Patents

Literature

68results about How to "Avoid graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

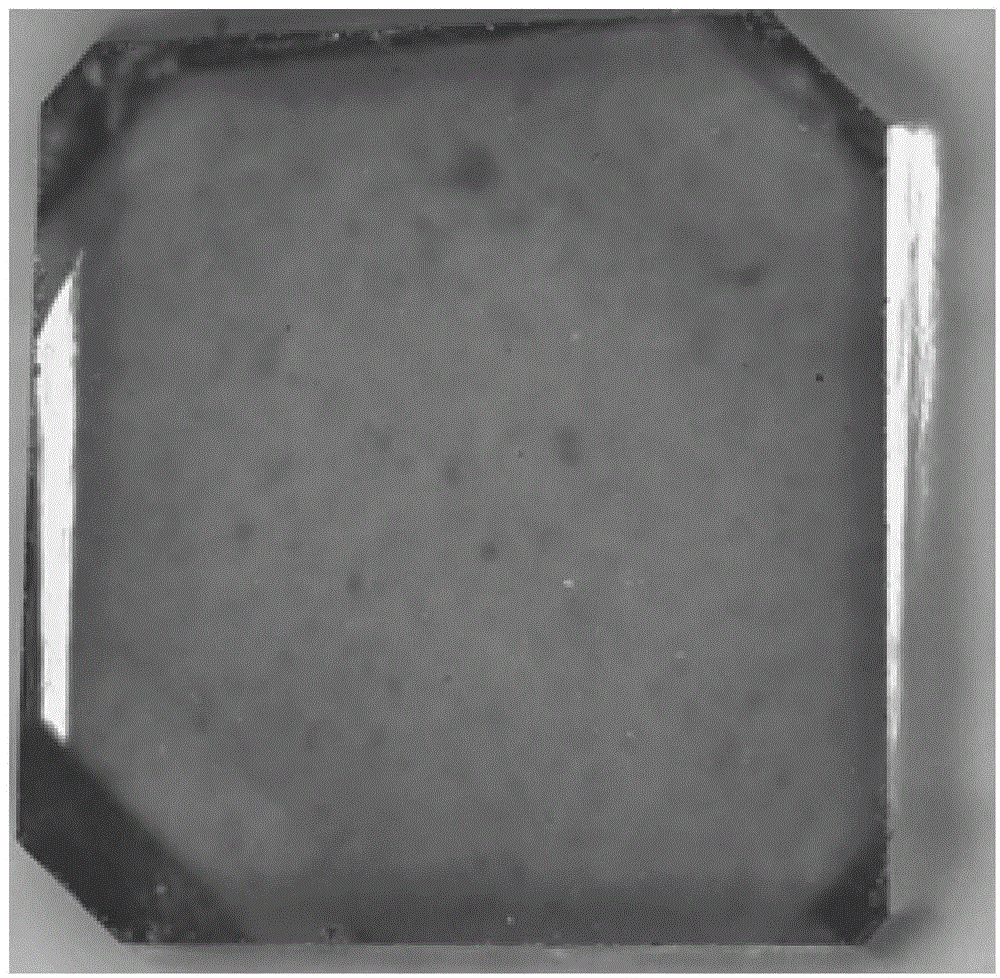

Special high-performance carbon paper for gas diffusion layer of fuel cell and preparation method of carbon paper

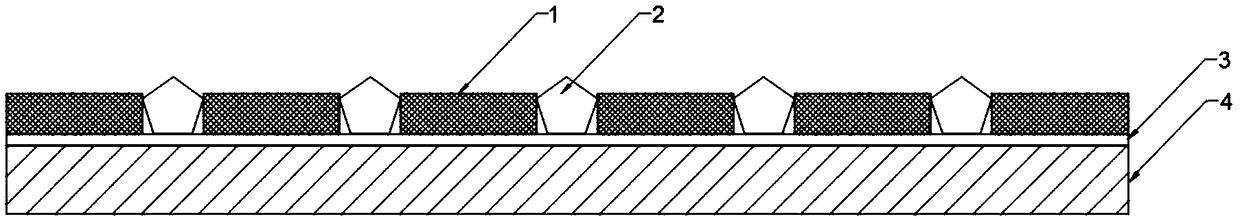

InactiveCN103556543ASimple processProduct quality is easy to controlSpecial paperCell electrodesThermal bondingPapermaking

The invention relates to carbon paper and a preparation method thereof and particularly relates to special high-performance carbon paper for a gas diffusion layer of a fuel cell and a preparation method of the carbon paper. By taking short carbon fibers, plant fibers, heat bonding fibers and carbon black as raw materials, the carbon paper is prepared by the following steps: defibering, pulping and proportioning; then carrying out papermaking by adopting a wet-method papermaking process; and carrying out waterproof pigment coating treatment. The ratios of all the raw materials are as follows in parts by weight: 65-75 parts of the short carbon fibers, 10-15 parts of the plant fibers, 10-15 parts of the heat bonding fibers and 0-10 parts of the carbon black. According to the special high-performance carbon paper for the gas diffusion layer of the fuel cell and the preparation method of the carbon paper, a production process combining wet-method formation, hot pressing and coating is adopted and has the characteristics of simple process flow, easiness for controlling product quality, environment-friendly production process and the like; the material ratio of each raw material can be accurately controlled in the production so as to be good for controlling the product quality.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

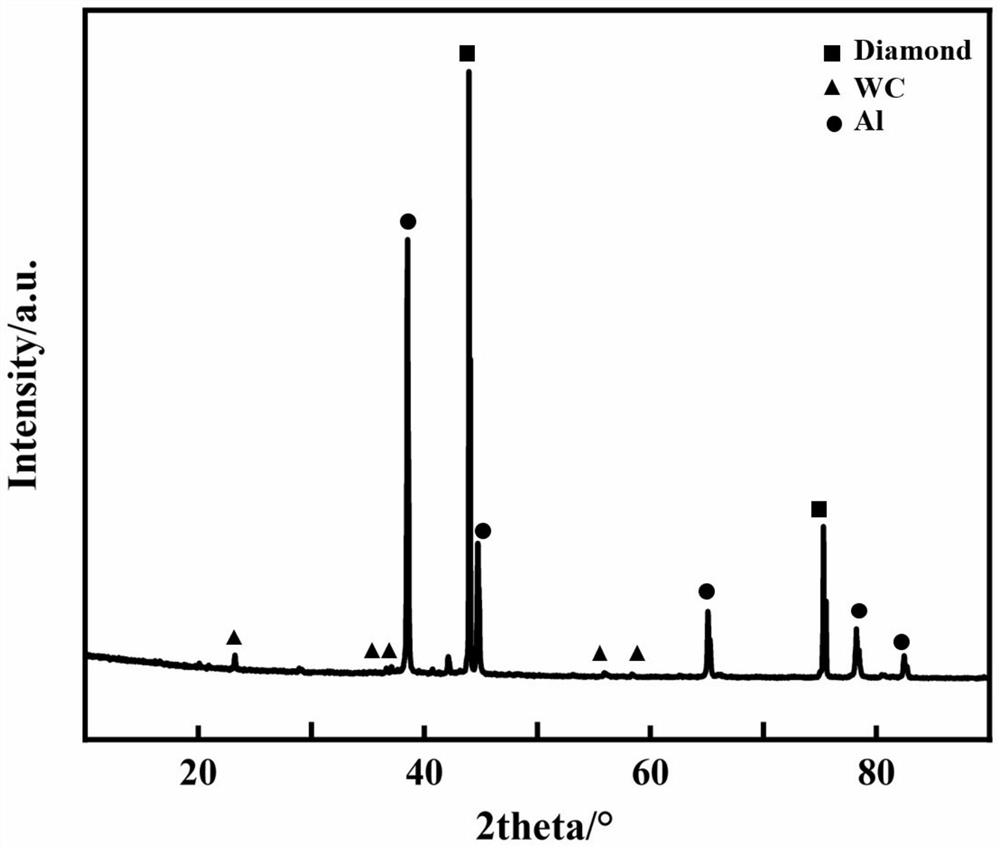

Method for producing diamond tool for grinding concrete floor

InactiveCN101518890ALow priceImprove stabilityAbrasion apparatusGrinding devicesHot pressHot pressing

The invention discloses a method for producing a diamond tool for grinding a concrete floor, which comprises the following steps: proportional irregular glomerocryst diamond and man-made diamond are uniformly distributed on the surface of a tire casing; a gap between the diamond is filled with metallic bond, and according to the ratio by weight, the metallic bond comprises 40 to 70 percent of cobaltco, 10 to 20 percent of copper, 15 to 20 percent of tungsten carbide, 5 to 10 percent of stannum and 0.5 to 3 percent of trace element; the operation of cold press molding is carried out, sections formed by the cold press molding are delivered to a vacuum hot press sintering furnace to be sintered, and the temperature is kept from 850 DEG C to 900 DEG C and the pressure from 10 to 15 tons; and the sintered sections are welded on a metal base body. The diamond tool produced by the method not only can increase the grinding efficiency and maintain the stable performance, but also can greatly prolong the service life.

Owner:邓国川 +2

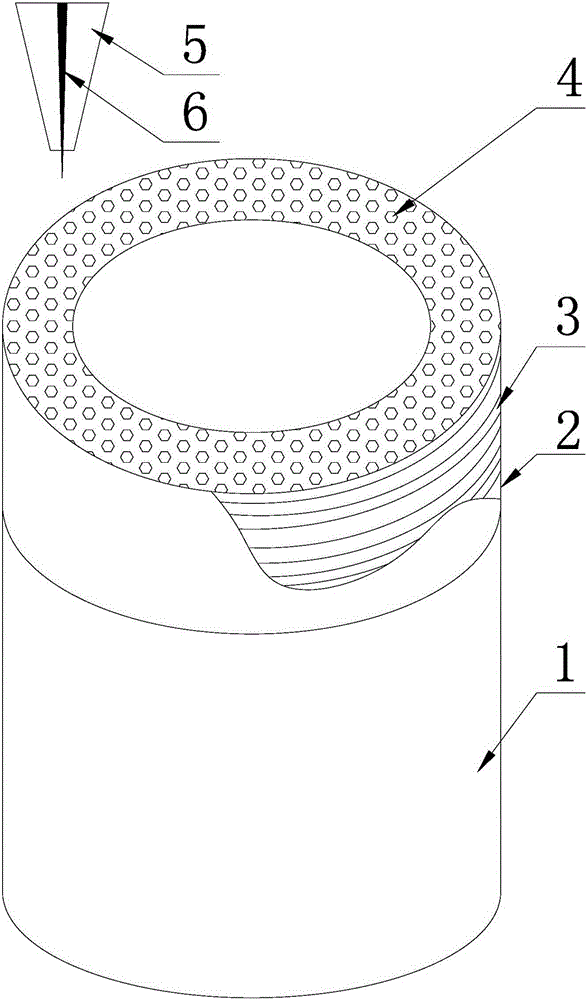

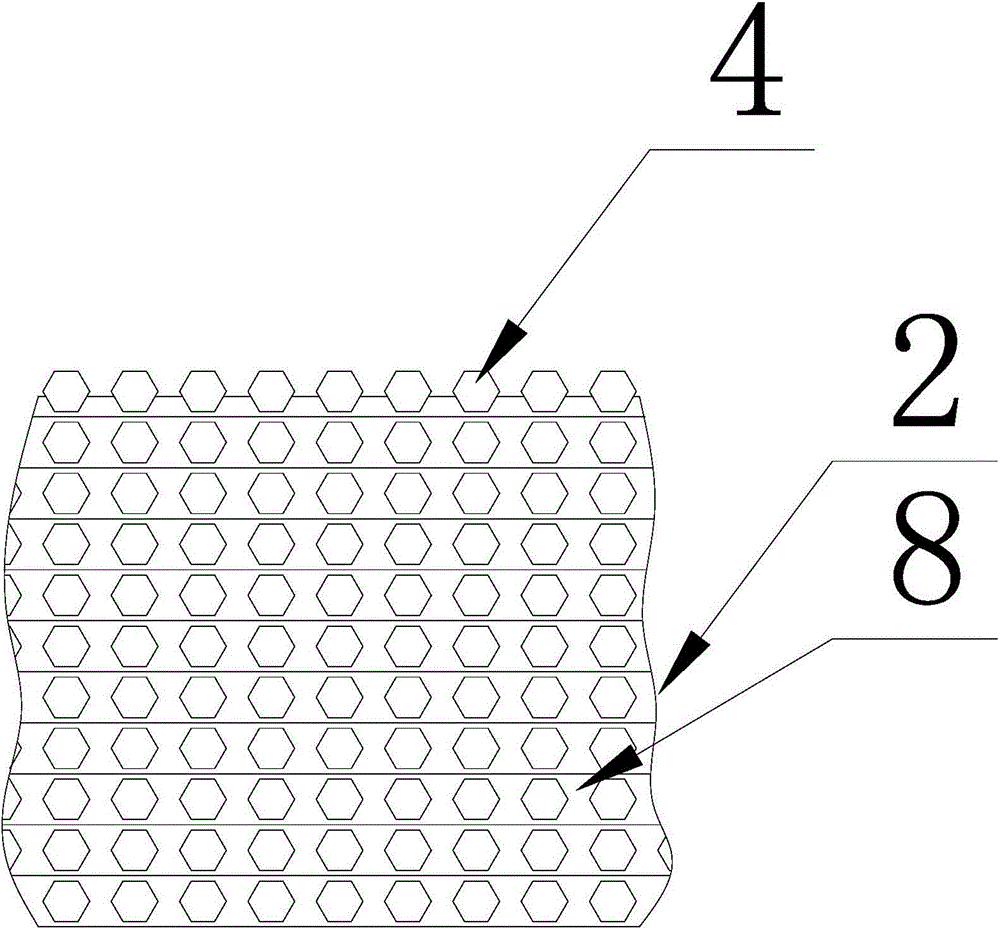

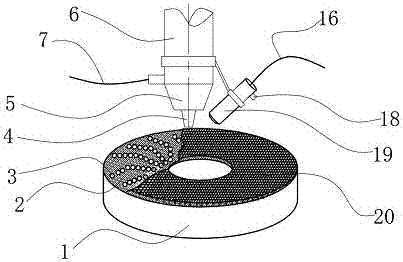

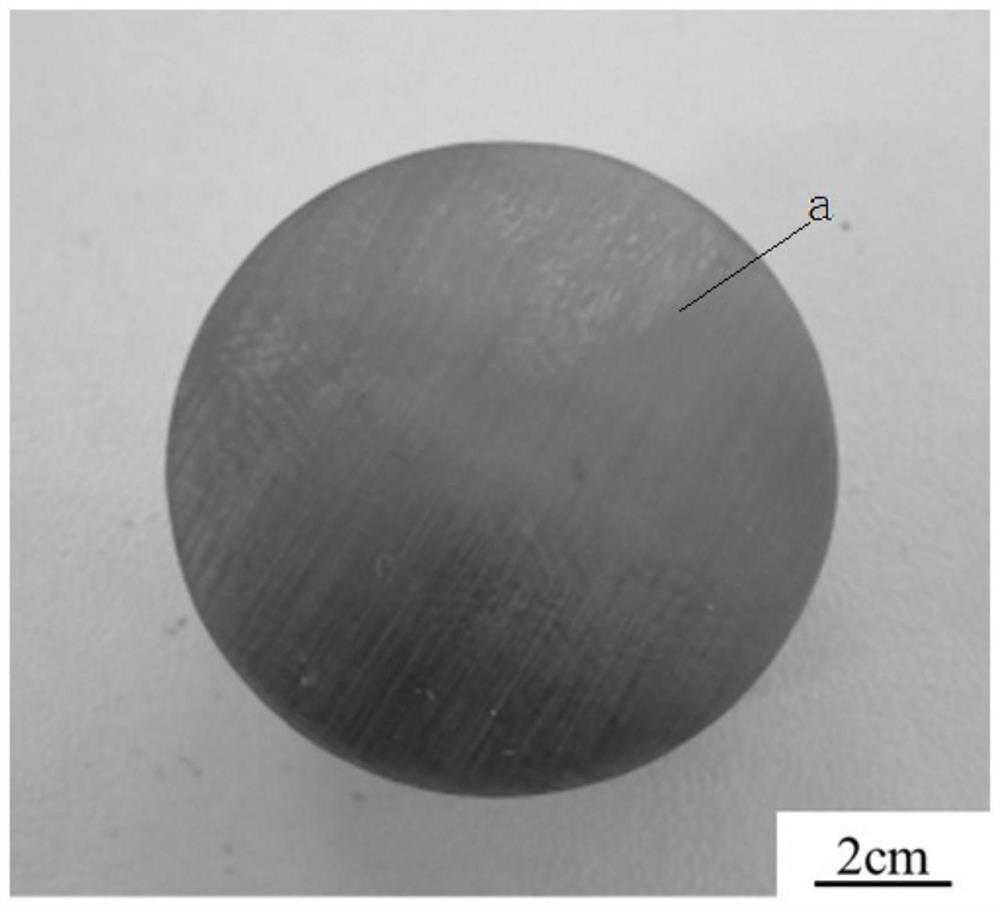

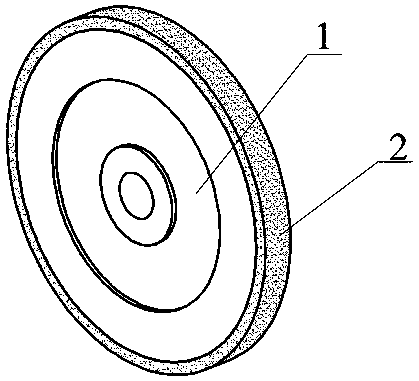

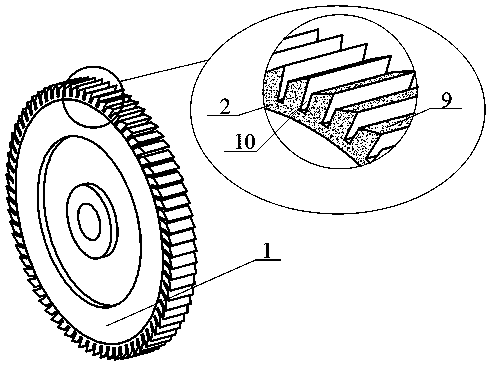

Diamond grinding wheel and production method thereof

InactiveCN106312843AAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesDiamond grindingBonding strength

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

Apparatus and process for the formation of monocrystalline silicon carbide (SiC) on a nucleus

InactiveUS6113692AGood effectImprove crystal qualityPolycrystalline material growthFrom chemically reactive gasesCarbideSingle crystal

The invention relates to an apparatus for forming SiC on a nucleus. The apparatus comprises a first enclosure (100) defined by at least one wall (102, 110, 112) and able to receive a SiC nucleus (122), a SiC powder reservoir (118) and means (120) for heating the enclosure and, according to the invention, the wall (102, 110, 112) is essentially covered by at least one SiC layer (116).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

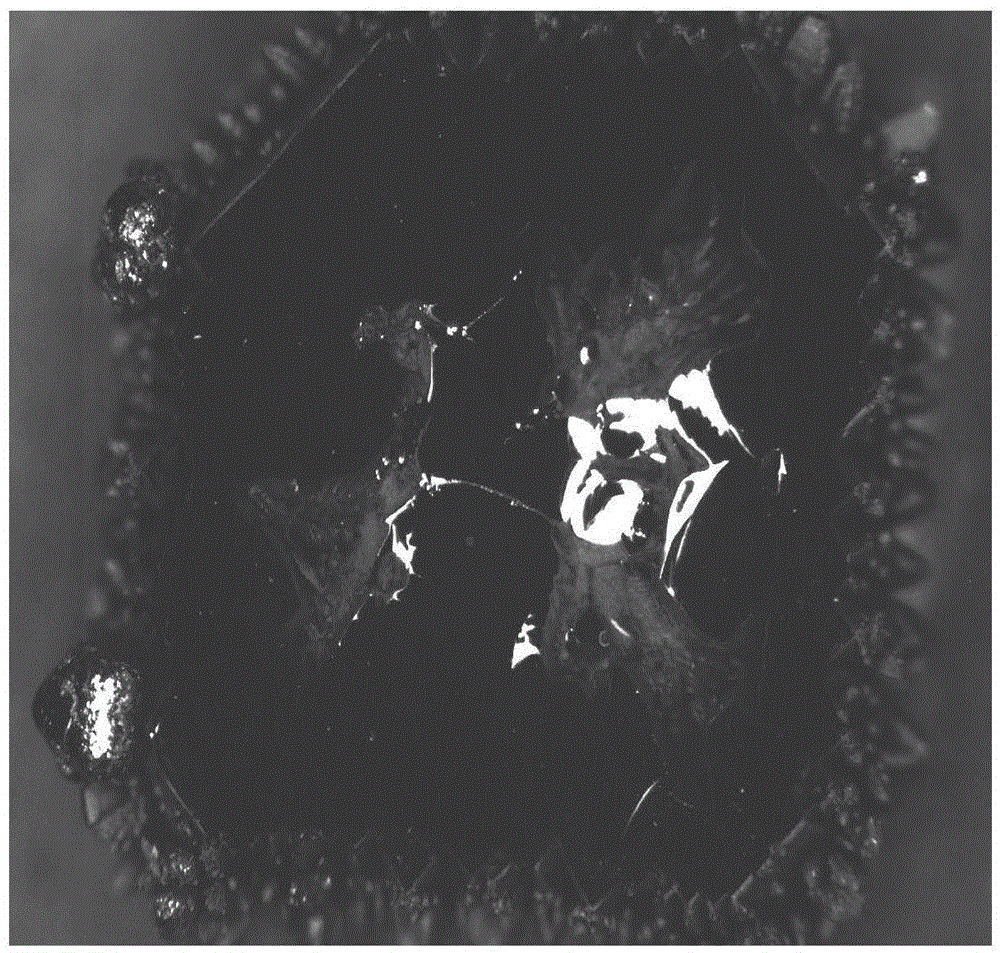

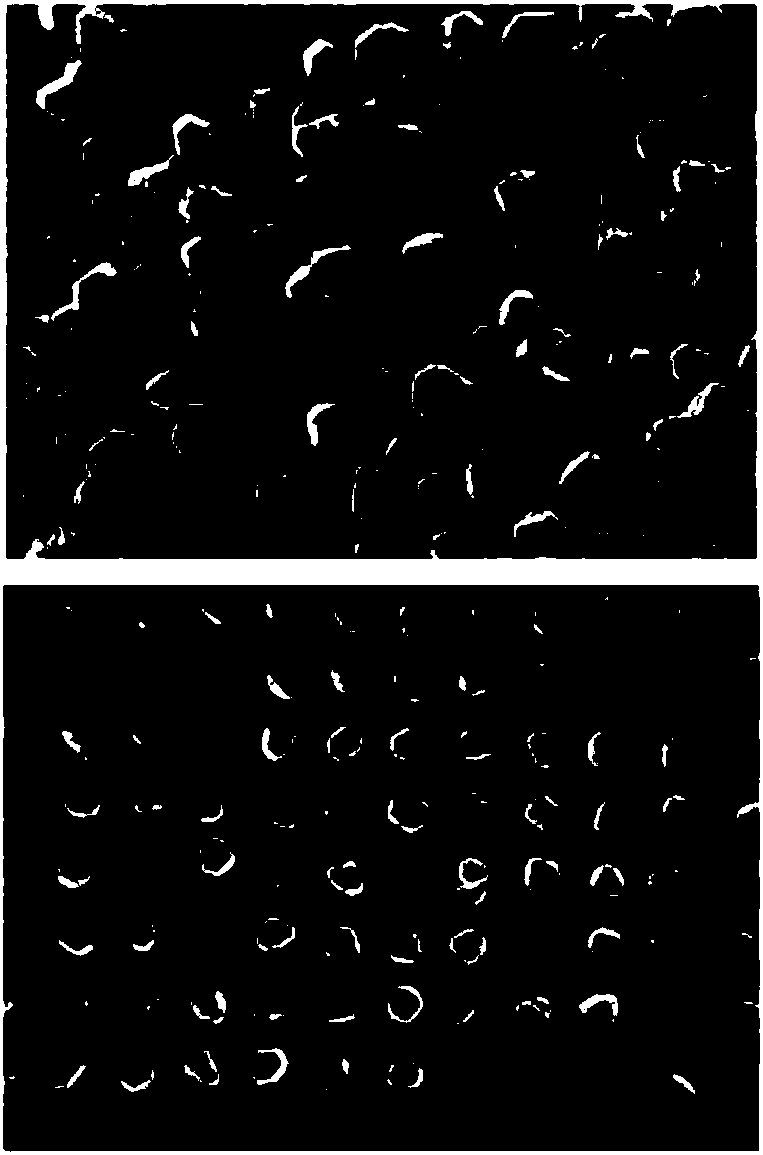

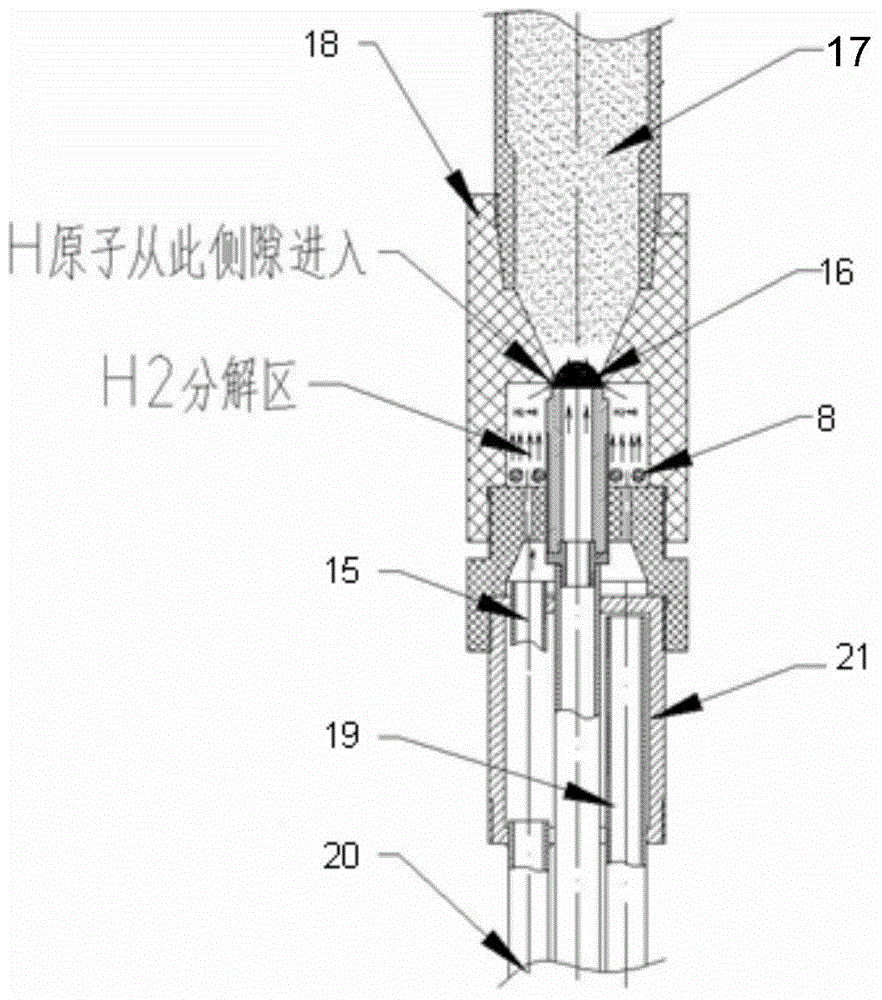

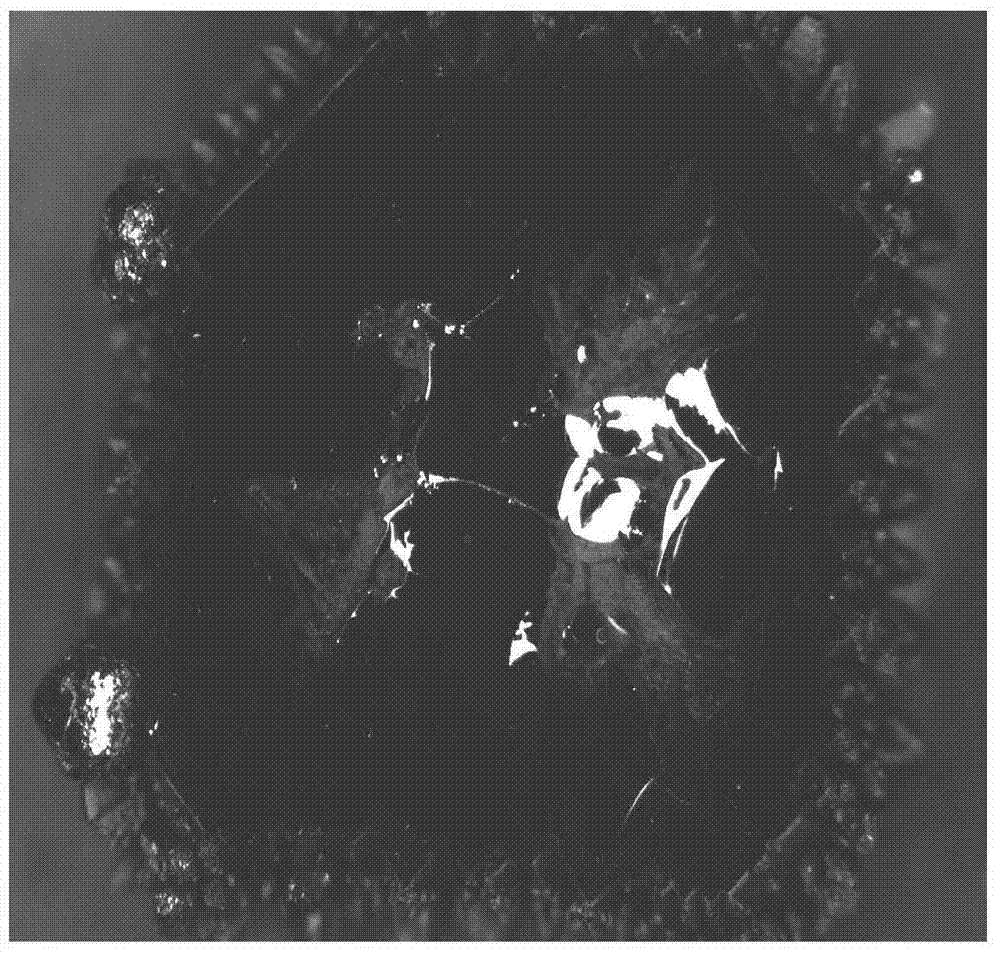

Method for improving quality of diamond seed crystal with hydrogen plasma multiple etching/annealing cyclic process

ActiveCN104975343AQuality improvementHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesCyclic processHydrogen

The invention relates to a method for improving the quality of diamond seed crystals with a hydrogen plasma multiple etching / annealing cyclic process, and relates to a method for improving diamond seed crystal quality. With prior arts, a method for improving diamond seed crystal quality has the defects of high time consumption and complicated operation. Seed crystal surface quality degradation can also be caused easily. The invention aims at solving the above problems. The method comprises the steps of 1, diamond seed crystal cleaning; 2, welding; 3, seed crystal placement; and 4, hydrogen plasma etching / annealing. With the hydrogen plasma etching / annealing treatment, crystal defect, surface and sub-surface damages on diamond seed crystal surfaces caused by mechanical polishing, and diamond seed crystal internal stress and defects can be removed at a same time in a same instrument; crystallinity can be improved, and high-quality seed crystals can be obtained; and the operation is greatly simplified, such that time and cost are saved. The method provided by the invention is applied in the technical field of crystal growth.

Owner:九桓碳构(威海)新材料有限公司

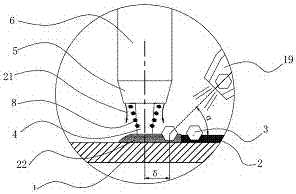

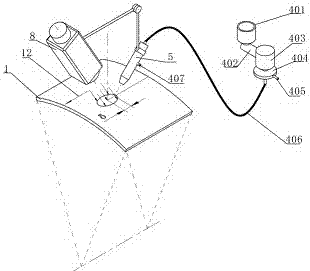

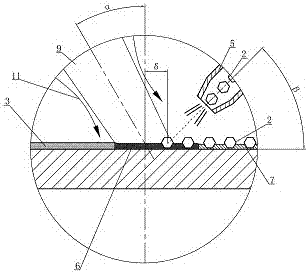

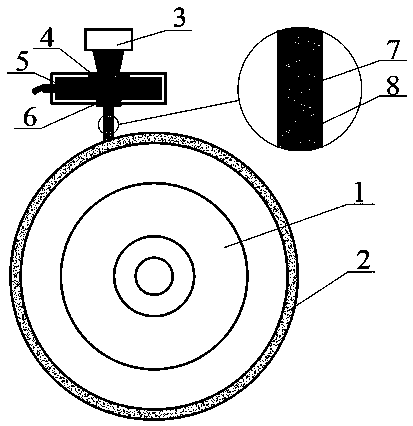

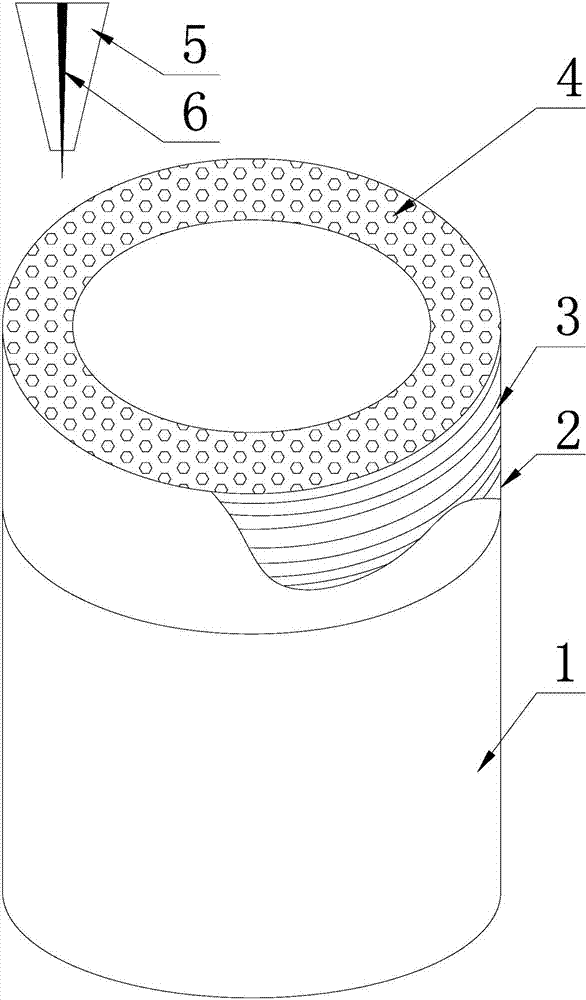

Additive manufacturing method for diamond tool

InactiveCN107150154AAvoid severe burning and oxidationAvoid graphitizationSoldering apparatusMaterials scienceLaser

The invention relates to an additive manufacturing method for a diamond tool. The method includes the steps that a diamond abrasive particle layer is formed at first; then a thin laser brazing layer is formed on the upper surface of the diamond abrasive particle layer, and the step is executed repeatedly until multiple thin laser brazing layers are formed on the upper surface of the diamond abrasive particle layer to cover diamond abrasive particles; the steps are repeated, and accordingly (N-1) laser brazing diamond abrasive particle layers are obtained; and an Nth laser brazing diamond abrasive particle layer is obtained, the laser brazing process is completed, and thus the laser brazing diamond tool with N layers of abrasive particles is prepared. The invention further relates to the diamond tool prepared through the method. According to the additive manufacturing method for the diamond tool, paraxial jet diamond abrasive particles are adopted for conducting multi-layer laser brazing, burning loss oxidation and graphitization of the diamond abrasive particles in the brazing process are avoided, the service life of a laser brazing diamond grinding wheel is prolonged, and orderly distribution and automatic production of the abrasive materials can be realized easily.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

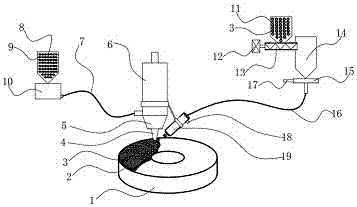

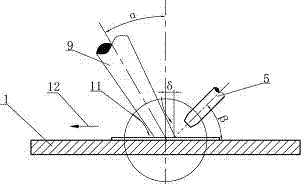

Method of laser brazing tool of monolayer diamond

ActiveCN107096972AAvoid severe burning and oxidationAvoid graphitizationSoldering apparatusLaser beam welding apparatusLaser lightLaser brazing

The invention relates a method for laser brazing tool of monolayer diamond. The method comprises the following steps: providing a basal body of a diamond tool; coating a brazing material on the surface of a diamond tool basal body to prepare a diamond tool blank; providing a jetting system including a hopper and a spray gun connected with the hopper; providing diamond abrasive grains and placing the diamond abrasive grains into the hopper; providing a laser brazing system including a laser generator and a laser brazing working head; aligning the laser brazing working head and the spray gun to a tool blank surface; starting the laser brazing system and the jetting system, and doing synchronous motion of the laser brazing working head and the spray gun to ensure that focused laser beams produced by the laser brazing working head are positioned in front of the working head and are irradiated on the preposed brazing material so as to molten the brazing material; and after laser light spot, the diamond abrasive grains are sprayed by adopting the spray gun into a brazing molten tank. The diamond abrasive grains are jetted by adopting a paraxle to carry out laser brazing, so that burning oxidization and graphitization of the diamond abrasive grains during brazing are avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

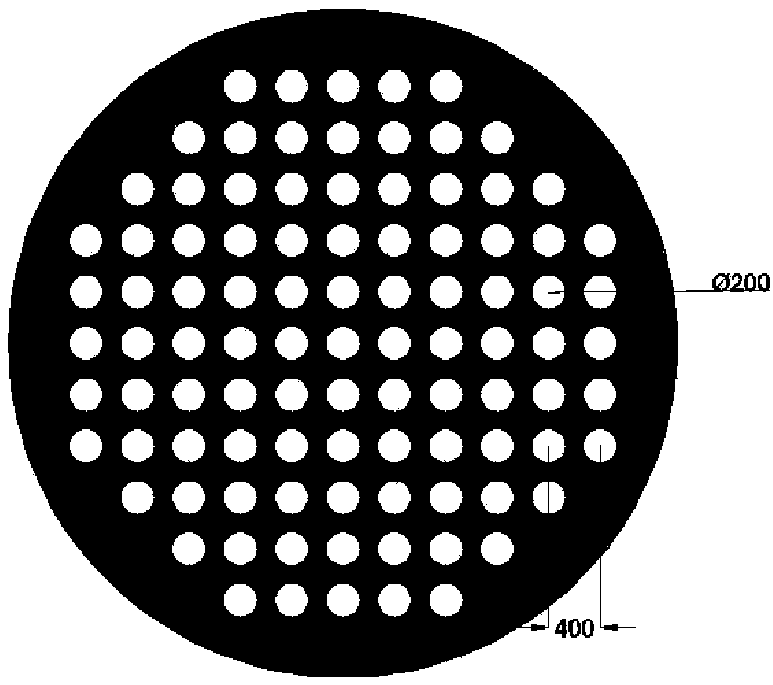

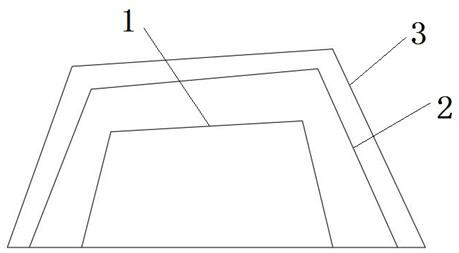

Method for preparing diamond abrasive material tool with orderly distributed abrasive particles by utilizing mask

The invention provides a method for preparing a diamond abrasive material tool with orderly distributed abrasive particles by utilizing a mask through single-layer chemical vapor deposition. The method comprises the following steps of after pretreating a substrate, coating a photoresist on the surface, and paving the mask on the surface of the photoresist; distributing diamond abrasive materials on the surface of the mask, vibrating the substrate, and enabling the abrasive materials to enter distribution holes of the mask; and removing excess diamond abrasive materials outside the distributionholes, taking the mask down, carrying out chemical vapor deposition on the substrate adhered with the diamond abrasive materials, forming a diamond coating, and obtaining the diamond abrasive material tool. Compared with the prior art, the method provided by the invention has the following beneficial effects that (1) the method provided by the invention can be used for preparing the tool with theorderly distributed diamond abrasive materials with the fine granularity being 100mum, and is suitable for precision grinding machining; and (2) the method provided by the invention is simple in adopted equipment, less in steps, simple and convenient to operate, and beneficial to mass production.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of diamond enhanced high-entropy alloy composite coating

ActiveCN109468638AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesHigh entropy alloysCorrosion

The invention discloses a preparation method of a diamond enhanced high-entropy alloy composite coating. The method comprises the following steps that a mechanical method is adopted for treating the surface of a workpiece in advance and carrying out oil and dust removing, Cu, Ni-Cr-B-Si, Co-Cr-B-Si and Fe-Cr-B-Si are subjected to ball milling and mixing to prepare high-entropy alloy powder, afterbeing mixed, the mixture is prefabricated on the surface of a steel base body and subjected to induction heating to prepare the high-entropy alloy coating, then under protection of inert gas Ar, heating is carried out, diamond with the particle diameter being 3*35 micrometers is pressed, and the diamond enhanced high-entropy alloy composite coating is prepared. The coating has higher hardness andwear resisting performance, the diamond is pressed at a high temperature, thus graphitizing of the diamond in the heating process is avoided, in addition, a small amount of carbide is formed on the interface of the diamond, and the connecting strength is improved. The high-entropy alloy base body and the diamond have the characteristics of high strength and high wear resistance, and thus the coating has good wear resisting performance and good corrosion resisting performance.

Owner:郑州亚新超硬材料有限公司

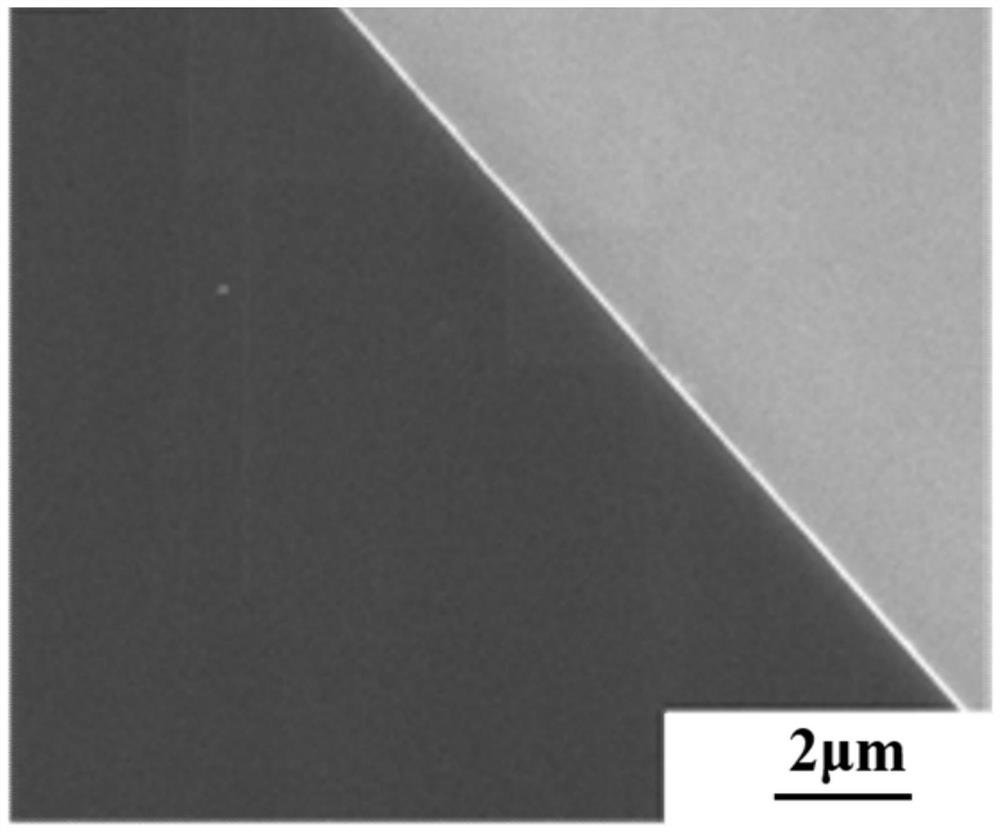

Manufacturing method of high-reliability and high-thermal-conductivity diamond reinforced metal matrix composite material

ActiveCN112981164AImprove thermal conductivityImprove reliabilityTransportation and packagingMetal-working apparatusHeat conductingCarbide

The invention discloses a manufacturing method of a high-reliability and high-thermal-conductivity diamond reinforced metal matrix composite material, and relates to a manufacturing method of a composite material. The method aims to solve the problems that an existing diamond reinforced metal matrix composite material is low in thermal conductivity, and the reliability is reduced. The method comprises the steps of carrying out cold pressing on diamond powder with a coating to obtain a diamond blank, carrying out spark plasma sintering under the vacuum or inert atmosphere protection to obtain a diamond preformed body, placing the diamond preformed body and a mold on the platform surface of a press, pouring a molten metal matrix to the top of the diamond preformed body in the mold, and carrying out pressure infiltration. According to the method, the coating on the diamond surface is sintered by spark plasma sintering to form a continuous heat conducting passage, so that the heat conducting property of the material is improved. The coating easily reacts with the diamond to generate carbide metal and is stable, so that the reliability of the manufactured composite material is improved. The method is suitable for manufacturing the diamond reinforced metal matrix composite material.

Owner:HARBIN INST OF TECH

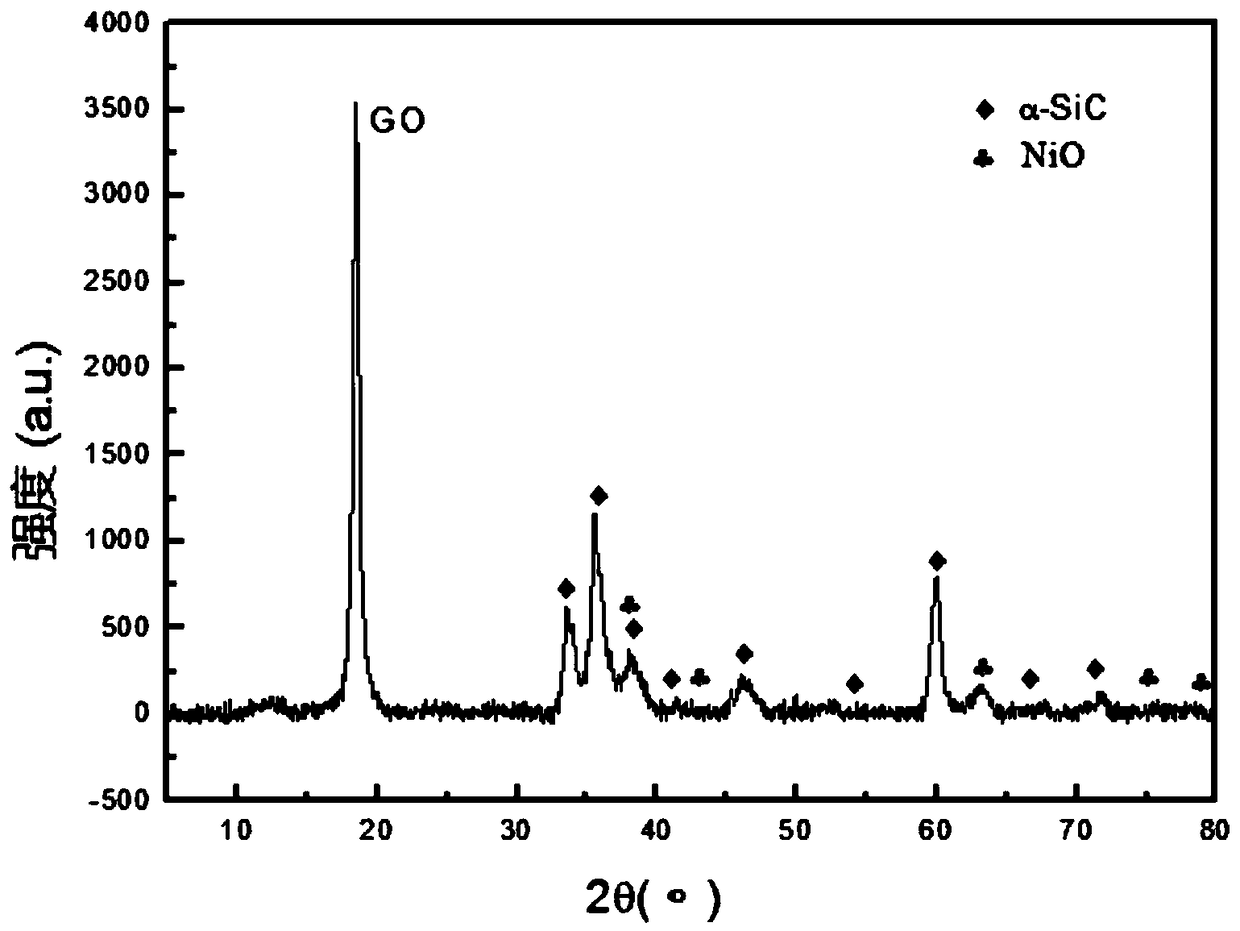

SiC-ferrite/carbon material high-temperature wave absorption composite material and preparation method thereof

The invention provides a SiC-ferrite / carbon material high-temperature wave absorption composite material and a preparation method thereof, and relates to a wave absorption composite material. The material aims at solving the technical problems of processing complexity, high cost and poor wave absorption effect of the existing wave absorption material. The wave absorption composite material provided by the invention is prepared from ferrite, silicon carbide and carbon materials. The preparation method comprises the following steps of 1, performing silicon carbide surface pretreatment, 2, uniformly mixing hydrophilic silicon carbide, ferrite preparation soluble salts, fluorides, a precipitant, a carbon material, a silane coupling agent, alcohol and water; performing hydro-thermal synthesis to obtain precursors; and then, roasting the precursors to obtain the wave absorption composite material. The 90-percent absorption can be reached at the X waveband being 8 to 12GHz; the reflection loss is lower than -10dB; and the maximum reflection loss reaches -28dB. The material can be used in the fields of monitoring of ground nuclear reactor systems, crude oil exploration, environment monitoring, aviation, spaceflight, radar, communication systems, high-power electronic converters and automobile motors.

Owner:HARBIN INST OF TECH

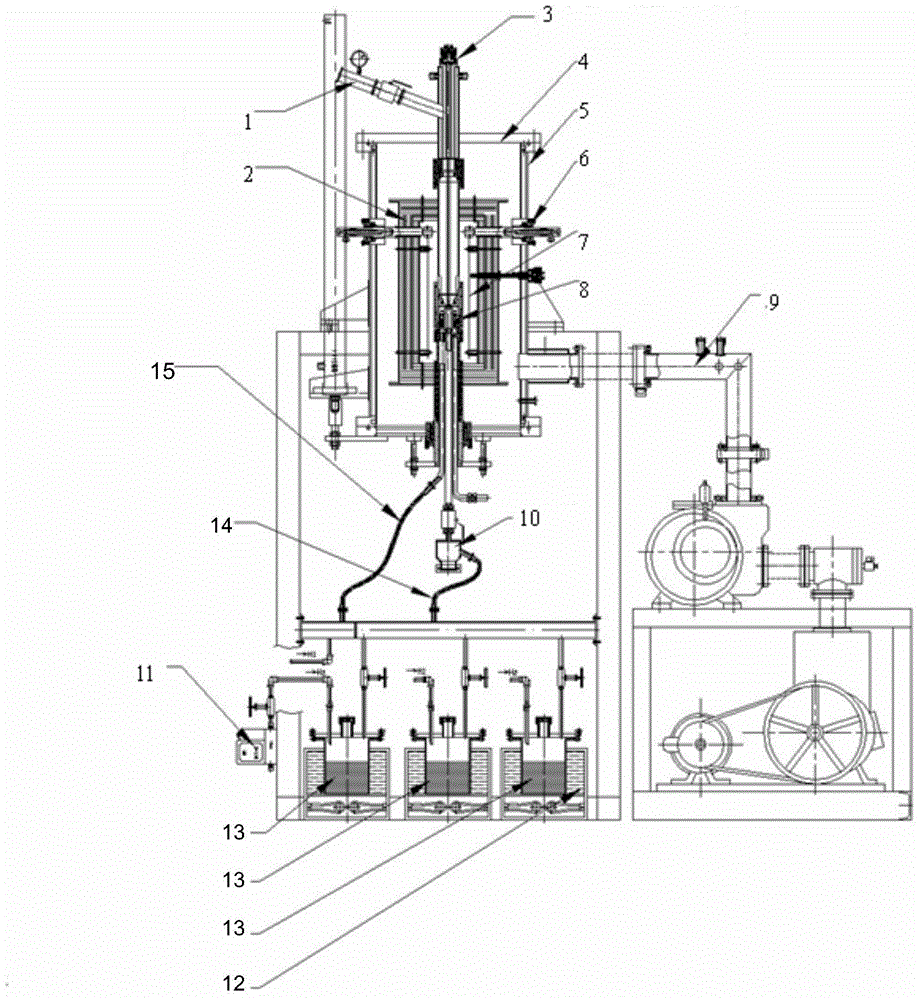

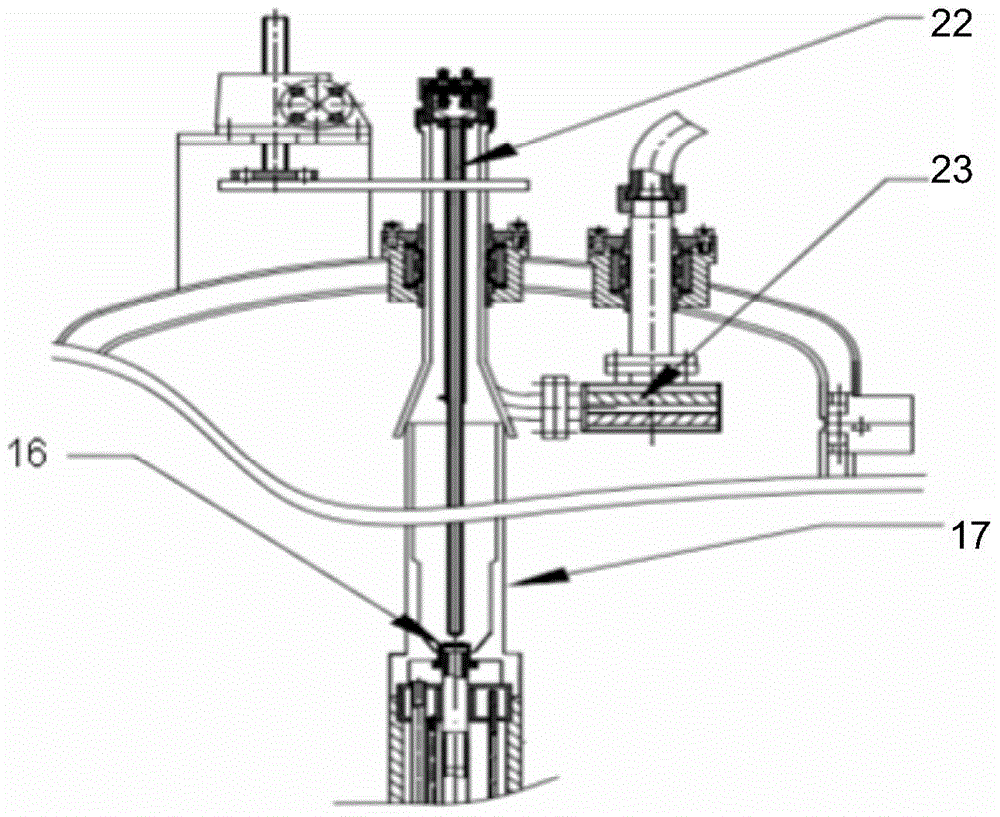

Fluidized bed device for coating film on surface of diamond, method and product prepared through method

ActiveCN105986247AAvoid graphitizationSmall particle sizeChemical vapor deposition coatingFluidized bedDiamond

The invention relates to a fluidized bed device for coating a film on the surface of diamond and particularly discloses a fluidized bed device. The fluidized bed device comprises a fluidized bed, a raw material air source and an atomic hydrogen generating device. The invention further discloses a method for coating a film on the surface of diamond powder through the fluidized bed device and diamond prepared through the method, and the surface of the diamond is coated with the film. The diamond prepared through the method is low in graphitization degree, uniform in coating layer and controllable in diamond powder particle size.

Owner:宁波晨鑫维克工业科技有限公司 +1

High-thermal-conductivity and high-wear-resistance silicon nitride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramics, and discloses high-thermal-conductivity and high-wear-resistance silicon nitride ceramic as well as a preparation method and application thereof. The preparation method of the silicon nitride ceramic comprises the following steps: adding diamond with a metal coating, Si3N4, a sintering aid MgO and Yb2O3 powder into ethanol and a Si3N4 ball-milling medium, carrying out ball-milling and mixing, and carrying out ball-milling and drying to obtain mixed powder; and heating the mixed powder to 1600-1700 DEG C under the axial pressure of 30-100 Mpa and under a protective atmosphere, conducting heat preservation, and carrying out spark plasma sintering. The silicon nitride ceramic provided by the invention has high thermal conductivity andwear resistance, good cutting performance and long cutting life, and can be applied to the field of ceramic cutters.

Owner:GUANGDONG UNIV OF TECH

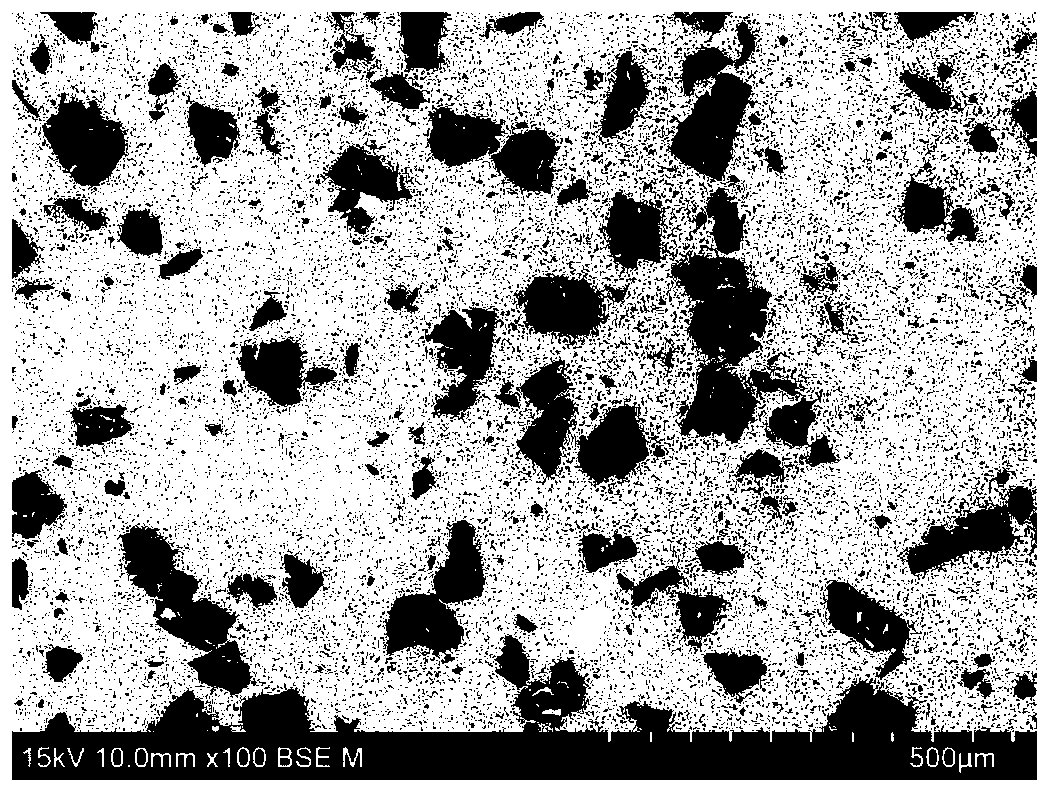

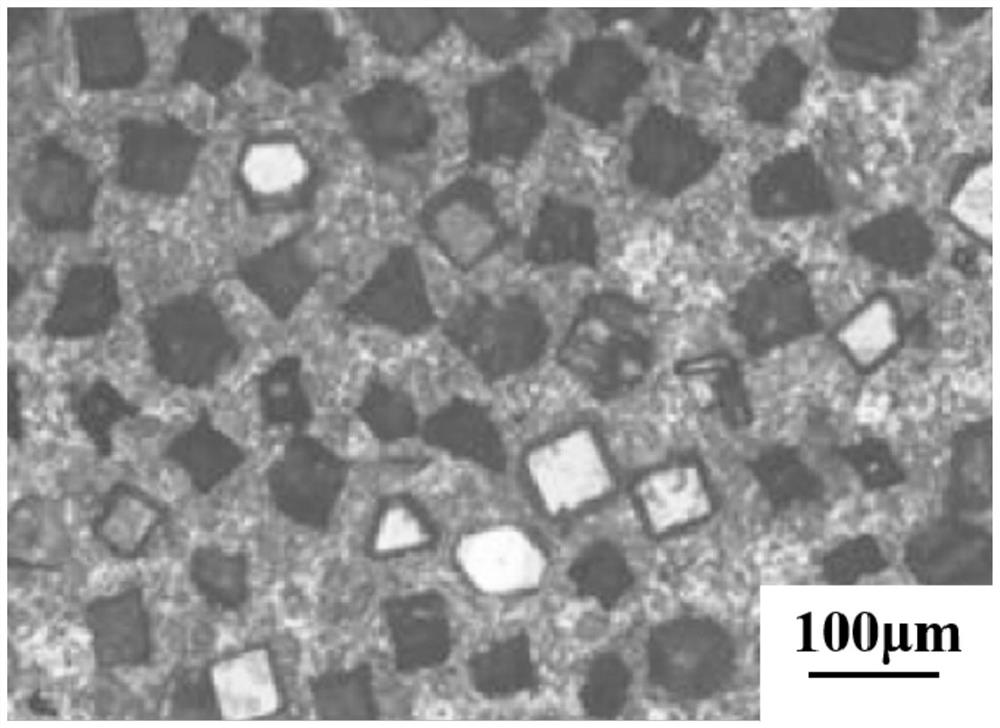

Method for preparing diamond sintered body by using discharge plasmas in sintering mode

The invention discloses a method for preparing a diamond sintered body by using discharge plasmas in a sintering mode. The mass ratio of the total mass of silicon powder and titanium powder to the diamond is (1-1.5):1; the mass ratio of the silicon powder to the titanium powder is (0.9-3.5):1; the method comprises the following steps of: putting the raw materials into a steel ball-milling tank; further putting a corundum milling ball of 18mm in diameter into the steel ball-milling tank, wherein the ratio of the ball material to the raw materials is 2:1; sealing up the steel ball-milling tank and opening a vacuum valve so as to vacuum the steel ball-milling tank; putting the ball-milling tank into a planet type ball mill, wherein the rotation speed of the planet type ball mill is 300r / min and the inverse frequency is 30Hz; continuously ball-milling for 30minutes, subsequently taking down the ball-milling tank and cooling down; and carrying out SPS sintering on the mixture under 10-100MPa at 1,100-1,650 DEF C for 5-20minutes so as to obtain the diamond sintered body. The method is simple in process, short in sintering time and low in energy consumption; the sintered diamond sintered body is fine in crystal grain and uniform in structure, the bending strength is improved to 200-440MPa, and the compactness is increased to 80-98%.

Owner:YANSHAN UNIV

Preparation method of diamond-ceramic composite material based on photocuring molding

ActiveCN113149002ASolve the accuracy problemSolve complexityAdditive manufacturing apparatusDiamondParaffin waxCeramic composite

The invention provides a preparation method of a diamond-ceramic composite material based on photocuring molding, which comprises the following steps: weighing diamond powder and titanium powder, and plating titanium on the surface of diamond through a molten salt method to obtain a diamond titanium-plated layer; coating the titanium-plated surface of the diamond with paraffin through a ball milling method, and obtaining a paraffin layer; weighing the secondarily coated diamond particles and glass phase ceramic powder, uniformly mixing in a ball mill, then drying in a drying oven, taking out and sieving to obtain diamond-glass phase ceramic mixed powder; putting the obtained mixed powder, light-cured resin, a dispersing agent and the like into a homogenizer, and uniformly mixing to obtain light-cured diamond-ceramic composite material slurry; then, performing DLP printing in an additive manufacturing technology; and carrying out thermal sintering to obtain the photo-cured DLP printed part containing the diamond-glass phase ceramic composite material. The part prepared through the method has the beneficial effects of being high in forming precision, high in shape complexity and good in comprehensive mechanical property.

Owner:JIHUA LAB

PCD grinding wheel capable of performing positive rake angle processing and provided with ordered micro slot structure and manufacturing method for PCD grinding wheel

ActiveCN108747858AImprove efficiencyImprove grinding efficiencyBonded abrasive wheelsGrinding devicesLaser processingPolycrystalline diamond

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-performance carbon paper for fuel cell gas diffusion layer and preparation method thereof

InactiveCN103556543BSimple processProduct quality is easy to controlSpecial paperCell electrodesFiberFuel cells

The invention relates to carbon paper and a preparation method thereof and particularly relates to special high-performance carbon paper for a gas diffusion layer of a fuel cell and a preparation method of the carbon paper. By taking short carbon fibers, plant fibers, heat bonding fibers and carbon black as raw materials, the carbon paper is prepared by the following steps: defibering, pulping and proportioning; then carrying out papermaking by adopting a wet-method papermaking process; and carrying out waterproof pigment coating treatment. The ratios of all the raw materials are as follows in parts by weight: 65-75 parts of the short carbon fibers, 10-15 parts of the plant fibers, 10-15 parts of the heat bonding fibers and 0-10 parts of the carbon black. According to the special high-performance carbon paper for the gas diffusion layer of the fuel cell and the preparation method of the carbon paper, a production process combining wet-method formation, hot pressing and coating is adopted and has the characteristics of simple process flow, easiness for controlling product quality, environment-friendly production process and the like; the material ratio of each raw material can be accurately controlled in the production so as to be good for controlling the product quality.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

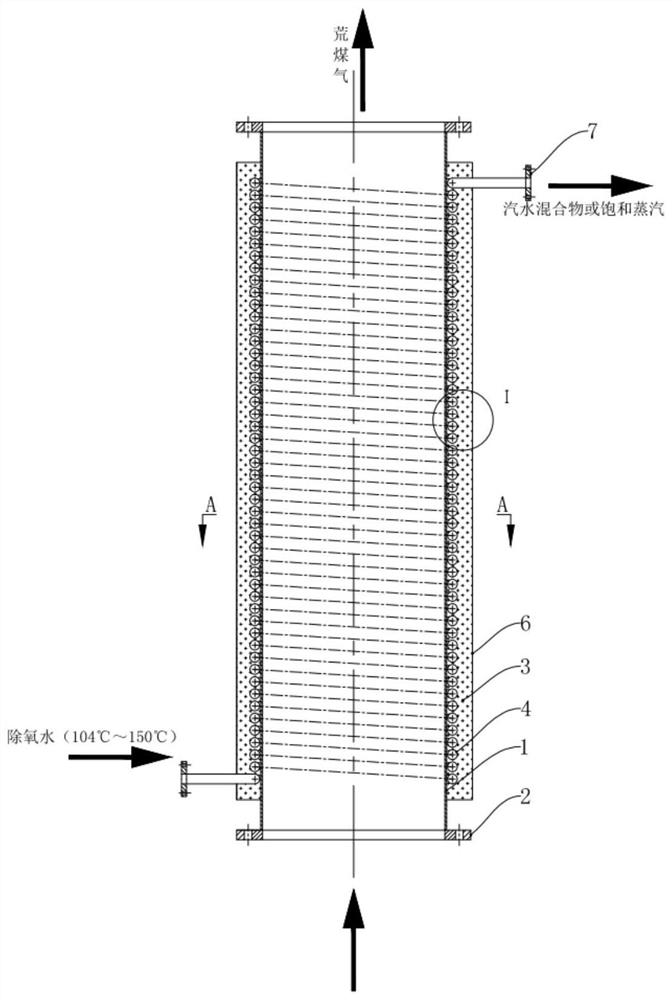

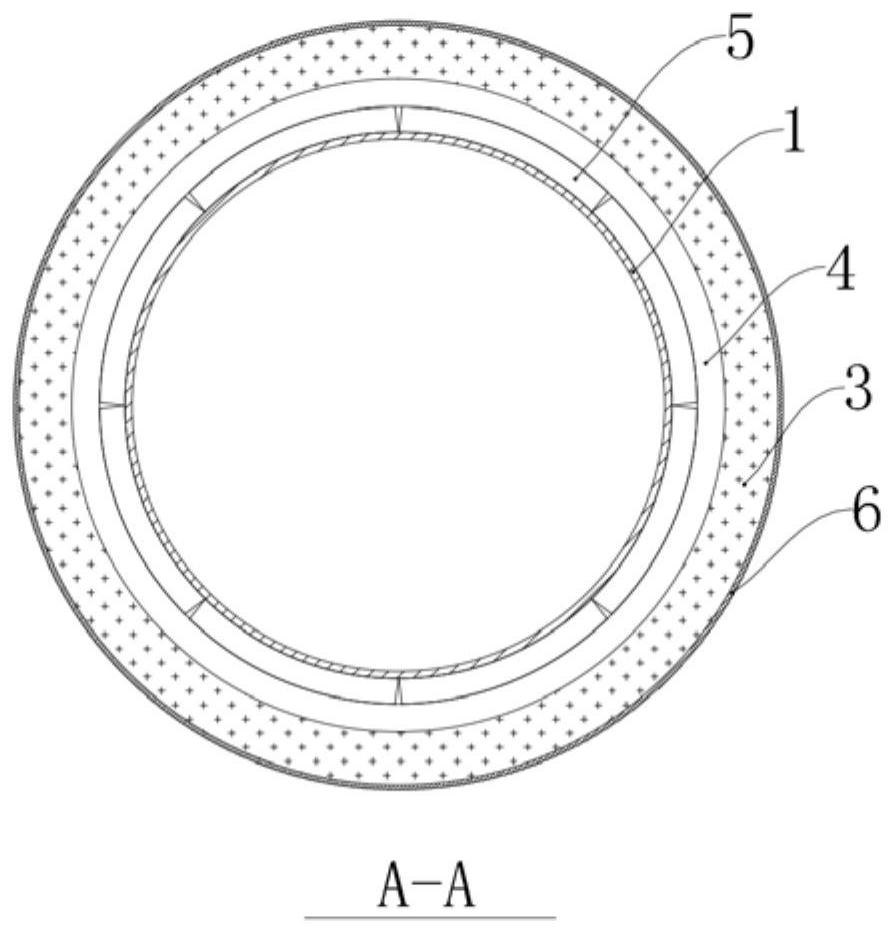

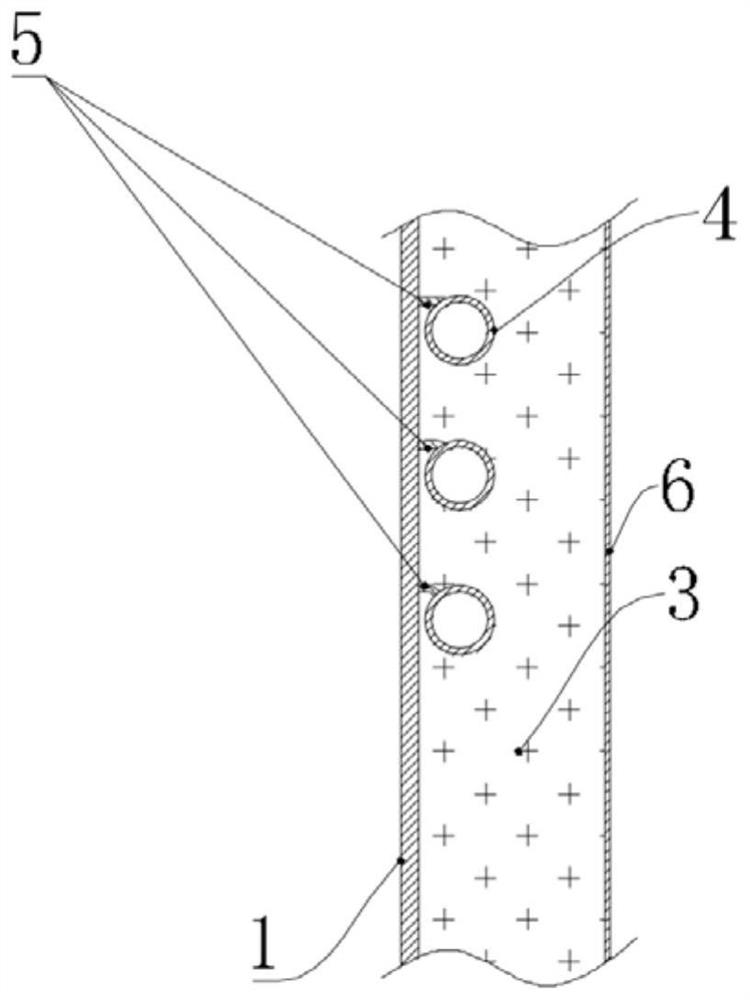

Heat exchanger applicable to recovery of water heat from ascension tube of coke oven

PendingCN111721145AAvoid cokingAvoid graphitizationEnergy inputStationary tubular conduit assembliesThermal dilatationEngineering

The invention discloses a heat exchanger applicable to recovery of water heat from an ascension tube of a coke oven and belongs to the technical field of waste heat recovery. The heat exchanger comprises an inner tube, an outer tube and the heat exchange tube, and further comprises a fin, wherein the inner tube and the outer tube are concentrically arranged in a sleeving manner; the heat exchangetube is arranged between the inner tube and the outer tube, and connected to the inner tube through the fin; the cross section of the fin is designed to be an arc-shaped plate or a bent plate; and twofree ends of the fin are correspondingly connected with the inner tube and the heat exchange tube. According to the heat exchanger, the inner tube wall temperature is stabilized at 360 DEG C or above, so that the problem caused by the condensation of tar on the inner wall of the inner tube can be avoided, and the heat exchange efficiency of the heat exchanger can be guaranteed; and through the fin and the heat exchange tube which are arranged outside of the inner tube, the impact of thermal expansion on the structure of the heat exchanger can be effectively eliminated, the isolation of a heatexchange medium from coke oven gas can be achieved, and the potential safety hazard caused by the accidental leakage of the heat exchange medium or the coke oven gas can be avoided.

Owner:YUNNAN FENG PU TECH

Efficient preparation method of diamond/metal matrix composite material

The invention discloses an efficient preparation method of a diamond / metal matrix composite material, and relates to a preparation method of a diamond / metal matrix composite material. The problems that an existing method for preparing a carbide coating on the surface of diamond is large in energy loss, graphitization of the diamond is prone to occurring, and the technology is complex are solved. The method comprises the following steps of weighing diamond powder with a metal coating, filling a graphite mold with the diamond powder, performing compacting, carrying out low-temperature diffusion treatment and high-temperature reaction treatment, and carrying out air pressure infiltration. According to the preparation method, a preheating temperature curve is changed, the diamond is subjected to low-temperature long-time diffusion and high-temperature short-time reaction, graphitization of the diamond is avoided through the high-temperature short-time reaction, a compact carbide coating is synthesized on the surface of the diamond in situ in the preparation process of the composite material, the energy loss is reduced, the process is simple, the efficiency is high, the product quality and stability are easy to control, the cost is low, and industrial production and application are easy to realize. The method is suitable for preparing the diamond / metal matrix composite material.

Owner:HARBIN INST OF TECH

Diamond-silicon carbide composite material, preparation method thereof and electronic equipment

The invention relates to a diamond-silicon carbide composite material, a preparation method thereof and electronic equipment, and the preparation method comprises the following steps: mixing diamond,a dispersing agent, polycarbosilane, a plasticizer and a solvent to prepare tape casting slurry; carrying out tape casting treatment on the tape casting slurry to prepare a green body; carrying out hot pressed sintering treatment on the green body; the diamond-silicon carbide composite material prepared by the method has the advantages of high density, high thermal conductivity, simple process, short production period, high automation degree and suitability for large-scale industrial production.

Owner:北京科技大学广州新材料研究院

Preparation method for special high-performance carbon paper for fuel cell

InactiveCN104264531ASimple processProduct quality is easy to controlSpecial paperCell electrodesFiberCarbon fibers

The invention relates to special high-performance carbon paper for a fuel cell, and a preparation method of the high-performance carbon paper. By taking chopped carbon fibers, plant fiber, thermally bonded fibers and carbon black as raw materials, the carbon paper is prepared by the following steps: performing papermaking by using a wet paper-making process after performing defibering, pulping and proportioning, and processing by coating a waterproof coating. The product disclosed by the invention is convenient to use; high-temperature carbonization and graphitization are avoided; repeated energy consumption is avoided fundamentally; the carbon paper can directly serve as a substrate for preparing an electrode of the fuel cell without pretreatment.

Owner:陈嗳

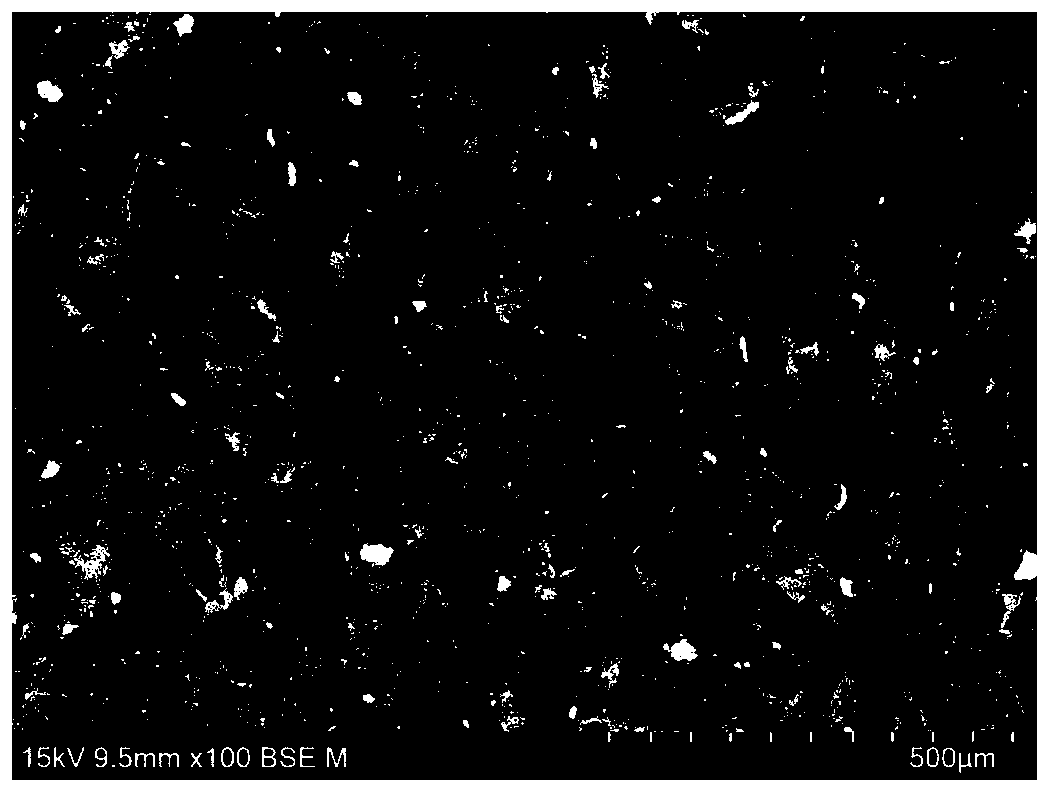

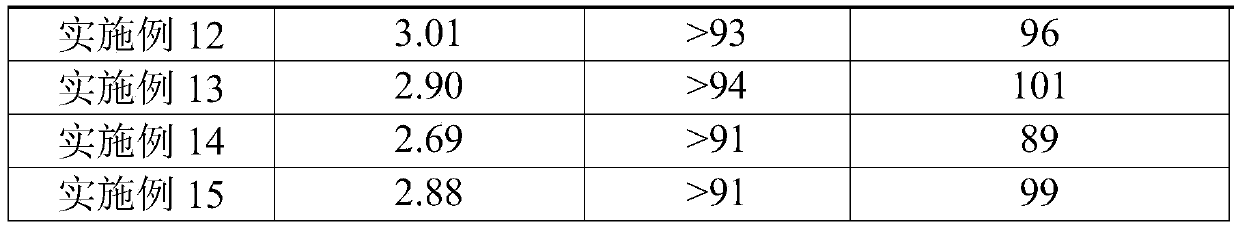

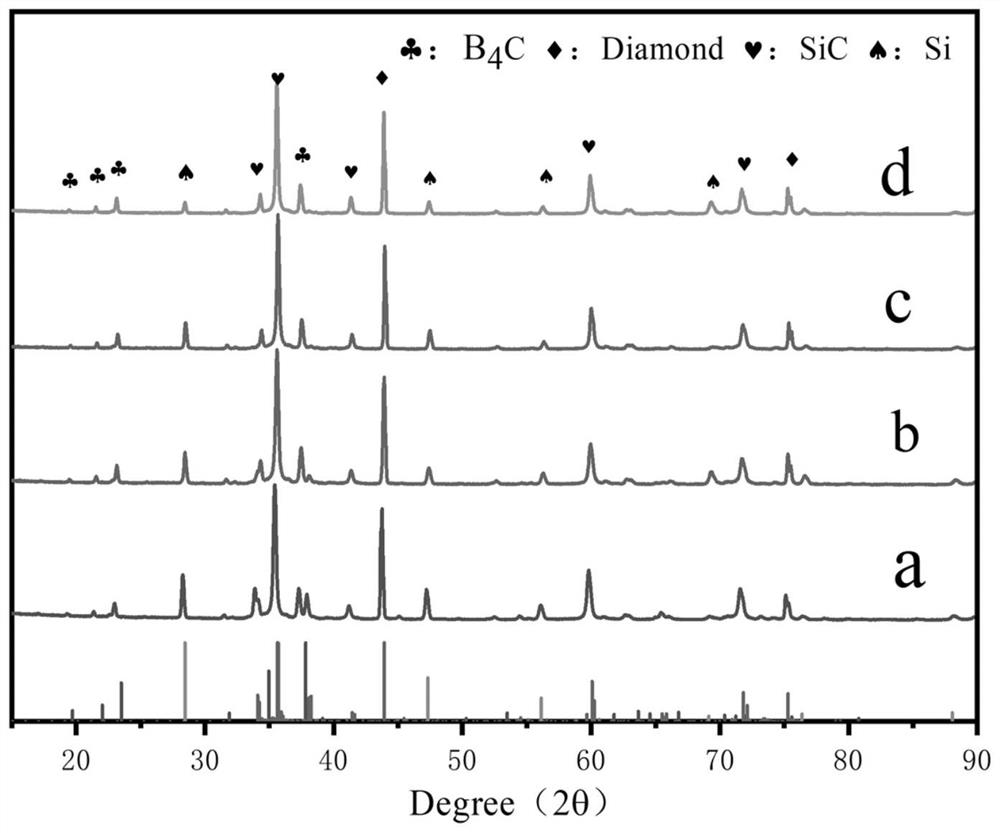

Two-step sintering method of diamond-B4C-SiC three-phase composite ceramic

The invention relates to a two-step sintering method of diamond-B4C-SiC three-phase composite ceramic, which comprises the following steps: taking a mixture of diamond powder, Si powder and B powder as a raw material, carrying out spark plasma sintering in situ by adopting a two-step method, and heating to the highest temperature T1 at the rate of 100-200 DEG C / min at the front stage of sintering; then, the highest temperature is reduced to T2 through the cooling process of 5-15 min, and therefore the diamond-B4C-SiC three-phase composite ceramic is obtained; wherein T1 ranges from 1550 DEG C to 1600 DEG C, T2 ranges from 1500 DEG C to 1550 DEG C, and the difference value between T1 and T2 is not smaller than 40 DEG C. According to the method, a traditional heat preservation stage is replaced by a stage of reducing the temperature to 1500-1550 DEG C at a constant speed, so that diamond graphitization is effectively prevented, the problem of diamond graphitization is solved at the temperature lower than the densification temperature of boron carbide, SiO2 residues in a sample are effectively inhibited, densification of the sample is promoted, the mechanical property is improved, and the method is suitable for industrial production. The obtained three-phase composite ceramic is compact in structure, good in interface bonding and free of graphite residues, and has the characteristics of light weight, superhardness, high strength and high toughness.

Owner:WUHAN UNIV OF TECH

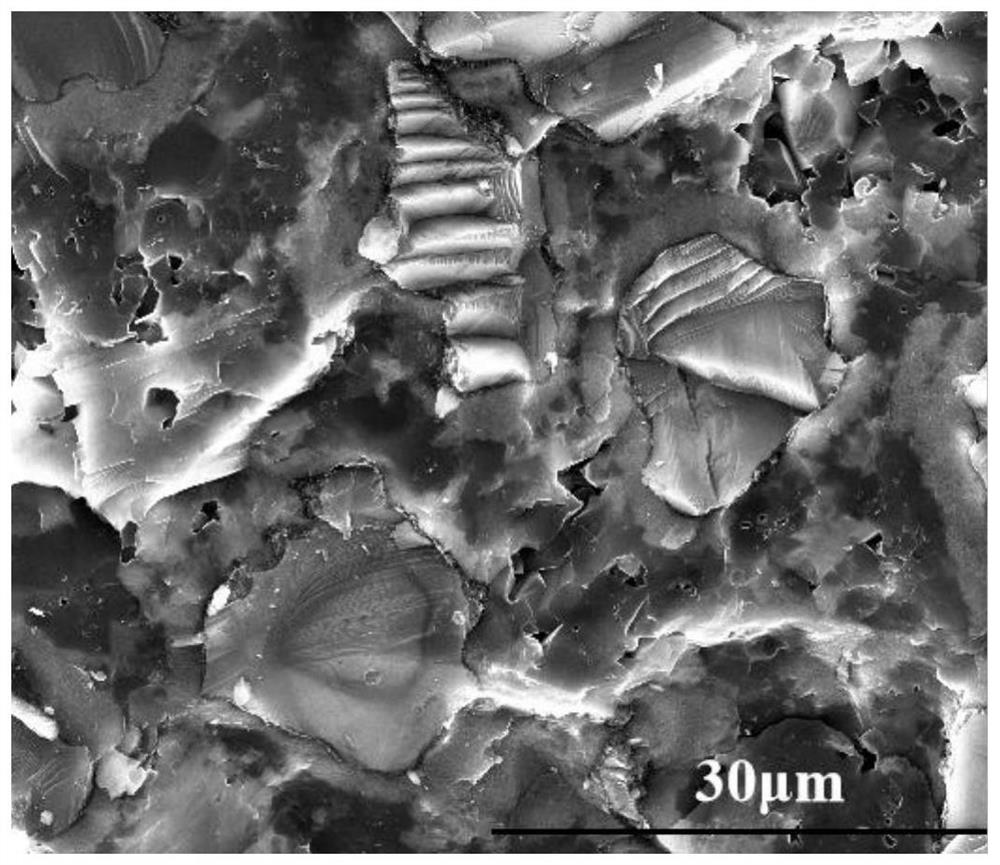

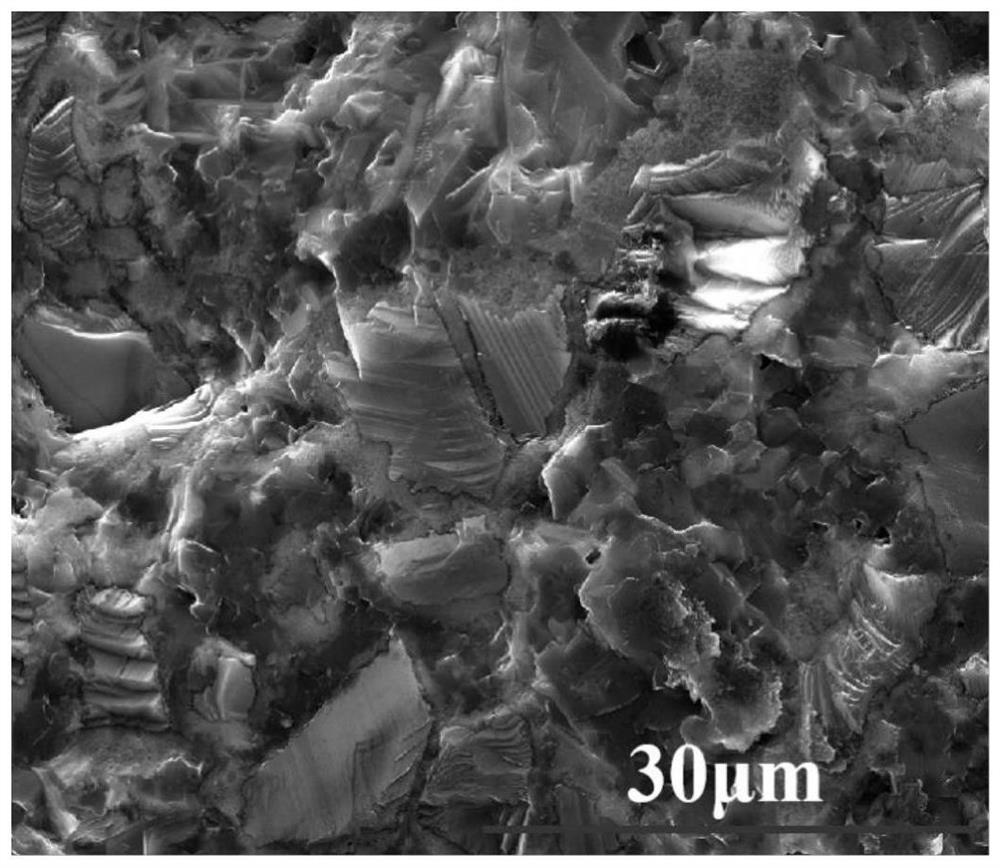

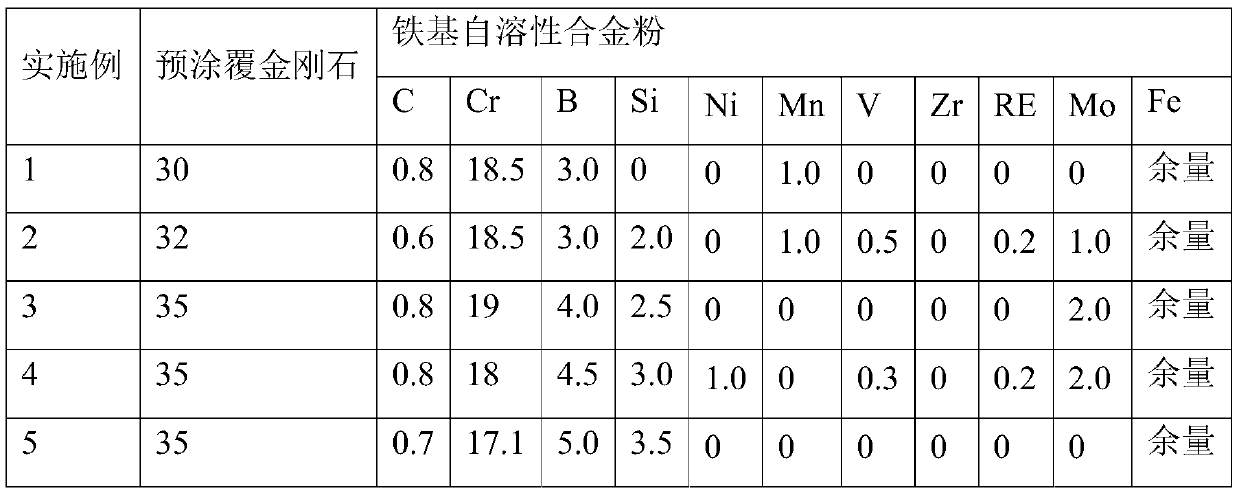

Diamond-iron based composite coating and application thereof as sealing layer of high-temperature valve

ActiveCN111270186AHigh hardnessImprove wear resistanceMolten spray coatingTransportation and packagingWear resistanceNonmetal

The invention discloses a diamond-iron based composite coating and application thereof as a sealing layer of a high-temperature valve. The diamond-iron based composite coating is prepared from the following raw materials in percentage by mass: 30%-35% of pre-coated diamond powder, 0.6%-0.8% of C, 18%-25% of Cr, 3%-5% of B, 2%-4% of Si, 3.0%-4.0% of other metal and nonmetal elements, and the balance of Fe. The high-temperature value adopting the diamond-iron based composite coating as the sealing layer has good heat conduction, sealing property, wear resistance and corrosion resistance.

Owner:HEFEI UNIV OF TECH

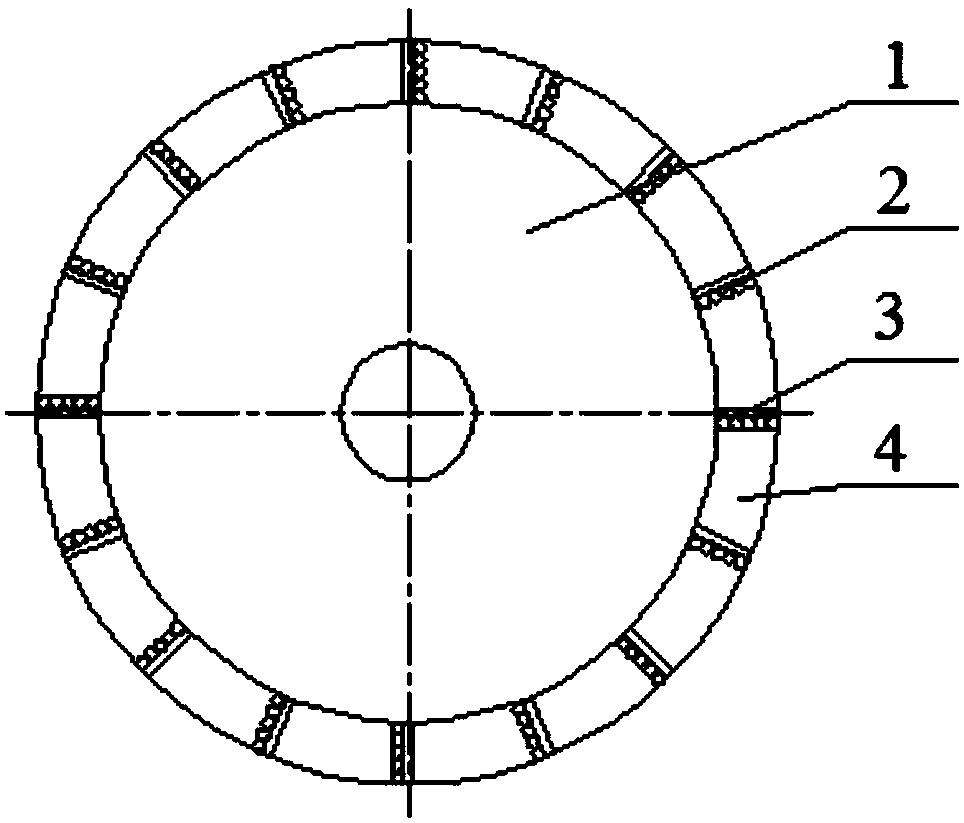

Self-lubricating diamond circular saw web

InactiveCN109648715AImprove gripReduce dosageStone-like material working toolsWear particleCircular saw

The invention belongs to the field of processing tools for stones and ceramics, and particularly relates to a self-lubricating diamond circular saw web. The circular saw web comprises a saw web base body, a diamond braze-welding base body which is brake-welded with diamond particles, and self-lubricating filler, wherein grooves are processed in the edge of the saw web base body at equal spacing; the diamond braze-welding base body is partially inserted into the grooves of the saw web base body for being fixed; the diamond braze-welding base body is partially exposed to the surface of the saw web base body; and the self-lubricating filler is filled in the exposed diamond braze-welding base body, so that the peripheral surface of the circular saw web is smooth and complete. A single-layer braze-welding diamond technology, an abrasive particle orderly arranging technology and a solid lubricating technology are applied to a manufacturing process of the diamond saw web, so that firm holdingof abrasive particles can be realized, and using efficiency of the abrasive particles can be improved; and meanwhile, diamond can be prevented from generating graphitization at a high temperature, and a plurality of problems in the using process of the diamond saw web can be effectively solved, so that using performance of the diamond saw web is improved.

Owner:NANJING UNIV OF SCI & TECH

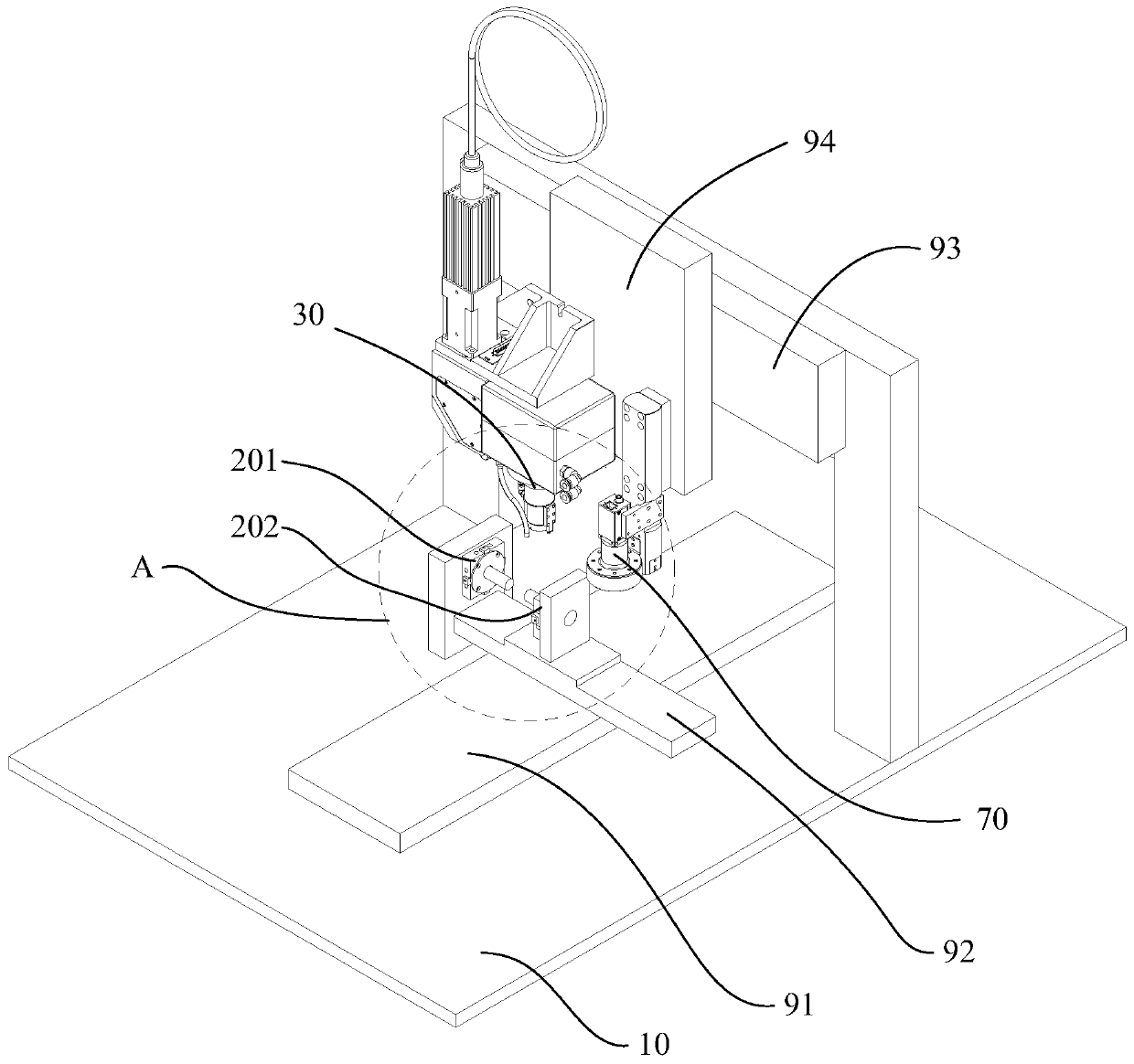

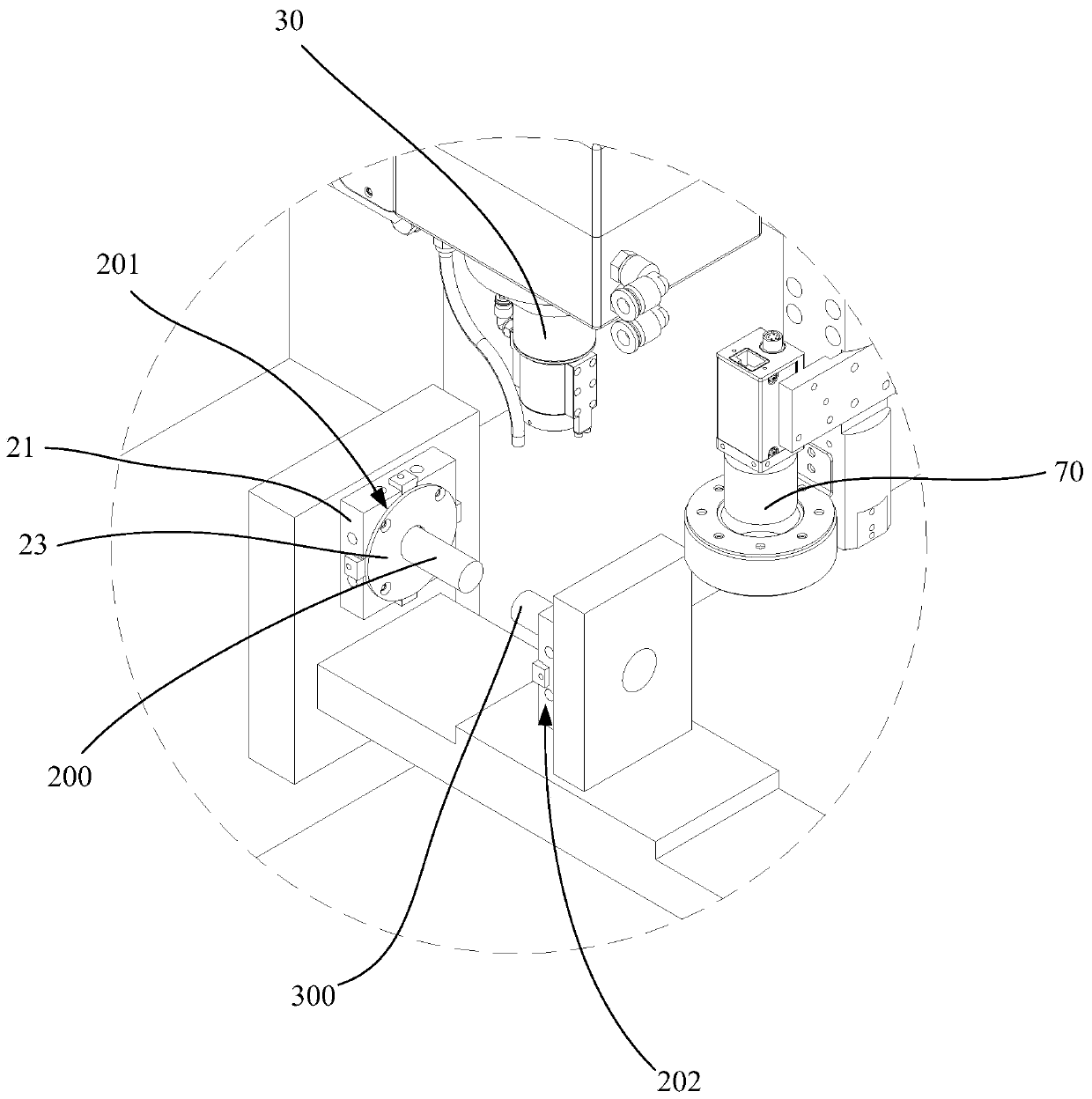

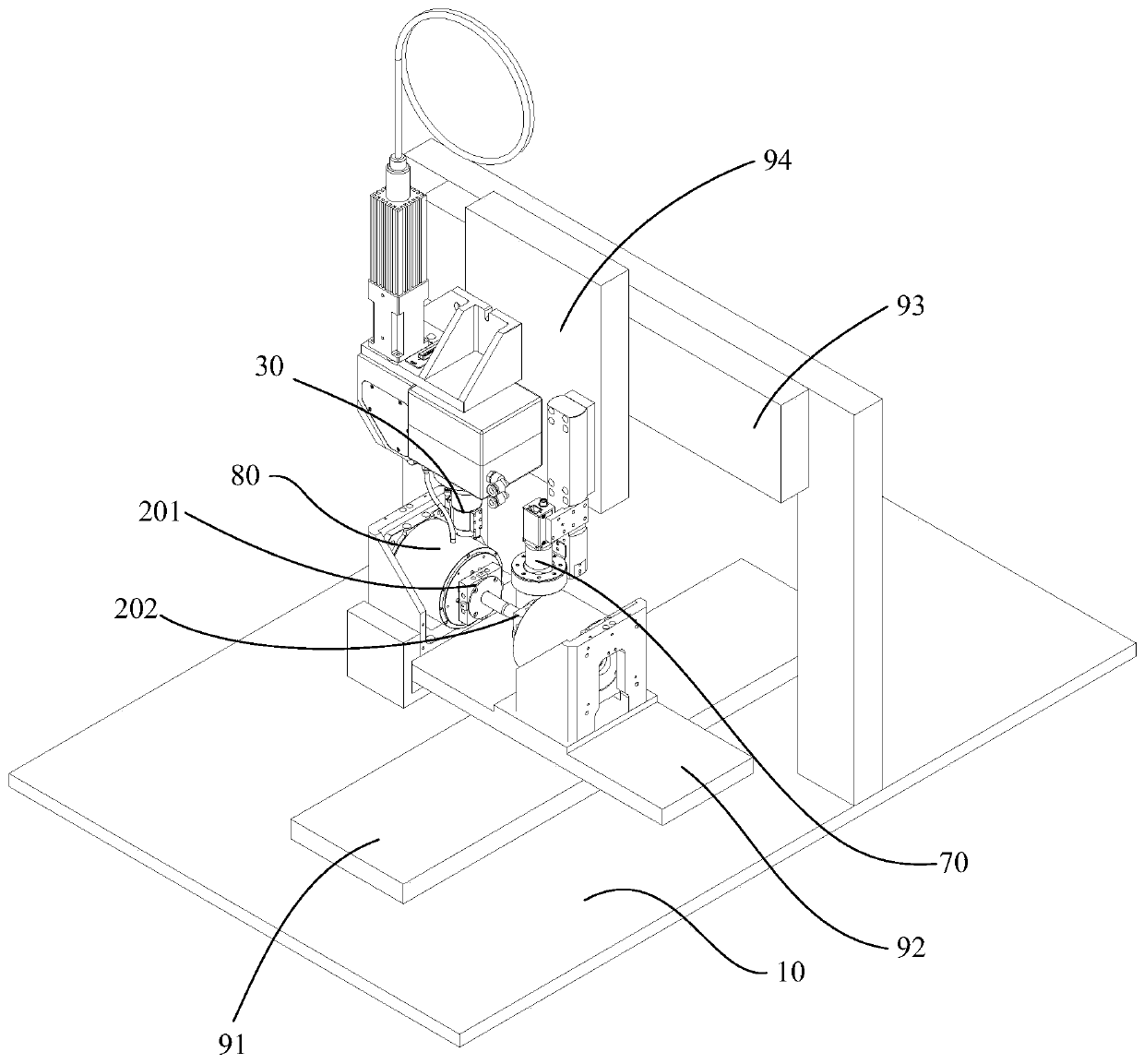

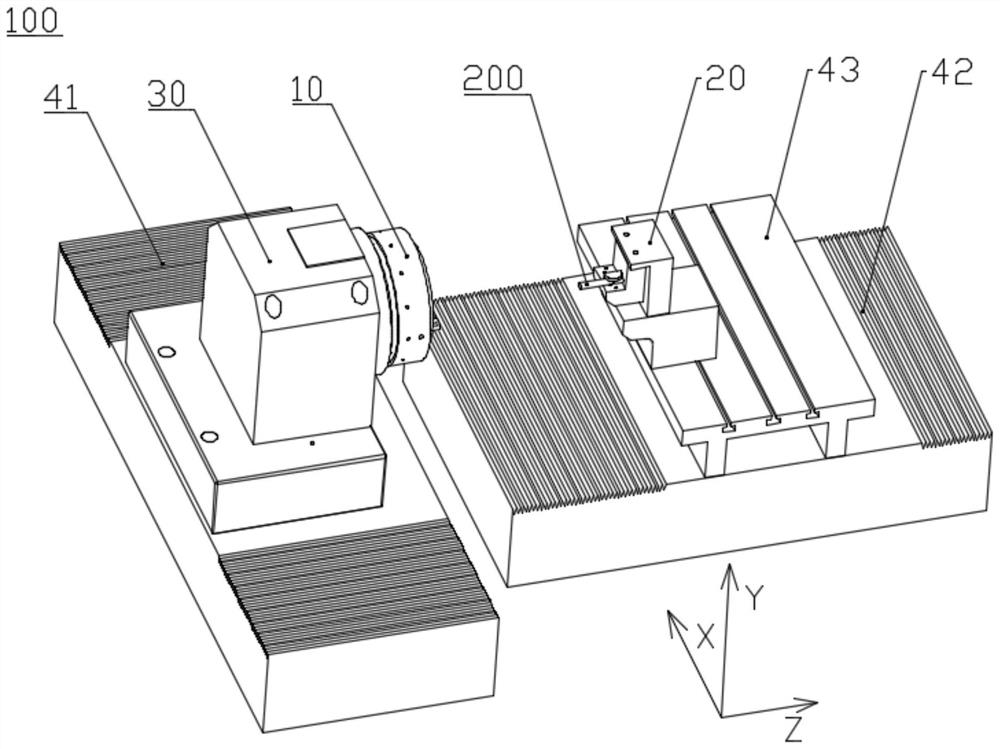

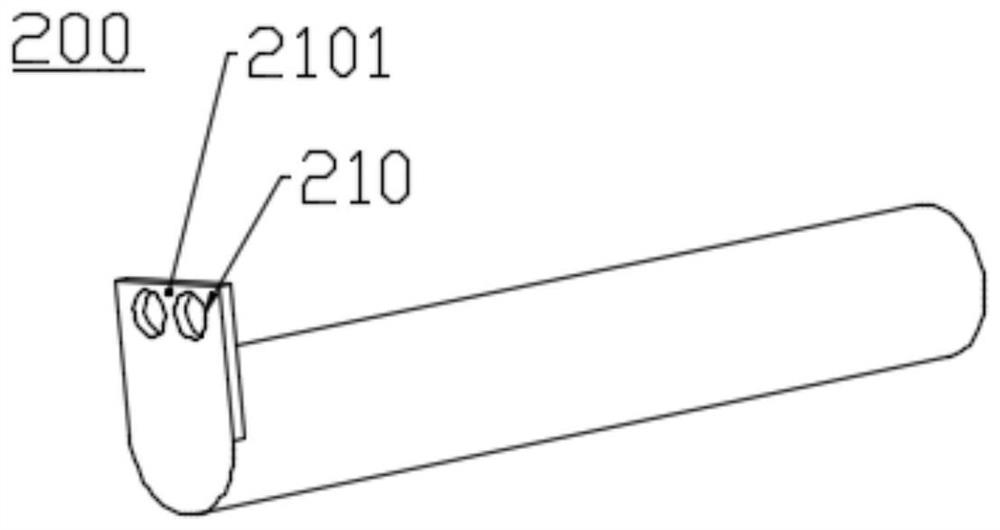

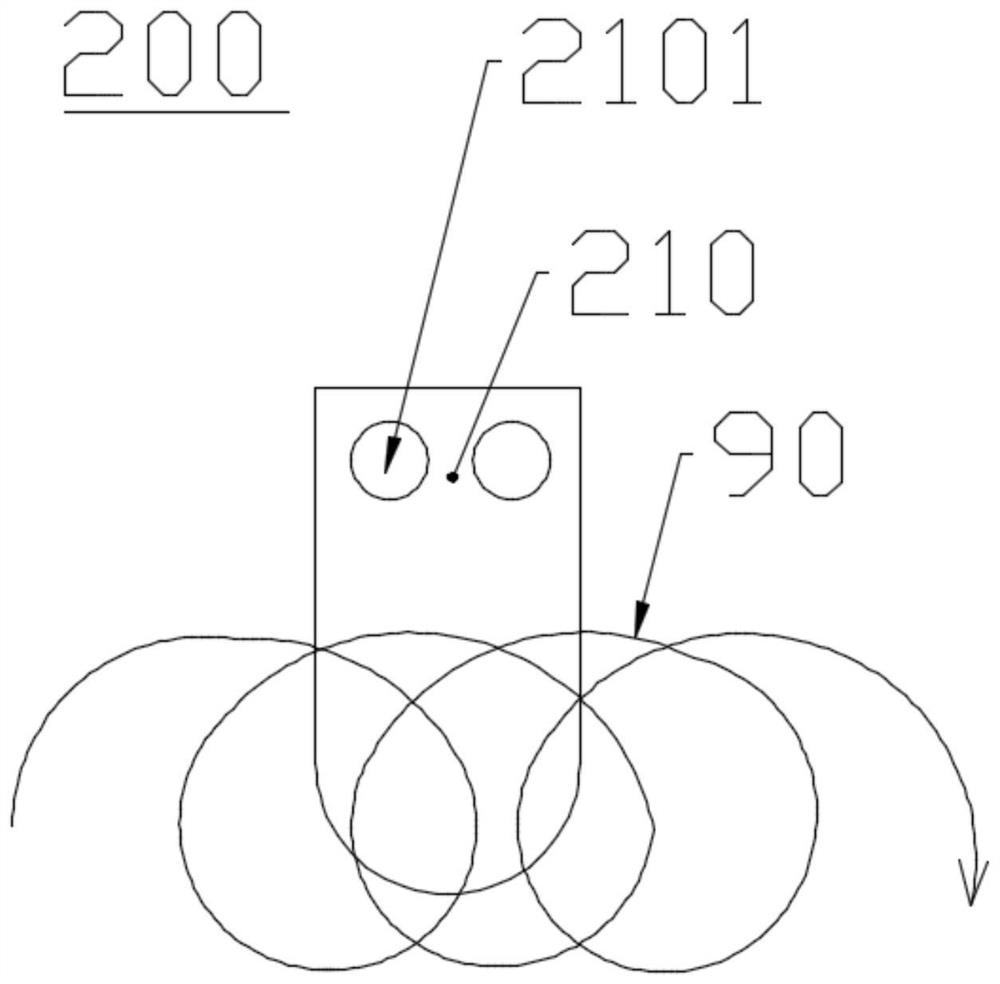

Welding equipment

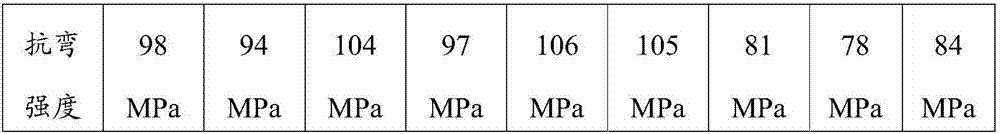

PendingCN110125545AAvoid graphitizationHigh strengthWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention discloses welding equipment for welding first welded parts and second welded parts, which are oppositely arranged. The welding equipment comprises a worktable, a clamping tool, a laser module and a cooling system, wherein the second welded parts are arranged on the worktable; the clamping tool is connected to the worktable; the first welded parts are clamped on the clamping tool; fluxes are fixed between the first welded parts and the second welded parts; the laser module is connected to the worktable, and is arranged corresponding to the fluxes or the second welded parts; and the cooling system is arranged on the clamping tool and connected with the first welded parts for cooling the first welded parts. The welding equipment can improve the strength and the plasticity of thewelded parts after welding to prevent the brittle failure.

Owner:SHENZHEN H TECH CO LTD

Ceramic bonding agent, preparation method and application thereof and diamond grinding tool

ActiveCN107953274ASimple processReduce processAbrasion apparatusGrinding devicesSilicon oxideZinc nitrate

The invention relates to a ceramic bonding agent, a preparation method and application thereof and a diamond grinding tool. The preparation method comprises the following steps that raw materials areprovided, wherein the raw materials comprise zinc nitrate, lithium nitrate, aluminum nitrate, magnesium nitrate, zirconium oxide, silica sol, organic fuel, a dispersing agent and an organic carbon source; the raw materials are dissolved in a solvent to form a mixed solution, and then the mixed solution is atomized and subjected to a combustion reaction so as to obtain a combustion powder product;and heat preservation treatment is carried out on the combustion powder product in inert gas atmosphere, so that partial silicon oxide in the combustion powder product and carbon elementary substancesare subjected to a carbothermal reduction reaction and a silicon carbide nanometer crystal whisker is grown in situ, and then calcination treatment is carried out on the combustion powder product under oxidizing atmosphere, so that carbide except for the silicon carbide nanometer crystal whisker formed in the carbothermic reduction process is oxidized to obtain the ceramic bonding agent. The ceramic bonding agent prepared by the method is small in particle size, is uniformly mixed and uniformly doped with SiCnw, and is capable of reducing the sintering temperature of the diamond grinding tool, capable of improving bending strength of the diamond grinding tool and capable of prolonging the service life of the diamond grinding tool.

Owner:HUNAN UNIV OF SCI & TECH

Iron-based material electric field auxiliary machining machine tool and machining method

ActiveCN112372001AInhibition of pair bindingAvoid graphitizationAuxillary equipmentEngineeringMachine tool

The invention provides an iron-based material electric field auxiliary machining machine tool and a machining method. The iron-based material electric field auxiliary machining machine tool comprisesa main shaft, a mounting piece, a diamond cutter and a power supply device, wherein the diamond cutter is mounted on the main shaft; the main shaft drives the diamond cutter to rotate; the mounting piece is opposite to the main shaft, and is used for mounting workpieces; and the power supply device is used for introducing variable currents into the workpieces, so that electrons in the workpieces are in a disordered state. In the iron-based material electric field auxiliary machining machine tool and the machining method, the power supply device is provided for introducing the variable currentsinto the workpieces, so that the electrons in the workpieces are in the disordered state, the electron pairing combination is inhibited, and the purpose of inhibiting graphitization of the diamond cutter is achieved; and the iron-based material electric field auxiliary machining machine tool is better in inhibition effect, can be applied to long-distance cutting, needs no complex process requirements and expensive equipment, and is lower in cost.

Owner:SHENZHEN UNIV

Method for Improving Diamond Seed Crystal Quality Using Hydrogen Plasma Multiple Etching/Annealing Cycle Process

ActiveCN104975343BQuality improvementHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesHydrogenCrystallinity

The invention discloses a method for improving the quality of diamond seed crystals by using hydrogen plasma multiple etching / annealing cycle technology, which relates to a method for improving the quality of diamond seed crystals. The present invention aims to solve the problems that the existing method for improving the quality of the diamond seed crystal takes a long time, the operation is relatively complicated, and the surface quality of the seed crystal is easily deteriorated. The method is as follows: 1. Diamond seed crystal cleaning; 2. Welding; 3. 1. Placing the seed crystal; 4. Hydrogen plasma etching / annealing, which is completed. The hydrogen plasma etching / annealing treatment of the present invention can simultaneously remove crystal defects, surface and subsurface damage, internal stress and defects of the diamond seed crystal caused by mechanical polishing on the surface of the diamond seed crystal in the same instrument, and improve the crystallinity, thereby obtaining High quality seeds and greatly simplifies operation, saving time and cost. The invention is applied in the technical field of crystal growth.

Owner:九桓碳构(威海)新材料有限公司

A kind of diamond grinding wheel and its production method

InactiveCN106312843BAvoid graphitizationConsistent blade heightBonded abrasive wheelsGrinding devicesWear particleHigh intensity

The invention discloses a diamond grinding wheel, which has multi-layer abrasive particle orderly arrangement, is high in bonding strength and is convenient to repair after being worn, and a production method thereof. The production method comprises steps of processing a grinding wheel basal body, cleaning and the like. According to the diamond grinding wheel and the production method thereof disclosed by the invention, a laser material increasing technology is adopted to accurately process, so that processing precision and processing quality are improved; a sandwich structure is adopted for sintering, so that the abrasive particles are prevented from moving, protruding height of the abrasive particles is guaranteed to be consistent, orderly arrangement of the diamond abrasive particles is realized, a chip space during grinding is great, grinding force is reduced, a grinding temperature is reduced, grinding efficiency is improved, and grinding surface quality is improved; power of a laser unit is controlled for controlling a sintering temperature, so that the diamond abrasive particles are prevented from graphitizing, and a metal bonder is combined with the diamond abrasive particles in a high-strength metallurgical mode; a manufacturing process further can be simplified; and the diamond grinding wheel is finished layer by layer after being worn, and then is continuously used, so that finishing is convenient, and the service life of the diamond grinding wheel is long.

Owner:HUNAN CITY UNIV

A kind of method for preparing copper-based diamond composite material

The invention discloses a method for preparing a copper-based diamond composite material. The method comprises the following steps: processing a copper alloy / pure copper material into a final size of a diamond / copper product to serve as a mold, then pouring diamond single crystal / coated diamond granules into the mold, jolt ramming, and dripping an adhesive solution; vacuum treating at 200-600 DEG C to prepare a porous diamond skeleton blank; filling the porous diamond skeleton blank and the copper alloy / pure copper mold in a sheath, carrying out hot isostatic pressure treatment, and cooling to obtain the composite material. The method disclosed by the invention can be used for achieving near-net forming, the post processing capacity is small, the process is simple and reliable, the prepared diamond / copper composite material is good in performance uniformity, the material has good comprehensive performance with being used as an electronic package material and a radiating substrate material, the thermal conductivity of the material can reach 700w / mk, the thermal expansion coefficient can be freely adjusted and is not less than 6.5*10<-6> m / l at a room temperature condition, and the density is higher than 99.9%.

Owner:BEIJING GANG YAN DIAMOND PROD CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com