PCD grinding wheel capable of performing positive rake angle processing and provided with ordered micro slot structure and manufacturing method for PCD grinding wheel

A grinding wheel and micro-groove technology, which is applied in the direction of bonded grinding wheels, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the quality of the processed surface, reducing the service life of the grinding wheel, and difficult to ensure the processing accuracy, so as to improve the grinding performance and grinding Cutting efficiency, enhanced chip removal ability, and improved grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the invention will be further described below in conjunction with the drawings.

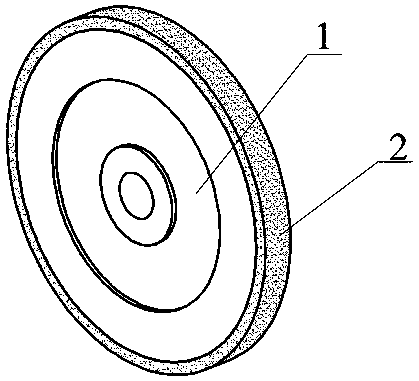

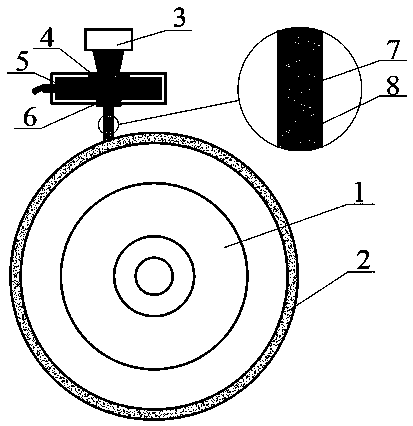

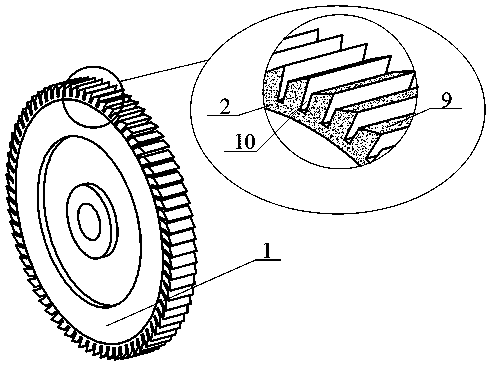

[0027] See Figure 1 to Figure 4 , PCD grinding wheel with a micro-grooved structure that can be processed with a positive rake angle, characterized in that the grinding wheel is composed of a hub 1, a PCD film 2, a large number of micro-grinding units 9 with a positive rake angle 11, and a micro-groove 10 with high aspect ratio ; The outer circumferential surface of the hub 1 is deposited with a PCD film 2 with a thickness of 1 to 2mm; the outer circumferential surface of the PCD film 2 has a large number of axial lengths equal to the thickness of the grinding wheel, a circumferential width of only tens of microns, and a depth of hundreds of microns. Microgrooves 10 with an aspect ratio of several tens, between two adjacent microgrooves 10 are microgrinding units 9 with a positive rake angle 11, and the microgrooves 10 and microgrinding units 9 are arranged in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com