Large-area freestanding carbon nanotube paper and preparation method thereof

A carbon nanotube paper and carbon nanotube technology, applied in the direction of nanotechnology, can solve the problems of complex process, large-scale application limitation, high cost, etc., and achieve the effect of expanding application range, large application value, and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

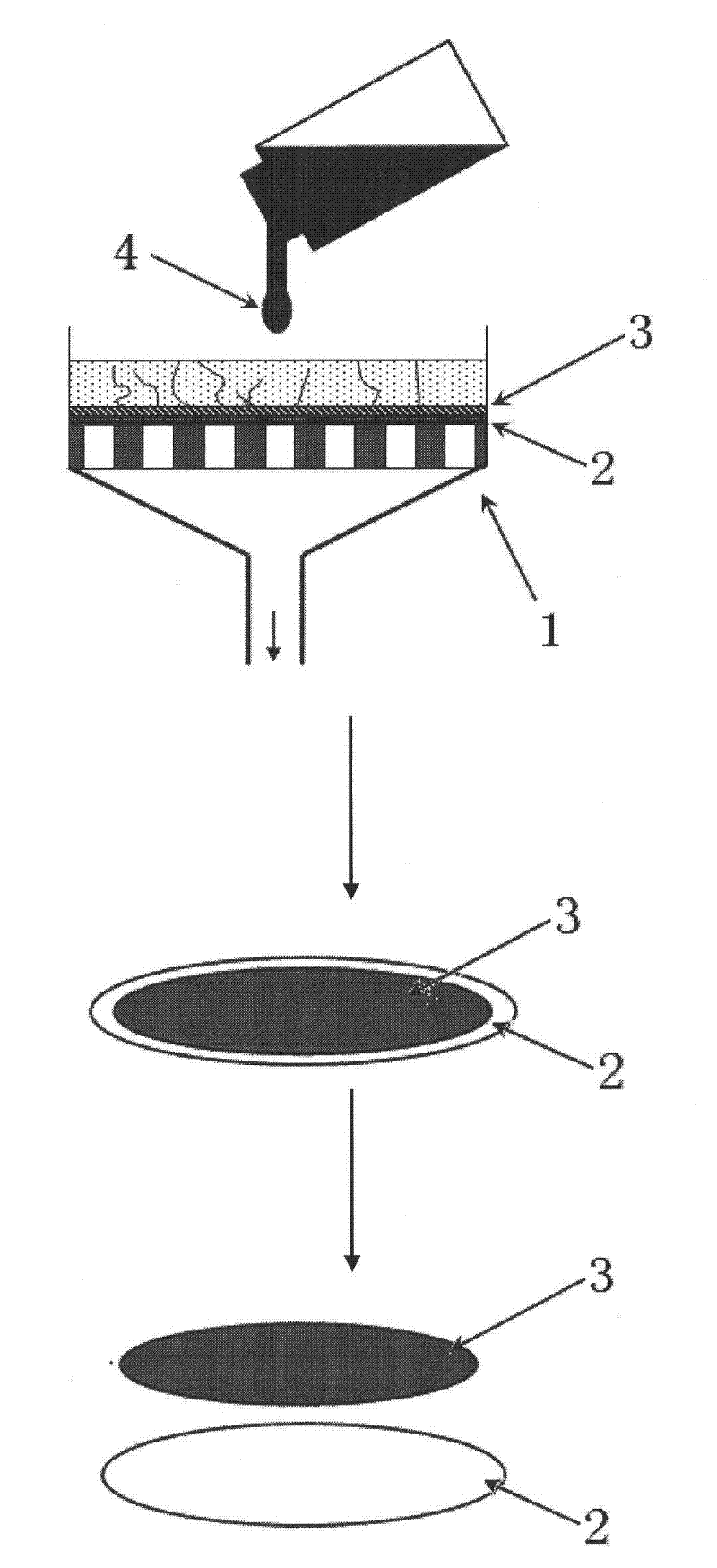

[0034] Further, the preparation method of the large-area self-supporting carbon nanotube paper may include the following steps:

[0035] a. Mix the carbon nanotube powder into the solvent, and disperse to make a relatively uniform dispersion liquid. The carbon nanotubes do not need to be monodispersed, and the degree of dispersion is controlled to be monodisperse or simple according to the needs of the finished carbon nanotube paper. Paste dispersion, the above-mentioned solvent may contain a dispersant, the concentration of the dispersant in the dispersion can be determined according to the nature of the solvent, the predetermined degree of dispersion of carbon nanotubes, and the properties of the carbon nanotube powder, but is preferably 0.1- 4wt%;

[0036] b. Suction filter the dispersion with suction filtration equipment, and then wash with water to remove residual dispersant and other impurities;

[0037] c. After the suction filtration, the carbon nanotube paper is sepa...

Embodiment 1

[0046] refer to figure 1 , weigh 500 mg of carbon nanotubes purified by hydrochloric acid, dissolve them in 1L of deionized water, and stir them with a high-shear mixer for several minutes. The bottom of the Buchner funnel is 25cm, and the Buchner funnel 1 is inserted on the suction filter bottle to filter with a vacuum pump, so that the carbon nanotubes are evenly deposited on the filter paper. After the filtration, the filter paper is taken out, and the carbon nanotube paper 3 is separated from the filter paper when it is half dry. Its thickness is about 60um, its flexibility is equivalent to ordinary soft cloth, and its square resistance is 2Ω / □. Referring to Figure 4, the carbon nanotube paper prepared by this method does not contain any dispersant impurities, and the carbon nanotubes are long, forming a good two-dimensional network structure. It is very beneficial to the in-plane electricity, heat transfer and supporting catalysts, and is conditionally used as an electr...

Embodiment 2

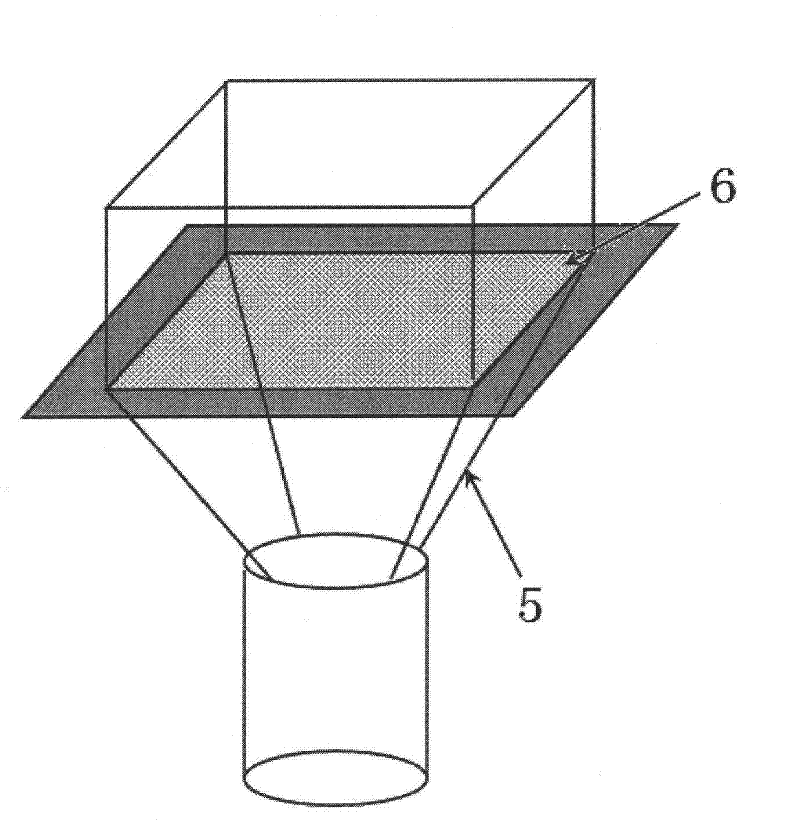

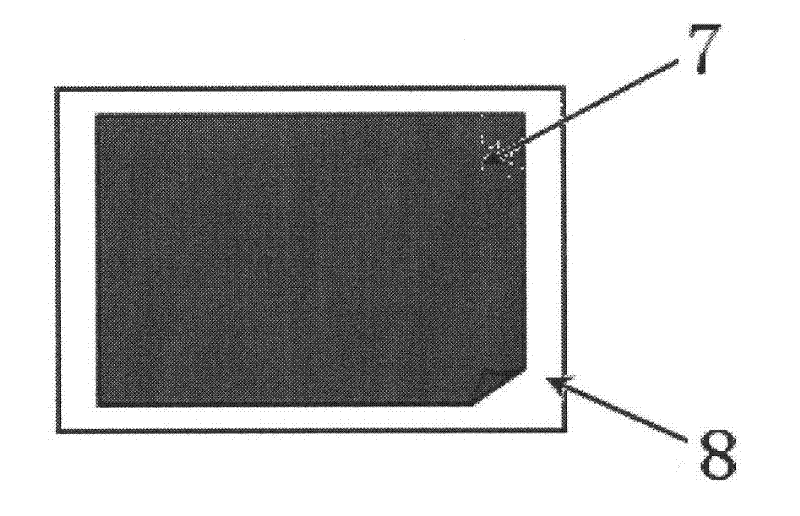

[0048] Referring to Figure 2, weigh 400 mg of carbon nanotubes, dissolve them in 1 L of deionized water containing 400 mg of sodium lauryl sulfate surfactant, and stir for 5 minutes with a high-shear mixer, and the carbon nanotubes form a slurry distribution therein. Self-made funnel 5 with a length and width of 20 cm and 11 cm respectively, and a porous steel plate 6 as a filter plate. Lay the fiber filter paper on the filter plate, insert the square funnel on the filter bottle and filter with a vacuum pump, so that the carbon nanotubes can be evenly deposited on the filter paper. After filtration, rinse with water several times to remove the remaining surfactant. After the washing is finished, the filter paper is taken out, and the carbon nanotube paper 7 is separated from the filter paper 8 when it is half dry. Its thickness is about 70um, and its structure is regular and uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com