises the following components by weight percent: 60-80% of desulfurized gypsu.phosphorous gypsum, 10-25% of pozzuolana active mineral material, 5-15% of activating material, 0.5-2% of coagulation accelerator, 0.2-1% of intensifier and 30-50% of light aggregate. The preparation method of the invention is as follows: carrying out vibration screening on subhumid original desulfurized gypsum.phosphorus gypsum, mixing and stirring with powder grinded active mineral material, exciting material, coagulation accelerator, reinforcing material, intensifier lightweight aggregate and proper amount of water, extruding and moulding, muggy maintaining and naturally maintaining. In comparison with the traditional methods of gypsum building blocks produced by sintered and cast beta-hemihydrate gypsum, the invention has higher intensity, lower breakage rate, better water-proof performance and higher coefficient of softening, is characterized by stable performance, low cost and easy popularization, and is uneasy to rot roots and crack, thus being applied to indoor separating walls and partitions.

Owner:SHANGHAI JINMA BUILDING MATERIALS

Lightweight gypsum block and its preparation method

InactiveCN103819163AReduce manufacturing costLight weightSolid waste managementCeramicwareEnvironmental resistanceFiber

The invention relates to a lightweight gypsum block and its preparation method. The block comprises the following components, by weight, 70-80% of desulfurized gypsum, 10-15% of ultrafine steel slag powder, 10-15% of perlite, 1-1.5% of a steel slag excitant, 0.3-0.5% of PP fiber, 0.05% of a retarder, 0.01-0.05% of a foaming agent and the balance water. According to the invention, industrial waste residues such as desulfurized gypsum, steel slag and the like are used as main raw materials to prepare the gypsum block, thus opening up a new way for comprehensive utilization of industrial solid wastes. Production cost of the gypsum block is reduced, and dual effects of environmental protection and waste utilization are achieved. Due to the addition of the ultrafine steel slag powder and the excitant, strength and water resistance of the product are enhanced. The prepared gypsum block has effects of light weight, sound insulation, thermal insulation, moisture retention and the like, and has good anti-seismic property. According to the invention, a new way for resource utilization of the solid wastes desulfurized gypsum and steel slag is opened up, natural environment is protected, and resources and energy are saved.

Owner:SHANGHAI YUPEI SPECIAL BUILDING MATERIAL +1

Gypsum block continuous production apparatus capable of adjusting thickness

InactiveCN1850470AIncrease productivityReduce manufacturing costDischarging arrangementMouldsProcess systemsEngineering

The invention discloses a continuous process system of the plaster block which can adjust the thickness. The present device can not adjust the die and when the plaster is out of the die, the die back plate should be opened. The die is made up of the external dummy plate, the inner dummy plate, the back plate and the die base plate. The stripper device includes the liftout shelf which can extend to the hollow from the bottom of the die car. The liftout plate is contacted to the base plate. The invention can make the process of pouring, solidifying and stripping independent. The space of the die dummy plate can be adjusted, so it can be used for many type of the plaster block.

Owner:张继忠 +1

Retarded water-resistant gypsum block and preparation method thereof

InactiveCN101597937AImprove mobilityThe ratio of water to material dropsSolid waste managementMixing operation control apparatusSlagSlurry

The invention discloses a retarded water-resistant gypsum block and a preparation method thereof. The retarded water-resistant gypsum block is prepared from the following raw materials in percentage by weight: 80 to 90 percent of powdery gypsum, 5 to 15 percent of fly ash or blast furnace slag, 1 to 5 percent of excitant, and 0.5 to 2.5 percent of water reducing agent, wherein the water-solid ratio is between 0.3 and 0.4. The fineness of the raw materials reaches that an oversize product of a sieve with a size of 0.08 mm is not greater than 5 percent. The raw materials are added into a stirring tank according to the mixture ratio, an irrigation pump is used to pour mixed slurry into a forming die after the raw materials are stirred evenly, and the gypsum block is obtained after the demolding and constant-temperature drying. The gypsum block has retarding and water-resistant characteristics, reduces rejection rate, reduces drying time, and reduces the energy consumption during the drying.

Owner:贵州金三利科技建材有限公司

Waterproof phosphogypsum building block and preparation method thereof

ActiveCN106830866AThe adding process is simple and easyLow water absorptionBuilding componentsEmulsionPolyvinyl alcohol

The invention discloses a waterproof phosphogypsum building block and a preparation method thereof. The waterproof phosphogypsum building block comprises 50-60 parts by weight of semi-aqueous phosphogypsum, 30-40 parts by weight of water, 1-3 parts by weight of ash calcium powder, 2-5 parts by weight of cement, 3-7 parts by weight of a crystal modifier, 1-3 parts by weight of polyvinyl alcohol, 1-5 parts by weight of glass microspheres, 0.1-0.3 part by weight of a high efficiency water reducing agent, 0.05-0.5 part by weight of organic silicone oil emulsion, 0.1-0.3 part by weight of a salt waterproof agent and 0.05-0.1 part by weight of an air entraining agent. The waterproof phosphogypsum building block has the beneficial effects that the ash calcium powder serves as an initiating agent; the cement and the semi-aqueous phosphogypsum harden with water; the glass microspheres have enhancement and filling effects; the salt waterproof agent, the polyvinyl alcohol and the organic silicone oil emulsion are mixed waterproof agents. The waterproof phosphogypsum building block has the advantages that the production is simple; special production equipment is not needed; the process is reasonable; a raw material adding working procedure is simple and practicable; the prepared phosphogypsum building block is a gypsum building block with high strength and low water absorption.

Owner:GUIZHOU LANTU NEW MATERIALS

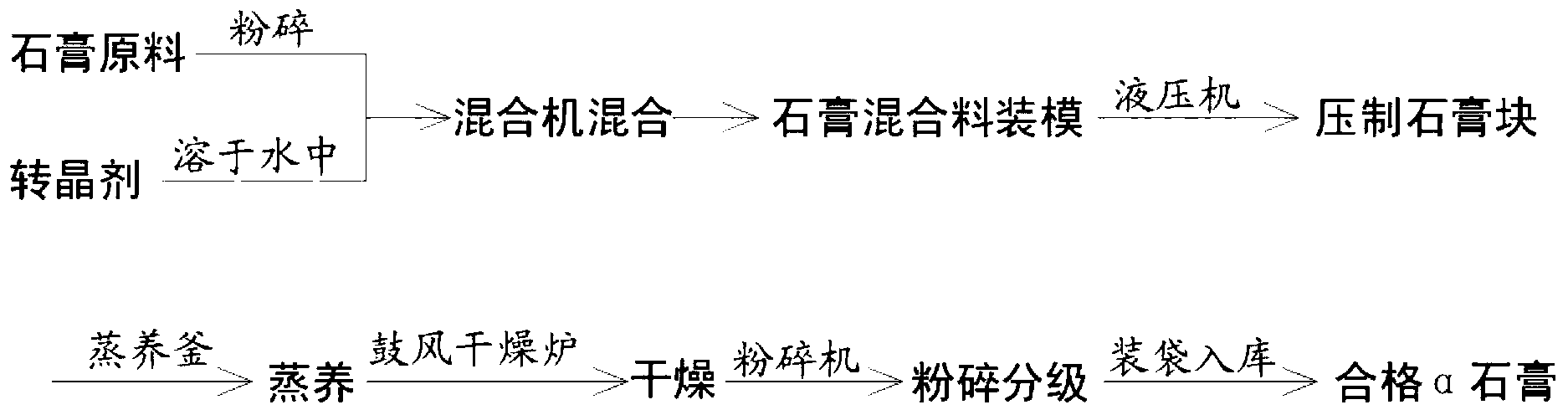

Process for producing high-strength alpha-gypsum from chemical gypsum by adopting dry method

The invention provides a process for producing high-strength alpha-gypsum from chemical gypsum by adopting a dry method. The process comprises the following specific steps of: placing a chemical gypsum as a raw material in a mixing machine, and spraying a mixed aqueous solution of a crystal modifier of sulfonate and maleic anhydride on the surface of the chemical gypsum raw material while mixing and stirring; uniformly mixing the mixed aqueous solution with gypsum during the stirring of the mixing machine; filling the uniformly-mixed gypsum material in a die; pressing the gypsum material on a pressure forming machine, and then steam-curing the gypsum material in a steam-curing kettle; drying the steam-cured gypsum block via a forced-air drying furnace, and then crushing; and grading to obtain the qualified alpha-gypsum product. The process for producing the alpha-gypsum product is low in water consumption and energy consumption in a production process, simple, few in production investment equipment, stable in the performance of producing the alpha-gypsum product, and low in cost.

Owner:平邑开元新型建材有限公司

Gypsum building block shaping machine

InactiveCN102672816AAchieve brokenRapid realization of crushing and recyclingCeramic shaping plantsCement mixing apparatusProduction lineMolding machine

The invention provides a gypsum building block shaping machine, comprising a rack and a mould fixedly arranged on a conveyance line. The gypsum building block shaping machine is characterized in that a powder material metering device, a water metering device, a stirring device and a plugging core machine for sealing the mould, scraping, crushing and recovering slurry are respectively installed on the rack; the powder material metering device and the water metering device are respectively installed on the upper part of the rack; powder materials and water can be sent into an internal chamber of a stirring warehouse through a powder material passage and a water passage; and the plugging core machine is installed on the lower part of the rack. In comparison with the current technique, the gypsum building block shaping machine has the advantages of simple structure, low manufacture cost, simple operation, and no redundant slurry discharged, thereby being especially applicable for the shaping of the gypsum building blocks in continuous efficient work of a gypsum building block shaping production line.

Owner:应明

Method for preparing alpha semi-hydrated gypsum pulp and plaster products by desulphurizing gypsum

Disclosed is a method which uses desulfurization dihydrate gypsum to prepare alpha-type semi-hydrated gypsum slurry, comprising the following steps: getting the power plant desulfurization dihydrate gypsum; mixing the power plant desulfurization dihydrate gypsum with water to form slurry with concentration between 10% and 50%; adding a crystal modifier into the slurry, wherein, the crystal modifier can be succinate, sodium succinate or succinate magnesium, and the dosage of the crystal modifier takes up 0.5 to 8 per mille of the mass of the desulfurization dihydrate gypsum; heating the slurring with crystal modifier to 120-160 DEG C and preserving the slurry for 1 to 4 hours so as to get the alpha-type semi-hydrated gypsum slurry. An alpha-type semi-hydrated gypsum product preparation method comprises the following steps: taking the alpha-type semi-hydrated gypsum slurry as the raw material, and then directly pouring the slurry into a mold through centrifugal or vacuum dehydration without drying, so as to obtain gypsum blocks or other alpha-type semi-hydrated gypsum products.

Owner:SOUTHEAST UNIV

Desulfurized building gypsum water-proof building block

InactiveCN102180647AImprove waterproof performanceGood environmental benefitsSolid waste managementSlagSlurry

The invention discloses a desulfurized building gypsum water-proof building block, belonging to the technical field of comprehensive utilization of building materials and solid industrial wastes. The building block comprises the following raw materials in percentage by mass: 30-94 percent of desulfurized building gypsum, 0-50 percent of silicon-calcium slag and 6-20 percent of low-alkalinity sulphate aluminum cement. A method for preparing an improved desulfurized building gypsum water-proof building block mainly comprises the following steps of: preparing for materials with desulfurized building gypsum and low-alkalinity sulphate aluminum cement as byproducts obtained after smoke discharged from a coal-burning thermal power plant is desulfurized and silicon-calcium slag as residue obtained after alumina is extracted from high-aluminum pulverized fuel ash as raw materials according to a formula; adding water and stirring to obtain slurry; molding by casting; demolding; and drying or naturally drying. In the invention, the low-alkalinity sulphate aluminum cement and the silicon-calcium slag are doped into the desulfurized building gypsum, so that the water resistance of a desulfurized gypsum building block is greatly enhanced, and very high using value is achieved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Composite waterproofing agent of gypsum

InactiveCN101050350AReduce capillary channelsEvenly dispersedOther chemical processesEmulsionPolyvinyl alcohol

This invention relates to a composite waterproof agent for gypsum. The composite waterproof agent is composed of: stearic acid, poly(vinyl alcohol), water, composite emulsifier, alunite, naphthaline-series water reducer and carboxylate at a ratio of (5-30):(2-10):(100-300):(0.05-0.5):(20-40):(5-8):(2-10). The composite waterproof agent is an emulsion that can be mixed with water at any ratio. The composite waterproof agent has such advantages as no toxicity, no stimulation, and high dispersion uniformity. The composite waterproof agent can improve the waterproof performance of gypsum by reducing the capillary pores of cured gypsum. The composite waterproof agent can be used on gypsum boards, gypsum wallboards and gypsum blocks.

Owner:UNIV OF JINAN

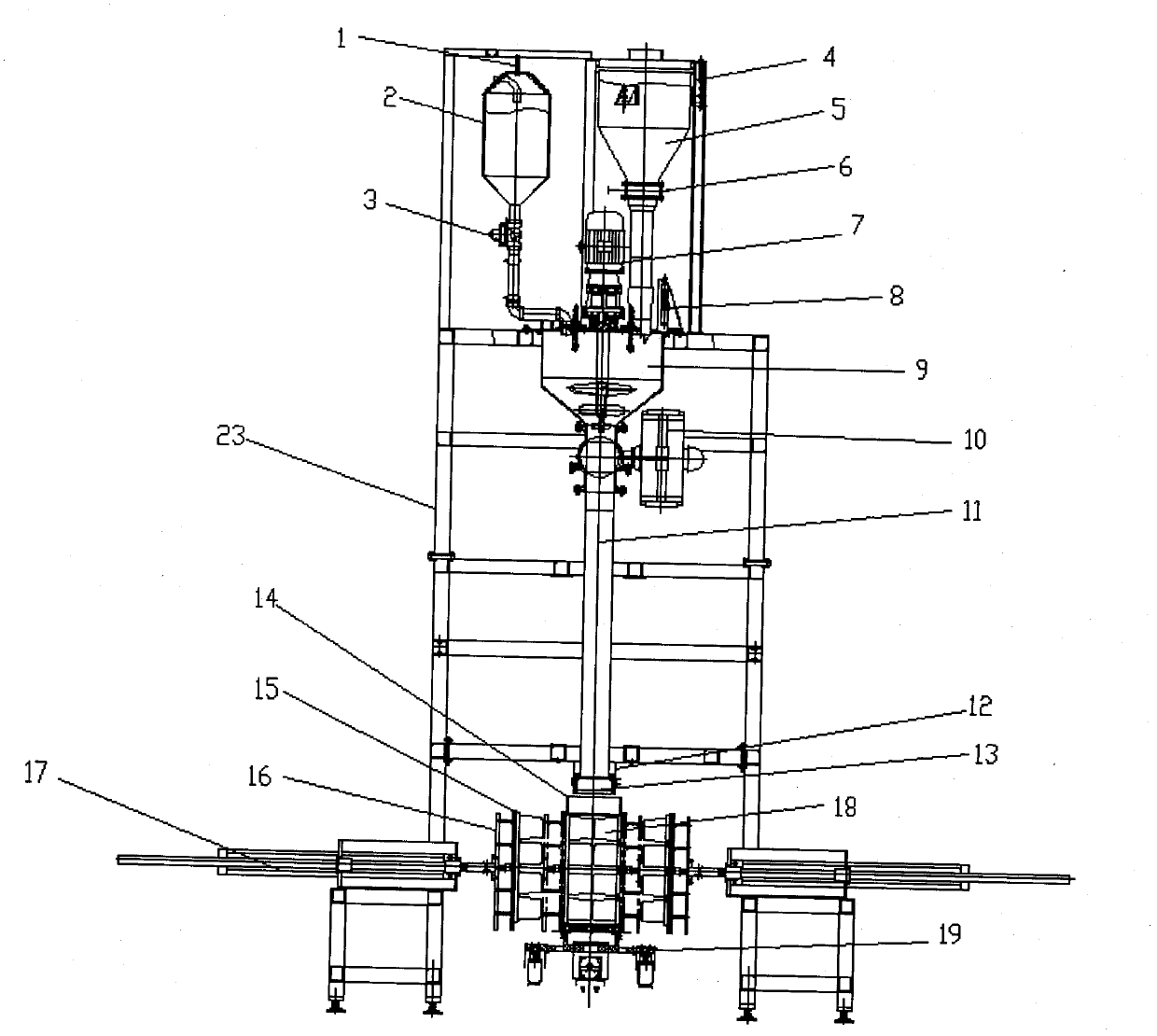

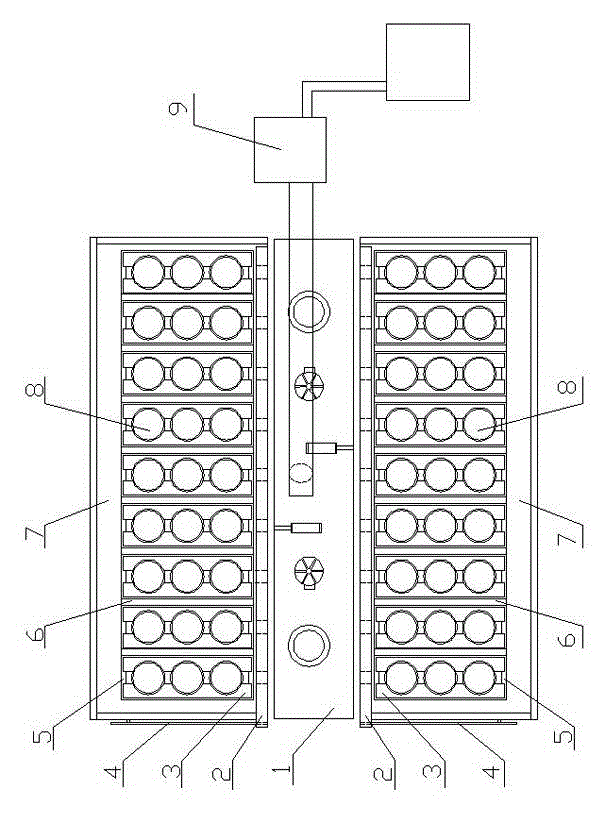

High-strength gypsum block making machine

ActiveCN102717426AImprove work efficiencyImprove equipment utilizationMixing operation control apparatusCeramic shaping plantsMechanical engineeringGypsum block

The invention discloses a high-strength gypsum block making machine which comprises a framework, a turning stirring bin, two forming devices and a feeding system. The two forming devices are symmetrically arranged below two sides of the turning stirring bin, each forming device consists of a box and a scraper, each box is divided into a plurality of forming mold cavities by longitudinal partition plates, each forming mold cavity is provided with a plurality of core columns fixedly connected with a bottom plate of the corresponding box, a lifting bottom mold is disposed above the bottom plate of each box, a plurality of mold holes corresponding to the core columns are arranged on the bottom molds, and the feeding system comprises a metering feeding hopper. The two forming devices are symmetrically arranged below the two sides of the stirring bin, accordingly, a previous operation process can be repeated when raw materials in the forming mold cavities on one side of the stirring bin are solidified, then the stirred raw materials are added into the forming mold cavities on the other side of the stirring bin, and the forming devices on the two sides of the turning stirring bin are used alternately. The high-strength gypsum block making machine is reasonable in structure, work efficiency and equipment utilization rate are greatly improved, time and labor are saved, and large quantities of human resources can be saved.

Owner:江苏科威建材有限公司

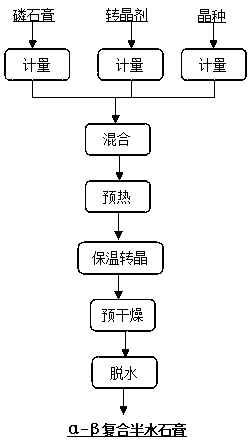

Method for preparing alpha-beta composite semi-hydrated gypsum from phosphogypsum

ActiveCN108059375ASimple production equipmentMild process conditionsResource utilizationWater requirement

The invention relates to a method for preparing alpha-beta composite semi-hydrated gypsum from phosphogypsum. The method comprises the following steps of: (1) mixing the phosphogypsum with crystal modifier and seed crystals fully, then putting the mixture into an alpha-semi-hydrated gypsum crystal transition box, performing preheating by using sub-saturated air, and then introducing normal-pressure steam to maintain the temperature and humidity so as to achieve conversion of partial dihydrate gypsum in the phosphogypsum into alpha-semi-hydrated gypsum; (2) introducing hot air for predrying; and (3) performing further dehydration so as to convert unhydrated dihydrate gypsum into beta-semi-hydrated gypsum which is the alpha-beta composite semi-hydrated gypsum. Compared with traditional beta-semi-hydrated gypsum, the prepared alpha-beta composite semi-hydrated gypsum has small water requirement of normal consistency and high strength, and compared with alpha-semi-hydrated gypsum, no high-pressure dehydration devices and hydrothermal conditions are needed, so that the method has a mild production process, simple devices and low energy consumption; the product can be widely used as building gypsum powder or multiple types of gypsum blocks, and a practical and feasible technical method for resource utilization of the phosphogypsum is provided.

Owner:湖北声荣再生资源利用有限公司

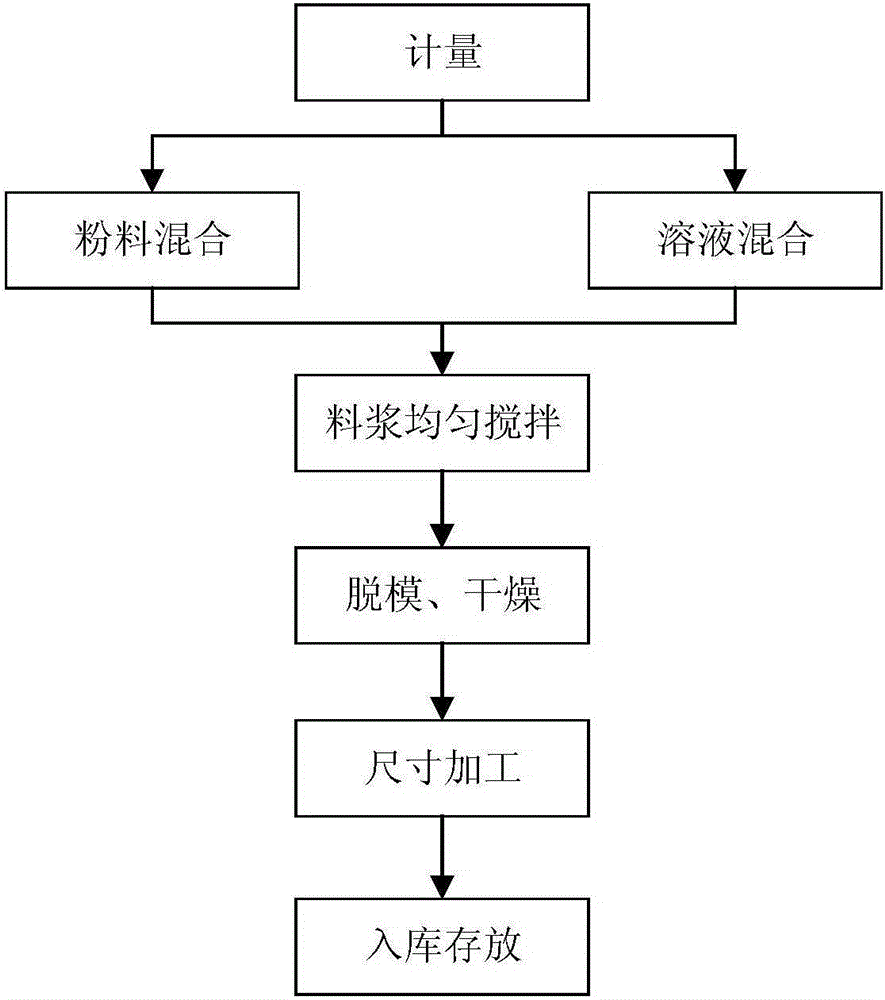

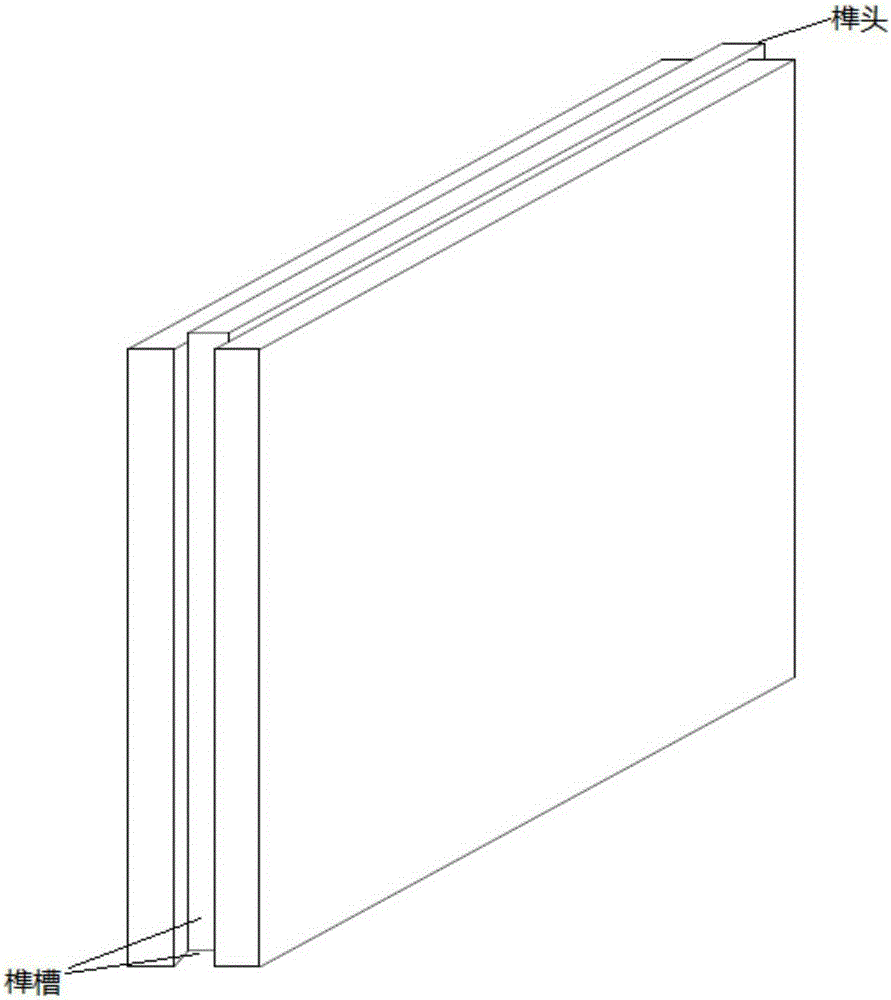

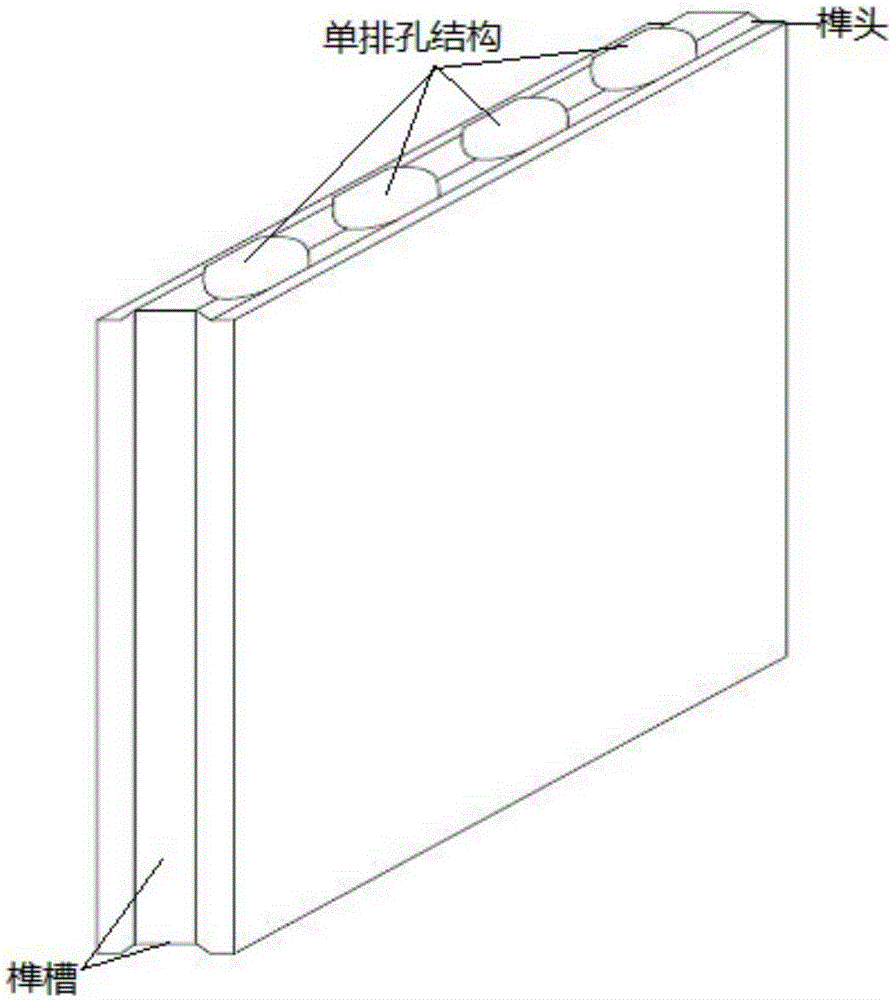

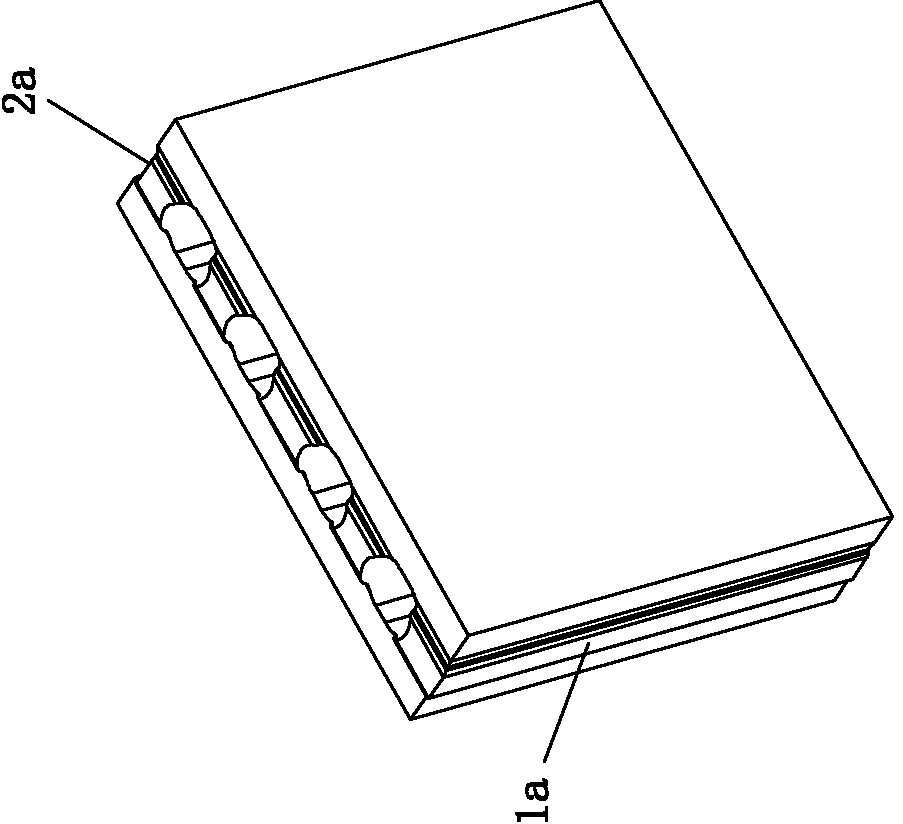

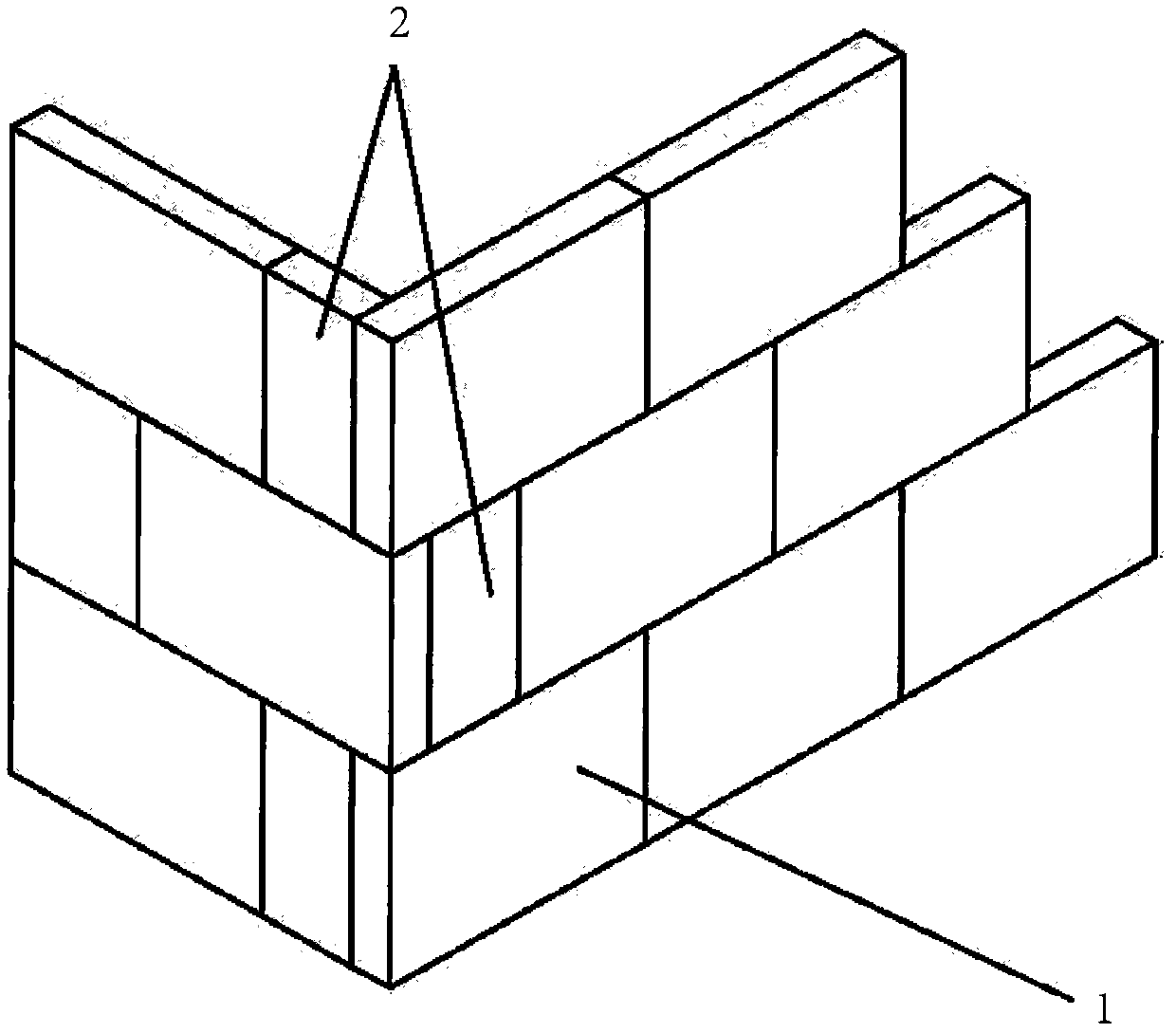

Green and environment-friendly wall system

ActiveCN103214225AEasy to installEliminate the plastering processWallsCeramicwareAdhesiveFire resistance

The invention provides a green and environment-friendly wall system which is composed of a plurality of rectangular gypsum blocks by splicing. Splicing places are connected by using a cured gypsum block adhesive. The gypsum blocks are obtained through the steps that: a gypsum raw material is stirred with water, and casting and shaping are carried out. The rectangular edges of the gypsum block are provided with concave recesses and convex keys. The gypsum block adhesive is powdery, and is formed by using a gypsum raw material. Before use, the gypsum block adhesive is well mixed with water. From a raw material selection process, a production process, and a site construction process, to a waste recovery process, the wall system completely satisfies a sustainable development goal. The system is a completely environment-friendly novel construction material. The system has the advantages of sound insulation, fire resistance, light weight, high strength, convenient construction, low application space occupation, and the like. The system is a low-carbon, environment-friendly, and healthy novel wall system satisfying development requirements of the time.

Owner:嘉信(香港)研发有限公司

Waterproofing agent for desulfurization gypsum block

InactiveCN103242018APrevent intrusionTo achieve the purpose of waterproofingCross-linkPolyvinyl alcohol

The invention relates to a waterproofing agent for a desulfurization gypsum block, and the waterproofing agent mainly comprises stearic acid, polyvinyl alcohol, cement, borate, semi-hydrated gypsum, accelerants, cross-linking agents, and the like. The waterproofing agent for the desulfurization gypsum block, which is disclosed by the invention, can change the structure of holes, pores and capillary holes which are positioned in the surface inside a gypsum product so as to change the surface from a hydrophilic surface to a hydrophobic surface, thereby preventing the moisture from invading and achieving the characteristics of waterproofing and the like.

Owner:张家港市创成纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com