Rust-removal cleaning device for inner wall of chemical construction metal pipeline

A technology for metal pipes and cleaning devices, which is applied in the direction of grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of high labor intensity and low grinding efficiency, and achieve high-efficiency grinding and grinding applicability Strong, easy-to-adjust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

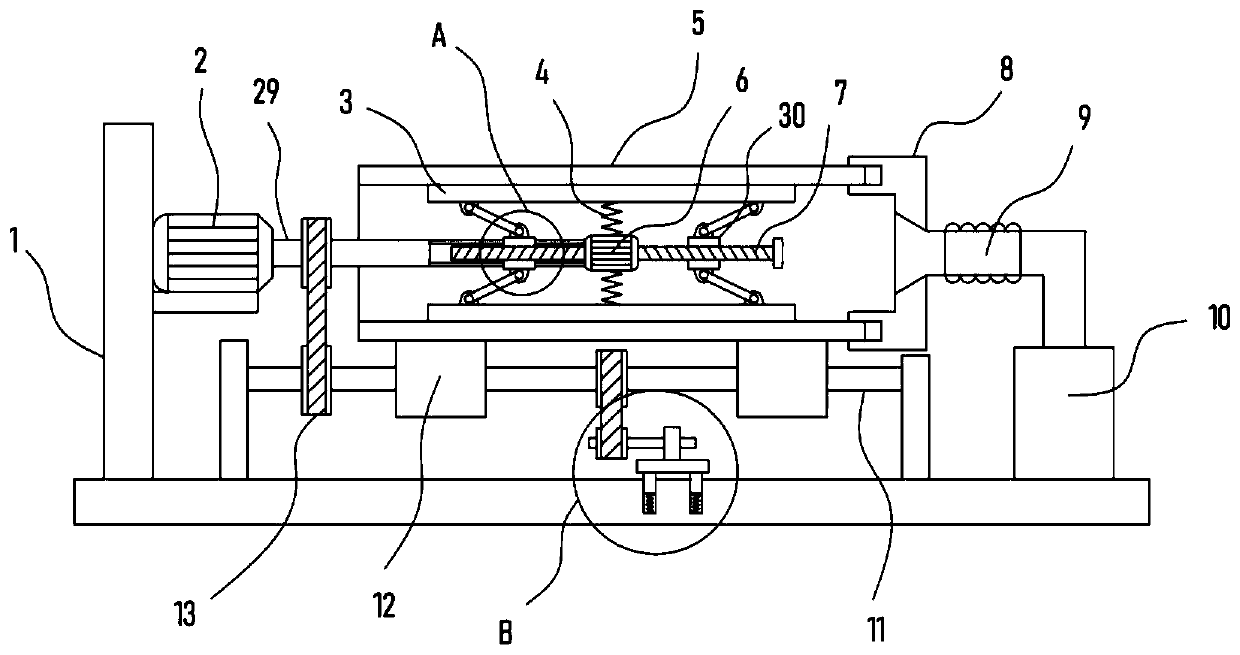

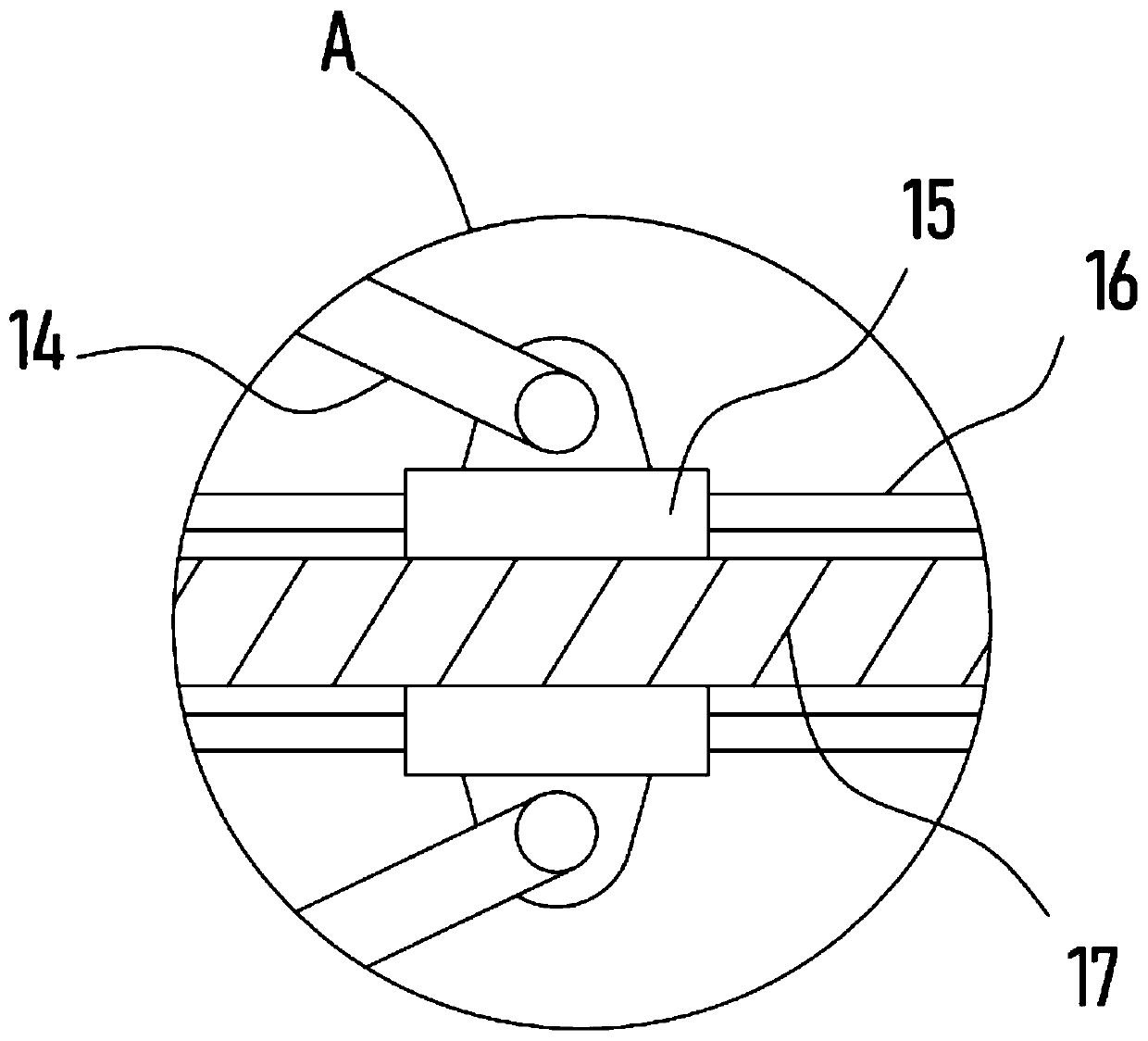

[0022] See Figure 1-4 , A derusting and cleaning device for the inner wall of a metal pipeline for chemical construction, comprising a support frame 1, a drive motor 2 fixed on the support frame 1, a drive shaft 29 is fixed coaxially on the output shaft of the drive motor 2, and a grinding mechanism is connected to the drive shaft 29 for transmission , The grinding mechanism includes a dual-axis motor 6. The two output shafts of the dual-axis motor 6 are coaxially fixed with a threaded shaft I7 and a threaded shaft II17 with opposite thread directions. The threaded shaft I7 and the threaded shaft II17 are respectively threaded with threaded sleeves. The pipe I30 and the threaded sleeve II15 are hinged on the threaded sleeve I30 and the threaded sleeve II15 via a support rod 14 with a grinding plate 3 abutting against the inner side wall of the metal pipe 5. Two transmission rods 16 are passed through the threaded sleeve II15, and the two ends of the transmission rod 16 are res...

Embodiment 2

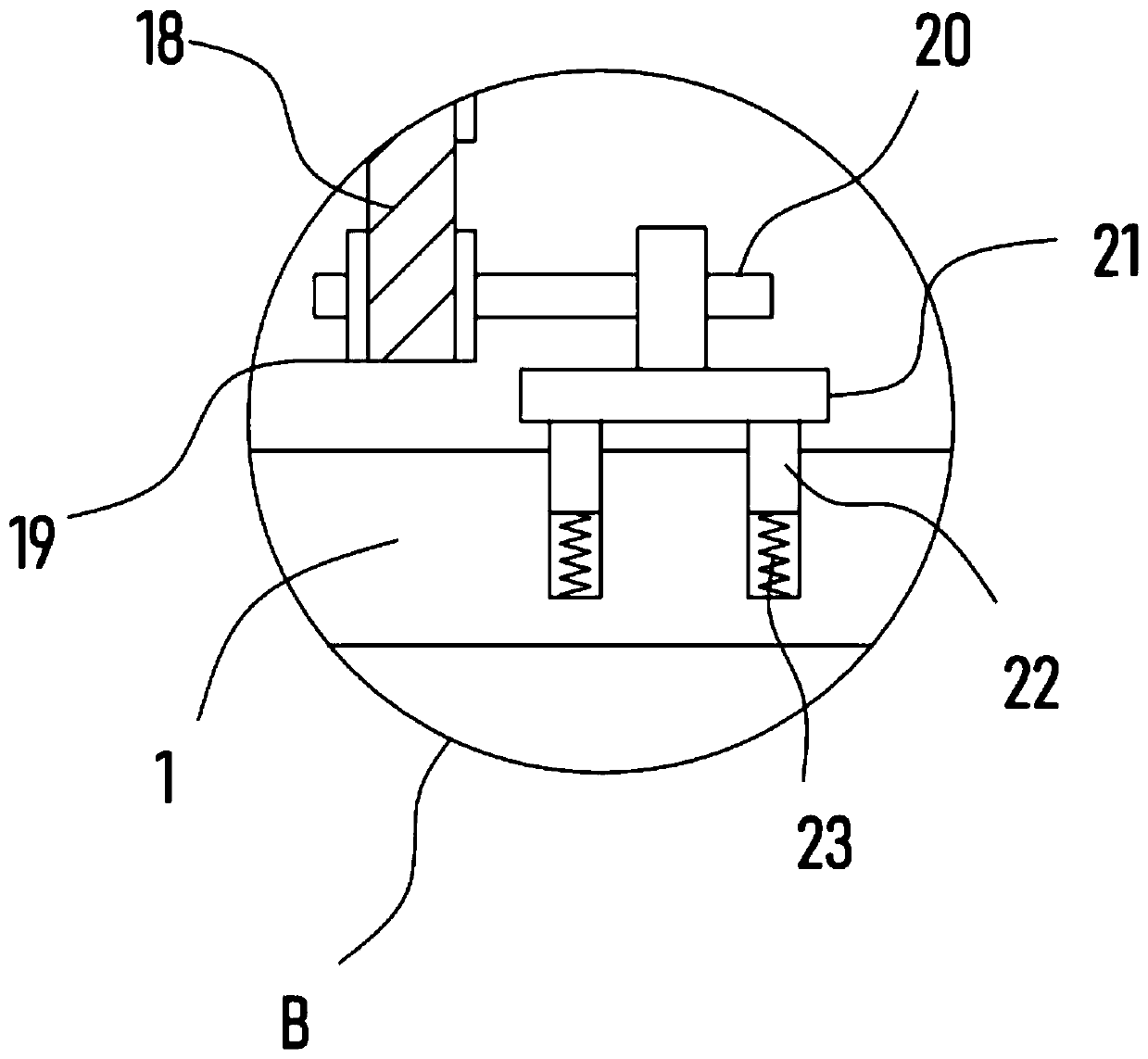

[0026] In order to further improve the efficiency of grinding and removing rust on the inner wall of the metal pipe 5, on the basis of embodiment 1, a rotating shaft I11 and a rotating shaft II24 are arranged horizontally on the support frame 1, and the rotating shaft I11 and the rotating shaft II24 are respectively sleeved The driving pulley 28 and the driven pulley 25 are fixed, the driving pulley 28 and the driven pulley 25 are sleeved with a belt 18, and the rotating shaft I11 and the rotating shaft II24 are sleeved and fixed with the outer wall of the metal pipe 5. The connected supporting roller 12, the drive shaft 29 and the rotating shaft I11 are drivingly connected with a pulley mechanism 13.

[0027] Through the above arrangement, when the drive shaft 29 rotates, the drive shaft 29 drives the rotating shaft I11 to rotate together with the driving pulley 28 through the pulley mechanism 13, and the driving pulley 28 drives the driven pulley 25 to rotate through the belt 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com