Preparation method of silicon nitride ceramic substrate

A technology of silicon nitride ceramics and silicon nitride powder is applied in the field of preparation of silicon nitride ceramic substrates, which can solve the problems of high cost of silicon nitride substrates, affecting product yield and high local temperature, and improving performance and yield. , The effect of avoiding product cracks and slowing down the reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of silicon nitride ceramic substrate is as follows:

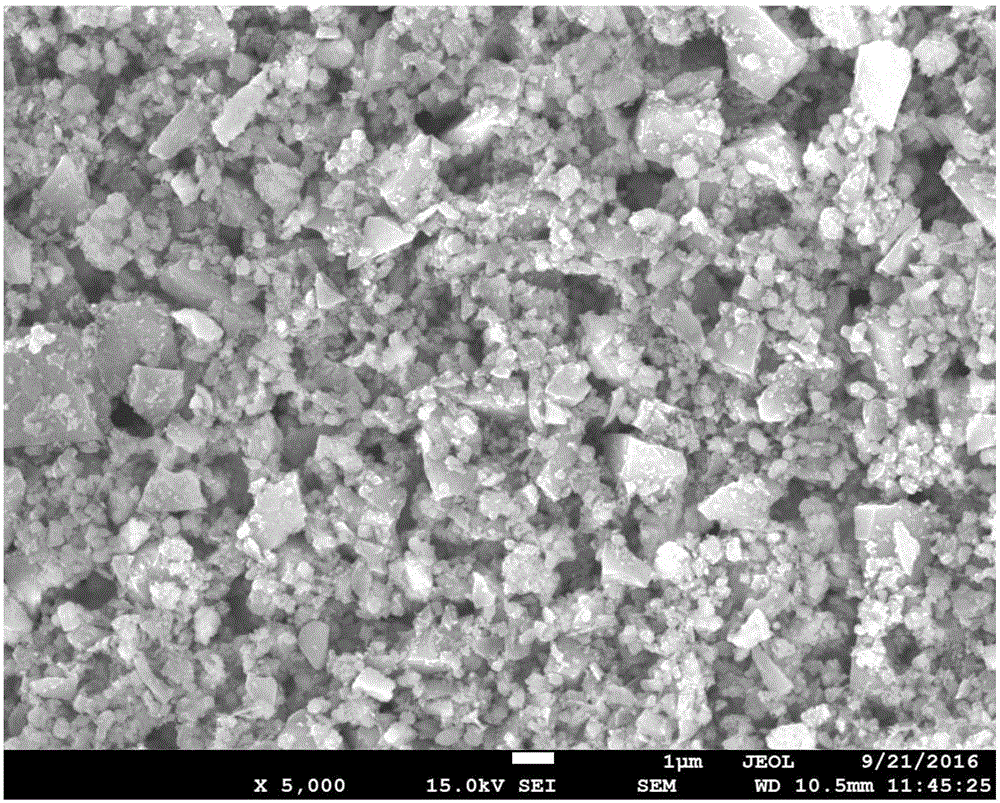

[0033] A: 15.75g silicon powder (median particle size is 10μm), 68.25g silicon nitride powder (median particle size is 0.2μm), 5.7g zirconia powder (ZrO 2 ), 2g magnesium oxide powder (MgO) and 8.3g gadolinium oxide powder (Gd 2 o 3 ) mixes, adds 1.68g castor oil, then adds 120g dehydrated alcohol-butanone mixed solvent (the mass ratio of dehydrated alcohol and butanone is 1:2), carries out ball milling for the first time with silicon nitride ball as ball milling medium, The ball milling rate is 80 rpm, the time is 24h; then add 4.2g adhesive polyvinyl butyral and 6.72g plasticizer for the second ball milling, the ball milling rate is 80 rpm, the time is 24h, wherein , the plasticizer is dioctyl sebacate and diisobutyl phthalate with a mass ratio of 1:1. After the ball milling is completed, it is defoamed under the condition of a vacuum of 0.1Pa to obtain a dynamic viscosity of 3000mPa at 25°...

Embodiment 2

[0038] The preparation method of silicon nitride ceramic substrate is as follows:

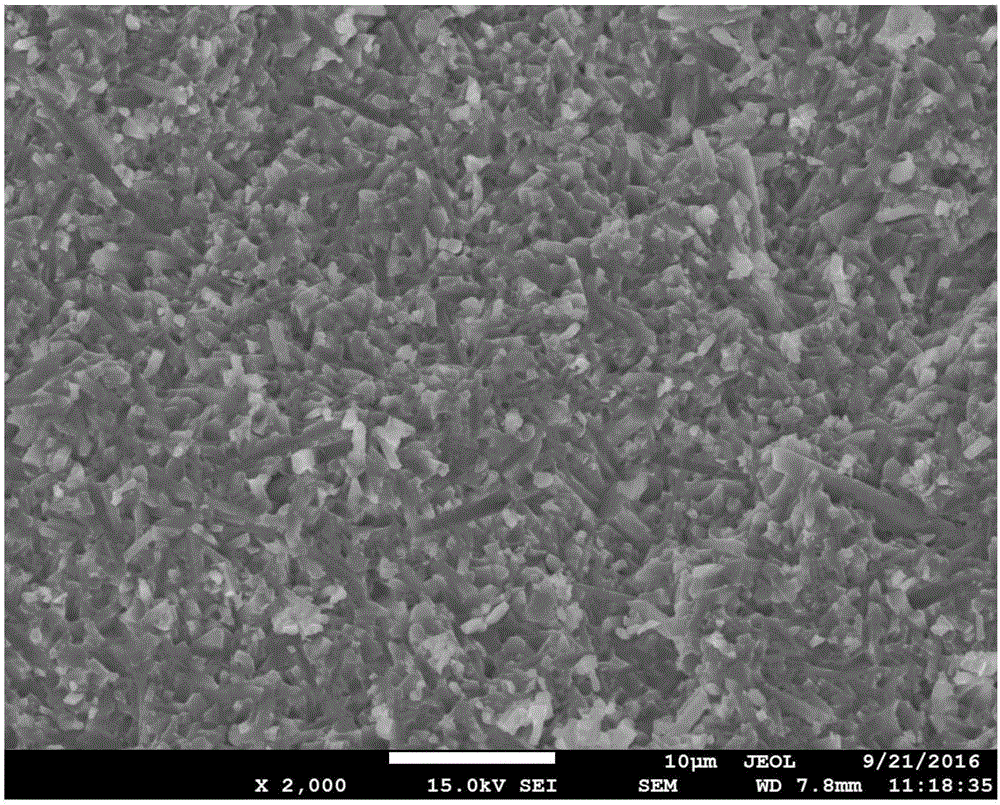

[0039] A: 47.25g silicon powder (median particle size is 6.5μm), 36.75g silicon nitride powder (median particle size is 0.2μm), 5.7gZrO 2 powder, 2g MgO powder and 8.3g Gd 2 o3 Powder mixing, add 1.68g castor oil, then add 150g dehydrated alcohol-butanone mixed solvent (the mass ratio of dehydrated alcohol and butanone is 1:2), carry out ball milling for the first time with silicon nitride ball as ball milling medium, The ball milling rate is 100 rpm, the time is 20h; then add 14.28g adhesive polyvinyl butyral and 10.5g plasticizer for the second ball milling, the ball milling rate is 100 rpm, the time is 24h, wherein , the plasticizer is dioctyl sebacate and diisobutyl phthalate with a mass ratio of 1:1. After the ball milling is completed, it is defoamed under the condition of a vacuum of 0.1Pa to obtain a dynamic viscosity of 20000mPa at 25°C. S slurry, the dynamic viscosity at 25°C is mea...

Embodiment 3

[0044] The preparation method of silicon nitride ceramic substrate is as follows:

[0045] A: 47.25g silicon powder (median particle size is 6.5μm), 36.75g silicon nitride powder (median particle size is 0.2μm), 5.7gZrO 2 powder, 2g MgO powder and 8.3g Gd 2 o 3 Powder mixing, add 1.68g castor oil, then add 150g dehydrated alcohol-butanone mixed solvent (the mass ratio of dehydrated alcohol and butanone is 1:2), carry out ball milling for the first time with silicon nitride ball as ball milling medium, The ball milling rate is 100 rpm, the time is 20h; then add 14.28g adhesive polyvinyl butyral and 10.5g plasticizer for the second ball milling, the ball milling rate is 100 rpm, the time is 24h, wherein , the plasticizer is dioctyl sebacate and diisobutyl phthalate with a mass ratio of 1:1. After the ball milling is completed, it is defoamed under the condition of a vacuum of 0.1Pa to obtain a dynamic viscosity of 30000mPa at 25°C. S slurry, the dynamic viscosity at 25°C is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com