Self-lubricating diamond circular saw web

A technology of diamond and circular saw blades, which is applied in the field of self-lubricating diamond circular saw blades, can solve the problems that cannot fundamentally solve the problem of diamond saw blades, and achieve the effects of reducing interference, noise, and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

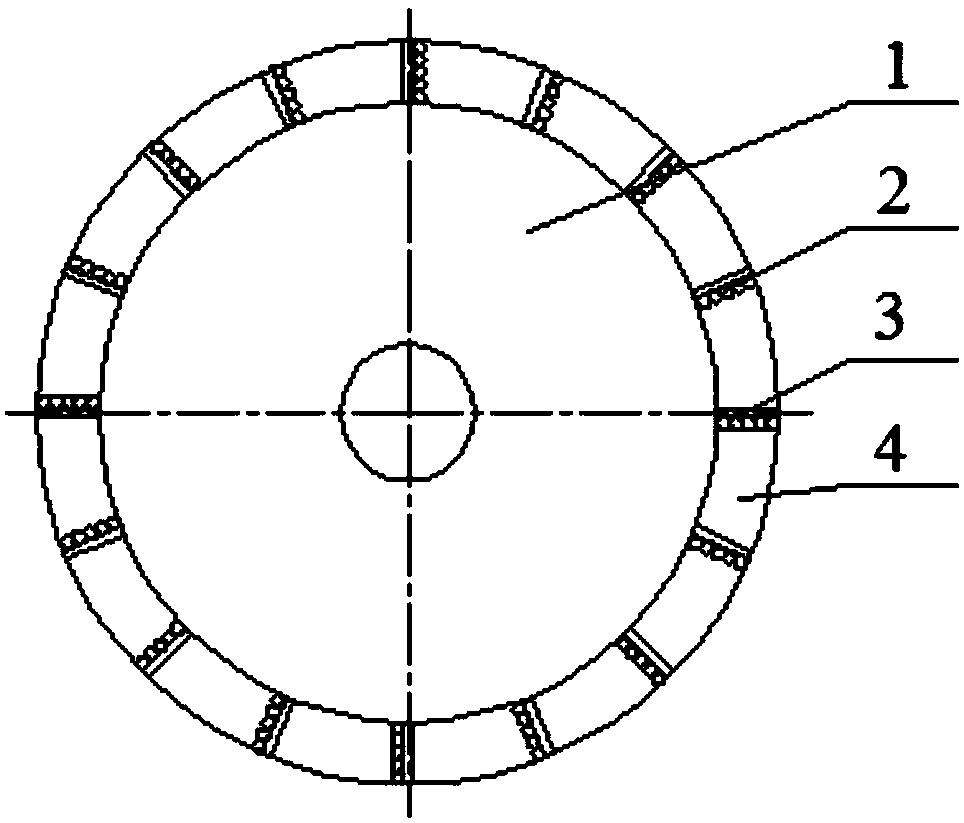

[0032] Such as figure 1 As shown, grooves at equal intervals are processed on the edge of the saw blade base 1 with a pitch of 5 to 20 mm. The diamond brazing base 3 brazed with diamond particles is inserted and welded into the grooves of the saw blade base 1 to The orderly arrangement of the diamond particles 2 in the circumferential direction of the saw blade is realized.

[0033] The saw blade structure mainly includes four parts: saw blade base 1 , diamond particles 2 , diamond brazing base 3 and self-lubricating filler 4 . First arrange the diamond particles in an orderly manner on the diamond brazing substrate, evenly sprinkle a layer of Ag-Cu-Ti alloy, put it into a vacuum furnace for brazing, the heating temperature is 900 ° C ~ 1100 ° C, and the holding time is 4 ~ 20 minutes , vacuum degree 1×10 -1 ~1×10 -3 Pa, cooled to room temperature with the furnace. Then, the diamond brazing matrix with welded diamond particles is welded on the saw blade matrix at equal int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com