Resin binder superhard material grinding wheel for roller high-speed grinding and manufacture method thereof

A superhard material and bonding agent technology, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems that the grinding wheel cannot achieve high-speed grinding and low bonding strength, and achieve high-speed and high-efficiency grinding and production. High efficiency and the effect of increasing the rupture speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

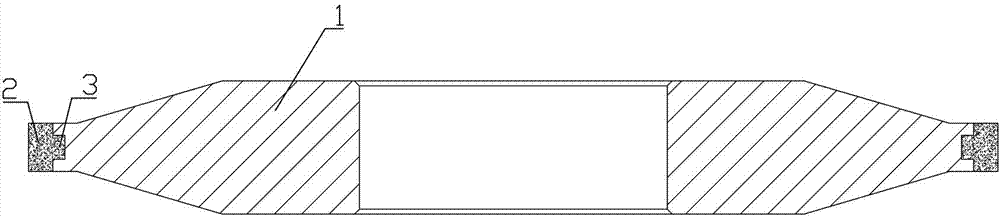

[0028] The specification of grinding wheel is φ350mm×30mm (total thickness of grinding wheel)×127mm (inner hole)×6mm (ring width of working layer)×10mm (thickness of working layer);

[0029] Superabrasive: Diamond.

[0030] Its raw material components and weight percentage content are: 140 / 170 mesh diamond 28%, 400 mesh modified phenolic resin powder 20%, 300 mesh copper powder 33%, W40 silicon carbide powder 14%, 300 mesh chromium oxide 3% , 320 mesh calcium oxide 2%. The raw material components and weight percentages of the modified phenolic resin powder are: 88% phenolic resin and 12% epoxy resin.

[0031] Concrete preparation method is as follows:

[0032] 1. After weighing the various raw material powders required by the above formula according to the proportion of the formula, put them into the three-dimensional mixer, add a wetting agent and mix evenly, and the time is 30 minutes;

[0033] 2. Put the working layer obtained in step 1 into the steel mold accord...

Embodiment 2

[0039] The specification of grinding wheel is φ400mm×35mm (total thickness of grinding wheel)×127mm (inner hole)×5mm (ring width of working layer)×12mm (thickness of working layer);

[0040] Superabrasive: nickel-plated cubic boron nitride.

[0041] Its raw material components and weight percentage content are: 325 / 400 mesh nickel-plated cubic boron nitride 55%, 400 mesh ultrafine polyimide resin powder 18%, W10 silicon carbide powder 20%, 400 mesh iron oxide red 2 %, 400 mesh zinc oxide 5%. The nickel plating ratio of nickel-plated cubic boron nitride is 50%.

[0042] Concrete preparation method is as follows:

[0043] 1. After weighing the various binder powders required by the above formula according to the proportion of the formula, put them into the three-dimensional mixer, add the wetting agent N, N dimethylformamide and mix evenly for 60 minutes;

[0044]2. Put the working layer molding material obtained in step 1 into the steel mold according to the reserved pos...

Embodiment 3

[0050] The specification of grinding wheel is φ450mm×40mm (total thickness of grinding wheel)×127mm (inner hole)×10mm (ring width of working layer)×30mm (thickness of working layer);

[0051] Superabrasive: Nickel-plated diamond.

[0052] Its raw material components and weight percentage content are: 120 / 140 mesh nickel-plated diamond 65%, 400 mesh phenolic resin powder 15%, W40 silicon carbide powder 11%, 300 mesh chromium oxide 4%, 320 mesh graphite powder 5%. Concrete preparation method is as follows:

[0053] 1. After weighing the various raw material powders required by the above formula according to the proportion of the formula, put them into the three-dimensional mixer, add a wetting agent and mix evenly, and the time is 50 minutes;

[0054] 2. Put the working layer obtained in step 1 into the steel mold according to the reserved position of the mold, and press it on a hot press with a temperature of 175 ° C and a pressure of 5 MPa for 45 minutes to obtain the blan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com