Patents

Literature

685results about How to "Efficient grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milled submicron chlorothalonil with narrow particle size distribution, and uses thereof

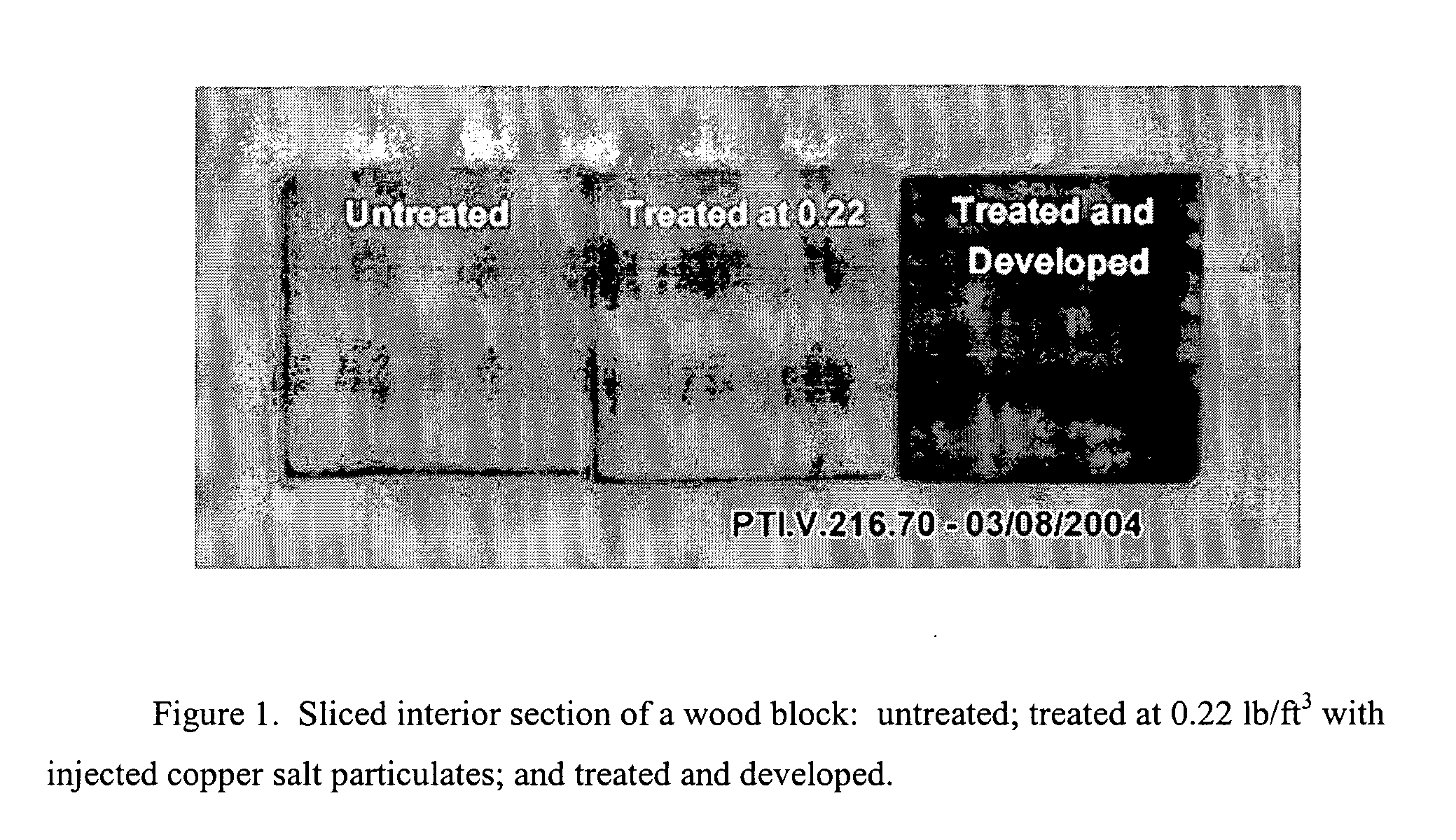

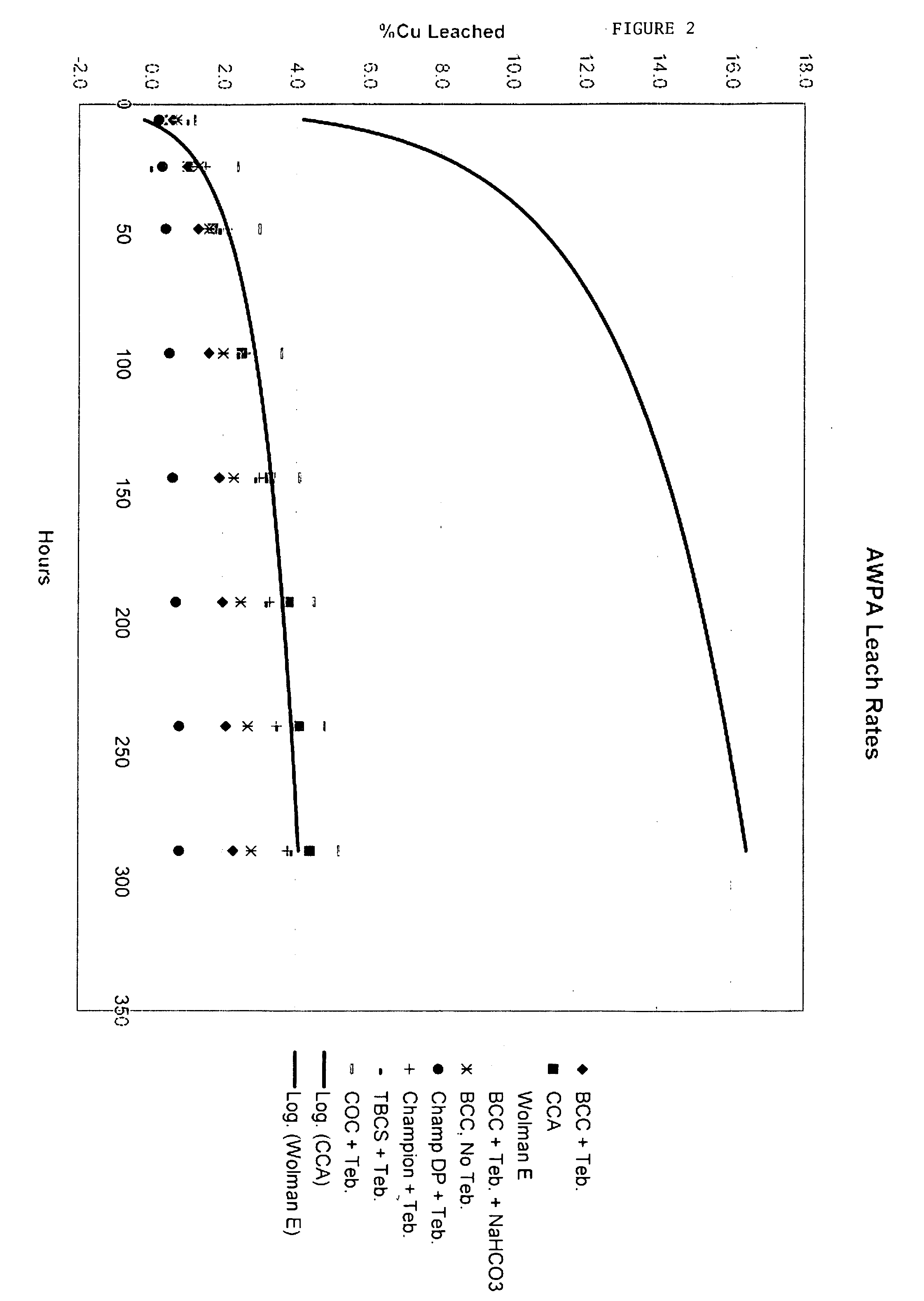

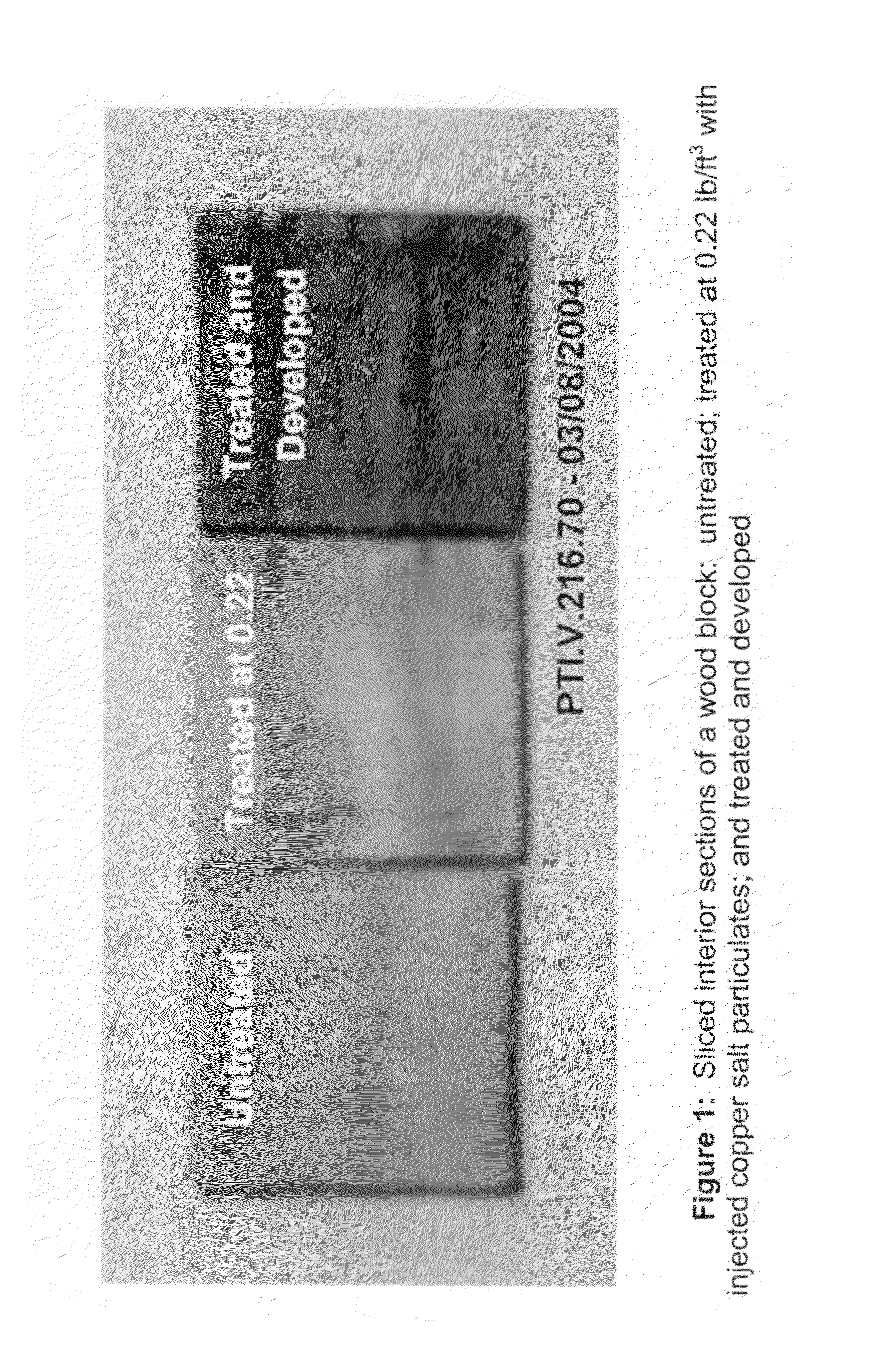

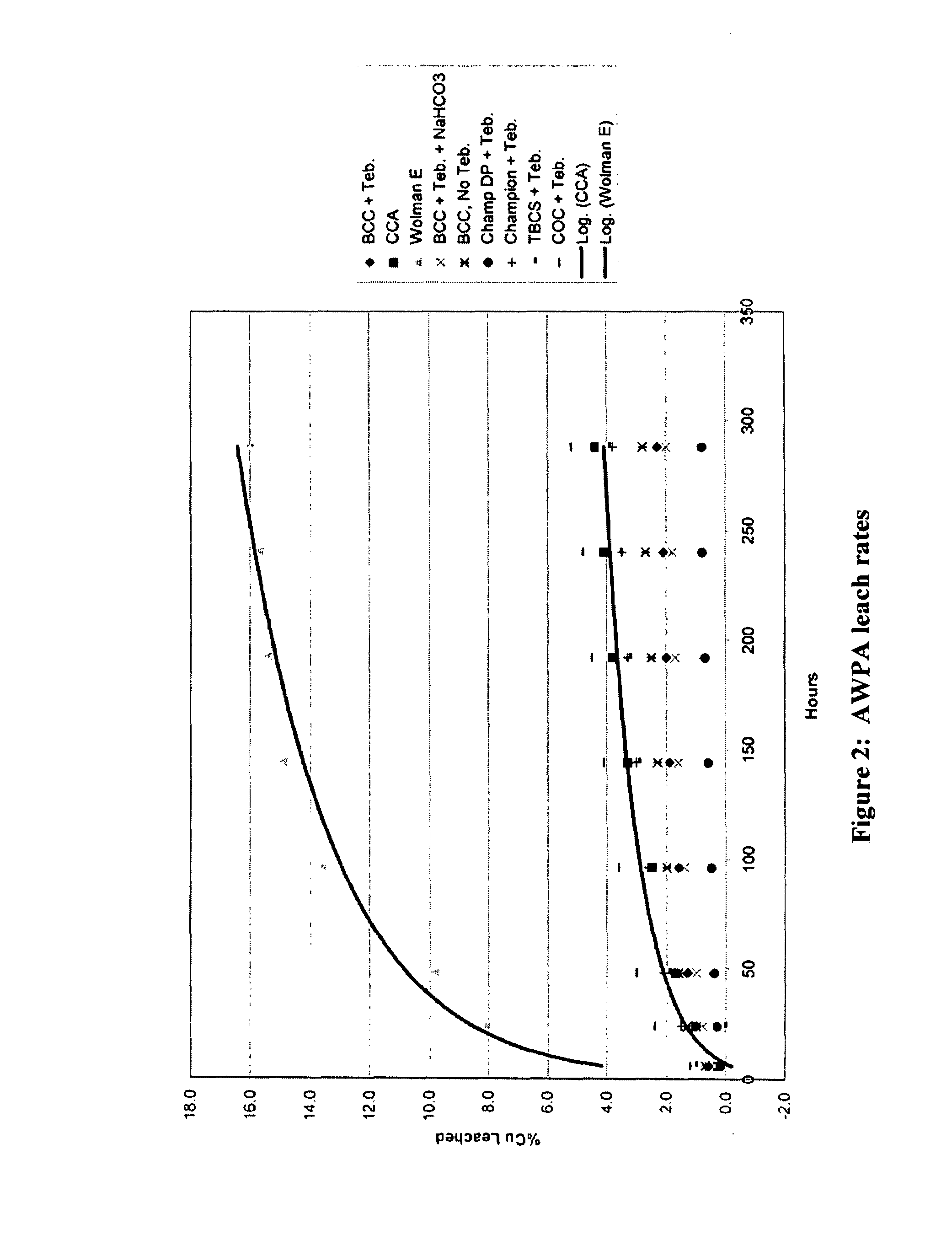

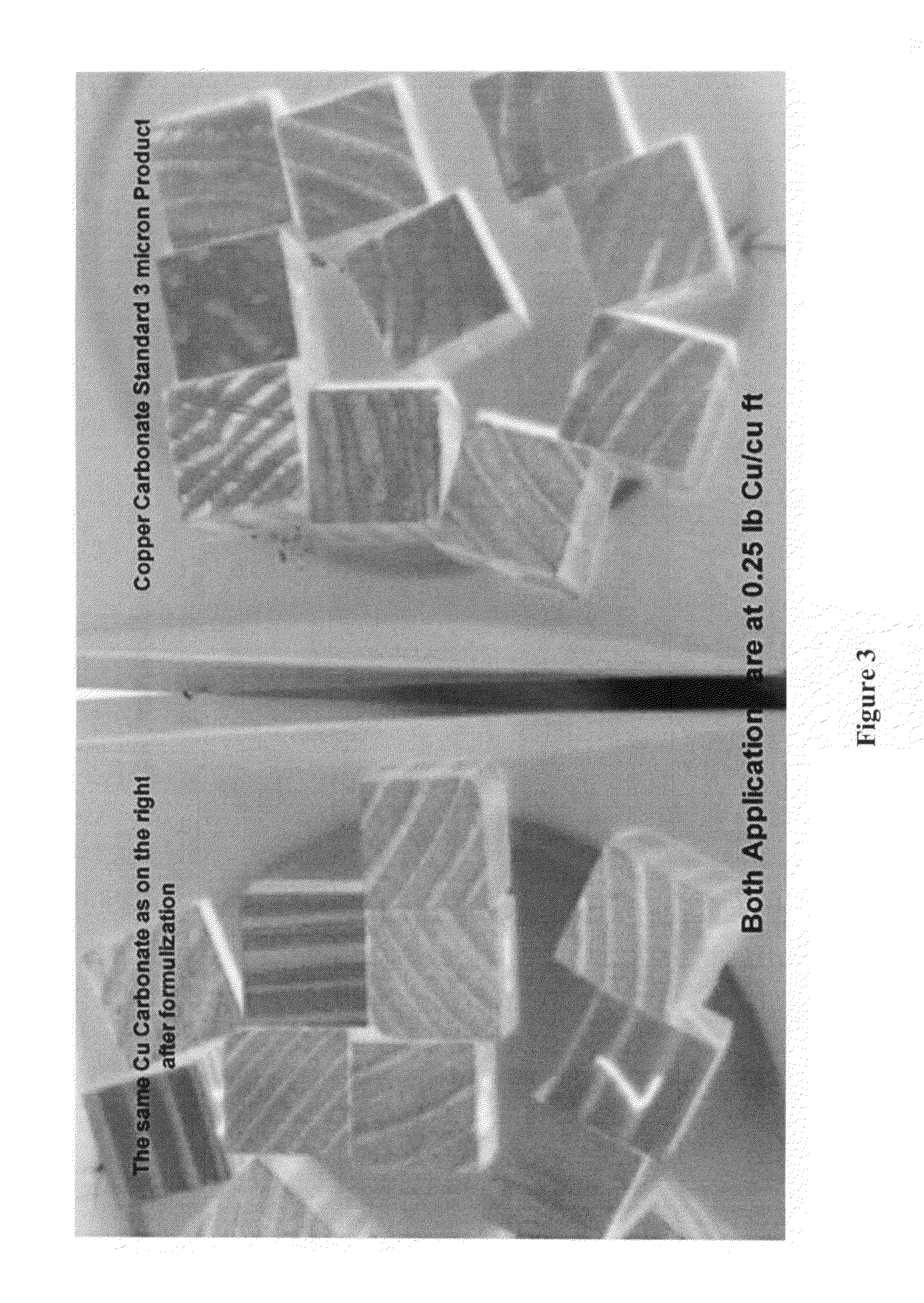

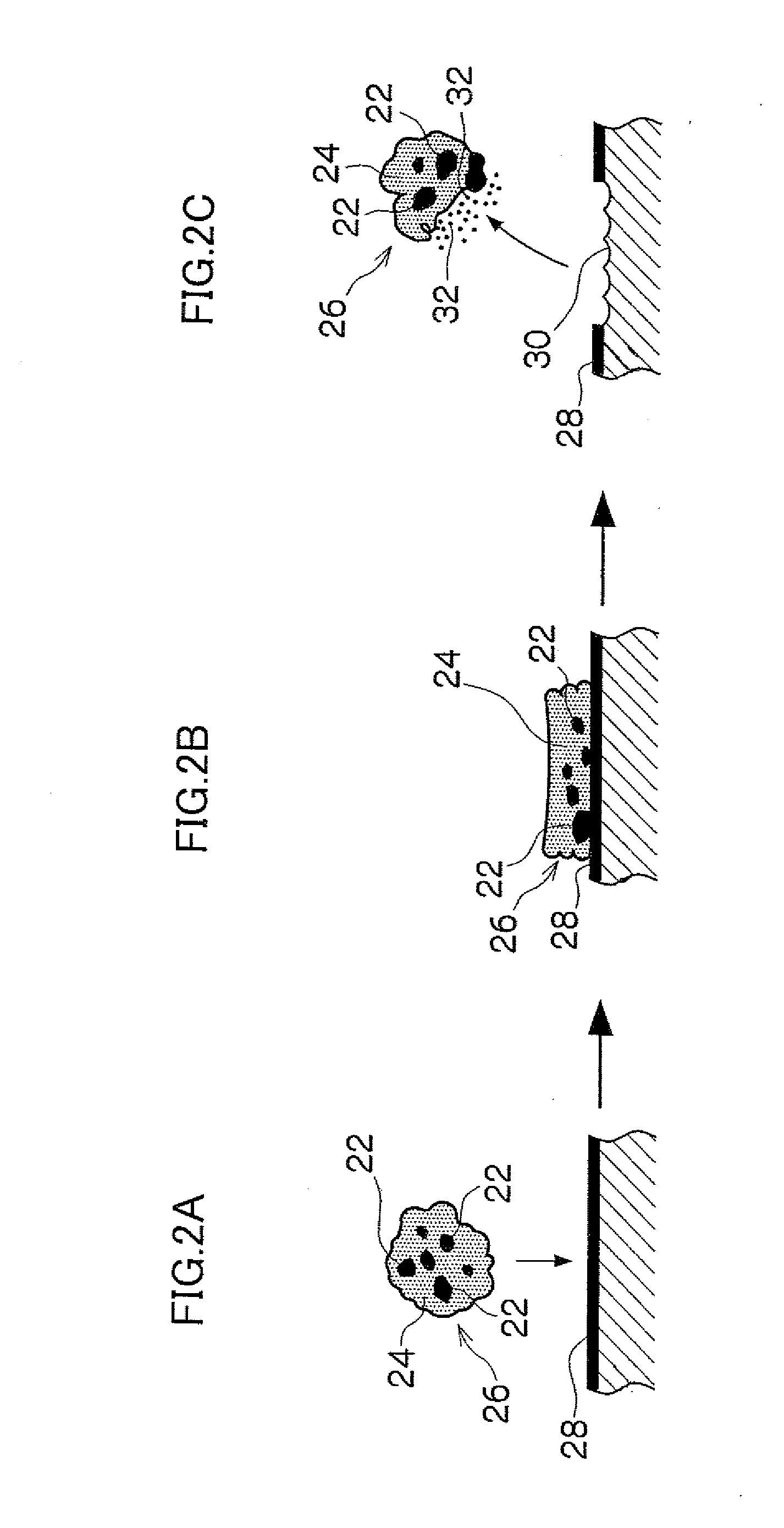

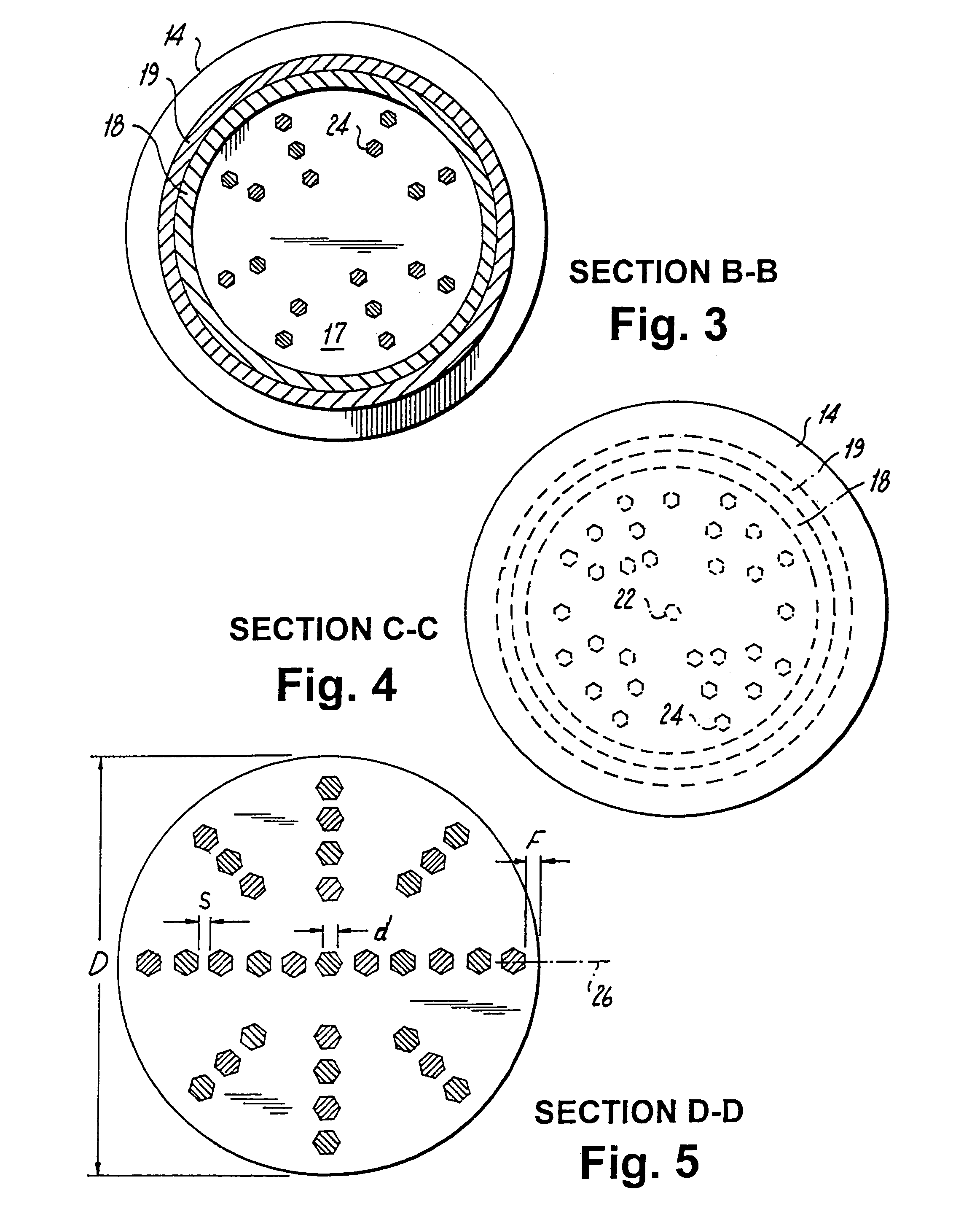

A method of milling chlorothalonil to form a sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the chlorothalonil with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the chlorothalonil suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid chlorothalonil particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

Milled submicron chlorothalonil with narrow particle size distribution, and uses thereof

A method of milling chlorothalonil to form a sub-micron product having a narrow particle size distribution is presented. The milling involves wet milling of the chlorothalonil with high density milling media having a diameter between 0.1 mm and 0.8 mm, preferably between 0.2 mm and 0.7 mm, and a density equal to or greater than 3.8 g / cc, preferably greater than 5.5 g / cc, in a ball mill using between about 40% and 80% loading of the mill volume with milling media, and having the chlorothalonil suspended in an aqueous milling liquid which comprises one or more surface active agents. The milling speed is preferably high, for example from about 1000 rpm to about 4000 rpm. The milled product can be used in foliar applications at a lower effective dosage than prior art formulations, can be used in improved antifouling paint formulations, and can be used in new applications such as the direct injection of solid chlorothalonil particulates in wood to act as a long lasting wood preservative.

Owner:KOPPERS PERFORMANCE CHEM

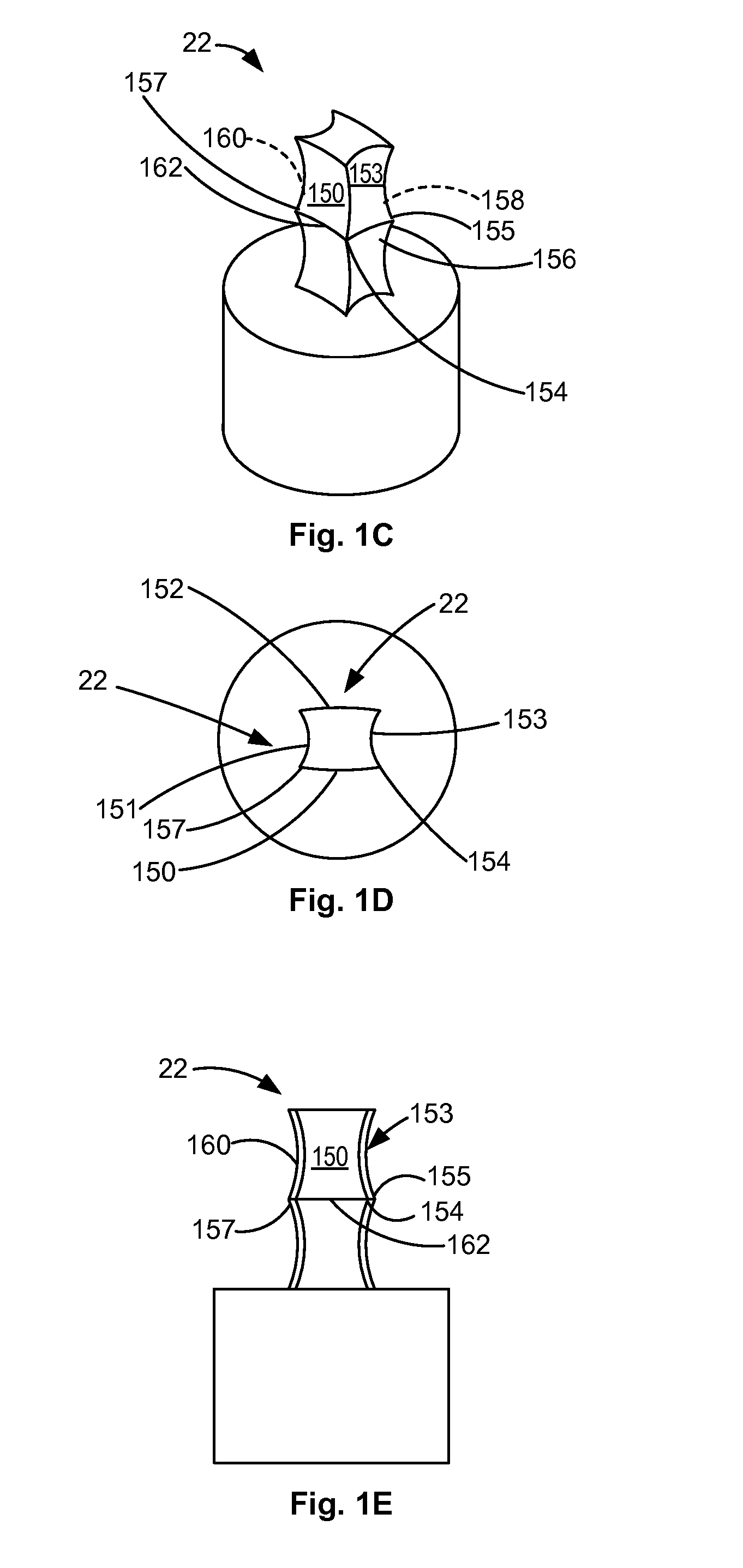

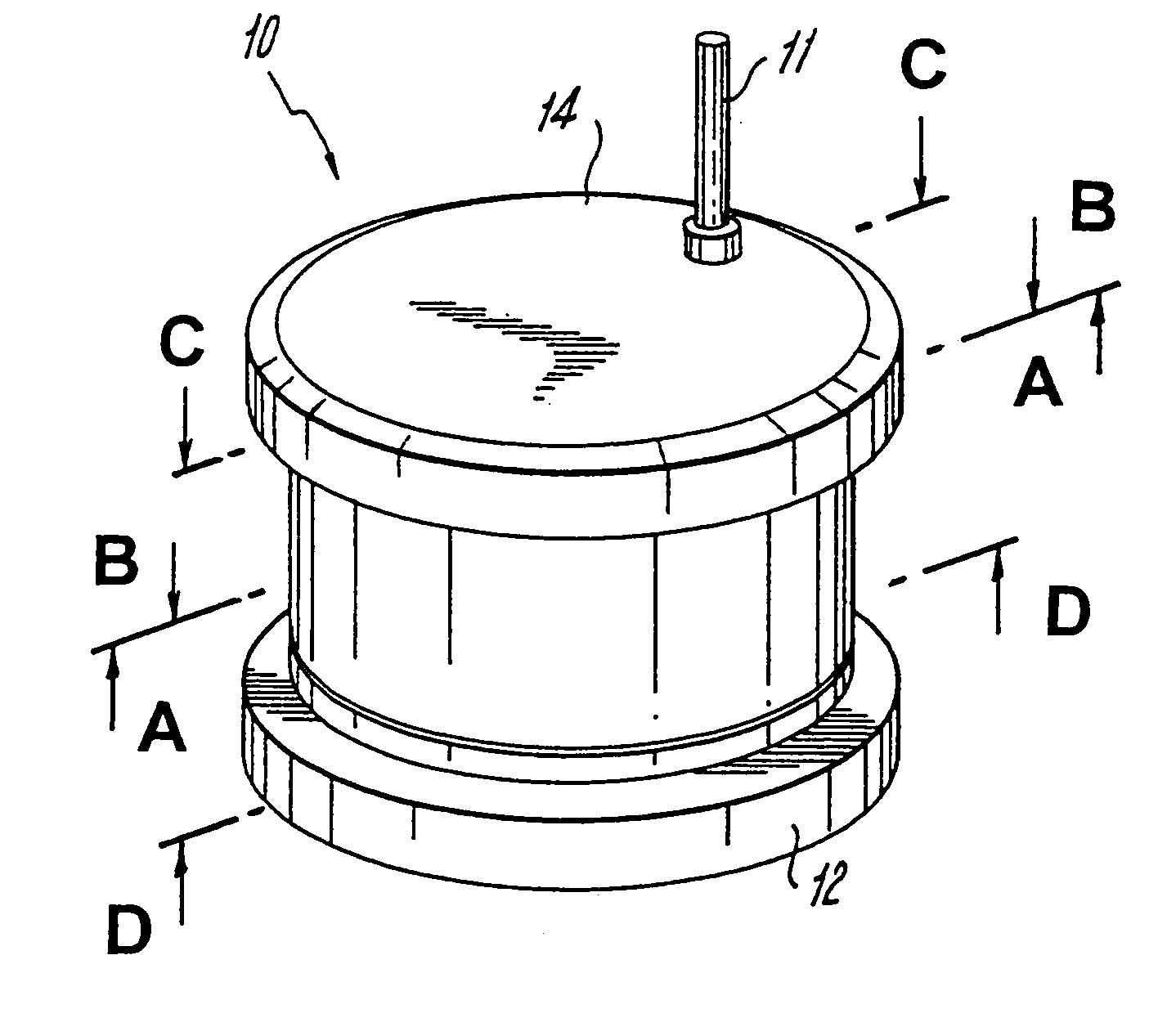

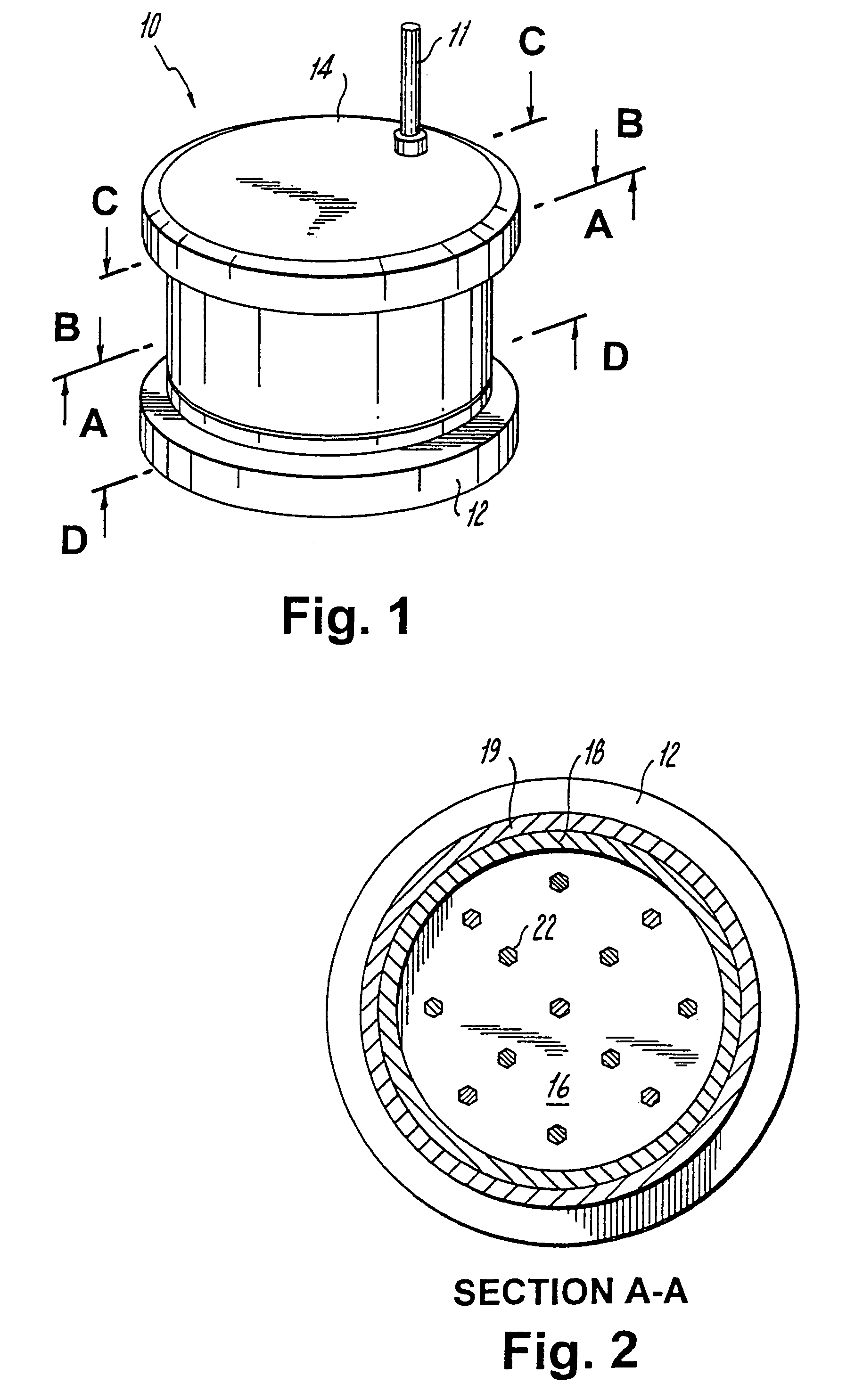

Herb grinder

ActiveUS20140217213A1Efficient grindingPortable and compact and efficientCoffee millsSpice millsHerbCounter rotating

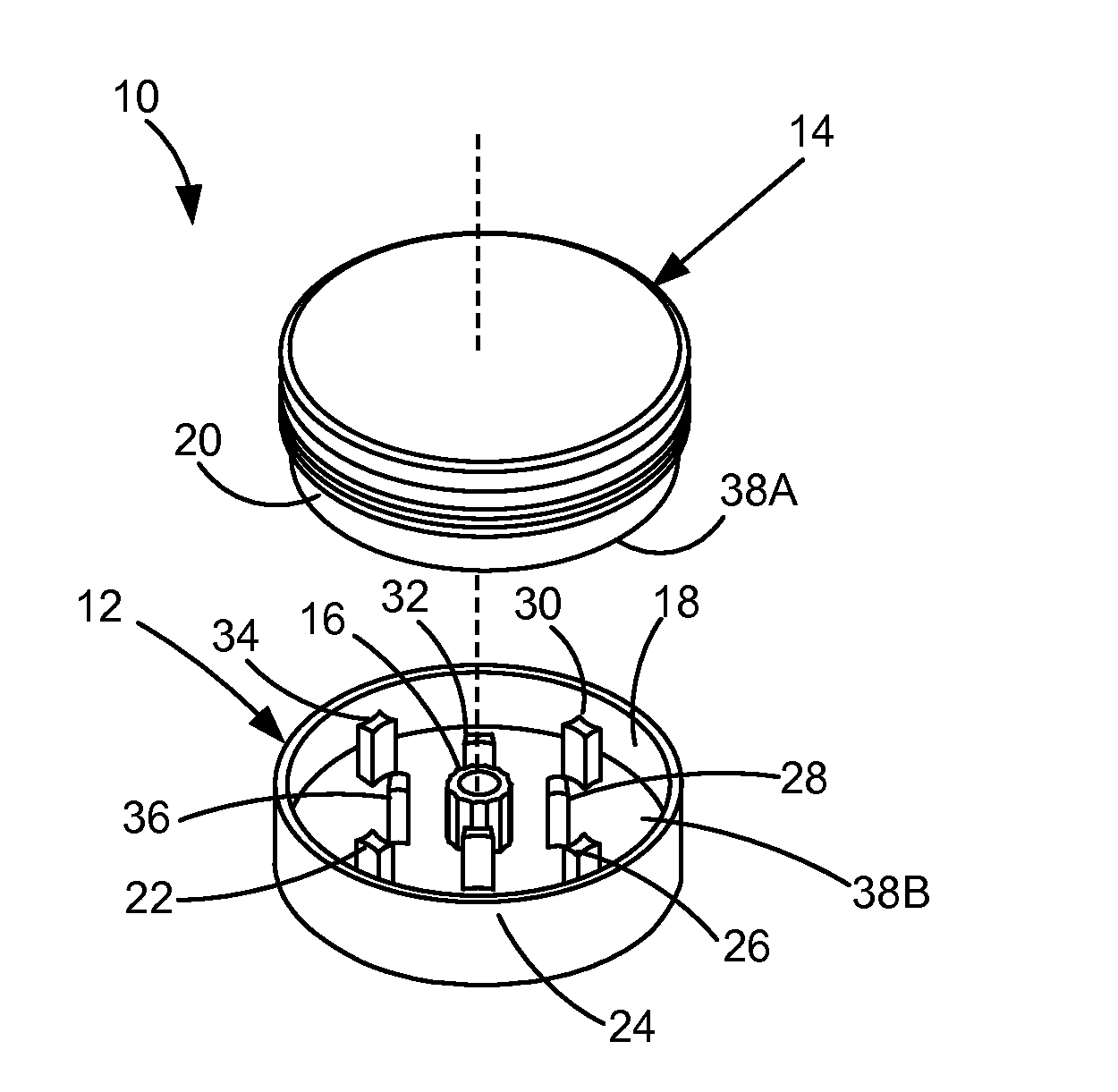

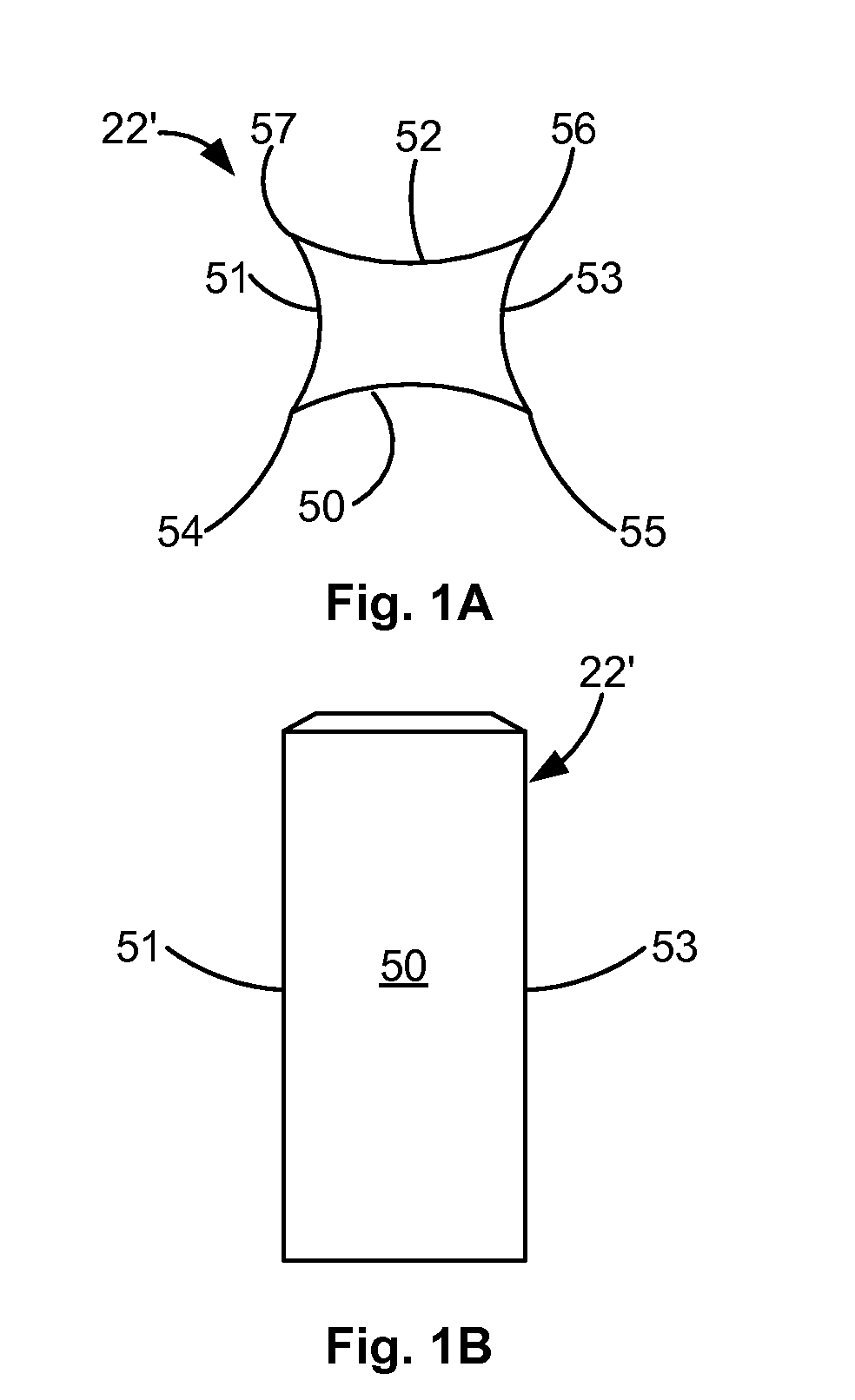

A shredder or grinder for dried material such as herbs of dried leaves comprises a cylindrical container formed of a top element and a base element forming a chamber, the top element and the base element each having a series of concentrically arranged teeth on a base plate, wherein the teeth that slidably engage one another in a slicing motion to form grinding surfaces against one another, wherein the teeth are serrated to efficiently grind the dried materials in the chamber when the teeth engage one another and are counter rotated relative to one another. In one embodiment the chamber discharges the ground contents through orifices in the base element, where the size is regulated by a screen, and in another embodiment, the ground contents remain in the chamber until the grinding head is removed.

Owner:SC SHREDDER IP LLC

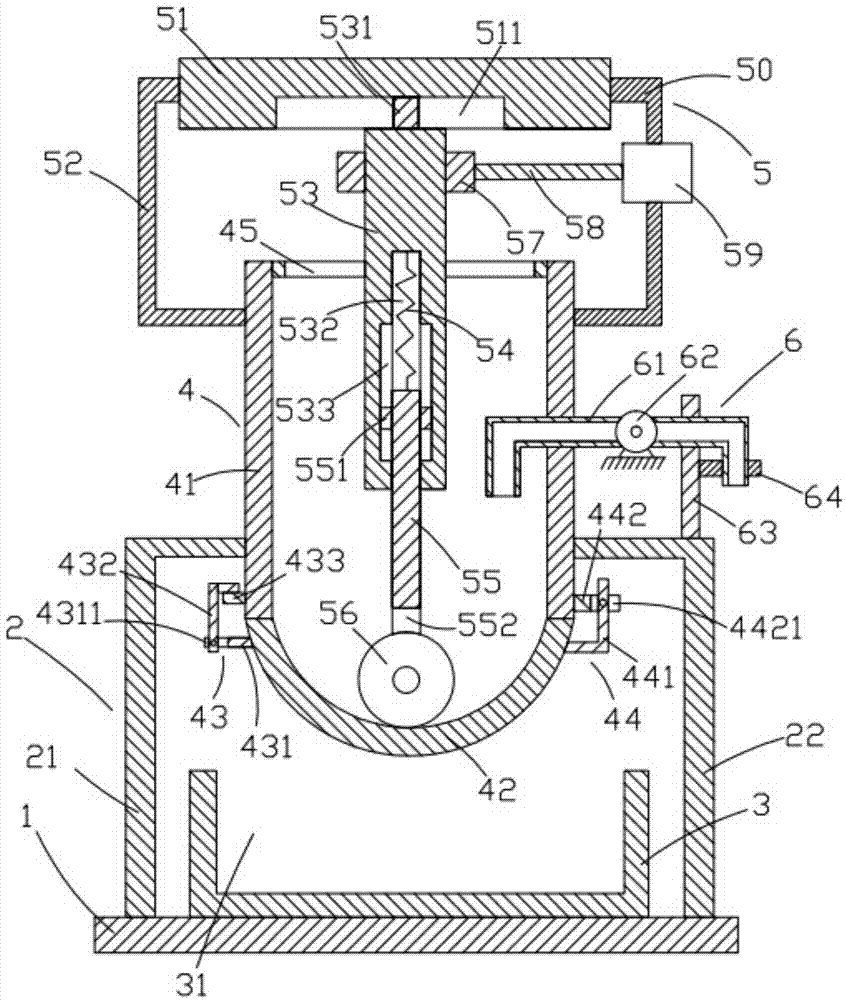

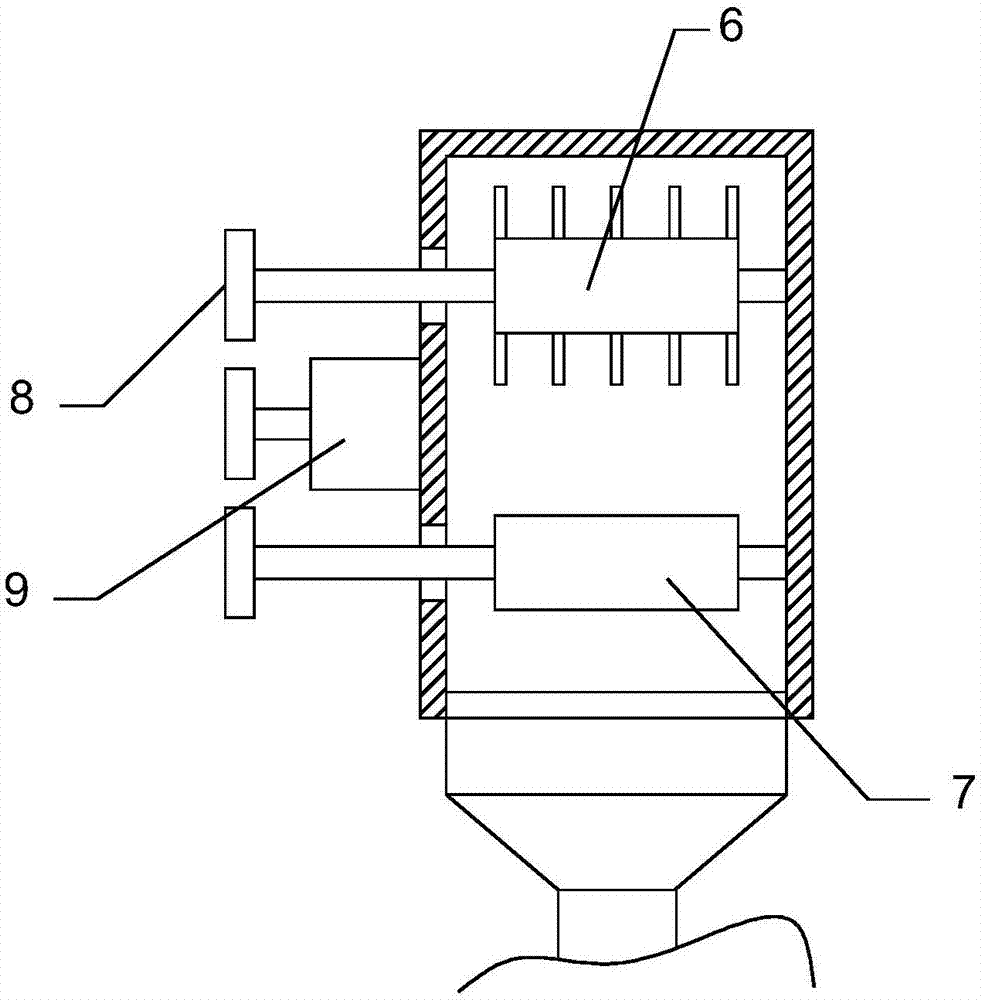

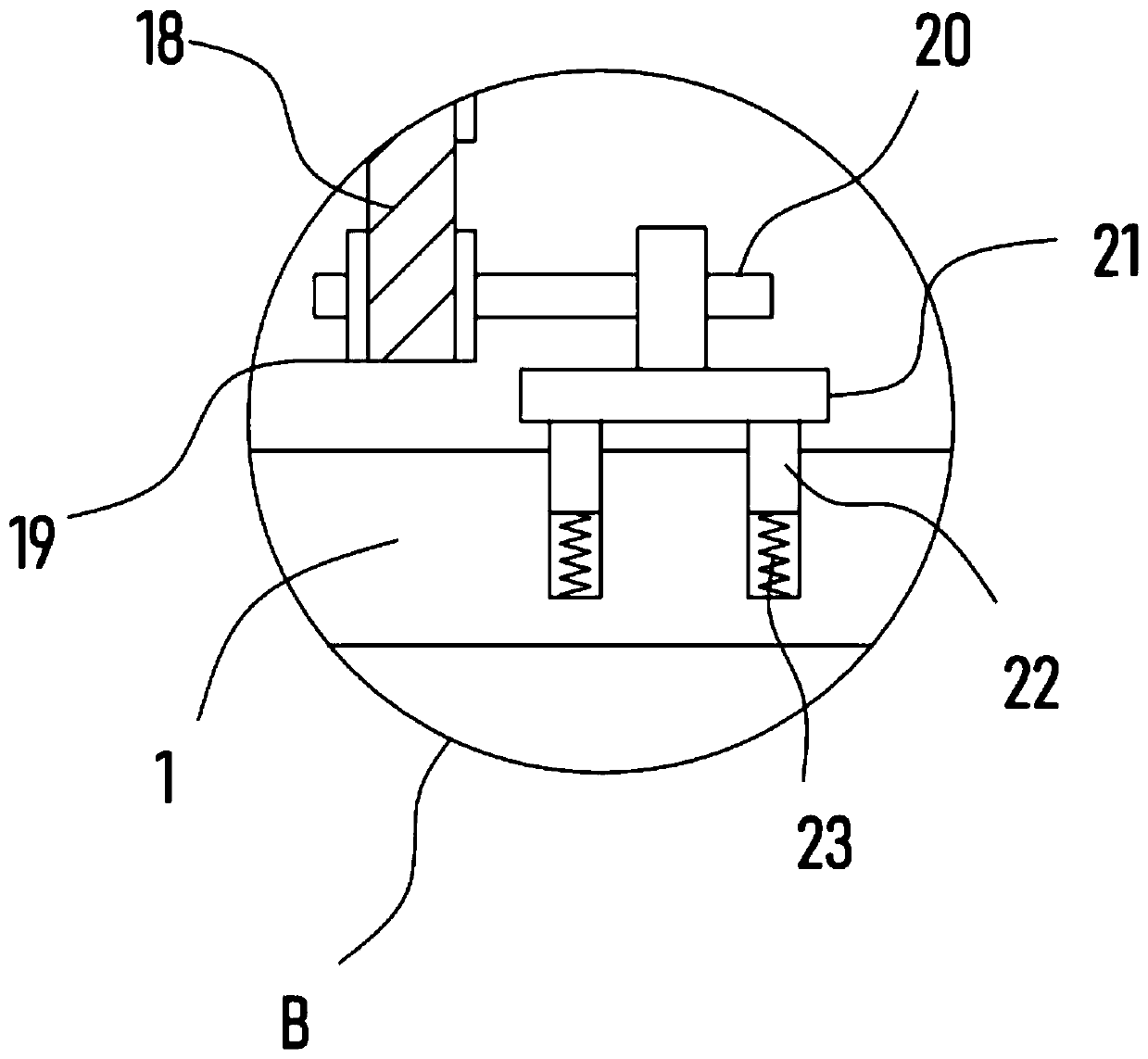

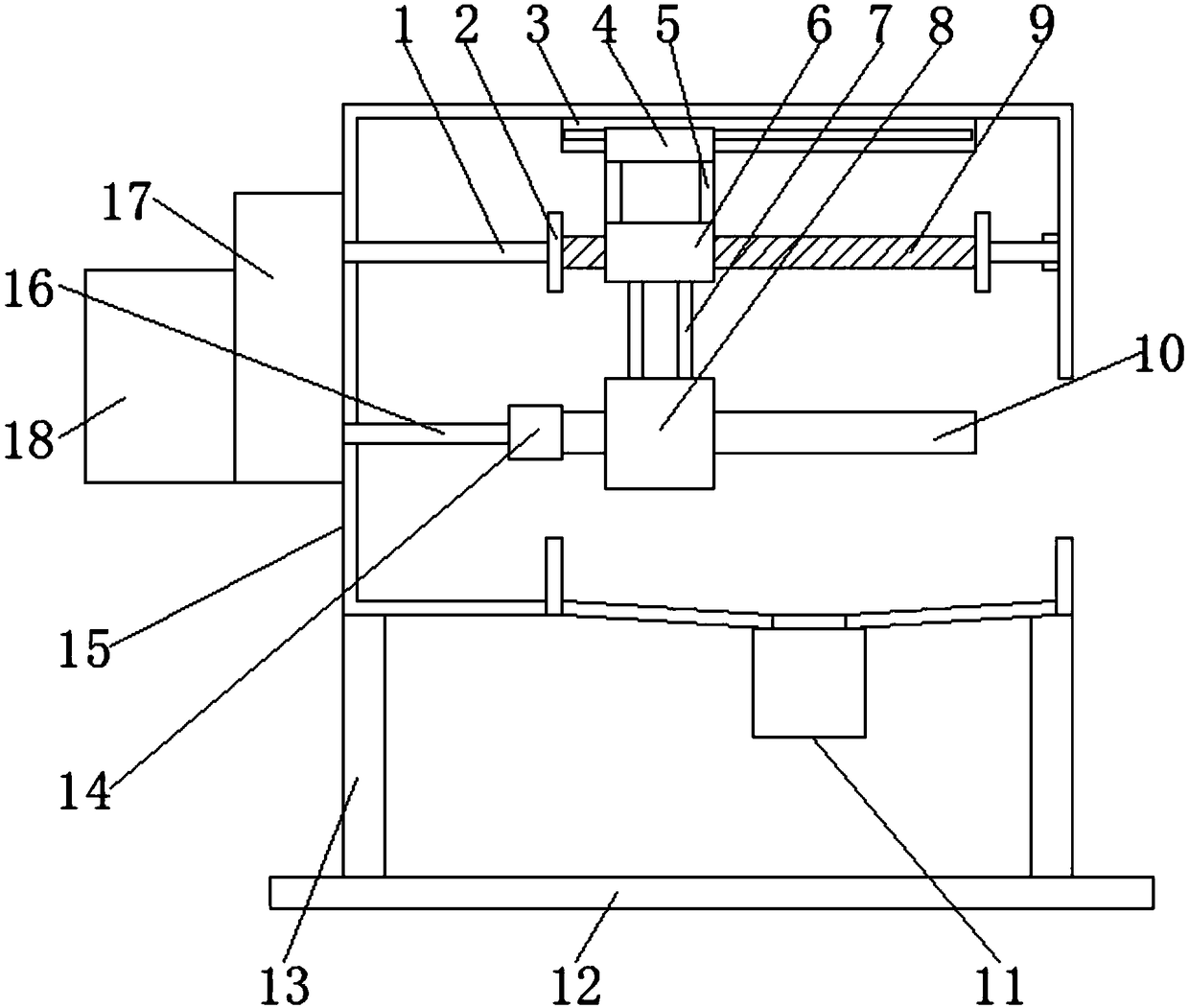

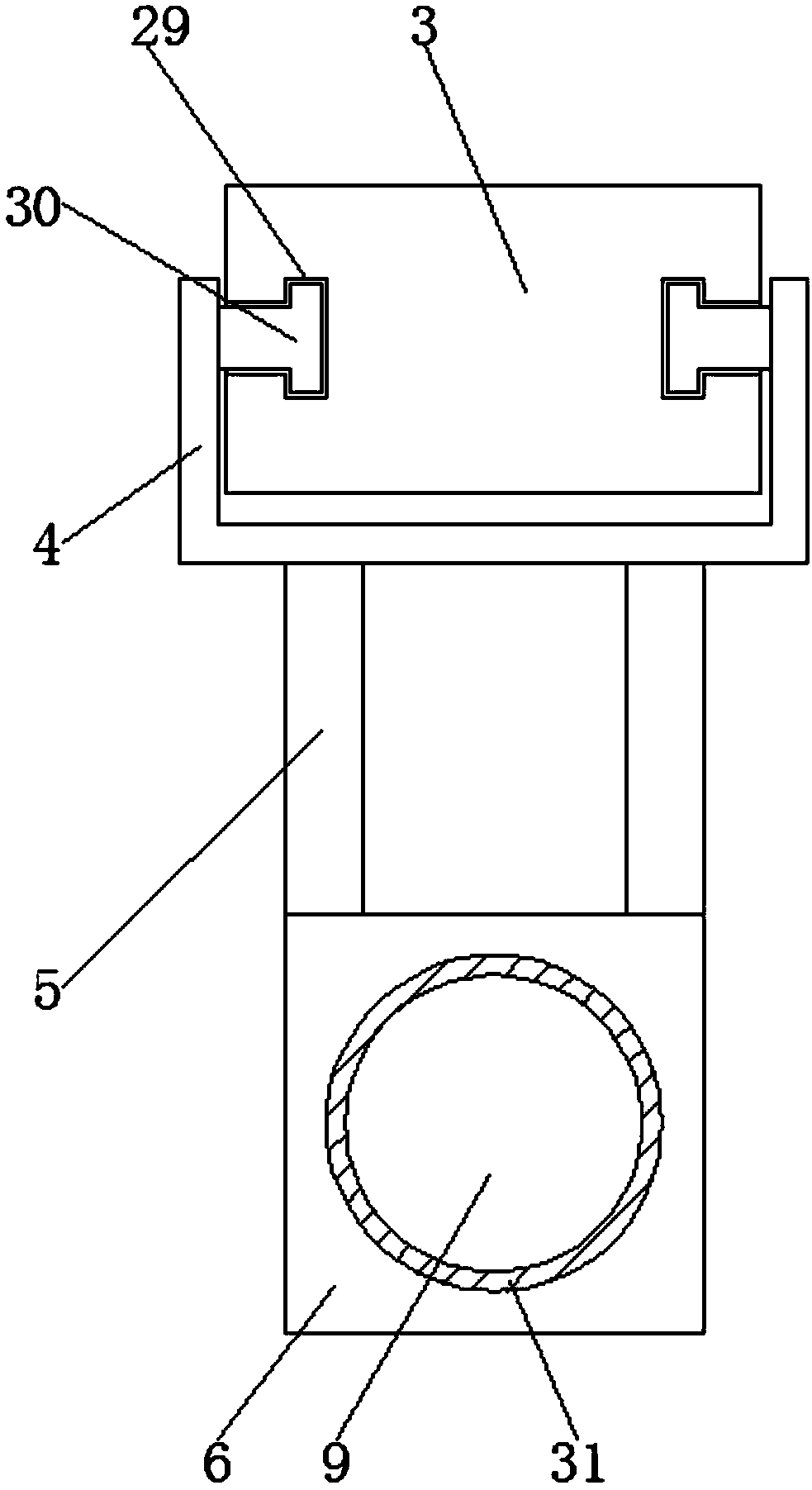

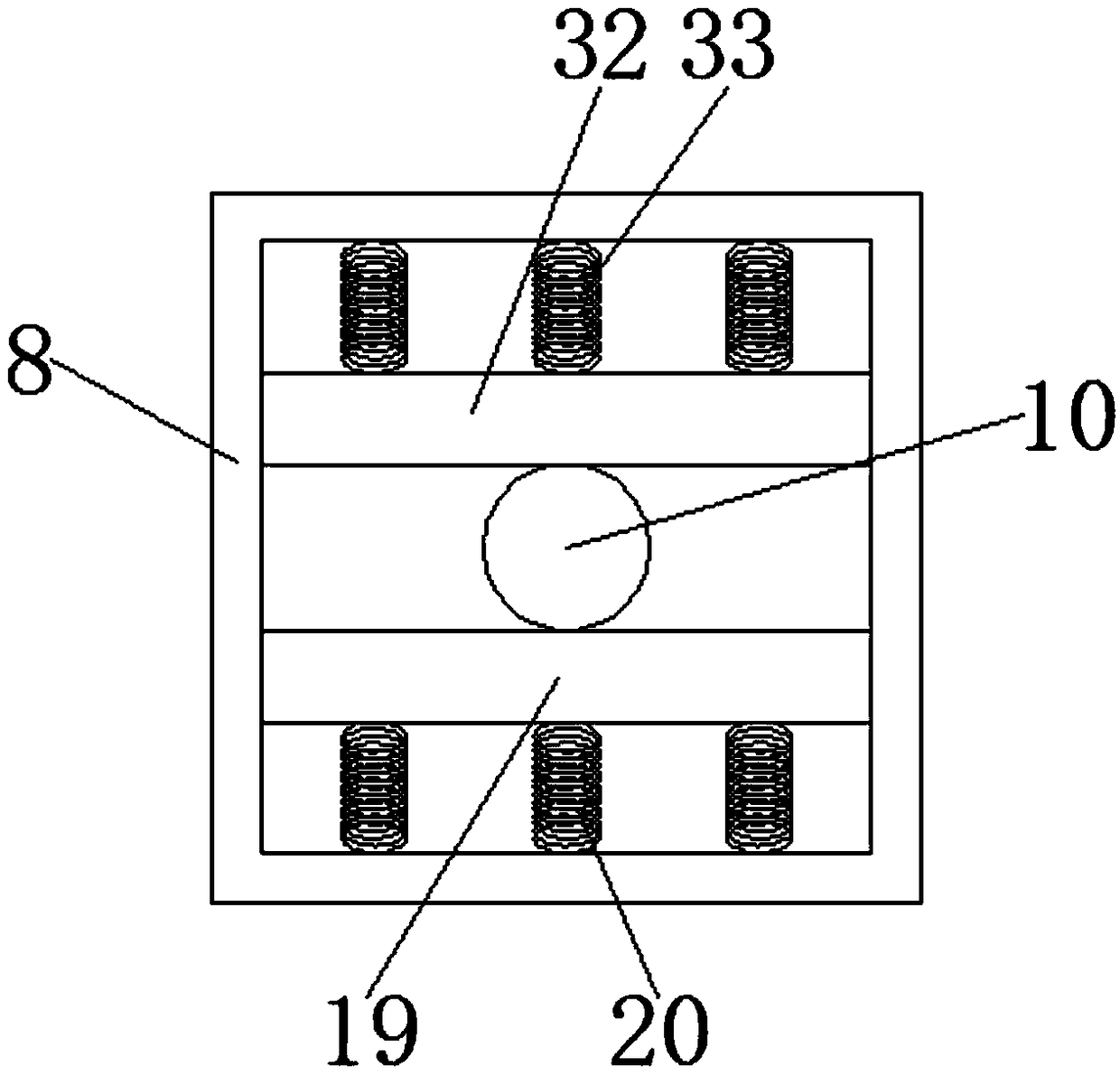

Medicine grinding device

The invention discloses a medicine grinding device. The medicine grinding device comprises a base, a bracket device, a frame body device, a grinding device, a blowing device and a material receiving box, wherein the bracket device comprises a first bracket and a second bracket; the frame body device comprises an upper frame body, a lower frame body, a first fastening device, a second fastening device and a first rectangular hole; the upper surface of the material receiving box is concave downwards to form a material receiving cavity; the lower surface of the upper frame body is concave upwards to form a first containing cavity; the upper surface of the lower frame body is concave downwards to form a second containing cavity; the first fastening device comprises a first horizontal rod, a first fastening rod and a second horizontal rod; the second fastening device comprises a connecting rod and a third horizontal rod; the grinding device comprises a positioning plate, a first supporting rod, a supporting column, a spring, an ejecting rod, a grinding wheel, a fixed block, a pushing rod, a cylinder, a second supporting rod and a third supporting rod; and the blowing device comprises a blowing pipe, a fan, a fourth supporting rod and a fifth supporting rod. The medicine grinding device disclosed by the invention has the advantages that the structure is simple, the use is convenient, the medicines can be effectively ground and the grinding effect is good.

Owner:CHAMFOND BIOTECH CO LTD

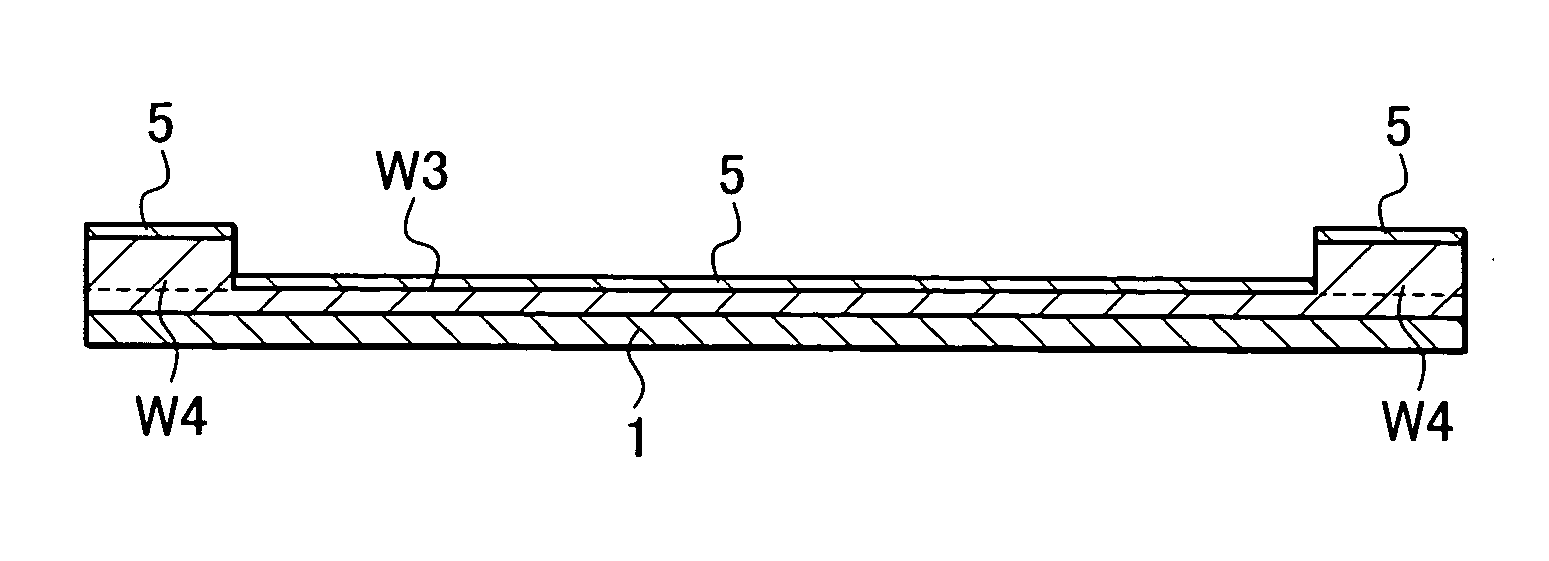

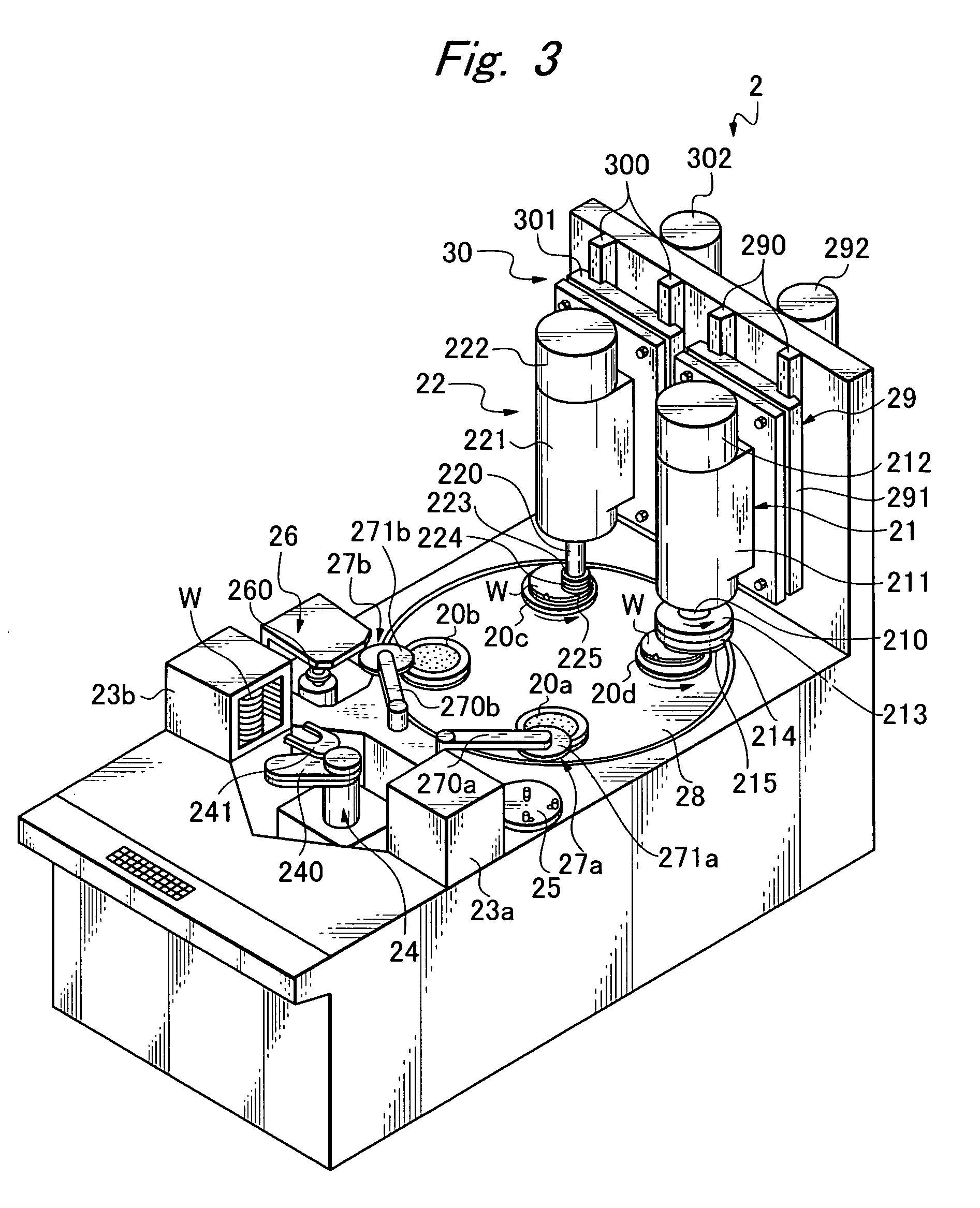

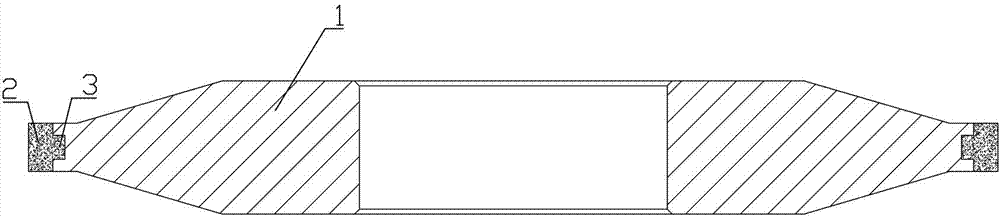

Processing method and grinding apparatus of wafer

ActiveUS20070020887A1Easy to disassembleDecrease productivitySemiconductor/solid-state device manufacturingPlane surface grinding machinesDevice formEngineering

To facilitate handling of a wafer in processing or carrying after the wafer being reduced in thickness by grinding, the whole back of a wafer having a surface on which a device region having a plurality of devices formed therein and a peripheral surplus region enclosing the device region are formed, is ground to be formed into a wafer having a predetermined thickness, and then a region corresponding to the device region in the back of the wafer is ground to form a concave portion having a predetermined thickness, so that a ring-like reinforcement portion is formed in a peripheral side of the concave portion, thereby the wafer is easily handled in a subsequent step or in wafer carrying between respective steps.

Owner:DISCO CORP

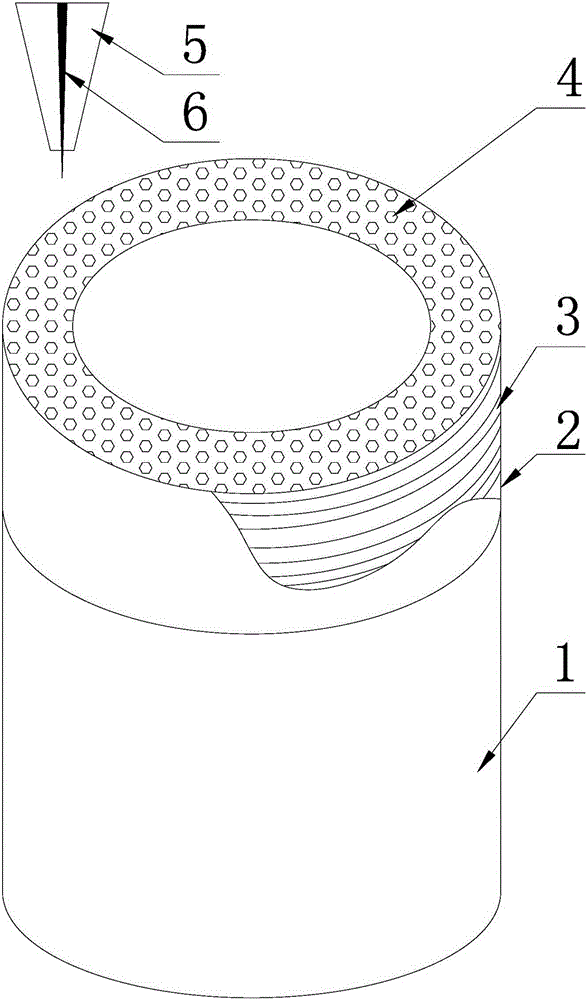

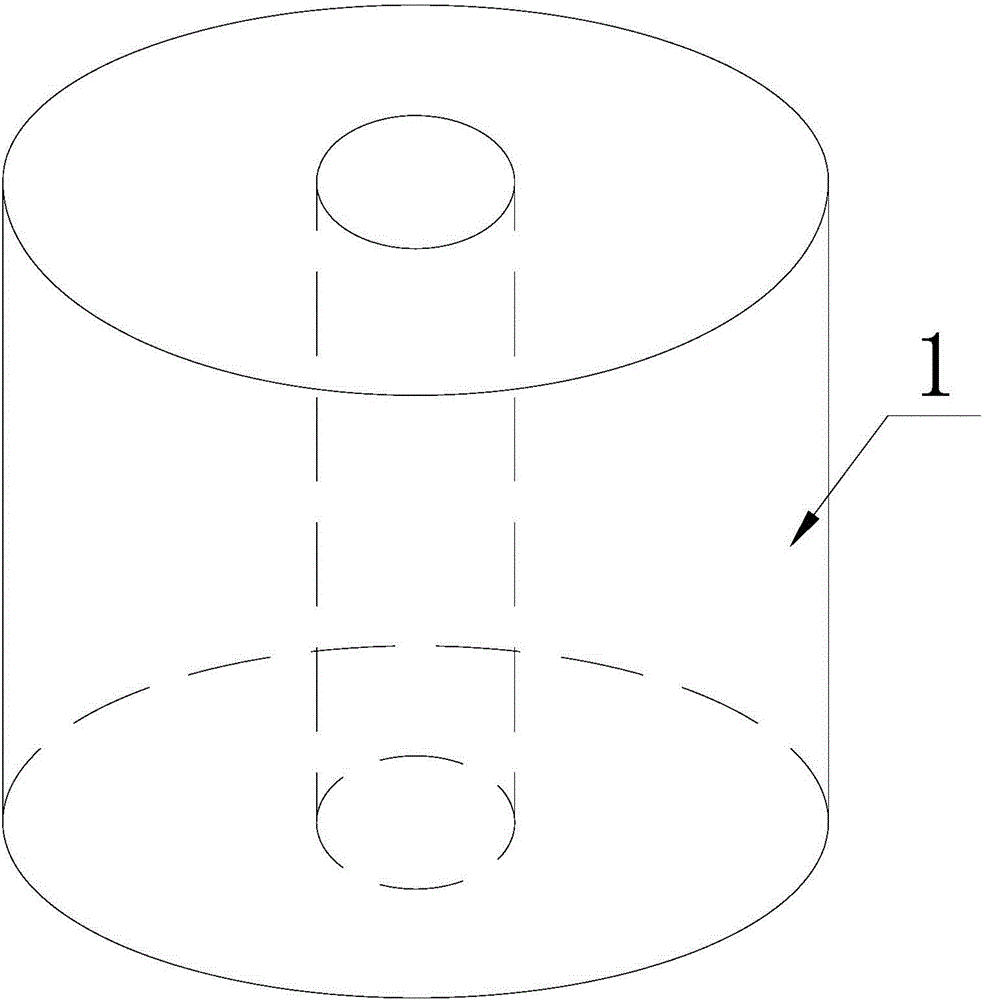

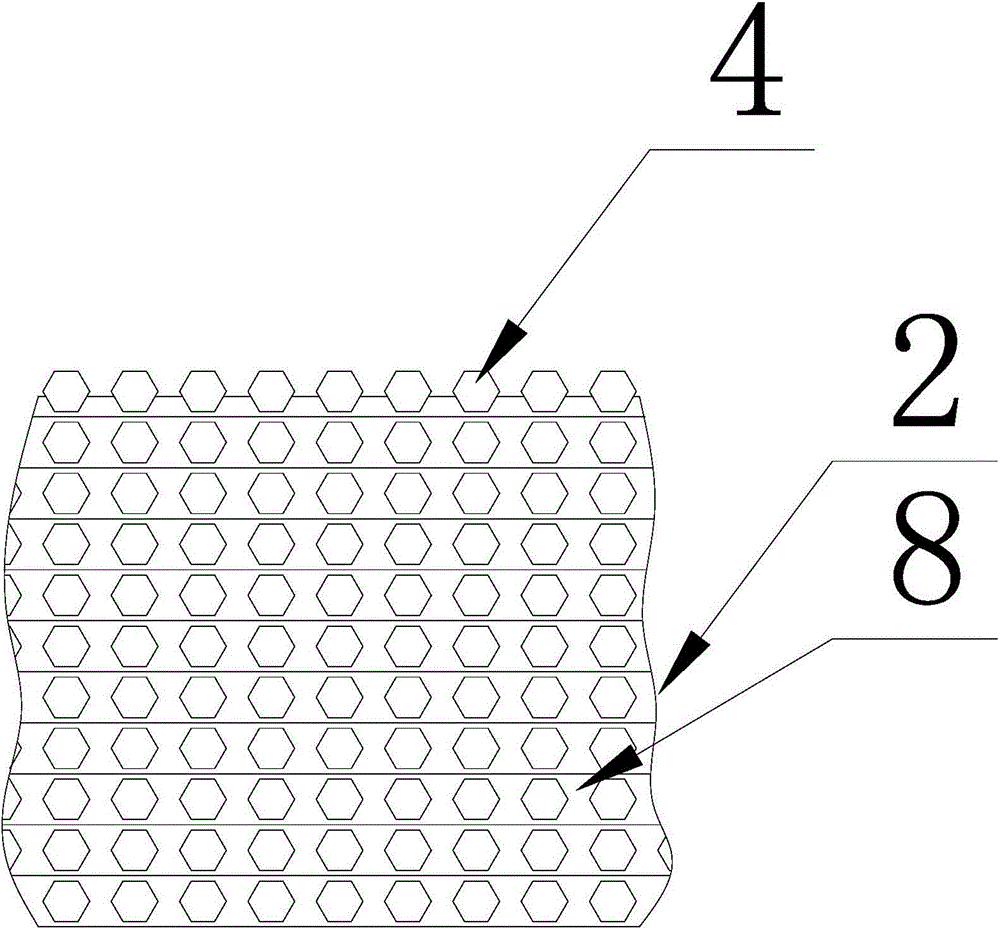

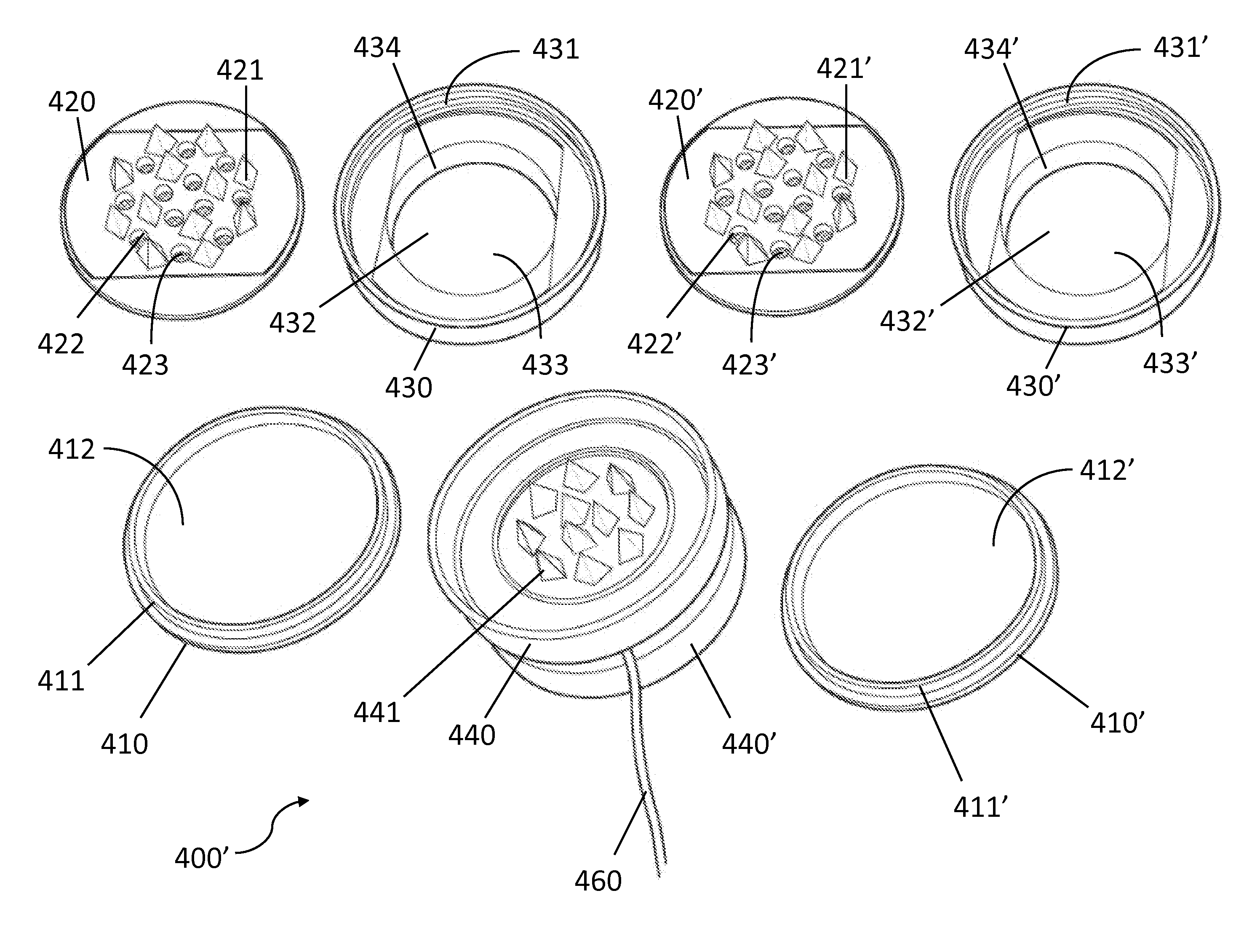

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

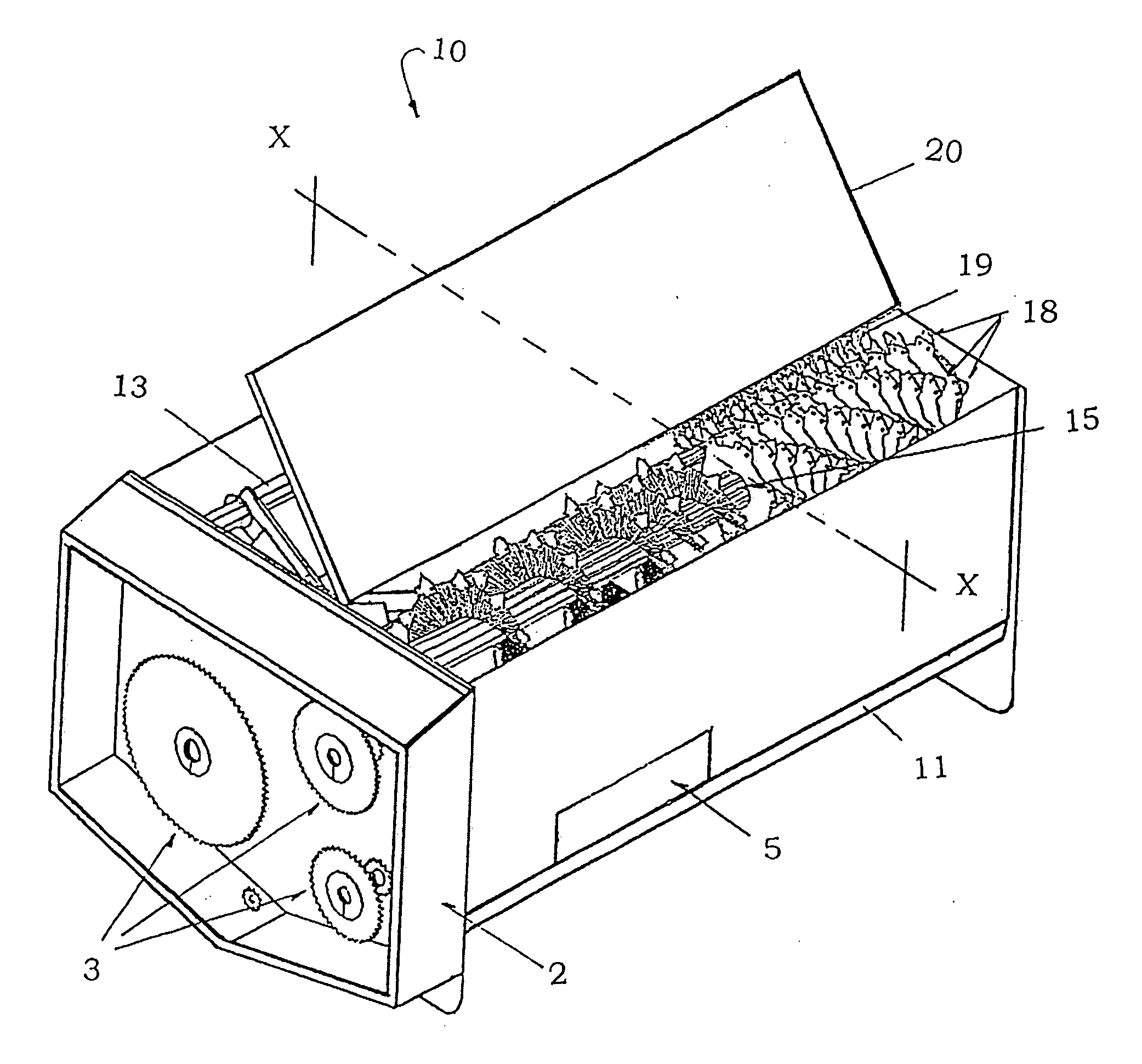

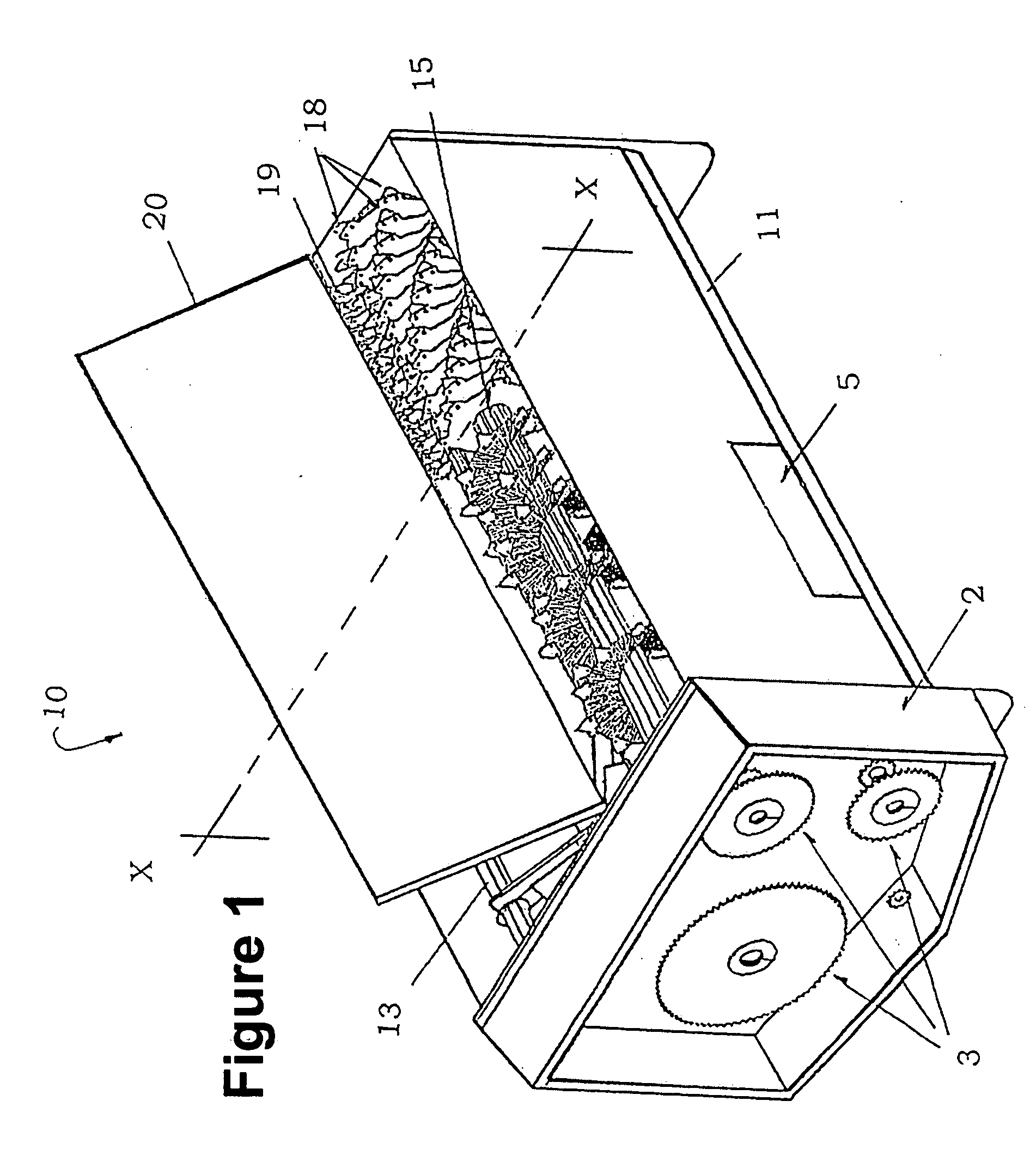

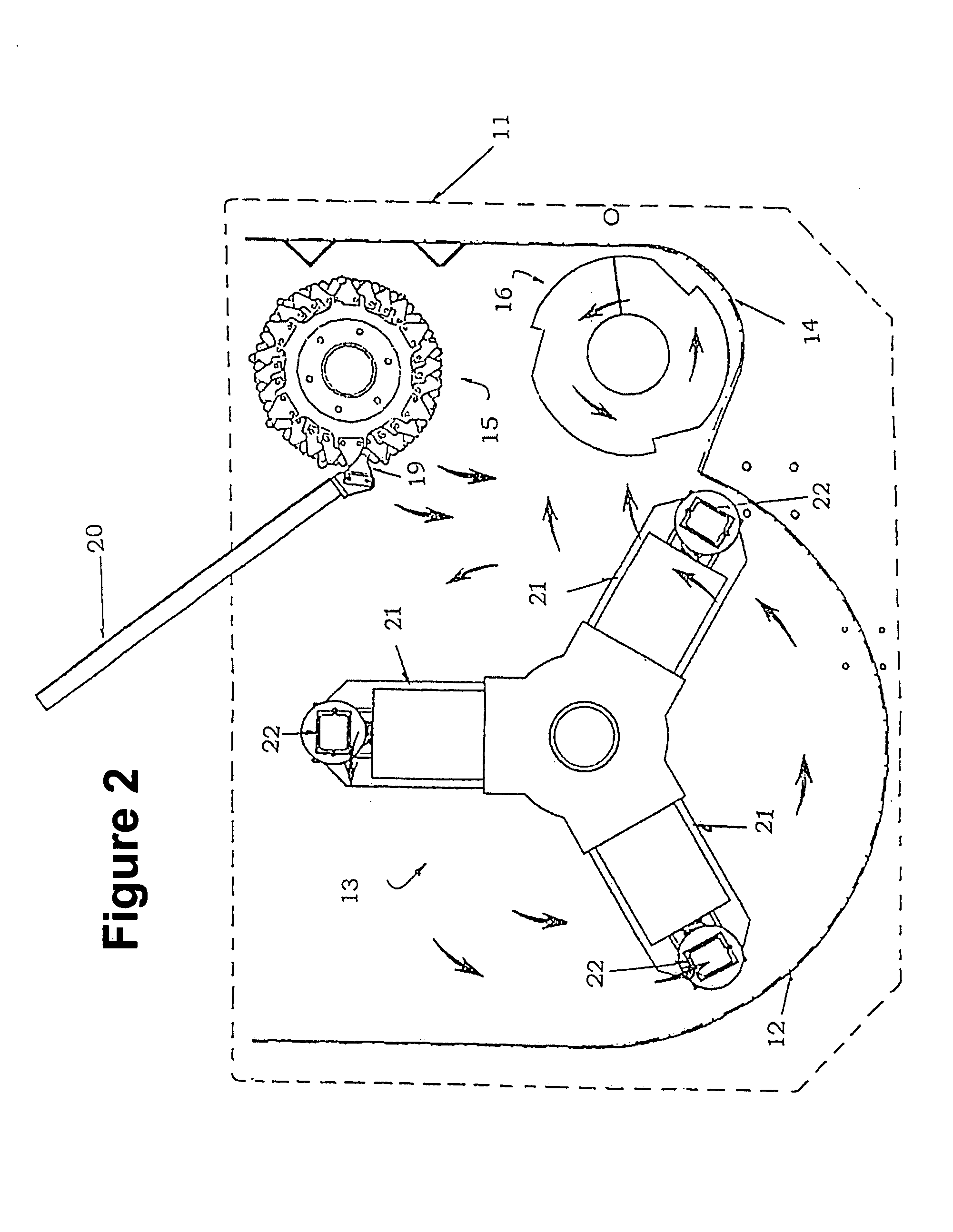

Livestock food processing mixing machine

InactiveUS20050087636A1Quick and efficient mannerCost savingGrain huskingGrain polishingLivestockEngineering

The present invention is related to a mixing machine which basically consists of a hopper, that has a main chamber within its housing, with a rotary member (rotor), where at said rotor ends there are cleaning elements for sweeping the floor and taking up the material, by feeding a secondary chamber, which is located in parallel adjacent to the main chamber, where said secondary chamber has a bottom worm conveying the material from one end of the mixing machine to the other end thereof, until collapsing with a loop found on its front portion and generating a material bubble; an upper worm to remove the material bubble and carrying it up to the middle part of the machine. At the middle part of the machine, the material is forced by a loop system having an upper worm to move towards the rotor area, such that the material is actually moving towards the back portion of the machine, completing a mixing cycle. Said upper worm has from the middle of its axis, a plurality of discs on which peripheral edge of each disc is mounted a series of exchangeable knives placed on a loop arrangement, which are passed through a counterplate, and which shows a series of exchangeable knives placed at the bottom part of the material collector chut, so when the upper worm discs plurality is rotating, it allows both, humid and dry fibers be efficiently crushed and / or ground and besides added to the other several common ingredients a unique and highly qualified mixing is achieved.

Owner:TORMEX IND DE C V

Resin binder superhard material grinding wheel for roller high-speed grinding and manufacture method thereof

InactiveCN103770030AIncreased Fracture Velocity LimitTightly boundAbrasion apparatusGrinding devicesSuperhard materialHigh-speed grinding

The invention aims at solving the problem that high-speed grinding cannot be realized through a hard alloy roller high-speed grinding wheel with low combination strength between a working layer and a base body and provides a resin binder superhard material grinding wheel for roller high-speed grinding and a manufacture method thereof. The grinding wheel comprises a base body and a grinding wheel working layer. A boss is arranged on the grinding wheel working layer. A groove corresponding to the boss is arranged on the base body. According to the grinding wheel, the boss is arranged on the grinding wheel working layer and is matched with the groove of the base body. The structure is favorable to compact combination of the grinding wheel working layer and the base body, increases the fracture speed restriction to the grinding wheel, realizes high-speed operation of the resin binder superhard material grinding wheel, breaks through restriction of low operation speed to the grinding wheel, and provides a better grinding tool for roller high-speed efficient grinding.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

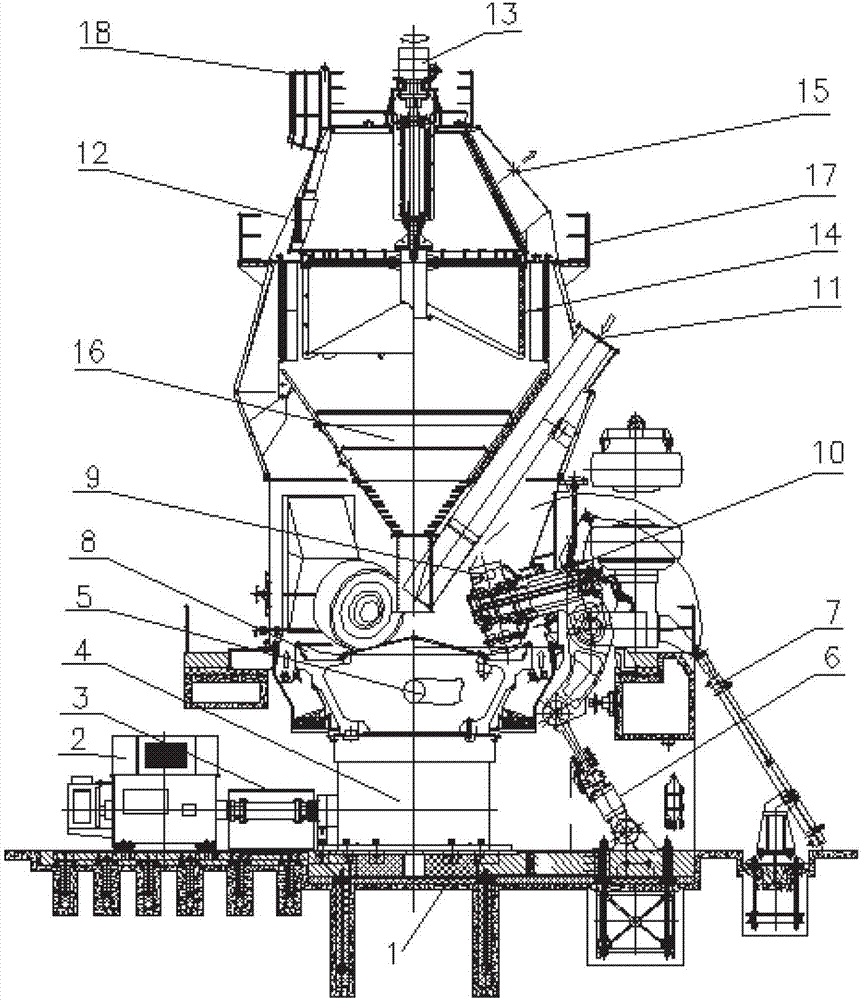

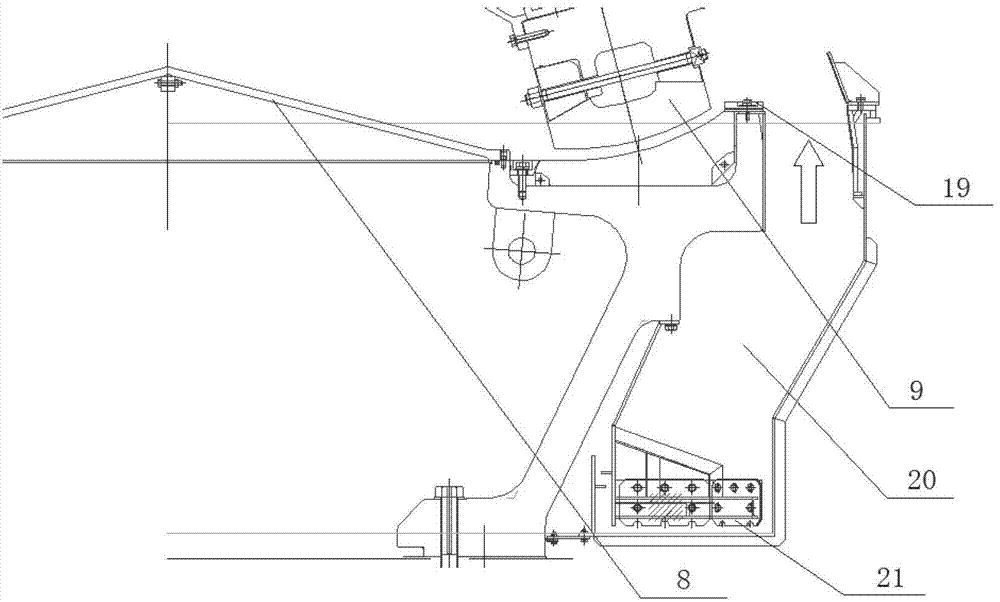

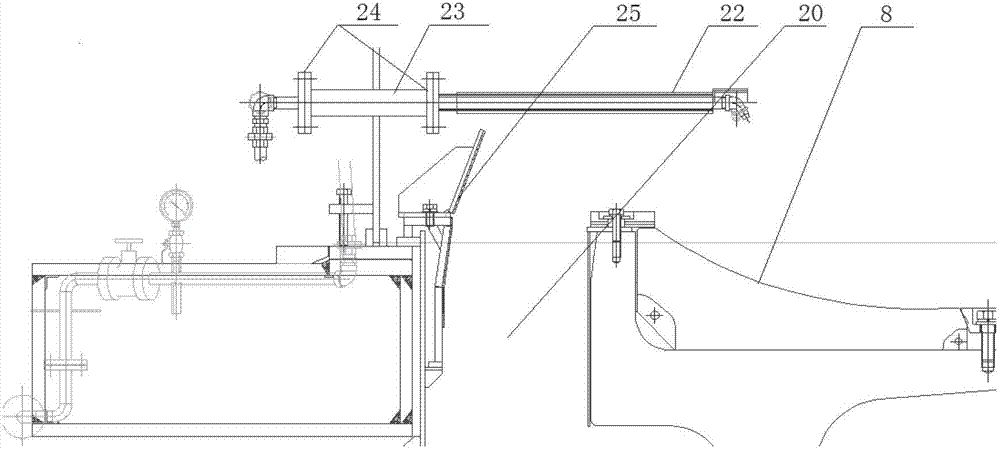

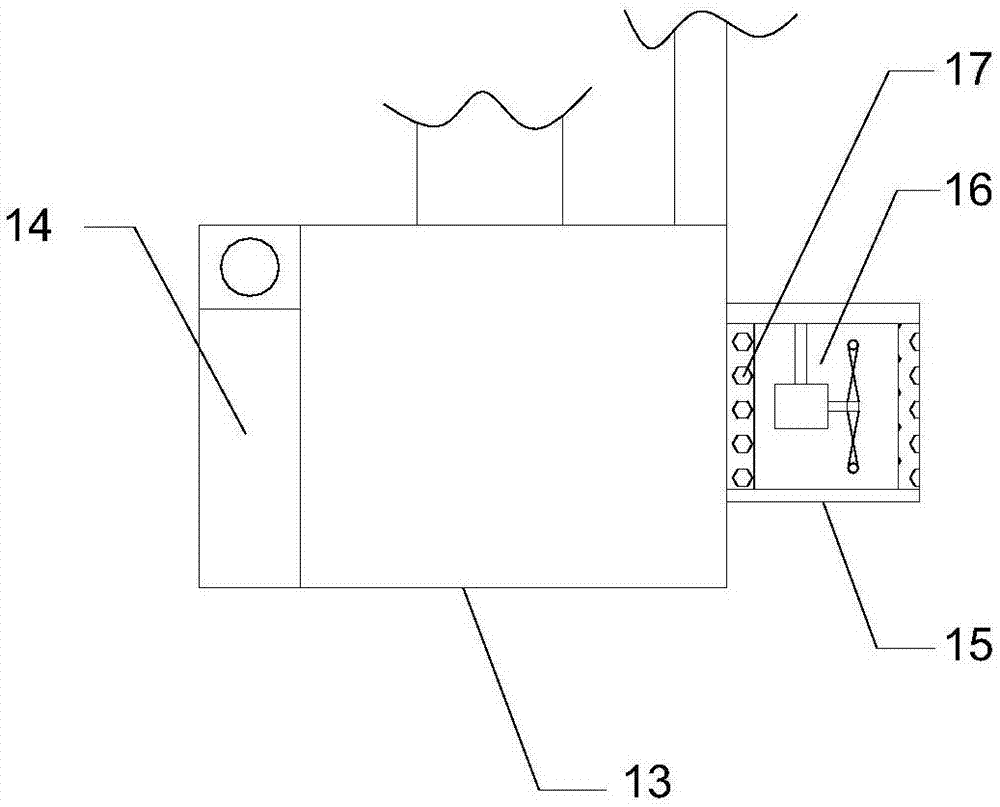

Vertical grinding mill

The invention discloses a vertical grinding mill, wherein a vertical grinding mill body is fixed on a concrete foundation; a grinding table is driven by a rotary power source and horizontally placed at the bottom of the vertical grinding mill; a discharging clearance exists between the grinding table and the inner wall of the vertical grinding mill; a non-grinding region in the center of the grinding table is of an upwards-raised cone; an edge grinding region is of an arc surface which is gradually raised upwards; and a grinding roller extends from the side of the vertical grinding mill to the upside of the grinding region of the grinding table and obliquely fixed downwards. The vertical grinding mill provided by the invention has the advantages of small grinding table diameter, high grinding table rotating sped, high work efficiency, low energy consumption and the like.

Owner:ANHUI CONCH KAWASAKI ENERGY CONSERVATION EQUIP

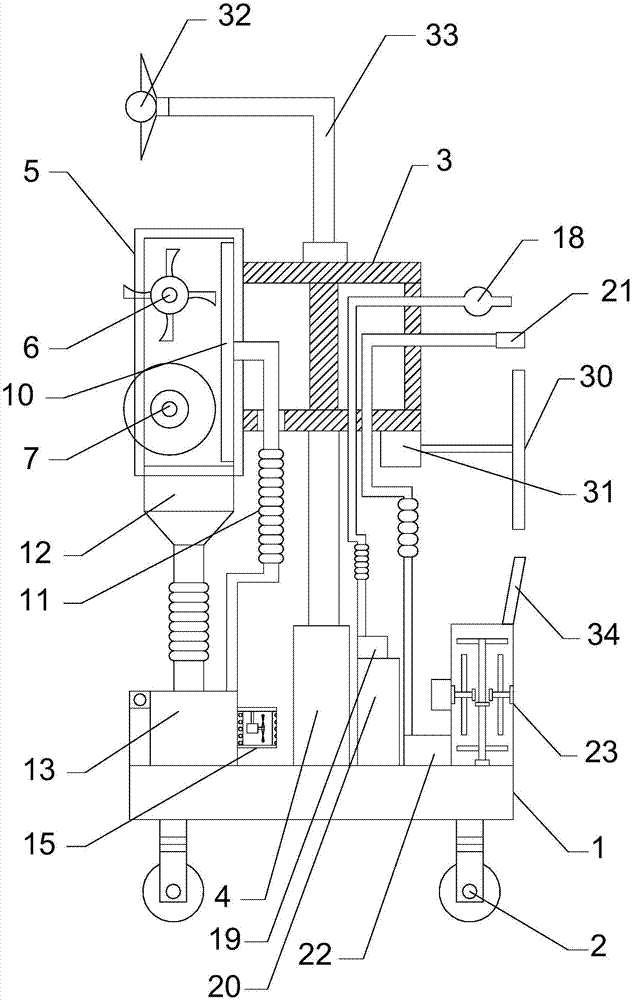

Multifunctional wall surface processing device

InactiveCN107882300AImprove mixing qualityImprove stirring efficiencyRotary stirring mixersTransportation and packagingSlagMultiple function

The invention discloses a multifunctional wall surface processing device which comprises a movable flat plate, universal wheels and a hydraulic cylinder. The universal wheels are arranged at the bottom of the movable flat plate. A lifting table is arranged above the movable flat plate and connected with the hydraulic cylinder through a piston rod. The left side of the lifting table is fixedly connected with a grinding box. By means of a horizontal stirring plate and a vertical stirring plate, putty paste is efficiently stirred and mixed, and the putty stirring quality and stirring efficiency are improved; by means of a scraper roller and a grinding wheel roller, scraping and grinding are efficiently conducted on a wall body, and wall peel is more thoroughly cleaned away; by means of a dustsuction cover, a dreg collecting hopper and a slag box, dust and slag produced in the operating process are efficiently collected, dust pollution is avoided, and slag is more easily cleaned away; bymeans of a material guide plate, dripped putty paste is collected and prevented from contaminating the ground, and raw materials are saved.

Owner:杭州智仁信息科技有限公司

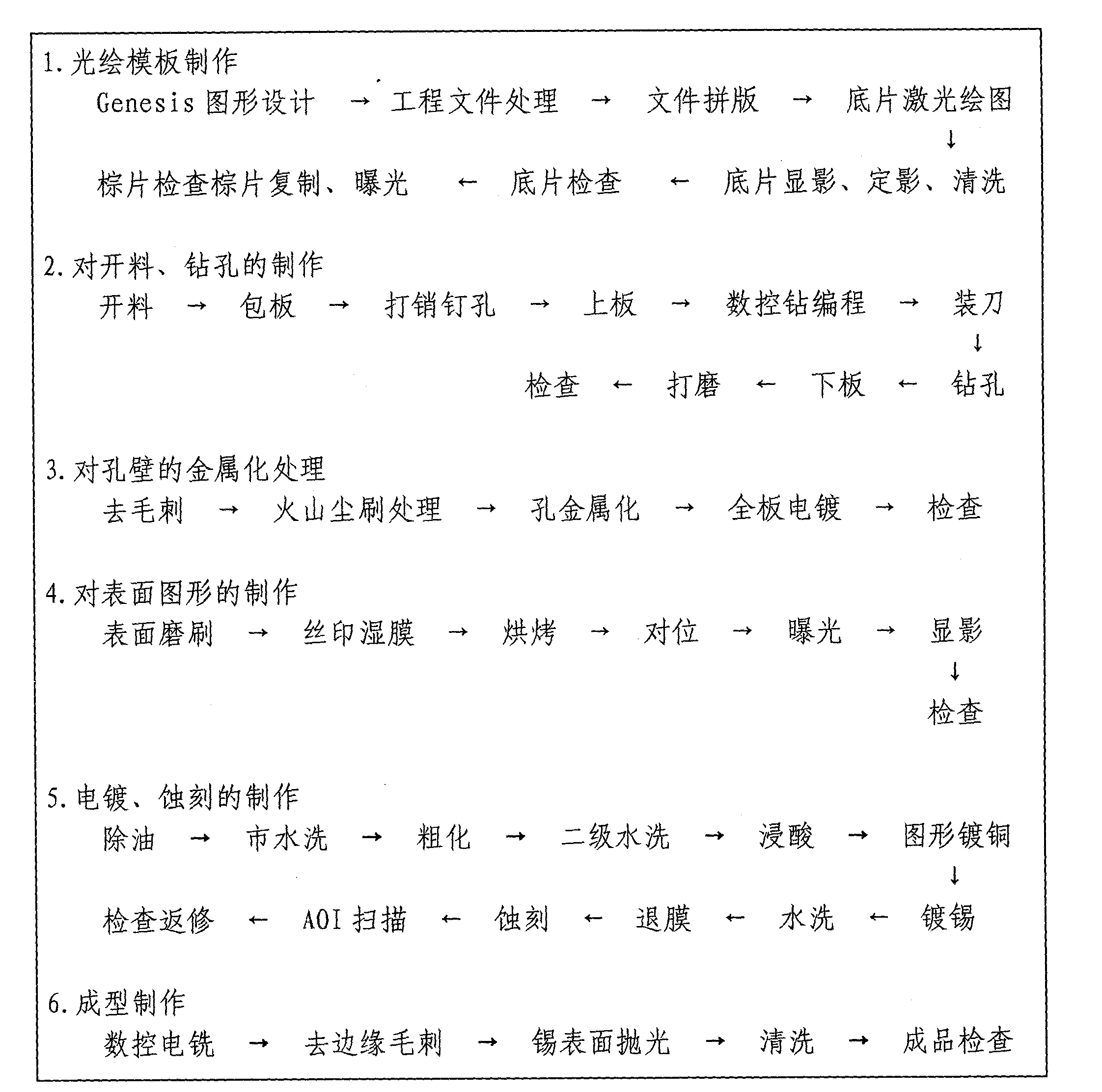

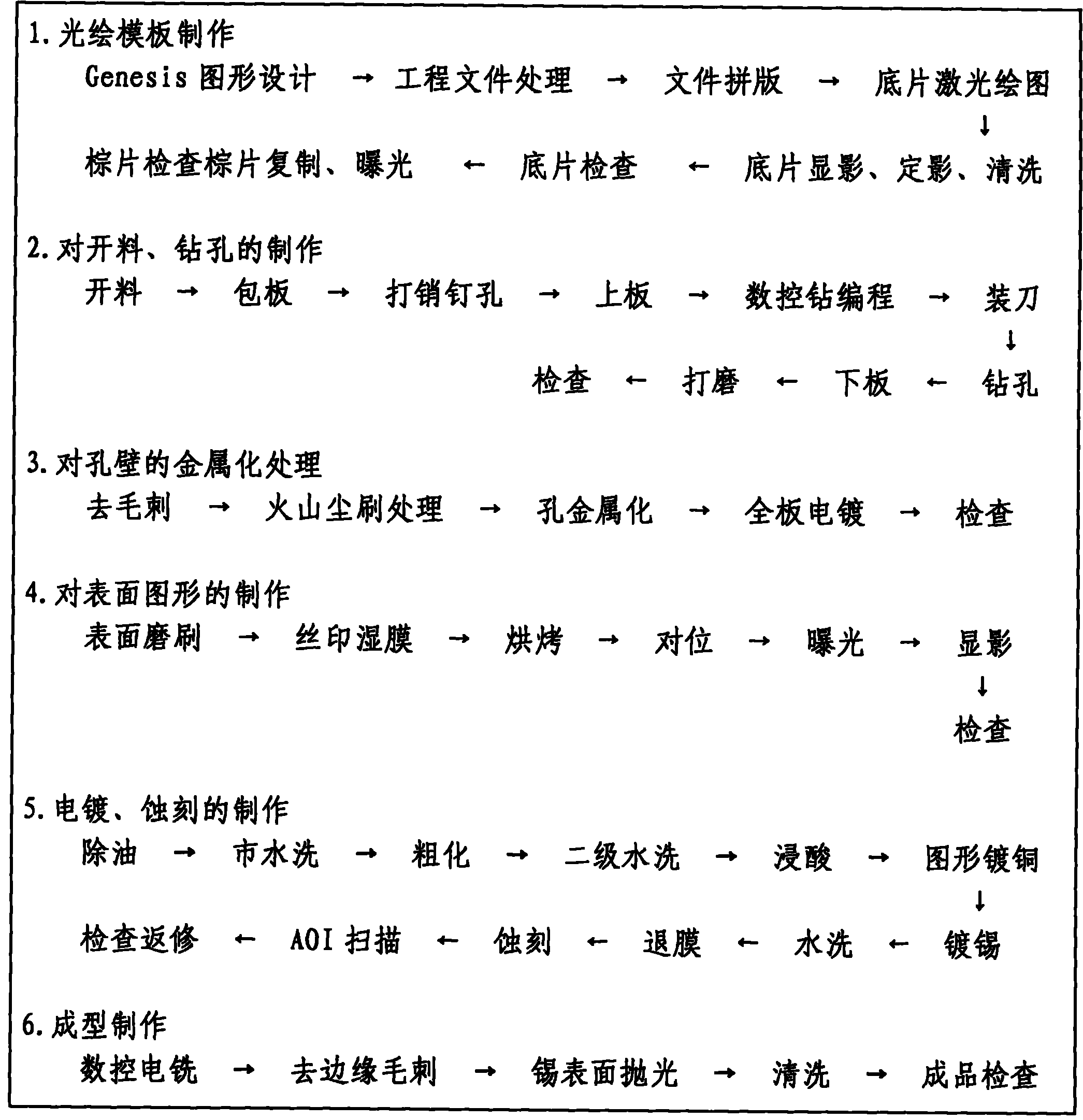

Method for manufacturing ultra-long microwave high-frequency circuit board

InactiveCN101808464AIncrease porosity densityImprove bindingConductive material chemical/electrolytical removalPrinted element electric connection formationMicrowaveEngineering

The invention discloses a method for manufacturing an ultra-long microwave high-frequency circuit board, comprising the following steps: (1) manufacturing a light potting template; (2) shearing to form an ultra-long combination board, and drilling holes on the ultra-long combination board; (3) metallizing the walls of the holes; (4) making patterns on the ultra-long combination board; (5) electroplating and etching the ultra-long combination board; and (6) forming the ultra-long combination board into the ultra-long microwave high-frequency circuit board. The method for manufacturing the ultra-long microwave high-frequency circuit board has high precision, and the ultra-long microwave high-frequency circuit board manufactured with the method has stable performance and can effectively improve the product quality and the work efficiency.

Owner:施吉连

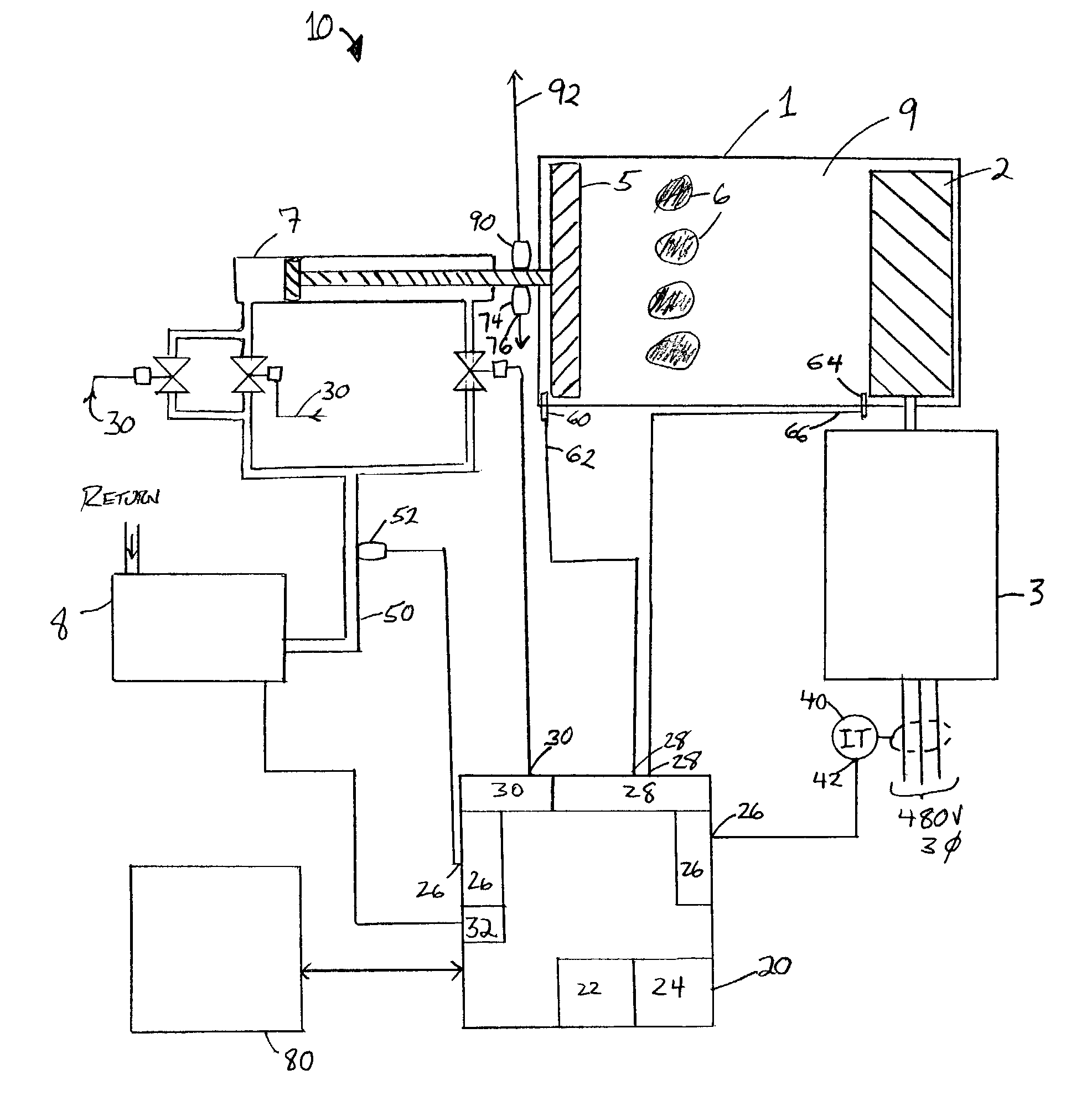

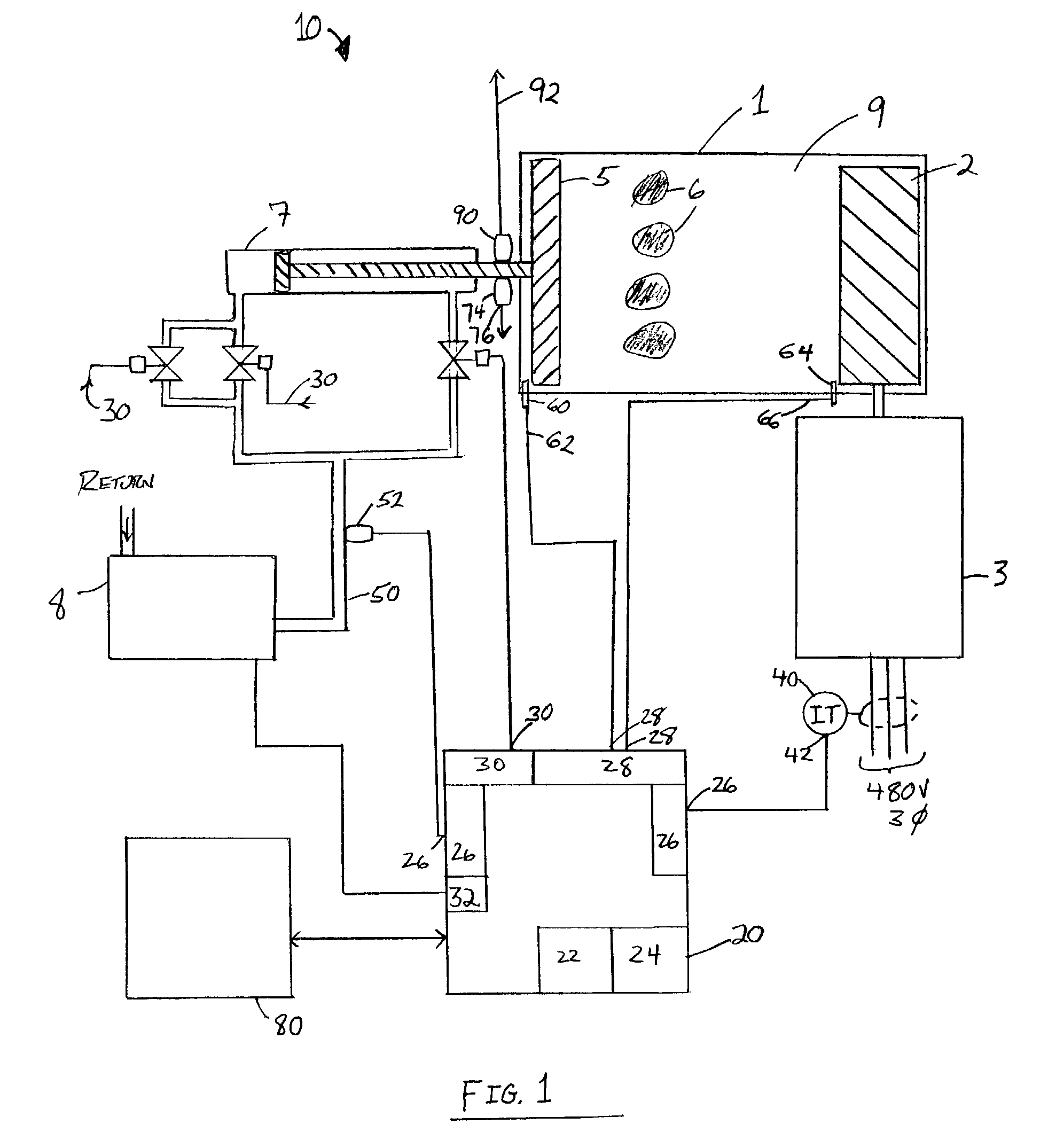

Rotary grinder control system and method

ActiveUS8360349B1Small sizeAverting costly time-consumingCocoaGrain treatmentsControl systemHydraulic ram

The present invention relates to a control system for a rotary grinder. Rotary grinders control systems of the present invention are, for example, used to grind plastic or wood to reduce the size of the material to a desired size. Material to be ground is forced by an hydraulic ram toward a rotor having a plurality of cutters thereon. The control system is capable of controlling the grinding operation as a function of ram velocity and pressure as well as power consumption by the rotor.

Owner:RAPID GRANULATOR INC

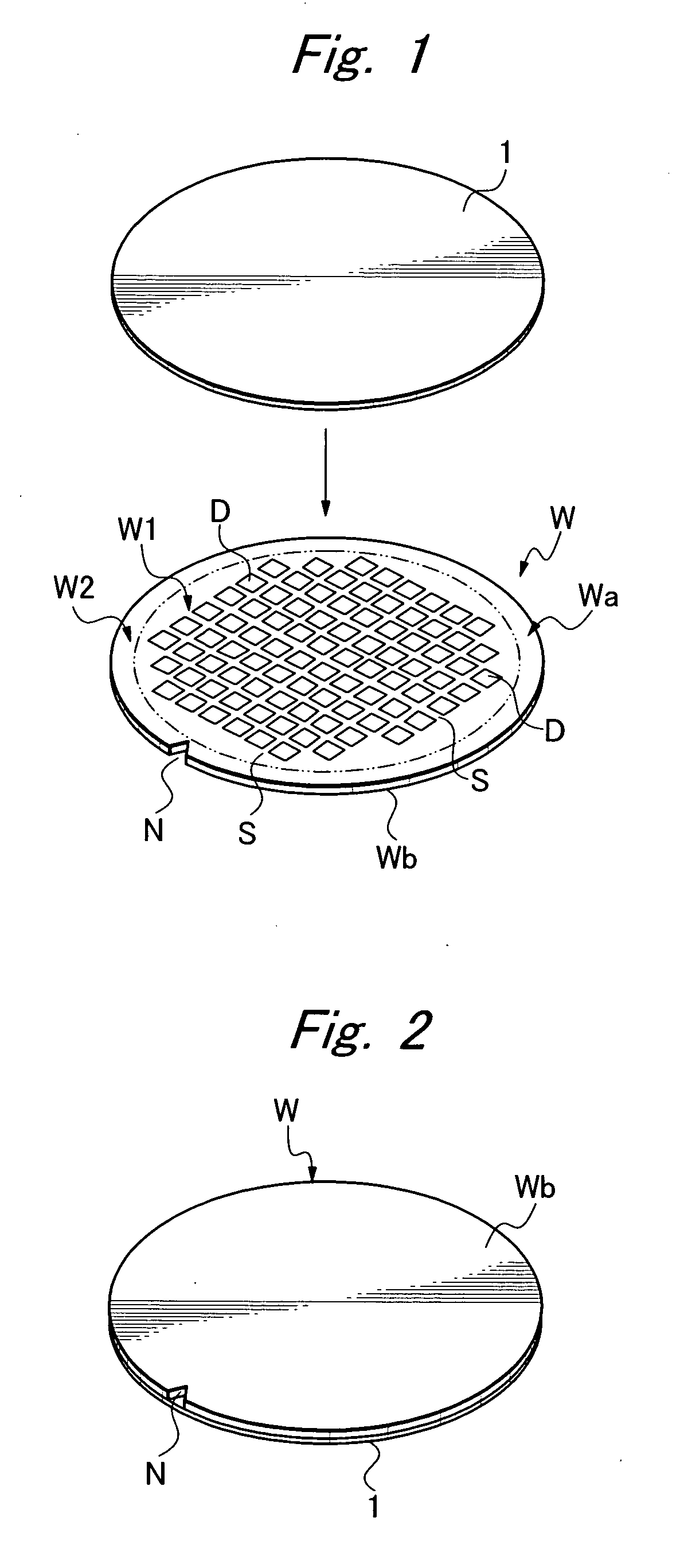

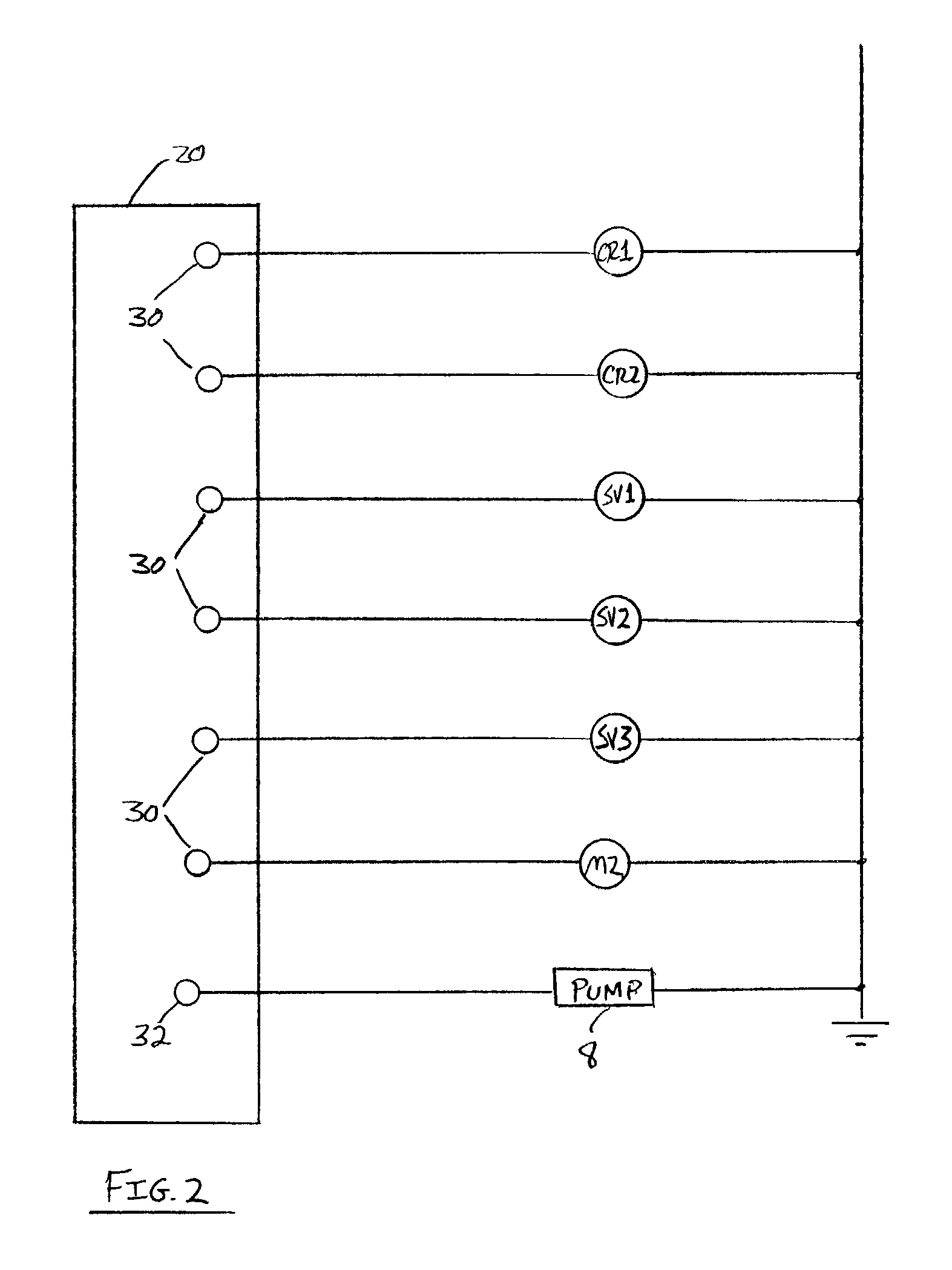

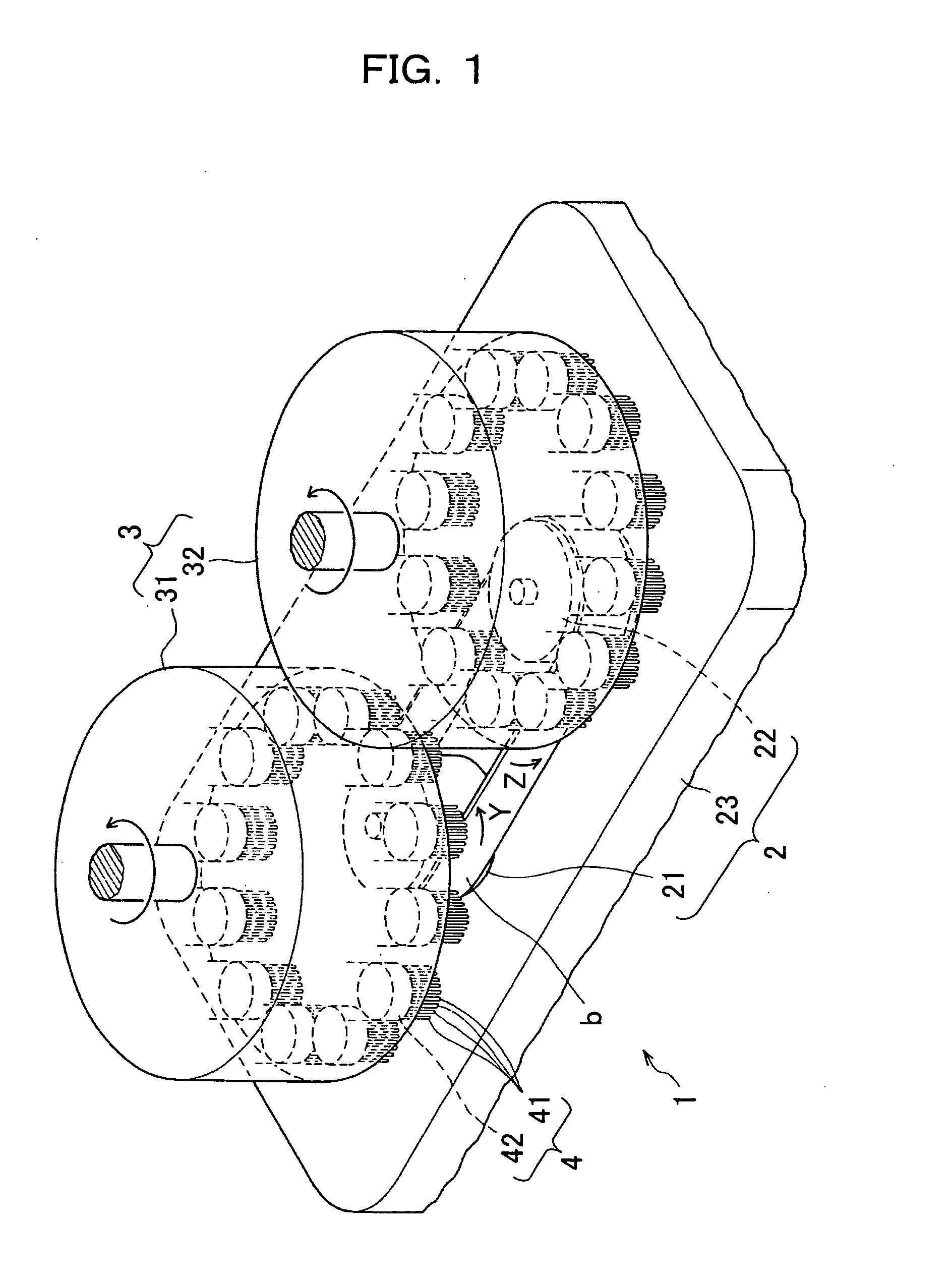

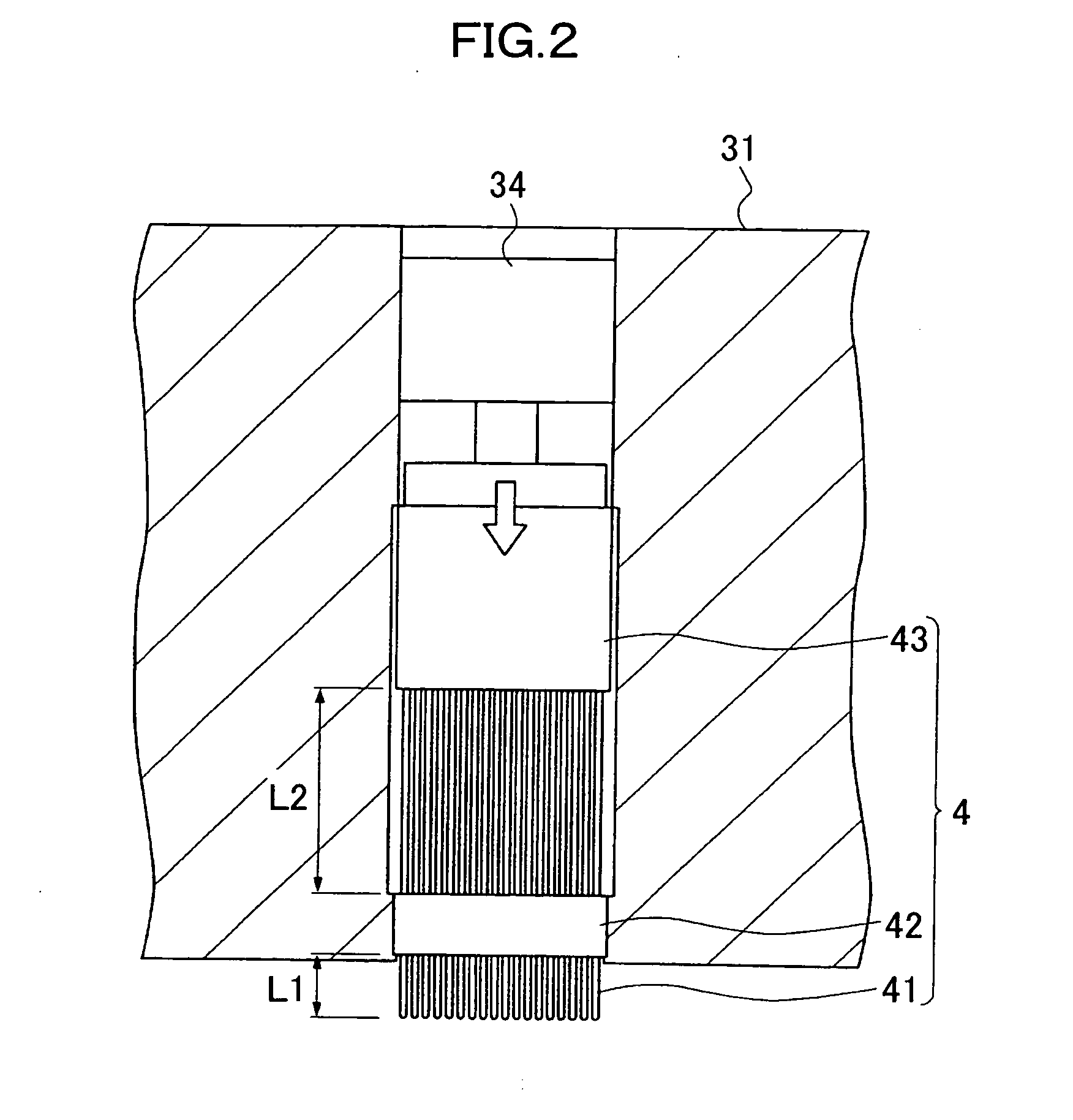

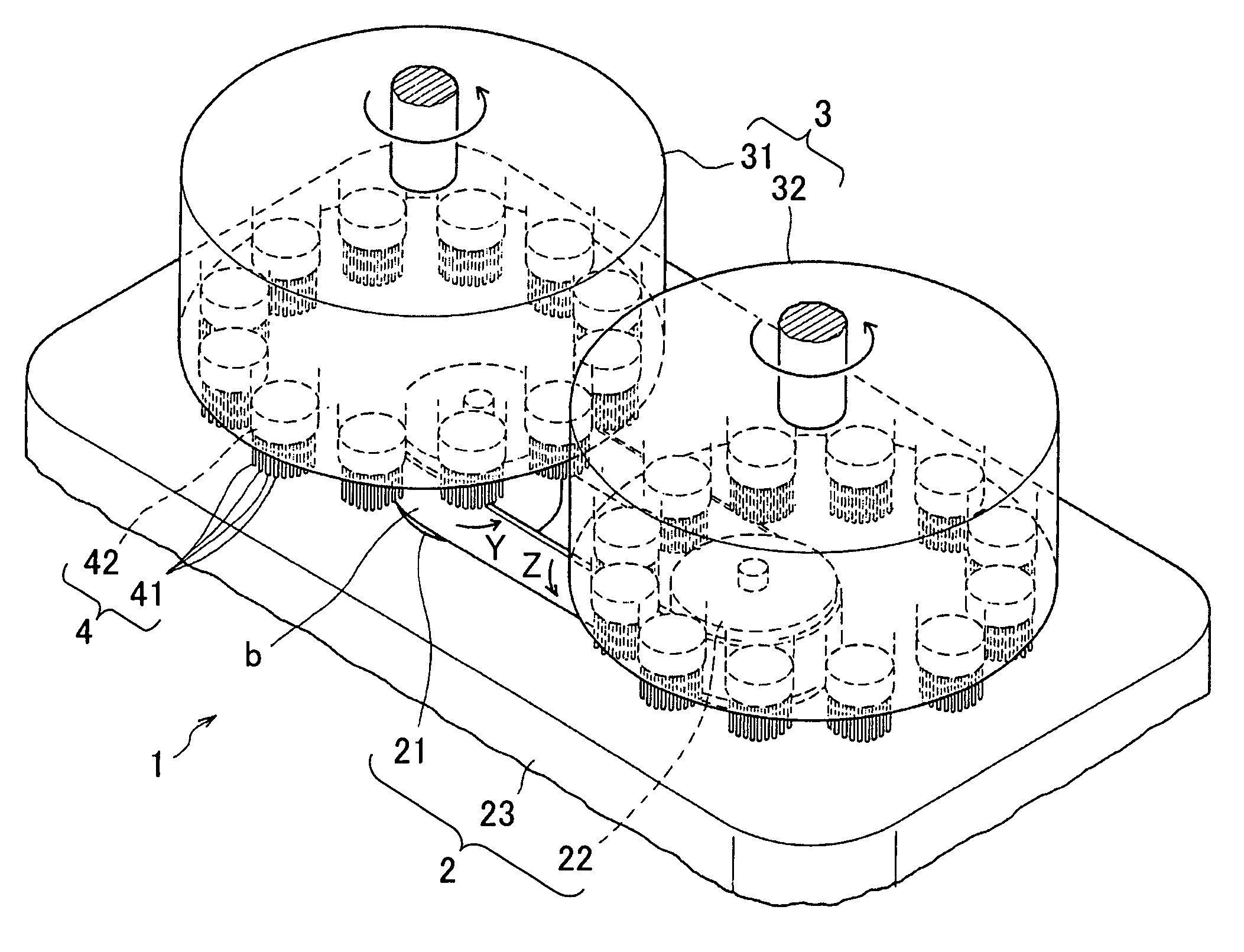

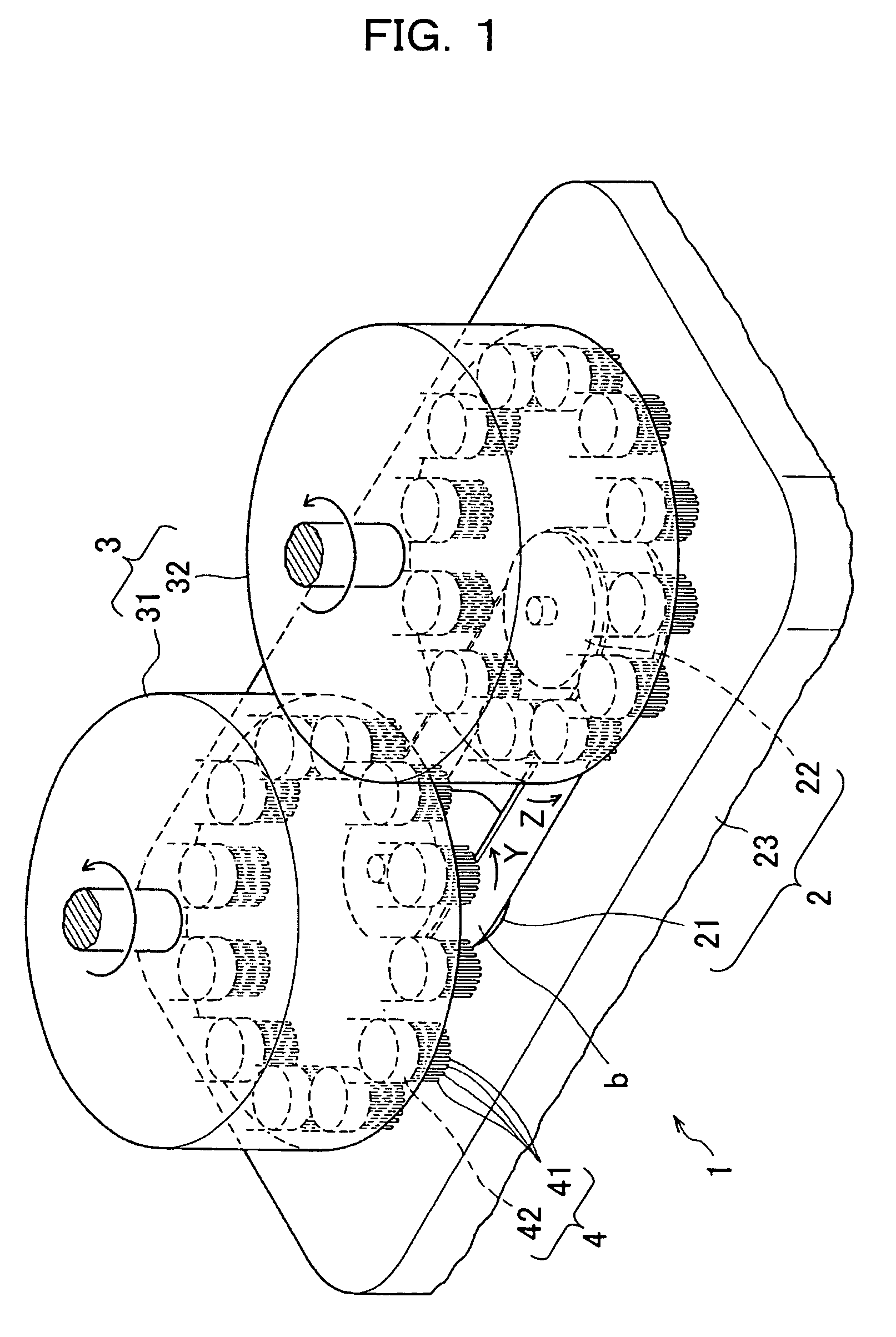

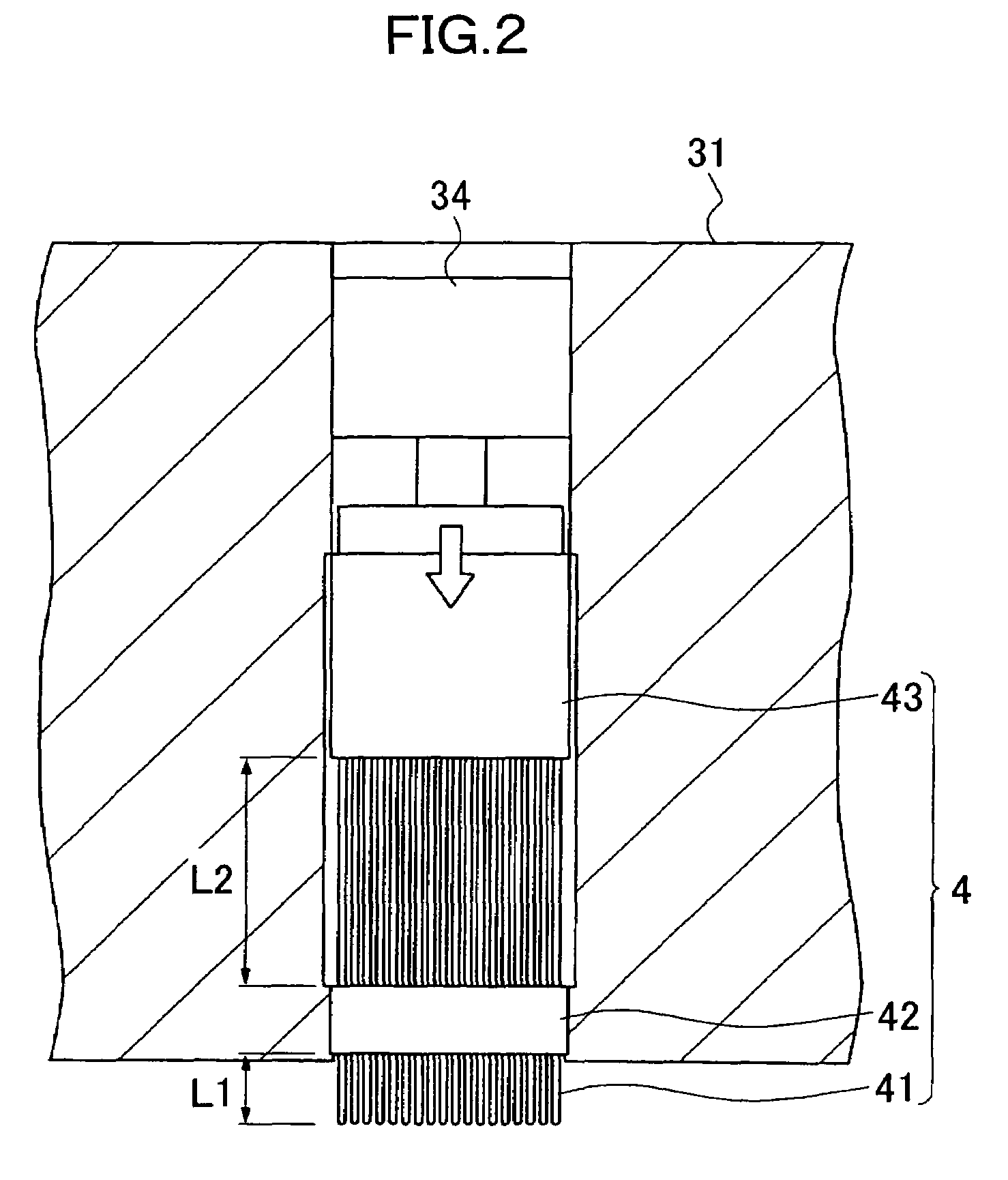

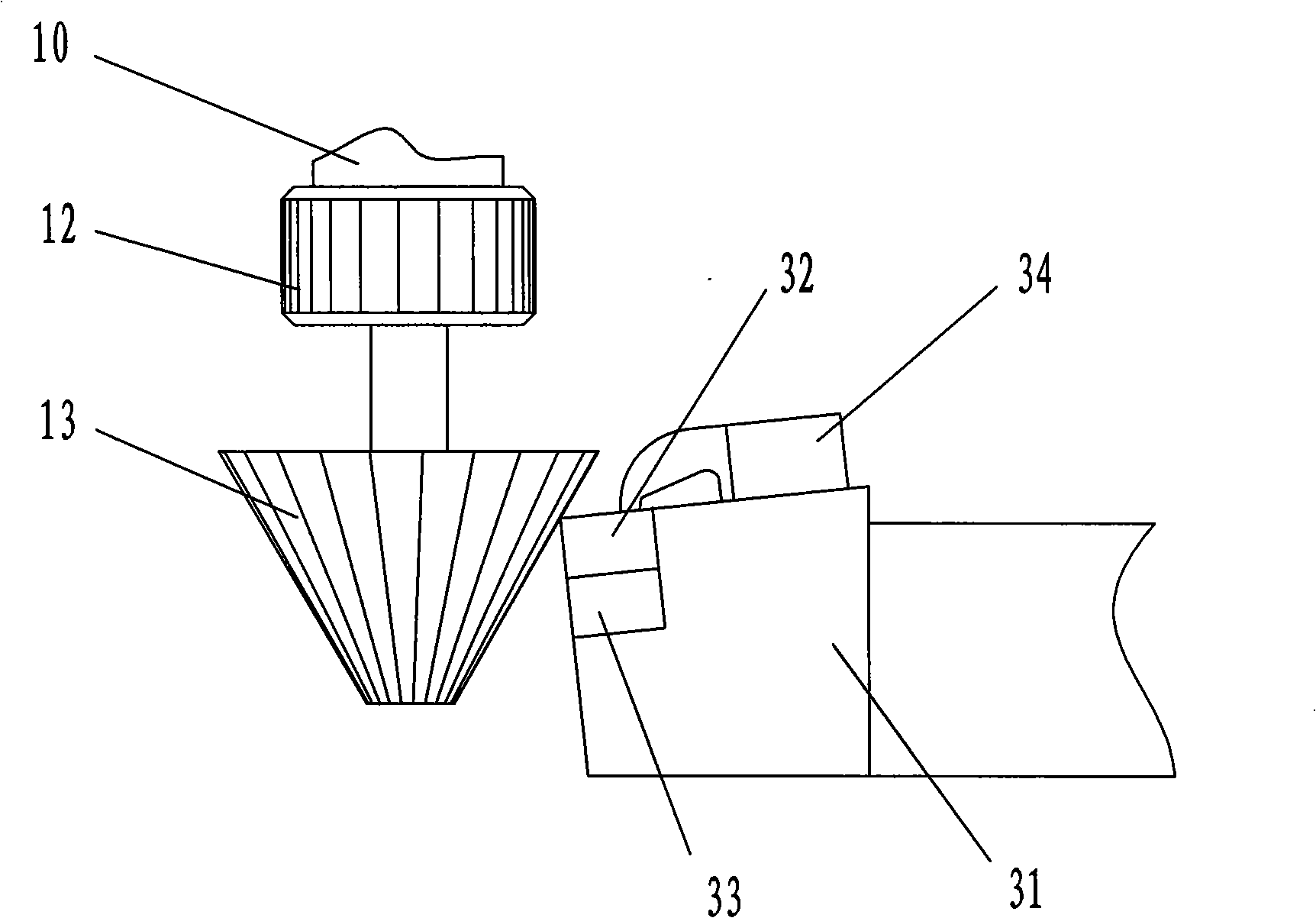

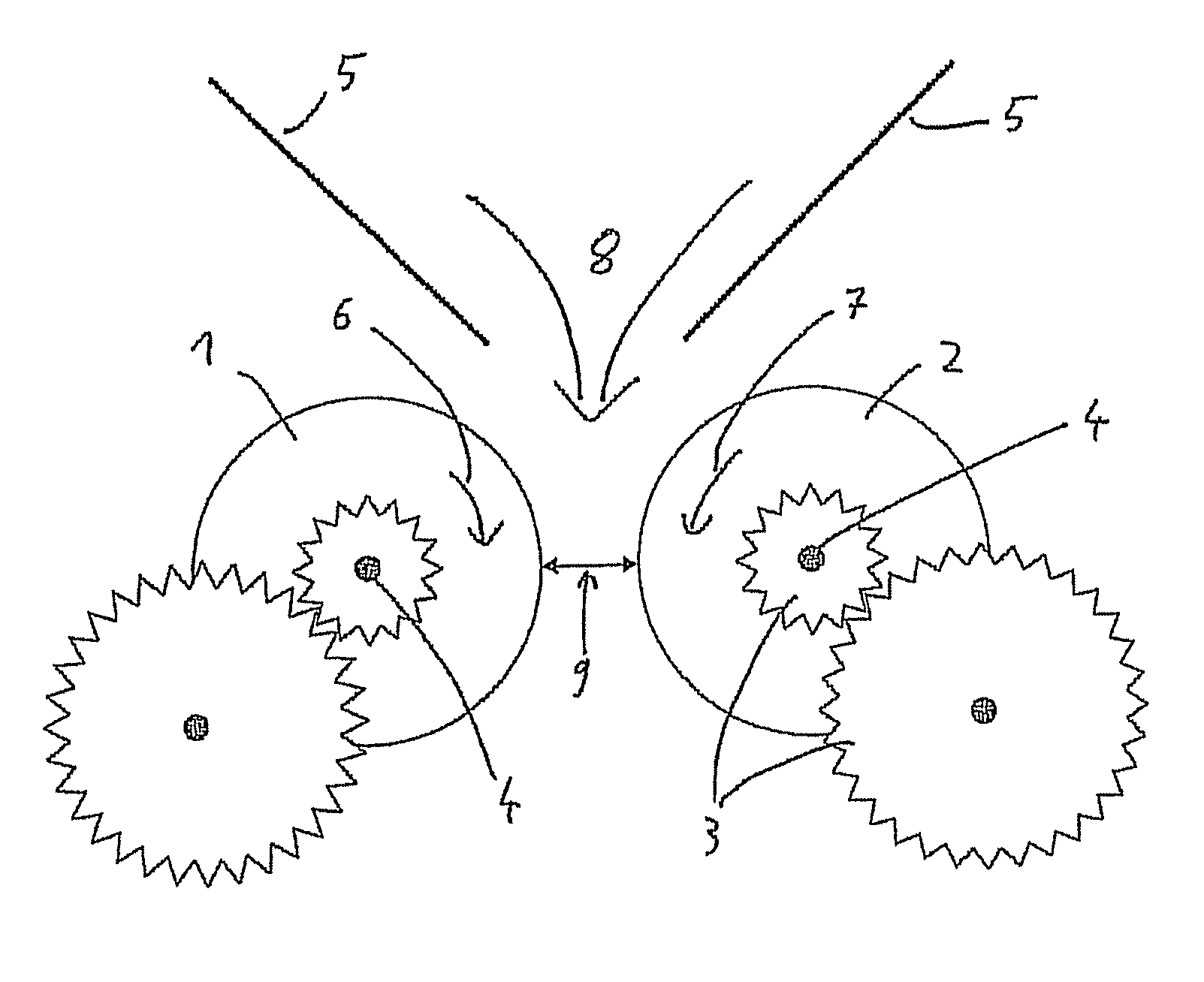

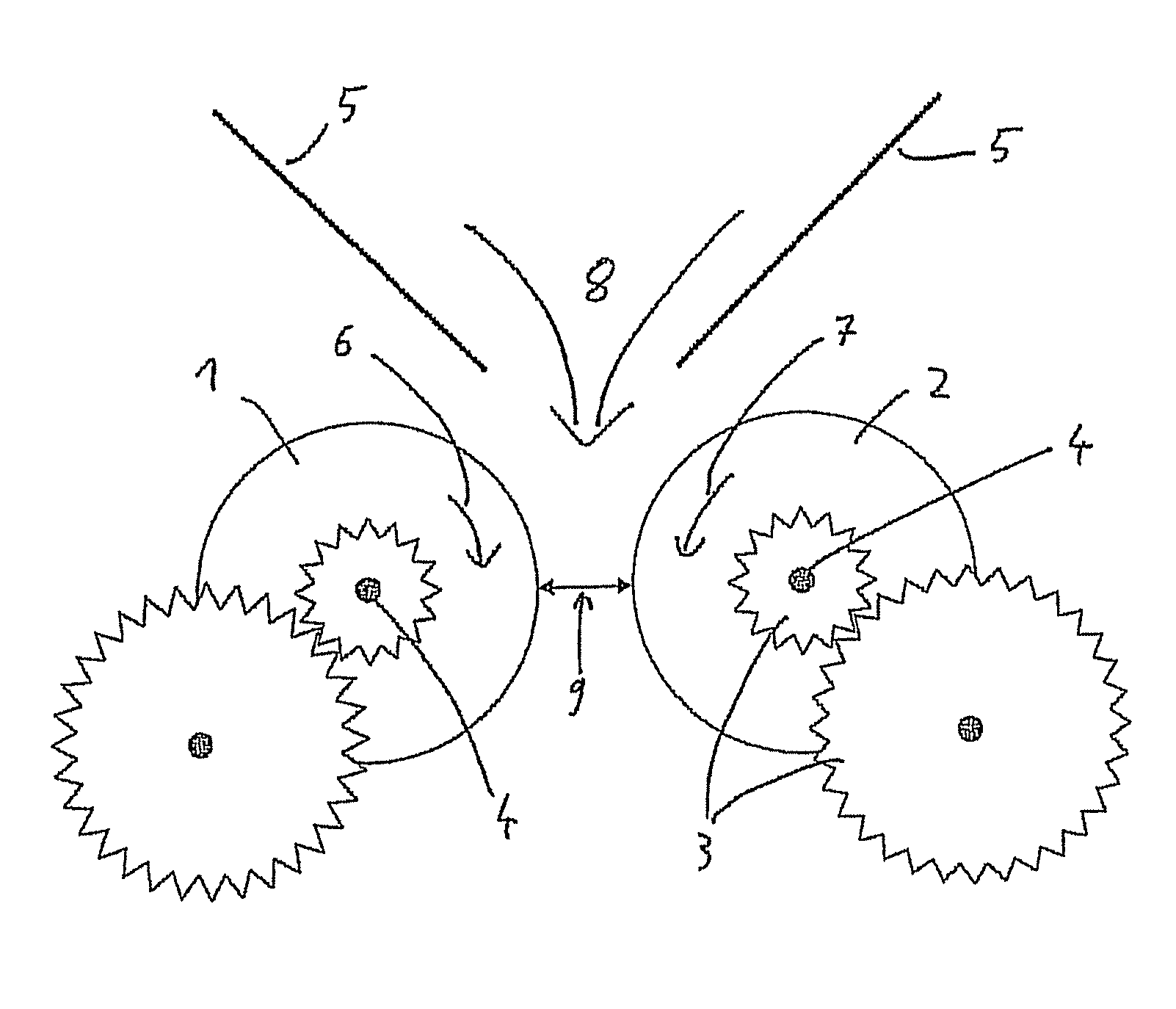

Grinding Apparatus And Grinding System

ActiveUS20080064304A1Extend grinding timeDecrease in grind forceEdge grinding machinesPolishing machinesEdge surfaceMechanical engineering

A grinding apparatus and a grinding system capable of efficient and superior grinding performance prevent the falling of a belt during the grinding of an edge surface thereof. The apparatus includes two rotating bodies 31 and 32 each having segment brushes 4, 4, . . . attached in the circumferential direction at the edge thereof. The rotating bodies 31 and 32 are rotated in the same direction. The tip of the segment brushes 4, 4, . . . is opposed to one edge surface of a belt b stretched between a driving roller 21 and a driven roller 22. The segment brushes 4 of the two rotating bodies enter toward the belt b at appropriate locations on the one edge surface, such that the falling of the belt can be prevented. A grinding apparatus 1 includes a grinder 3 consisting of the rotating bodies 31 and 32, and a holder consisting of the rollers 21 and 22 and a casing 23 by which the rollers are rotatably supported. A plurality of such grinding apparatuses 1 are disposed at regular intervals, whereby a grinding system 10 is constructed.

Owner:TOYOTA JIDOSHA KK

Rust-removal cleaning device for inner wall of chemical construction metal pipeline

ActiveCN109693169AIncrease displacementImprove grinding efficiencyGrinding drivesGrinding machinesRelative displacementDrive shaft

The invention discloses a rust-removal cleaning device for the inner wall of a chemical construction metal pipeline, and relates to the technical field of chemical construction. The rust-removal cleaning device comprises a supporting frame, a driving motor is fixed to the supporting frame, a driving shaft is coaxially fixed to an output shaft of the driving motor, a threaded shaft I and a threadedshaft II which are opposite in thread rotating direction are coaxially fixed to two output shafts of a double-shaft motor correspondingly, and polishing plates abutting against the inner side wall ofthe metal pipeline are hinged to a threaded sleeve I and a threaded sleeve II through supporting rods. According to the rust-removal cleaning device, the driving motor drives the driving shaft to rotate, thus a polishing mechanism conducts rotary polishing on the inner wall of the metal pipeline, meanwhile, a supporting rotary roller drives the metal pipeline and the polishing mechanism to rotatein the reverse direction, thus relative displacement of the polishing plates and the metal pipeline is greatly increased, the polishing efficiency is higher, the arranged polishing mechanism can adjust the polishing radius through the double-shaft motor, thus the metal pipelines with the different inner diameters are efficiently polished, adjusting is convenient, and polishing applicability is high.

Owner:HEFEI NORMAL UNIV

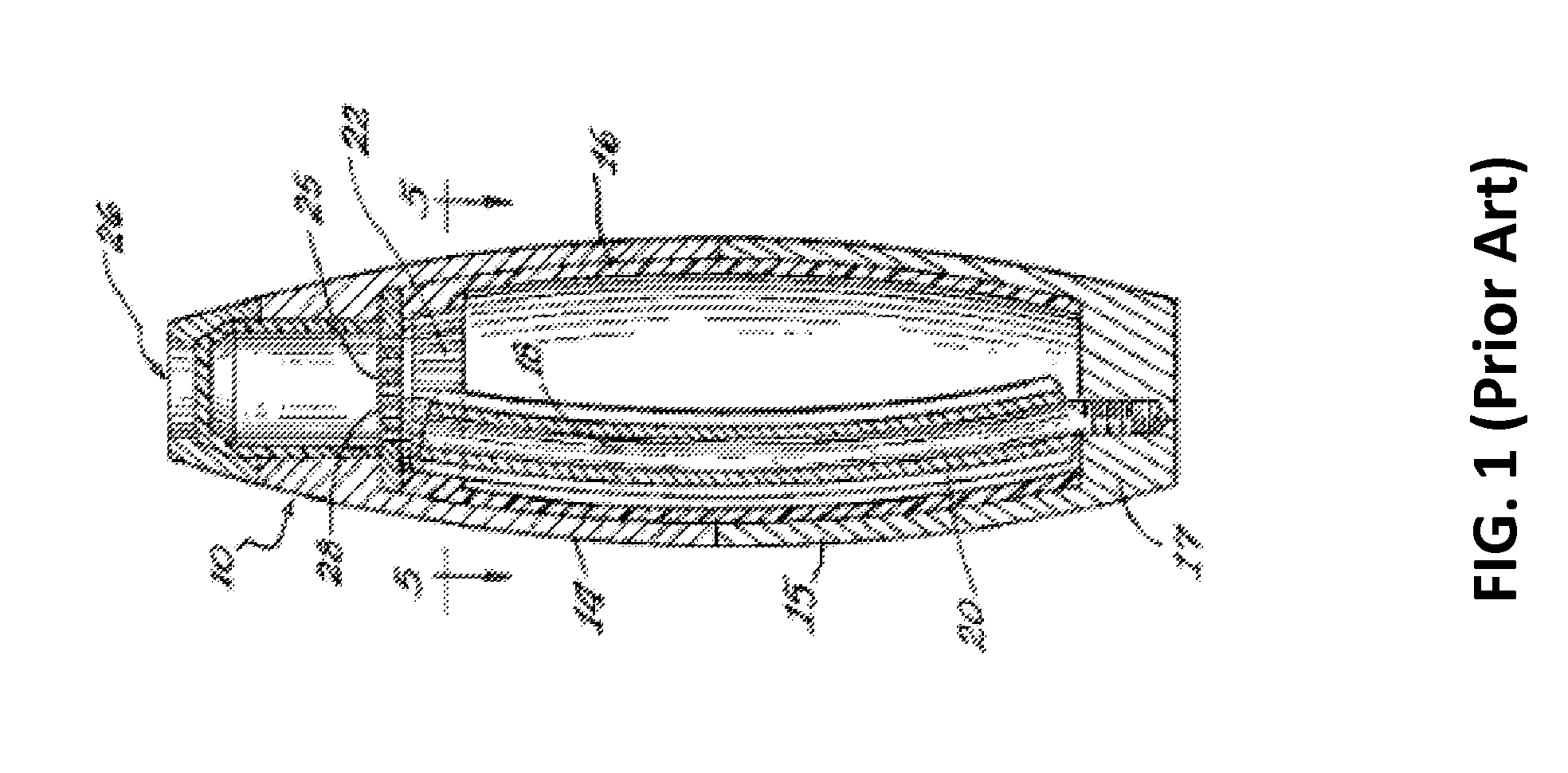

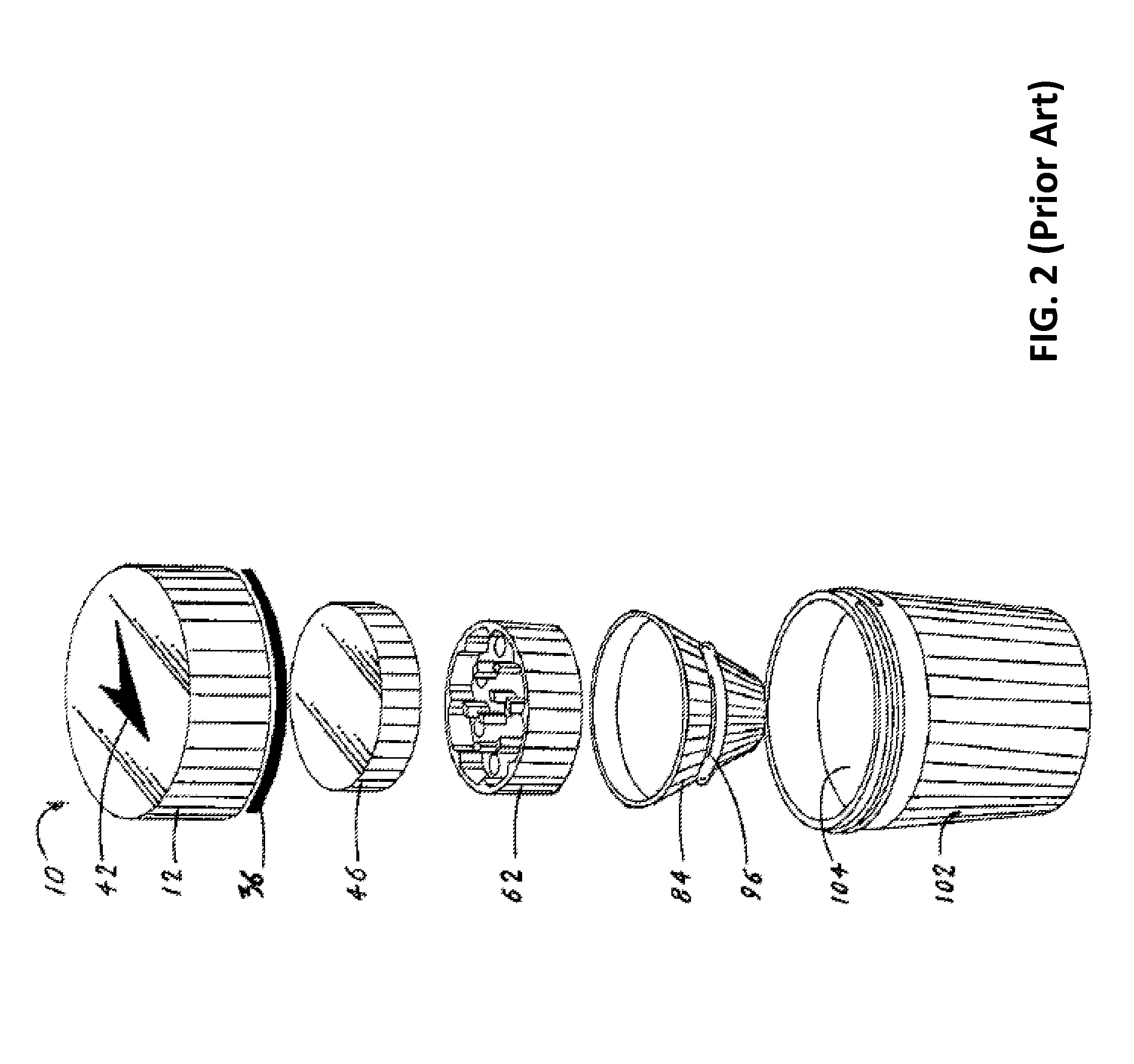

Portable grinder

InactiveUS20140138465A1Save effortEfficient grindingCoffee millsTobacco treatmentMechanical engineeringEngineering

A portable grinder may include a side cover having inner threads and a cover receiving space, said inner threads used to engage with middle inner threads of a middle piece; a first grinding piece, one side of which having a plurality of first grinding protrusions and a plurality of through holes scattered at various locations between the first grinding protrusions; and the other side having a screening unit; a middle piece adapted to receive the first grinding piece and connect to a second grinding piece through a bearing; and a second grinding piece having a plurality of second grinding protrusions facing the first grinding protrusions, wherein substances to be grinded are disposed in a second receiving space between first and second grinding protrusions, and the first and second grinding protrusions of the portable grinder are driven by gravity to spin to grind the substances therein.

Owner:YEN ALAN JEI

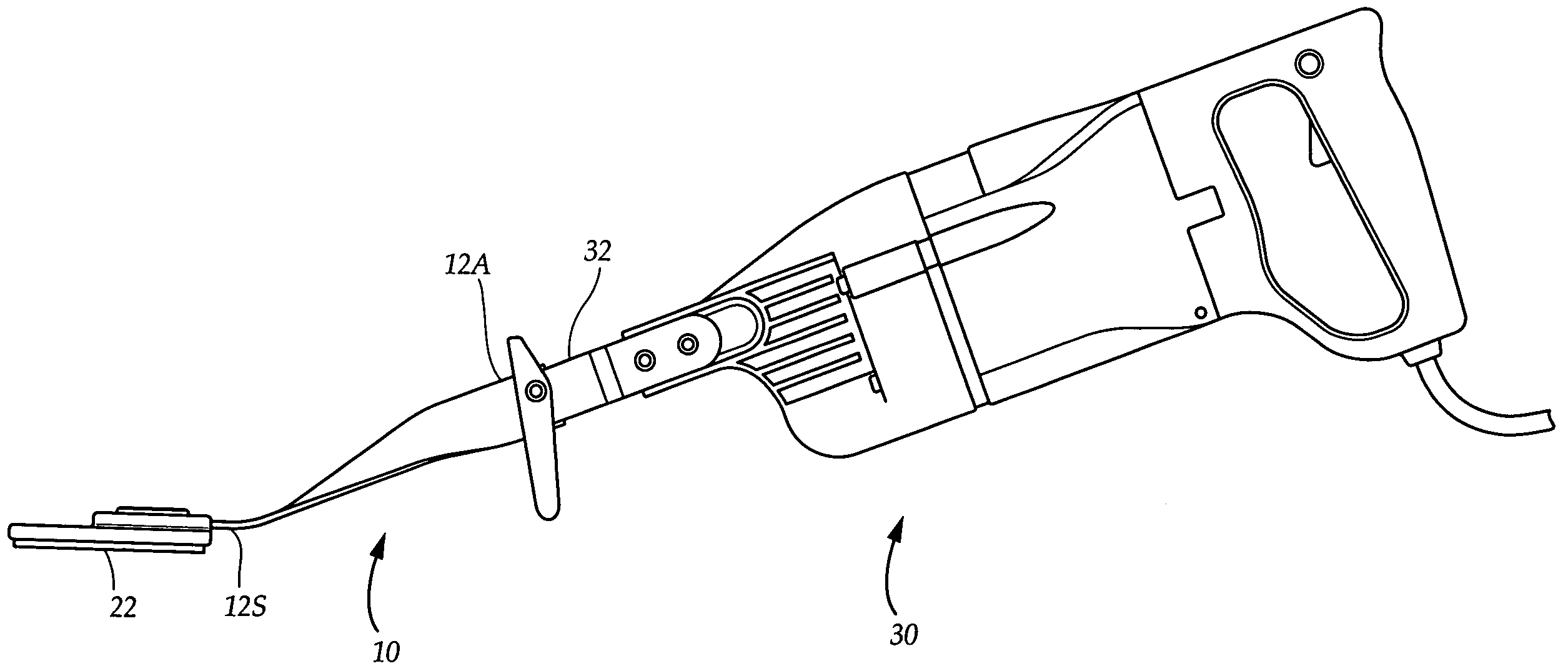

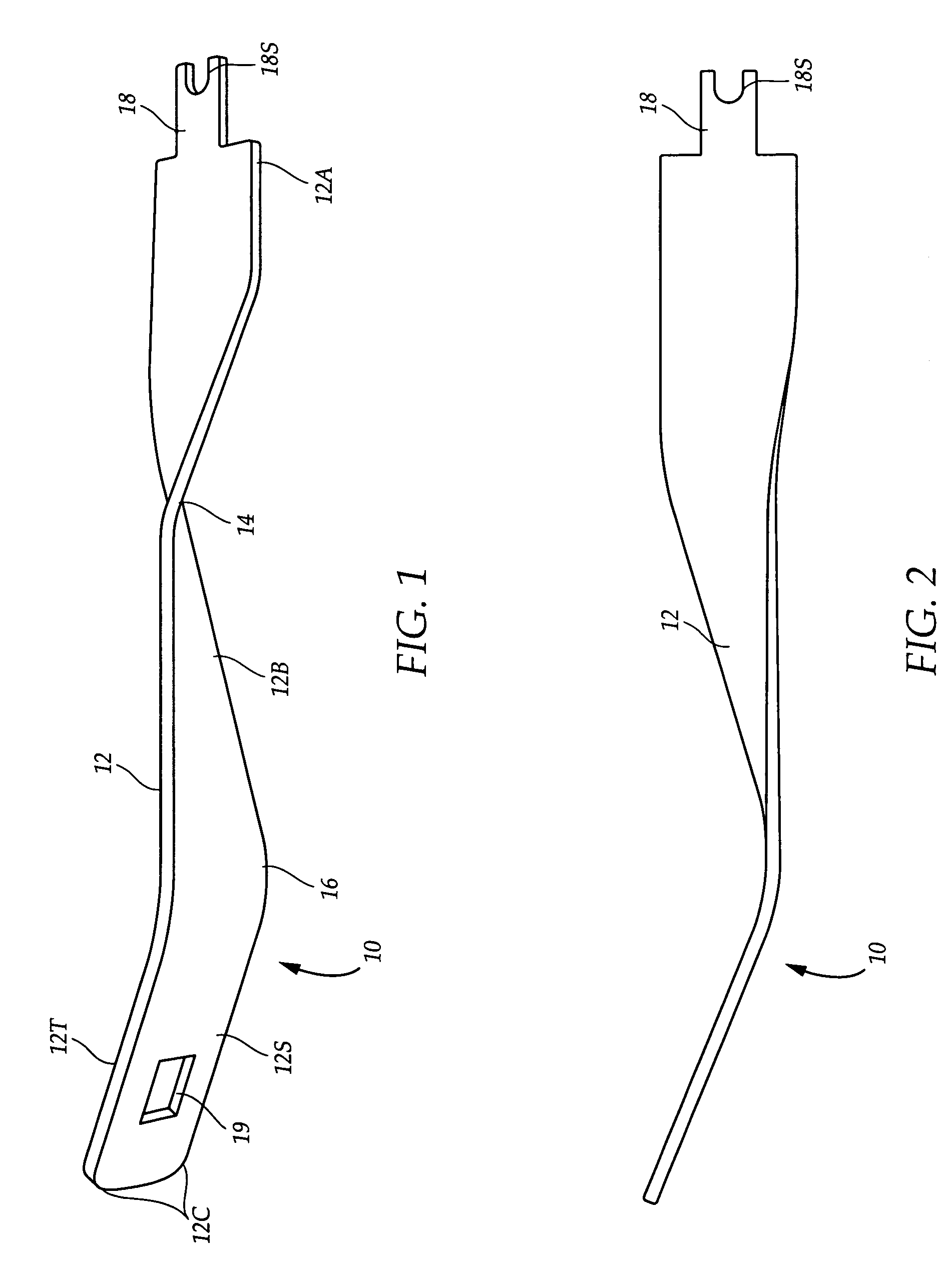

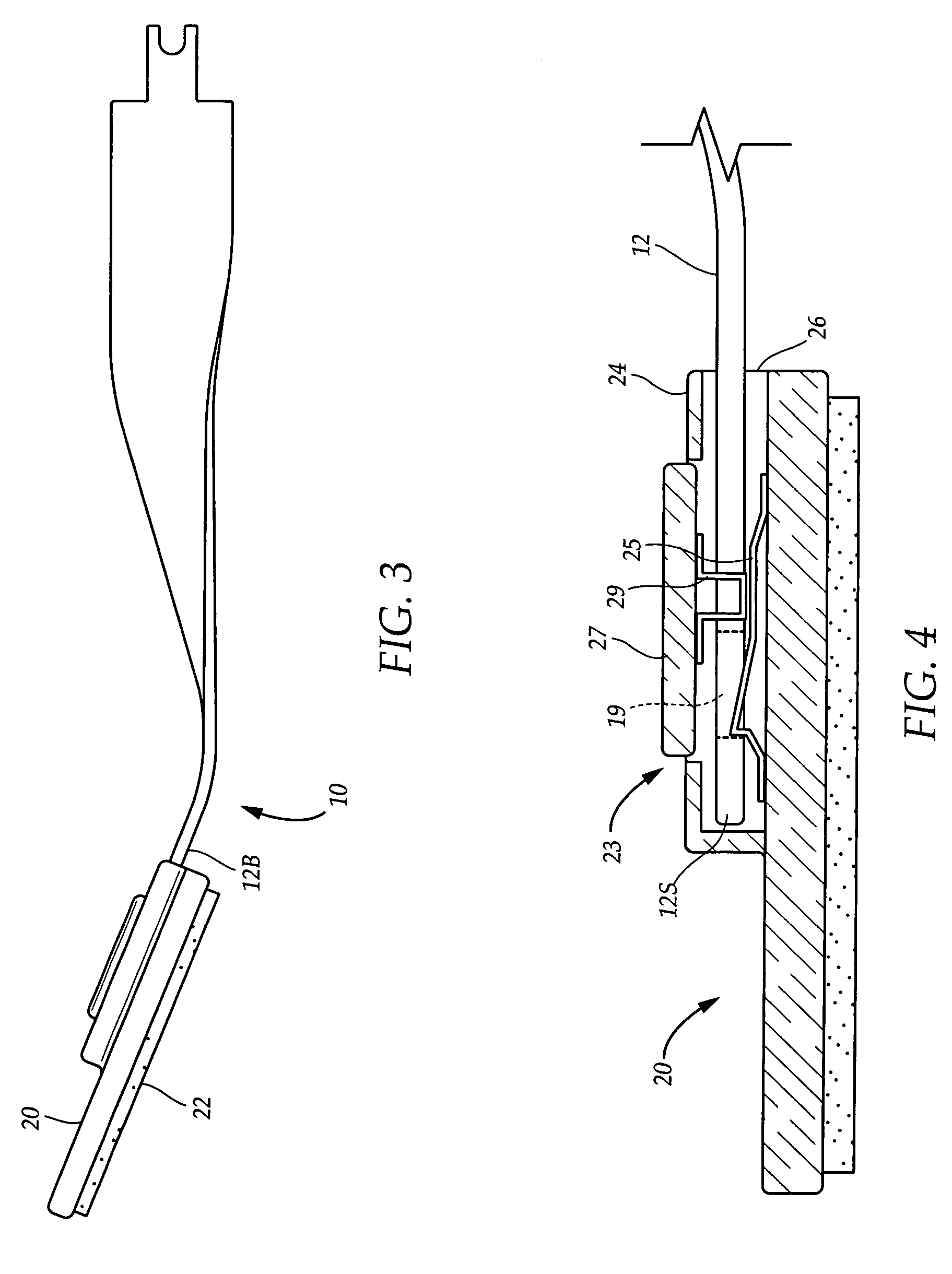

Sanding attachment for a reciprocating power tool

InactiveUS7285038B1Not become damaged and deformedCost is not prohibitivePortable grinding machinesPlane surface grinding machinesPower toolRough surface

A sanding attachment, for use in conjunction with an existing reciprocating power tool, for sanding a rough surface of an existing object. The sanding attachment comprises a main part being an elongated strip of metal having an attachment end for selective attachment to the power tool, and a sanding end. Attached to the sanding end is a sanding pad having a sanding surface for efficiently sanding an object. The sanding attachment has a twist which results in the attachment end and the sanding end being substantially mutually perpendicular to one another. After the sanding attachment has been selectively attached to the power tool, and the power tool is held within the hands of the user is the usual fashion, the sanding attachment is suitably positioned for efficiently sanding a substantially horizontal surface.

Owner:JIOIA LES

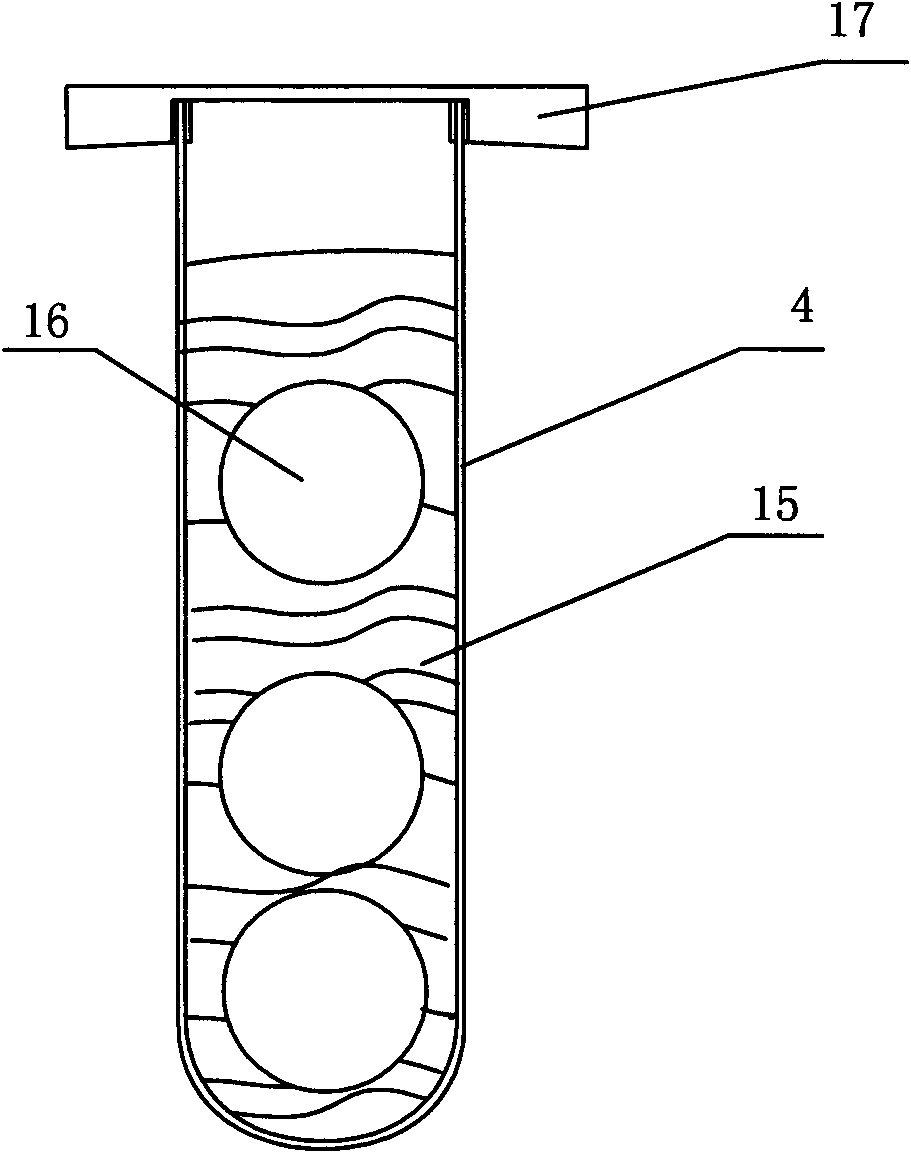

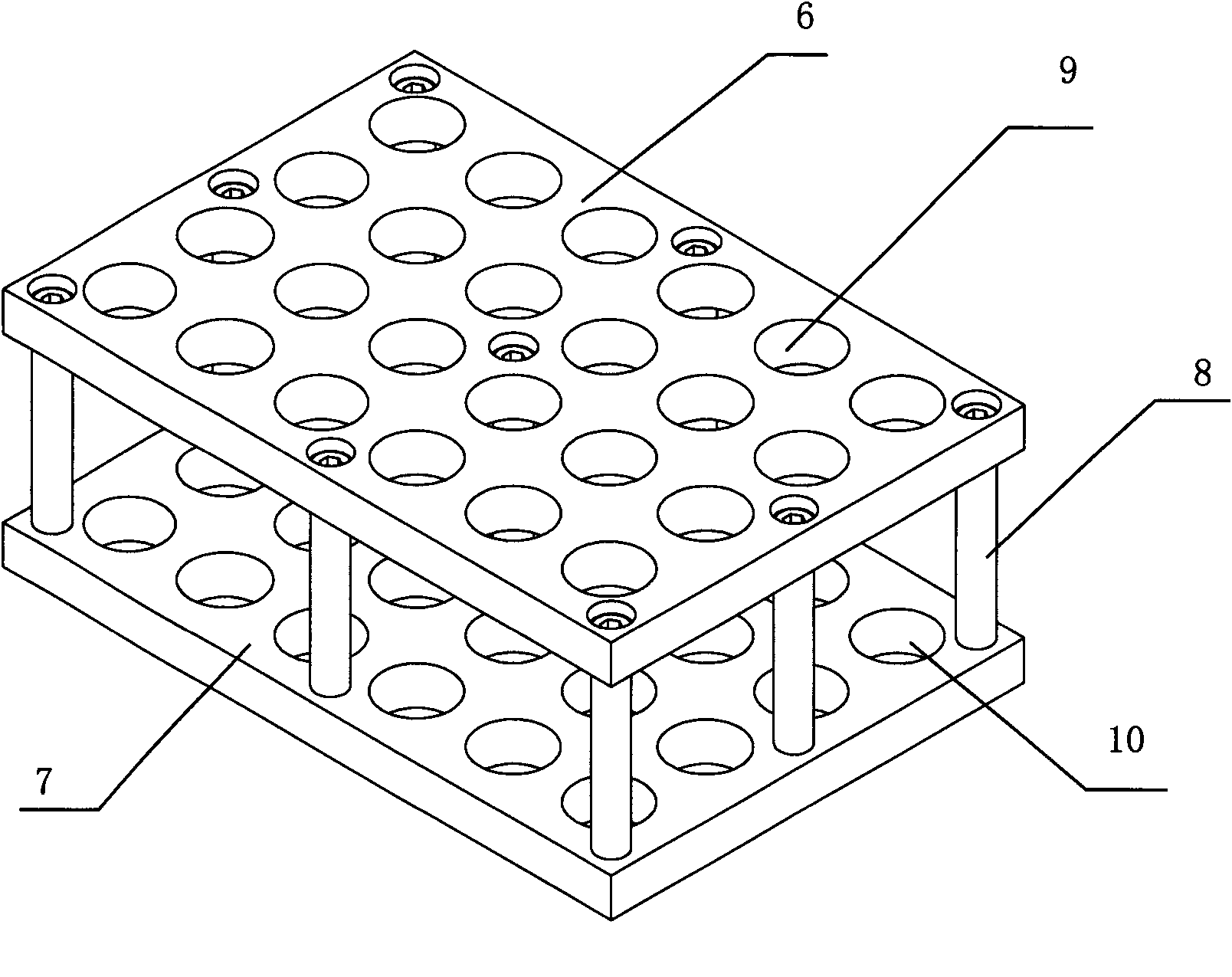

High pass tissue grinder and grinding method

InactiveCN101650274AQuick fixSimple structurePreparing sample for investigationGrain treatmentsReciprocating motionBall impact

The invention discloses a high pass tissue grinder and a grinding method. 1-5 grinding balls are placed into a sample pipe, and the diameters of the grinding balls are between 2 mm and 30 mm; a samplebox is immerged into liquid nitrogen to be cooled for 1 minute-2 minutes; the sample box reciprocates under the action of a swing mechanism; and the reciprocating times of the swing mechanism is 200times / minute-3000 times / minute. The invention has the advantages that the grinding balls are placed into the sample pipe, the sample pipe is vibrated in a reciprocating way along a vertical directionunder the action of the swing mechanism or along a horizontal direction or along an arc direction, the grinding balls impacts samples at high speed to complete the grinding of the samples, the frictional impact among the grinding balls can effectively lead to the smash of sample tissues or cells; the closed sample pipe is used so as to be difficult to cause cross infection among raw material samples; and in addition, multiple samples can be simultaneously fast and effectively ground within 2-4 minutes, thus the grinding efficiency is greatly enhanced.

Owner:NINGBO SCIENTZ BIOTECH

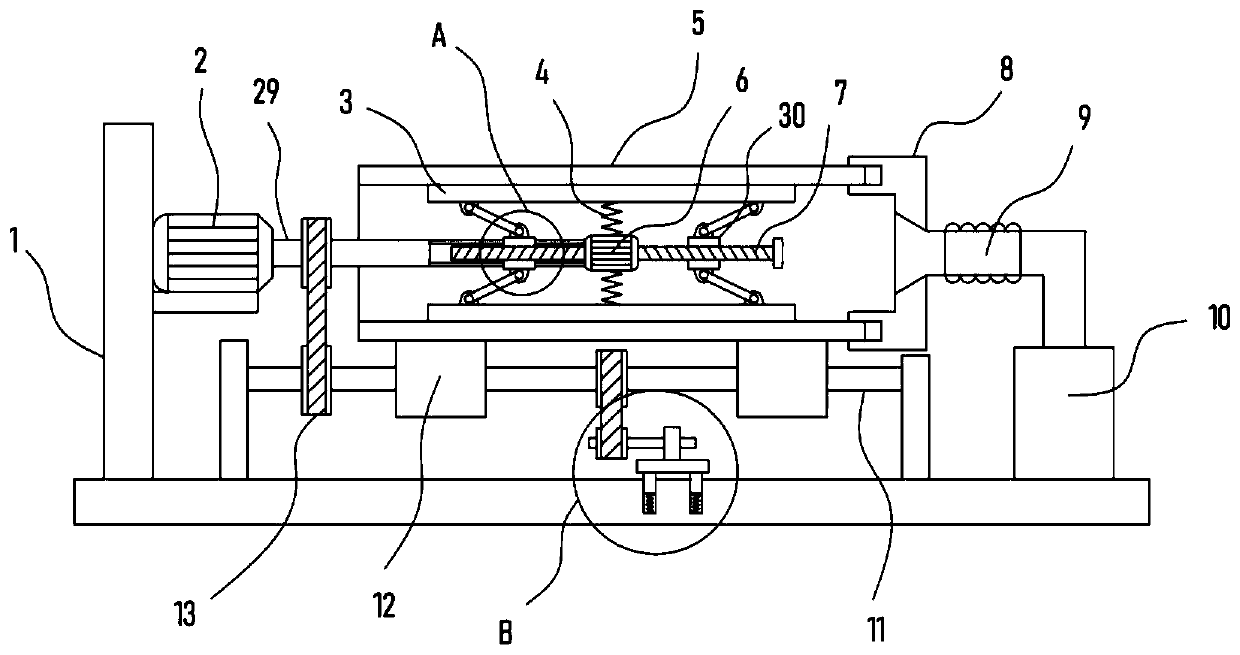

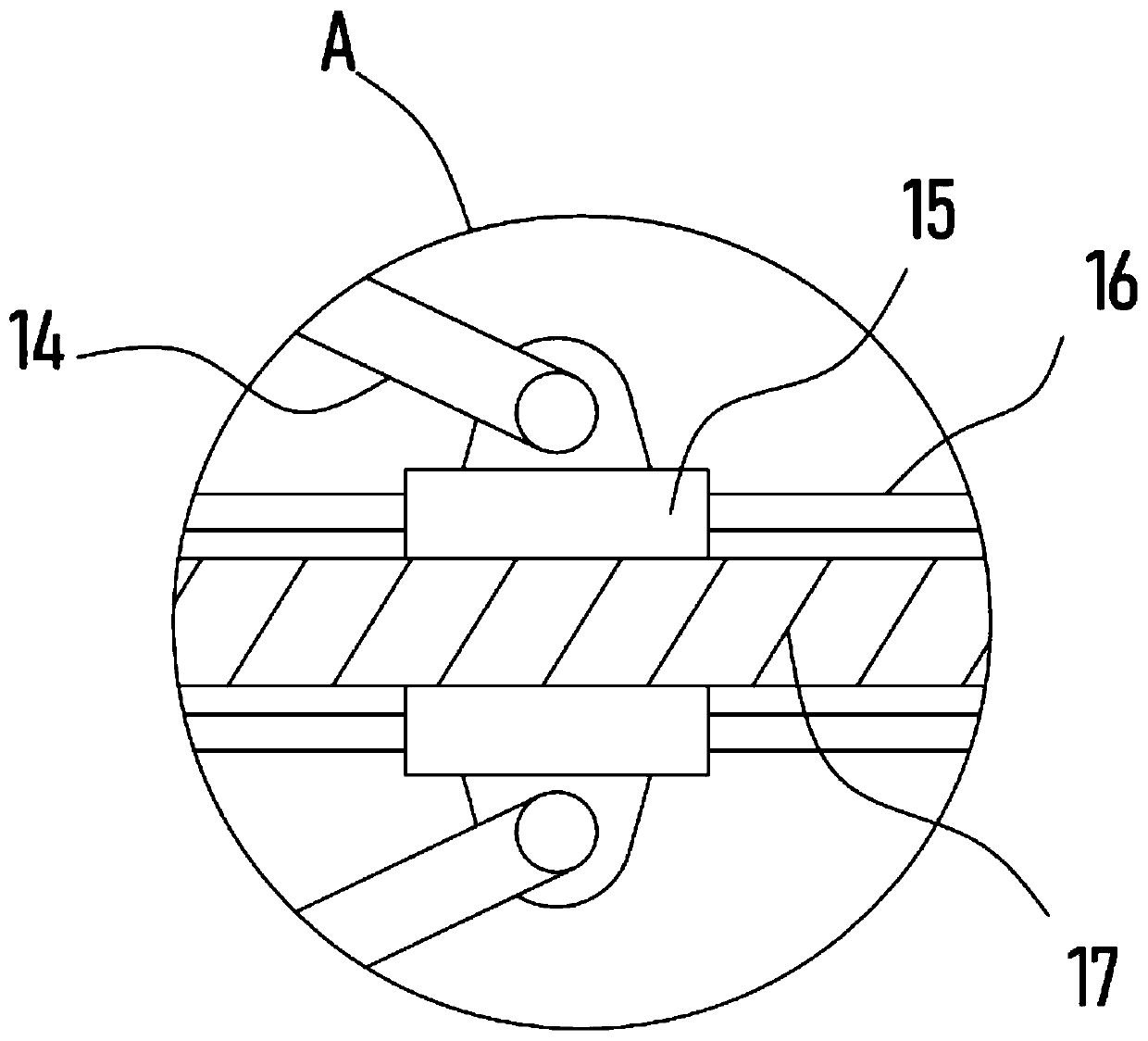

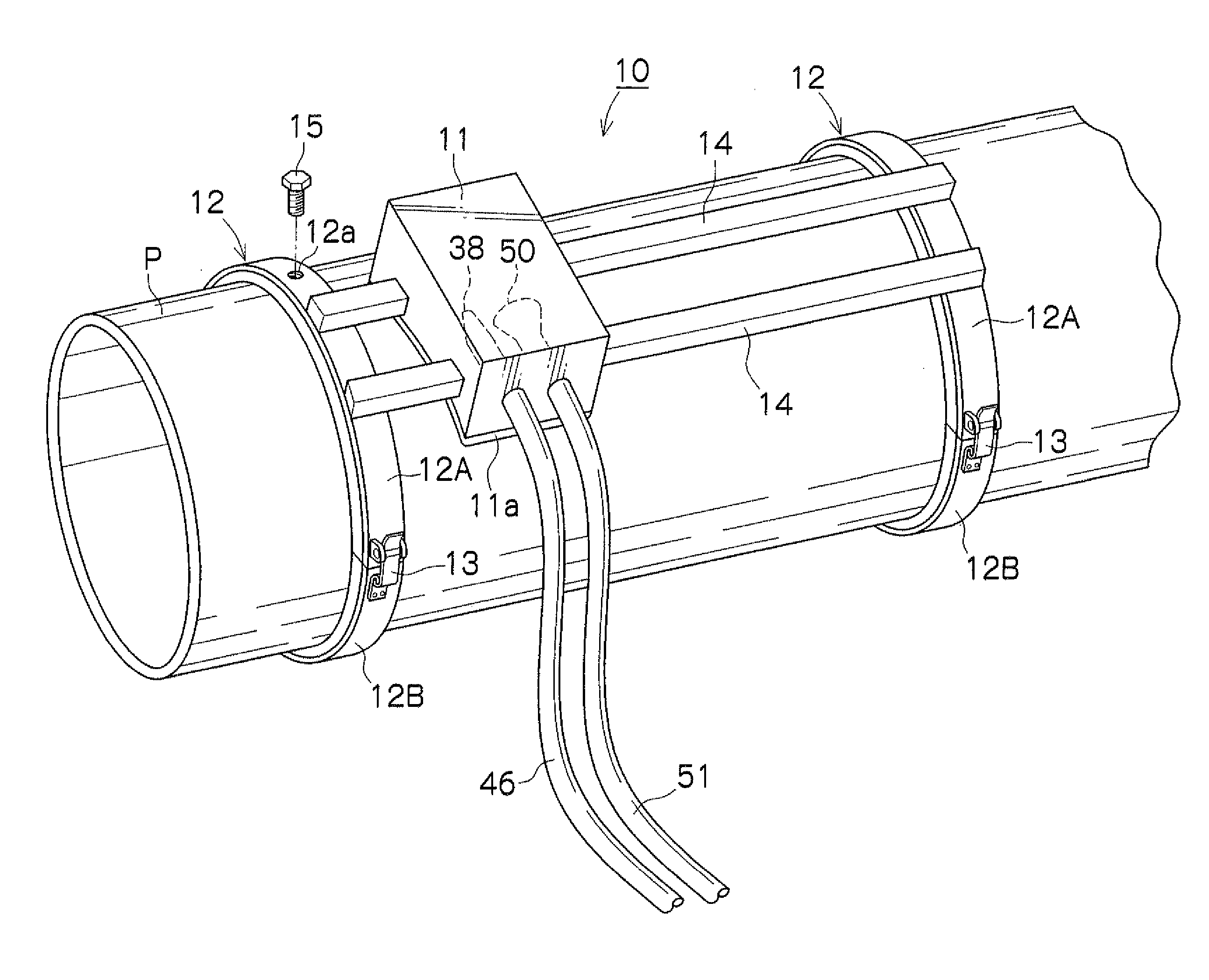

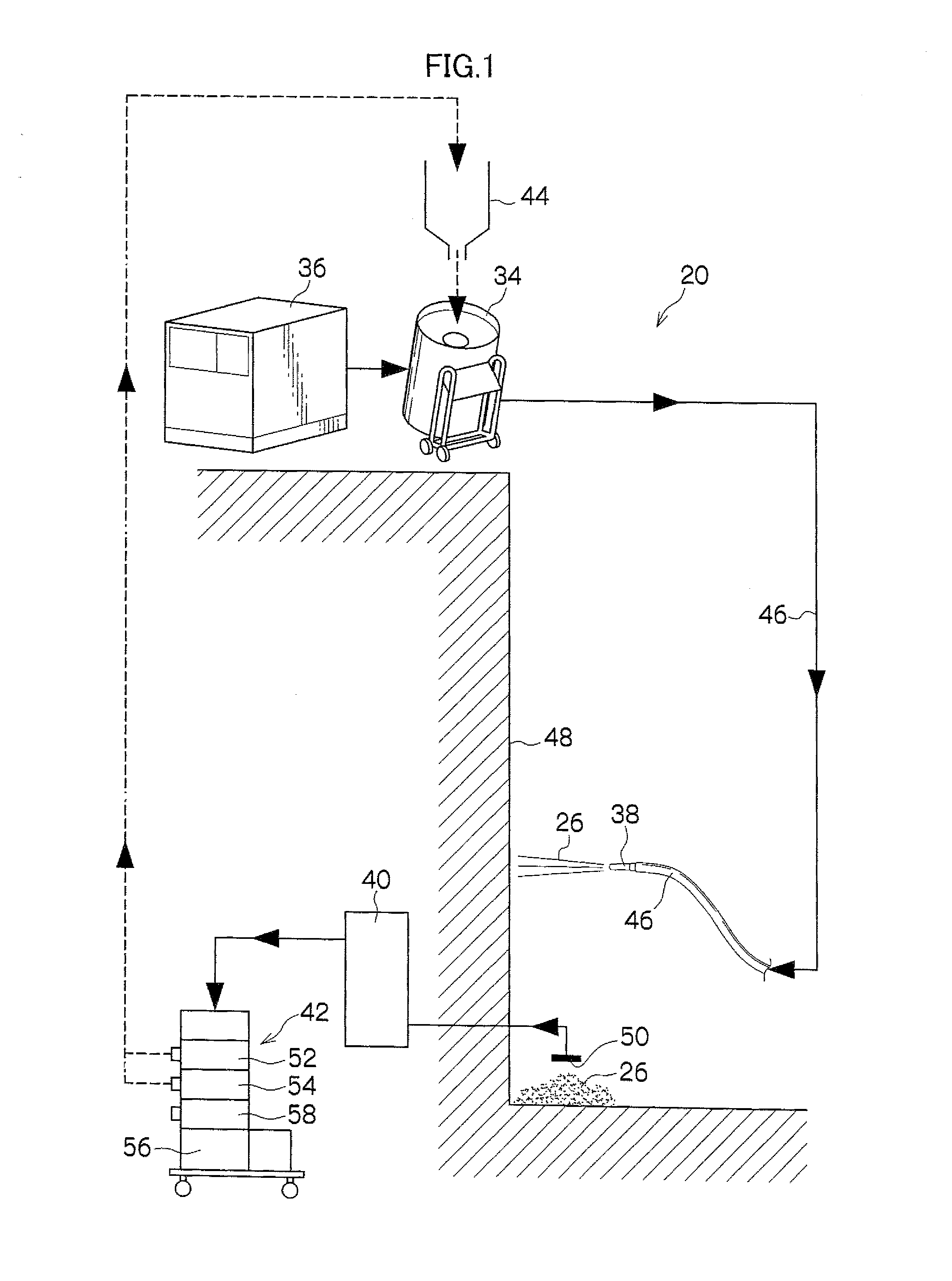

Blasting apparatus for outer surface of pipe

InactiveUS20080038990A1Efficient grindingEasy to operateGrinding feed controlAutomatic grinding controlEngineeringDust particles

The present invention provides a blasting apparatus for an outer surface of a pipe which ejects a blast material to an outer side of a pipe and grinds the outer surface, comprising: a blast head containing a nozzle which ejects the blast material and a suction port which sucks a blast material used for grinding and dust particles; a guide member which is provided along a longitudinal direction of the outer surface of the pipe, and guides the blast head along the longitudinal direction of the outer surface of the pipe; and a ring member which is a ring member constructed by connecting at least two half-split members and having an inside diameter larger than an outside diameter of the pipe, and which is disposed to have the pipe inserted through the ring member, holds the guide member, and guides the blast head in a circumferential direction of the outer surface of the pipe by turning in the circumferential direction on the outer surface of the pipe.

Owner:HITACHI PLANT TECH LTD

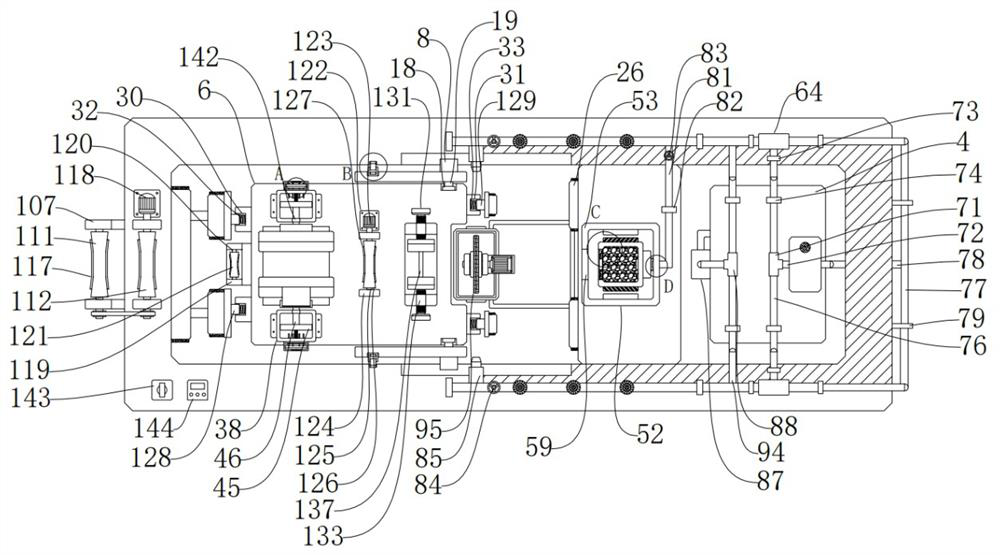

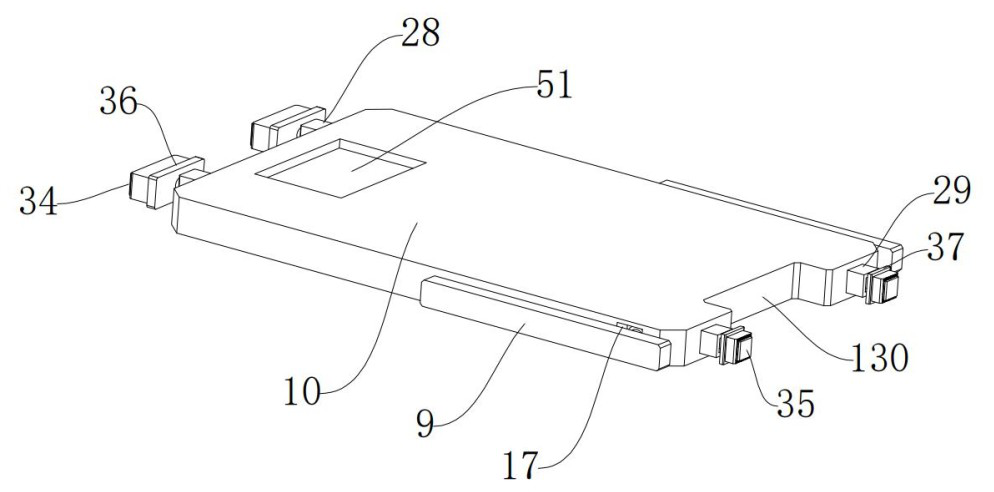

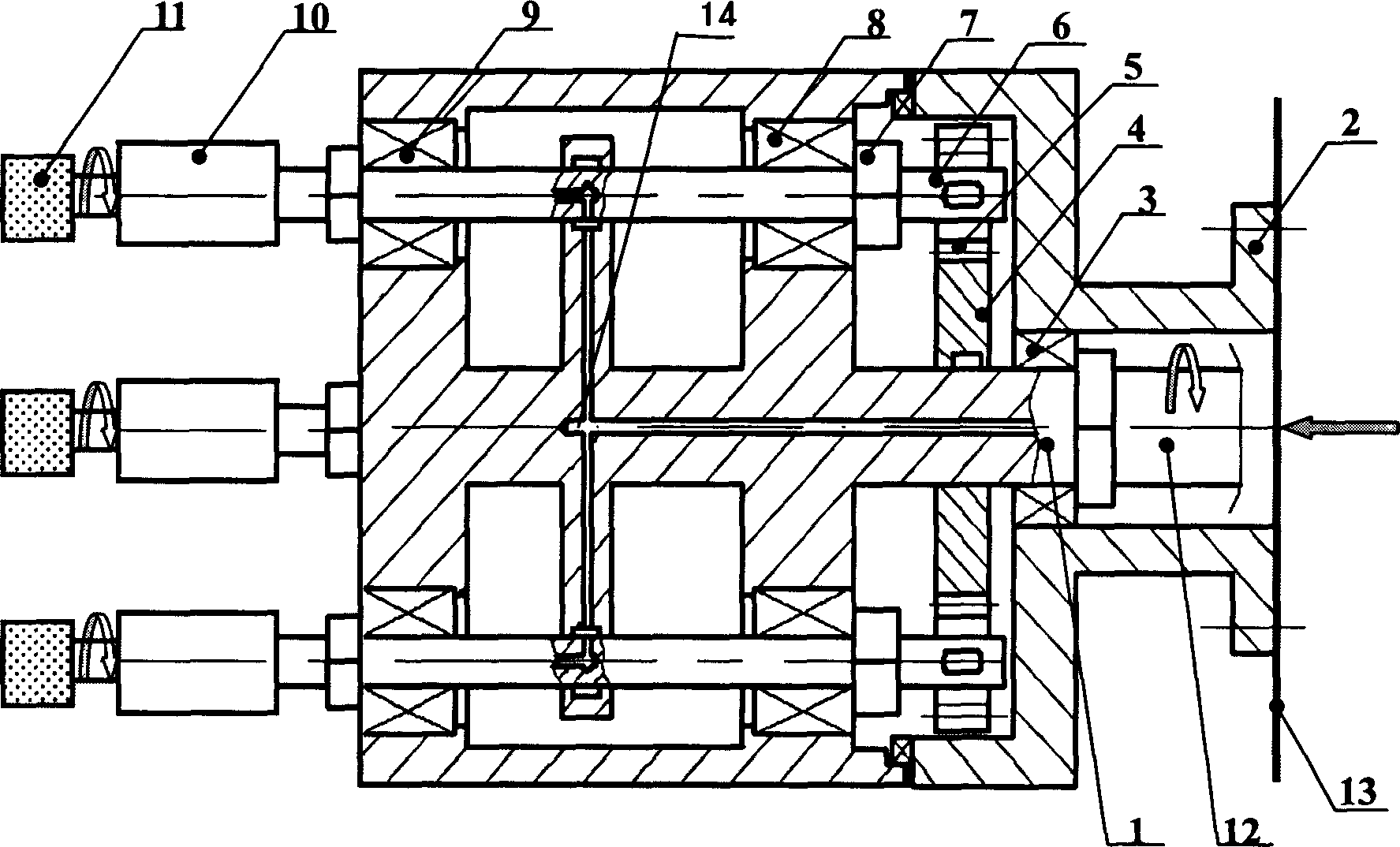

All-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of three-phase rotating structure

ActiveCN113385964AGuaranteed accuracyEasy to adjustOther manufacturing equipments/toolsMetal working apparatusStructural engineeringMachine

The invention discloses an all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of a three-phase rotating structure. The all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine comprises a base, a supporting column, a machining frame, a cooling water mist box, a grinding plate, a magnetic attraction type moving mechanism, an expansion type clamping mechanism, an unpowered grinding mechanism, a vortex separation type cooling mechanism, an all-dimensional atomization dustproof mechanism, a high-precision cutting device, a linkage feeding mechanism, a positioning material moving mechanism and a positioning clamping mechanism. The invention belongs to the technical field of pipe cutting and grinding devices, and particularly provides the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure, so that integration of pipe cutting, grinding and scrap iron adsorption treatment is achieved, all-around scrap collection is facilitated, self-adaptive clamping and fixing on pipes can be carried out according to different cross section shapes and sizes of the pipes through the arrangement of an expansion type clamping mechanism, and due to the arrangement of the linkage feeding mechanism, the labor intensity of workers can be reduced conveniently, and therefore the all-dimensional dust suppression expansion type pipe clamping and machining all-in-one machine of the three-phase rotating structure can machine the pipes efficiently.

Owner:徐州中顺尚奕机械制造有限公司

Grinding apparatus and grinding system

ActiveUS7500905B2Preventing the falling of the metal beltEfficient grindingEdge grinding machinesPolishing machinesEdge surfaceEngineering

A grinding apparatus and a grinding system capable of efficient and superior grinding performance prevent the falling of a belt during the grinding of an edge surface thereof. The apparatus includes two rotating bodies 31 and 32 each having segment brushes 4, 4, . . . attached in the circumferential direction at the edge thereof. The rotating bodies 31 and 32 are rotated in the same direction. The tip of the segment brushes 4, 4, . . . is opposed to one edge surface of a belt b stretched between a driving roller 21 and a driven roller 22. The segment brushes 4 of the two rotating bodies enter toward the belt b at appropriate locations on the one edge surface, such that the falling of the belt can be prevented. A grinding apparatus 1 includes a grinder 3 consisting of the rotating bodies 31 and 32, and a holder consisting of the rollers 21 and 22 and a casing 23 by which the rollers are rotatably supported. A plurality of such grinding apparatuses 1 are disposed at regular intervals, whereby a grinding system 10 is constructed.

Owner:TOYOTA JIDOSHA KK

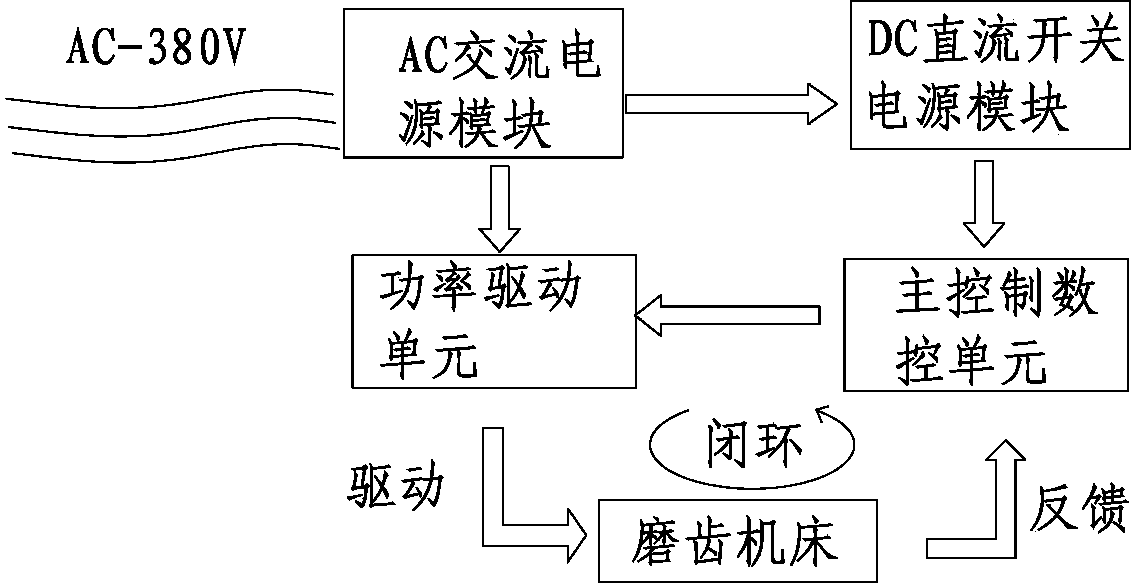

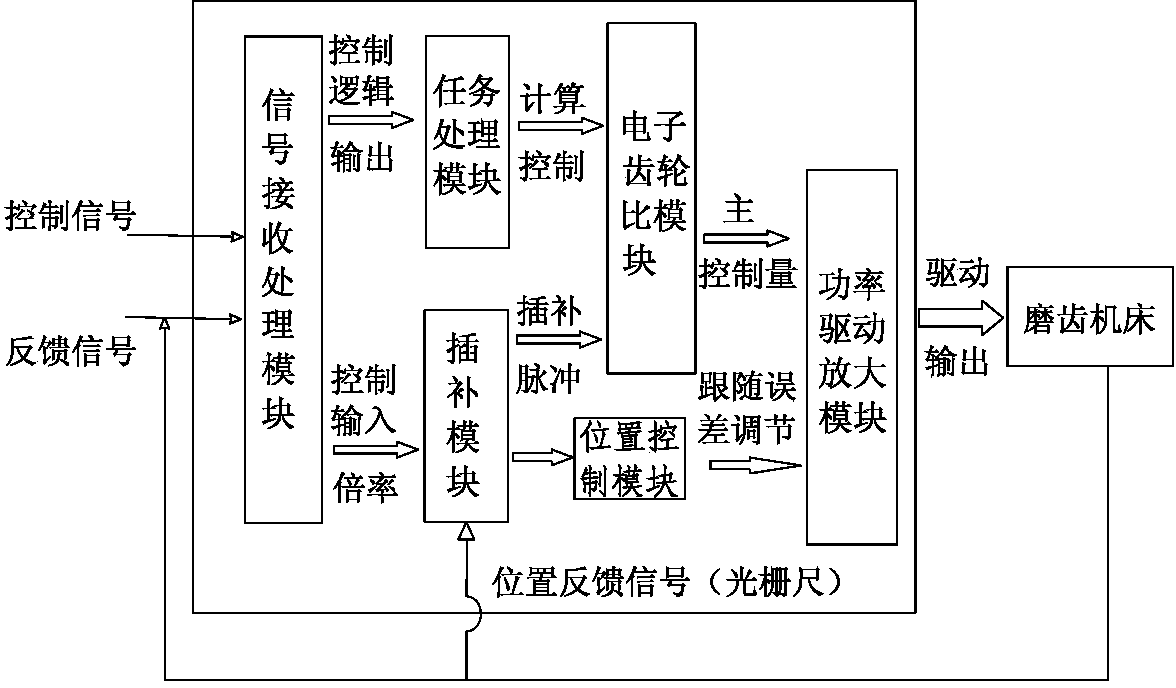

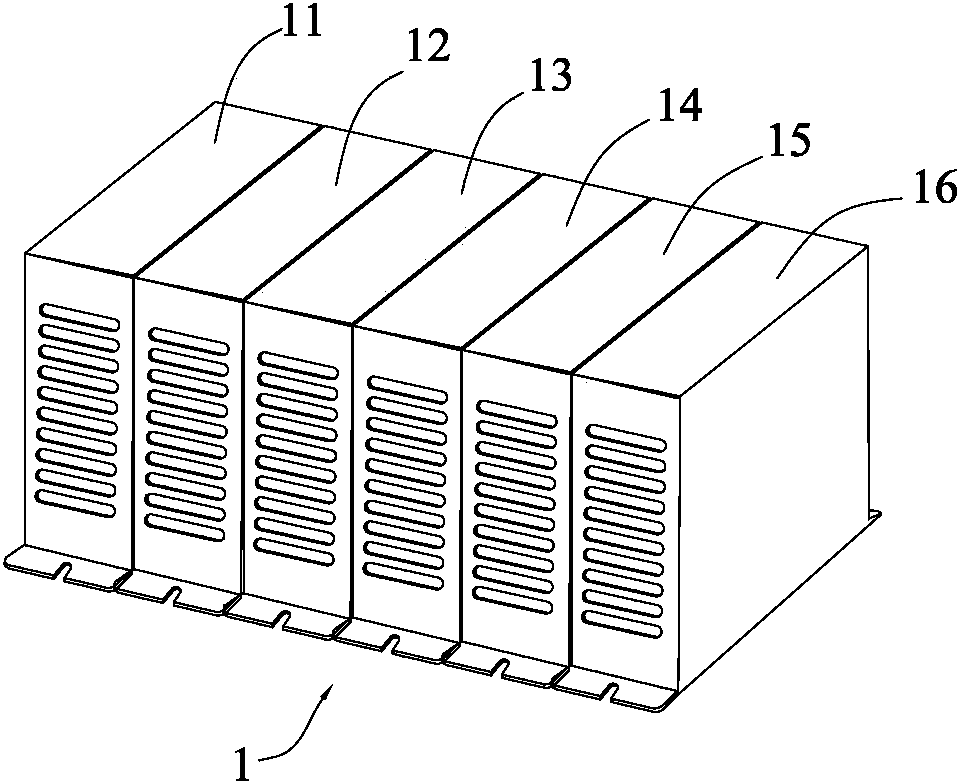

Novel high-precision gear grinding numerical control system

ActiveCN103419077AReal-time dynamic balance monitoringIngenious designAutomatic control devicesFeeding apparatusGear grindingDynamic balance

The invention discloses a novel high-precision gear grinding numerical control system which comprises a split type case, an AC power module, a DC switch power module, a main control numerical control unit and a power drive unit. The split type case comprises a plurality of independent case bodies which are arranged side by side; the AC power module, the DC switch power module, the main control numerical control unit and the power drive unit are arranged in the corresponding independent case bodies respectively and are connected with one another. The novel high-precision gear grinding numerical control system is ingenious and reasonable in design, the split type modular structural design is adopted, position relation is reasonably distributed according to difference of functions, strong and weak power and power consumption, the working stability is good, operation and daily maintenance work are controlled easily, and the working efficiency is effectively improved. Moreover, the novel high-precision gear grinding numerical control system has the gear grinding and repairing functions, dynamic balance monitoring can be conducted on gears and grinding wheels in real time, trimming and compensation can be provided timely, the grinding machining operation can be finished with high efficiency and high precision, the quality of the gears is effectively ensured, and wide popularization and application are facilitated.

Owner:ZHONGSHAN MLTOR CNC TECH CO LTD

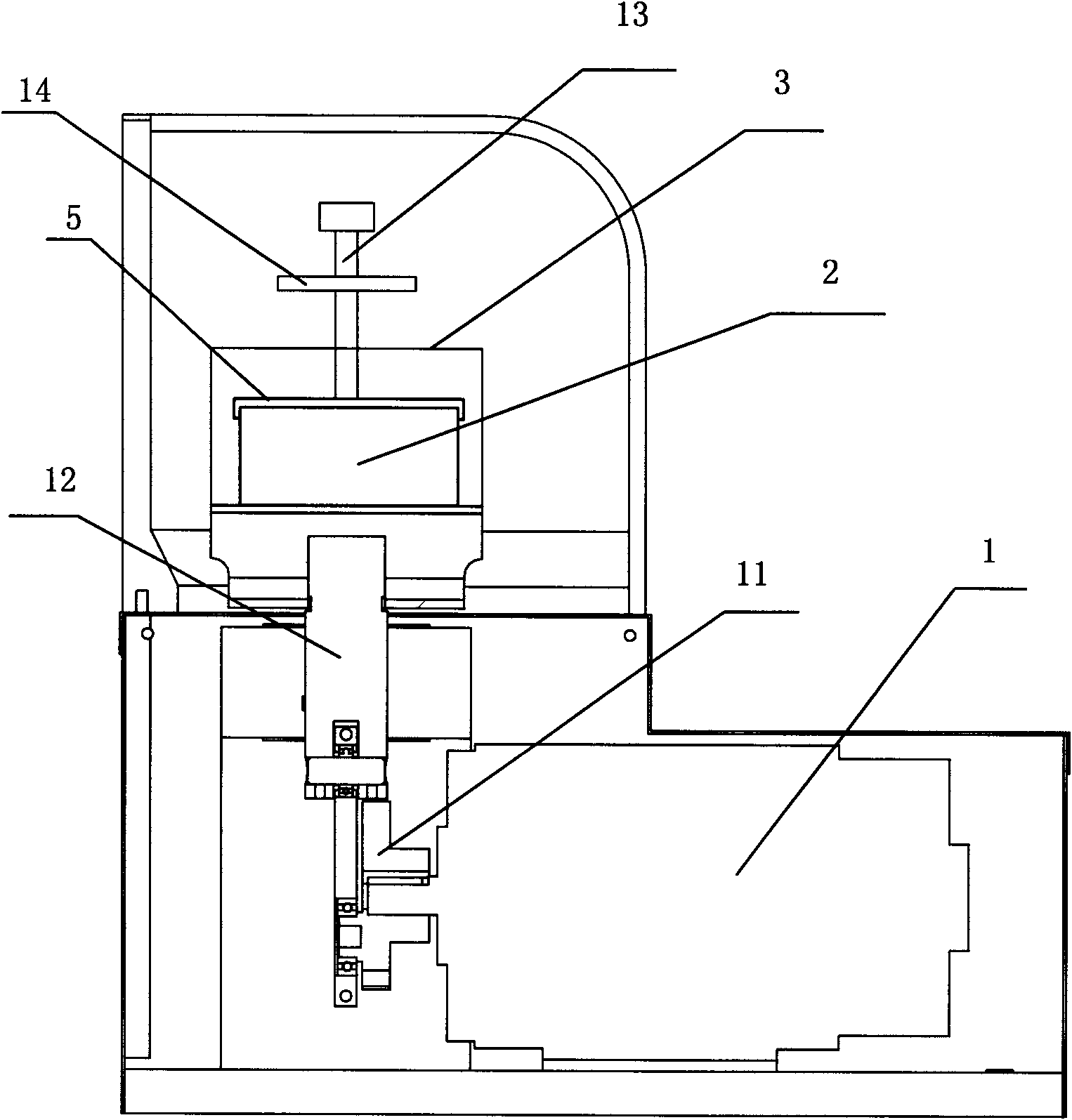

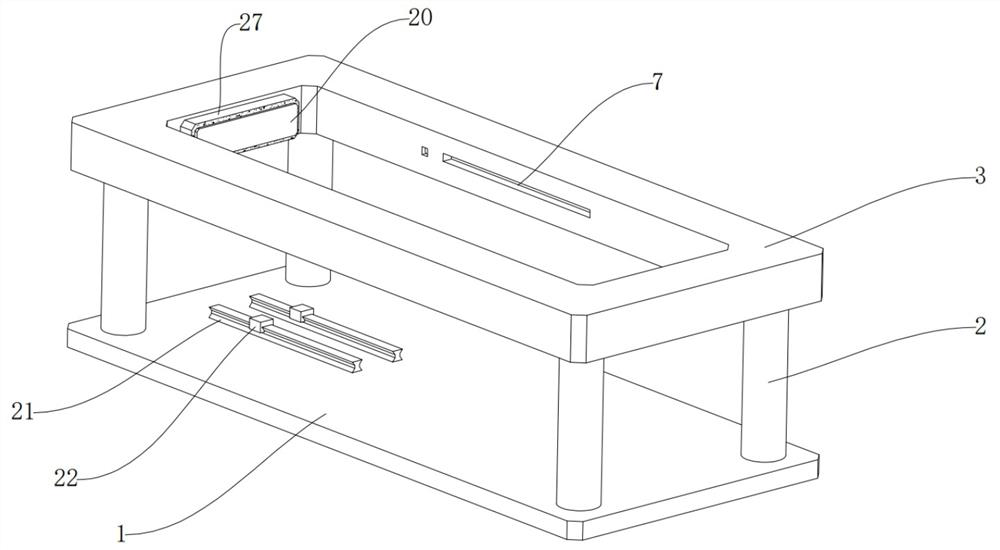

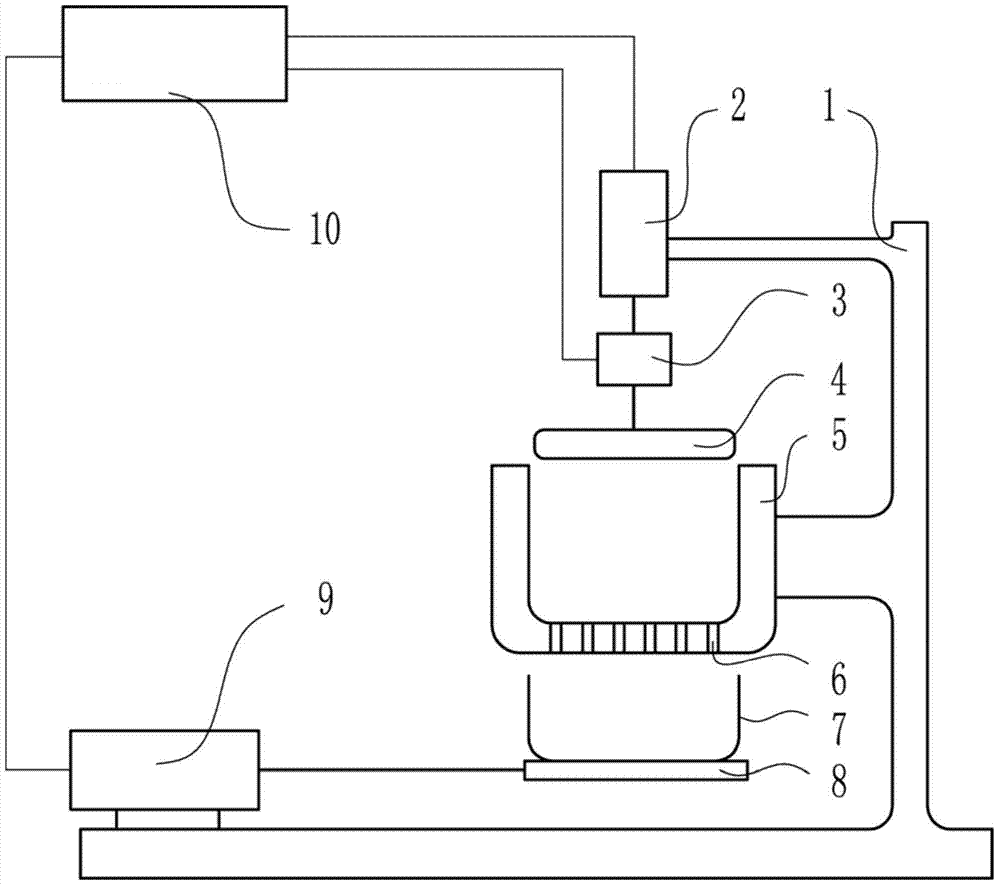

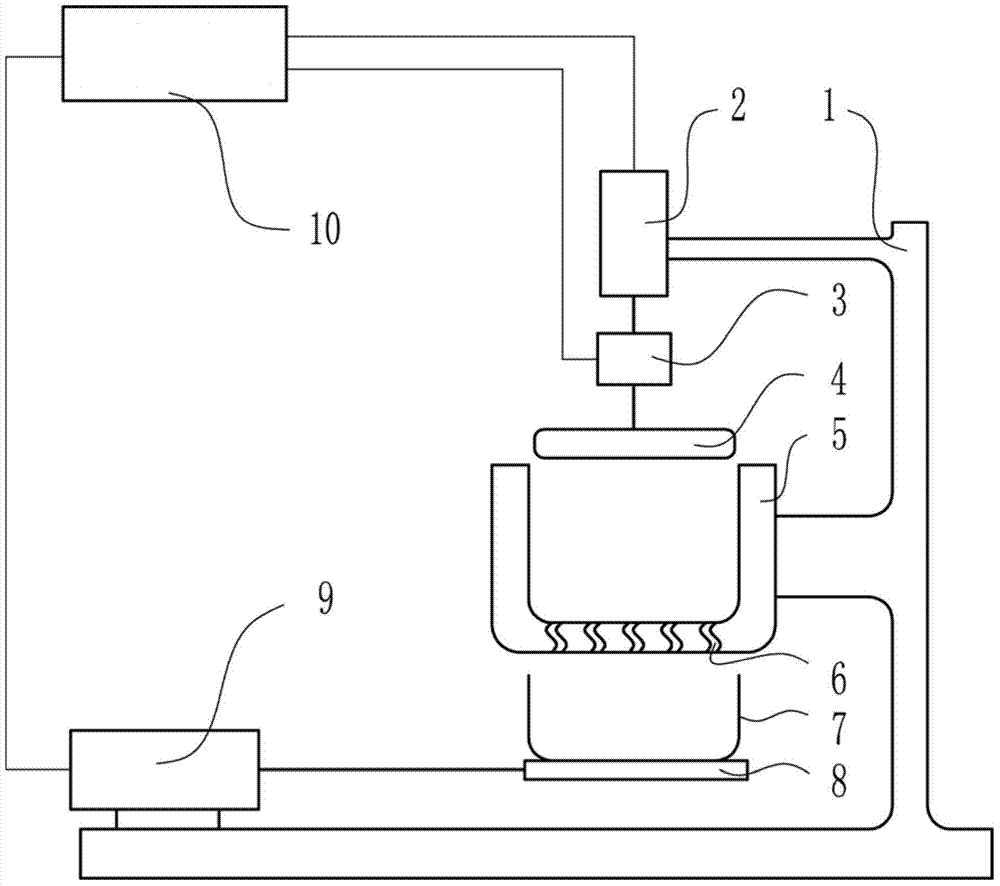

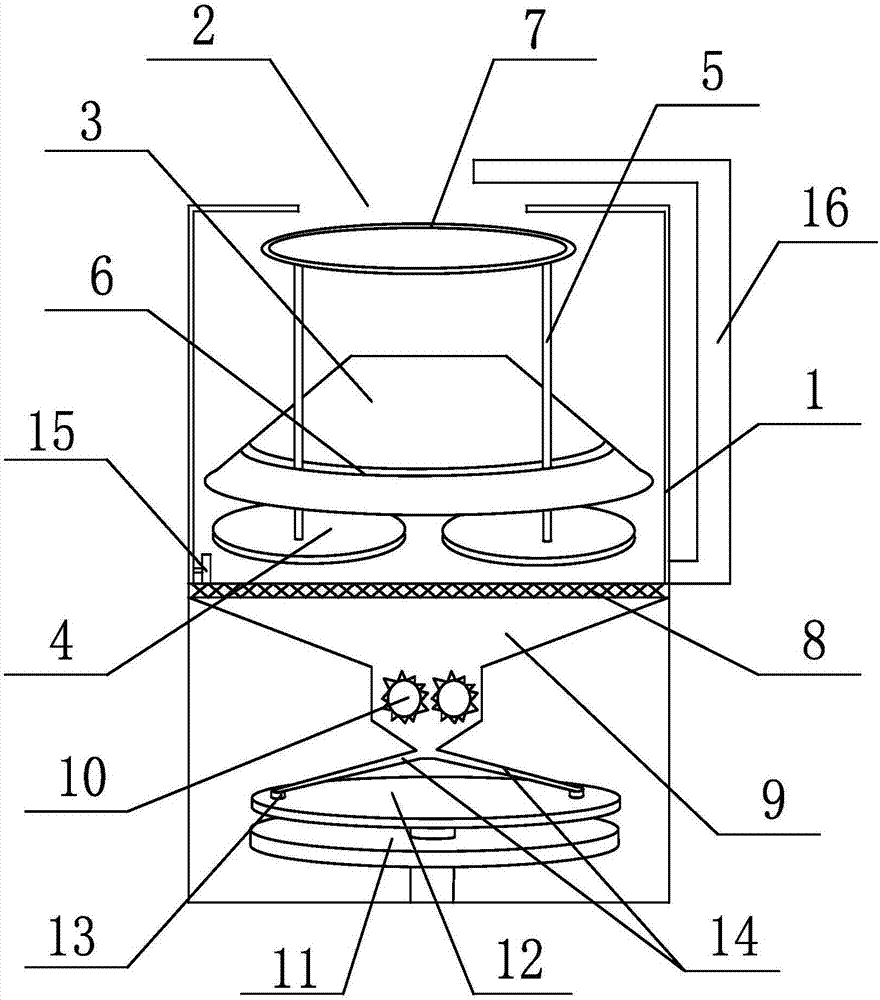

Full-automatic traditional Chinese medicine mortar device

ActiveCN104772182ARealize fully automated operationLow costGrain treatmentsMedicineTraditional Chinese medicine

The invention relates to a mortar device and in particular relates to a full-automatic traditional Chinese medicine mortar device. The full-automatic traditional Chinese medicine mortar device comprises an upper cylinder, a lower cylinder, a grinding motor, a grinding head and a medicine bowl, wherein the upper cylinder and the lower cylinder are arranged on a rack, the grinding motor is arranged right below the upper cylinder and the lower cylinder, the grinding motor is connected with the upper cylinder and the lower cylinder, the grinding head is arranged right below the grinding motor and is connected with the grinding motor, the medicine bowl is arranged right below the grinding head and is matched with the grinding head, the medicine bowl is arranged on the rack, a material receiving cylinder is arranged right below the medicine bowl and is arranged on a tray in a separated manner, the tray is connected with a left cylinder and a lower cylinder, and the left cylinder and the right cylinder are arranged on the rack. According to the full-automatic traditional Chinese medicine mortar device, full-automatic operation is realized, the operation is time-saving and labor-saving, the grinding effect is good, and the full-automatic traditional Chinese medicine mortar device is sanitary and clean, has a simple structure, can be used conveniently and can be maintained easily.

Owner:山西宝泰药业有限责任公司

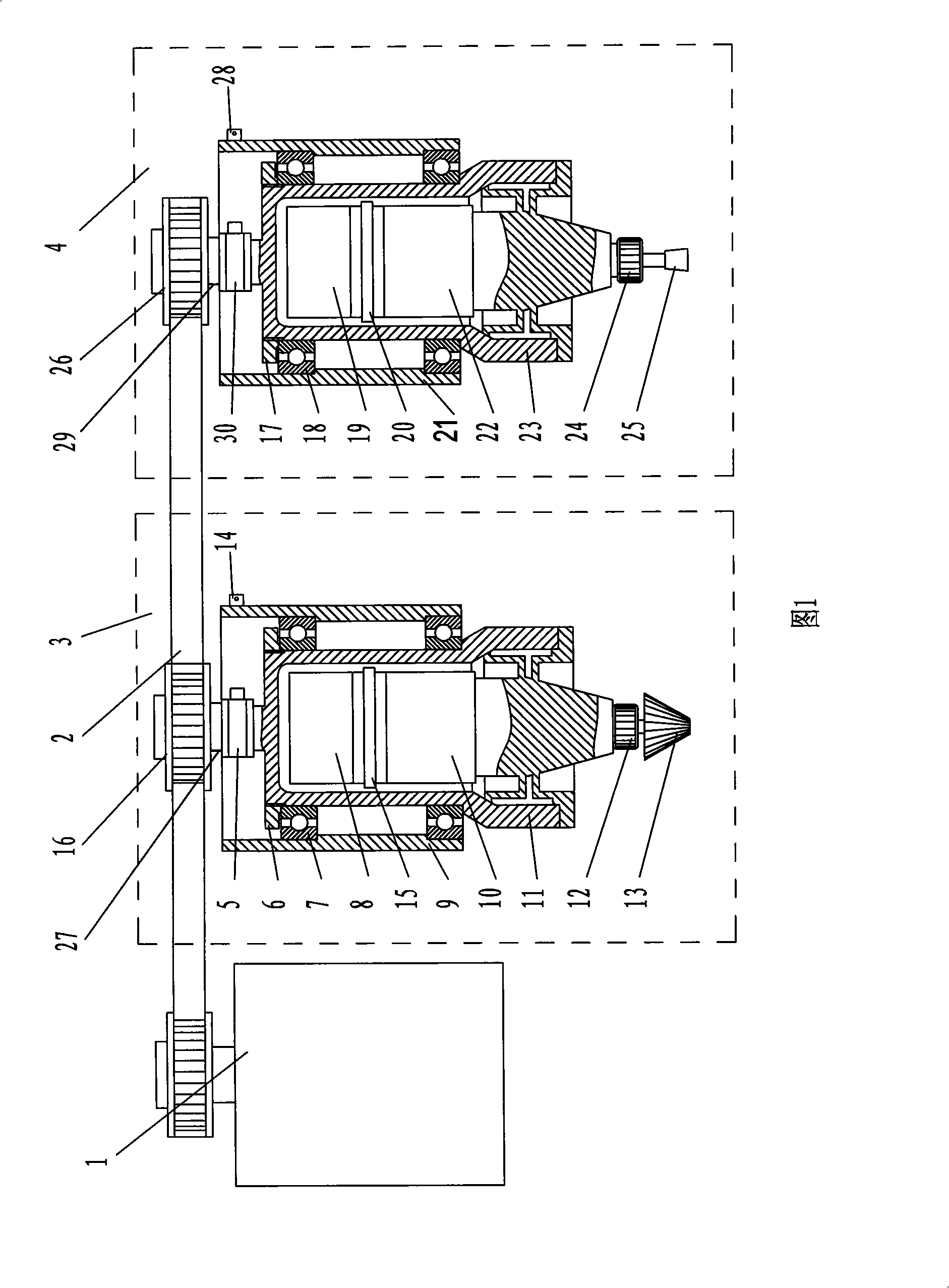

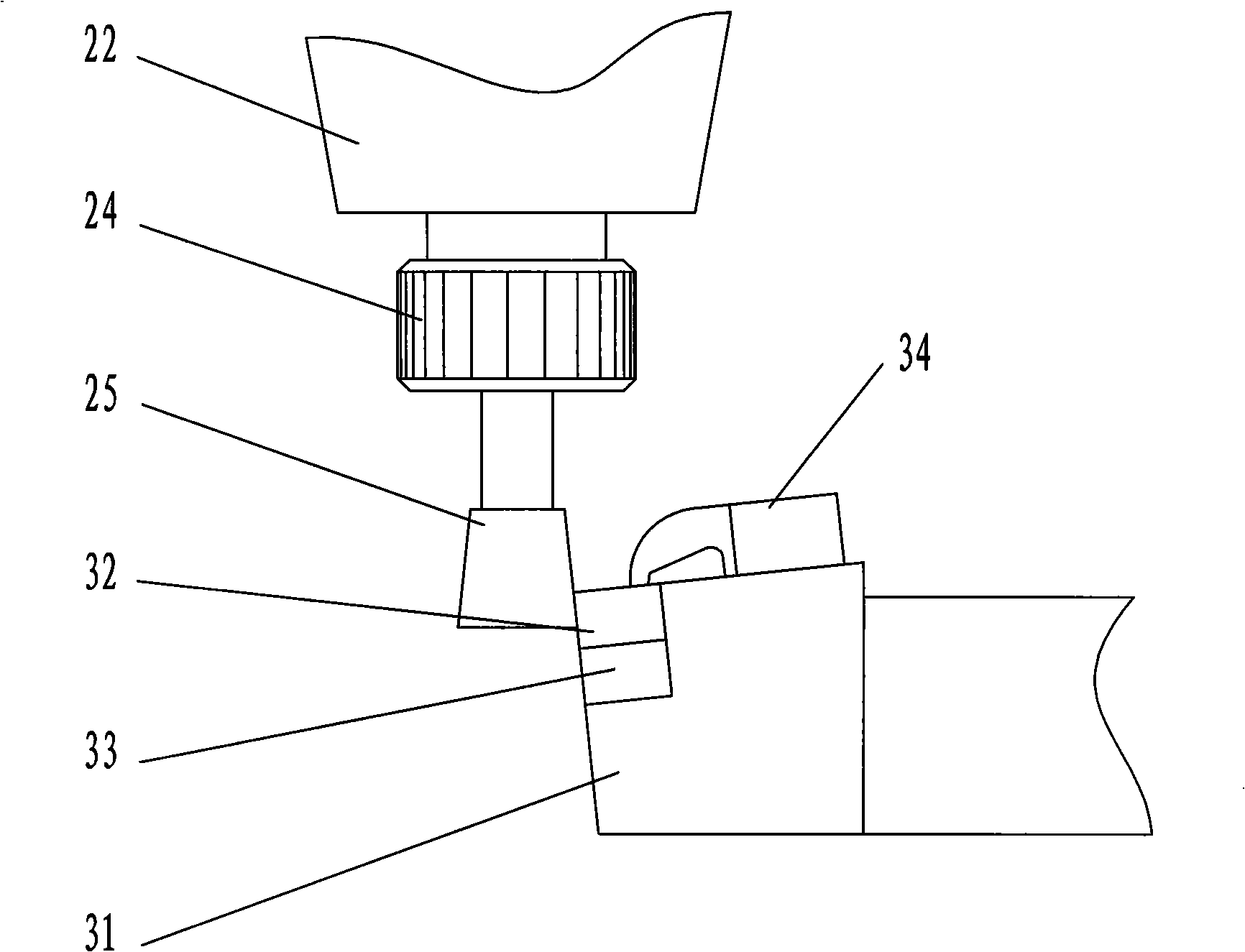

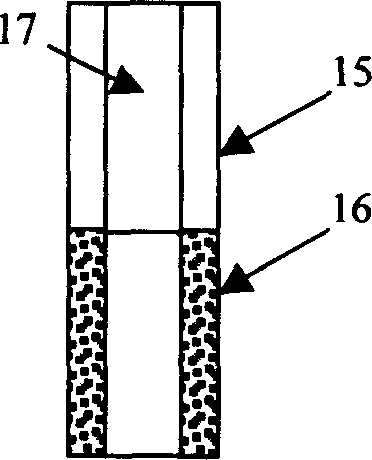

Numerically controlled machine knife tool on-line coping device

InactiveCN101323093AImprove work efficiencySolve online timing automatic grindingGrinding machine componentsPolishing machinesNumerical controlTransformer

The invention relates to an online coping device for a cutting tool of a numerical control tool, which effectively solves the online coping problem of the cutting tool. The device is a polishing head spindle, one end of which is provided with a tooth shaped belt wheel and the other end is provided with an elastic clamp polishing head which is provided with an amplitude transformer, a transducer is arranged on a first half axis which is connected with the amplitude transformer at the lower side by a thread and which is arranged in a shell of the polishing head , the shell is arranged in an installation seat of the polishing head, the same side of a grinding head spindle and a tooth-shaped belt of the polishing head is provided with the tooth-shaped belt wheel of the grinding head, the grinding head is arranged at the lower part of the amplitude transformer of the grinding head by the elastic clamp, the upper part of the amplitude transformer is provided with a piezoelectric ceramic transducer of the grinding head, the piezoelectric ceramic transducer of the grinding head is arranged on the first half axis of the grinding head, is connected with the amplitude transformer of the grinding head at the lower side by thread on the first half axis of the grinding head and is arranged in the shell of the grinding head, the shell is arranged in the installation seat, and a motor, the tooth-shaped belt wheel of the polishing head and the tooth-shaped belt wheel of the grinding head are integrated into a whole by the tooth-shaped belt. The online coping device can be effectively used for coping of the blade of the numerical control tool and is a large innovation in the field of the numerical control tool.

Owner:黄建明

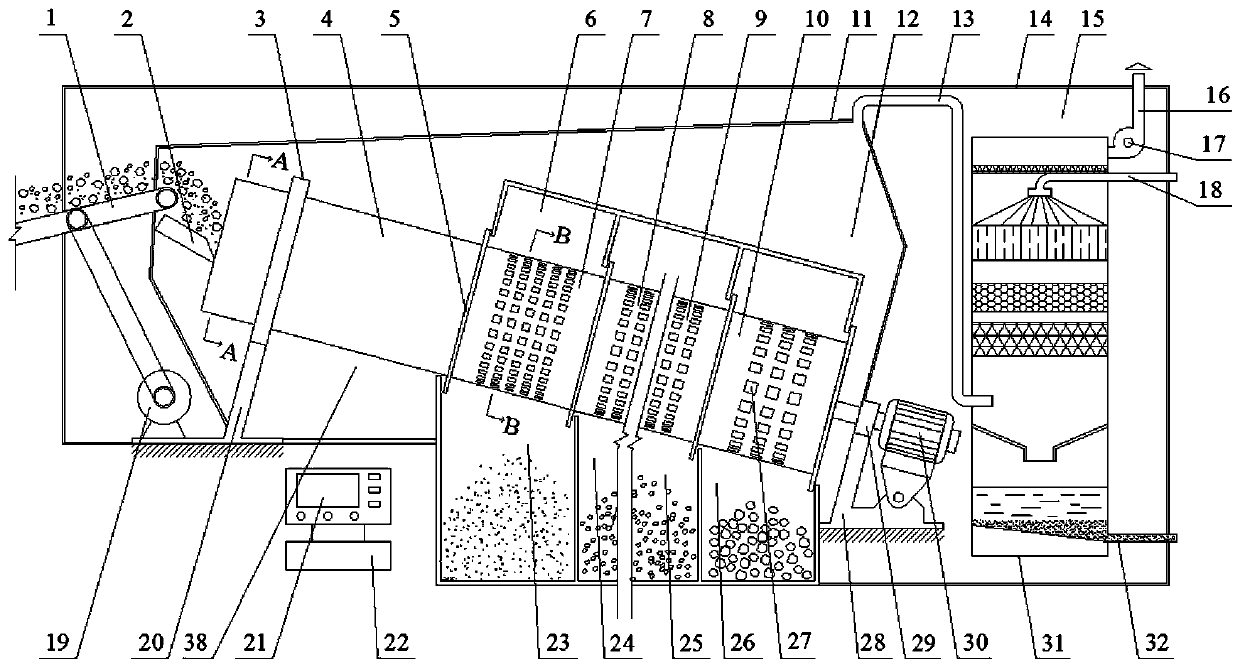

Efficient pulverizer used for preparation of traditional Chinese medicine decoction pieces

The invention discloses a high-efficiency pulverizer for preparing Chinese herbal decoction pieces, which comprises a pulverizer body, a feeding port is arranged above the pulverizer body, a conical barrel-shaped feeding cover is provided below the feeding port, and a feeding table is provided below There are a plurality of disc-shaped cutters, the upper surface of the cutters is connected with a driving rod, and a circular through-slot is opened on the side of the material passing cover, and the driving rod passes through the through-slot and the upper end is connected to a circular driving rod. On the track, there is a screen under the cutter, a funnel-shaped gathering hopper under the screen, a crushing roller at the bottom opening of the gathering hopper, and a grinding base and a grinding disc under the gathering hopper. The high-efficiency pulverizer of the present invention can process the size of Chinese medicinal materials step by step through multiple processes, and can efficiently and quickly cut, pulverize and grind Chinese medicinal materials, avoiding the damage of the crushing device caused by directly crushing raw materials, and at the same time After crushing, the seamless connection of grinding is realized, which greatly improves the processing efficiency of Chinese herbal medicines and saves time and cost.

Owner:谭证书

Roller mill for coffee

ActiveUS8690087B2Reduce adverse effectsGrind the coffee efficientlyCoffee millsSpice millsEngineeringVelocity ratio

Owner:BAUERMEISTER ZERKLEINERUNGSTECHN

Comminuting device

InactiveUS7147174B2Easy interchangeReduce harmCoffee millsJuice extractionComminutionElectrical and Electronics engineering

Owner:MANSEN JOEL D

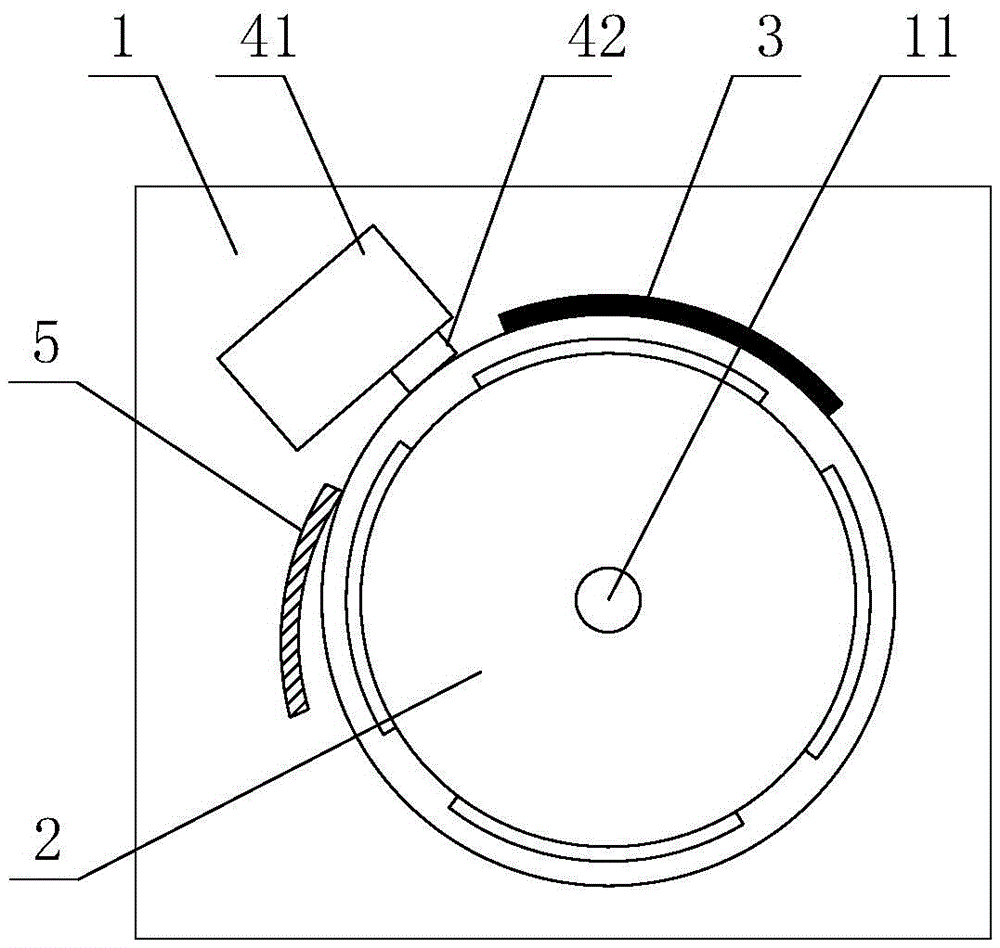

Polishing device for outer surfaces of brake linings

The invention discloses a polishing device for outer surfaces of brake linings. A vertically arranged rotating shaft is arranged on a base, a circular truncated cone is rotationally mounted on the base by the aid of the rotating shaft and comprises a mounting part and a supporting part, the mounting part is located above the supporting part, the outer diameter of the supporting part is larger than that of the mounting part, at least one brake lining mounting position is arranged on the outer wall of the mounting part, a polishing mechanism is located on the base and on one side of the circular truncated cone, and a limiting bulge is arranged on the base and is located on the periphery of the circular truncated cone and between the circular truncated cone and the polishing mechanism; during machining, each brake lining is placed in the mounting position of the circular truncated cone and enters a polishing position with rotation of the circular truncated cone, the polishing mechanism polishes the outer surface of the brake lining, and the polished brake lining is discharged from the circular truncated cone along a guiding plate, so that the outer surface of the brake lining is efficiently polished.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

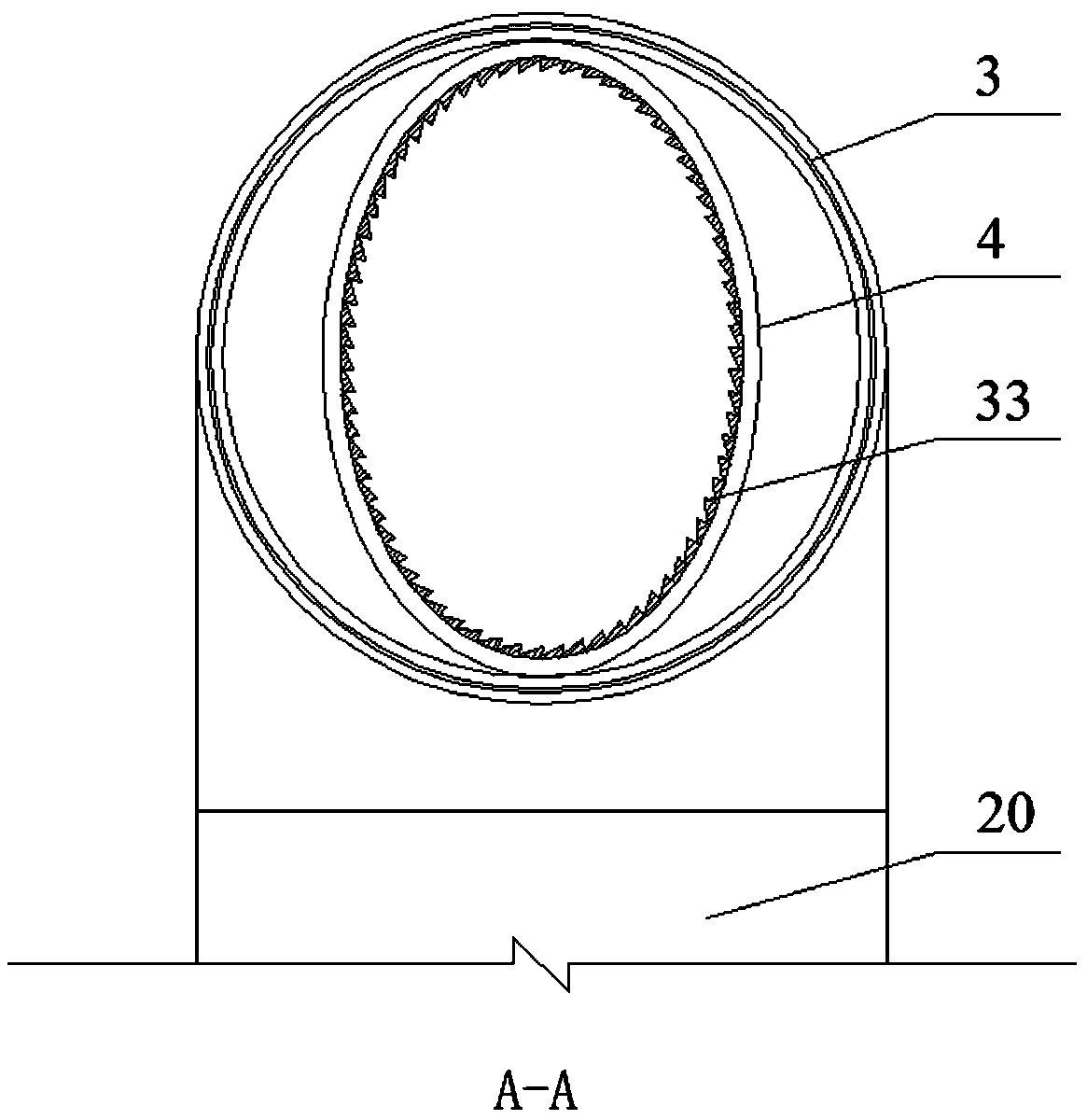

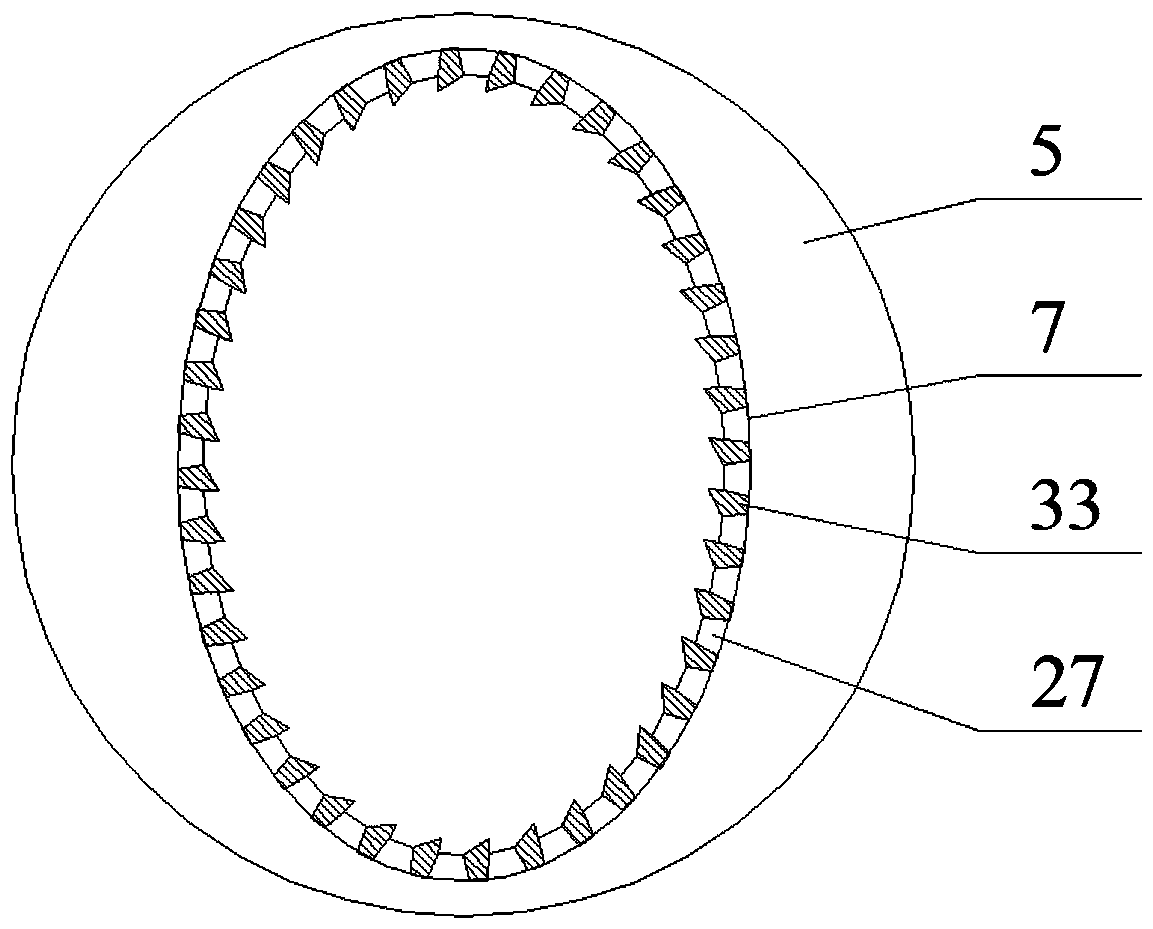

Recycled aggregate shaping barrel and recycled aggregate shaping equipment using shaping barrel

The invention relates to a recycled aggregate shaping barrel and recycled aggregate shaping equipment using the shaping barrel. The recycled aggregate shaping barrel comprises a barrel body which is provided with a shaping section and a feeding hole, wherein support parts which are in rotating and supporting fit with corresponding support seats are arranged on the barrel body; and the cross section of the shaping section is in an elliptical shape. When recycled aggregates are shaped, the barrel body is driven by a driving mechanism to rotate, and back-and-forth rollover and impact of the innerpart of the barrel body is driven by the elliptical shaping section, so that through the arrangement of the elliptical shaping section, increment on impact force of an inner wall to particles and gyratory motion amplitude and frequency of the particles in the barrel body are facilitated, so that a mortar weak layer on the surfaces of the recycled aggregates is effectively abraded and removed; andin addition, because of the elliptical structure, excessive acting force on the recycled aggregates is avoided, and the recycled aggregates are prevented from being broken, so that the shapes of theparticles of the shaped recycled aggregates are close to squircle, damage to internal structures of the aggregates is reduced to a maximum extent while the good shaping effect is realized at the sametime, and a desired shaping reinforcement effect is achieved.

Owner:ZHENGZHOU UNIV

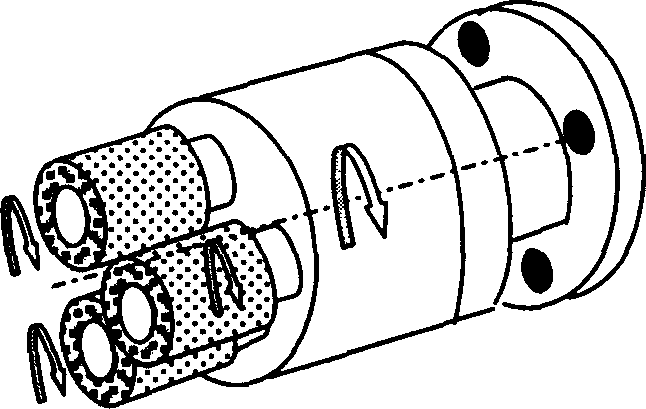

Planetary framework diamond abrasive tools

InactiveCN1836845AAvoid loweringMaintain sharpnessGrinding machinesMetal working apparatusDrive shaftGear wheel

The planetary mechanism diamond grinding tool is one workpiece grinding diamond grinding wheel apparatus with great grinding width, high efficiency, low cost and grinding wheel without needing trimming measure and tool. It has planetary gear mechanism, spring clamp sleeve, cooling pipeline, fixing and connecting casing and rotating casing. The planetary gear mechanism is provided with bearing, sun gear, planetary gear, nut, bearing and pressurized cooling liquid inflow pipeline. The rotating casing is connected to the driving shaft integrally, the bearing is set between the driving shaft and the fixing and connecting casing, the sun gear is set on the driving shaft for rotation, the planetary gear is connected to the sun gear, the spring clamp sleeve is set in the output end of the planetary shaft, the cooling liquid inflow pipeline is set in the axial center of the driving shaft and has one end connected to the built-in cooling pipeline inside the rotating casing.

Owner:XIAMEN UNIV

Iron rod polishing device for hardware processing

InactiveCN108527136AEasy to polishImprove grinding effectPolishing machinesGrinding drivesEngineeringMechanical equipment

The invention provides an iron rod polishing device for hardware processing, and relates to the field of mechanical equipment. The iron rod polishing device includes a base, supporting legs are fixedly connected to four corners of the top of the base, and a shell is fixedly connected to the tops of the supporting legs. An attle recycling device is fixedly connected to the right side of the bottomof the shell, and a transmission device is fixedly connected to the left side of the shell. A driving device is fixedly connected to the left side of the transmission device, and a first rotating shaft is arranged in the shell. According to the iron rod polishing device for hardware processing, through the arrangement of the attle recycling device, generated attle can fall onto a collecting bottomplate in the attle recycling device while grinding, and then falls into a collecting tank through a second collecting opening and a first collecting opening; a recycling door is opened, the collecting tank can be easily drawn out, and the attle in the collecting tank can be recycled; and cleaning, recycling and reusing of the attle are effectively facilitated, and the cleaning efficiency is improved.

Owner:新昌县盛南建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com