Inverter-integrated electric compressor

A technology for electric compressors and inverters, which is applied to machines/engines, liquid fuel engines, electric components, etc., can solve the problems of reduced noise suppression, longer wiring components, and increased inductive components, and achieves noise suppression. Improved effect, downsizing, and effective cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

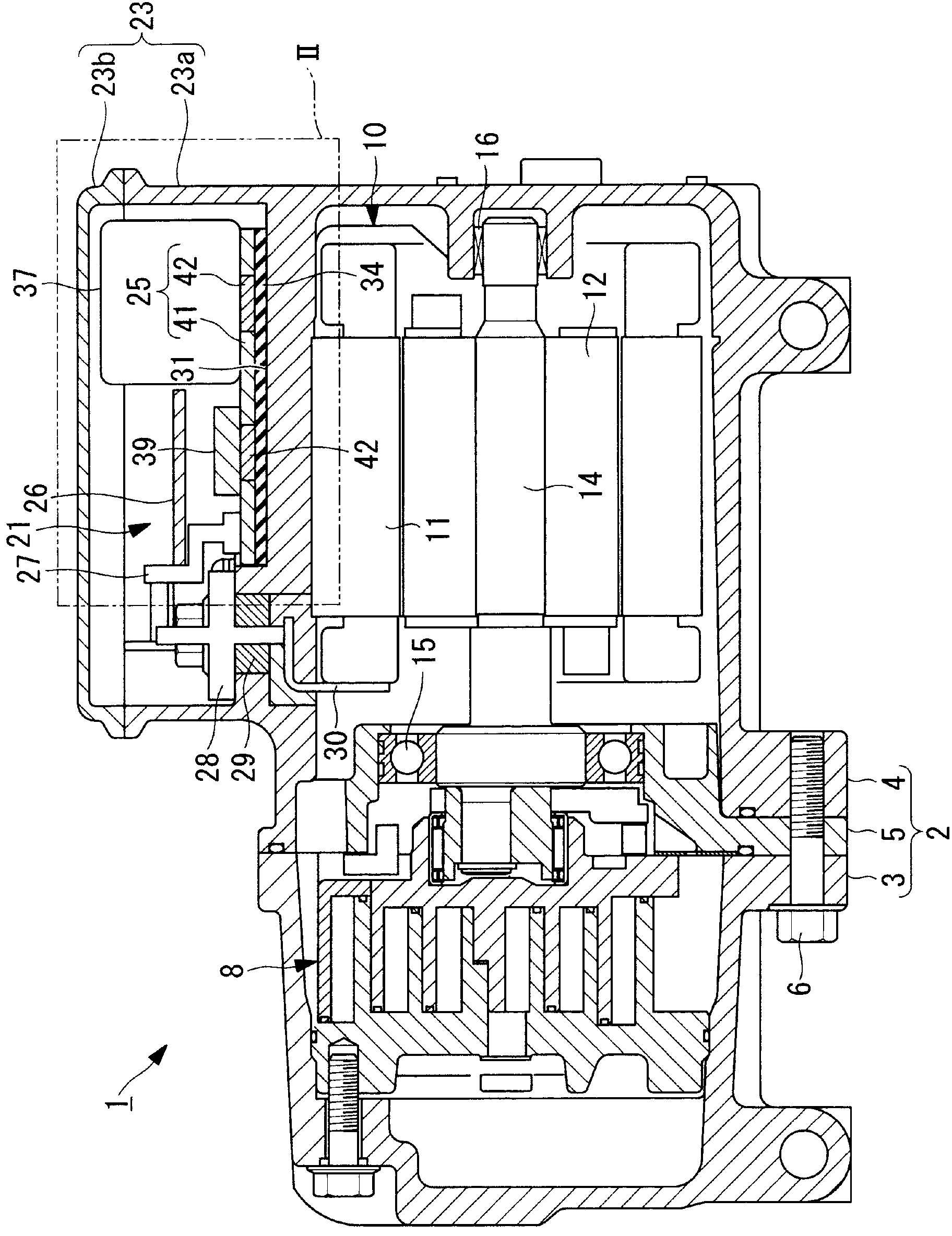

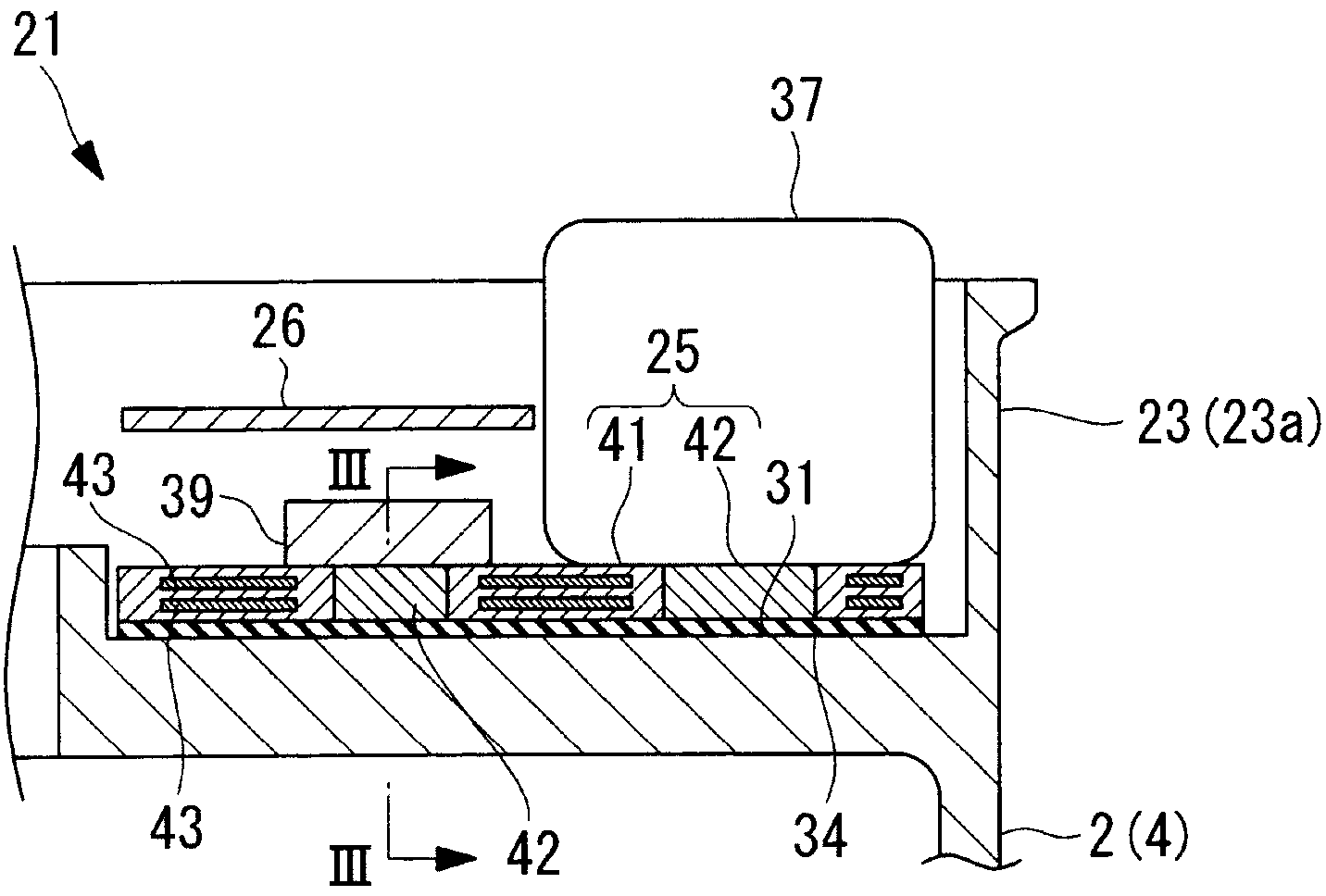

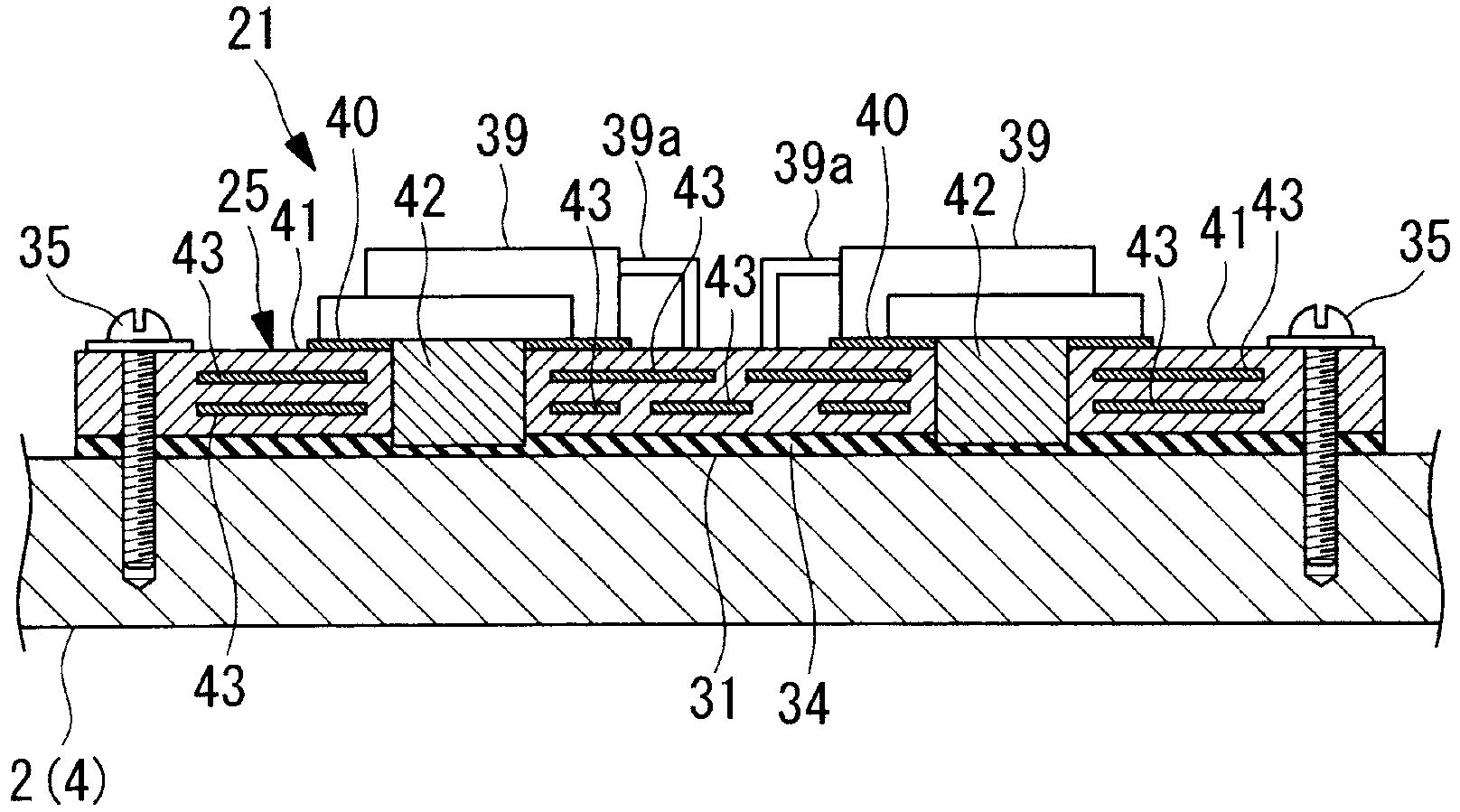

[0057] Figure 1 ~ Figure 4 Showing the first embodiment of the present invention, figure 1 It is a longitudinal sectional view for explaining a schematic structure of the inverter-integrated electric compressor according to the first embodiment of the present invention. This inverter-integrated electric compressor is a compressor used in a vehicle air conditioner, and its drive rotation speed is controlled by an inverter.

[0058] The inverter-integrated electric compressor 1 has an aluminum alloy casing 2 constituting its outer casing, and the casing 2 sandwiches a bearing casing 5 between a compressor-side casing 3 and a motor-side casing 4 and screws it. 6. It is formed by fastening and fixing the compressor side casing 3 and the motor side casing 4.

[0059] A known scroll compression mechanism 8 is housed in the compressor-side housing 3 . In addition, a stator 11 and a rotor 12 constituting the motor 10 are housed in the motor-side housing 4 . The scroll compression...

no. 2 approach

[0080] Figure 5 It is a longitudinal sectional view showing an inverter-integrated electric compressor according to a second embodiment of the present invention. In this inverter-integrated electric compressor 51, the structure other than the inverter 52 is the same as that of figure 1 Since the inverter-integrated electric compressor 1 of the first embodiment shown is the same, the same reference numerals are assigned to the respective parts, and description thereof will be omitted.

[0081] This inverter-integrated electric compressor 51 is a type in which an inverter box 53 accommodating an inverter 52 is provided on the rear end surface of the casing 2 (motor-side casing 4 ). The main reason for providing the inverter box 53 on the rear end surface of the casing 2 in this way is that when the inverter-integrated electric compressor 51 is installed in the engine room of a hybrid vehicle or an electric vehicle, the inverter box 53 In the case of an elongated shape that do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com