Diamond-silicon carbide composite material, preparation method thereof and electronic equipment

A composite material and diamond technology, which is applied in the field of diamond-silicon carbide composite materials and its preparation, can solve the problems of large-scale substrate material difficulties, complex shape preparation, and low thermal conductivity of materials, so as to avoid local temperature rise and process Simple, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

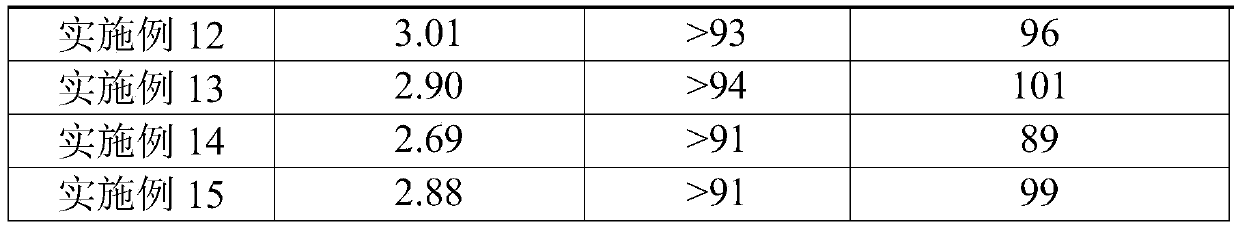

Examples

preparation example Construction

[0024] The preparation method of the diamond-silicon carbide composite material of one embodiment, comprises the following steps:

[0025] S110: mixing diamond, polycarbosilane and a plasticizer to prepare casting slurry;

[0026] Wherein, the diamond, dispersant, polycarbosilane, plasticizer and solvent are mixed in a weight ratio of 40-60:1-5:5-10:5-10:30-35. The content of each component within this range can facilitate subsequent tape casting to prepare an ultra-thin green body.

[0027] In one embodiment, the step of adding silicon powder is also included when preparing the casting slurry, and the weight ratio of silicon powder to polycarbosilane is 0.01˜0.1:1. Preferably, the weight ratio of silicon powder to polycarbosilane is 0.01˜0.05:1.

[0028] In one embodiment, the average particle size of the diamond is 30 μm˜150 μm, and the average particle size of the silicon powder is 5 μm˜15 μm. Diamond and silicon powder are controlled within a suitable particle size rang...

Embodiment 1

[0051] In this embodiment, the weight ratio of diamond, dispersant, binder, plasticizer and solvent is 50:3:6:6:35. Wherein, the dispersant is triethyl phosphate, the solvent is the azeotropic liquid of ethanol and ethyl acetate, the binder is polycarbosilane, and the plasticizer is dioctyl phthalate.

[0052] The preparation method of the diamond-silicon carbide composite material of the present embodiment comprises the following steps:

[0053] 1) Mix the diamond, dispersant, and solvent according to the above ratio, and perform ball milling for 6 hours, then add polycarbosilane and plasticizer, and continue ball milling for 12 hours to obtain casting slurry; wherein, the average particle size of diamond is 30 μm.

[0054] 2) Vacuum defoaming the cast slurry for 30 minutes under the condition of vacuum degree of -87.5KPa, and then tape-cast the defoamed slurry. The thickness of the green body after tape-casting is 0.4mm; set the height of the scraper to 1.5mm, demould after...

Embodiment 2

[0057] In this embodiment, the weight ratio of diamond, dispersant, binder, plasticizer and solvent is 50:3:6:6:35. Wherein, the dispersant is triethyl phosphate, the solvent is the azeotropic liquid of ethanol and ethyl acetate, the binder is polycarbosilane, and the plasticizer is dioctyl phthalate.

[0058] The preparation method of the diamond-silicon carbide composite material of the present embodiment comprises the following steps:

[0059] 1) Mix the diamond, dispersant, and solvent according to the above ratio, and perform ball milling for 6 hours, then add polycarbosilane and plasticizer, and continue ball milling for 12 hours to obtain casting slurry; wherein, the average particle size of diamond is 150 μm.

[0060] 2) Vacuum defoaming the cast slurry after ball milling for 30 minutes under the condition of vacuum degree of -87.5KPa; then tape-cast the defoamed slurry, and the thickness of the green body after tape-casting is 0.3mm; set The height of the scraper is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com