Desulfurized building gypsum water-proof building block

A technology for desulfurization of building gypsum and building blocks, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems of multiple components, difficult operation, and high cost, and achieve improved waterproof performance and environmental benefits. Significant, widening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

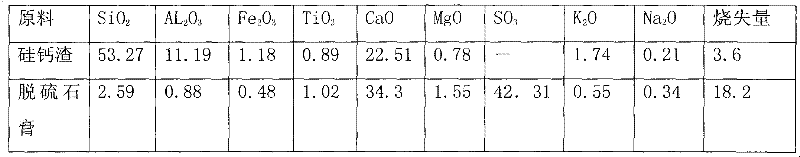

[0018] The formula of desulfurization building gypsum waterproof block of the present invention is (mass percentage)

[0019] Desulfurization building gypsum 60%, calcium silicate slag 30%, low alkalinity sulphoaluminate cement: 10%.

[0020] Production method: first measure the water according to the water-cement ratio of 0.7-0.8 and add it to the mixing tool, then add the measured 30% calcium silicate slag, 10% low-alkalinity sulphoaluminate cement, and 60% desulfurized building gypsum to the mixer in sequence Stir inside, stir for 1-2 minutes, pour the mixed slurry into the forming mold, and after solidifying for 2-3 minutes, start the hydraulic ejector to eject the block from the mold from the lower part of the forming machine, press the block Place them on the drying cart at a distance of 3 cm, and then move them by rails to a continuous hot air drying kiln for drying, or put them in a drying yard for natural drying, and finally tie them up and pack them.

Embodiment 2

[0022] The formula of desulfurization building gypsum waterproof block is (mass percentage)

[0023] Desulfurization building gypsum 70%, calcium silicate slag 20%, low alkalinity sulphoaluminate cement: 10%.

[0024] Production method: first measure the water according to the water-cement ratio of 0.7-0.8 and add it to the mixing tool, then add the measured 20% calcium silicate slag, 10% low-alkalinity sulphoaluminate cement, and 70% desulfurized building gypsum to the mixer in sequence Stir inside, stir for 1-2 minutes, pour the mixed slurry into the forming mold, and after solidifying for 2-3 minutes, start the hydraulic ejector to eject the block from the mold from the lower part of the forming machine, press the block Place them on the drying cart at a distance of 3 cm, and then move them by rails to a continuous hot air drying kiln for drying, or put them in a drying yard for natural drying, and finally tie them up and pack them.

Embodiment 3

[0026] The formula of desulfurization building gypsum waterproof block is (mass percentage)

[0027] Desulfurization building gypsum 60%, calcium silicate slag 30%, low alkalinity sulphoaluminate cement: 8%.

[0028] Production method: first measure the water according to the water-cement ratio of 0.7-0.8 and add it to the mixing tool, then add the measured 30% calcium silicate slag, 8% low-alkalinity sulphoaluminate cement, and 60% desulfurized building gypsum to the mixer in sequence Stir inside, stir for 1-2 minutes, pour the mixed slurry into the forming mold, and after solidifying for 2-3 minutes, start the hydraulic ejector to eject the block from the mold from the lower part of the forming machine, press the block Place them on the drying cart at a distance of 3 cm, and then move them by rails to a continuous hot air drying kiln for drying, or put them in a drying yard for natural drying, and finally tie them up and pack them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com