Recycled aggregate shaping barrel and recycled aggregate shaping equipment using shaping barrel

A technology of recycled aggregate and equipment, applied in the direction of filter screen, grid, electrostatic effect separation, etc., can solve the problem of easily damaged recycled aggregate, and achieve the effect of preventing crushing, improving grinding effect, and avoiding adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

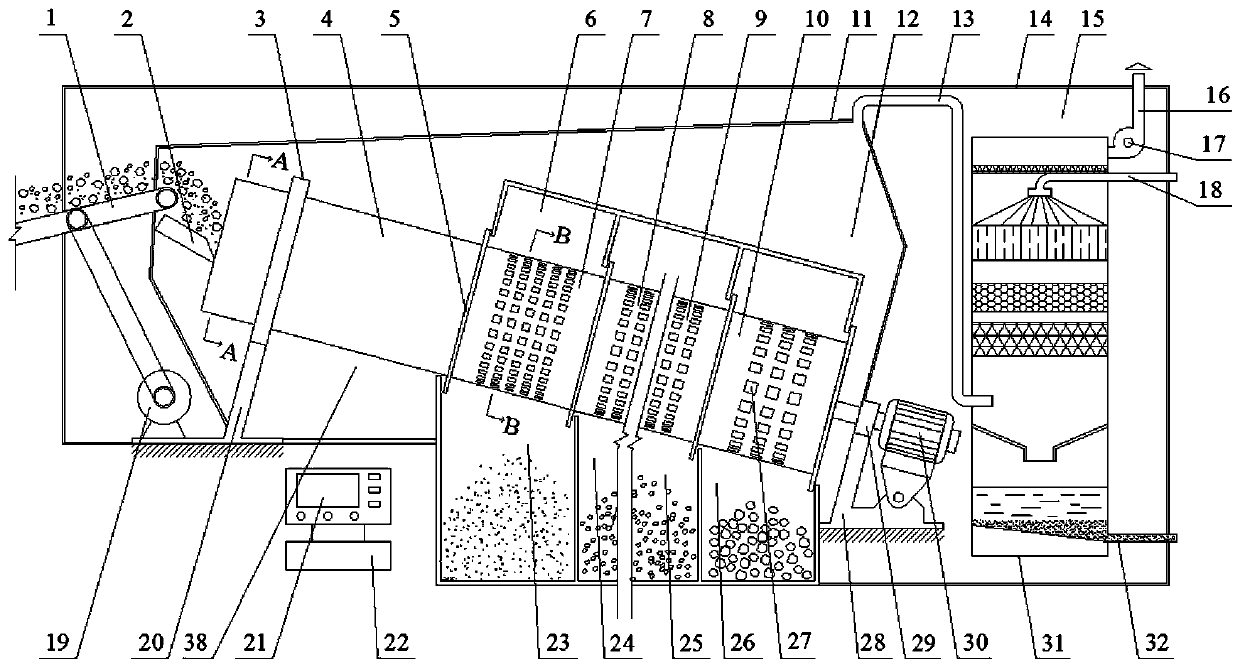

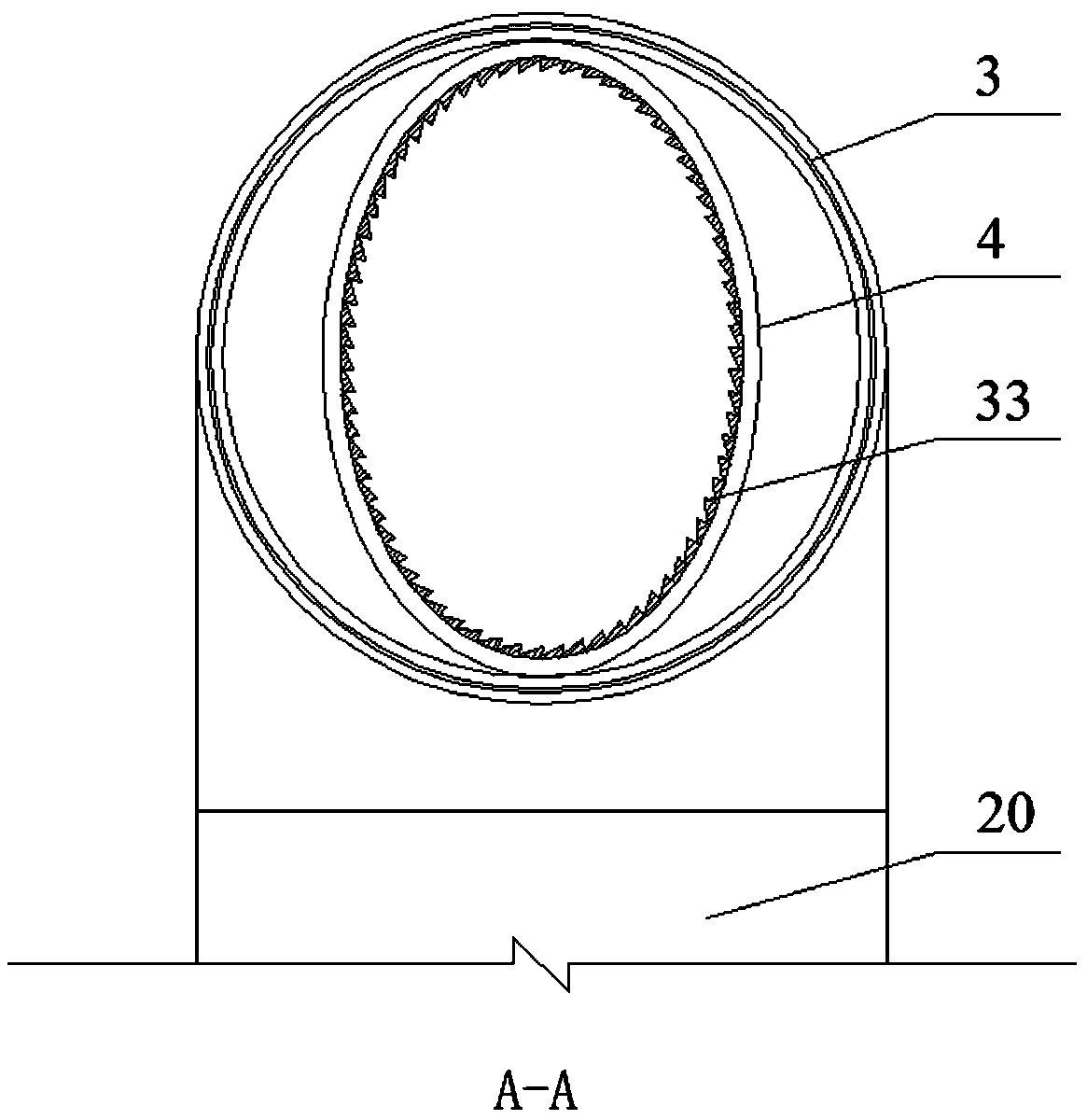

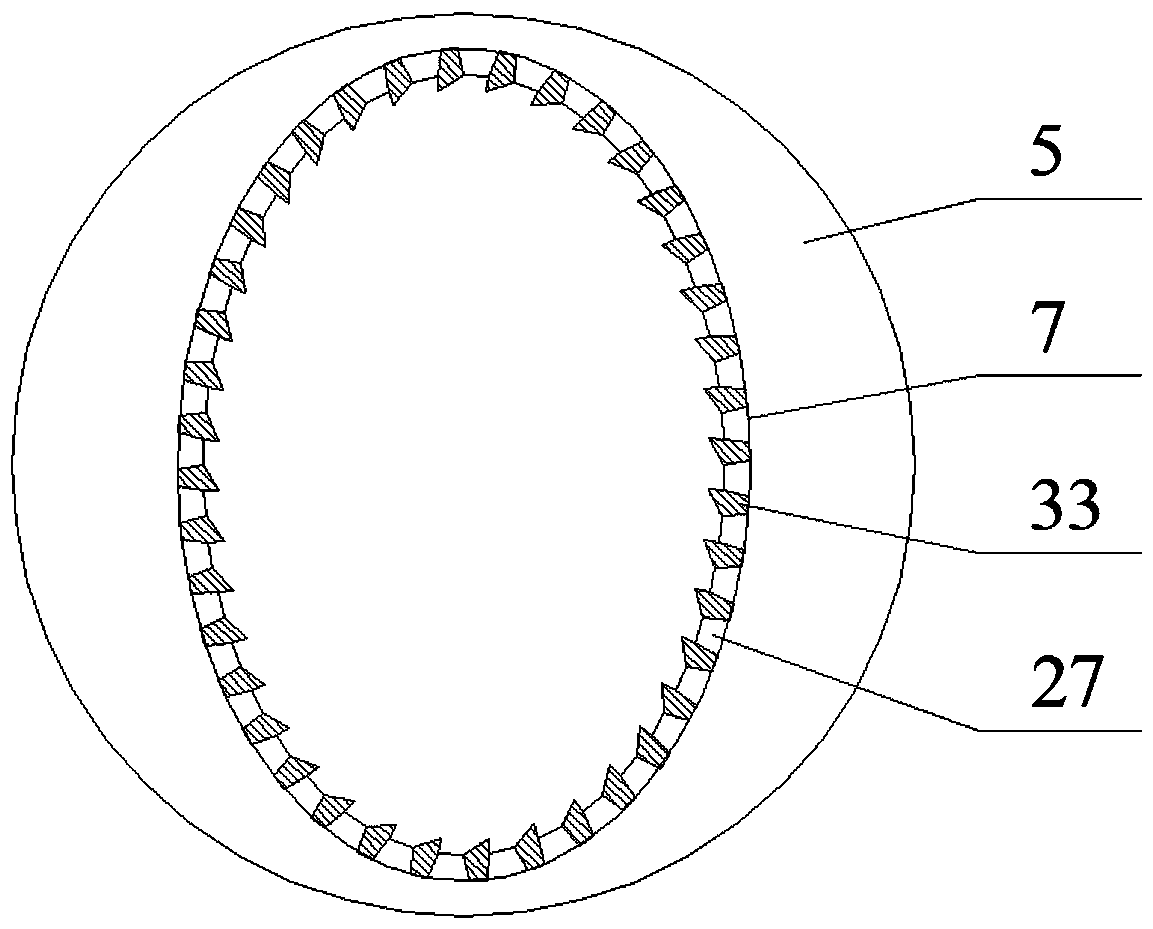

[0032] Embodiment 1 of recycled aggregate shaping equipment such as Figure 1~3 Shown: including feeding mechanism, recycled aggregate shaping cylinder, noise reduction device and dust purification equipment, recycled aggregate shaping cylinder includes a cylinder 38 with a shaping section and a feeding port, the cylinder 38 is as figure 1 In the middle, the front is high and the rear is low, the front end of the shaping section is provided with a support cylinder with a cylindrical cross section, and the rear end of the shaping section is provided with a support shaft coaxial with the support cylinder. Both the support cylinder and the support shaft are A support part is provided, and the support part on the support cylinder is rotatably supported and matched with the bearing ring 3 on the second base 20 , and the support part on the support shaft is rotatably supported and matched with the active bearing 29 on the first base 28 . The recycled aggregate shaping equipment also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com