Novel high-precision gear grinding numerical control system

A numerical control system, high-precision technology, applied in the direction of gear teeth, gear cutting machines, automatic control devices, etc., can solve the problems of high signal handshake and communication failure rate, lack of flexibility, waste of resources, etc., to achieve rich software content and stable work. Good performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

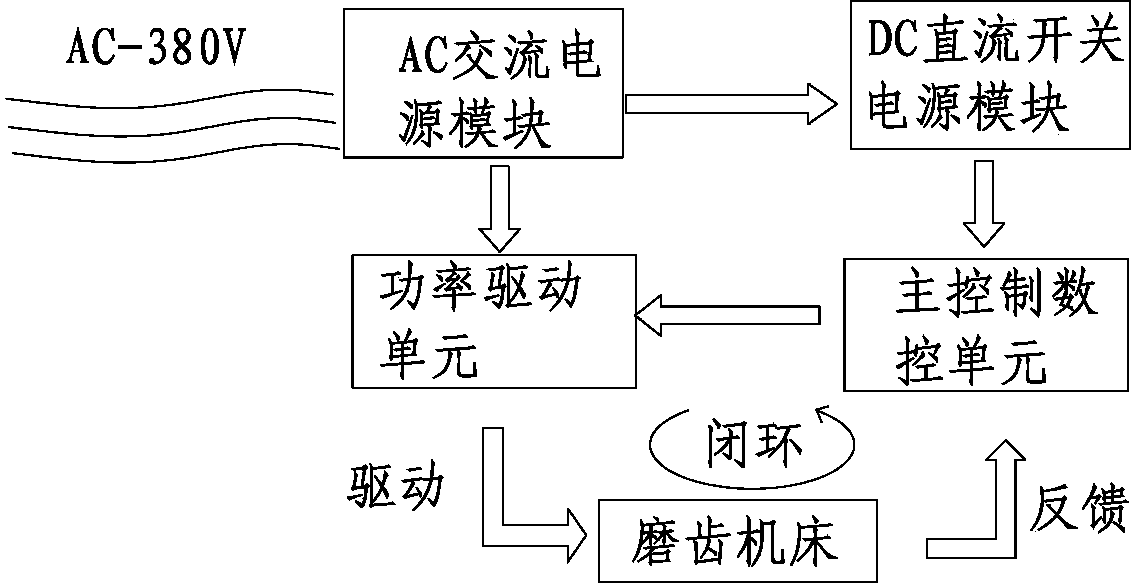

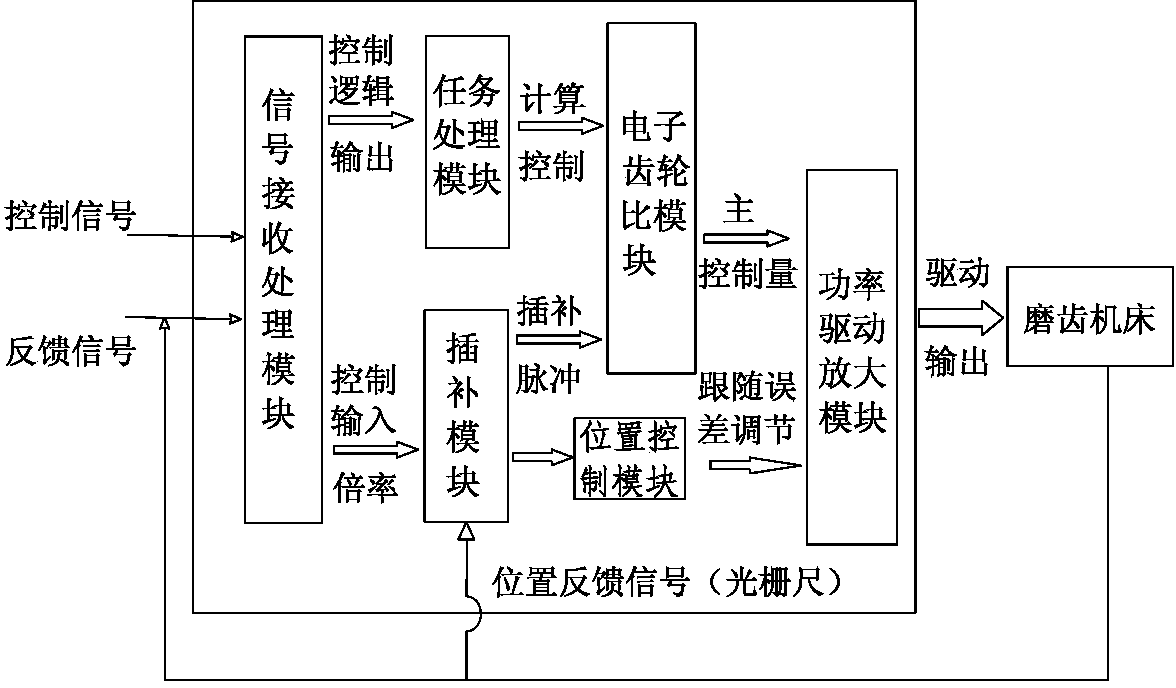

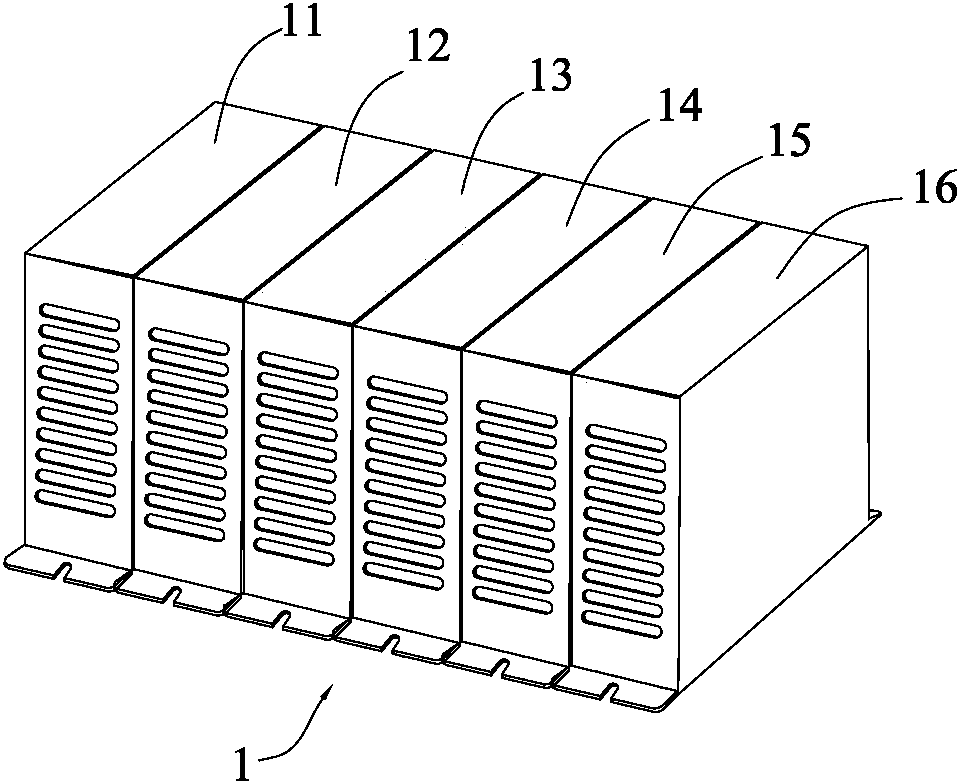

[0030] see Figure 1 to Figure 6 , a new type of high-precision grinding gear numerical control system provided in this embodiment, which includes a split chassis 1, an AC AC power supply module, a DC switching power supply module, a main control numerical control unit and a power drive unit. In this embodiment, the present invention The new high-precision grinding gear numerical control system also includes a signal input and output interface module and a digital position control board 2 .

[0031] The split cabinet 1 includes a plurality of independent cabinets arranged side by side, specifically an independent cabinet 11 , an independent cabinet 12 , an independent cabinet 13 , an independent cabinet 14 , an independent cabinet 15 and an independent cabinet 16 .

[0032]According to different functions, strong and weak currents and power consumption, the power drive unit, AC AC power supply module, DC switching power supply module, main control numerical control unit, signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com