SiC-ferrite/carbon material high-temperature wave absorption composite material and preparation method thereof

A carbonaceous material and composite material technology, applied in electrical components, antennas and other directions, can solve the problems of complex processing of absorbing materials, poor absorbing effect and high cost, achieve high yield, improve absorbing performance, and avoid graphitization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

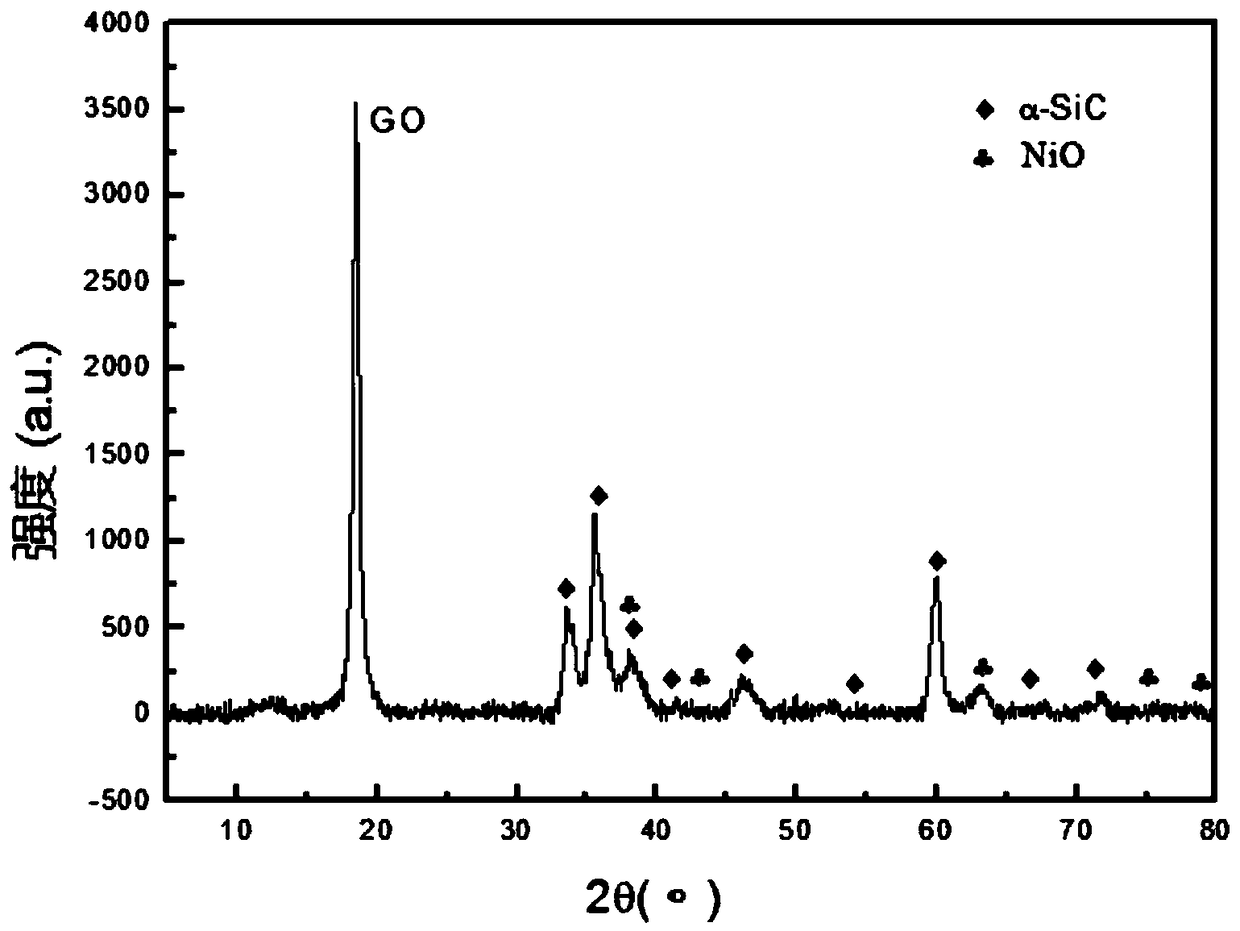

[0025] Embodiment 1: The SiC-ferrite / carbonaceous material high-temperature wave-absorbing composite material of this embodiment is composed of ferrite, silicon carbide and carbonaceous materials, wherein the carbonaceous materials are graphene, reduced graphene, oxide Graphene, conductive carbon black or carbon nanotubes; carbonaceous materials are graphene, reduced graphene or graphene oxide, ferrite and silicon carbide are supported on graphene sheets; carbonaceous materials are conductive carbon black, conductive carbon Black is evenly mixed with ferrite and silicon carbide; the carbonaceous material is carbon nanotubes, and ferrite, silicon carbide and carbon nanotubes are evenly mixed.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment is different from Embodiment 1 in that the ferrite is nickel oxide, iron oxide or cobalt oxide. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the preparation method of the SiC-ferrite / carbonaceous material high-temperature wave-absorbing composite material described in specific embodiment one is carried out according to the following steps:

[0028] 1. Silicon carbide surface pretreatment:

[0029] a. Add silicon carbide with a particle size of 1-10 μm to a silicon carbide ball mill for 12h-24h; put it into a tube furnace, and heat it up to 500-600°C for 2h-4h under air or nitrogen for oxidation treatment to remove surface impurities the goal of;

[0030] b. Disperse silicon carbide in an acidic hydrophilic solution and stir for 2-3 hours, then ultrasonically disperse for 1-2 hours, and microwave for 1-2 hours to improve its hydrophilicity; then wash with distilled water, filter, and dry at 15-30°C dry to obtain hydrophilic silicon carbide;

[0031] 2. One-pot synthesis of SiC-ferrite / carbonaceous materials:

[0032] a. Weigh hydrophilic silicon carbide, ferrite soluble salt, flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com