Gypsum building block shaping machine

A gypsum block and molding machine technology, which is applied to ceramic molding machines, ceramic molding workshops, and raw material supply devices for sales, can solve the problems of difficult recycling, low production efficiency, and complicated operations, and achieves guaranteed molding effects and low production costs. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

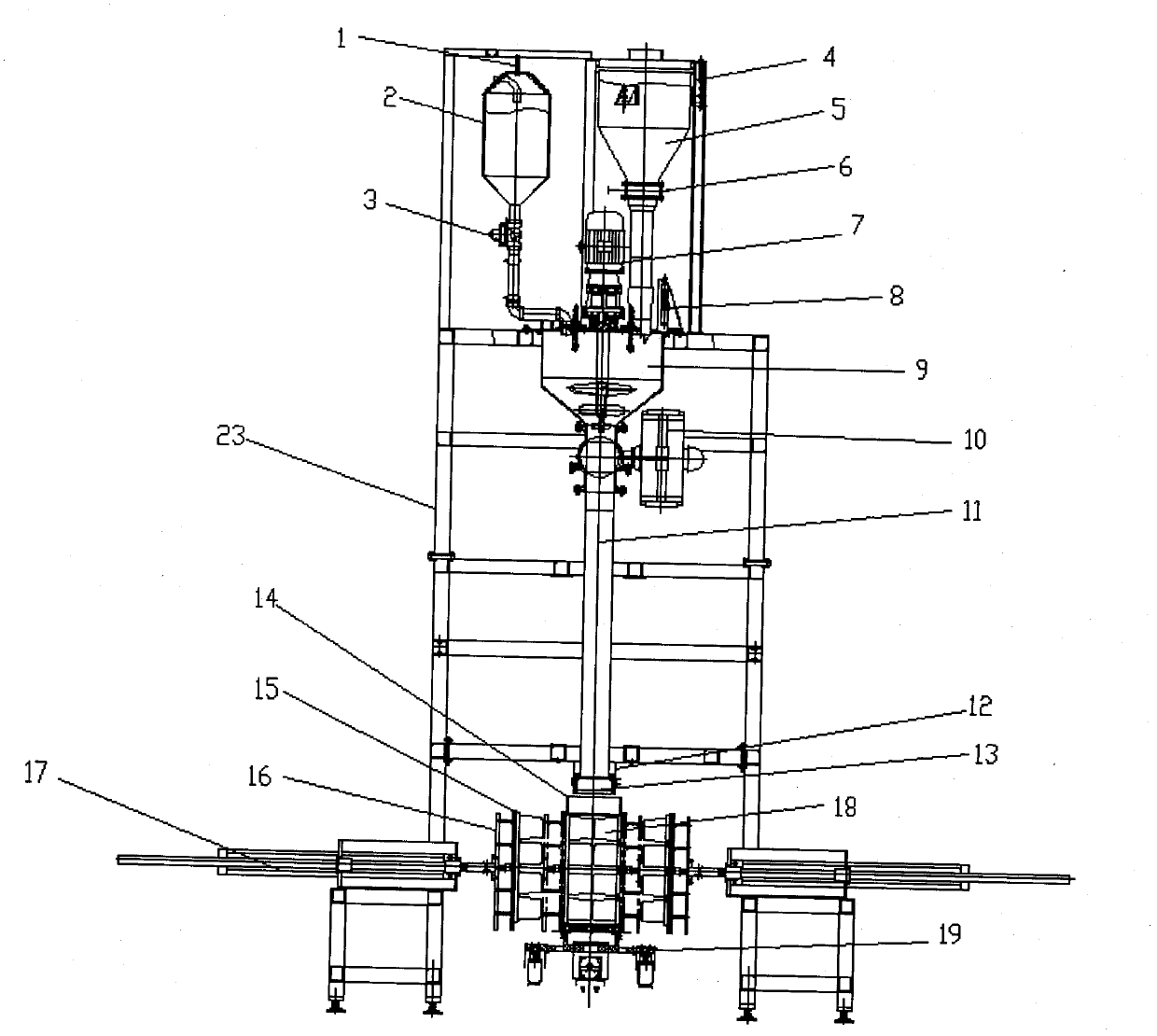

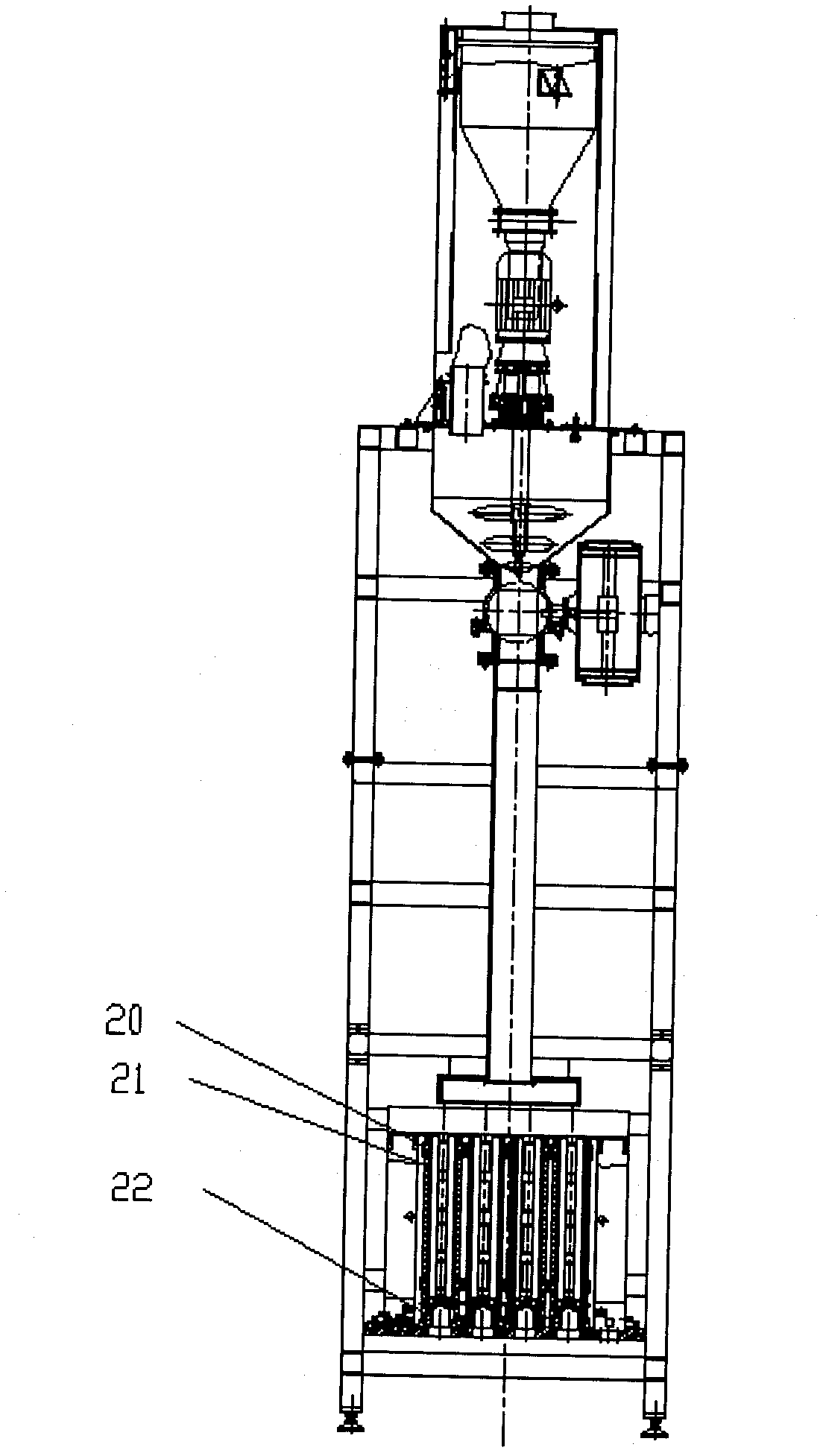

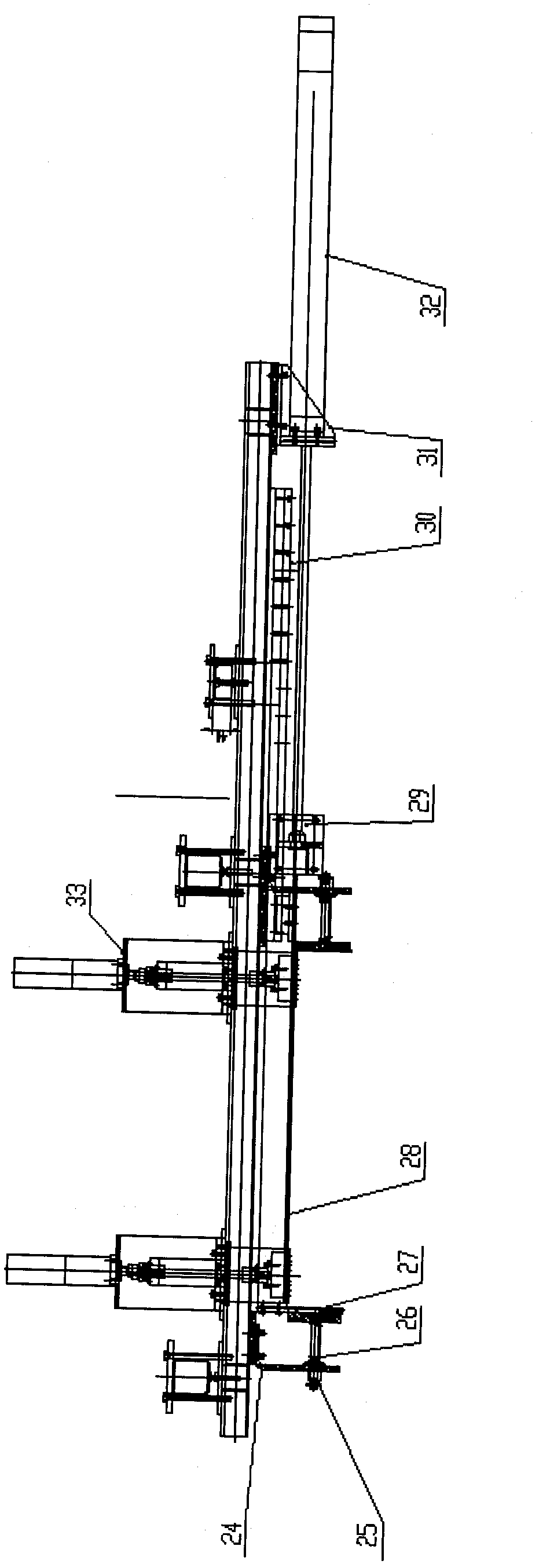

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , figure 2 , image 3 , a gypsum block forming machine in this embodiment, comprising a frame and a forming mold, characterized in that: the frame is equipped with a powder metering device, a water metering device, a stirring device and a mold for sealing, scraping, A core-inserting machine for crushing and recovering pulp; the powder metering device and water metering device are respectively installed on the upper part of the frame 23, and the powder and water can be sent into the inner cavity of the mixing chamber 9 through the powder channel and the water channel, and the pumping and insertion The core machine is installed in the lower part of the frame.

[0024] The powder metering device includes a powder metering hopper 5, a load cell 4 matched with the powder metering hopper and a butterfly valve 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com