Blasting apparatus for outer surface of pipe

a technology for outer surfaces and blasted pipes, which is applied in the direction of grinding/polishing apparatus, grinding machine components, manufacturing tools, etc., can solve the problems of poor operability, degrading operability, and hygiene problems, and achieve the effect of reducing dust particles, remarkably improving operation environment, and easy movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

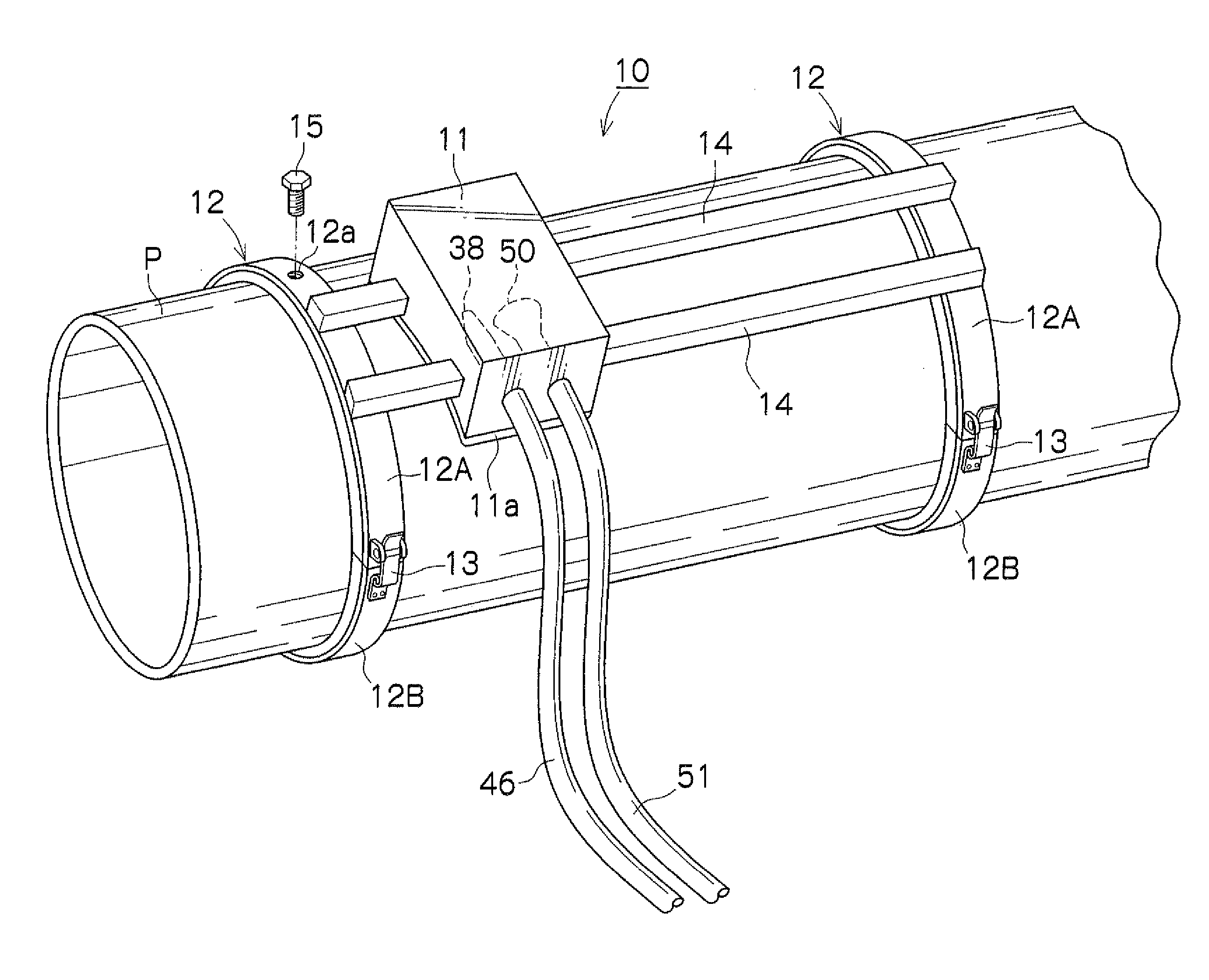

[0032] A preferred embodiment of a blasting apparatus for an outer surface of a pipe according to the present invention will now be described in detail with reference to the accompanying drawings. In this embodiment, explanation will be made with an example of a sponge blasting apparatus using a blast medium in a sponge piece form in which abrasives are contained in a porous elastic body as a blast material. The same members are assigned with the same numerals and characters in each drawing.

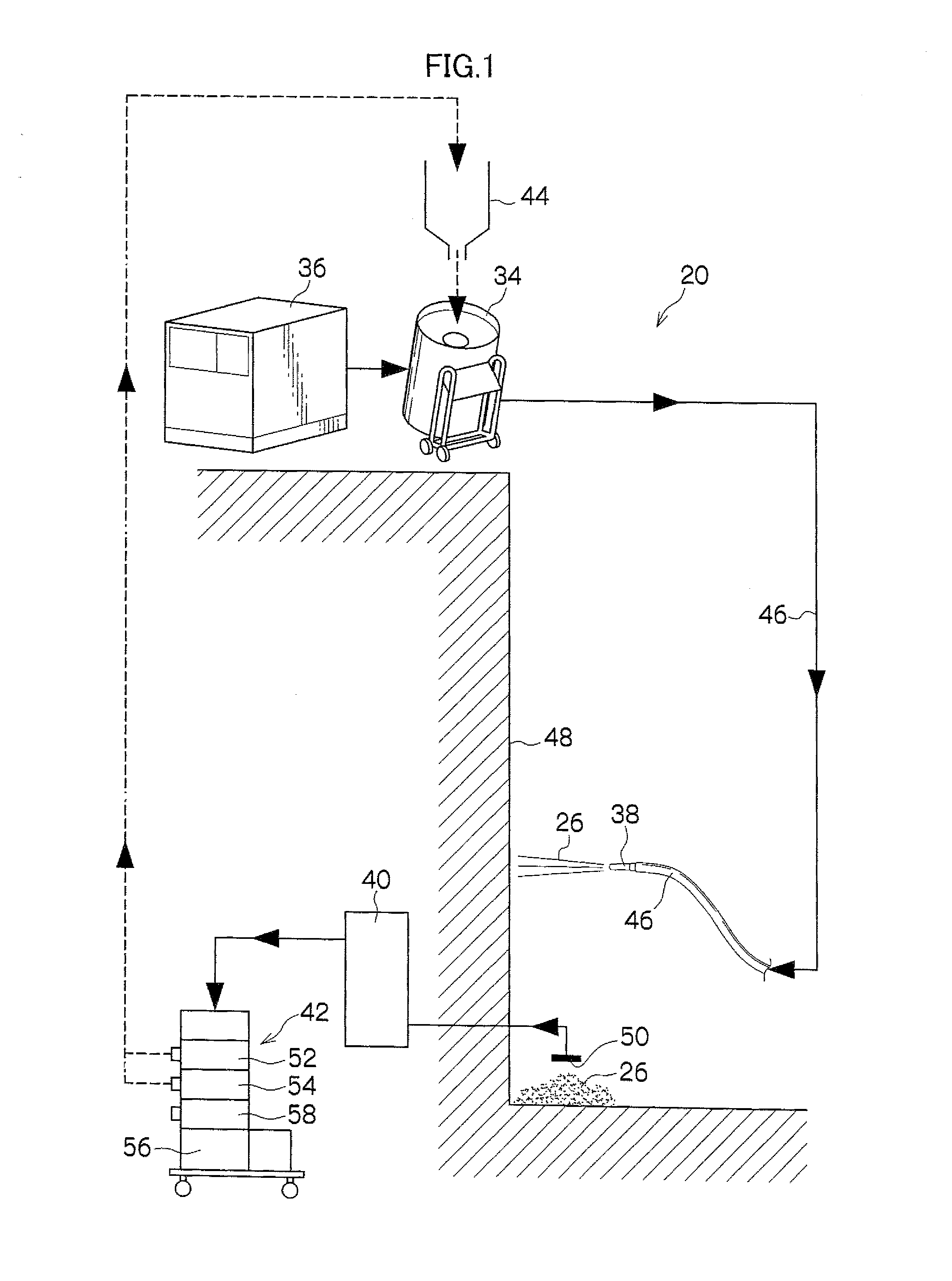

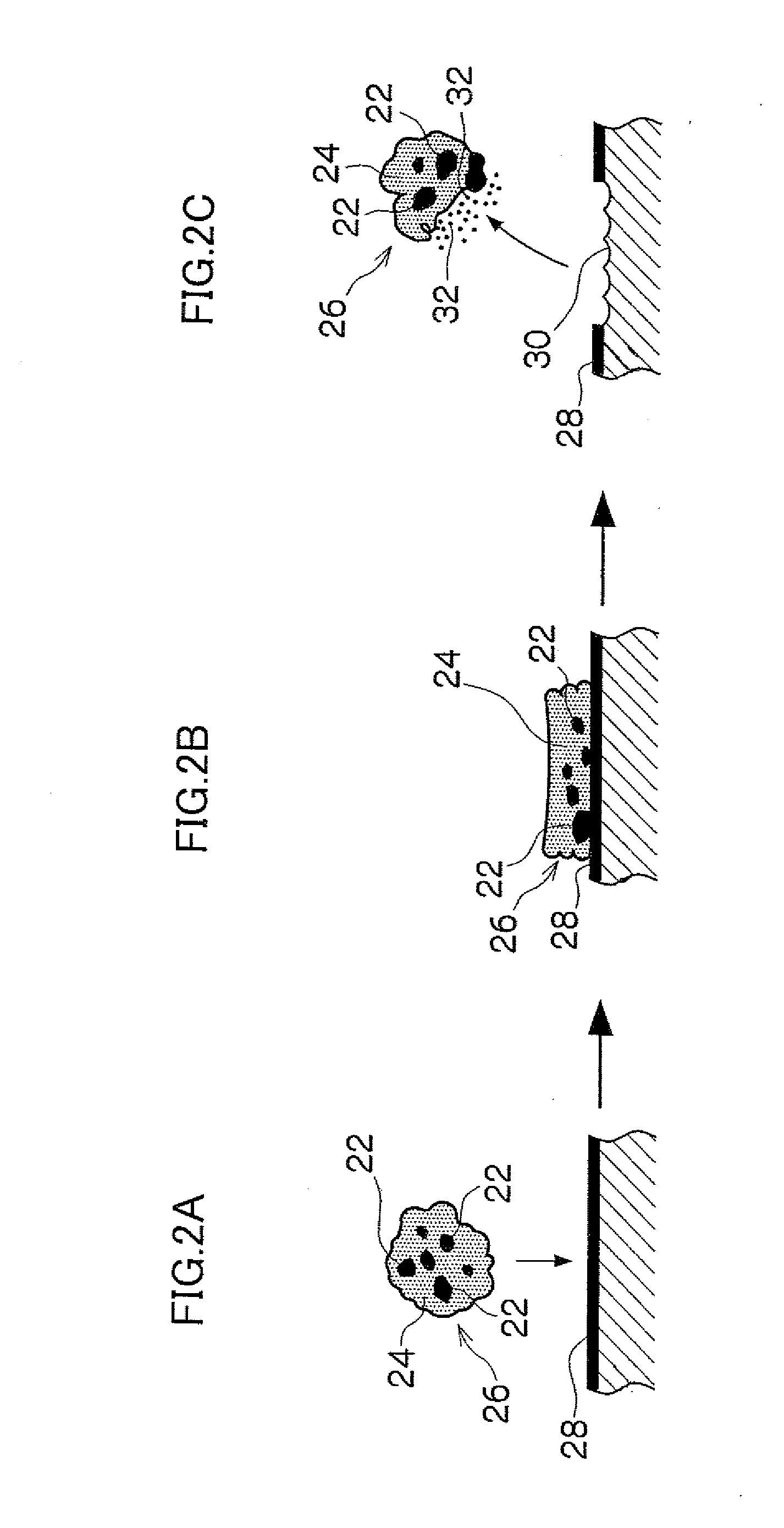

[0033]FIG. 1 is an explanatory view showing a basic structure of a sponge blasting apparatus 20 which is applied to the blasting apparatus for an outer surface of a pipe of the embodiment. Explaining the sponge blasting technique using the sponge blasting apparatus 20 first, the blast medium 26 as the blast material used in this technique is made by sticking abrasives (also called a grinding material in the case of an urea resin) of a different material (steel grit, alumina, star light, an urea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com