Two-step sintering method of diamond-B4C-SiC three-phase composite ceramic

A composite ceramic and sintering method technology, which is applied in the field of three-phase composite ceramics to achieve the effect of promoting low temperature densification, improving mechanical properties and good bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

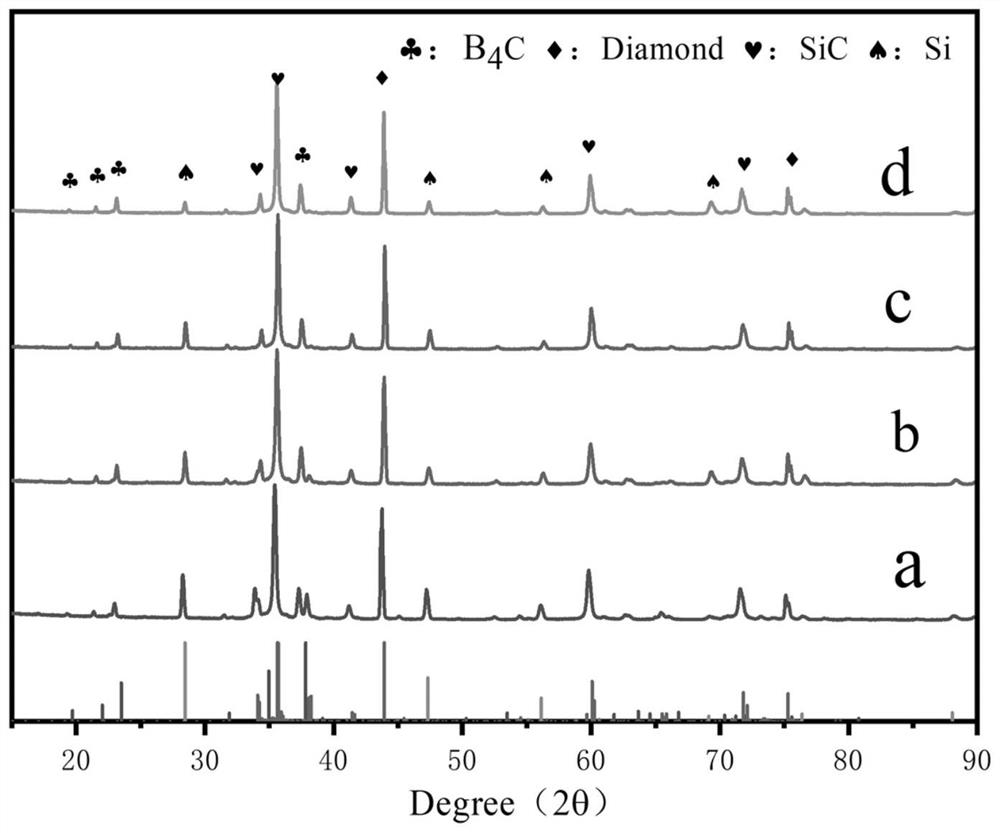

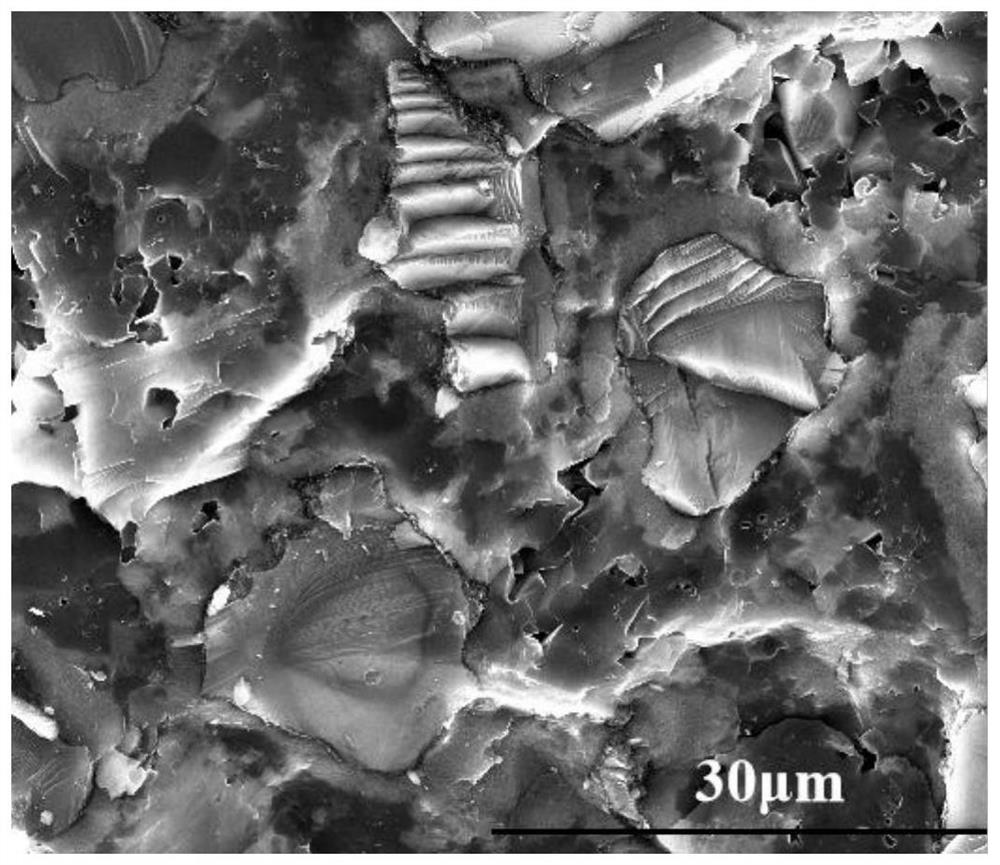

[0030] Embodiment 1 (comparative example)

[0031] A Diamond-B 4 The preparation method of C-SiC three-phase composite ceramics comprises the following steps:

[0032] (1) Take by weight 40% diamond powder, 30% Si powder, 30% B powder respectively by mass percentage, the diamond powder particle size is 40 μ m, the B powder particle size is 1 μ m, the Si powder particle size is 1 μ m, and the grinding ball is SiC, The ball-to-material ratio is 5, dispersed with anhydrous ethanol, ball milled for 6 hours and then dried by a rotary evaporator. After drying, the mixed powder (that is, diamond-Si-B ternary mixed powder) is dried in a vacuum oven for 24 hours.

[0033] (2) Disperse the diamond-Si-B ternary mixed powder through a 100-mesh sieve to prevent hard agglomeration of the powder, and weigh the powder into In the graphite mold, the inner wall of the graphite mold, the indenter and the powder are separated by graphite paper, and the graphite mold is wrapped with graphite fe...

Embodiment 2

[0038] A Diamond-B 4 The two-step sintering method of C-SiC three-phase composite ceramics comprises the following steps:

[0039] (1) Take by weight 40% diamond powder, 30% Si powder, 30% B powder respectively by mass percentage, the diamond powder particle size is 40 μ m, the B powder particle size is 1 μ m, the Si powder particle size is 1 μ m, and the grinding ball is SiC, The ball-to-material ratio is 5, dispersed with anhydrous ethanol, ball milled for 6 hours and then dried by a rotary evaporator. After drying, the mixed powder (that is, diamond-Si-B ternary mixed powder) is dried in a vacuum oven for 24 hours.

[0040] (2) Disperse the diamond-Si-B three-phase mixed powder through a 100-mesh sieve to prevent hard agglomeration of the powder, and weigh the powder into In the graphite mold, the inner wall of the graphite mold, the indenter and the powder are separated by graphite paper, and the graphite mold is wrapped with graphite felt.

[0041] (3) Put the graphite...

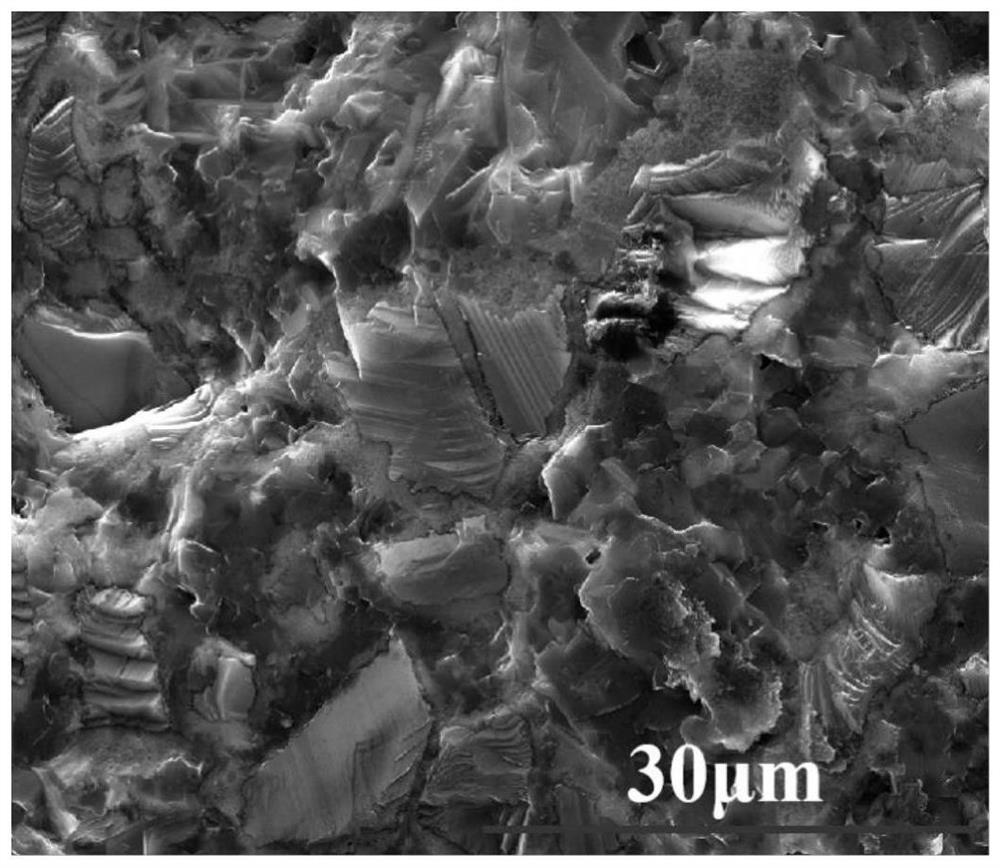

Embodiment 3

[0044] A Diamond-B 4 The two-step sintering method of C-SiC three-phase composite ceramics comprises the following steps:

[0045] (1) Take by weighing 55% diamond powder, 30% Si powder, 15% B powder respectively by mass percentage, the diamond powder particle size is 25 μ m, the B powder particle size is 3 μ m, the Si powder particle size is 3 μ m, and the grinding ball is SiC, The ball-to-material ratio is 4, dispersed with absolute ethanol, ball-milled for 12 hours, and then dried by a rotary evaporator. After drying, the mixed powder (that is, diamond-Si-B ternary mixed powder) is placed in a vacuum drying oven for 12 hours.

[0046] (2) Disperse the diamond-Si-B ternary mixed powder through a 100-mesh sieve to prevent hard agglomeration of the powder, and weigh the powder into In the graphite mold, the inner wall of the graphite mold, the indenter and the powder are separated by graphite paper, and the graphite mold is wrapped with graphite felt.

[0047] (3) Put the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com