Diamond-iron based composite coating and application thereof as sealing layer of high-temperature valve

A composite coating, diamond technology, applied in metal material coating process, coating, metal processing equipment and other directions, can solve problems such as high requirements for service life and safety, loss of valve function, and impact on enterprise production efficiency. , to achieve the effect of good hardenability, extended service life and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

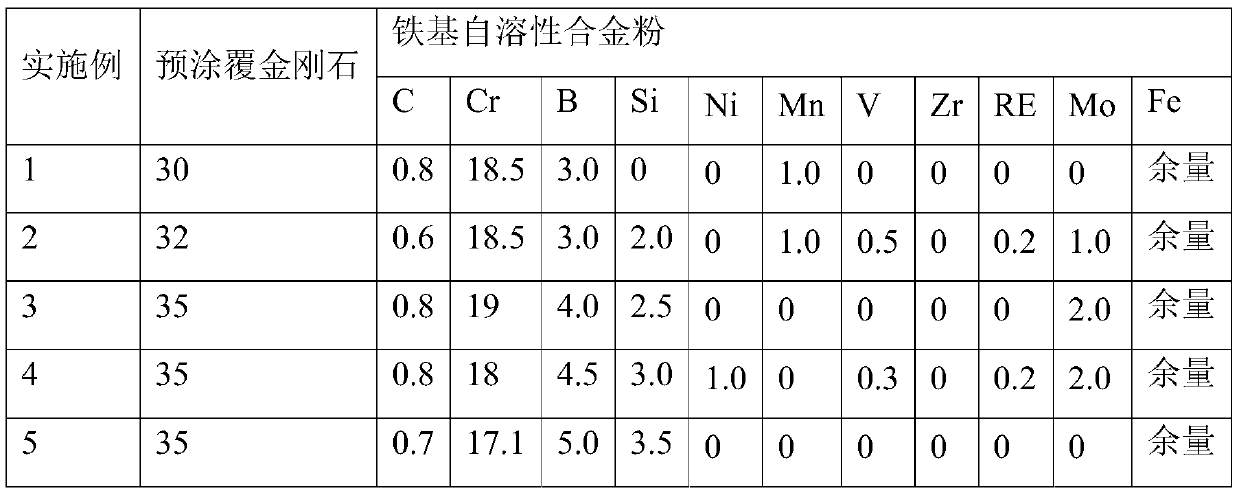

[0029] The ingredients of this embodiment are shown in Table 1.

[0030] 1. Preparation of pre-coated diamond powder

[0031] Evenly mix diamond with Ti powder and Hf powder (more than 99% of purity), put into a sealed quartz test tube, and vacuumize to 10 -3 Pa, then place the test tube in a resistance furnace and heat it to 900°C for 1 hour, then use a 200-mesh standard sieve to separate diamond from Ti powder and Hf powder to obtain pre-coated diamond powder. The quality of the alloy layer accounts for 21%-40% of the mass of the pre-coated diamond powder.

[0032] 2. Plasma spray welding

[0033] The iron-based self-dissolving alloy powder and the pre-coated diamond powder are fed separately, and coated on the surface of the steel substrate by plasma spray welding to form a composite cladding layer, which is combined with the steel substrate.

[0034] Surfacing welding process parameters are as follows: current 150A, walking speed 70mm / min, swing frequency 22min -1 , sw...

Embodiment 2

[0036] The ingredients of this embodiment are shown in Table 1.

[0037] 1. Preparation of pre-coated diamond powder

[0038] Evenly mix the diamond with Ti and Hf powder (more than 99% in purity), put it into a sealed quartz test tube, and evacuate to 10 -3Pa, then place the test tube in a resistance furnace and heat it to 900°C for 1 hour, then use a 200-mesh standard sieve to separate diamond from Ti and Hf powder to obtain pre-coated diamond powder. The mass of the transition layer accounts for 21%-40% of the mass of the pre-coated diamond powder.

[0039] 2. Plasma spray welding

[0040] The iron-based self-dissolving alloy powder and the pre-coated diamond powder are separately fed and coated on the surface of the steel substrate by plasma spray welding to form a composite cladding layer, which is combined with the steel substrate.

[0041] Surfacing welding process parameters are as follows: current 150A, walking speed 70mm / min, swing frequency 22min -1 , swing widt...

Embodiment 3

[0043] The ingredients of this embodiment are shown in Table 1.

[0044] The preparation method of this embodiment is the same as that of Example 2. The mass of the transition layer accounts for 21%-40% of the mass of the pre-coated diamond powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com