Fluidized bed device for coating film on surface of diamond, method and product prepared through method

A surface coating and fluidized bed technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the difficulty of controlling the uniformity of the coating surface, the difficulty of covering the entire surface of powder materials, and the efficiency Low and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0189] Embodiment 1 prepares the diamond 1 of surface coating coating

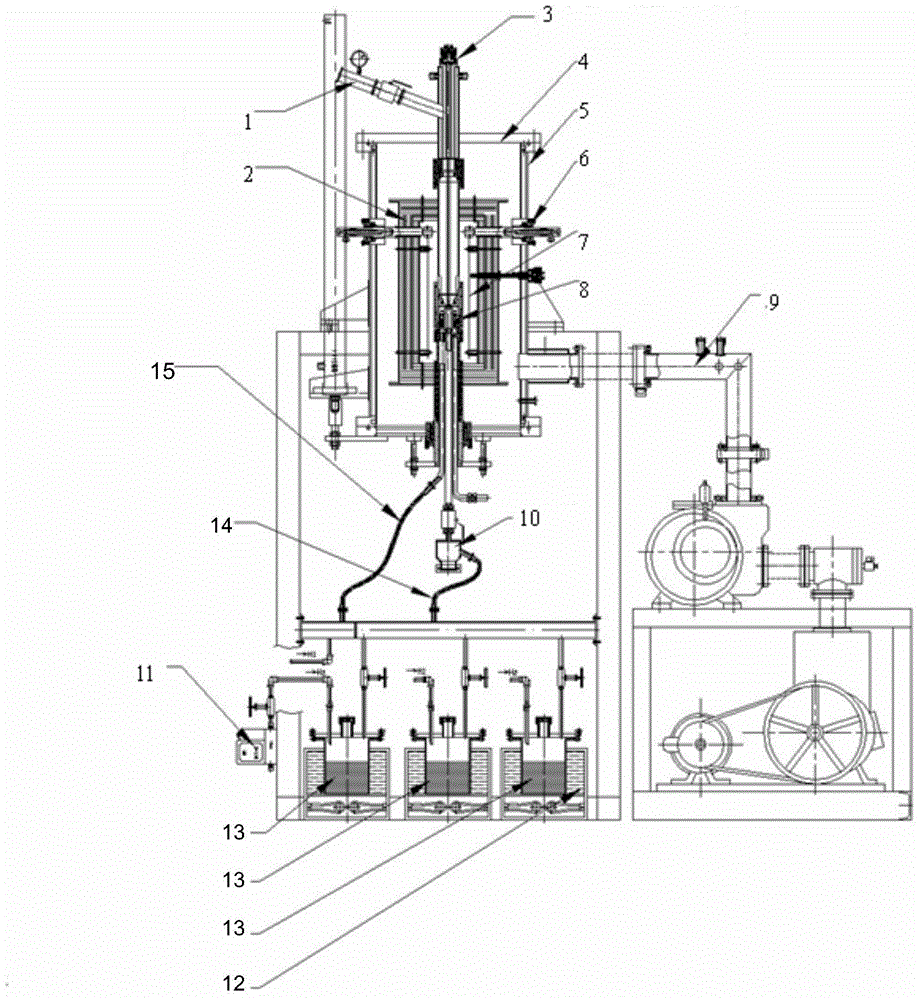

[0190] Use the fluidized bed device of diamond powder surface coating coating of the present invention, wherein heating element is molybdenum, the step of preparing the diamond of surface coating coating is as follows:

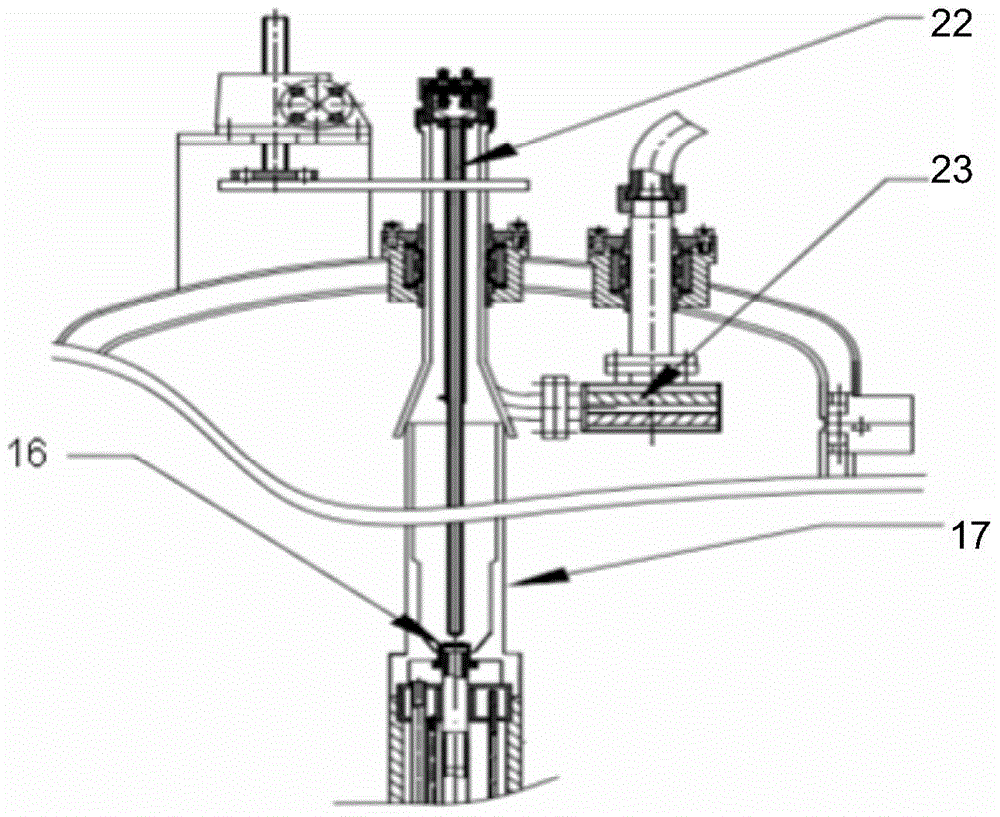

[0191] 1) Add 10nm diamond powder into the fluidized bed, and use the turbo screw lifter to adjust the gas guide rod so that it fits the mesh nozzle.

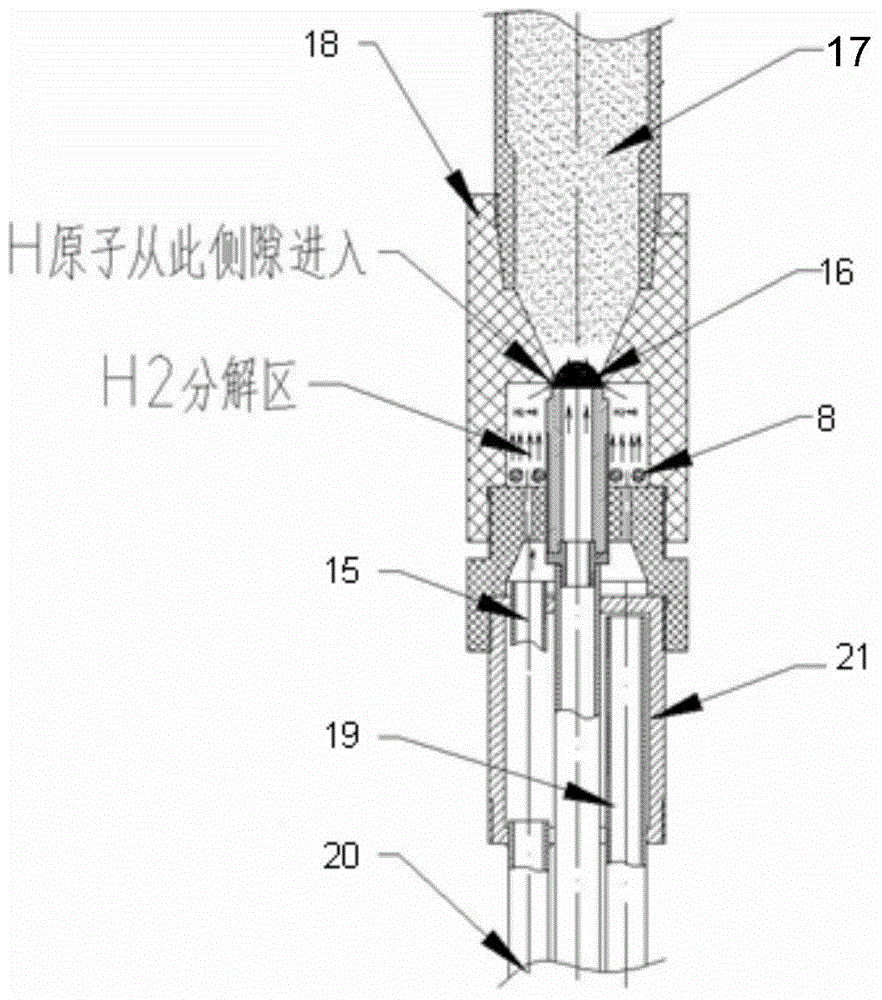

[0192] 2) Turn on the hydrogen mass flow meter, the hydrogen enters the atomic hydrogen generator through the outer ring gas pipe, and is heated by the tantalum heating wire, and the atomic hydrogen enters the fluidized bed from the side slit of the mesh nozzle.

[0193] 3) Hydrogen enters the fluidized bed through the central gas pipe and the mixing tank, and the diamond powder is fluidized by adjusting the mass flow meter. Heat the fluidized bed to 900°C, turn on the mass flow meter, and hydrogen and methane enter the fluidized bed throu...

Embodiment 2

[0198] Embodiment 2 prepares the diamond 2 of surface coating coating

[0199] Use the fluidized bed device of diamond powder surface coating coating of the present invention, wherein heating element is graphite, the step of preparing the diamond of surface coating coating is as follows:

[0200] 1) Add 10nm diamond powder into the fluidized bed, and use the turbo screw lifter to adjust the gas guide rod so that it fits the mesh nozzle.

[0201] 2) Turn on the hydrogen mass flow meter, the hydrogen enters the atomic hydrogen generator through the outer ring gas pipe, and is heated by the tantalum heating wire, and the atomic hydrogen enters the fluidized bed from the side slit of the mesh nozzle. Hydrogen enters the fluidized bed through the central gas pipe and mixing tank, and the diamond powder is fluidized by adjusting the mass flow meter.

[0202] 3) Heat the fluidized bed to 1000°C, turn on the mass flow meter, and hydrogen and methane enter the fluidized bed through th...

Embodiment 3

[0206] Embodiment 3 prepares the diamond 3 of surface coating coating

[0207] Use the fluidized bed device of diamond powder surface coating coating of the present invention, wherein heating element is molybdenum, the step of preparing the diamond of surface coating coating is as follows:

[0208] 1) Add 10nm diamond powder into the fluidized bed, and use the turbo screw lifter to adjust the gas guide rod so that it fits the mesh nozzle.

[0209] 2) Turn on the hydrogen mass flow meter, the hydrogen enters the atomic hydrogen generator through the outer ring gas pipe, and is heated by the tantalum heating wire, and the atomic hydrogen enters the fluidized bed from the side slit of the mesh nozzle. Hydrogen enters the fluidized bed through the central gas pipe and mixing tank, and the diamond powder is fluidized by adjusting the mass flow meter.

[0210] 3) Heat the fluidized bed to 1050°C, turn on the mass flow meter, and hydrogen and methane enter the fluidized bed through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com