Patents

Literature

305 results about "High power electronics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Power Electronics (6880) The High Power Electronics Branch serves as the principal NRL resource for the science and technology of solid state high-power electronic devices.

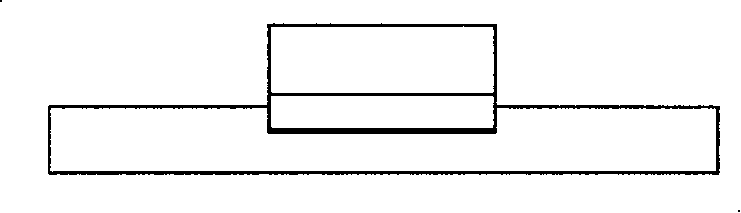

Carbon nanotube array and method for forming same

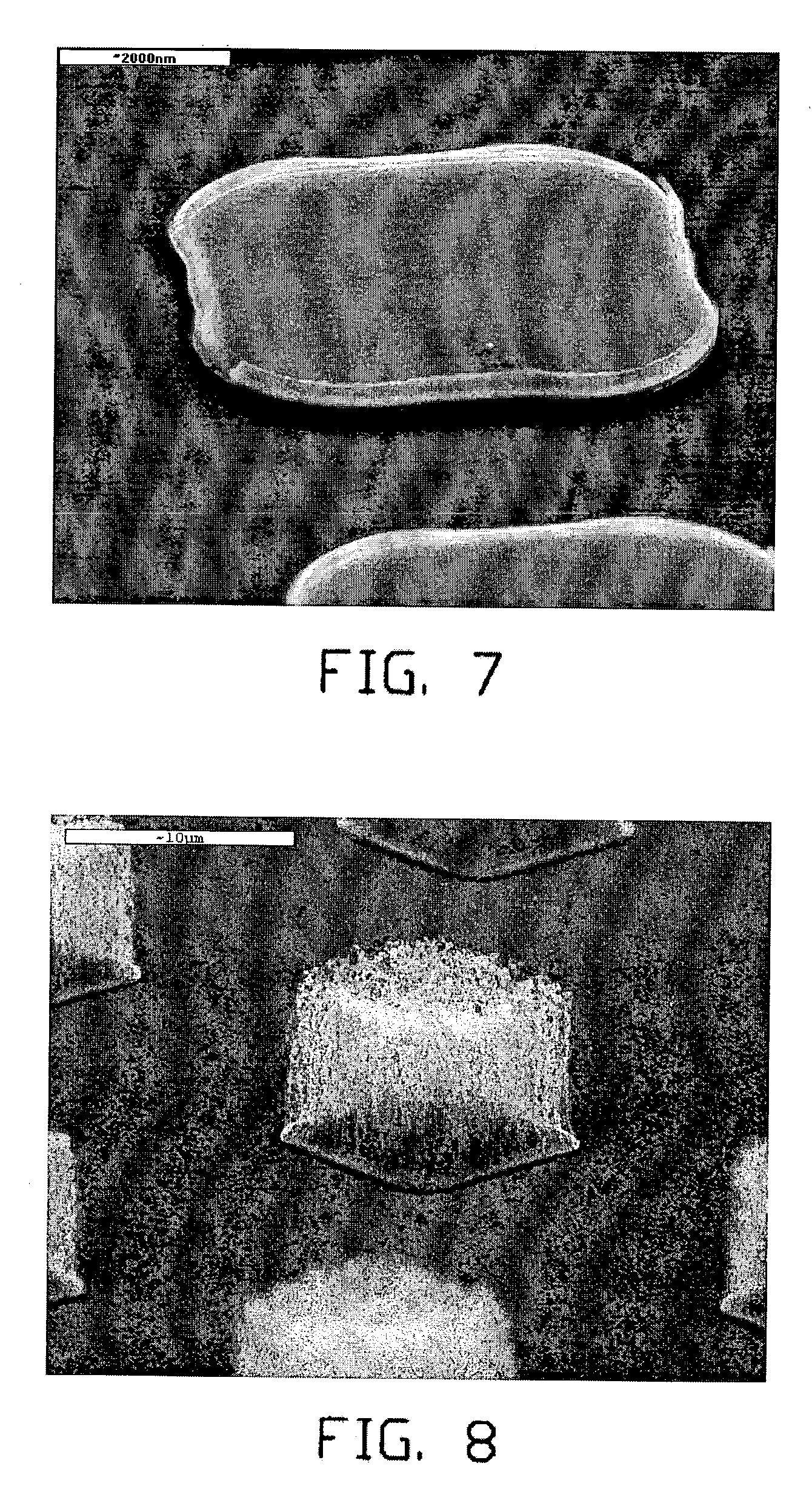

ActiveUS7160532B2Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceCarbon nanotube

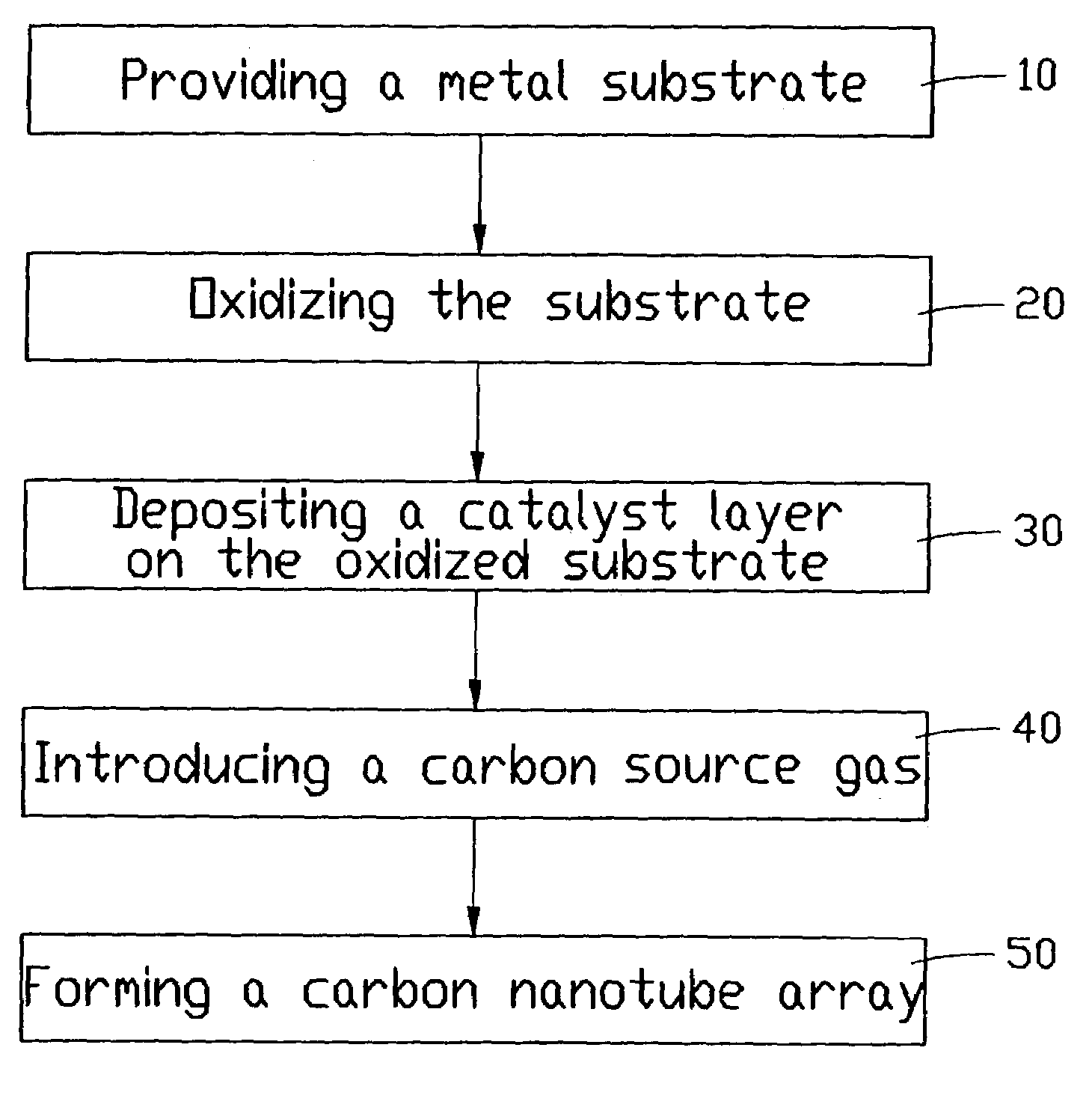

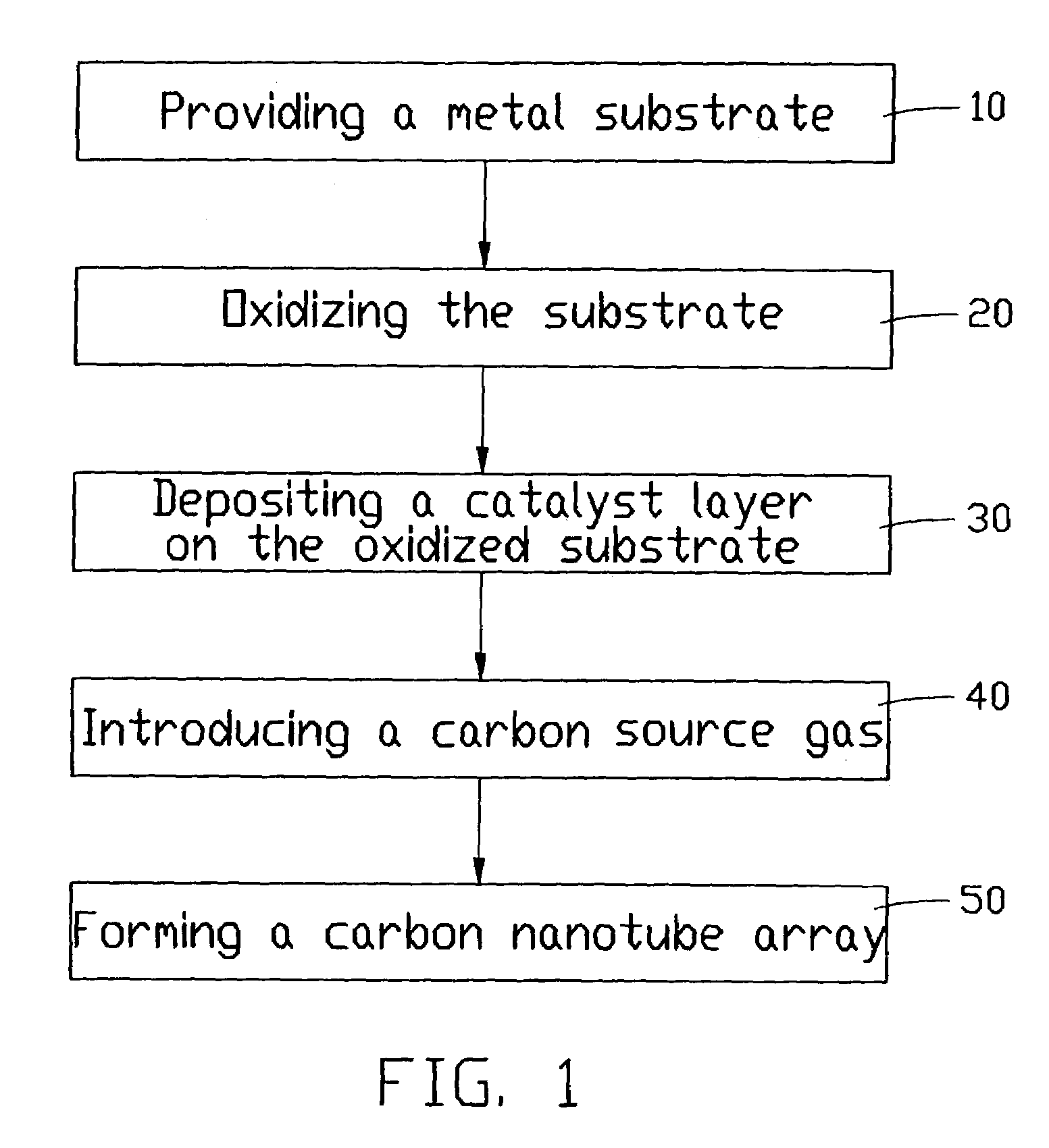

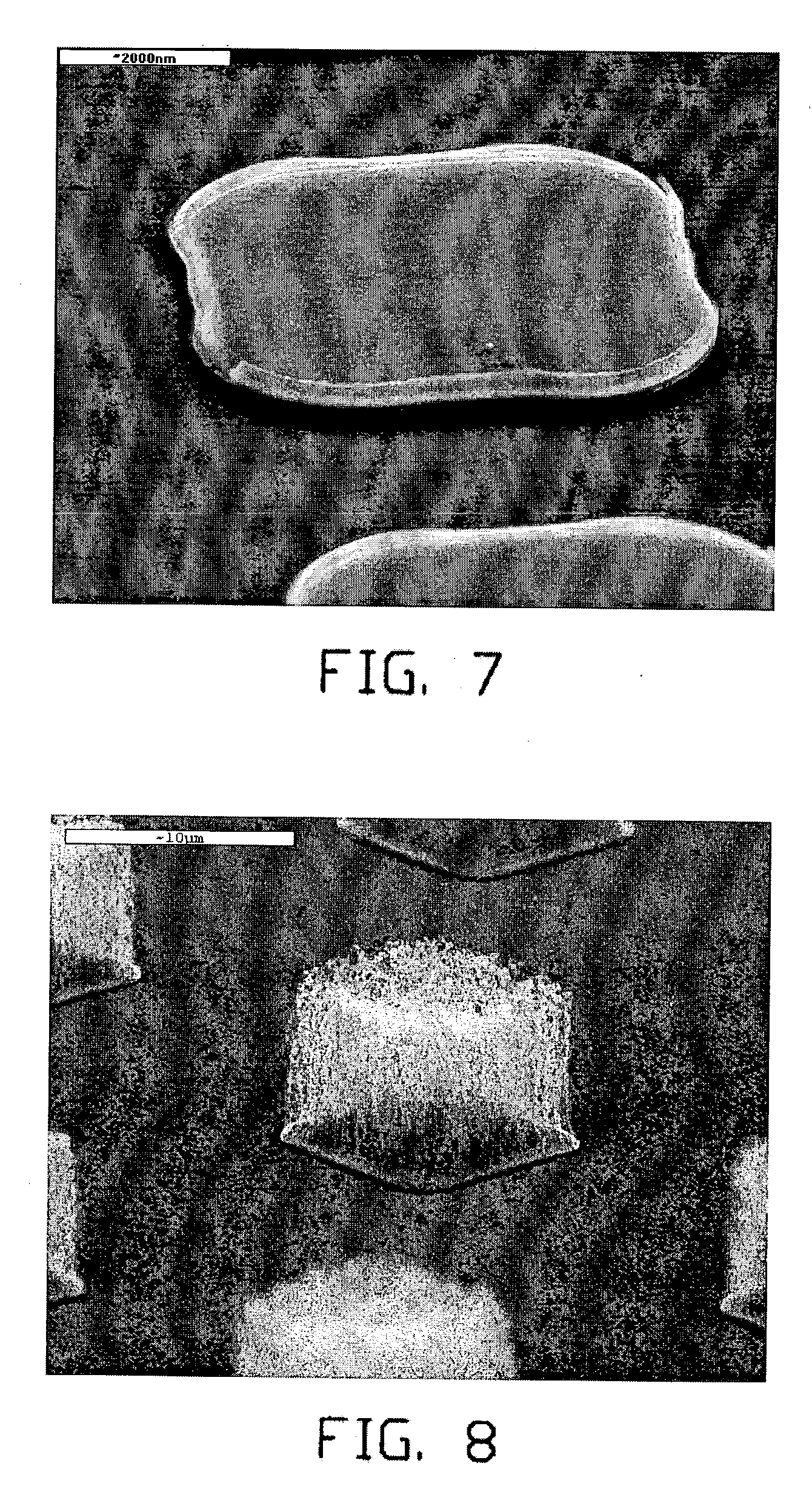

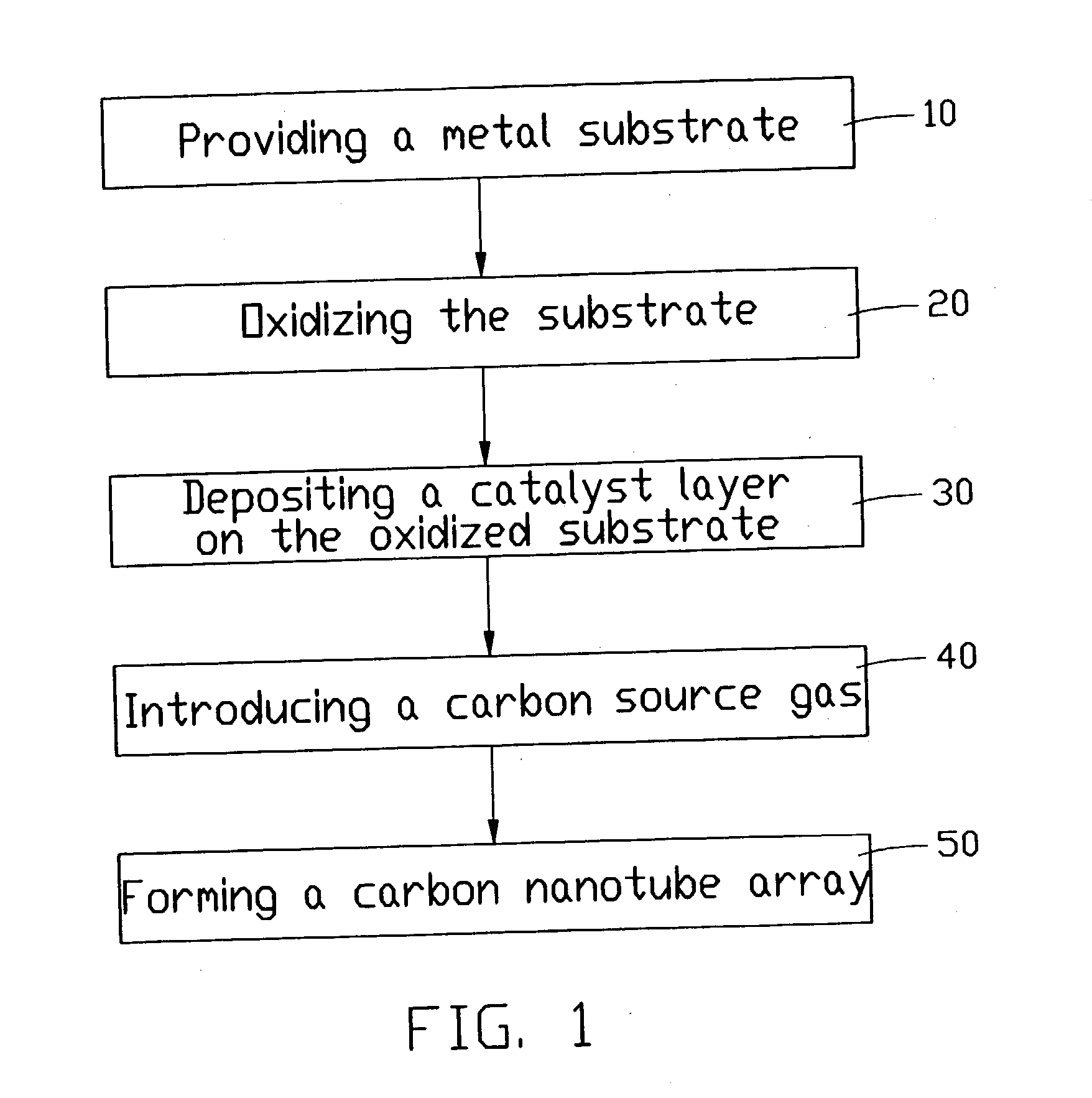

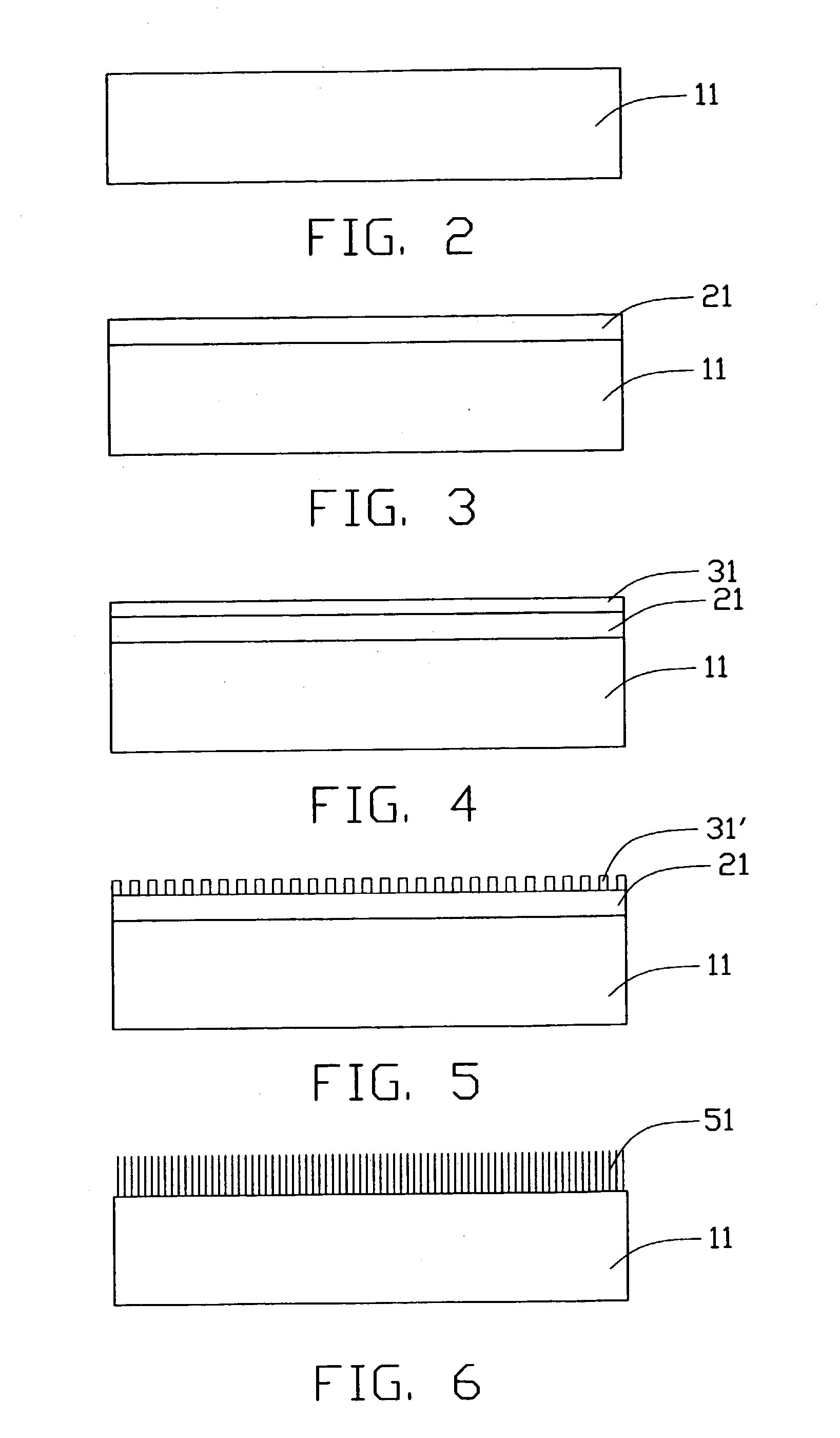

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

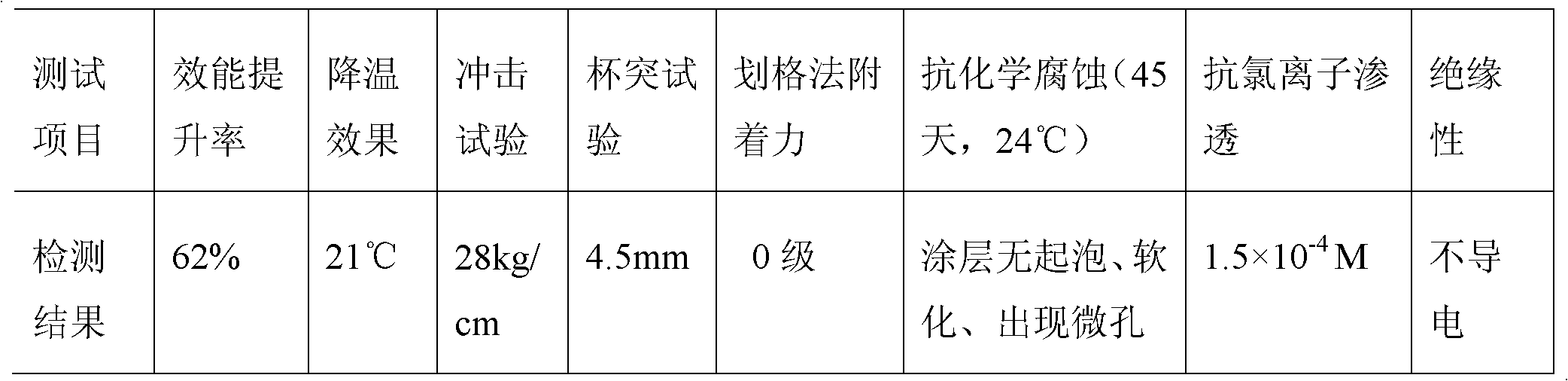

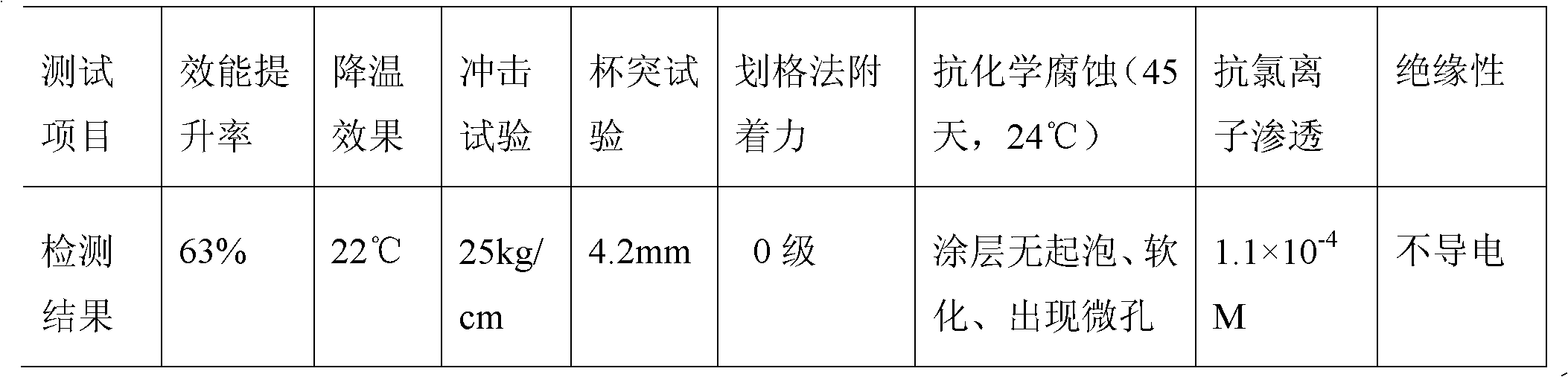

Environmental-protection anti-corrosive heat-dissipation powder paint, and preparation method and application thereof

ActiveCN102061121AFacilitate cross-linkingImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsHexagonal boron nitrideCooling effect

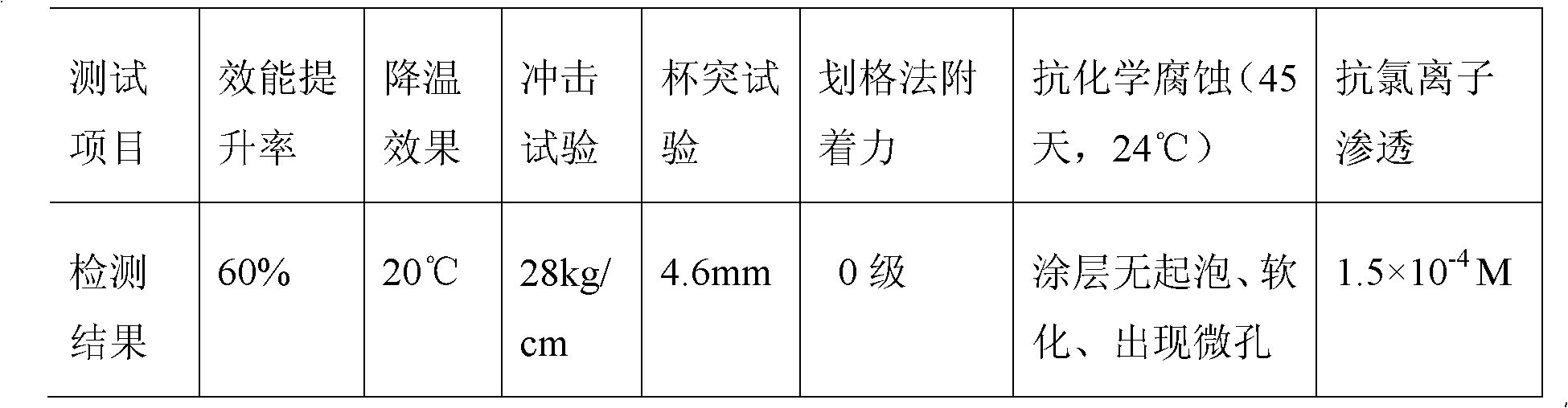

The invention discloses an environmental-protection anti-corrosive heat-dissipation powder paint, and a preparation method and application thereof. The environmental-protection anti-corrosive heat-dissipation powder paint comprises the following raw materials in parts by weight: 40-90 parts of matrix resin, 2-40 parts of curing agent, 0.5-10 parts of carbon nanotube, 0.5-2 parts of additive, 0-4.5 parts of hexagonal boron nitride, 0-15 parts of aluminum nitride, 0-10 parts of magnesium nitride, 0-10 parts of silicon carbide and 5-30 parts of pigment and filler. The composition and proportioning of the raw materials of the powder paint disclosed by the invention are scientific and reasonable. The experimental result indicates that the powder paint has the advantages of favorable heat-dissipation effect, high efficacy enhancement rate (higher than 60%) and favorable cooling effect (more than 20 DEG C), and can effectively solve the problem of poor heat-dissipation effect in the high-power electronic product, thereby prolonging the service life of the electronic product. The powder paint disclosed by the invention is free of organic solvent, and is environment-friendly and safe; the powder paint disclosed by the invention also has favorable comprehensive properties, such as flexibility, hardness, adhesive force and the like, and stable chemical properties; and the coating formed by the powder paint has the advantages of high corrosion resistance and shock resistance, favorable insulation property and wide application range.

Owner:TIGER DRYLAC TAICANG

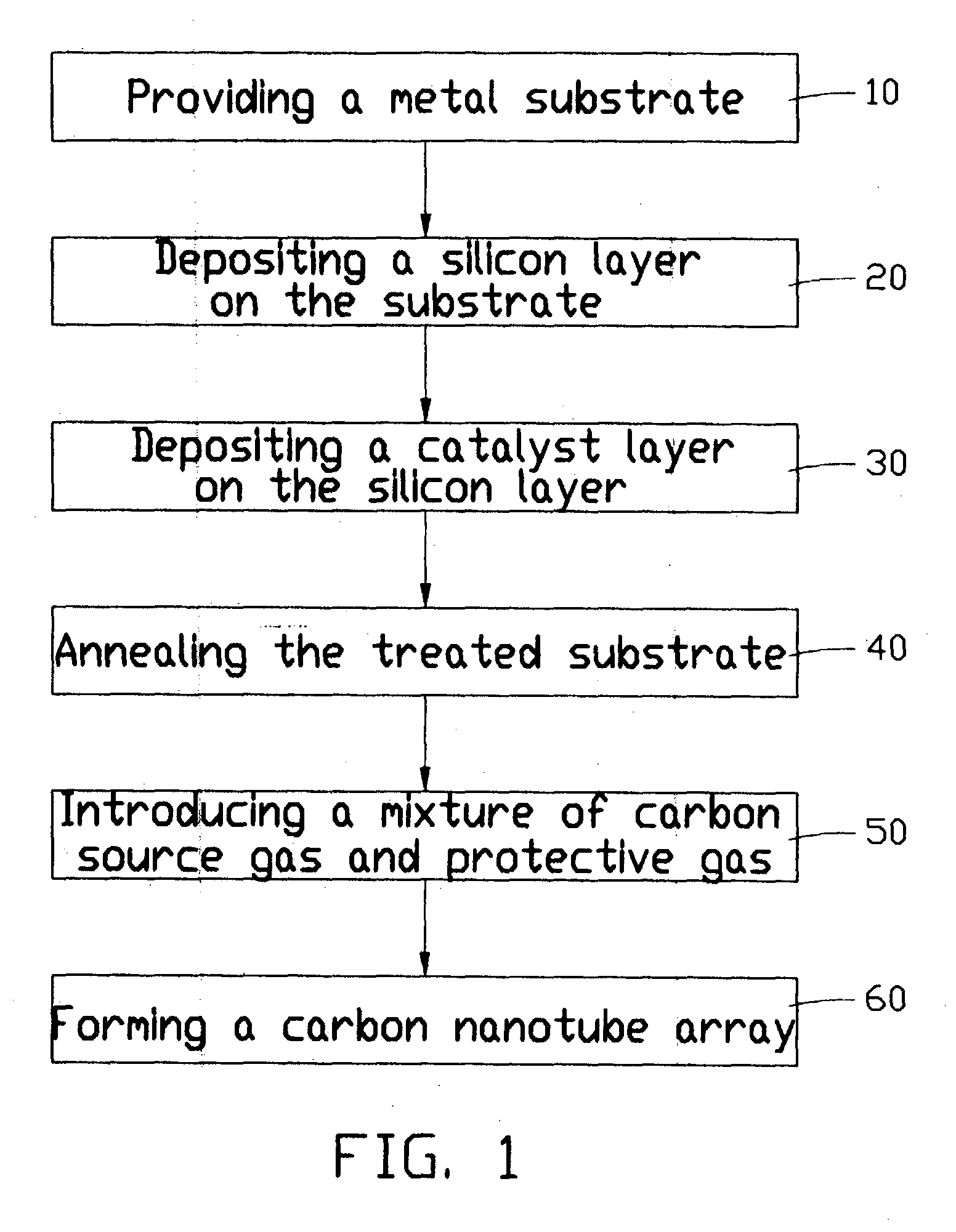

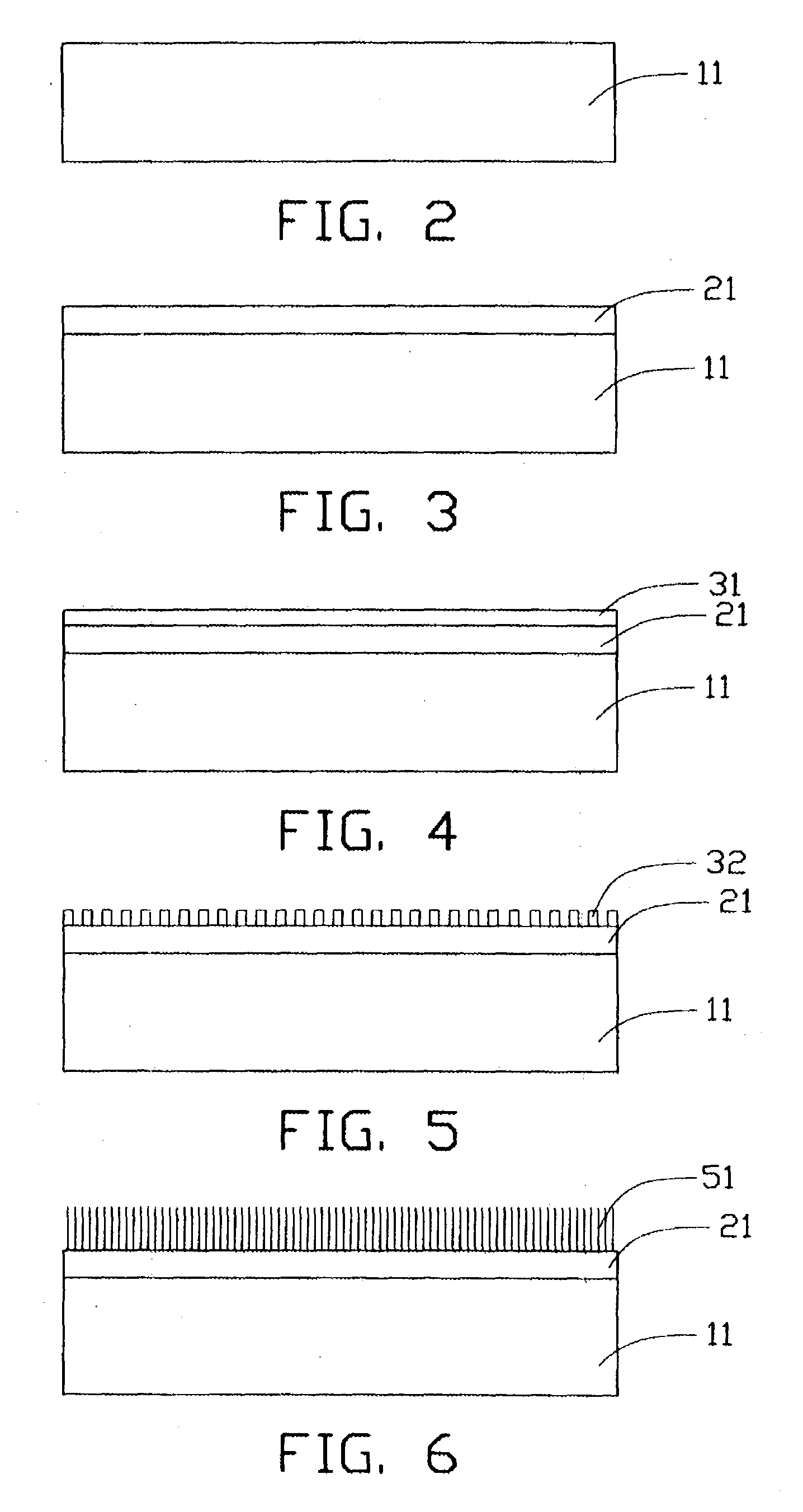

Carbon nanotube array and method for forming same

ActiveUS20040101468A1Damage formationInhibition formationMaterial nanotechnologyLayered productsField emission deviceMetallic materials

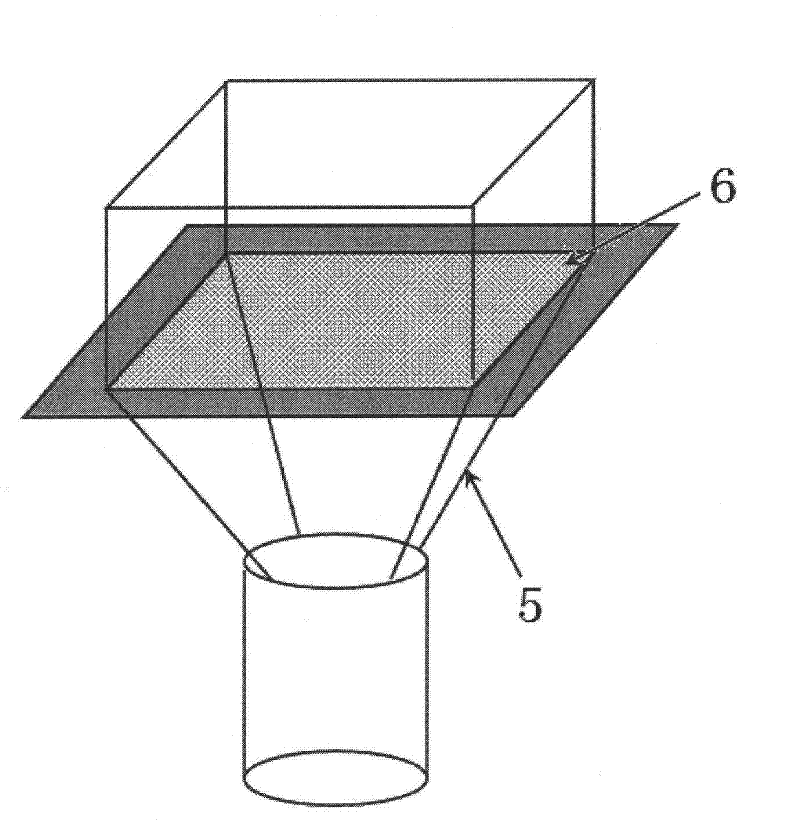

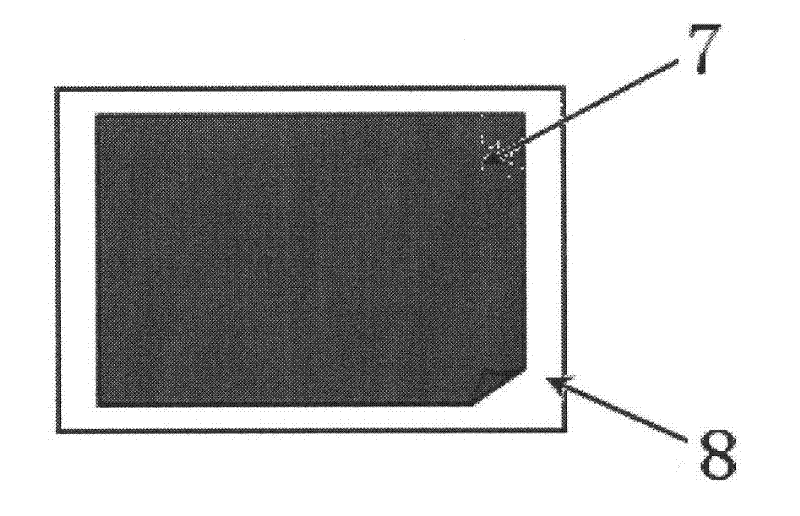

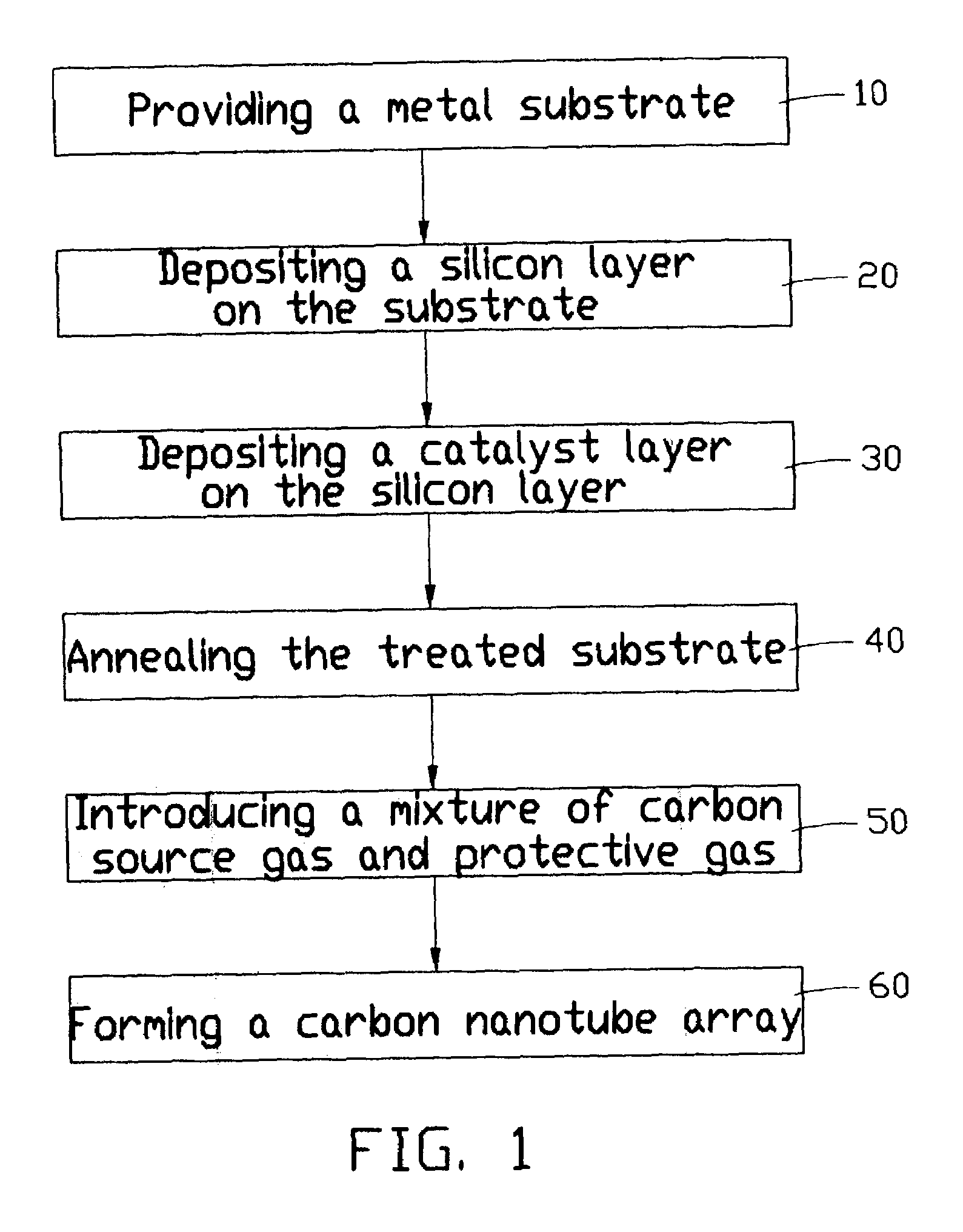

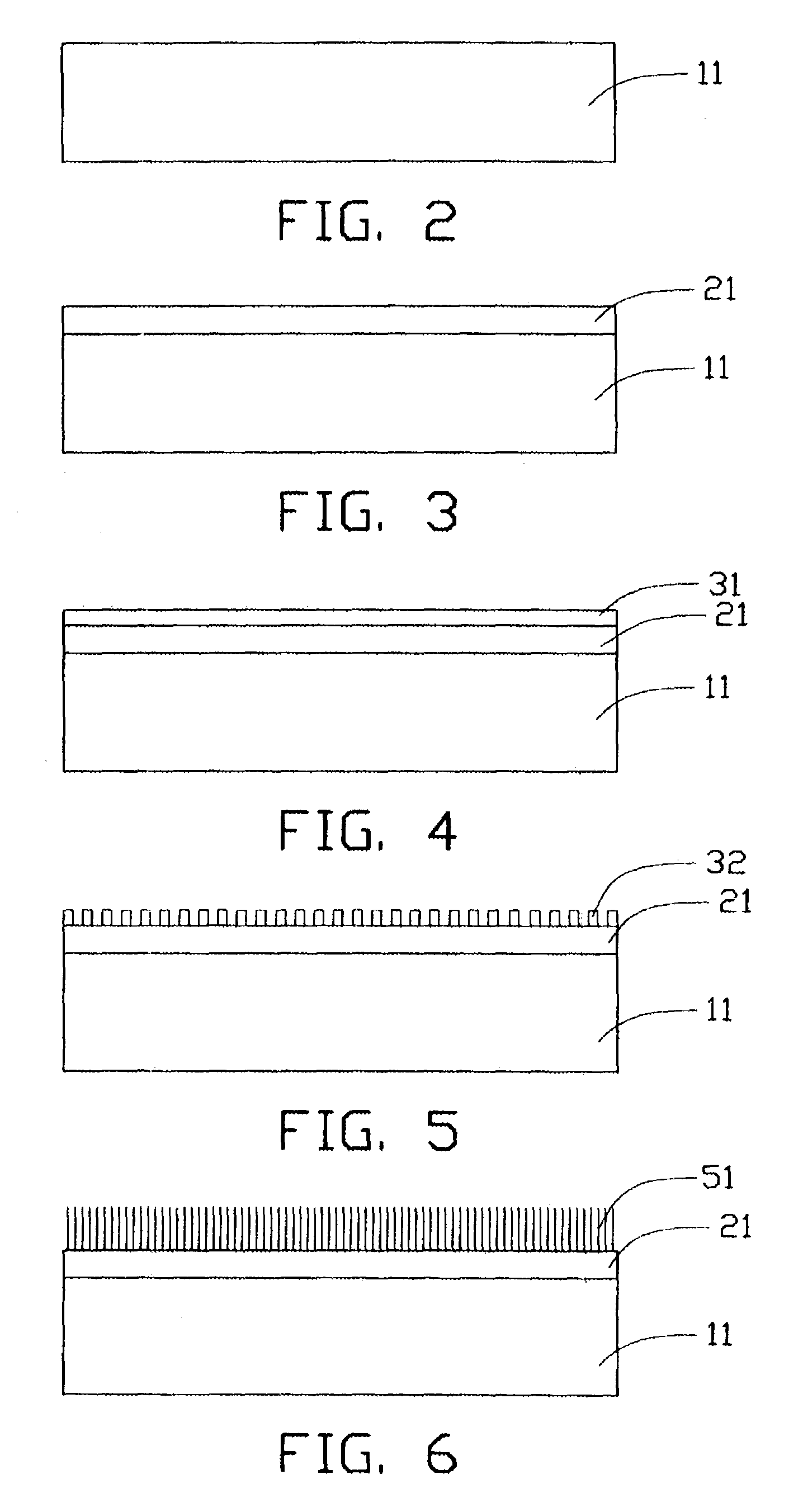

A method for forming a carbon nanotube array on a metal substrate includes the following steps: providing a metal substrate (11); depositing a silicon layer (21) on a surface of the metal substrate; depositing a catalyst layer (31) on the silicon layer; annealing the treated substrate; heating the treated substrate up to a predetermined temperature in flowing protective gas; introducing a carbon source gas for 5-30 minutes; and thus forming a carbon nanotube array (51) extending from the treated substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

Carbon nanotube array and method for forming same

ActiveUS20040184981A1Damage formationInhibition formationMaterial nanotechnologyFibre chemical featuresField emission deviceMetallic materials

A method for forming a carbon nanotube array using a metal substrate includes the following steps: providing a metal substrate (11); oxidizing the metal substrate to form an oxidized layer (21) thereon; depositing a catalyst layer (31) on the oxidized layer; introducing a carbon source gas; and thus forming a carbon nanotube array (61) extending from the metal substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

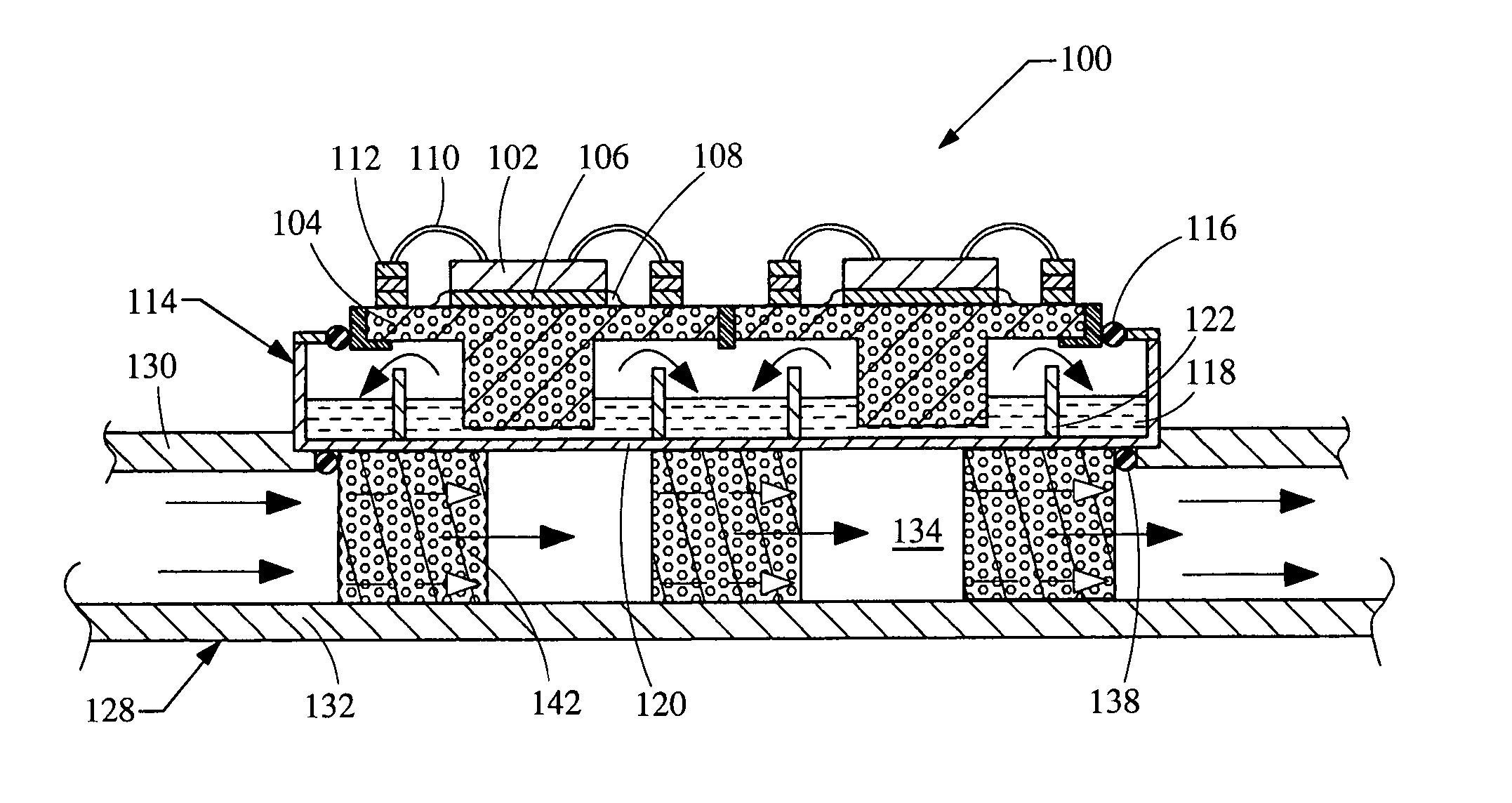

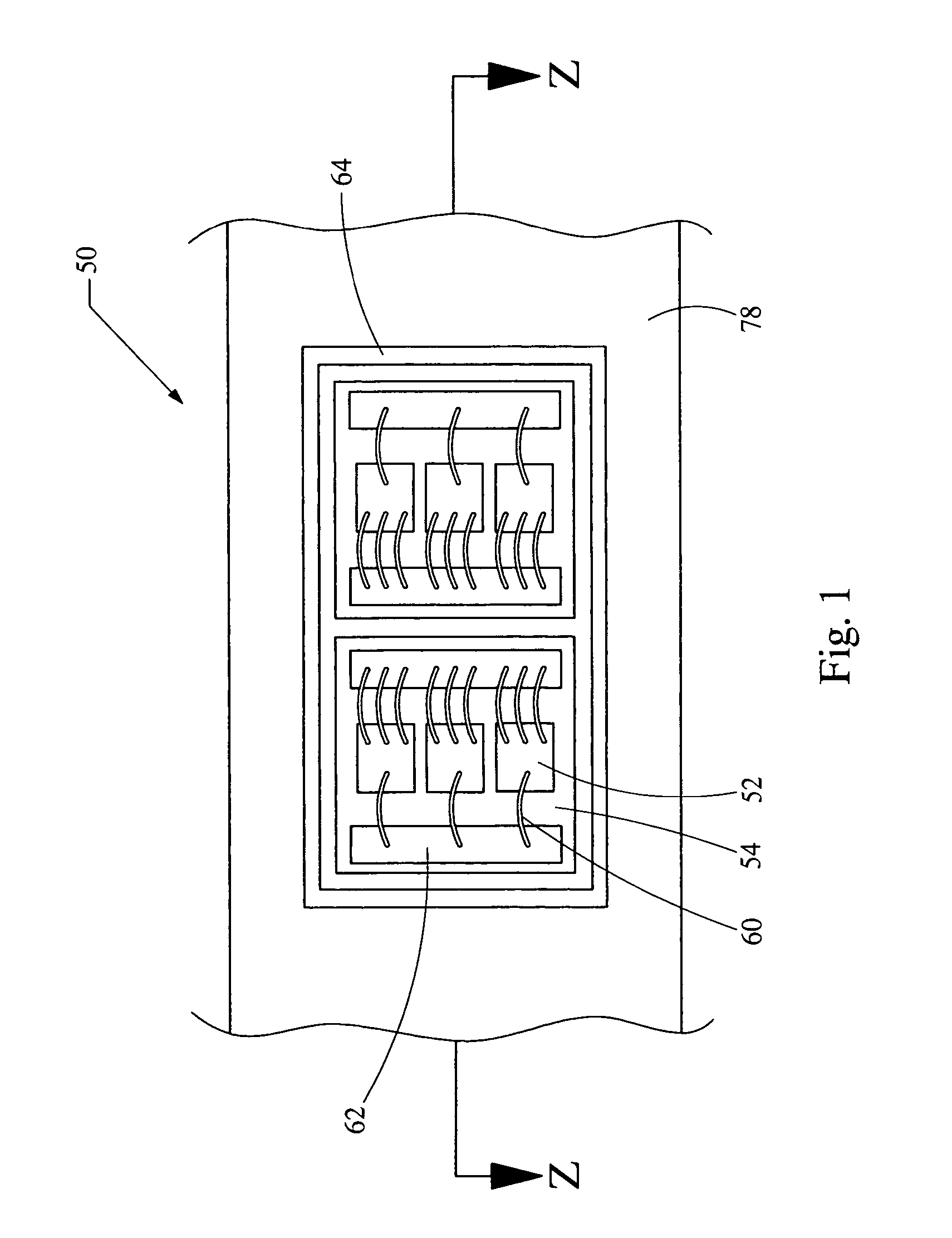

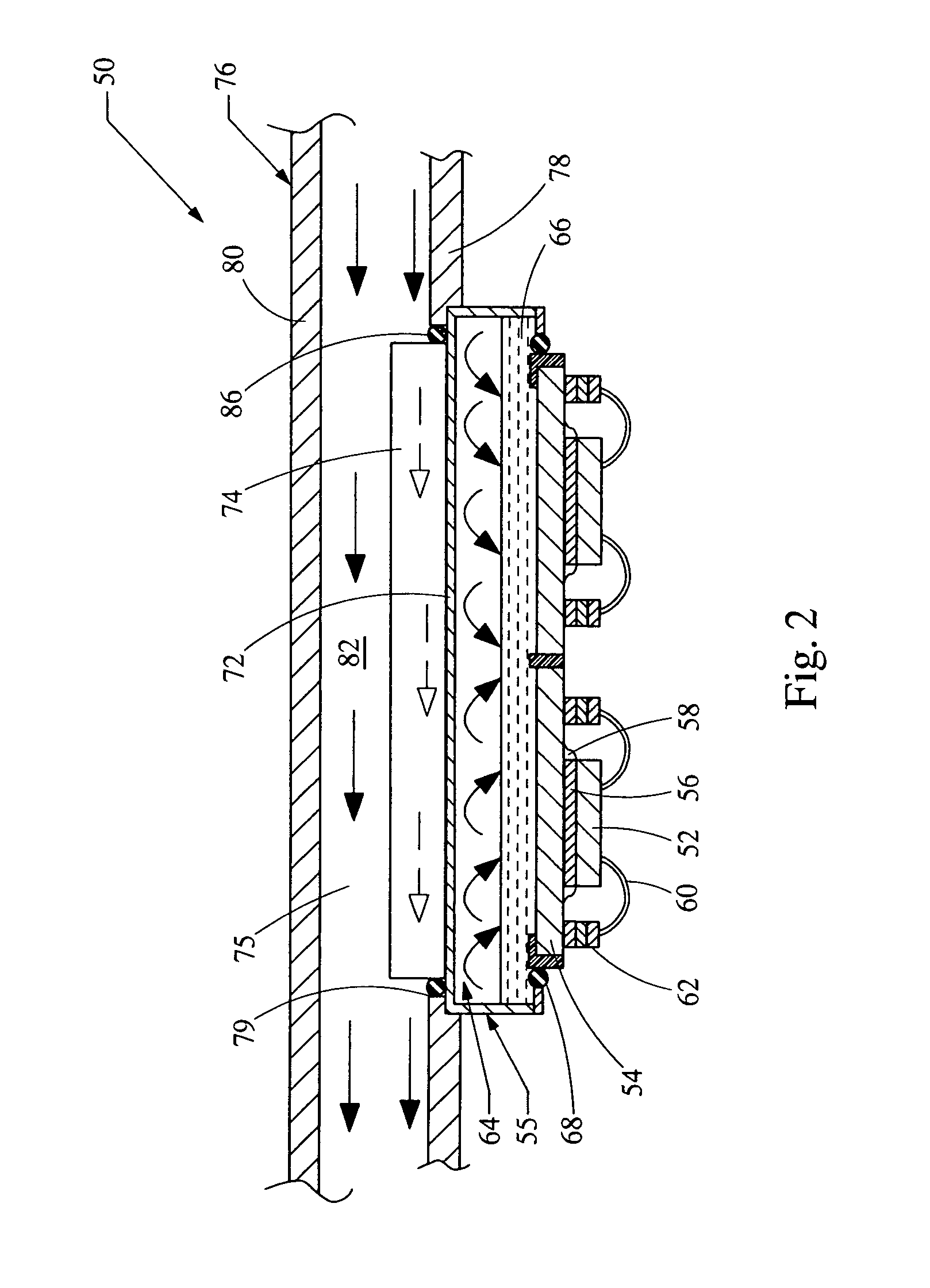

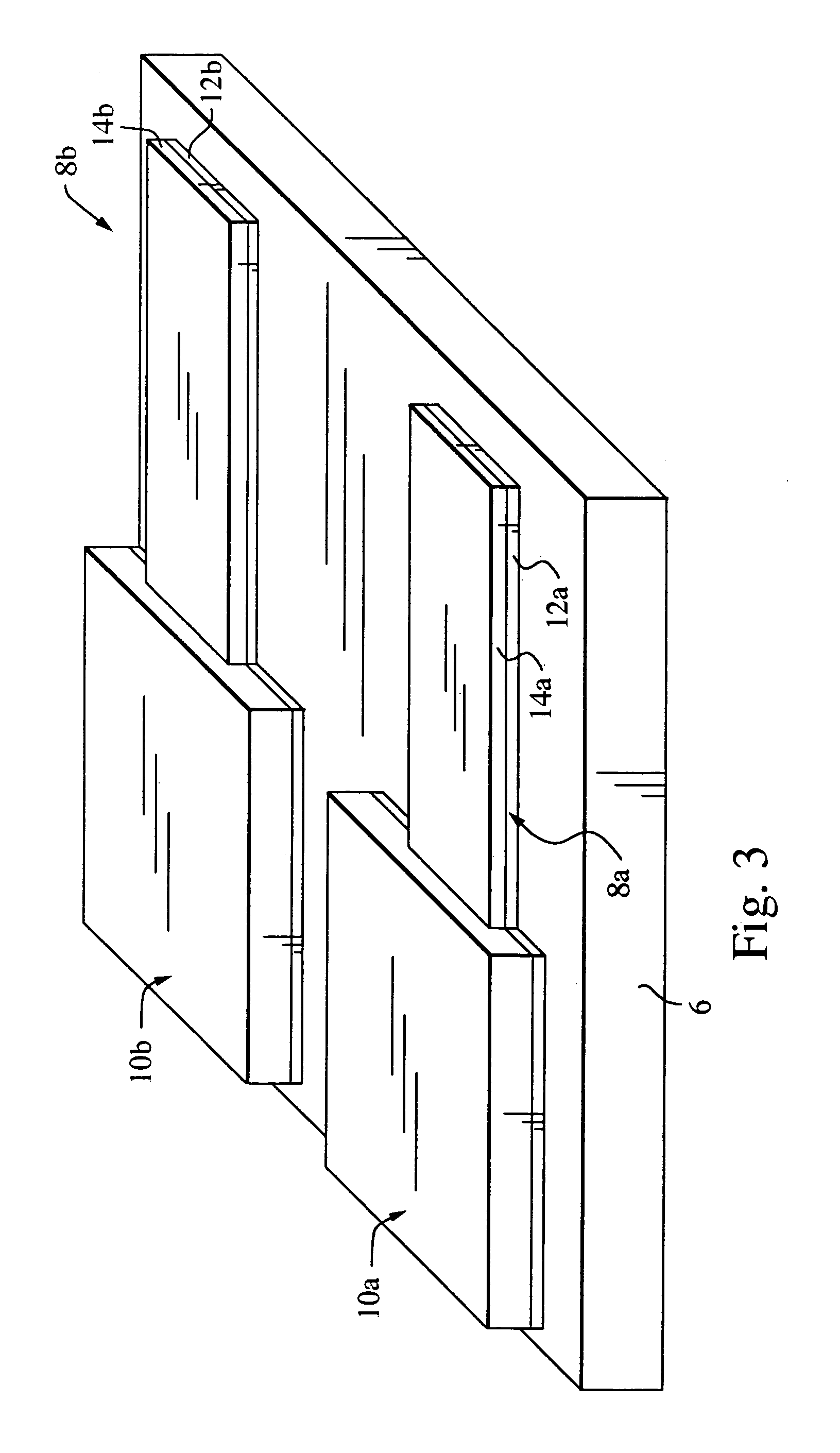

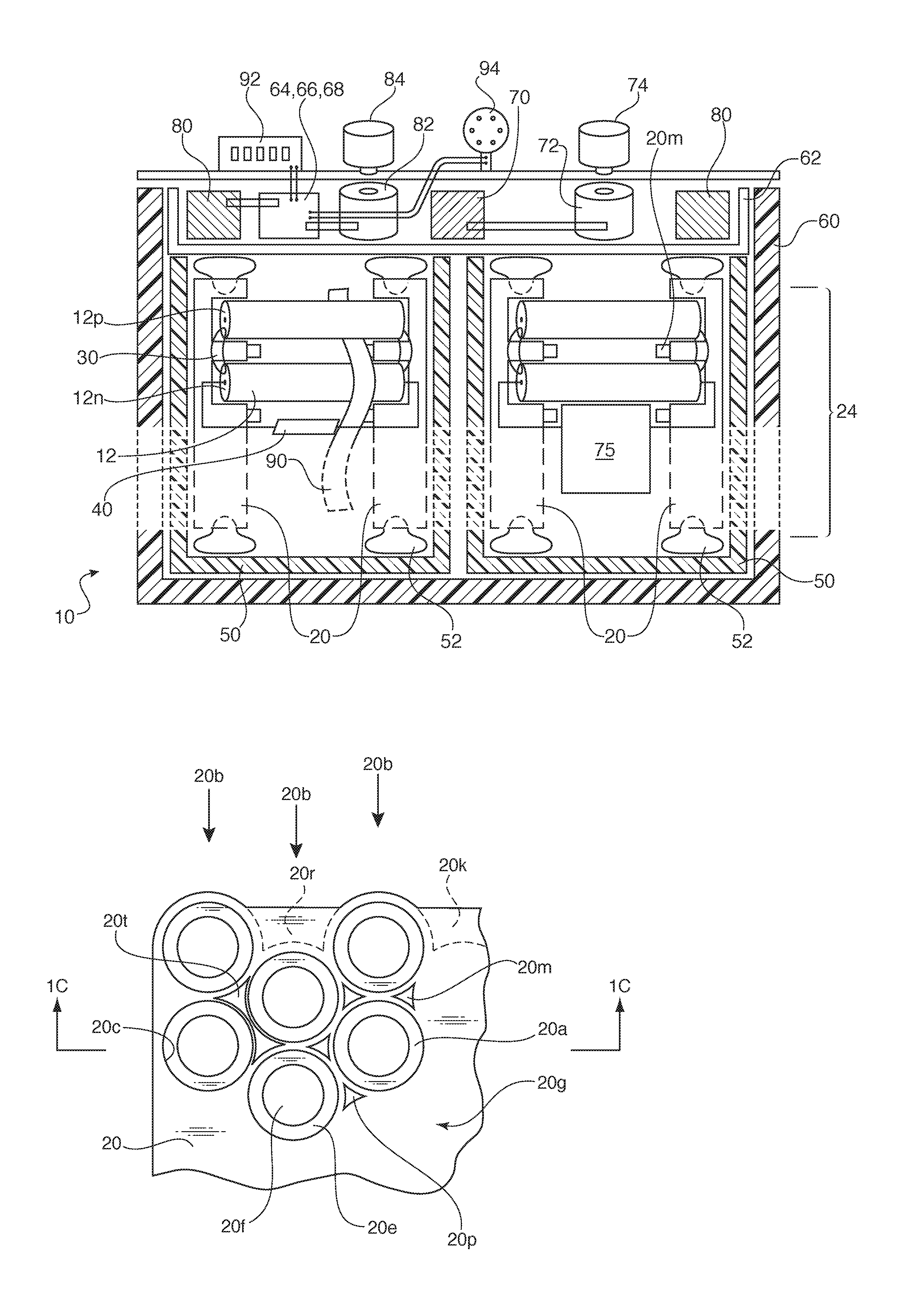

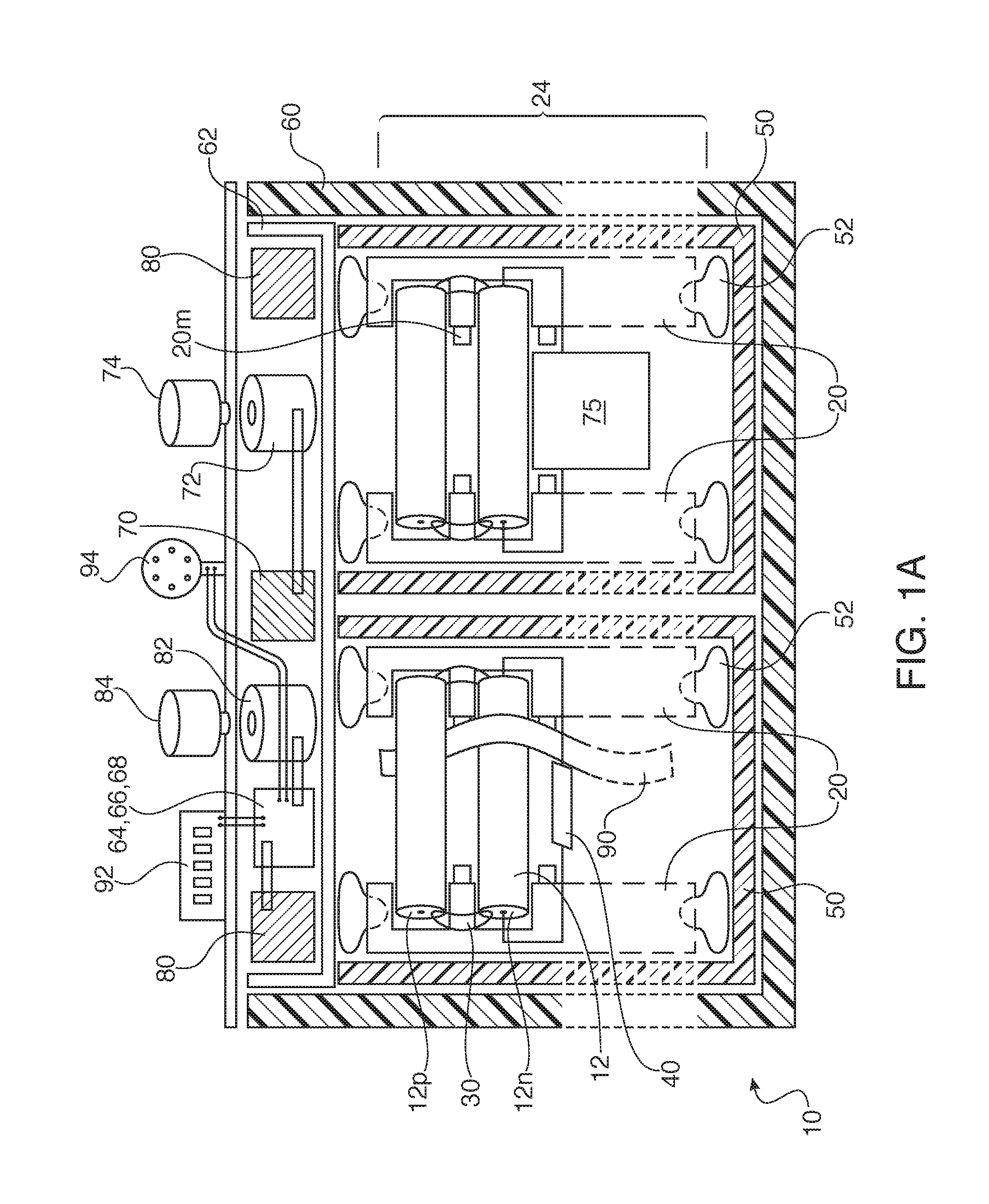

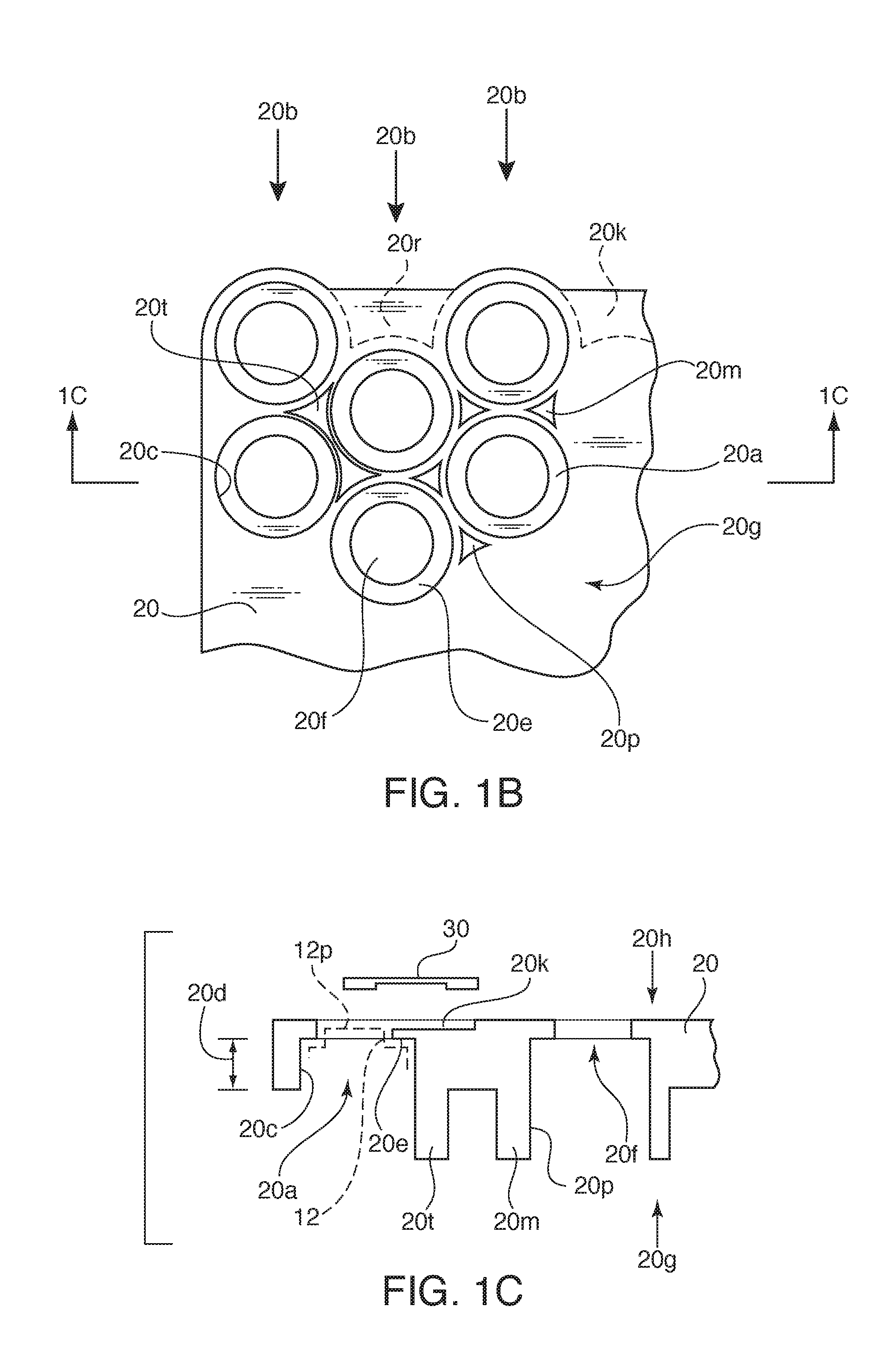

Dielectric thermal stack for the cooling of high power electronics

InactiveUS20050083655A1Improve heat transfer performanceIncrease surface areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A system for dissipating heat in an electronic power module is provided. The system includes a semiconductor die, a substrate, and a heat sink in which is contained a first fluid, and a conduit through which a second fluid is permitted to flow. The substrate is attached on one surface to the die and configured to conduct heat from the die. The heat sink is attached to another surface of the substrate and transfers heat from the die to the first fluid contained therein, which evaporates due to the heat provided by the substrate. The fluid is condensed on a condensing wall cooled by the second fluid, which flows across the outer surface of the condensing wall, to transport heat away from the heat sink.

Owner:VISTEON GLOBAL TECH INC

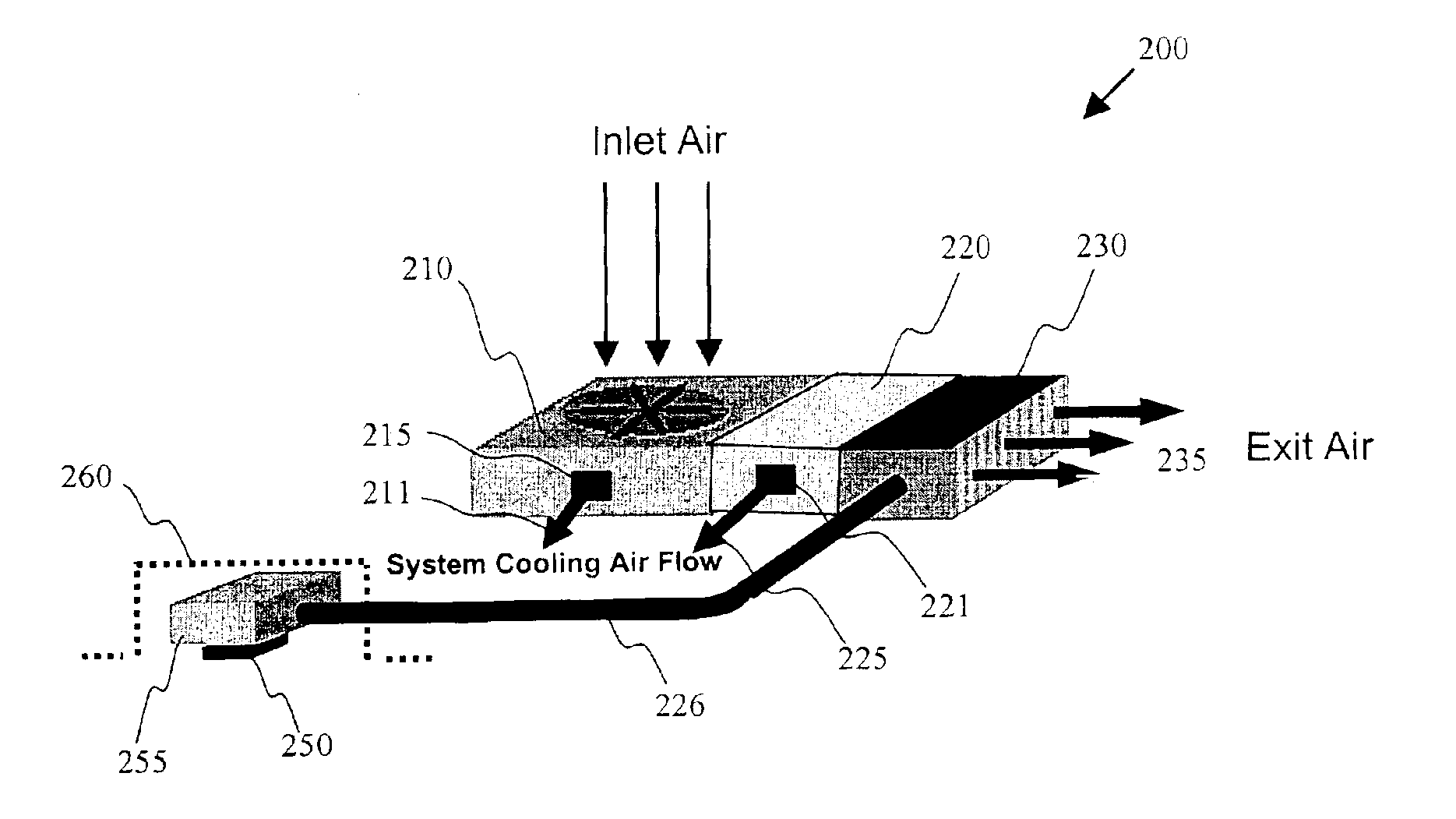

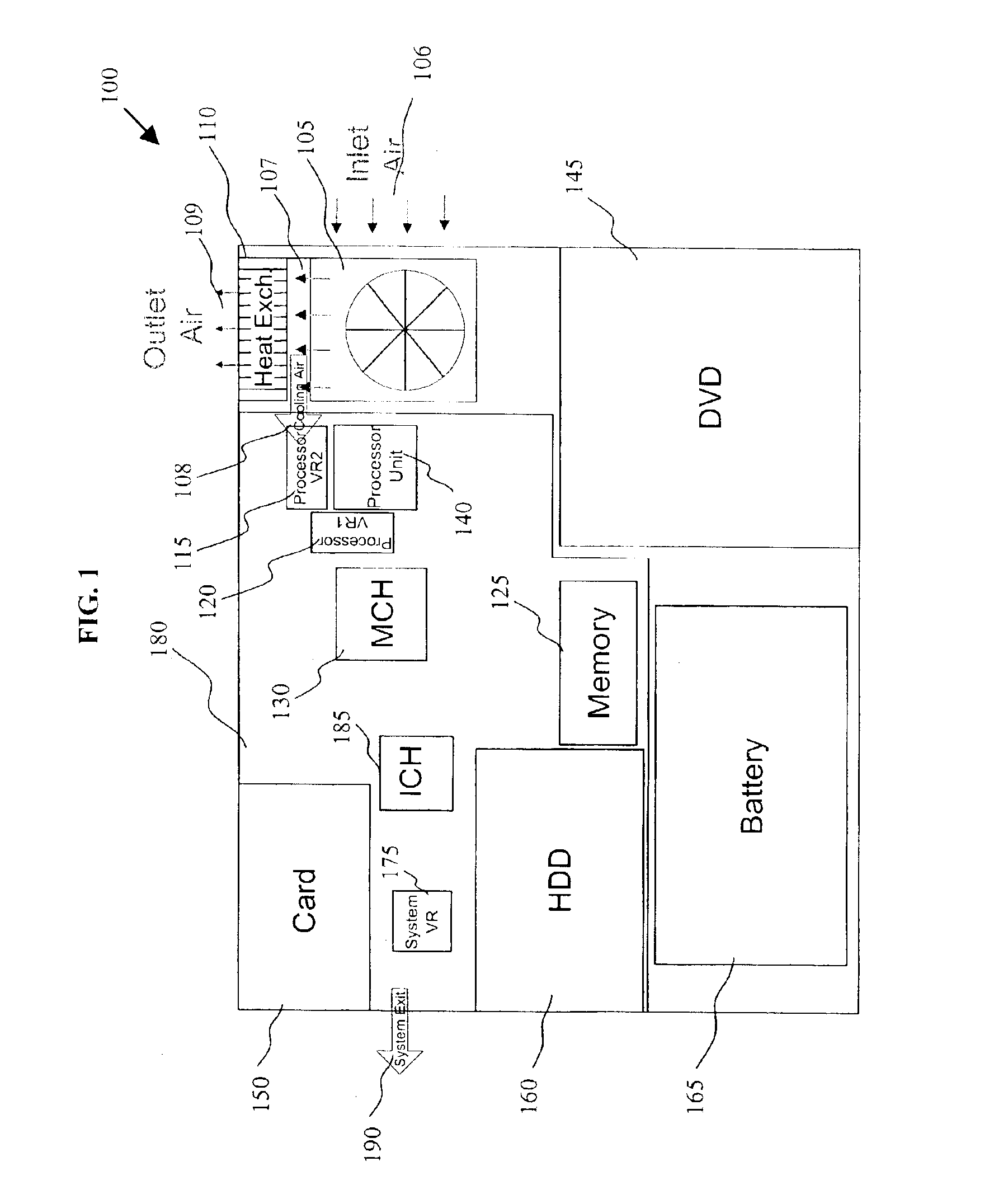

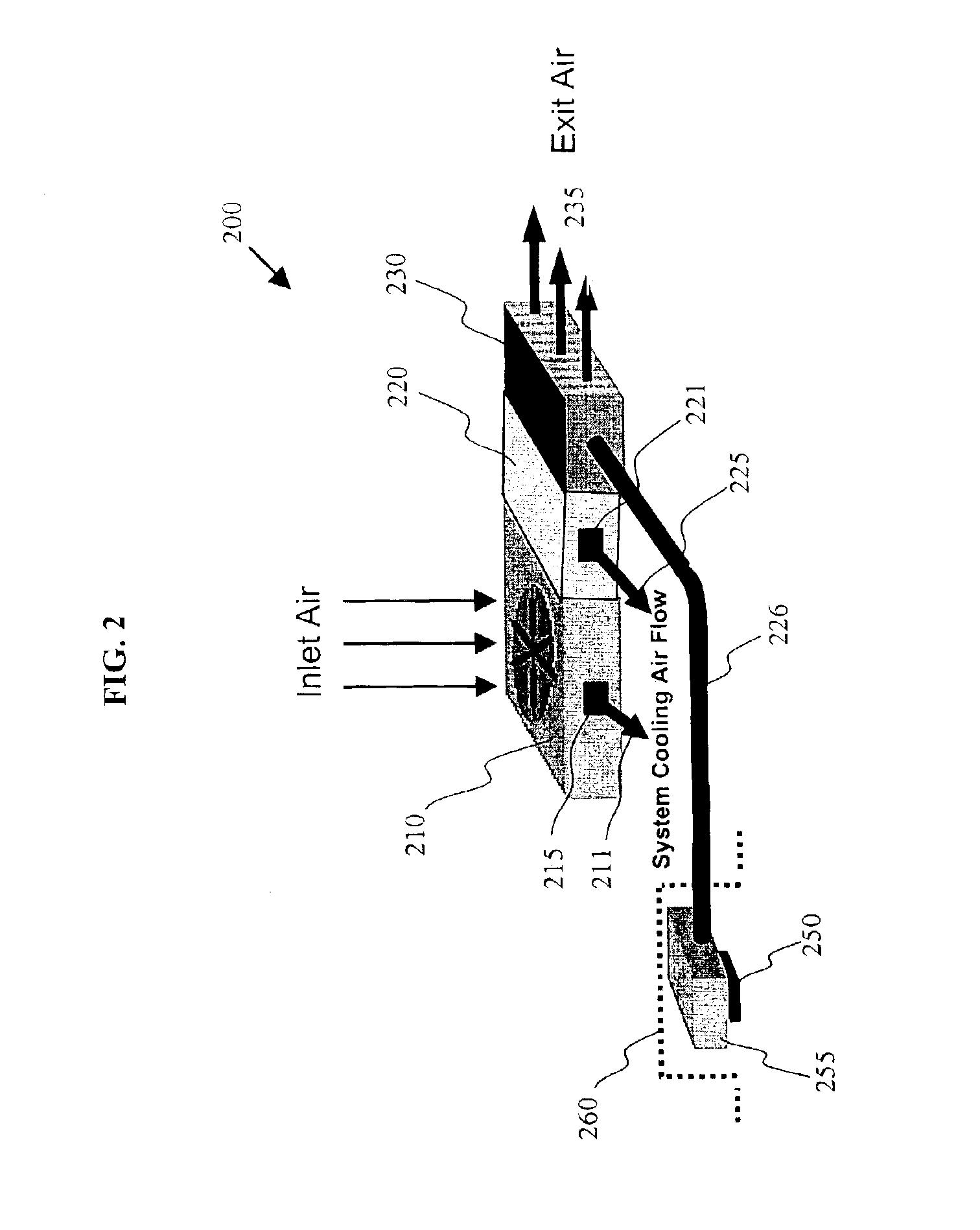

Method and system for computer system ventilation

InactiveUS6924978B2Digital data processing detailsIndirect heat exchangersActive coolingComputerized system

Embodiments of the present invention provides an electronic component cooling system and method that diverts a portion of a cooling fan's cooling air from high power electronic components such as processors and directs the cooling air to other electronic components of a system. Active cooling air may be provided at higher velocities and lower temperatures to cool electronic components of a system such as a computer or other electronic device. An attach block may be thermally coupled to a first electronic component. A heat exchanger may be thermally coupled to the attach block. A cooling fan may receive inlet air and may generate cooling air. A plenum duct between the cooling fan and the heat exchanger may direct the generated cooling air from the fan to the heat exchanger. A portion of the generated cooling air from the cooling fan may be diverted towards a second electronic component included in the system.

Owner:INTEL CORP

Method and apparatus for dispersing heat from high-power electronic devices

ActiveUS7457118B1Increase heatDigital data processing detailsCooling/ventilation/heating modificationsEngineeringHigh power electronics

Owner:EMC IP HLDG CO LLC

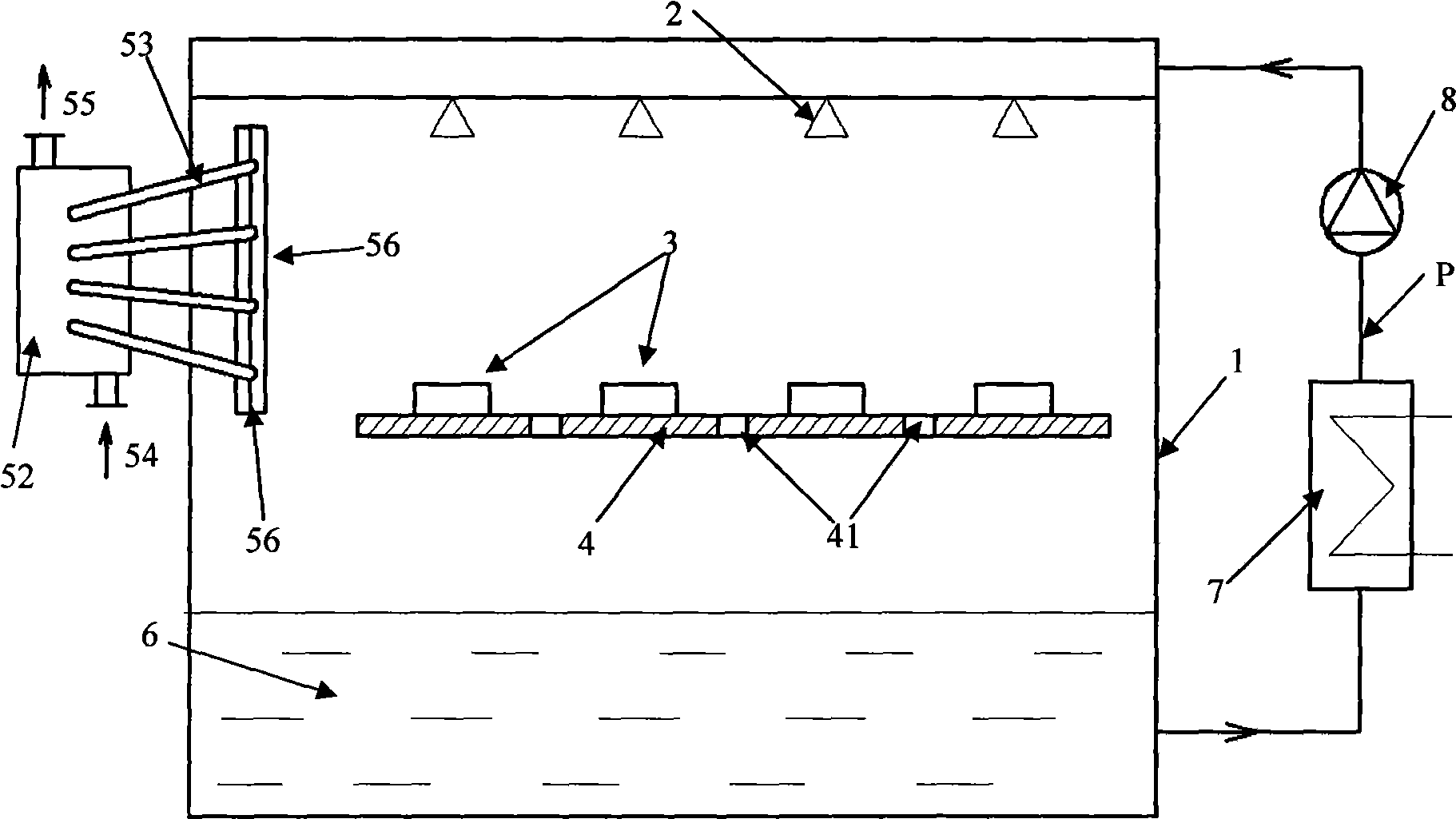

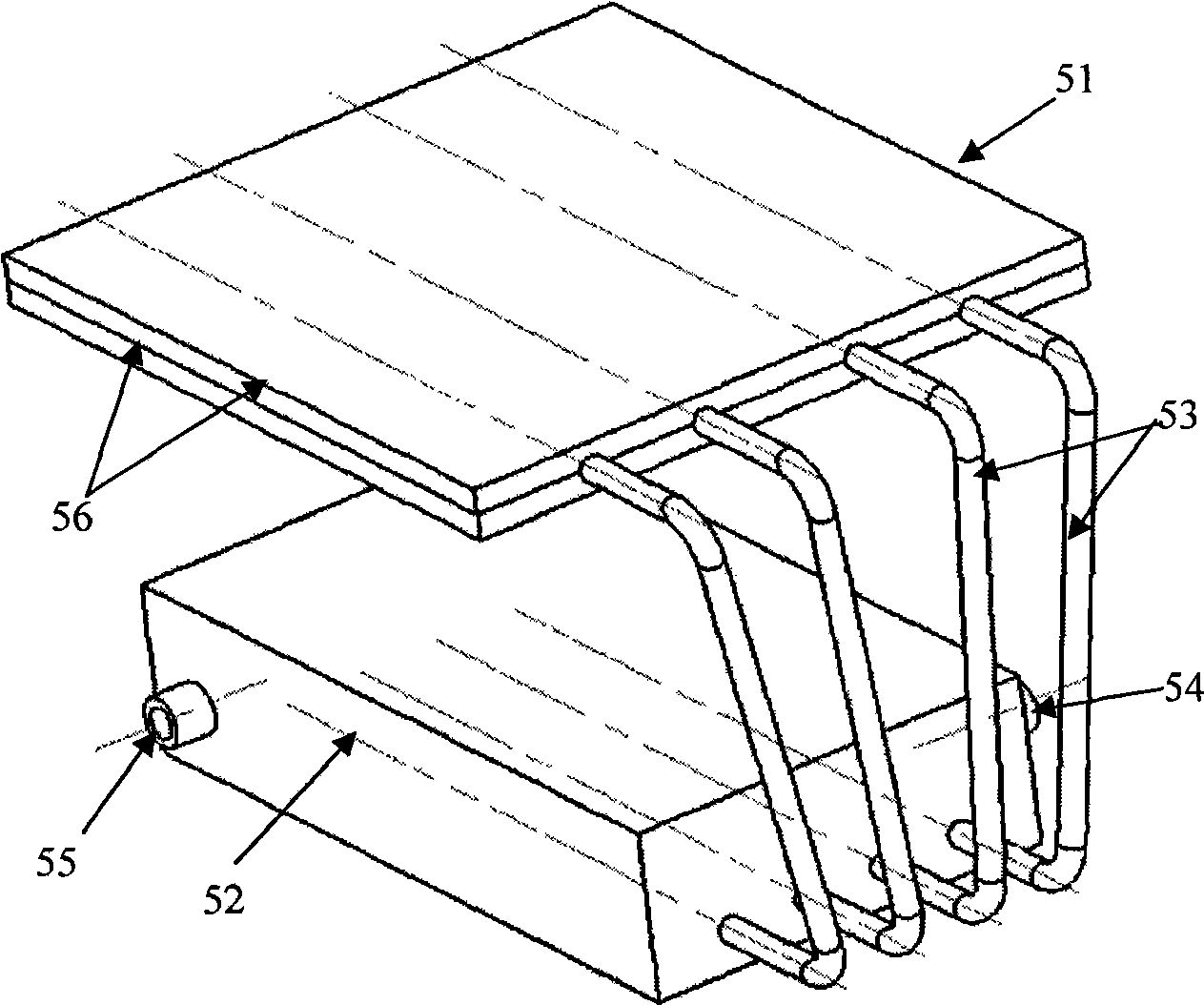

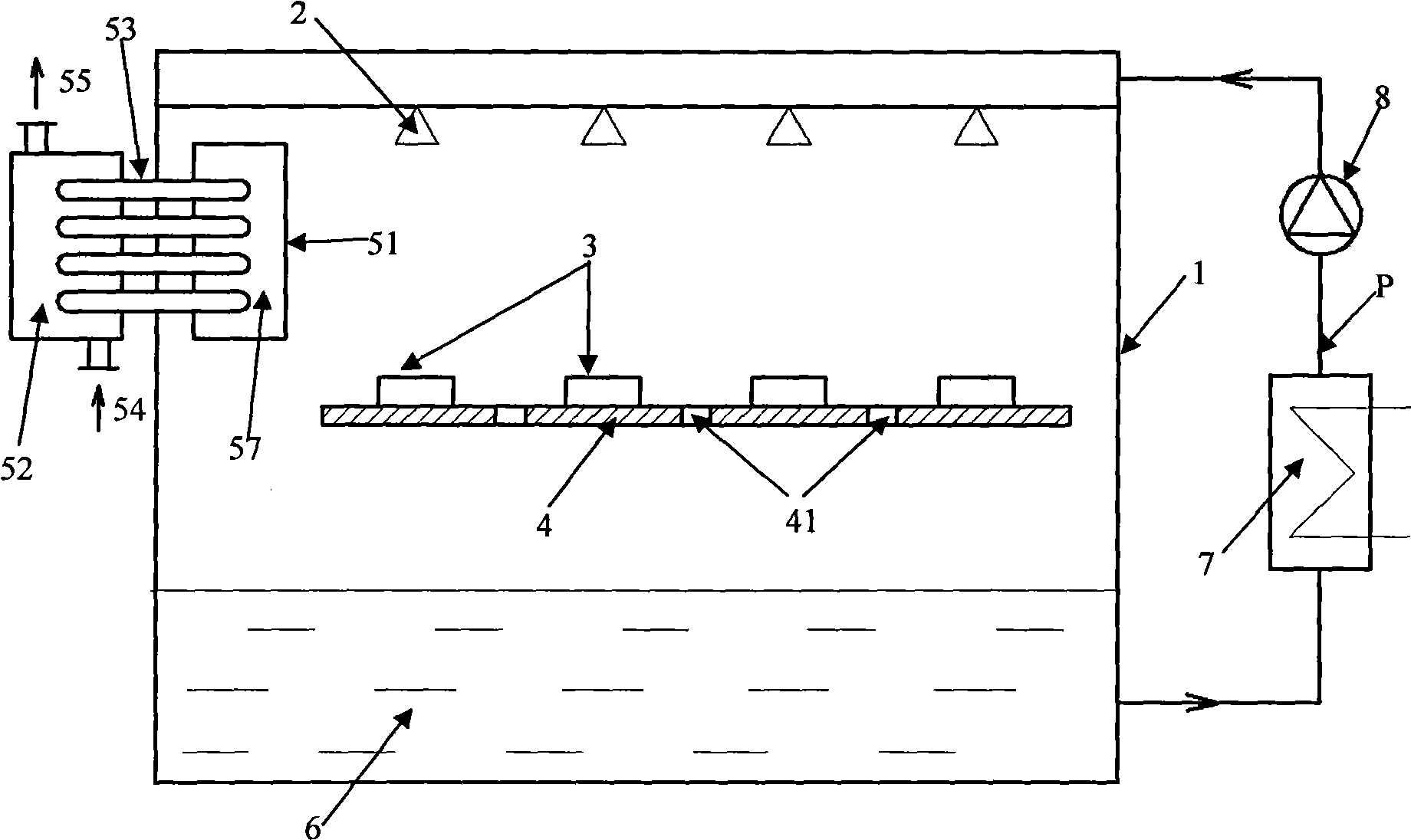

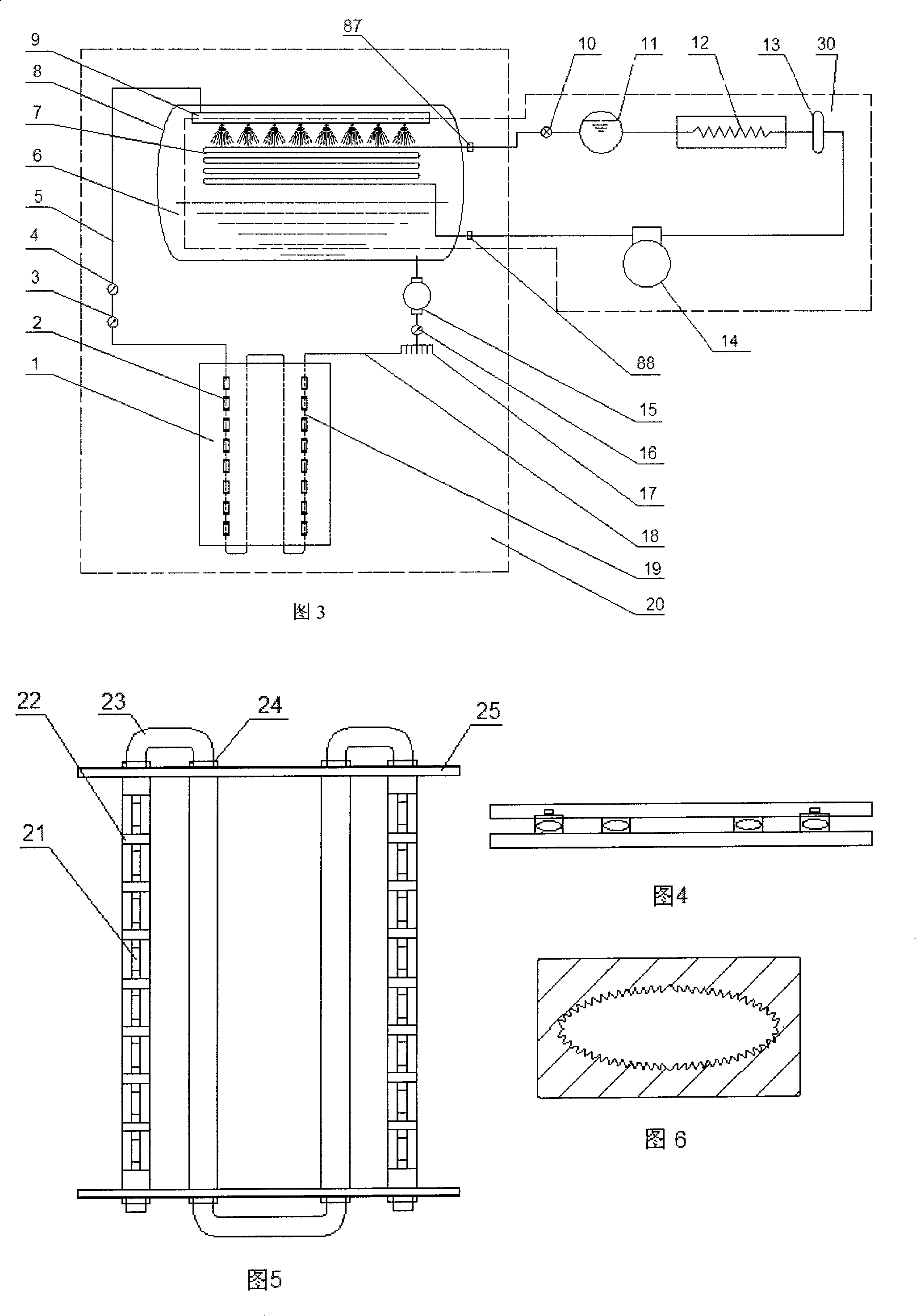

High-effective integral spray cooling system

InactiveCN101534627AReduce heat transfer areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention relates to a high-effective integral spray cooling system, which solves heat dissipation problem in field such as high power electron or laser system. The spray cooling system includes a spray cavity, a heat exchanger, a cooler, a circulating pump and a system working medium circulation pipeline, wherein the heat exchanger is a heat pipe heat exchanger; one end of the heat pipe of the heat pipe heat exchanger is a condensation end, and the other end is an evaporation end; the evaporation end is arranged in the spray cavity and is a steam condenser, and the condensation end is arranged in a water cooling shell-and-tube heat exchanger outside the spray cavity. The invention separates steam cooling and liquid cooling, which is beneficial to respectively increase heat transfer effect in condensation and cooling process; employs the heat pipe condenser to further increase heat transfer performance in condensation process and reduce heat exchange area of the condenser; and arranges the condenser in the spray cavity for making spray cooling structure more compact and reducing flow resistance of working medium steam, thereby reducing operating pressure of the spray cavity and being beneficial to increase general heat dispersion performance of spray cooling.

Owner:UNIV OF SCI & TECH OF CHINA +1

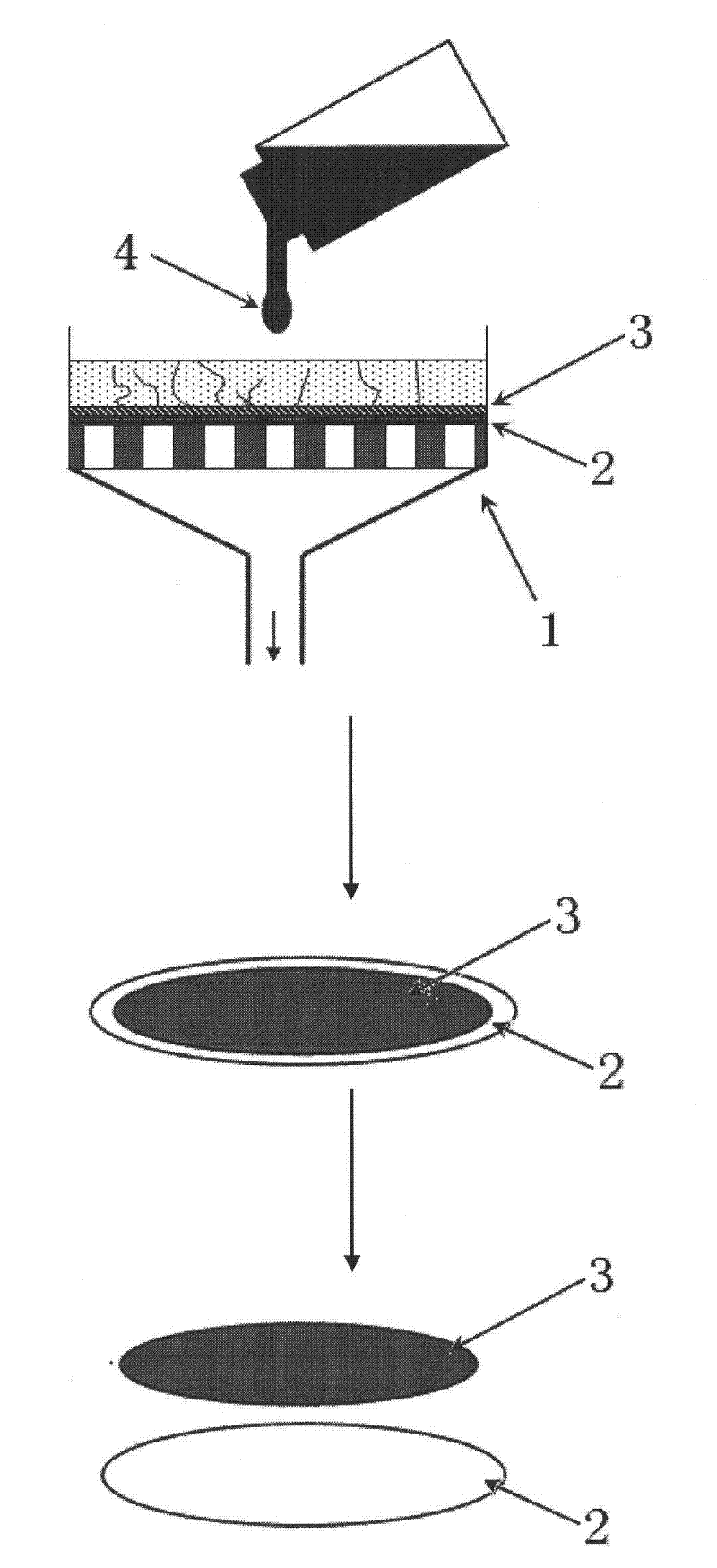

Large-area freestanding carbon nanotube paper and preparation method thereof

The invention provides large-area freestanding carbon nanotube paper and a preparation method thereof. The carbon nanotube paper is composed of disordered carbon nanotubes and in a non-woven fabric form. The preparation method comprises the steps of: dissolving carbon nanotube powder in a solvent, dispersing it uniformly and placing the dispersion solution in a pumping filtration device, conducting pumping filtration to deposit the carbon nanotube on filter paper, then separating the carbon nanotube paper and the filter paper, thus obtaining a target product with thickness ranging from micrometers to hundreds of micrometers. The method of the invention is not limited to a specific carbon nanotube kind, pumping filtration device and dispersion degree, and can be realized by ordinary filtering equipment and dispersion equipment. With an area more than 50cm<2>, the prepared carbon nanotube paper has the advantages of freestanding capability, low content and easy removal of a dispersing agent, controllable flexibility and poriness, simple operation technology, and low cost, thus being applicable extensively in the fields of new energy, heat radiation of high power electronics, advanced chemistry, chemical and biological separation, filtering membranes and high performance light polymer composite materials.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Carbon nanotube array and method for forming same

ActiveUS7288321B2Simple structureDamage formationMaterial nanotechnologyLayered productsField emission deviceCarbon nanotube

A method for forming a carbon nanotube array on a metal substrate includes the following steps: providing a metal substrate (11); depositing a silicon layer (21) on a surface of the metal substrate; depositing a catalyst layer (31) on the silicon layer; annealing the treated substrate; heating the treated substrate up to a predetermined temperature in flowing protective gas; introducing a carbon source gas for 5-30 minutes; and thus forming a carbon nanotube array (51) extending from the treated substrate. Generally, any metallic material can be used as the metal substrate. Various carbon nanotube arrays formed using various metal substrates can be incorporated into a wide variety of high power electronic device applications such as field emission devices (FEDs), electron guns, and so on. Carbon nanotubes formed using any of a variety of metal substrates are well aligned, and uniformly extend in a direction substantially perpendicular to the metal substrate.

Owner:TSINGHUA UNIV +1

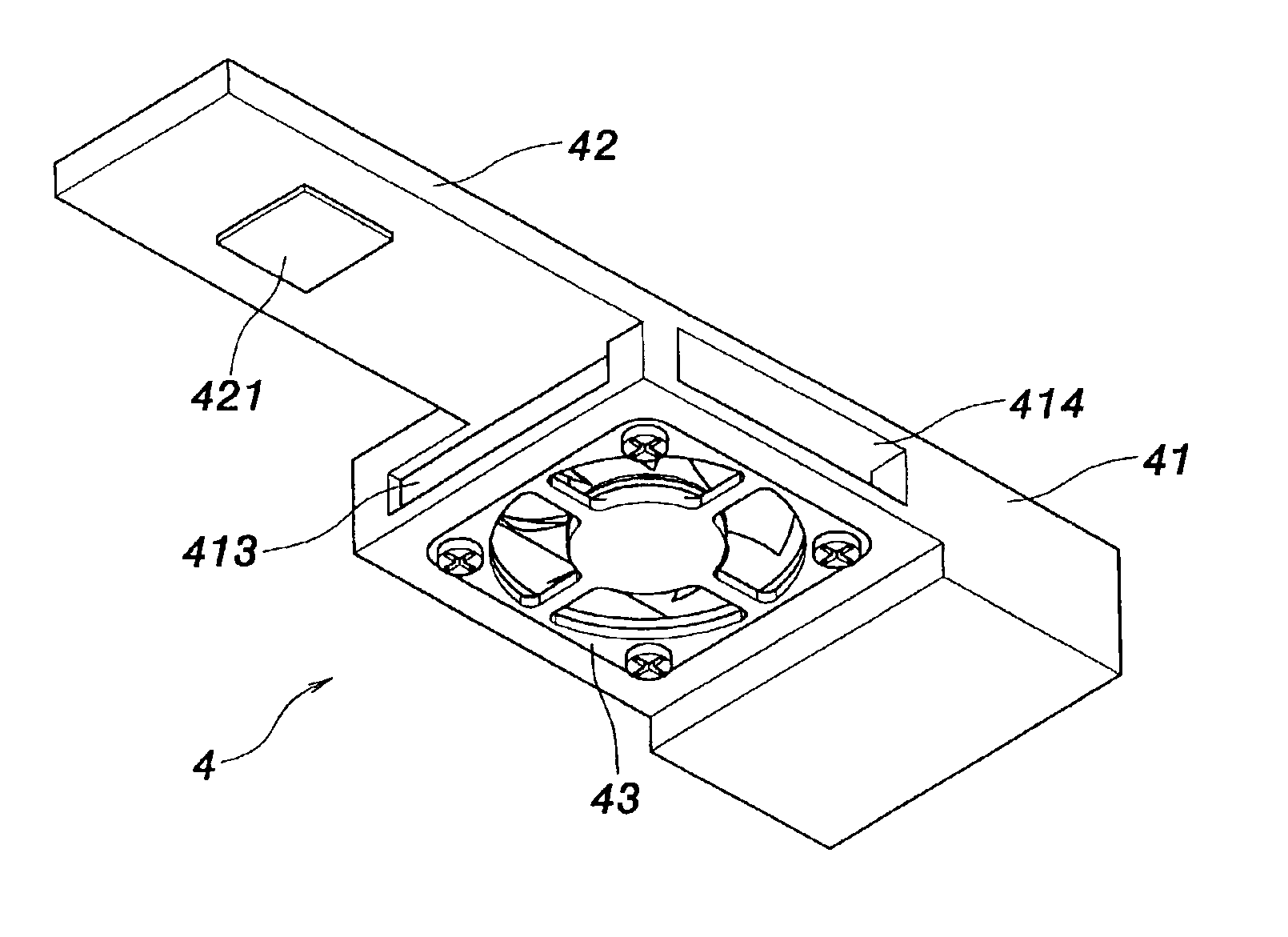

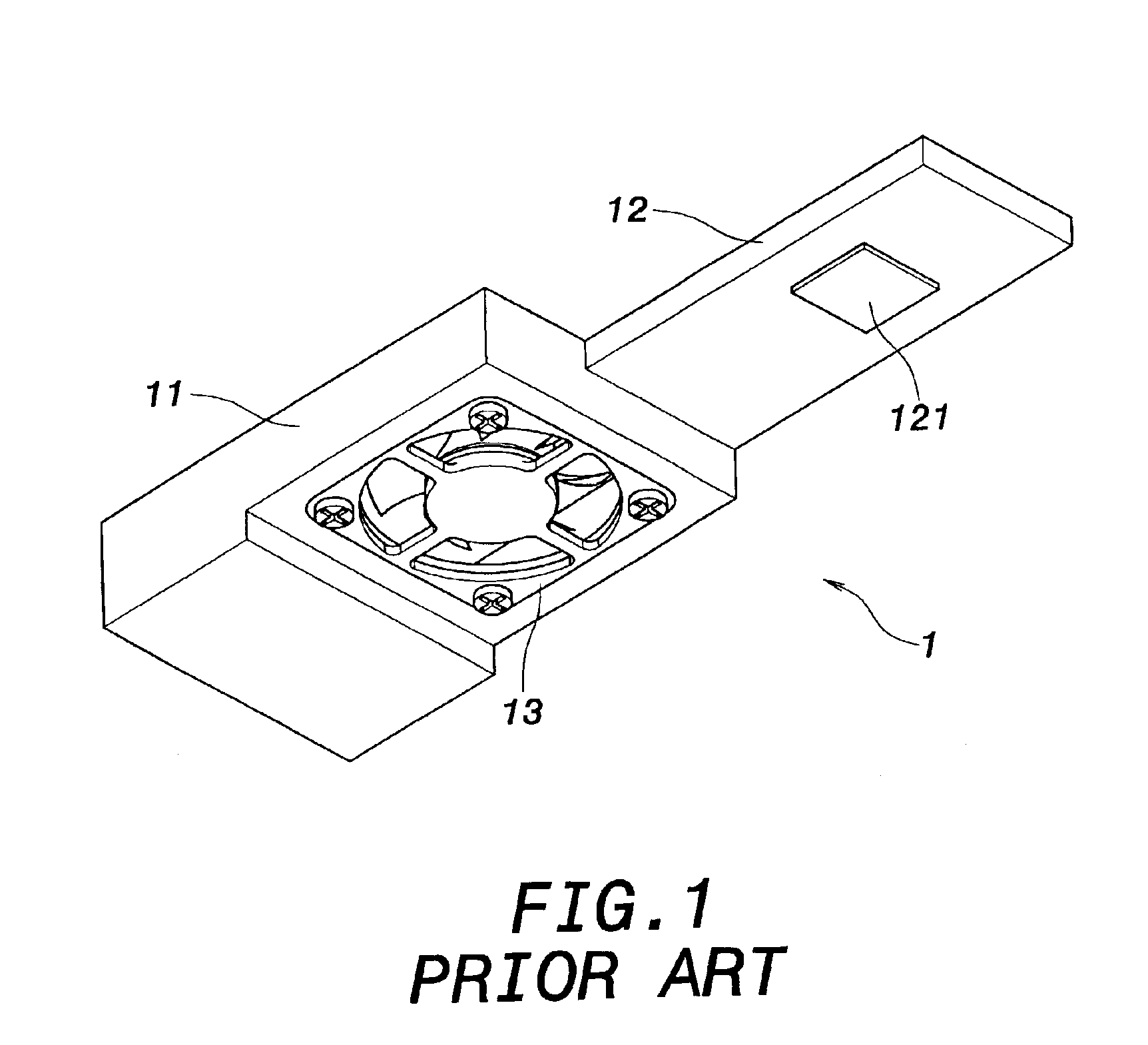

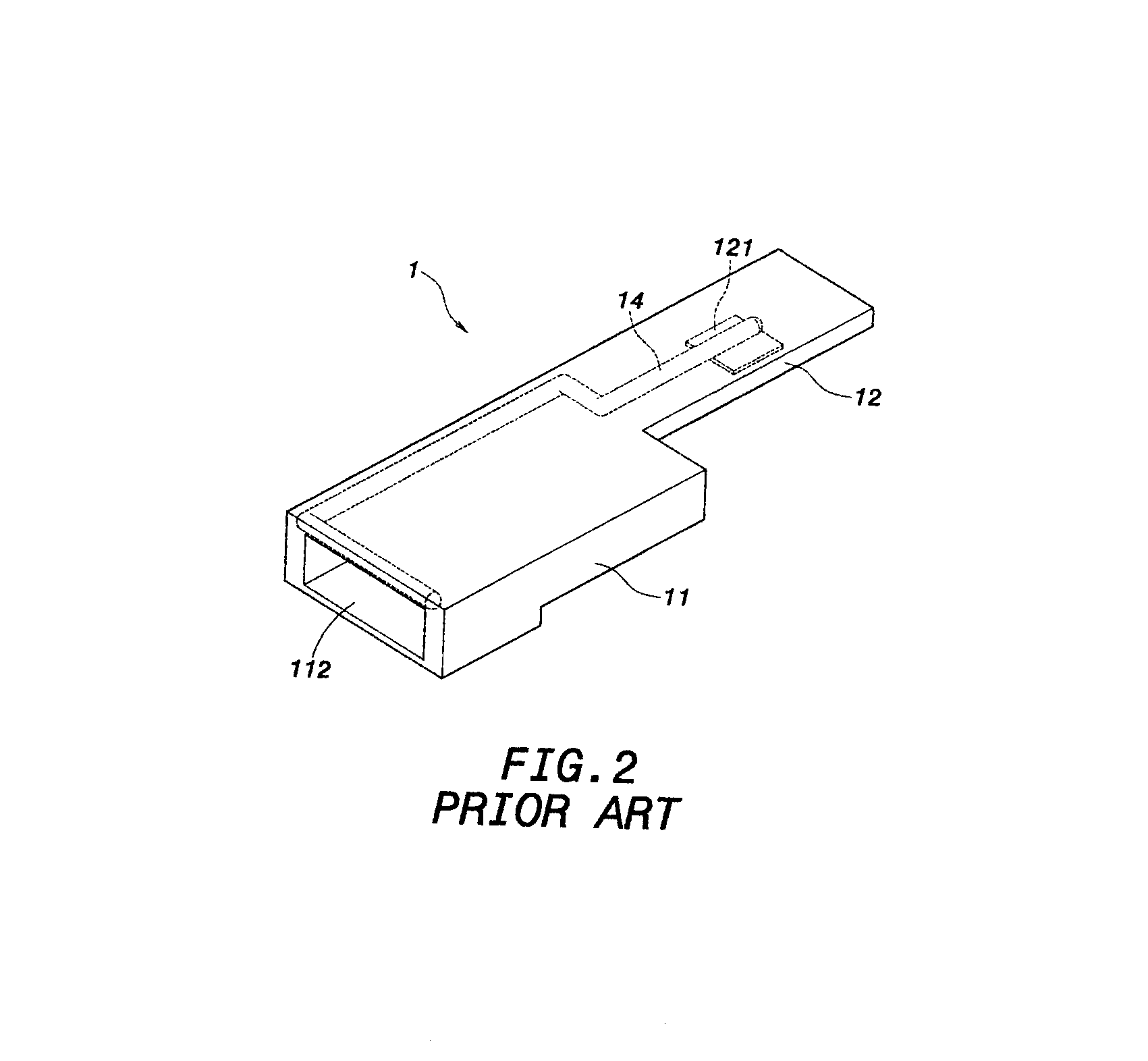

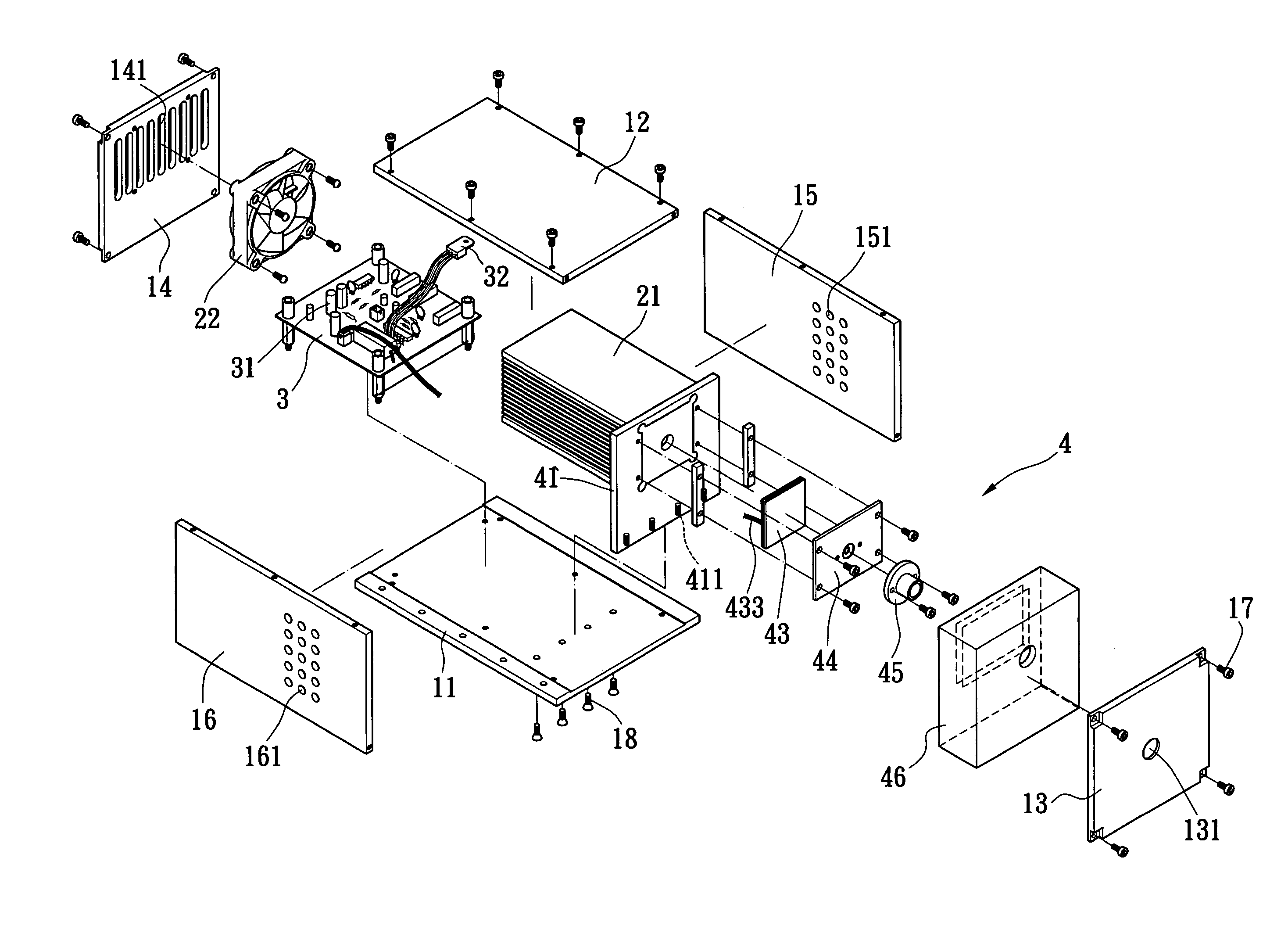

Multi-opening heat-dissipation device for high-power electronic components

InactiveUS6914782B2Good effectPump componentsDigital data processing detailsHigh power electronicsEngineering

A multi-opening heat-dissipation device for high-power electronic components includes a body, an extension extended from the body, and a radial fan. The radial fan is mounted on a bottom aperture of the body. The body further comprises a primary opening on a first face and a cavity communicating between the bottom aperture and the primary opening as a wind path. The body further includes at least one additional opening on a second face of the body. The at least one additional comprises a second opening faces a circuit board on which a high-power electronic component is mounted. The cool air can flow to at least one of the topside and bottom side of the circuit board through the second opening and cool the high-power electronic components directly.

Owner:VIA TECH INC

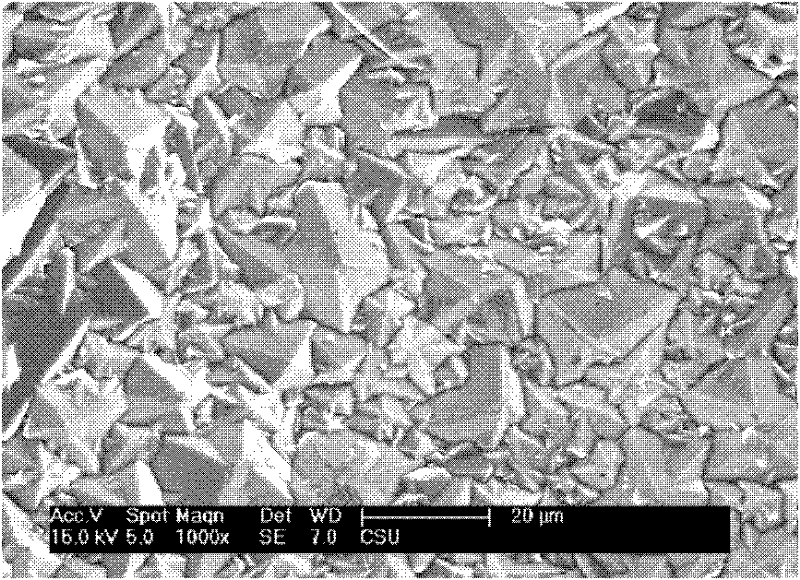

High-performance directional heat conduction copper-base diamond composite material and preparation method thereof

ActiveCN102244051AHigh thermal conductivityHigh melting pointSemiconductor/solid-state device detailsSolid-state devicesCopperElectronic packages

The invention discloses a high-performance directional heat conduction copper-base diamond composite material and a preparation method thereof. A plurality of diamond sticks are distributed on a copper base body in parallel in the same direction; the diameters of the diamond sticks are 0.5 to 10 millimeters; and distances among the diamond sticks are 0.5 to 50 millimeters. As the plurality of columnar diamond sticks with high heat conduction rate are arranged in the copper base body in the same direction, the composite material has high directional heat conduction performance along the direction; and the composite material can be used as electronic package, heat sink materials and the like and can solve the problem of package of high-temperature, high-frequency and high-power electronic devices.

Owner:CENT SOUTH UNIV

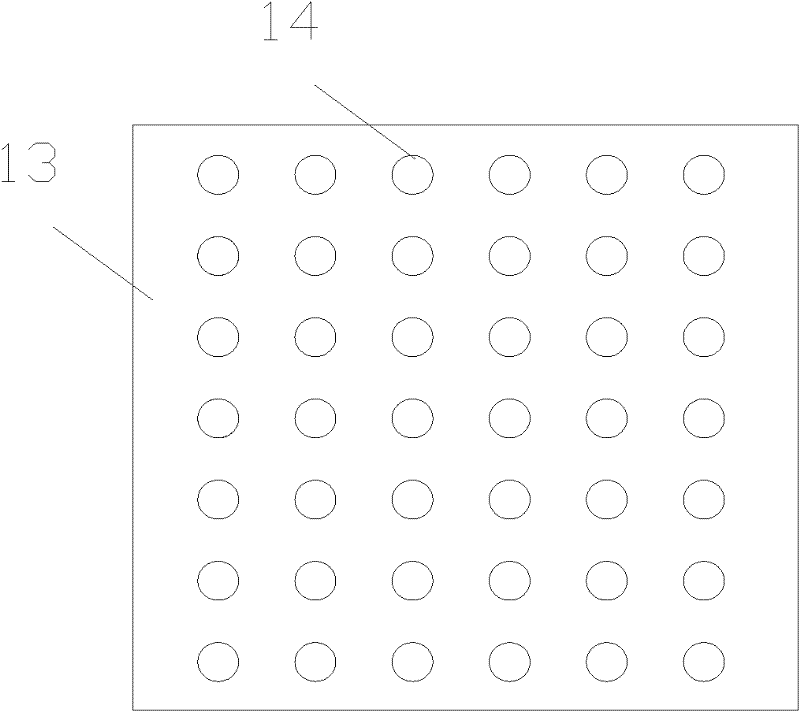

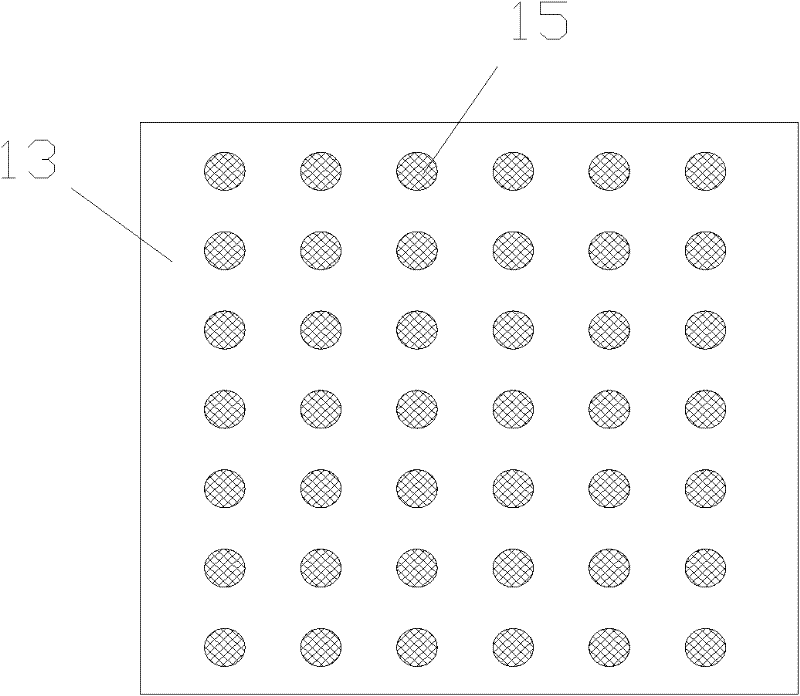

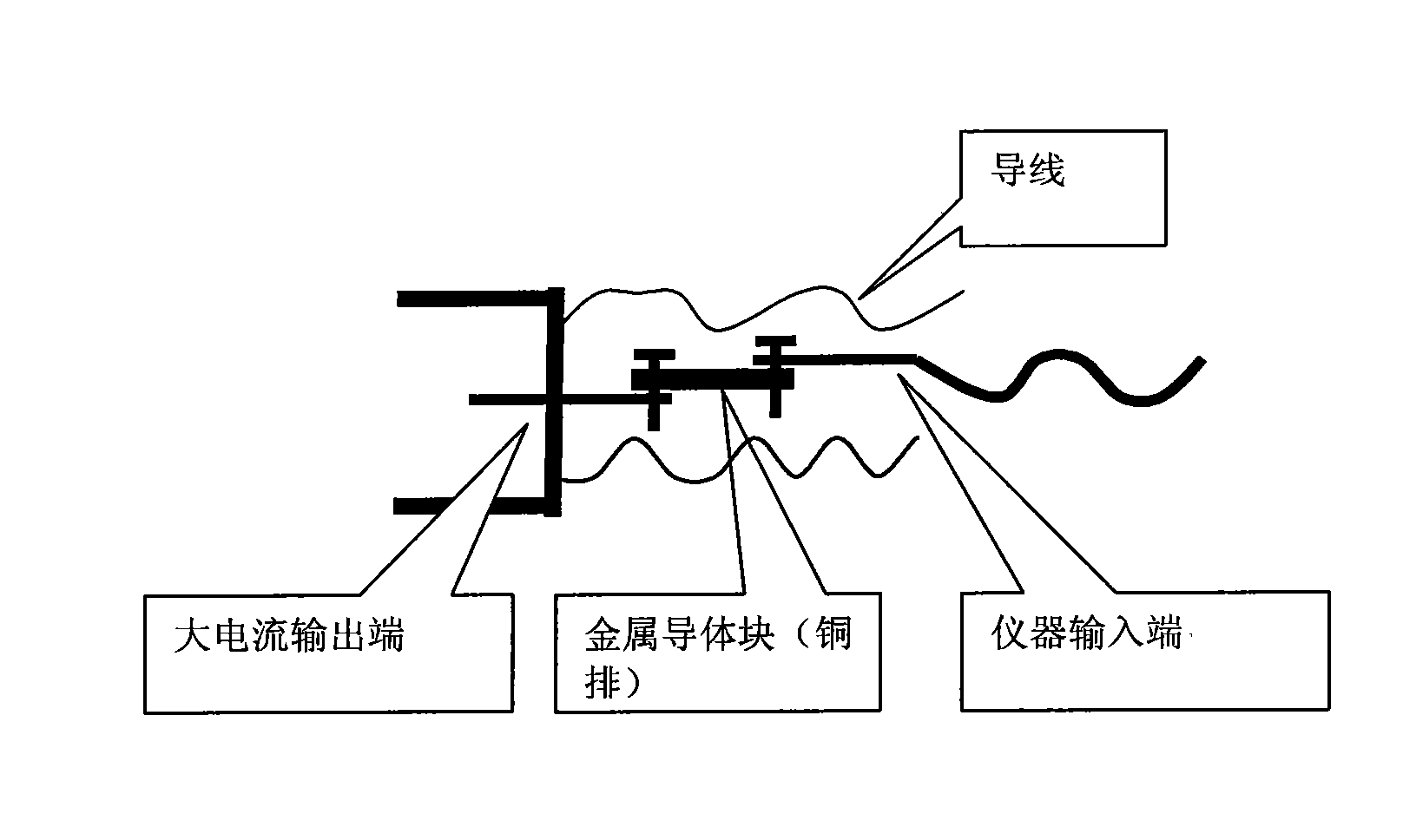

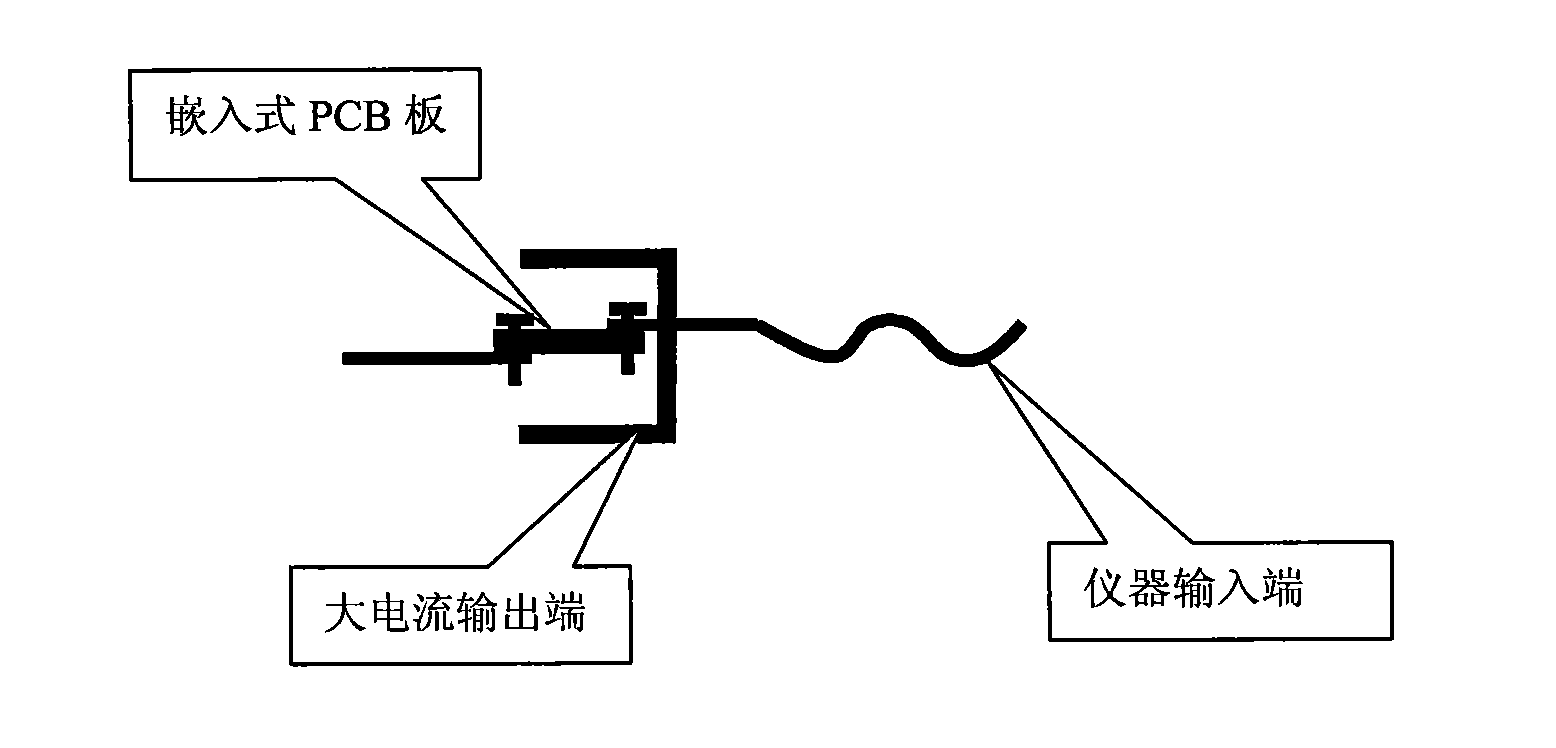

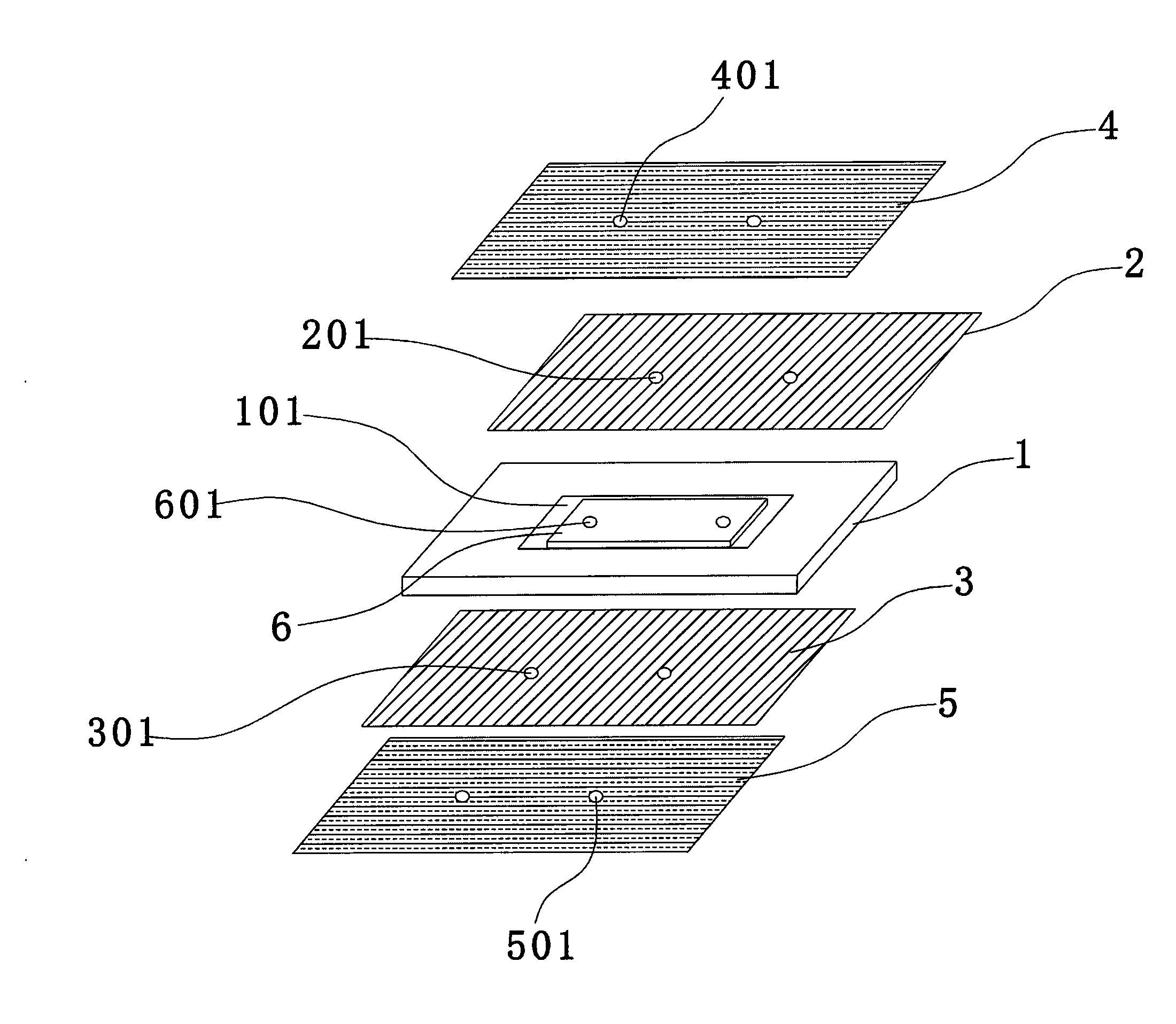

Embedded strong-current high-power PCB (Printed Circuit Board) and manufacturing method thereof

ActiveCN102123560APrinted circuit detailsPrinted circuit manufactureState of artElectrical conductor

The invention discloses an embedded strong-current high-power PCB (Printed Circuit Board) and a manufacturing method thereof. The method comprises: (1) milling a hollow groove on a core board; (2) fixedly clamping and embedding a conductor structure member which is same as the hollow groove in shape and not larger than the core board into thickness in the hollow groove; (3) laminating a first copper foil layer on the upper surface of the core board by a first semicuring piece, and laminating a second copper foil layer on the lower surface of the core board by a second semicuring piece; (4) drilling the laminated product, performing image transfer and image making on the first and second copper foil layers, forming a circuit needed by design and a part meeting large power and circuit control on the copper foil layers, simultaneously, performing hole metallization on the formed through hole to obtain the thickness of copper needed on the hole wall, and then performing solder masking manufacture; and (5) performing blind-sink hollowing on corresponding parts, needing to be connected on the product, of the conductor structure member after solder masking, exposing the conductor structure member, drilling the conductor structure member to form wire holes connected with other external connecting pieces. Compared with the prior art, in the invention, the conductor structure member is embedded into the inner layer of the PCB, interconnection of a large-current output end and an instrument input end by utilizing holes or surfaces on the conductor structure member, simultaneously, component packaging is performed by other circuit part lines except the high-power conductor structure member embedded into the PCB so as to control the circuit, so that the original wire connection is replaced to achieve the circuit control part, and the problems in the integration process of the power and circuit control parts of strong-current high-power electronic products are solved.

Owner:BOMIN ELECTRONICS CO LTD

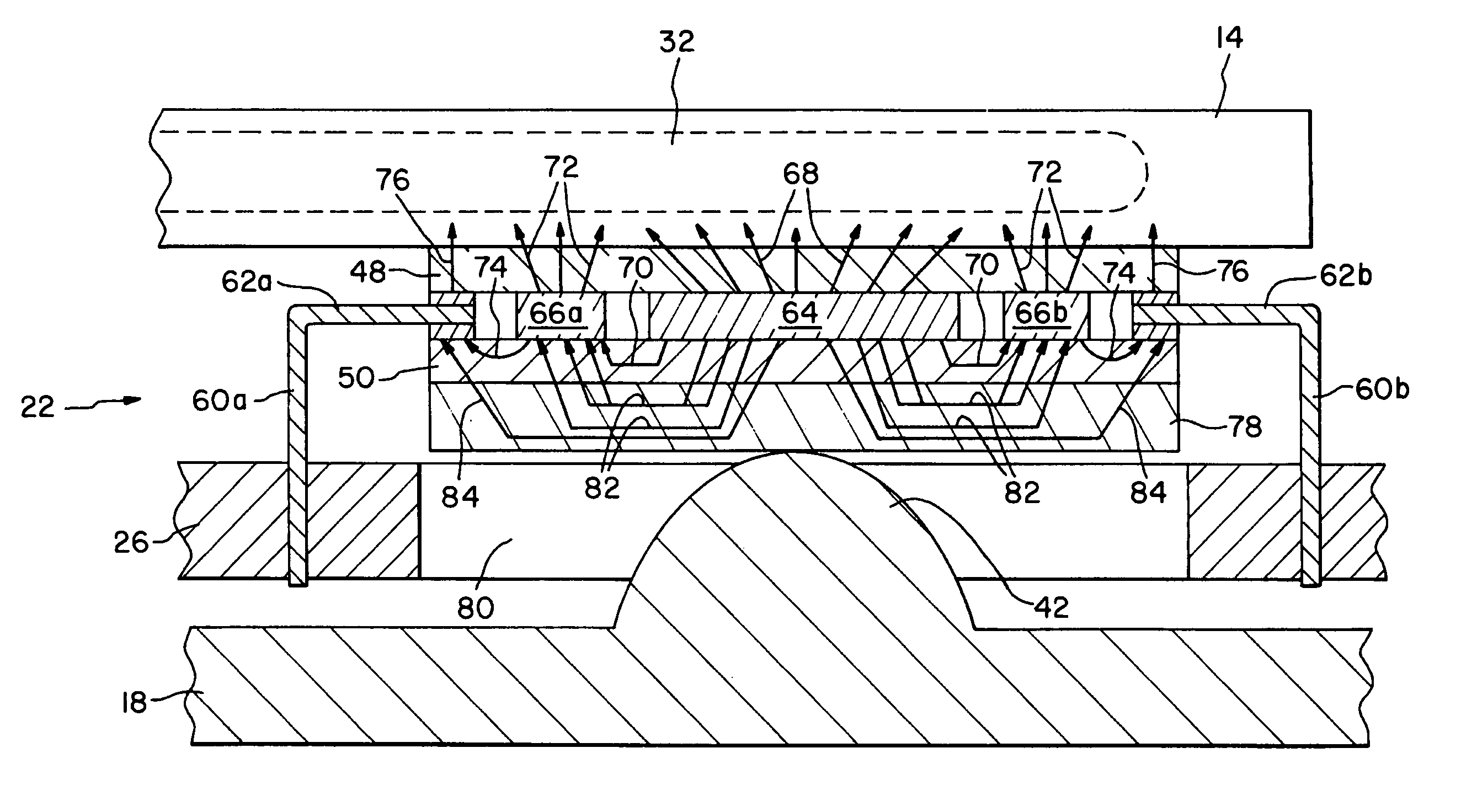

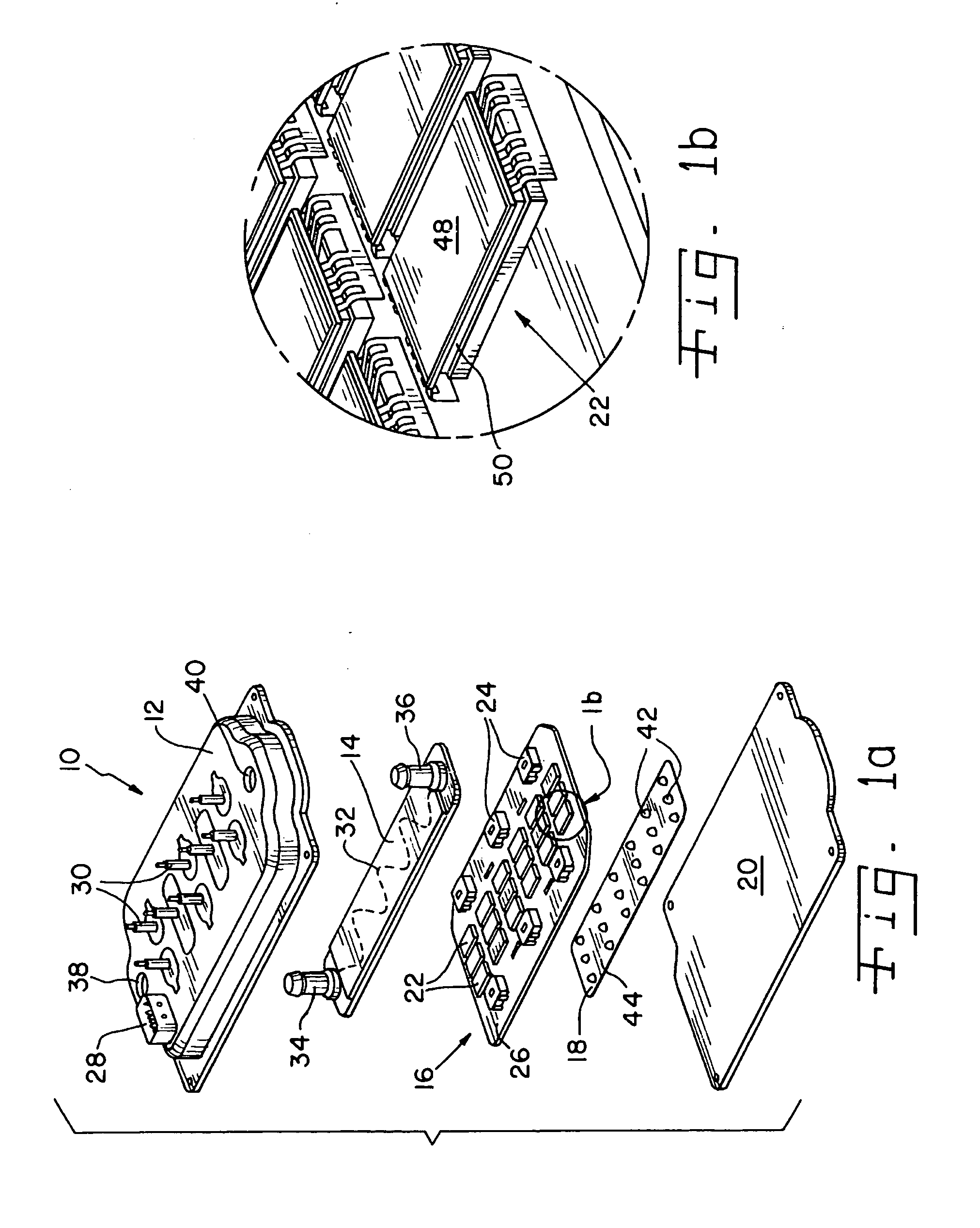

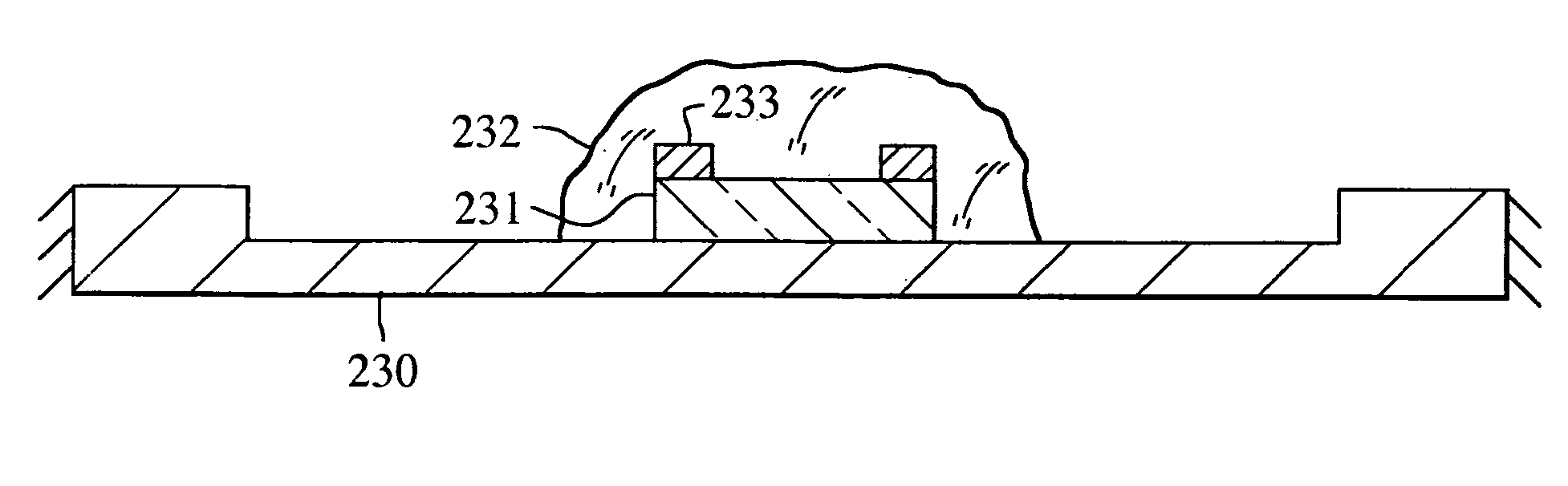

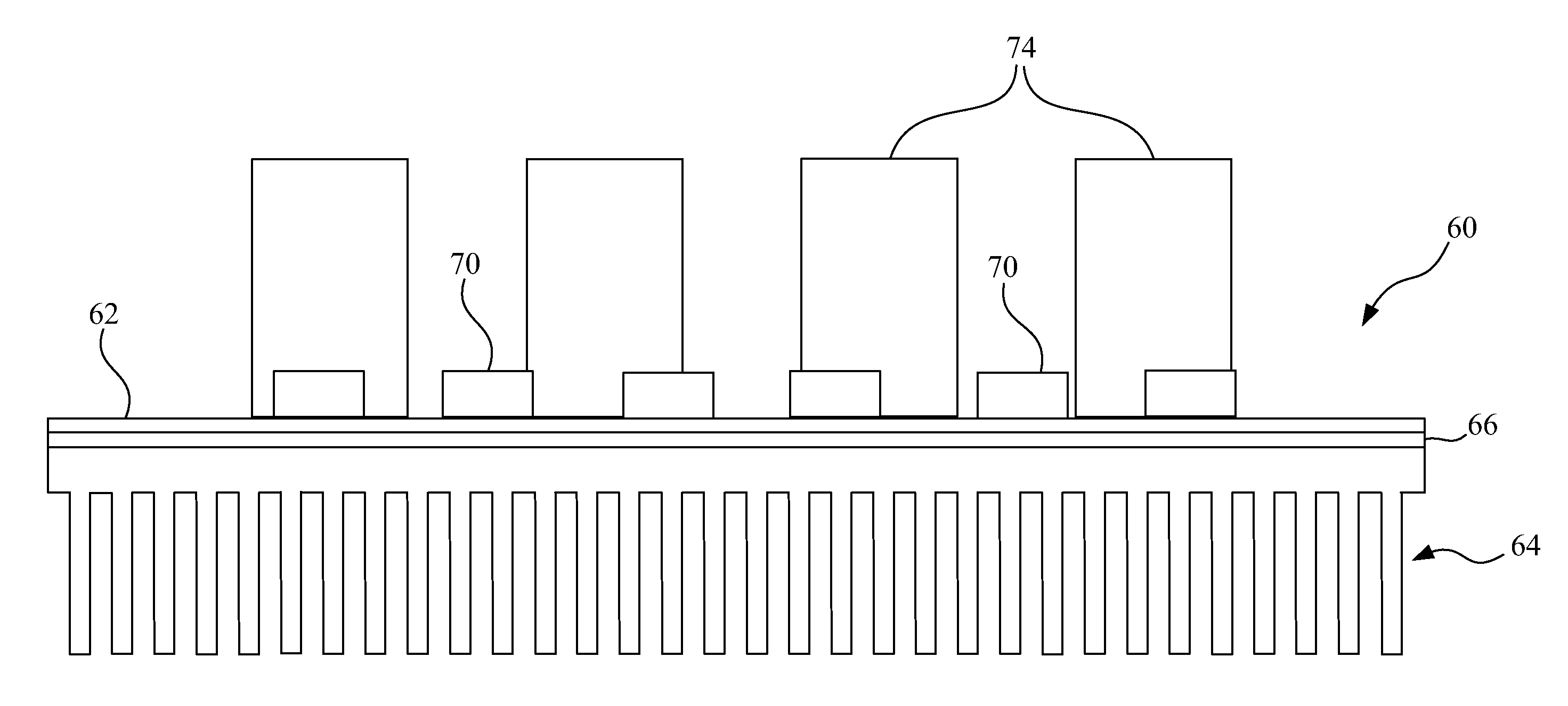

High power electronic package with enhanced cooling characteristics

ActiveUS6943293B1Heat dissipationIncrease ratingsSemiconductor/solid-state device detailsSolid-state devicesElectronic componentPower electronics

A power electronics module includes a heat sink and an electronic package having a first layer in direct thermal communication with the heat sink. At least one electronic component is disposed between the first layer and a second layer. A thermally conductive element is in direct thermal communication with the second layer and carries heat from a first portion of the second layer to a second portion of the second layer such that the heat is transferred from the second portion of the second layer to the heat sink through the first layer.

Owner:DELPHI TECH IP LTD

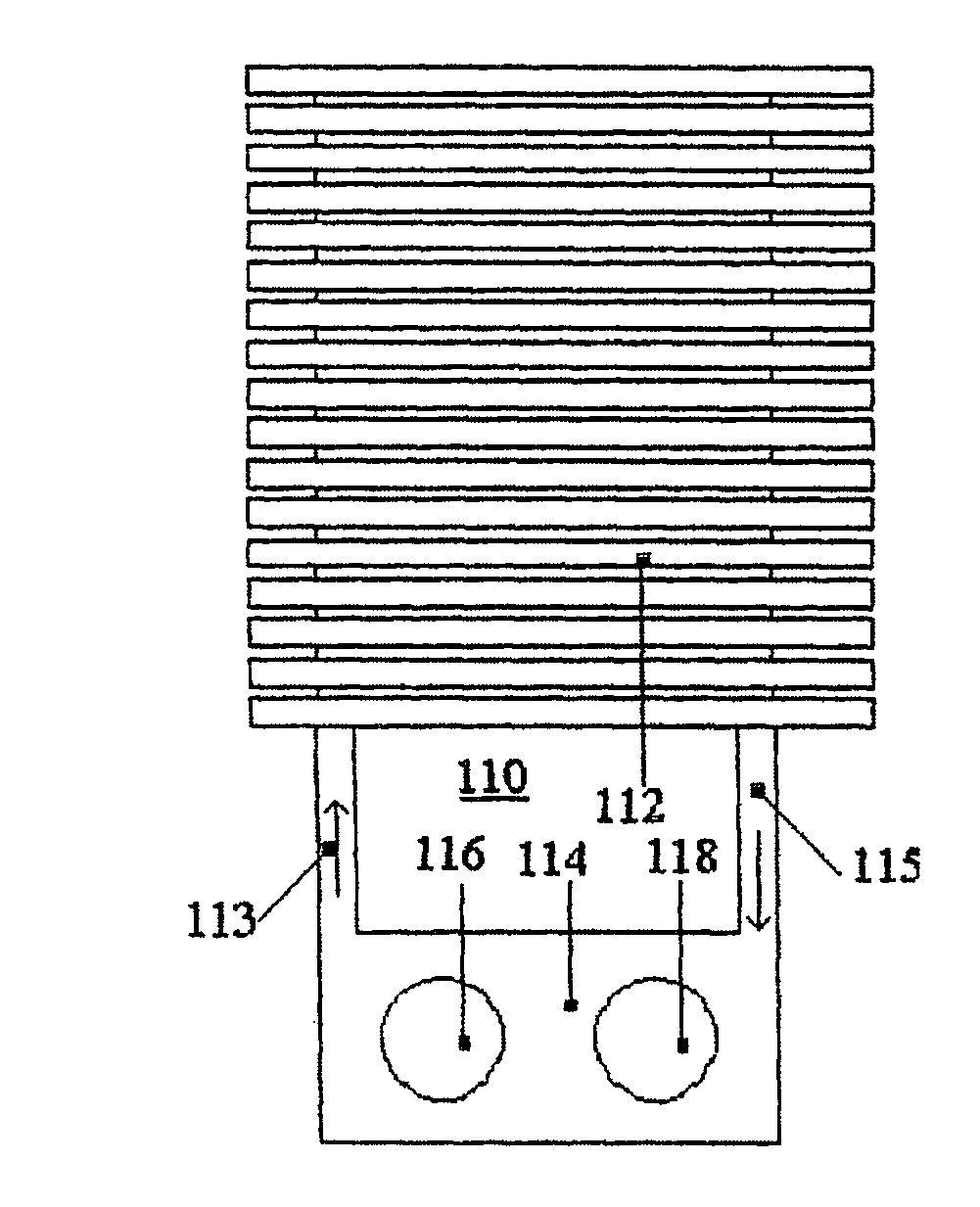

Cooling devices for various applications

InactiveUS20070184320A1Effective, not bulky, and inexpensivePoor heat resistanceInternal combustion piston enginesFuel cells groupingHeat fluxMicroheater

The figure displays the diagram of a laminar flow water cooler (110) for a microprocessor comprising an integral radiator (112) provided with thin-walled and hollow fins which are produced by controlled compression of double convex bellows of a polymer or glass hot-blown blank. In order to form a closed circuit filled with water at the atmospheric pressure, the manifolds (113, 114, 115) of the radiator (112) are connected to the manifolds of an original component (114) formed by a mini heater (116) provided with a copper heating plate with internal grooved face and a mini pump (118) provided with a brushless electric motor devoid of a centrifugal turbine, wherein said mini heater and mini pump are disposed in a rigid small-sized moulded polymer hose. The total thermal resistance of said cooler can be equal to 0.15° / W that is of interest, in particular for high performance microprocessors for dissipating more than 200 W through the very hot central area of 1.5 cm2 of the heat dissipating surface thereof. The concept of the production of the inventive cooler makes it possible to design efficient and low-cost cooling devices which are usable for microprocessors, high-power electronic devices, thermal engines or fuel cells, in particular mounted in a motor vehicle. Said invention can be used for cooling any component dissipating a given thermal flux within the determined power and temperature limits.

Owner:TECH DE LECHANGE THERMIQUE TET

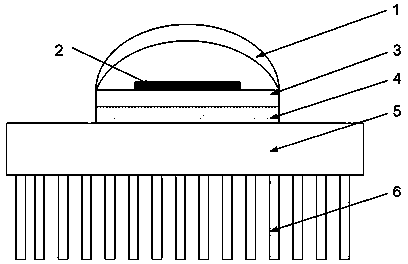

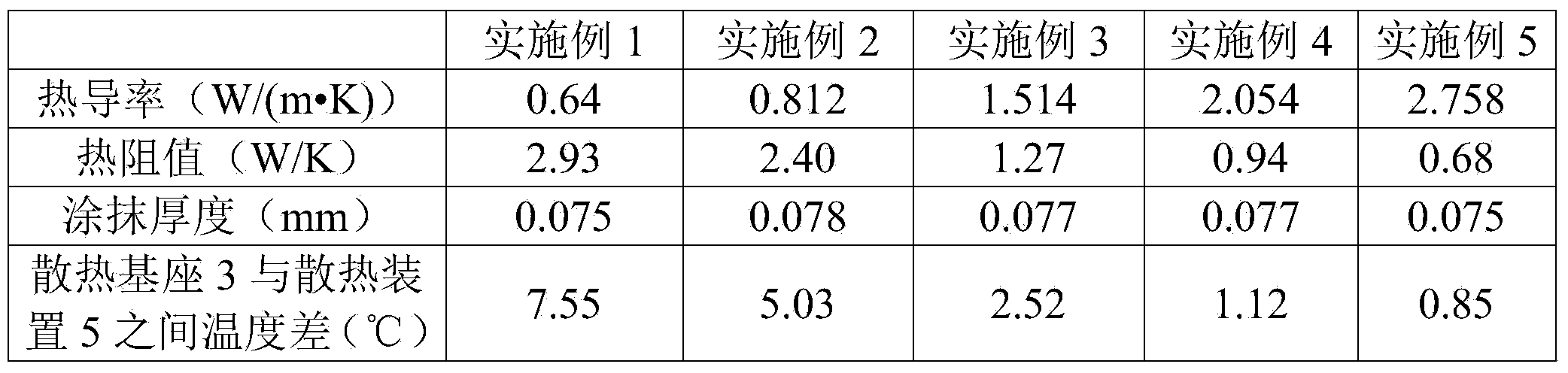

Low-filling-capacity and high-heat-conductivity graphene/silicone grease composite material and preparation method thereof

The invention discloses a low-filling-capacity and high-heat-conductivity graphene / silicone grease composite material and a preparation method thereof. Heat-conductive silicone grease is prepared by filling functional reduction-oxidation graphene sheet with silicone oil. The preparation method of the composite material comprises the following steps: preparing the functional reduction-oxidation graphene sheet as heat-conductive filler; sufficiently mixing the modified heat-conductive filler and dimethicone matrix in a double-roller open mill to uniformly disperse the functional reduction-oxidation graphene sheet in the silicone oil matrix. The heat-conductive silicone grease provided by the invention can be used for effectively avoiding the contacting gap between a high-power electronic component heating element and a heat radiation device, so that the interface contact thermal resistance can be reduced, a high-efficiency heat radiation passage is formed, and heat transfer is accelerated; the silicone grease is beneficial to encapsulation and radiation of the high-power electronic components, can be used for improving the reliability of the electronic component products and prolonging the service life of the products, and is simple in preparation process.

Owner:GUANGDONG UNIV OF TECH

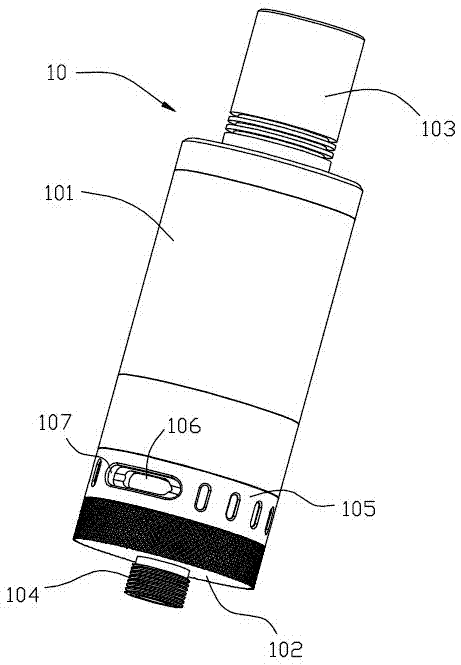

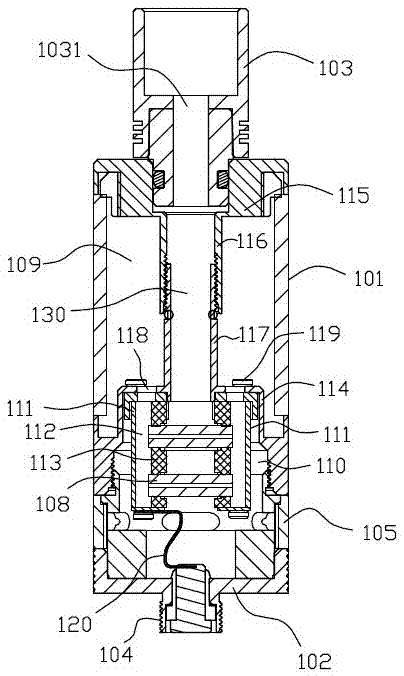

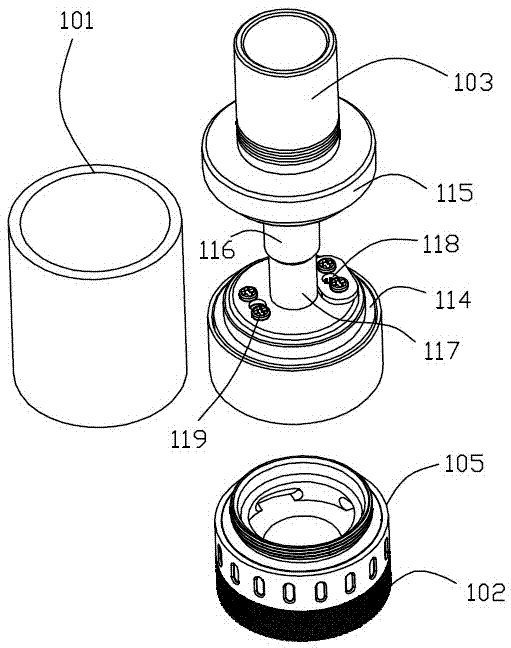

Atomizer and electronic smoking device

PendingCN105433443AWith heating functionEasy to assembleAdditive manufacturingOhmic-resistance waterproof/air-tight sealsCapillary actionLiquid storage

The invention discloses an atomizer and an electronic smoking device. The atomizer comprises a shell, an electric conduction part arranged on the shell and a suction nozzle with a gas outlet, a liquid storage cavity used for containing tobacco liquid is formed in the interior of the shell, the shell is further internally provided with at least one heating element which is electrically connected with the electric conduction part, each heating element comprises a liquid conduction carrier with a micropore structure and a heating part which forms an integral structure with the liquid conduction carrier, and the liquid conduction carrier can make contact with the tobacco liquid; the heating elements heat and atomize the tobacco liquid sucked by the liquid conduction carrier through the capillary action. The heating elements in the atomizer have the functions of sucking the tobacco liquid and heating simultaneously, and the atomizer is simple in structure and capable of being applied to high-power electronic smoking devices.

Owner:SHENZHEN FIRST UNION TECH CO LTD

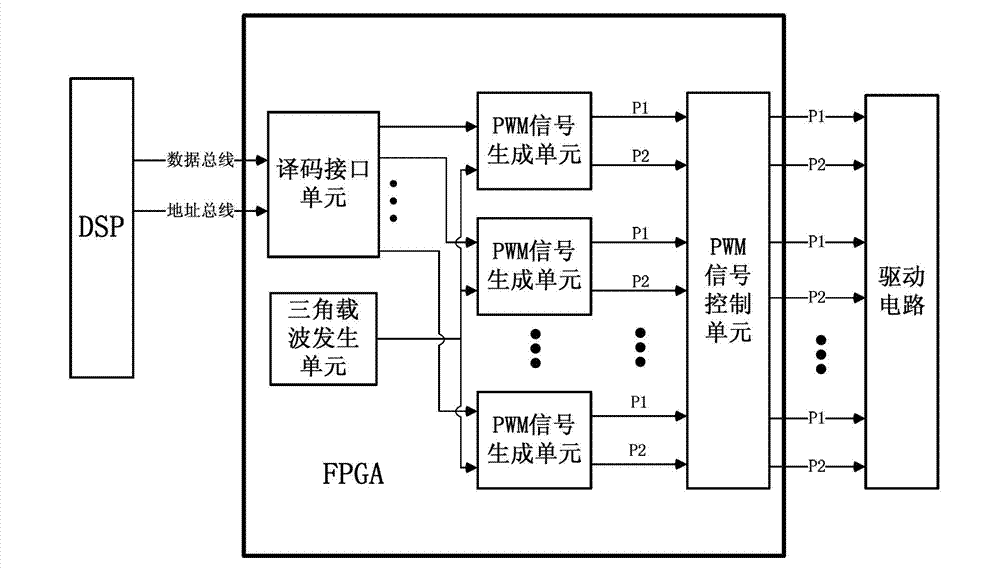

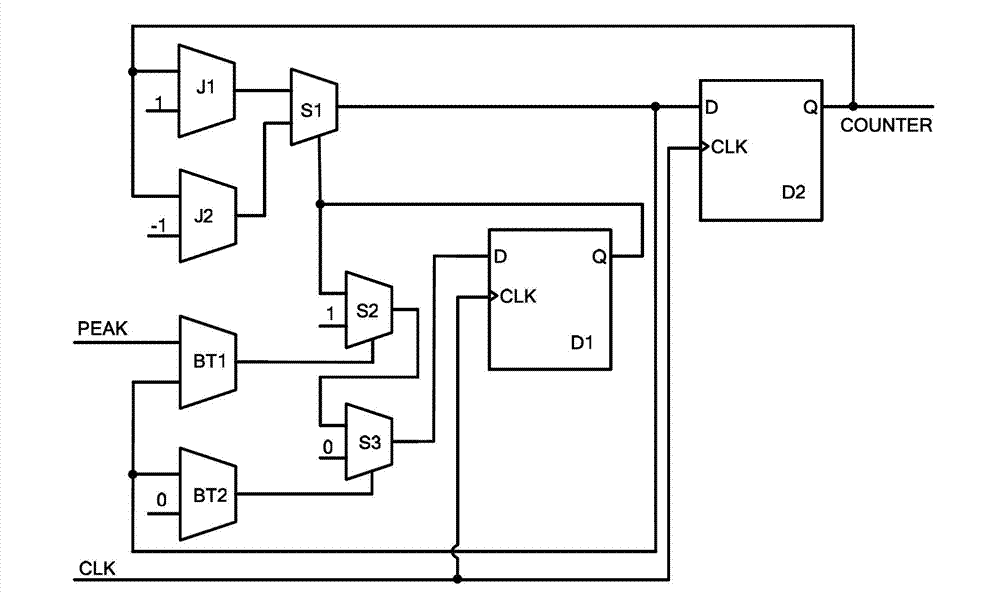

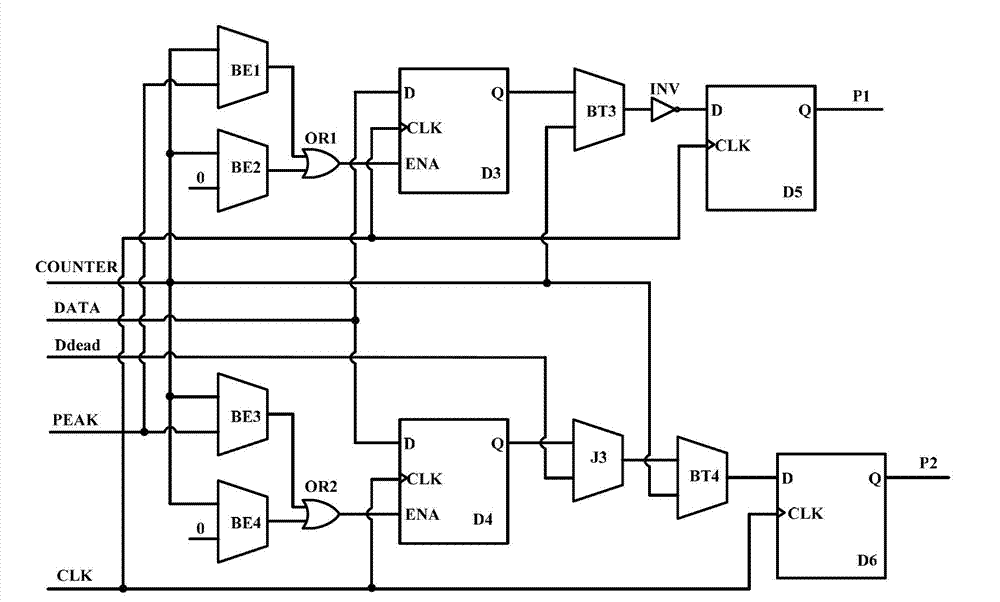

Pulse wavelength modulation (PWM) generator based on field programmable gate array (FPGA)

InactiveCN103178815AReduce design costImprove reliabilityPulse duration/width modulationWavelength modulationDigital control

The invention discloses a pulse wavelength modulation (PWM) generator based on field programmable gate array (FPGA). The generator comprises an FPGA, wherein the FPGA is loaded with a decoding interface unit, a triangular carrier generating unit and n PWM signal generating units. The novel PWM signal generator disclosed by the invention can be realized by combining with FPGA hardware programming language and FPGA circuit design software tool, so as to better solve the problem in a high-power electronic system that the precision is affected since computation is heavy and digital control is delayed due to multiple paths of PWM signals; the carrier frequency, the dead time and the enable signal can be designed according to demands of the system, and the application range is wide and flexible application to various situations is realized; and meanwhile, the PWM generator still has the advantages of high reliability, reduced hardware design cost, strong antijamming capability and the like when being applied to other PWM signal generating circuits.

Owner:ZHEJIANG UNIV +1

High heat-conducting insulating silicon rubber and preparation method thereof

The invention discloses high heat-conducting insulating silicon rubber and a preparation method thereof. Dimethyl vinyl silicon rubber is used as base rubber; 2,5-dimentyl-2,5-di (peroxy-tert-butyl) hexane is used as a curing agent; needle-like ZnO, spherical Al2O3, flaky BN and columnar AIN are used as heat-conducting fillers; and the fillers are closely accumulated by reasonably matching the heat-conducting fillers in different forms and with different particle diameters to form a large quantity of heat-conducting passages. The silicon rubber has high heat resistance and is not deformed after long-term use, the heat conductivity reaches 3.8W / m.K (ASTM D 5470, Hot Disk method), the strength is 5MPa, the volume resistivity is 1,014 omega.cm, the Shore hardness is 50 to 70, and the siliconrubber can meet the heat dissipation and insulating requirements of various high-power electronic devices.

Owner:HEFEI UNIV OF TECH

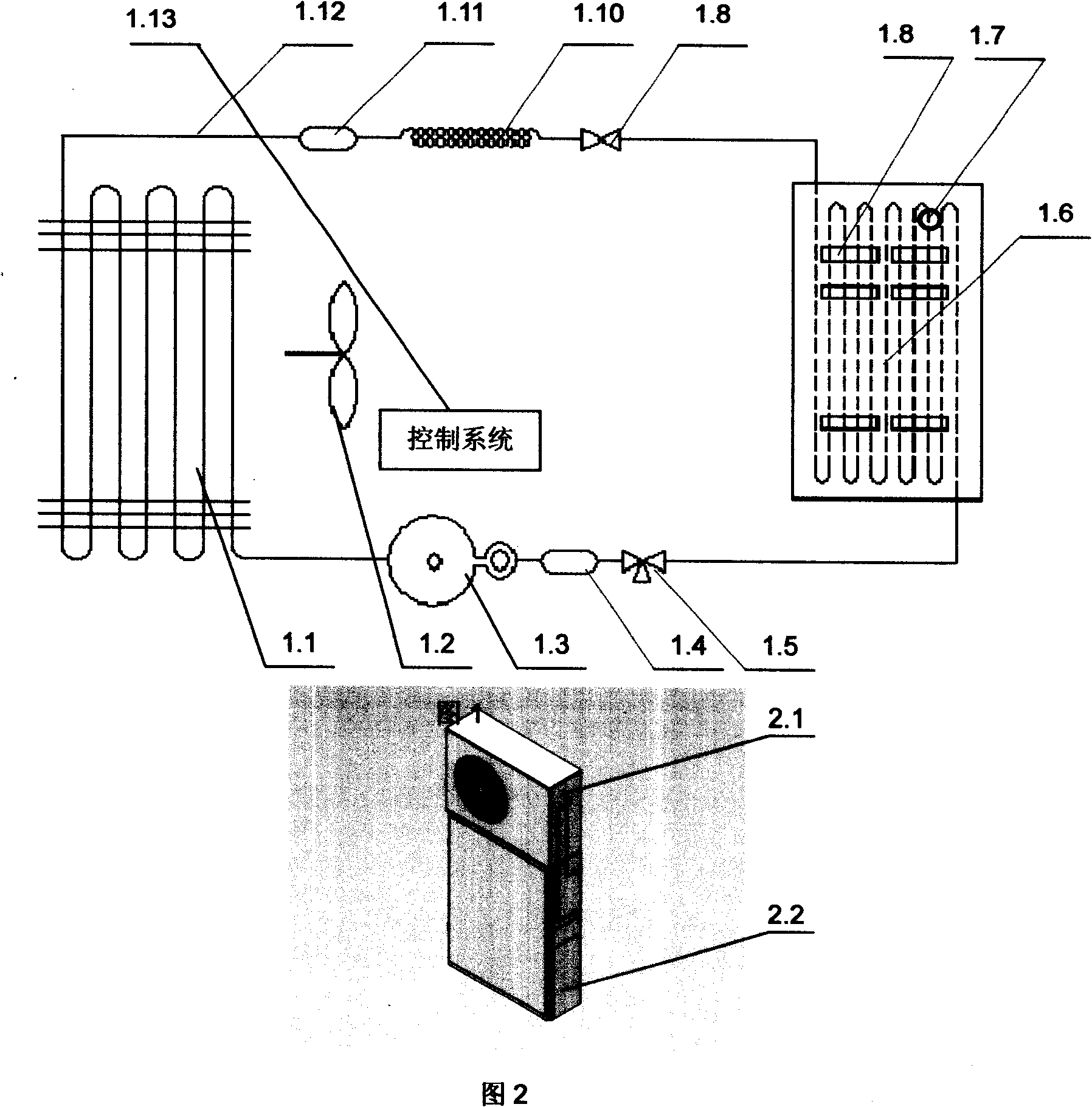

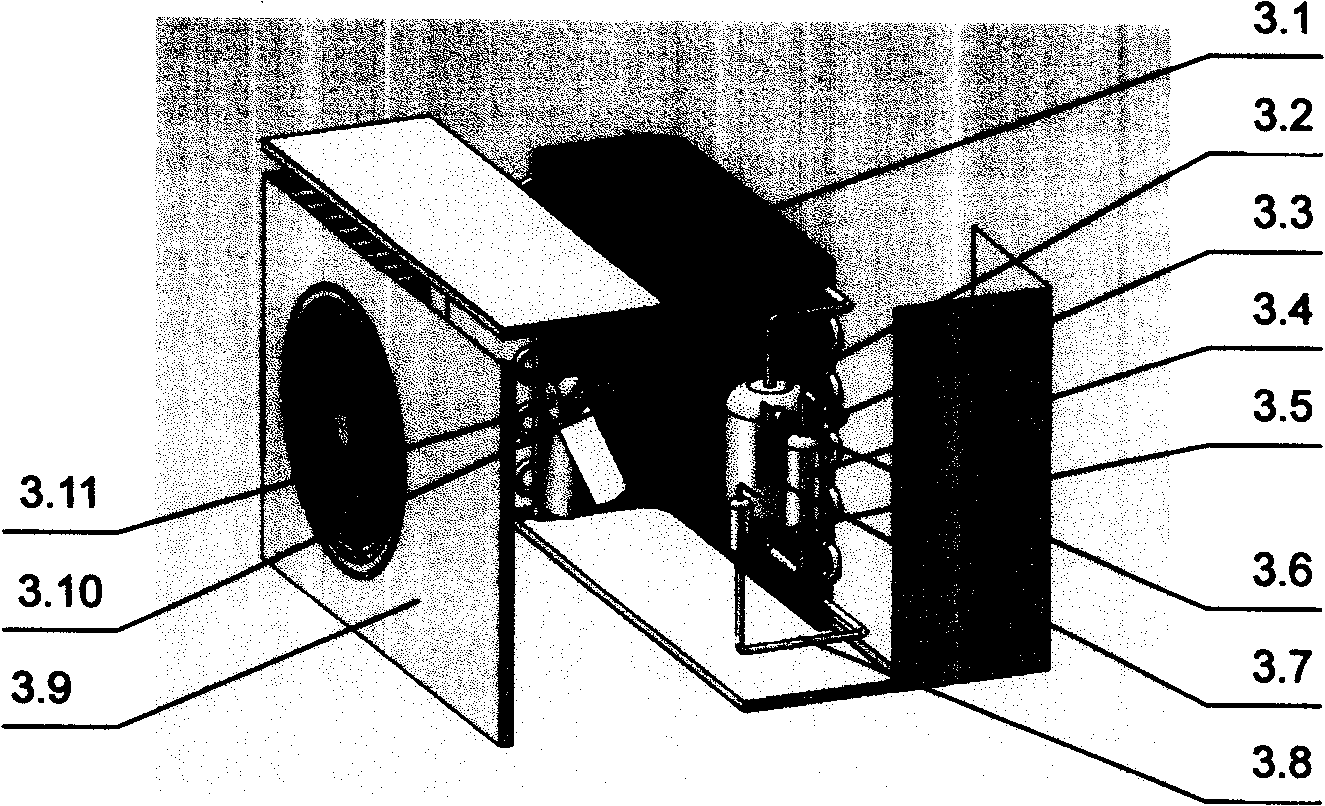

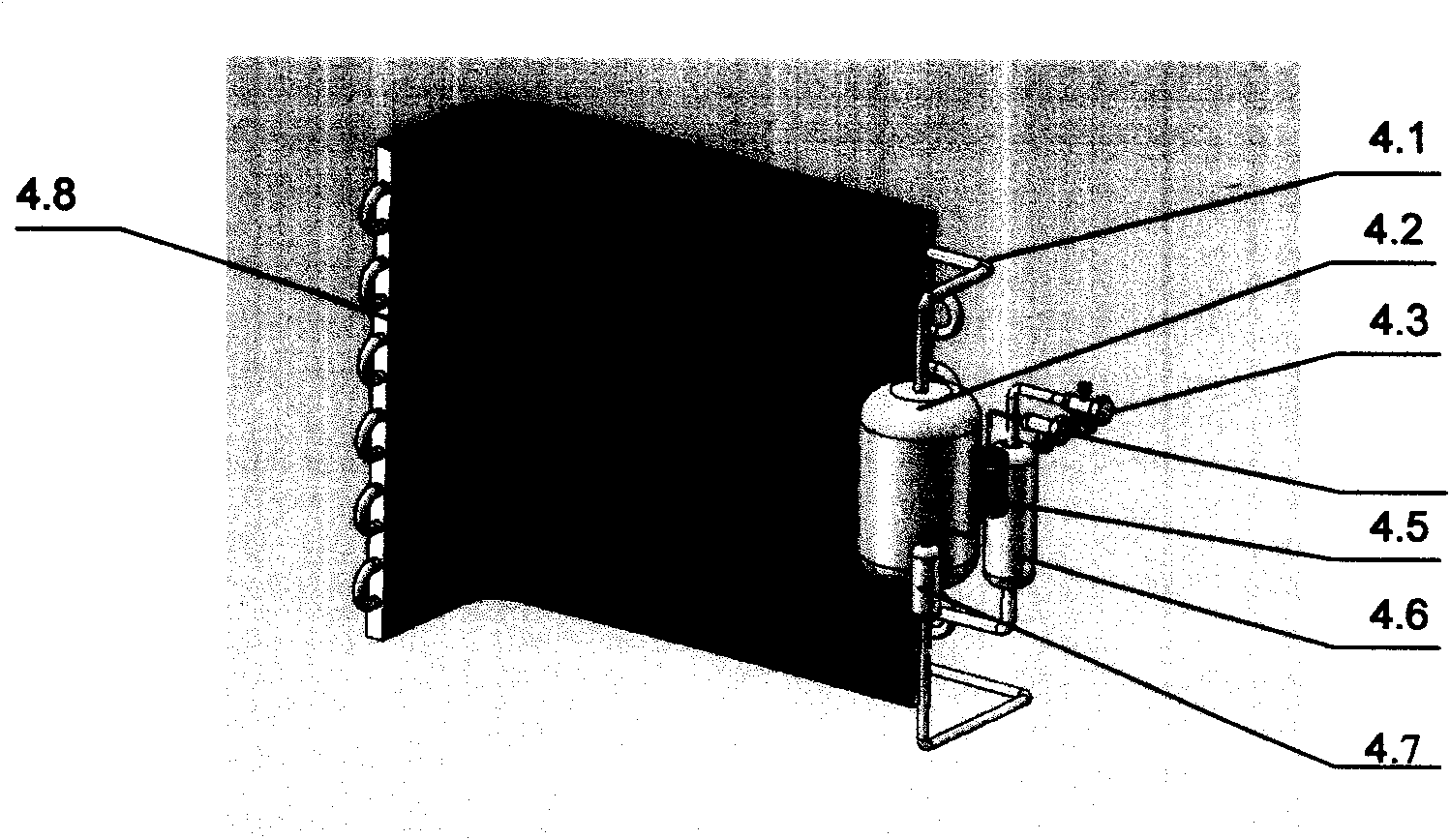

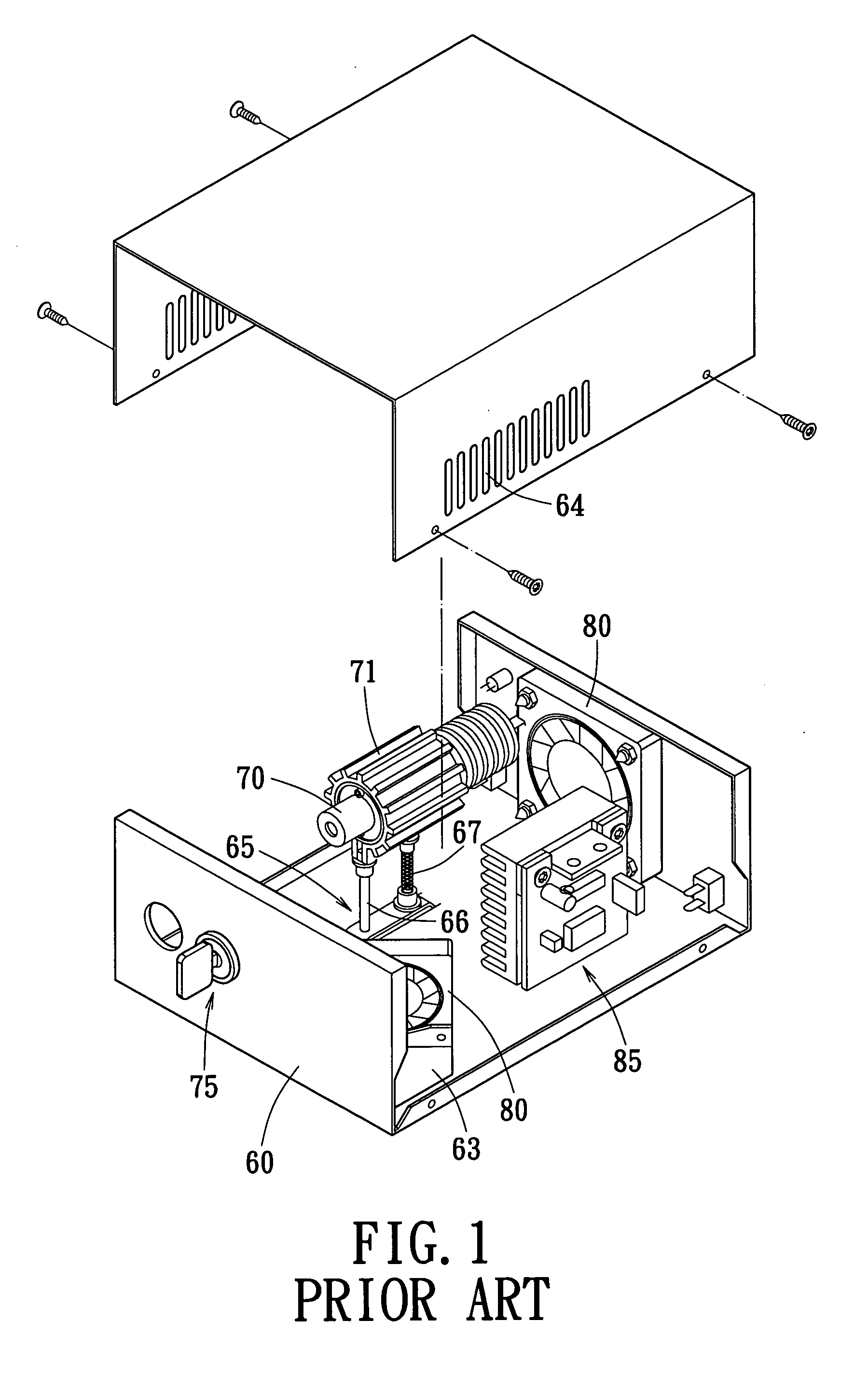

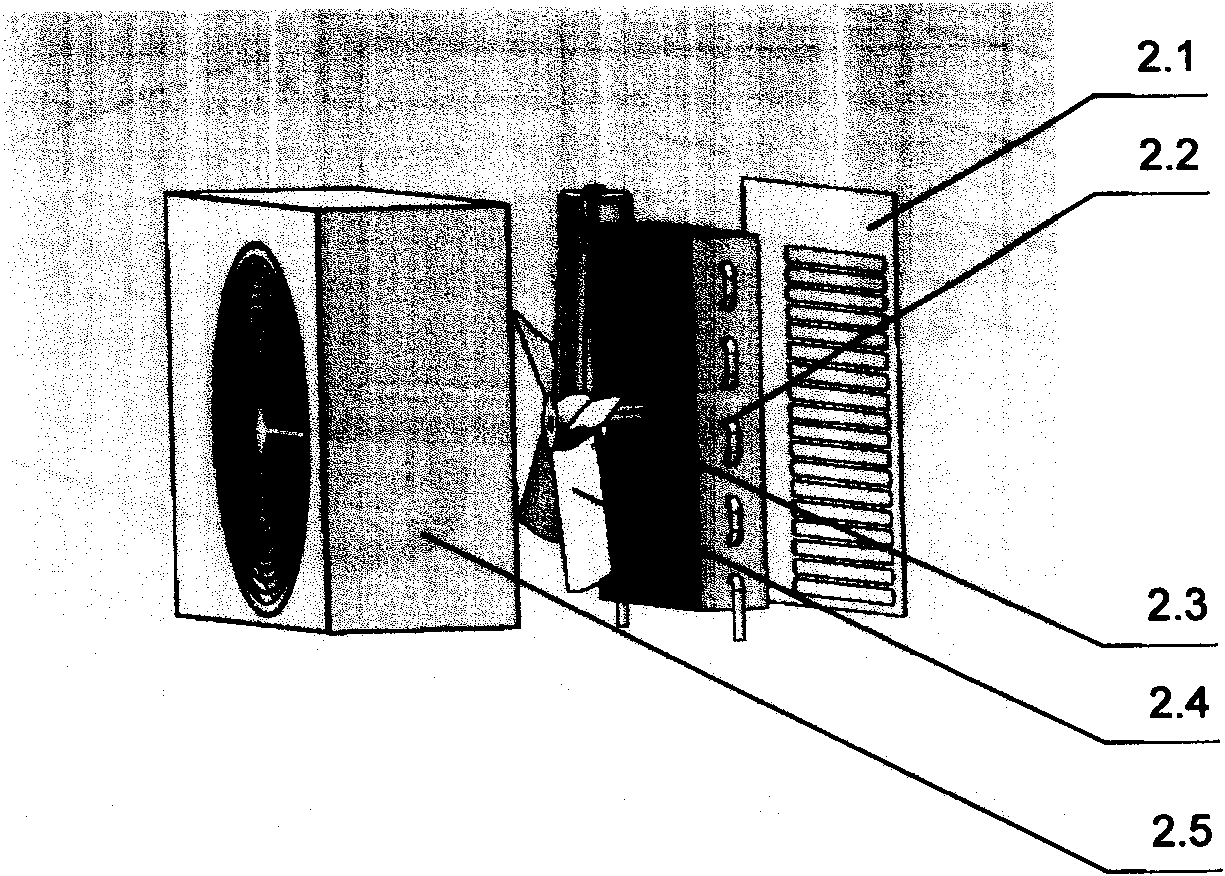

Compressor cooling type fully sealed high-efficiency radiating electronic cabinet

InactiveCN101610660ALow costImprove reliabilityMagnetic/electric field screeningCompression machines with non-reversible cycleLow noiseElectromagnetic shielding

The invention relates to radiating technology applied to fully sealed electronic cabinets, in particular to a radiating method and a radiating device applied to high power electronic equipment required to be fully sealed in outdoor severe environment. By adopting a Carnot refrigeration cycle principle, a low temperature and low pressure liquid cooling medium enters a cold plate radiator (also called internal heat exchanger) arranged in a sealed cabinet through a sealed pipe, absorbs heat generated when calorific electronic elements arranged on the cold plate radiator work, and is evaporated into low temperature and low pressure superheated steam; the low temperature and low pressure superheated steam passes through a liquid-vapor separator, and dried superheated gas is sent into a compressor, and compressed into high temperature and high pressure gas; the high temperature and high pressure gas is sent into a condenser to release heat, and is condensed into supercooled liquid; the supercooled liquid is subjected to pressure reduction by resistance of capillarity tubes into low temperature and low pressure two-phase fluid; and the fluid passes through a filter and a pipe, and is sent into the cold plate radiator, and the heat of the fluid is absorbed by the cold plate radiator to realize circulation, wherein an electronic mainframe adopts a fully sealed cabinet structure so as to achieve the waterproof, dampproof, dustproof and electromagnetic shielding aims. The device adopting the radiating technology has the advantages of high power, small volume, easy control of temperature, low noise, low cost, high heat exchange efficiency and the like.

Owner:沈国忠

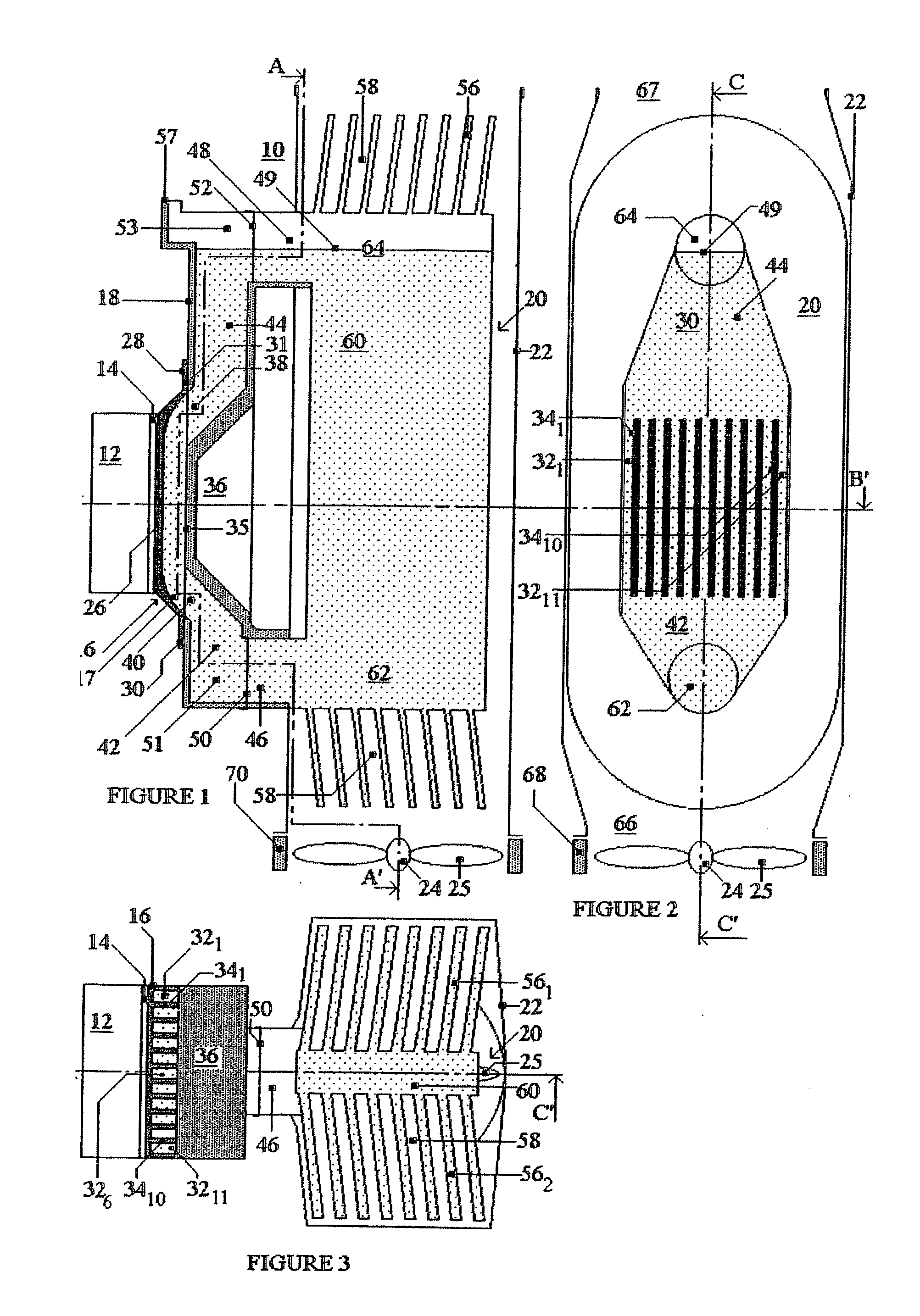

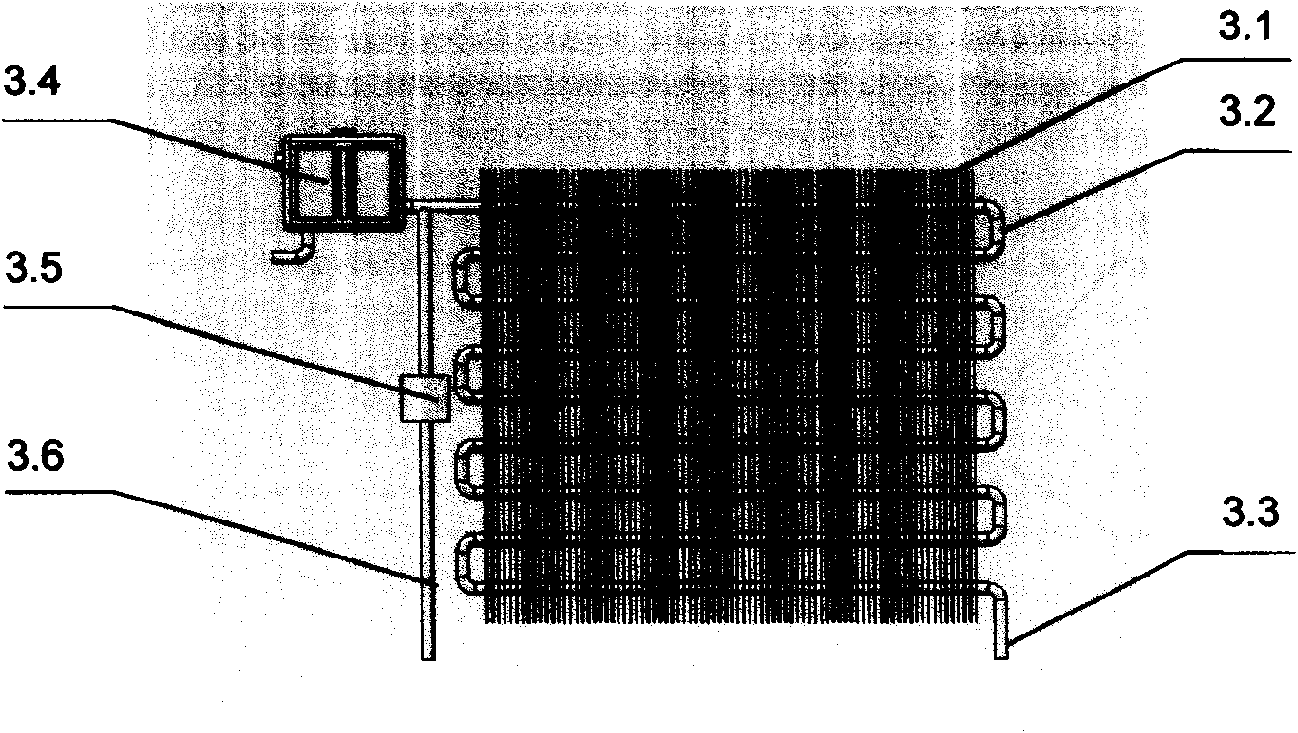

Heat radiation method for high-power electronic part and heat radiation device using this method

InactiveCN101193526AReduce volumeEasy temperature controlCooling/ventilation/heating modificationsLow noiseEngineering

The invention relates to a technology for heat dissipation, in particular, a method of heat dissipation and a device of heat dissipation for a large power electronic device. The invention adopts a two-level cyclic cooling device, among which, a first level cooling device is a cyclic liquid cooling device, and the cyclic liquid of the cyclic liquid cooling device exchanges heat with a radiator fixed with a heating electronic device so as to cool the heating device on the radiator; while a second cyclic cooling device is a heat pump refrigerating plant which cools the cyclic liquid. The invention cools the large power electronic device by combining liquid cooling and evaporative cooling. The invention has the advantages of small volume, manageable temperature, low noise, low cost, and high efficiency of heat exchange, etc.

Owner:沈国忠

High temperature circuit structures with thin film layer

InactiveUS6989574B2Maintain physical integrityAcceleration measurement using interia forcesSemiconductor/solid-state device detailsMicrometerThermal coefficient

A high temperature hybrid-circuit structure includes a temperature sensitive device which comprises SiC, AlN and / or AlxGa1-xN(x>0.69) connected via electrodes to an electrically conductive mounting layer that is physically bonded to an AlN die. The die, temperature sensitive device and mounting layer, which can be a thin film of W, WC or W2C less than 10 micrometers thick, have temperature coefficients of expansion within 1.06 of each other. The mounting layer can consist entirely of a W, WC or W2C adhesive layer, or an adhesive layer with an overlay metallization having a thermal coefficient of expansion not greater than about 3.5 times that of the adhesive layer. Applications include temperature sensors, pressure sensors, chemical sensors and high temperature and high power electronic circuits. Without the mounting layer, a thin film piezoelectric layer of SiC, AlN and / or AlxGa1-xN(x>0.69), less than 10 micrometers thick, can be secured to the die.

Owner:HEETRONIX

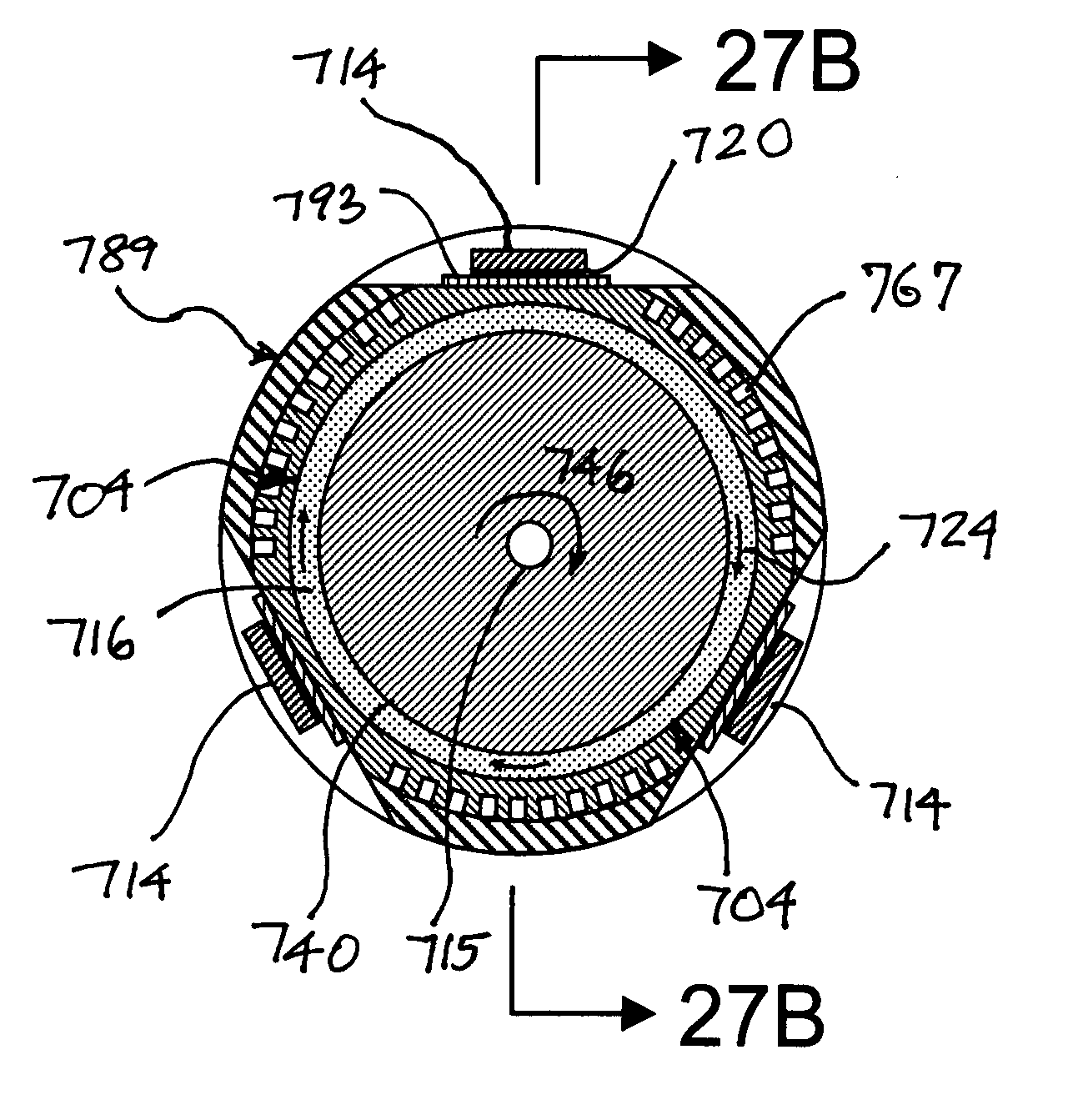

Thermal management for solid state high-power electronics

InactiveUS20120273164A1Little powerSuitable for large volumeEnergy efficient heating/coolingSemiconductor/solid-state device detailsMagnetic tension forceLiquid metal

The invention is for an apparatus and method for removal of waste heat from heat-generating components including high-power solid-state analog electronics such as being developed for hybrid-electric vehicles, solid-state digital electronics, light-emitting diodes for solid-state lighting, semiconductor laser diodes, photo-voltaic cells, anodes for x-ray tubes, and solids-state laser crystals. Liquid coolant is flowed in one or more closed channels having a substantially constant radius of curvature. Suitable coolants include liquid metals and liquids with low vapor pressure. The former may be flowed by magneto-hydrodynamic effect or by electromagnetic induction. The latter may be flowed by magnetic forces. Alternatively, an arbitrary liquid coolant may be used and flowed by an impeller operated by electromagnetic induction or by magnetic forces. The coolant may be flowed at very high velocity to produce very high heat transfer rates and allow for heat removal at very high flux.

Owner:VETROVEC JAN

High power semiconductor laser lighting device

InactiveUS20050254537A1Maintain temperatureAvoid thermal efficiencySemiconductor laser structural detailsLaser cooling arrangementsThermoelectric coolingInsulation layer

A high power semiconductor laser lighting device has a housing, a fan module arranged in an exhaust hole in the housing, a base connected to the bottom wall of the housing and disposed on a side of the fan module, and a semiconductor laser constant-temperature module. The base has a driving unit with at least one high power electronic component connected to fins of the fan module. The semiconductor laser constant-temperature module has a metallic partition to enclose a vacuum formed in a front portion of the housing, and a heat insulation layer arranged in the vacuum. The metallic partition has a side connecting the heat dissipation plate and an opposite side connecting a heating portion of a thermoelectric cooling chip, which includes a cooling portion connecting to a semiconductor laser lighting module. The high power semiconductor laser lighting device to keep an output power thereof constant within various environments.

Owner:EINS TECH

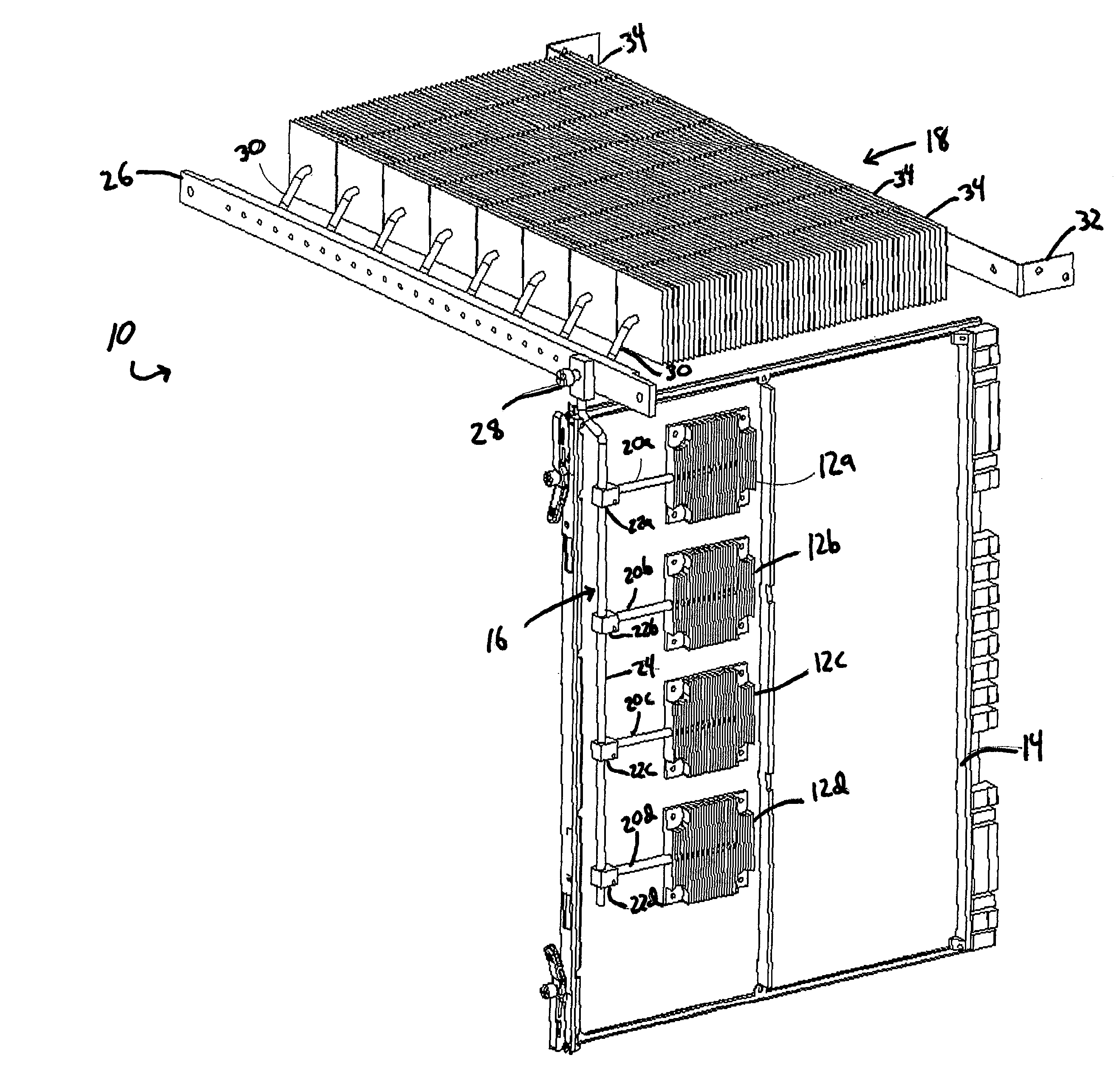

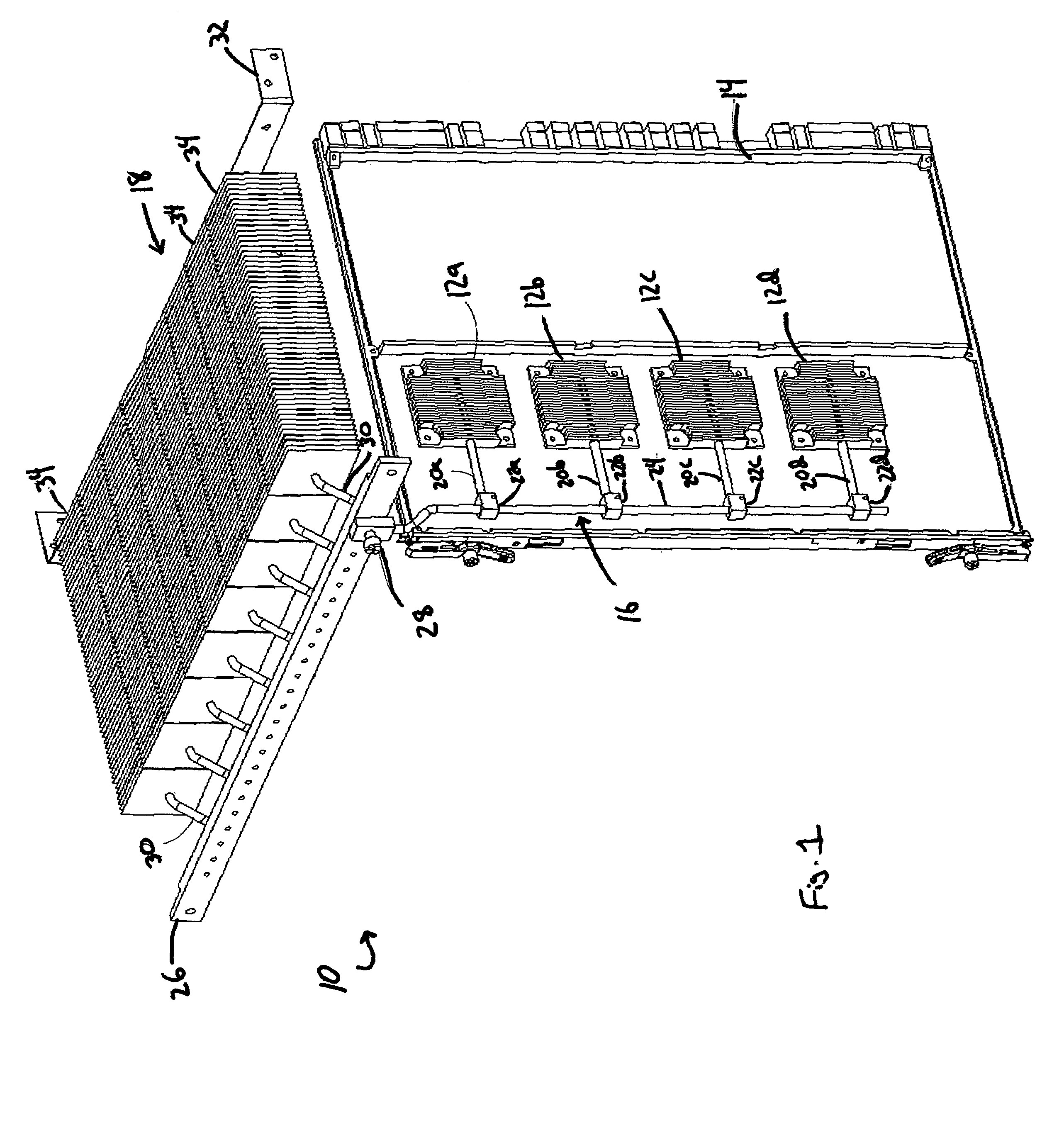

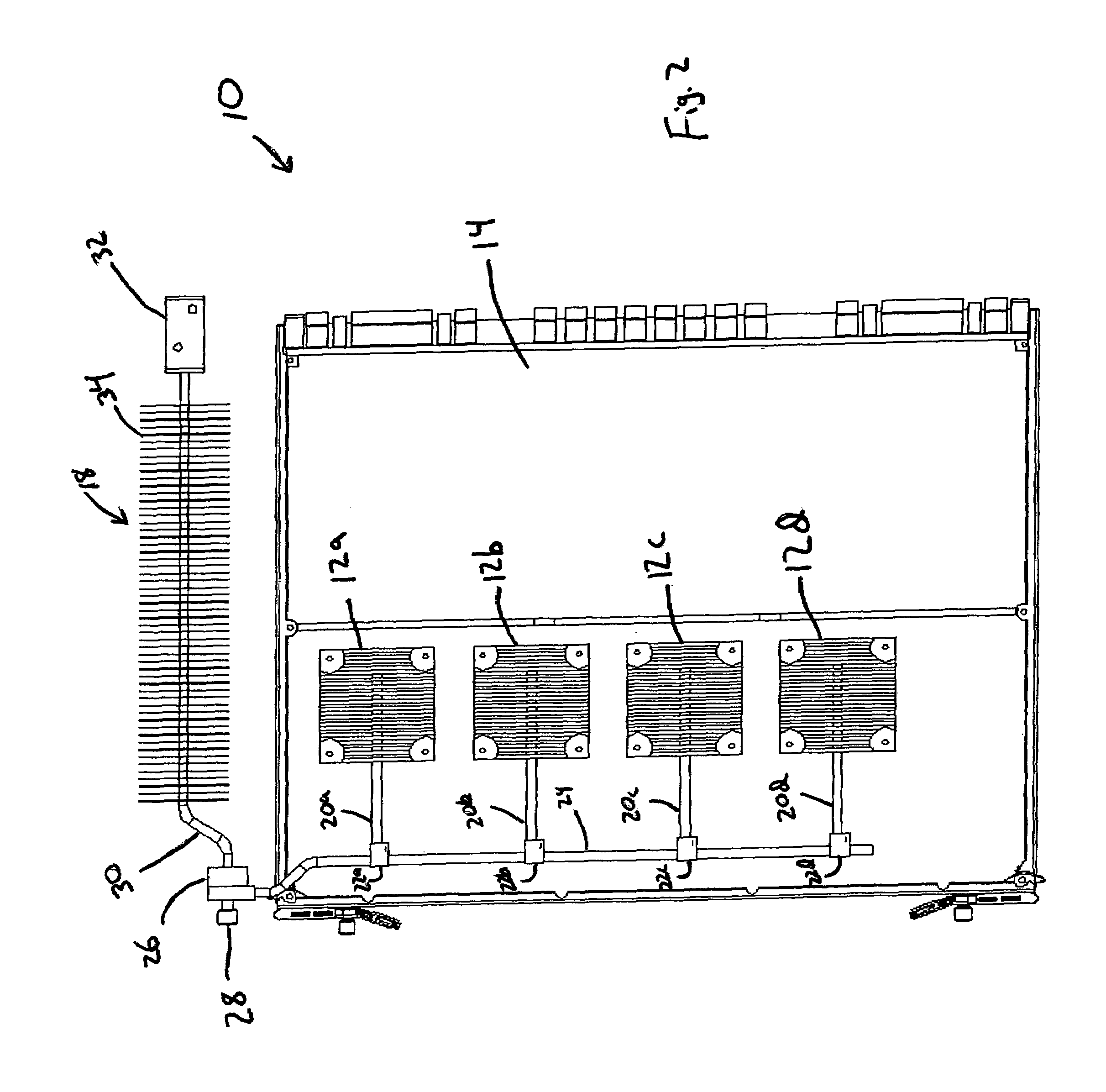

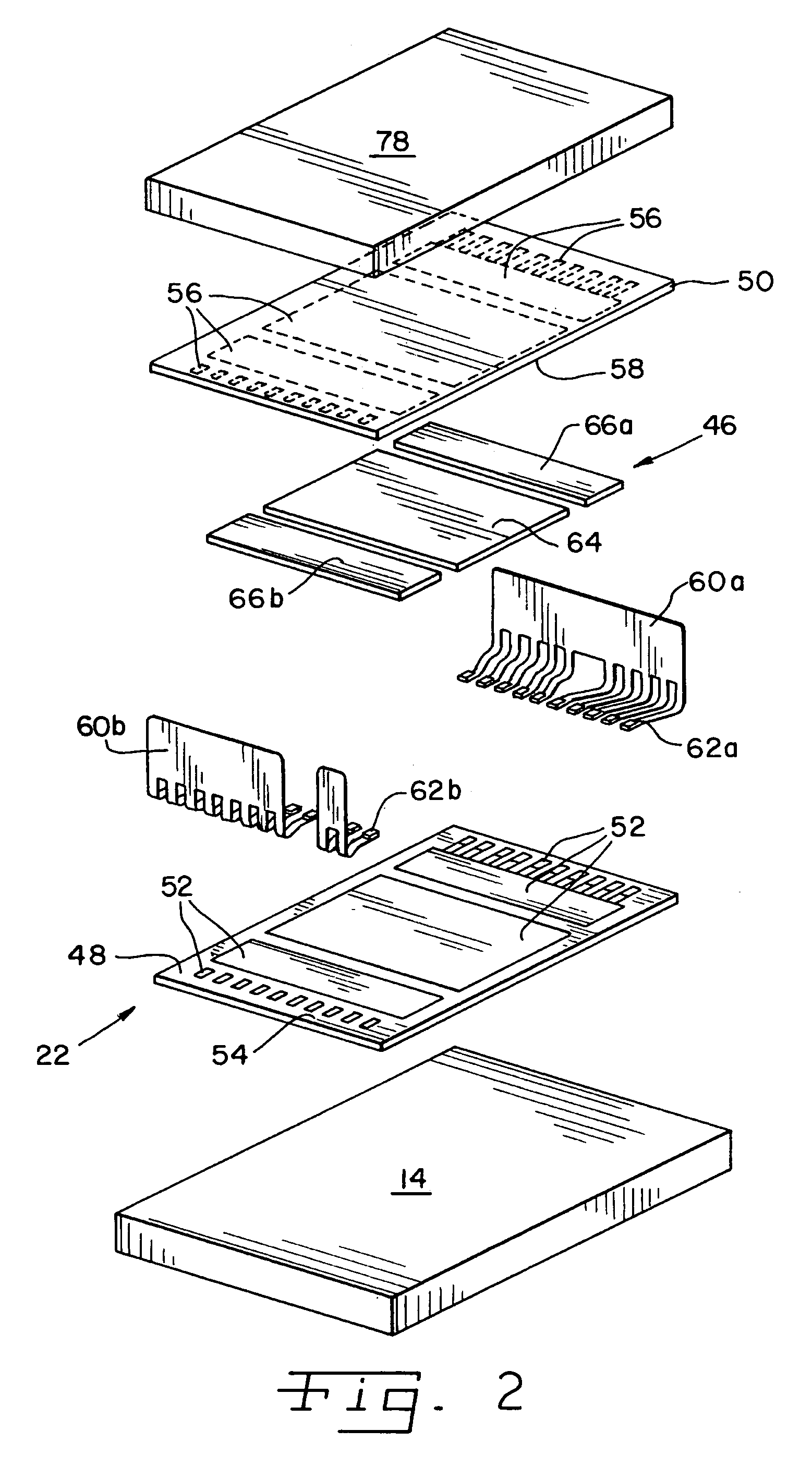

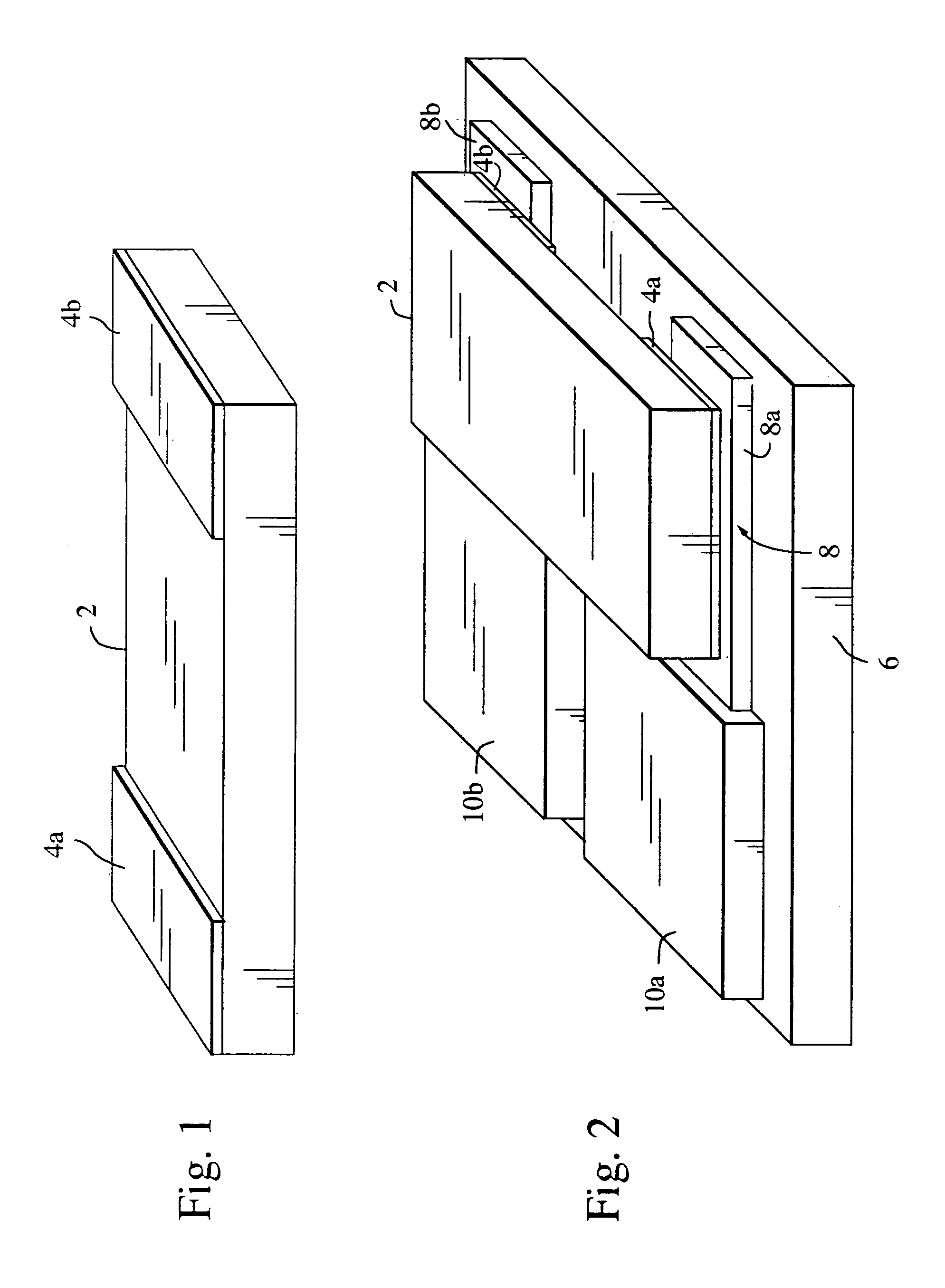

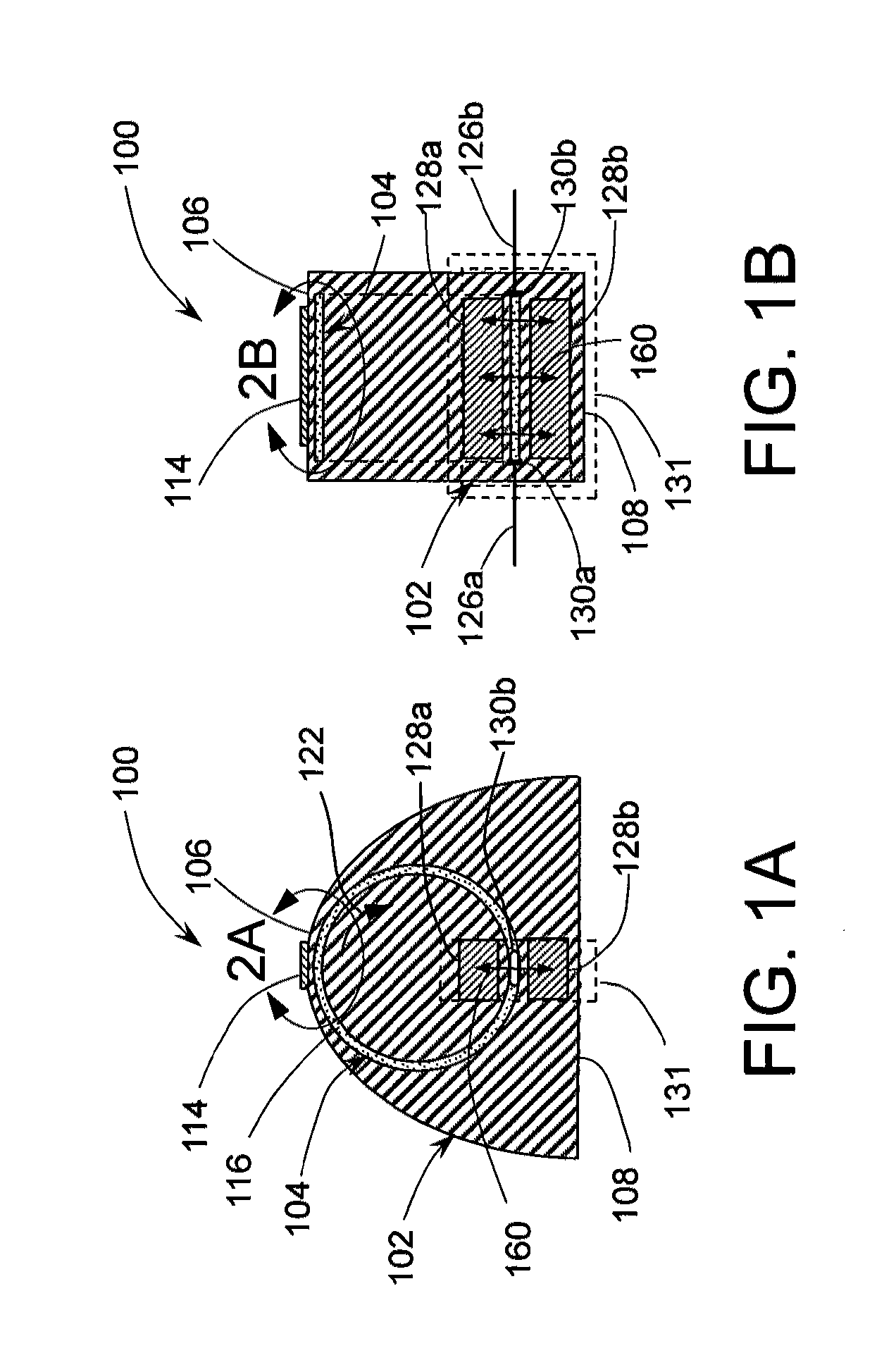

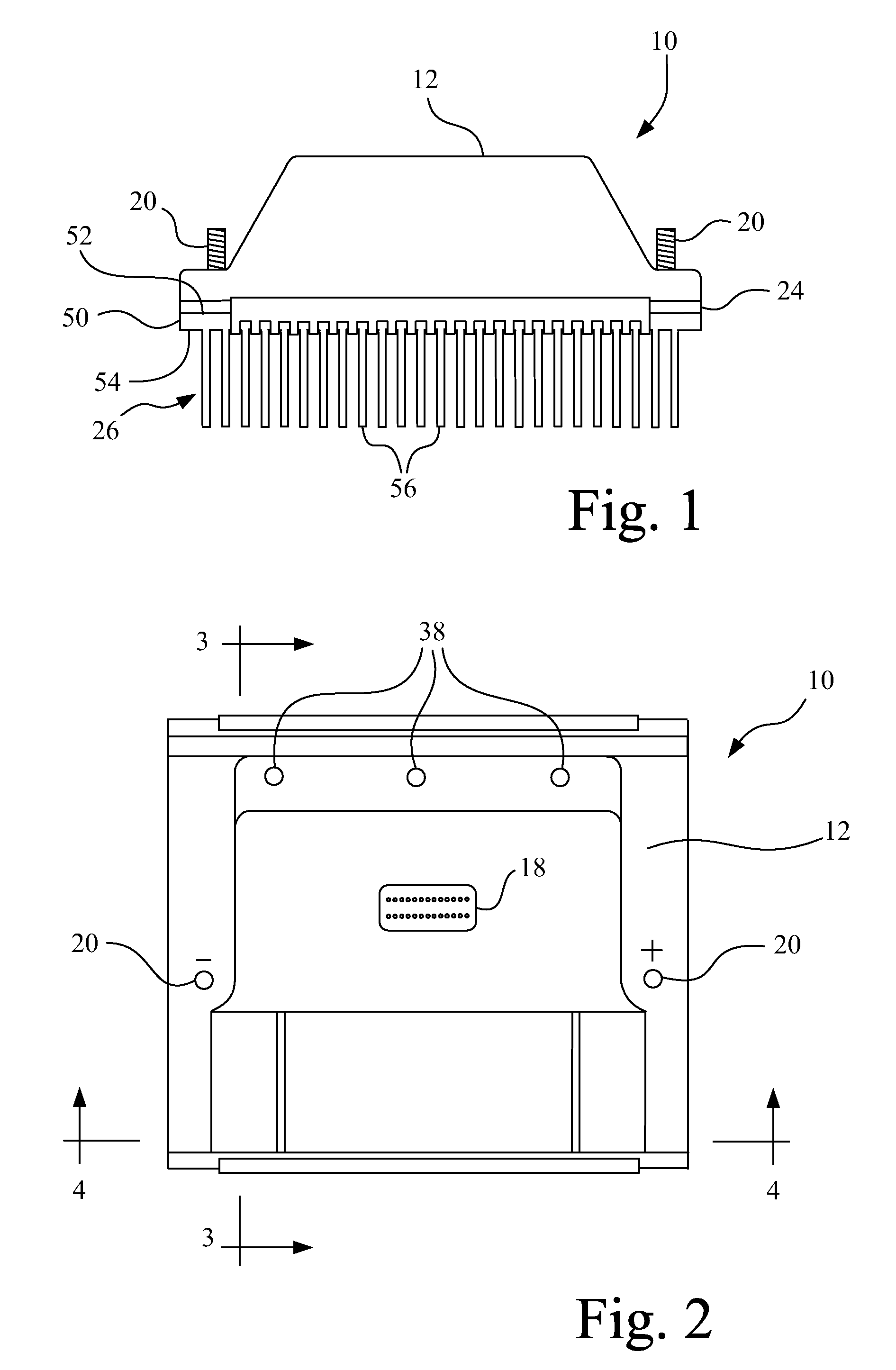

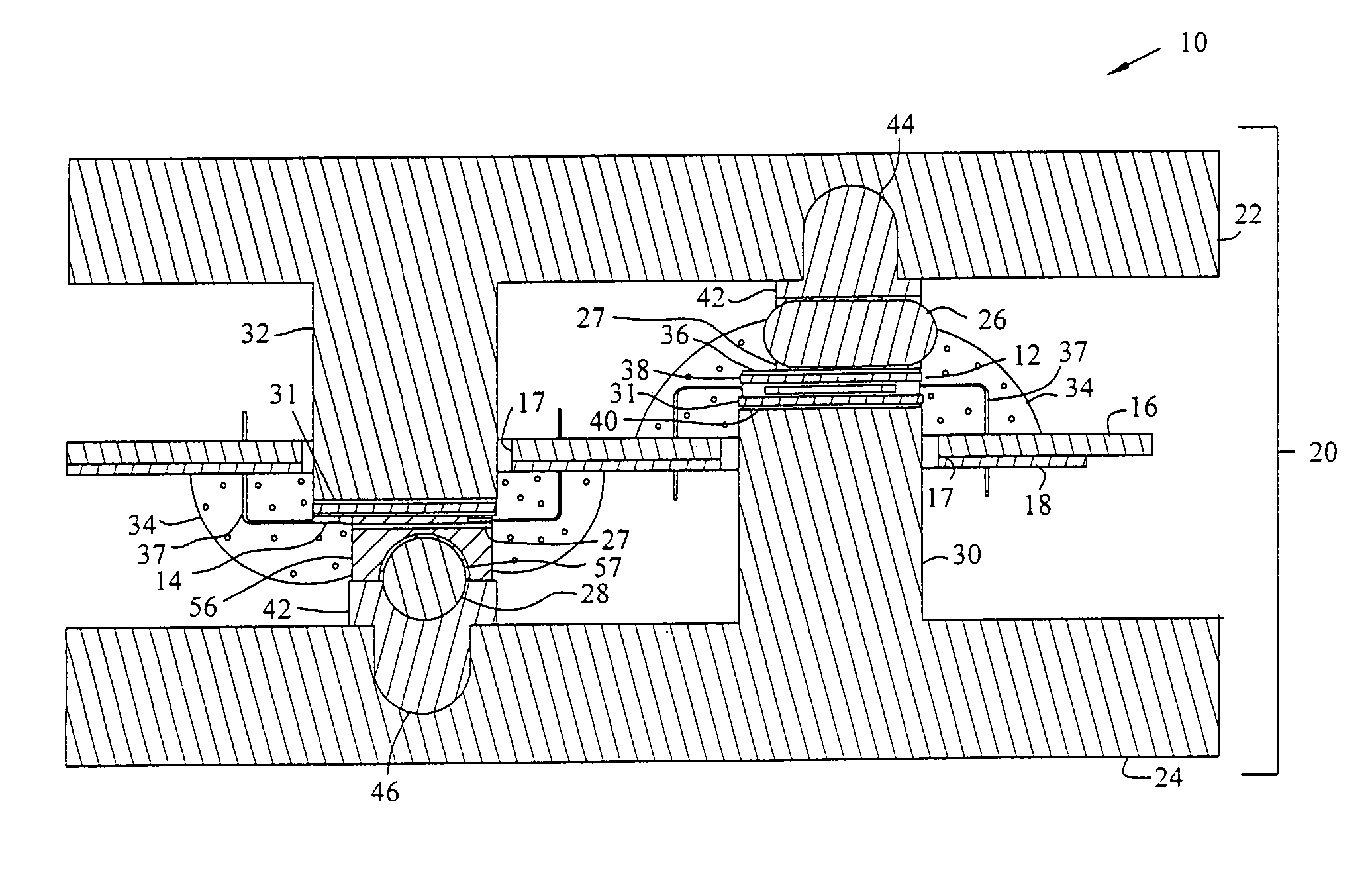

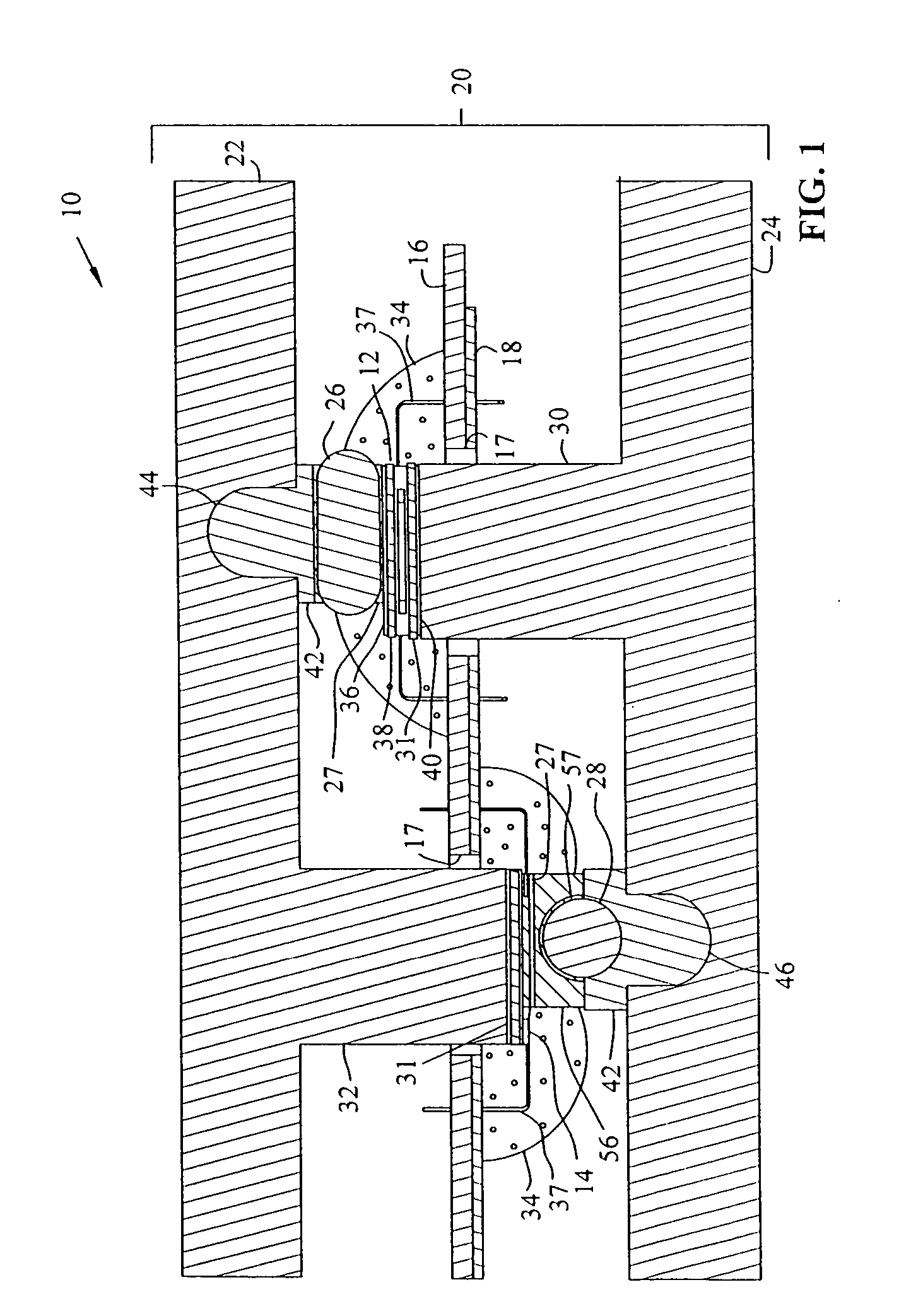

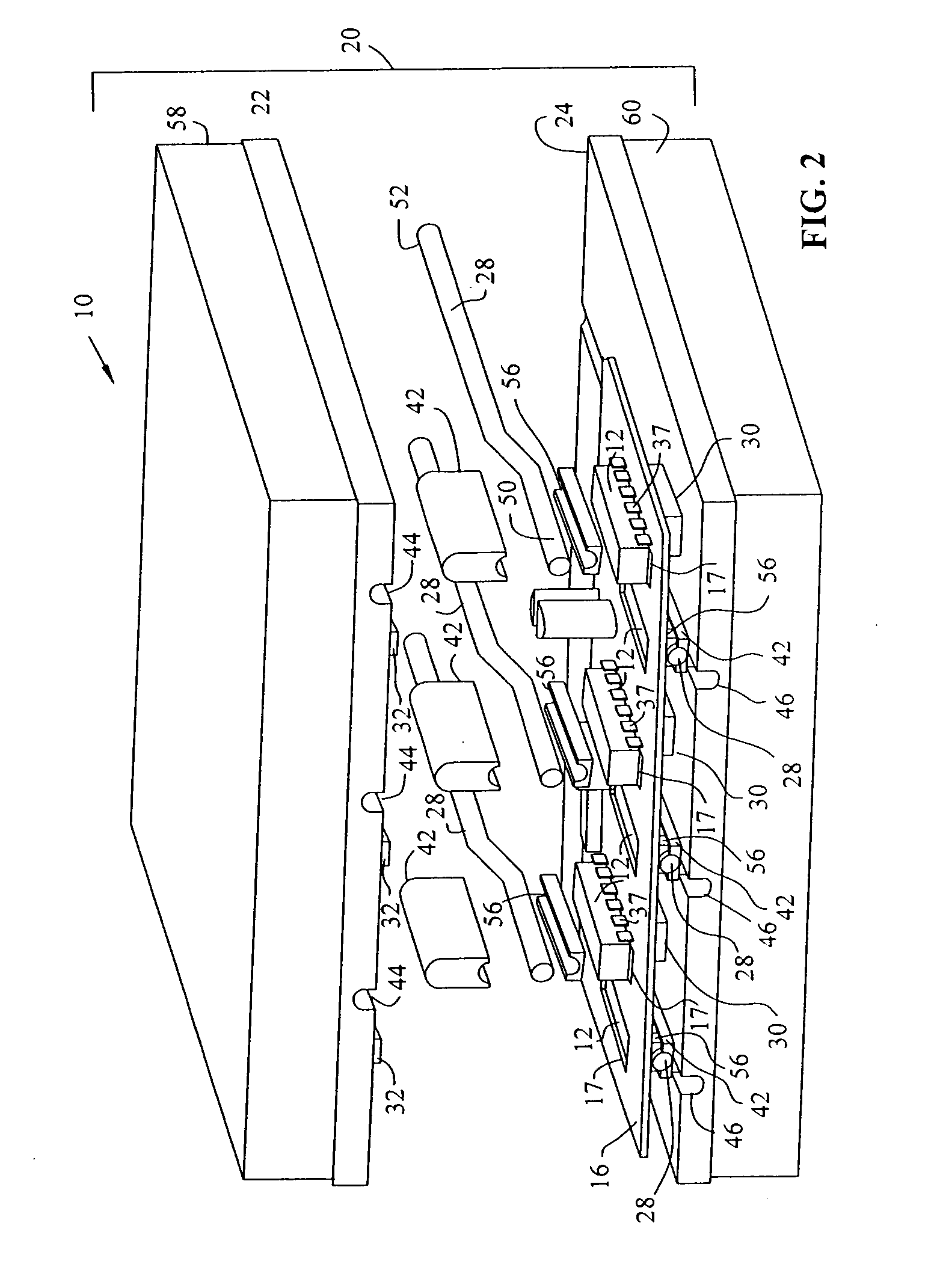

Electrical circuit assembly for high-power electronics

InactiveUS20080247139A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectricityAdhesive

An electrical circuit assembly includes an electrical circuit substrate having a first side; a heat sink including a metal base plate having a first side and a second side, and a plurality of fins extending from the second side; and a thermally conductive and electrically insulating adhesive directly interconnecting at least a portion of the first side of the electrical circuit substrate with the first side of the base plate.

Owner:DEERE & CO

Preparation method and application of high thermal and electrical conductivity adhesive

ActiveCN108102579AInhibition of sintering activityImprove transmission efficiencyNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesiveElectronic chip

The invention discloses a preparation method and application of a high thermal and electrical conductivity adhesive. The heat transfer between a high-frequency, high-heat and high-density electronic chip and a heat sink is satisfied, and the reliability and the stability of the service of high-power electronic components are improved. A conductive filler used in the high thermal and electrical conductivity adhesive provided by the invention is nano-silver heat-reduced from flake silver powder and an organic silver complex. The high thermal and electrical conductivity adhesive is prepared fromthe following raw materials by mass percent: 65 to 75 wt% of flake silver, 13 to 22 wt% of organic silver complex, and 12 to 18 wt% of organic carrier. The preparation method and application of the high thermal and electrical conductivity adhesive disclosed by the invention have the advantages that an organic silver complex solution is adopted to effectively regulate and control the viscosity of aslurry, the microscopic interface defects caused by the flake silver as a 'framework' are overcome, the phonon transmission efficiency is improved, and a more efficient thermal conductivity path is constructed; on the other hand, during heat curing, the organic silver complex undergoes in-situ reduction sintering while resin is cured by heating, an effective link between a substrate and a chip can be achieved, and a high-thermal-conductivity structure can be constructed.

Owner:KUNMING INST OF PRECIOUS METALS

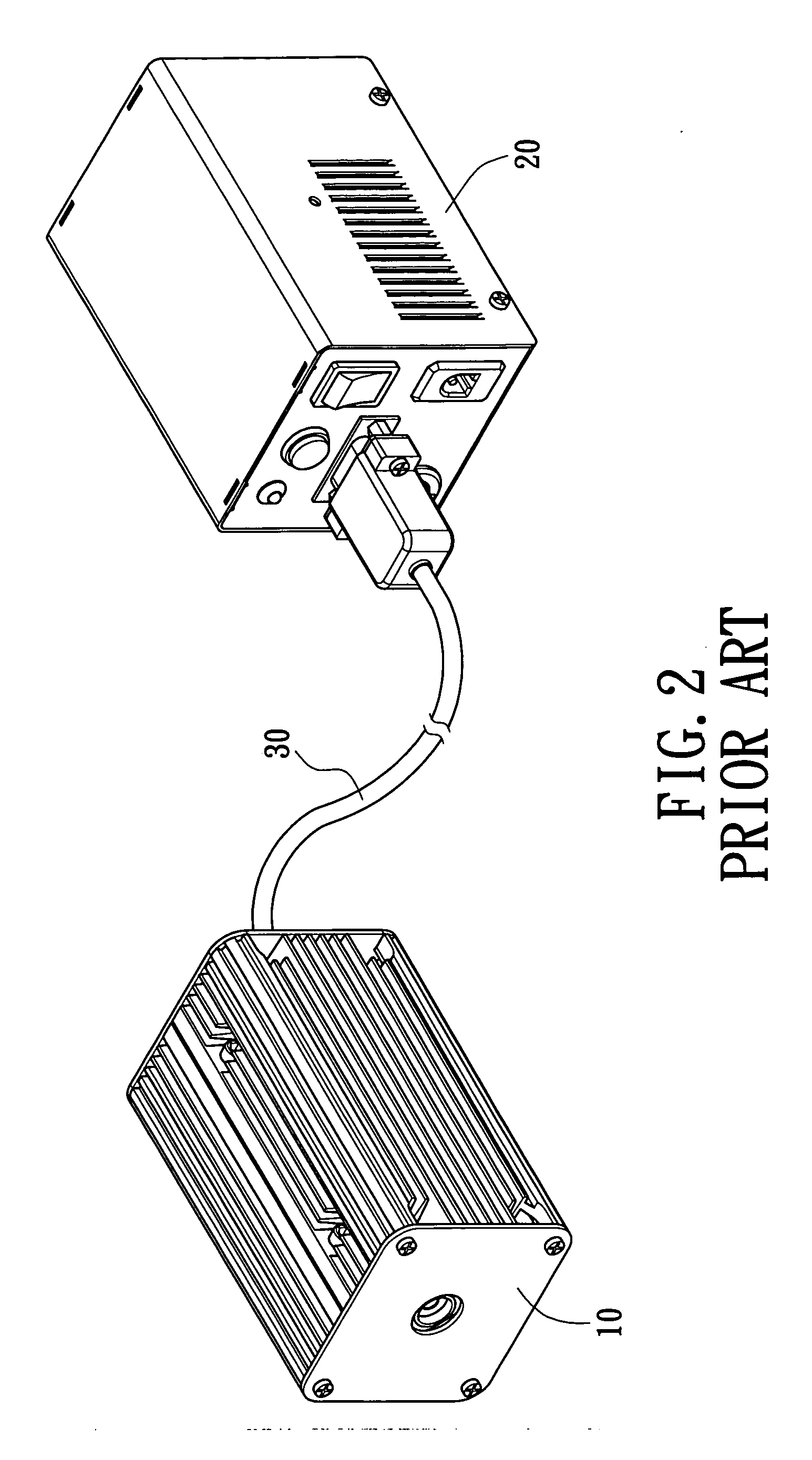

Liquid-cooled fully sealed high-efficiency radiating electronic cabinet

InactiveCN101610661AIncrease powerReduce volumeMagnetic/electric field screeningCompression machines with non-reversible cycleLow noiseElectromagnetic shielding

The invention relates to radiating technology applied to fully sealed electronic cabinets, in particular to a radiating method and a radiating device applied to high power electronic equipment required to be fully sealed in outdoor severe environment. The invention adopts a cooling liquid circular cooling device; cooling liquid absorbs heat generated when power elements work through a liquid-cooled radiator arranged in a mainframe; a recycle liquid pump conveys the cooling liquid having absorbed the heat into a high-efficiency radiator outside the mainframe; and a fan of the high-efficiency radiator performs enforced air cooling on the cooling liquid so as to achieve the aim of high-efficiency radiating, wherein the mainframe adopts a fully sealed cabinet structure so as to achieve the waterproof, dampproof, dustproof and electromagnetic shielding aims. The device adopting the radiating technology has the advantages of high power, small volume, easy control of temperature, low noise, low cost, high heat exchange efficiency and the like.

Owner:沈国忠

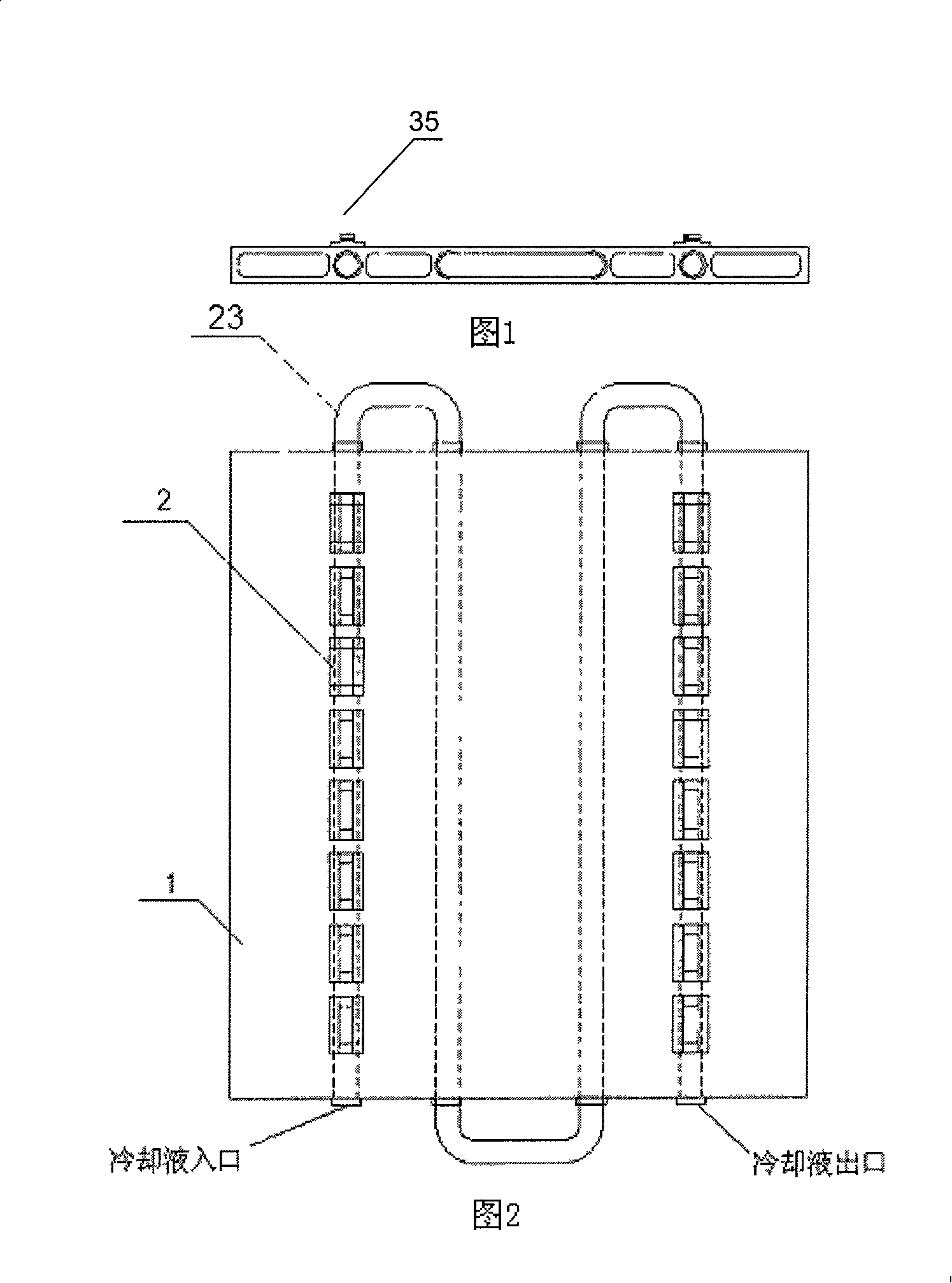

Secondary Battery Housing with Control Electronics

ActiveUS20160372801A1Reduce noiseCircuit monitoring/indicationCharge equalisation circuitLow noiseMOSFET

Rechargeable cells in cylindrical form are arranged within frames in a honeycomb structure and coupled by connecting straps outside the frames to form cell pack. Several cell packs, an electronic switch and control circuit are integrated into the battery housing. A bus bar extends around the perimeter of the housing. A high density MOSFET switch is coupled between the bur bar and the battery contact. A high power electronic clamp disposed across the battery terminals absorbs or redirects transients. An active, high-efficiency, low-noise cell balance converter or a LC based resonant converter may also be provided. For advanced battery applications a +5V CAN bus interface is provided via two circular connectors. Thermistors are provided for use in a thermal protection scheme.

Owner:BREN TRONICS INC

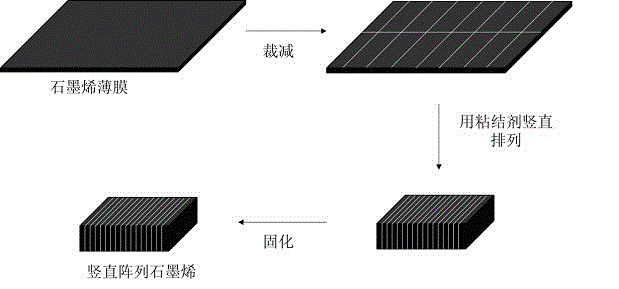

Preparation method of vertically arrayed graphene thin films

ActiveCN104609405ATroubleshoot hot spot overheatingFacilitated DiffusionHeat-exchange elementsPolymer adhesiveThermal solution

The invention relates to a preparation method of vertically arrayed graphene thin films. The preparation method comprises the following steps: a), preparing an oxidized graphene solution; b), coating a substrate with the oxidized graphene solution; c), reducing oxidized graphene into a graphene thin film through a strong reducing agent; d), cutting the graphene thin film in a designed mold, and folding the cut graphene thin films into vertically arrayed graphene thin films; e), curing the vertically arrayed graphene thin films with a binding agent; f), polishing the surfaces of the cured graphene thin films to ensure that the polished graphene thin films are in better contact with the surface of a device, and finally filling the polished graphene thin films with a polymer adhesive to improve the interlayer contact between the graphene thin films. The vertically arrayed graphene thin films prepared according to the preparing method can be applied to the field of high-power electronic devices, such as being used as an interface heat dissipation material to provide a heat dissipation solution.

Owner:上海瑞烯新材料科技有限公司

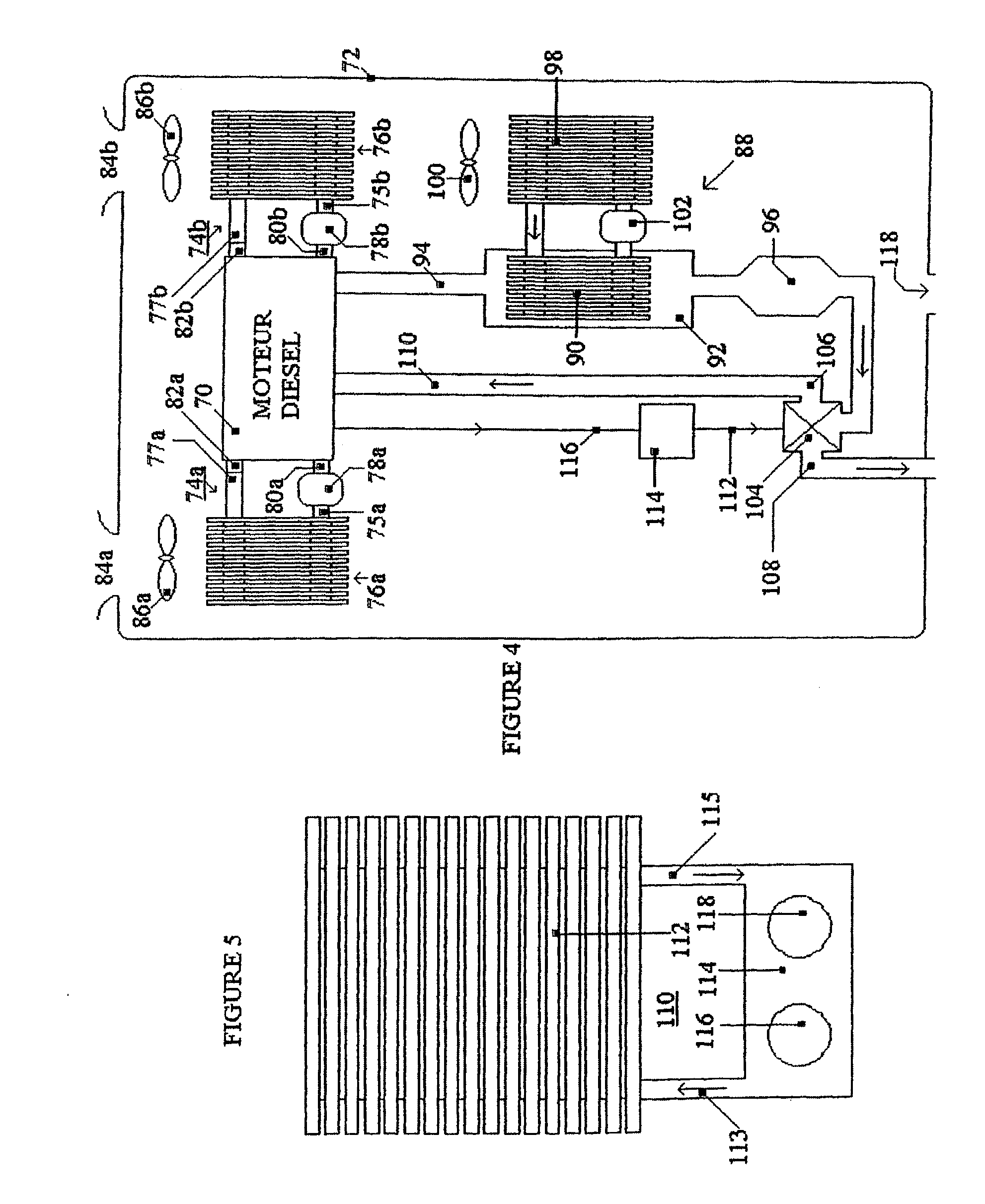

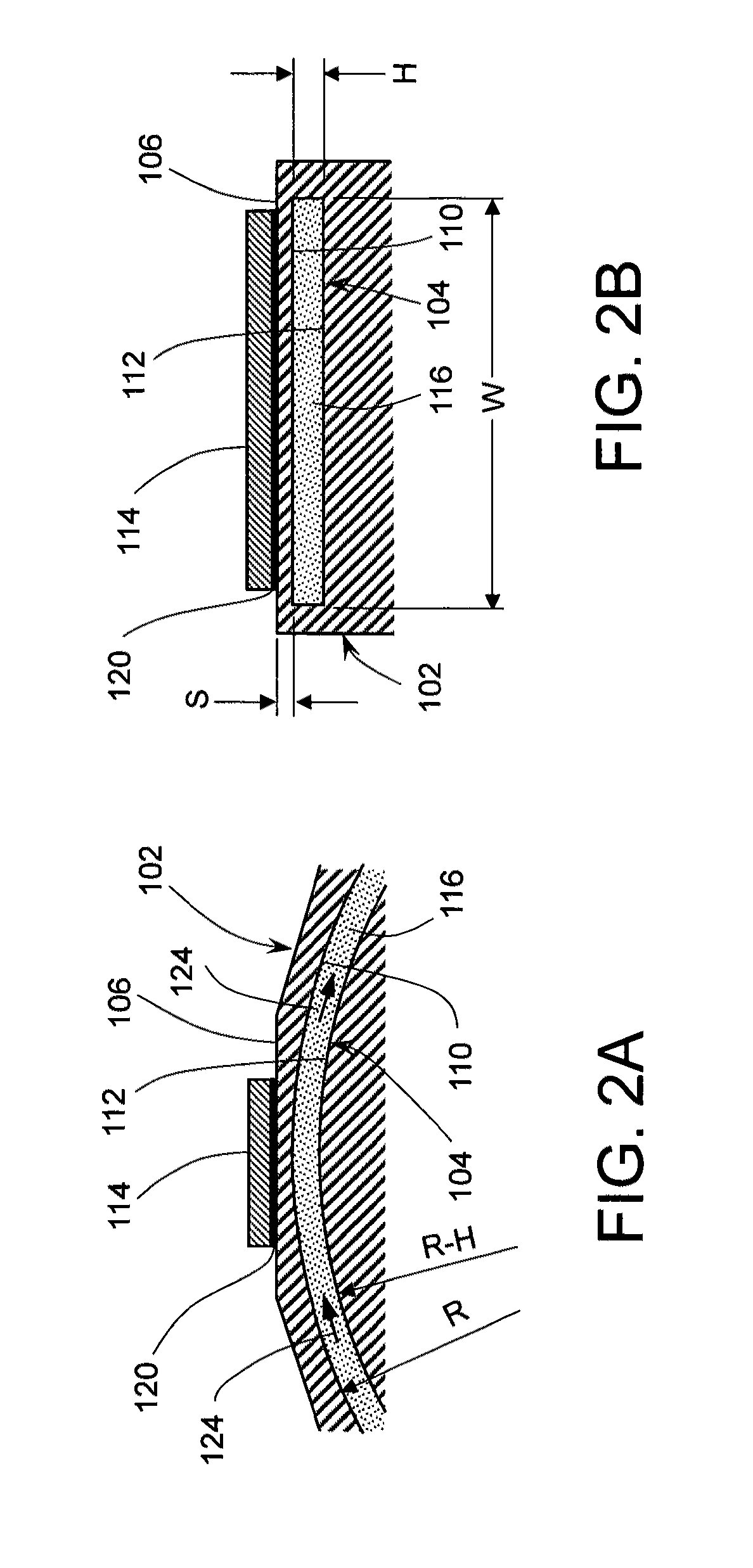

Power electronic system with passive cooling

ActiveUS20050088822A1High-performance coolingImprove performanceSemiconductor/solid-state device detailsSolid-state devicesElectric forceElectronic systems

The present invention relates to an apparatus and method for dissipating heat from high-power electronic devices. The assembly includes a high-current substrate, such as a printed circuit board supporting an electronic device, a heat pipe thermally coupled with the electronic device and an assembly case which also forms a heat sink, and thermal transient suppression material which may be thermally coupled with the electronic device and the heat pipe.

Owner:DELPHI TECH IP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com