Patents

Literature

497results about How to "Uniform process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

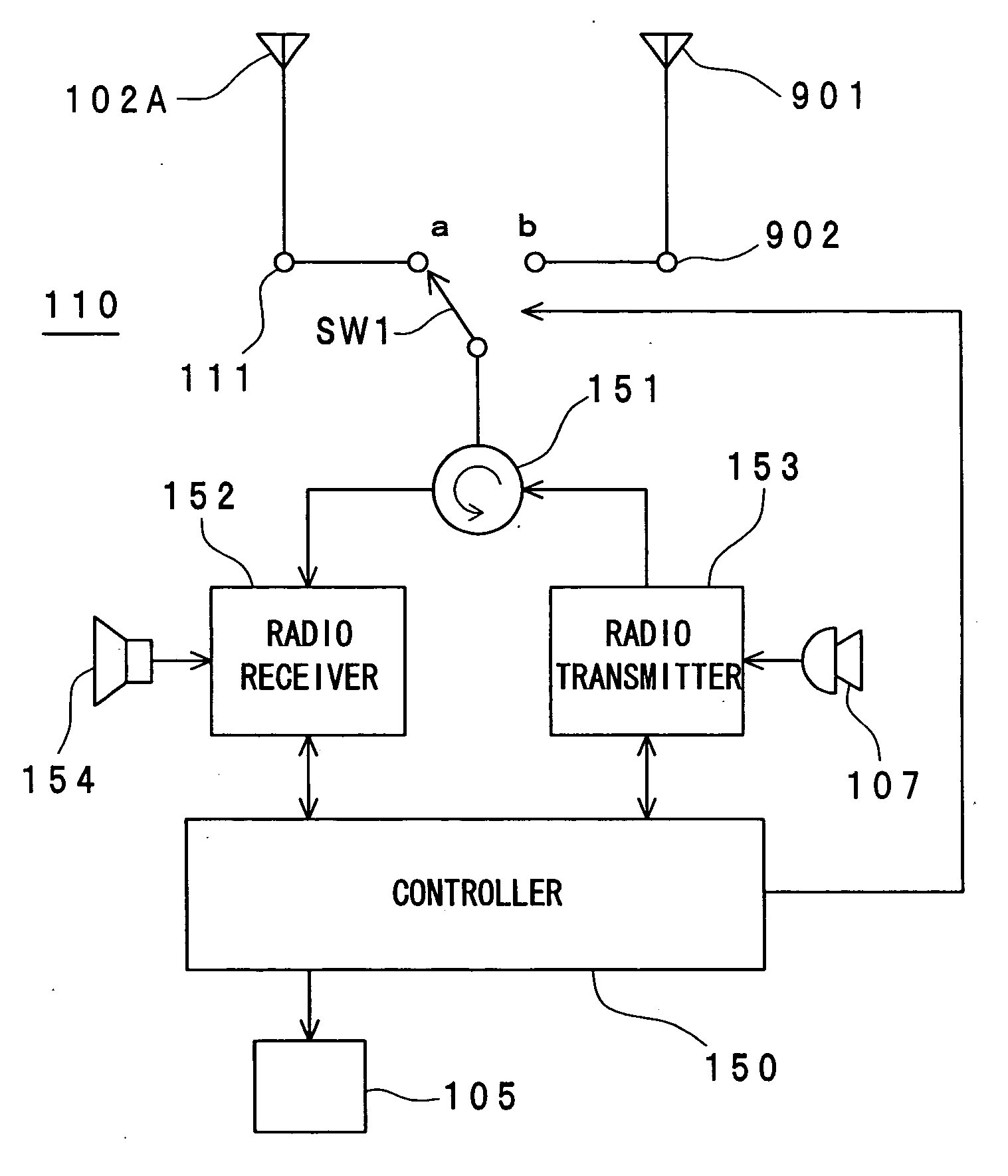

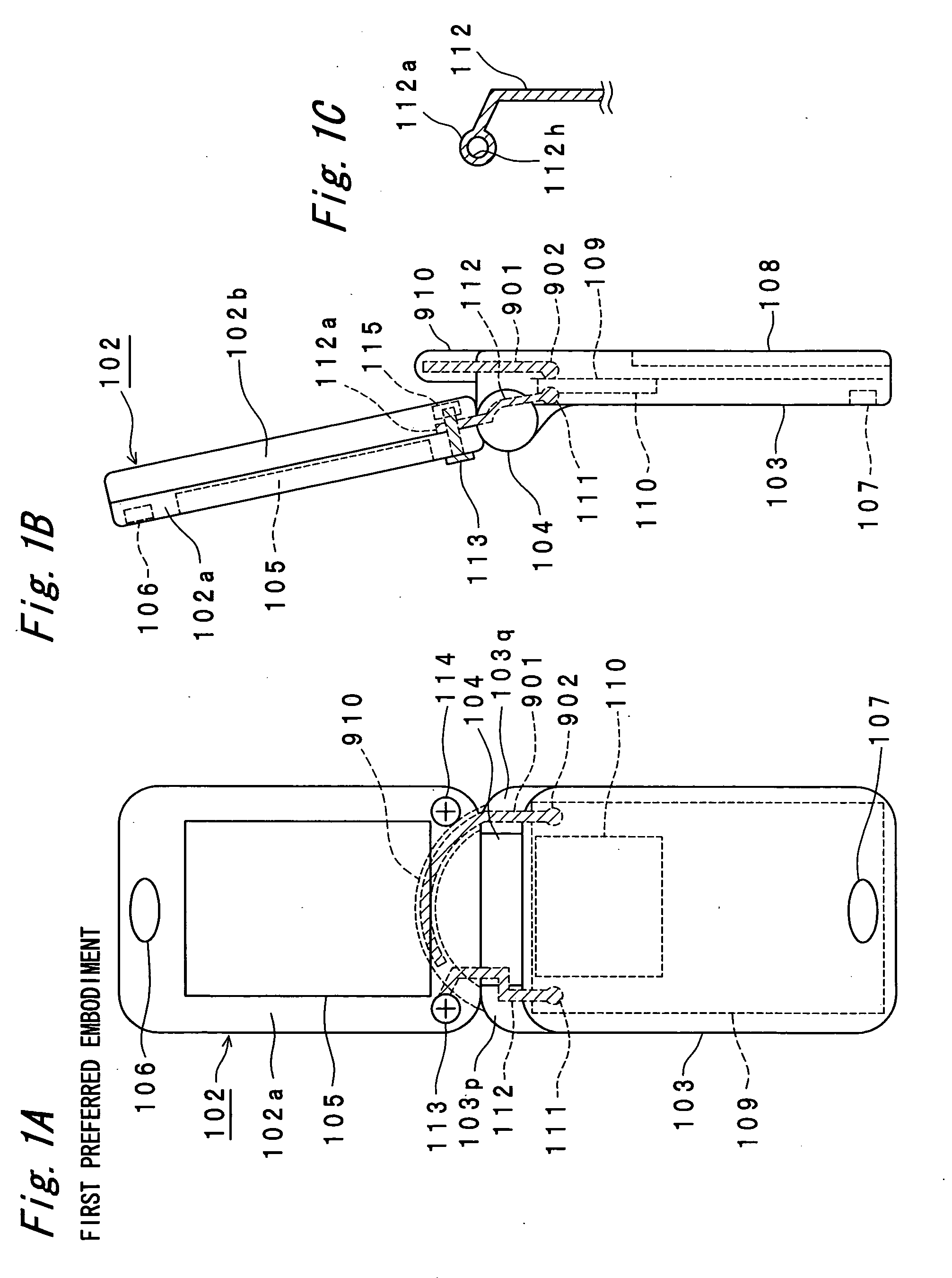

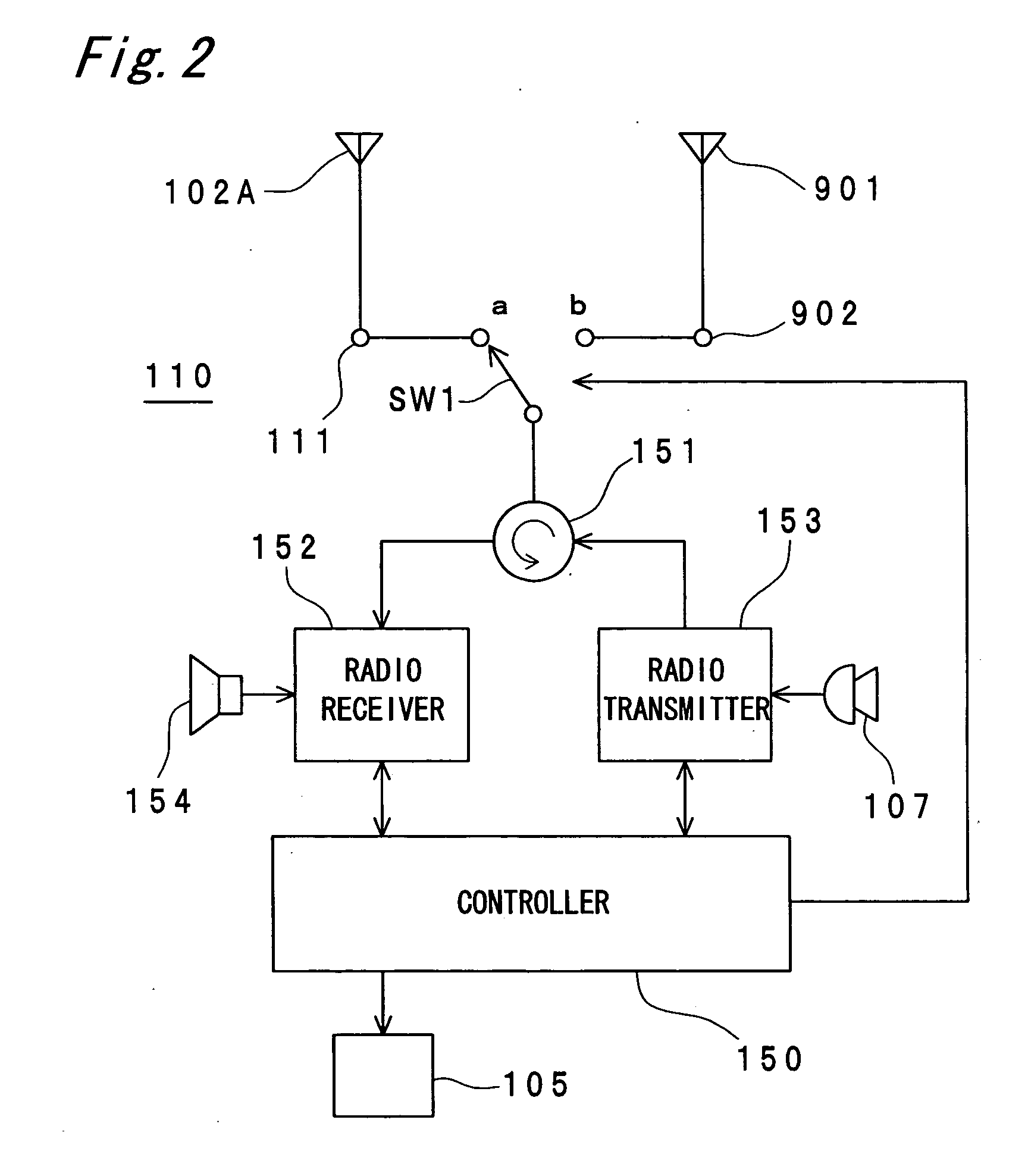

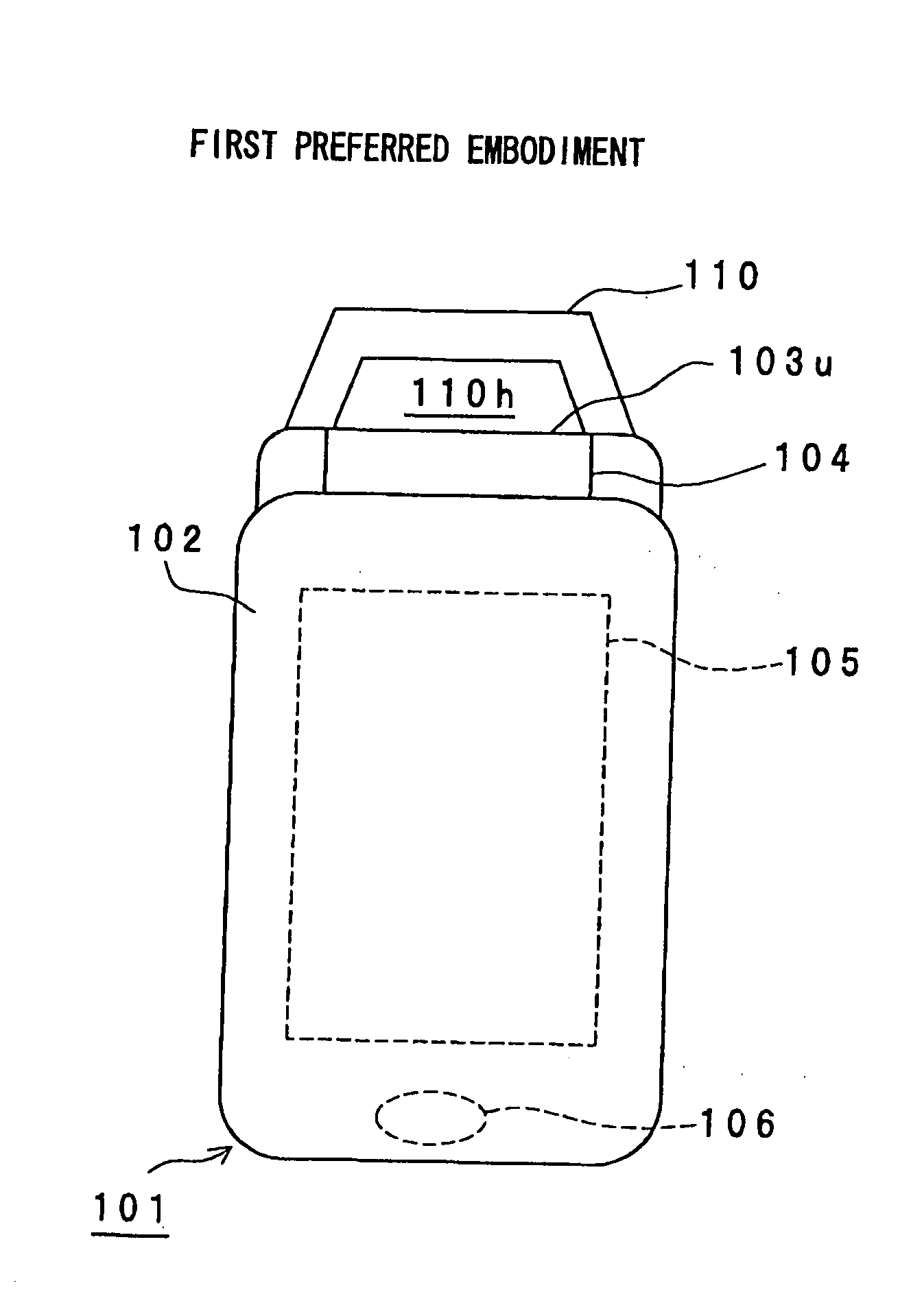

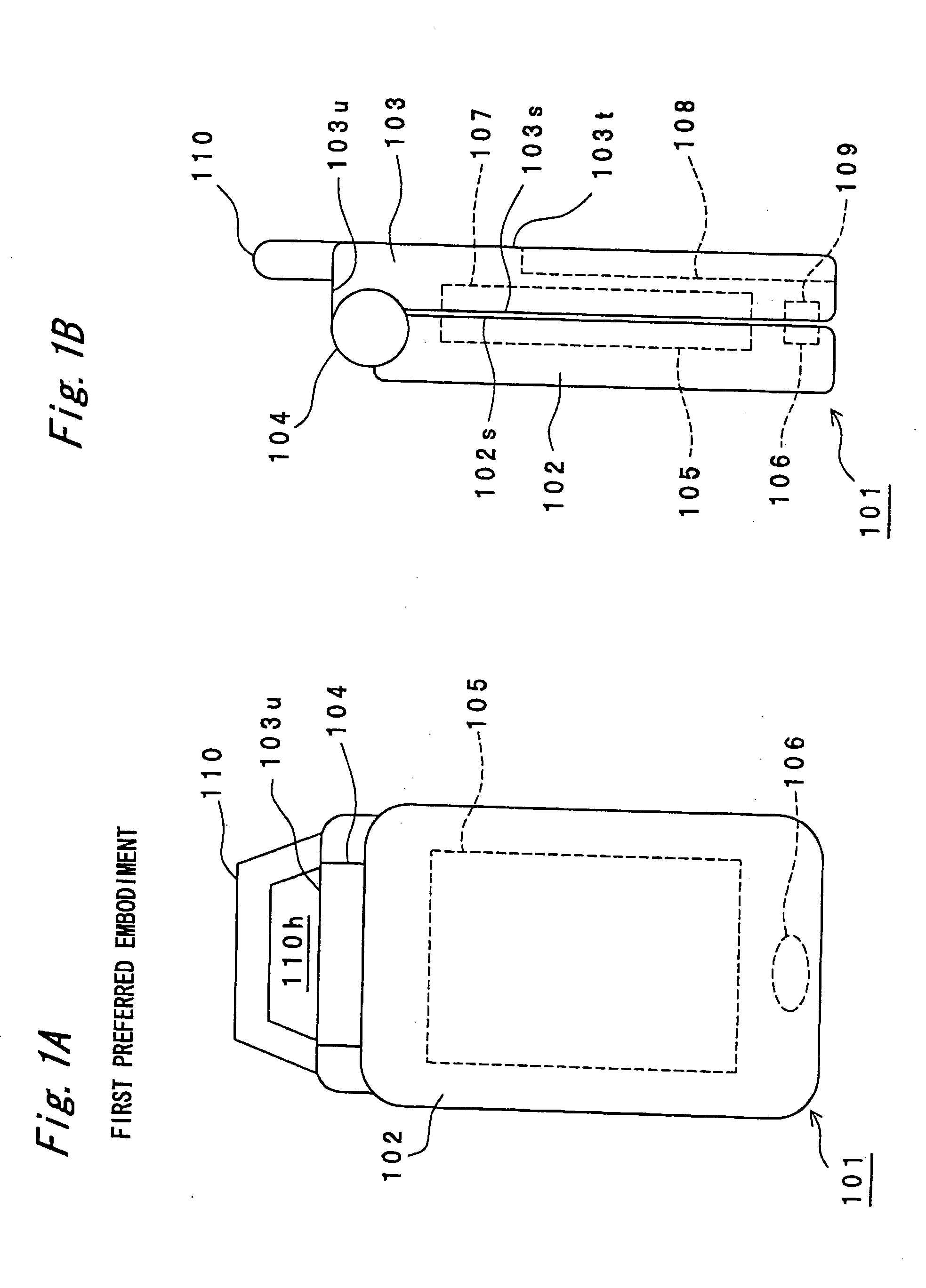

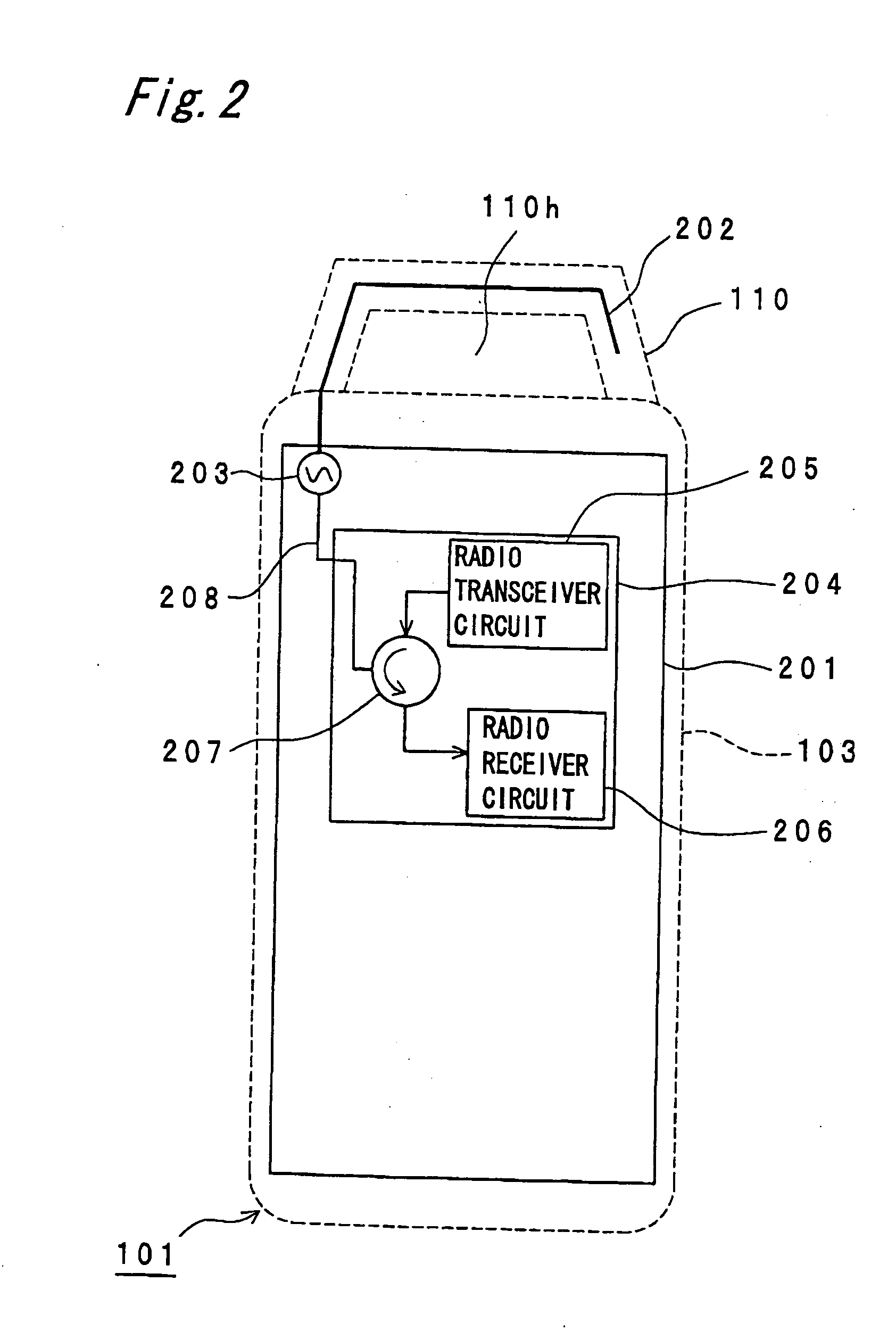

Portable radio communication apparatus provided with a boom portion and a part of housing operating as an antenna

ActiveUS20040219956A1Uniform processImprove featuresAntenna arraysSimultaneous aerial operationsElectrical conductorCantilever

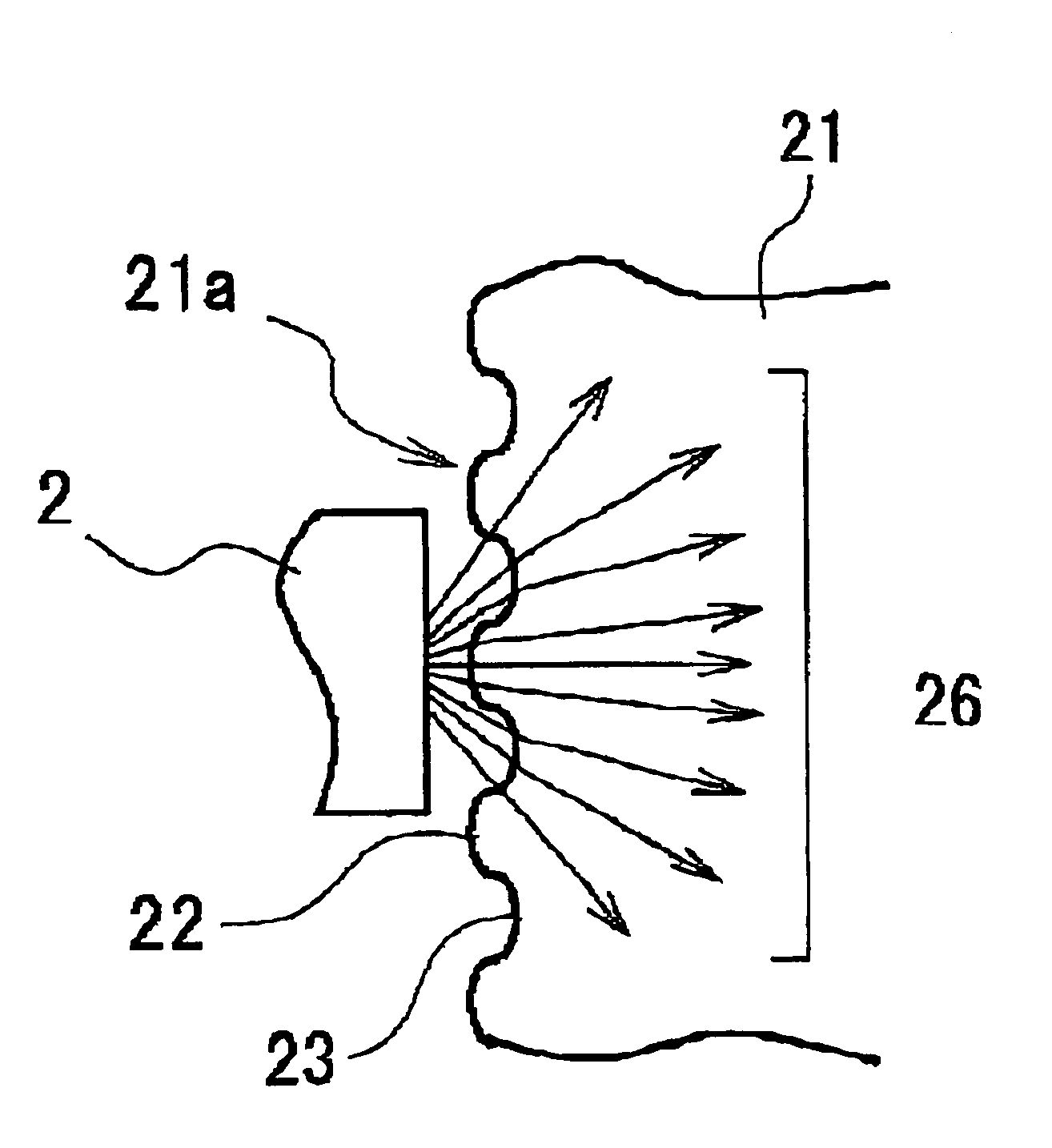

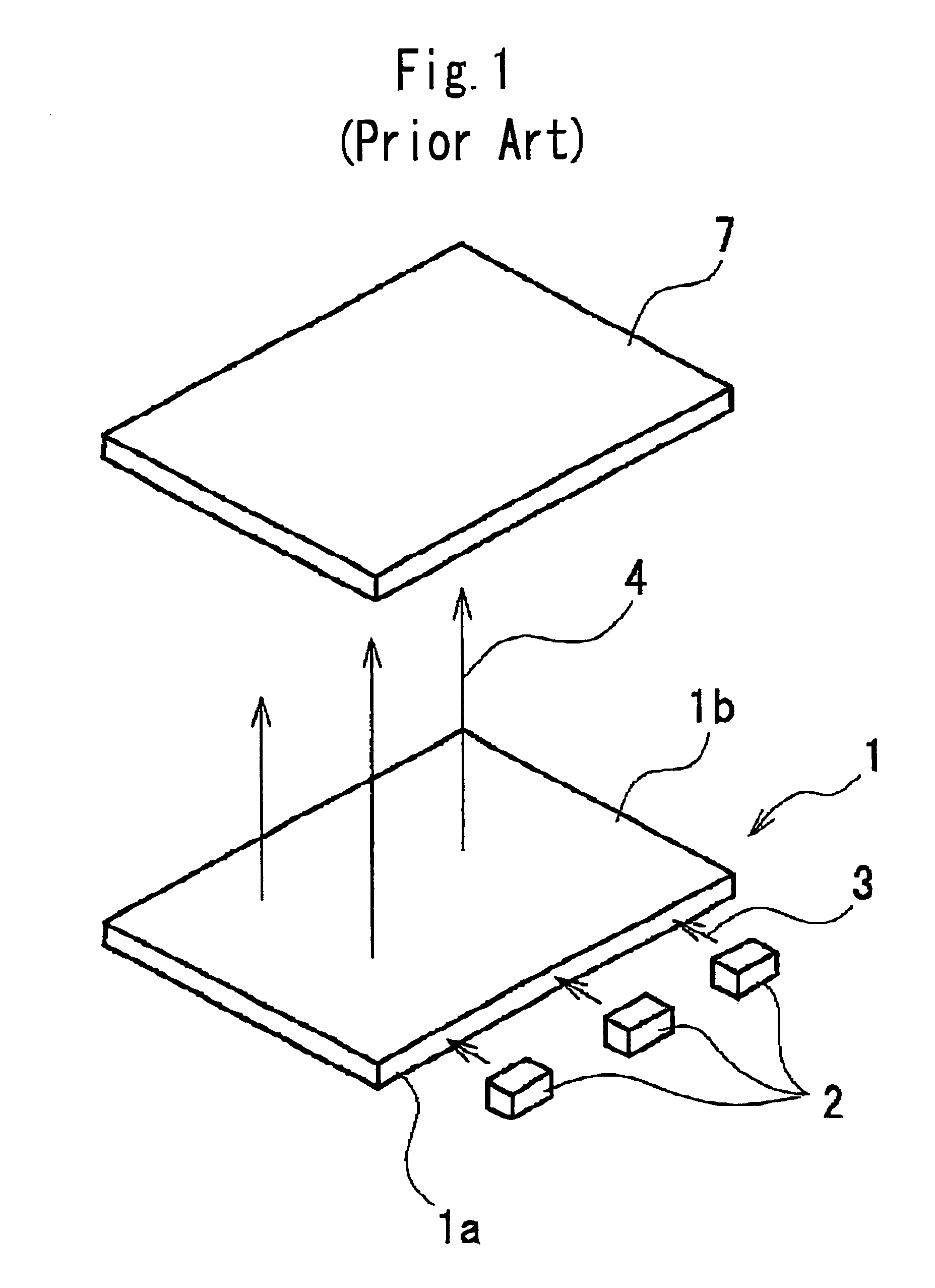

In a portable radio communication apparatus including a housing, at least one part of at least one of the housing is formed as a housing electrical conductor portion by an electrically conductive material. The housing electrical conductor portion is connected with a radio communication circuit of the portable radio communication apparatus so as to operate as at least one part of an unbalanced type antenna of the radio communication circuit. Further, the portable radio communication apparatus further includes a boom portion coupled with the housing at least at two positions so as to provide at least one penetrating hole between the housing and the boom portion.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

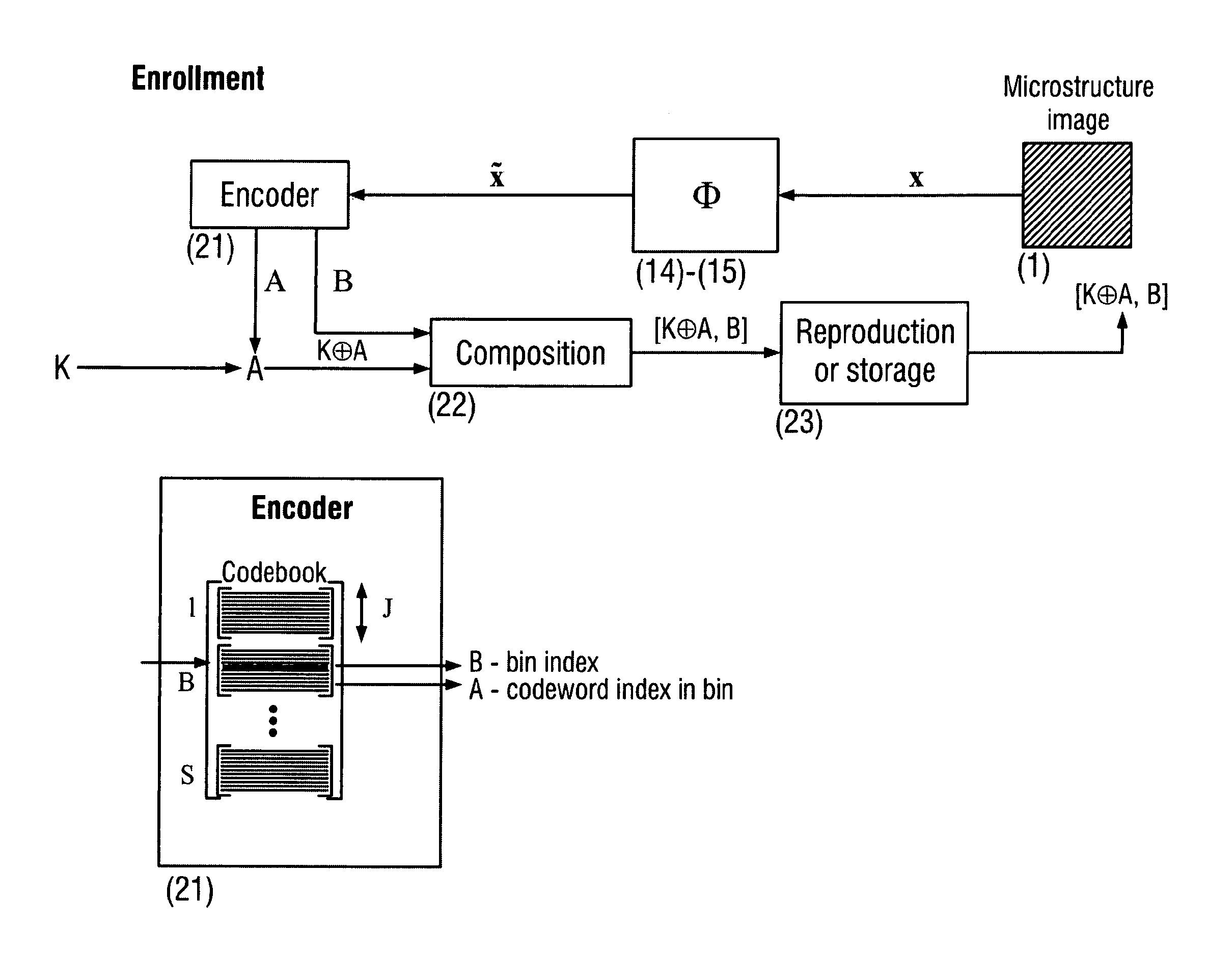

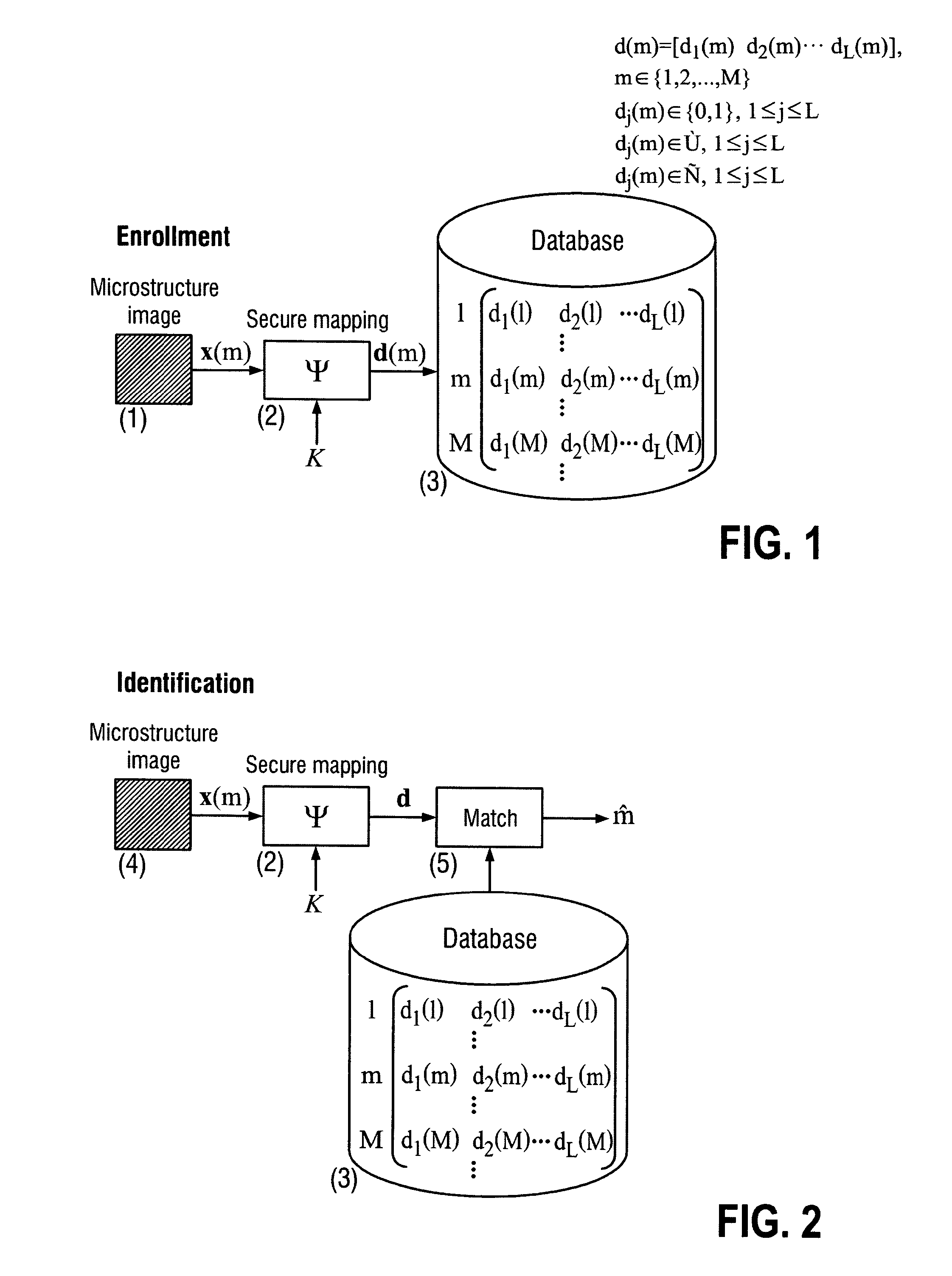

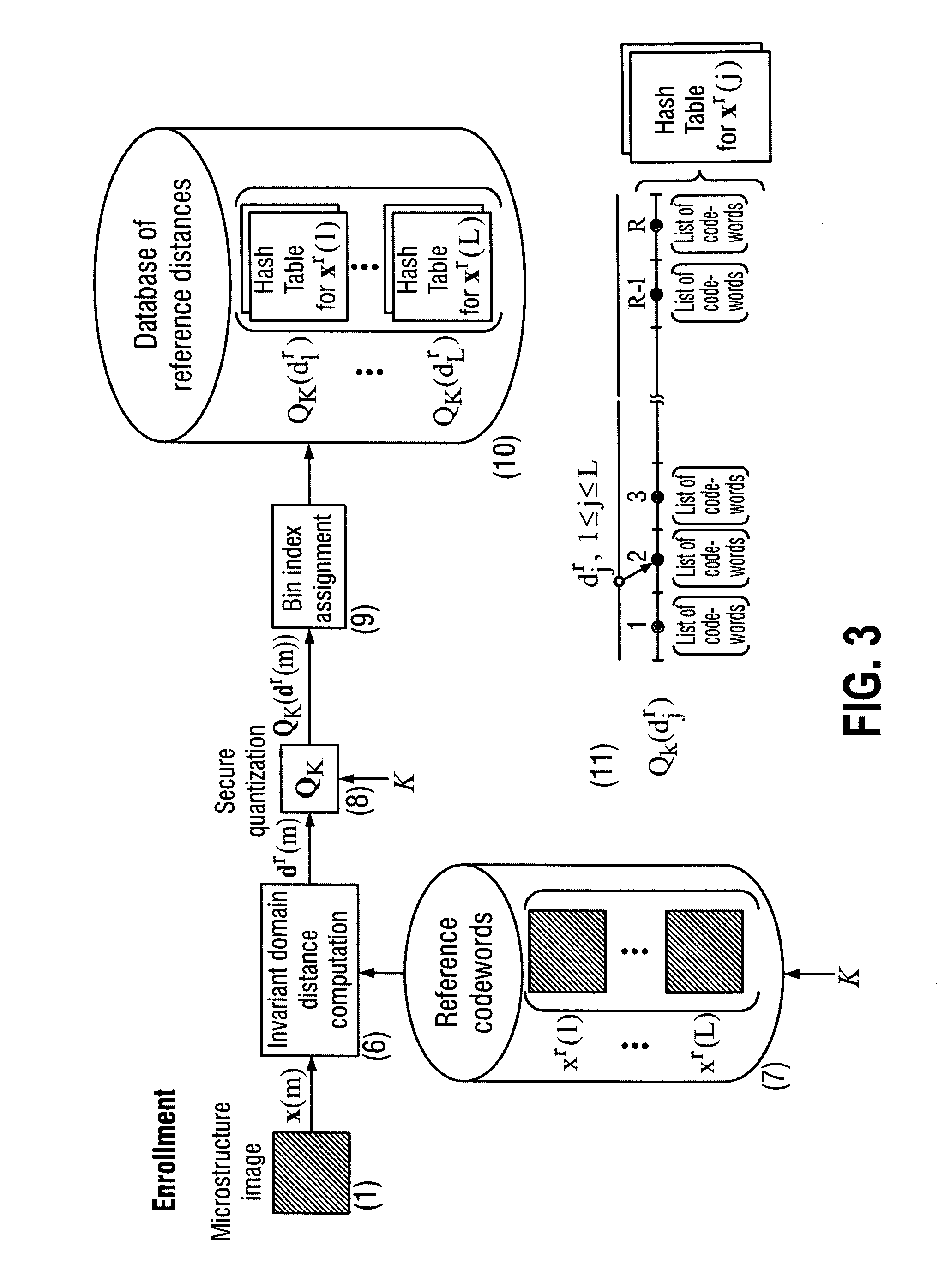

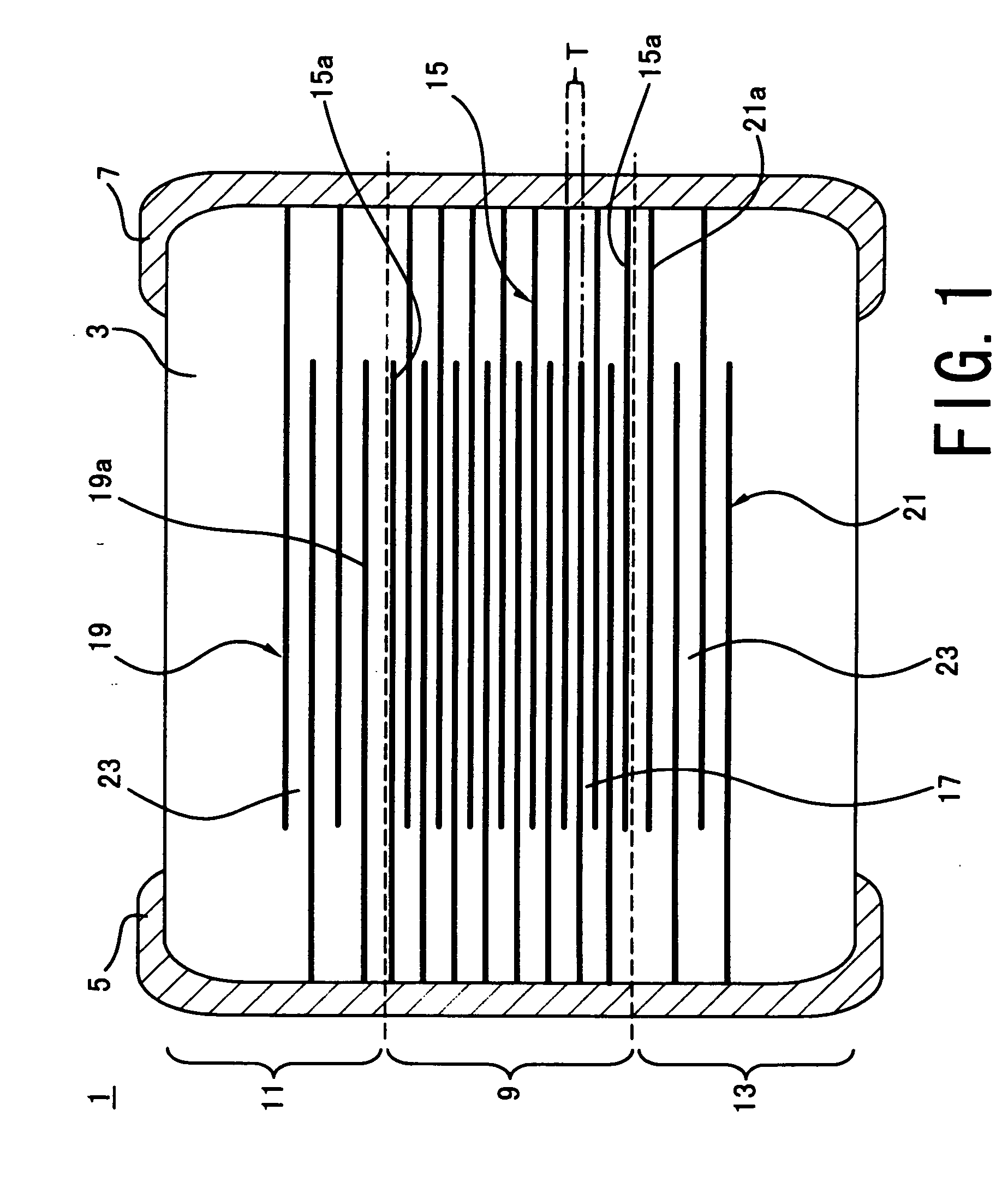

Secure item identification and authentication system and method based on unclonable features

ActiveUS20110096955A1Improve efficiencyEasy to usePaper-money testing devicesCharacter and pattern recognitionKey exchangeDistributed source

The present invention is a method and apparatus for protection of various items against counterfeiting using physical unclonable features of item microstructure images. The protection is based on the proposed identification and authentication protocols coupled with portable devices. In both cases a special transform is applied to data that provides a unique representation in the secure key-dependent domain of reduced dimensionality that also simultaneously resolves performance-security-complexity and memory storage requirement trade-offs. The enrolled database needed for the identification can be stored in the public domain without any risk to be used by the counterfeiters. Additionally, it can be easily transportable to various portable devices due to its small size. Notably, the proposed transformations are chosen in such a way to guarantee the best possible performance in terms of identification accuracy with respect to the identification in the raw data domain. The authentication protocol is based on the proposed transform jointly with the distributed source coding. Finally, the extensions of the described techniques to the protection of artworks and secure key exchange and extraction are disclosed in the invention.

Owner:UNIVERSITY OF GENEVA

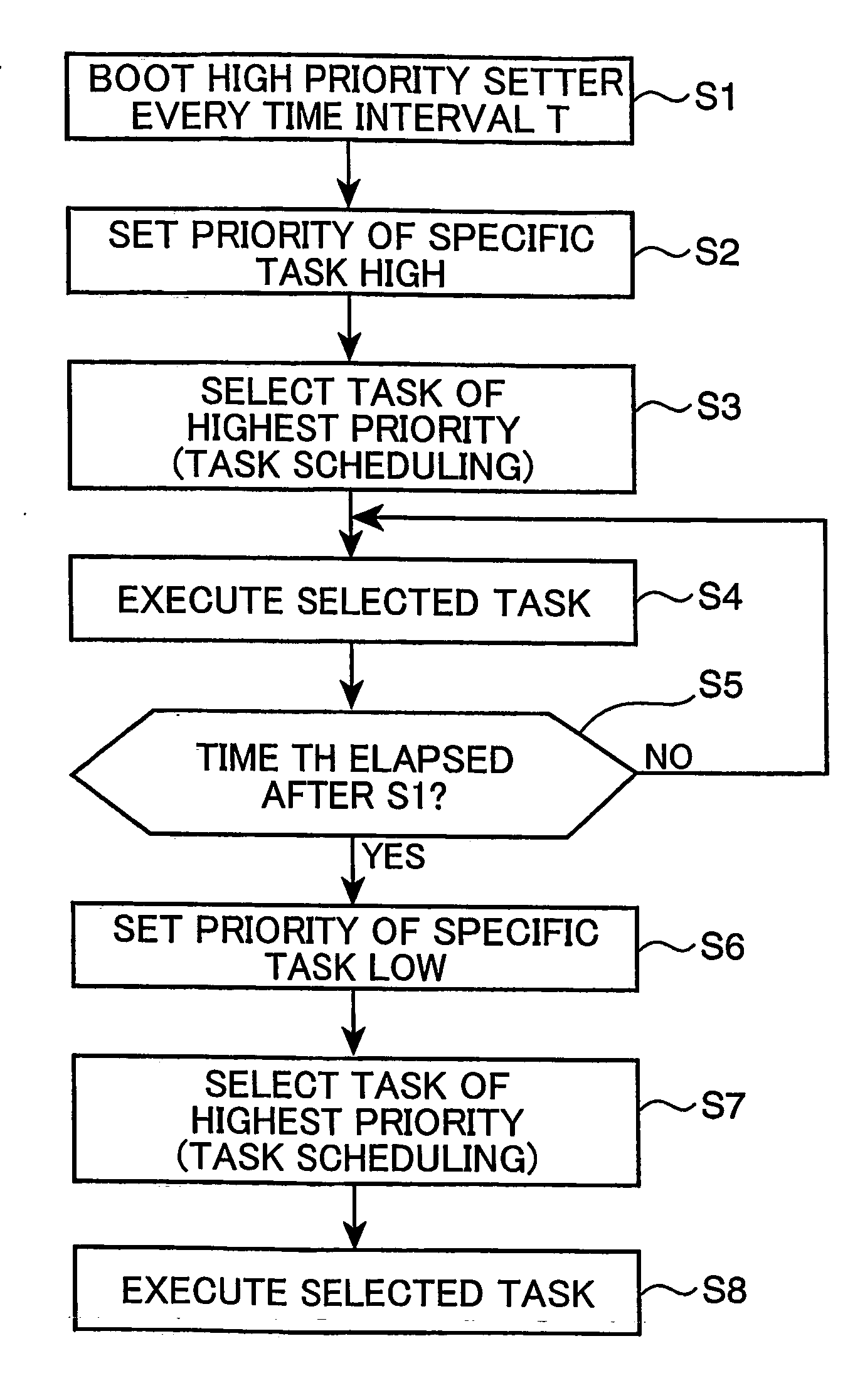

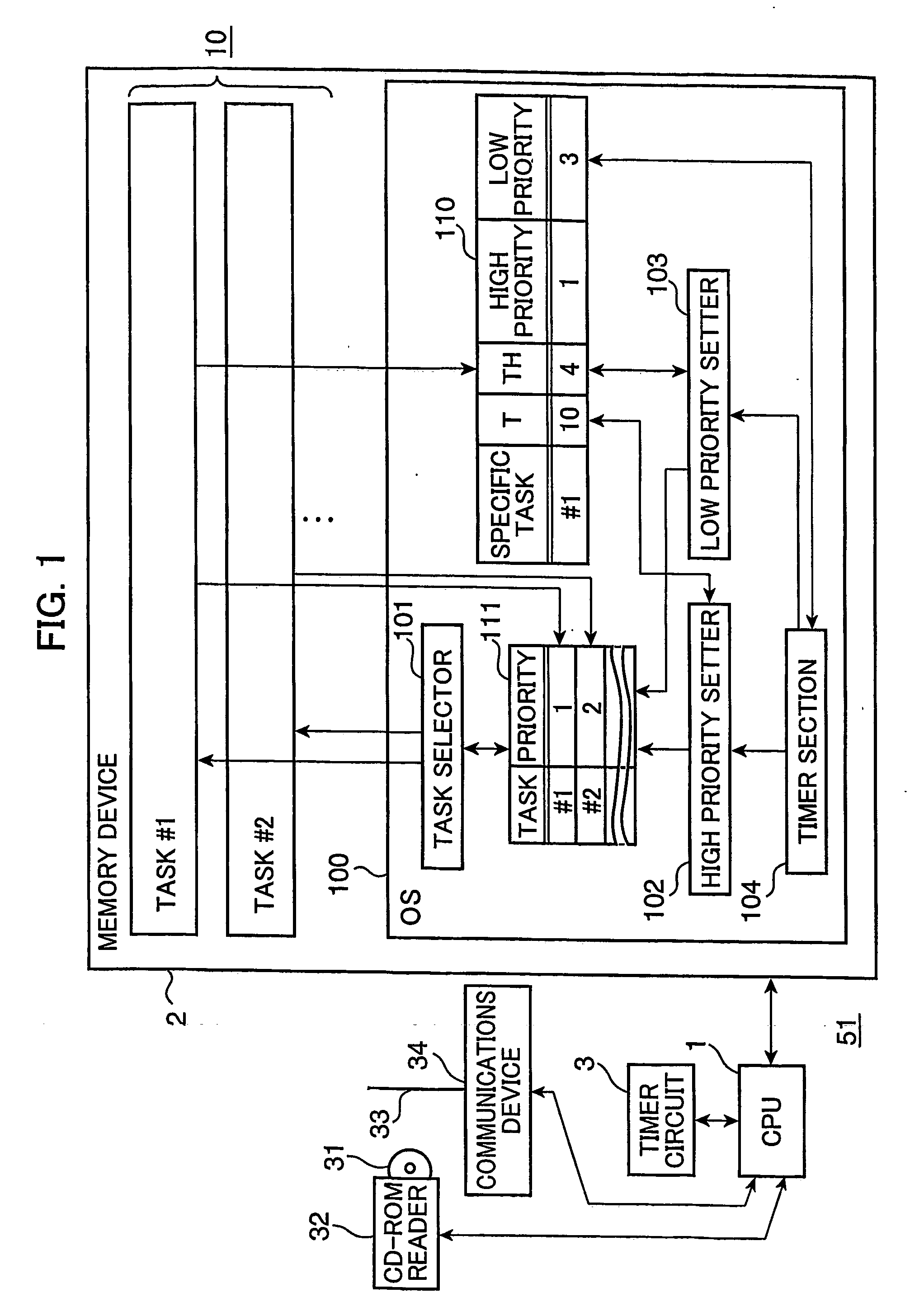

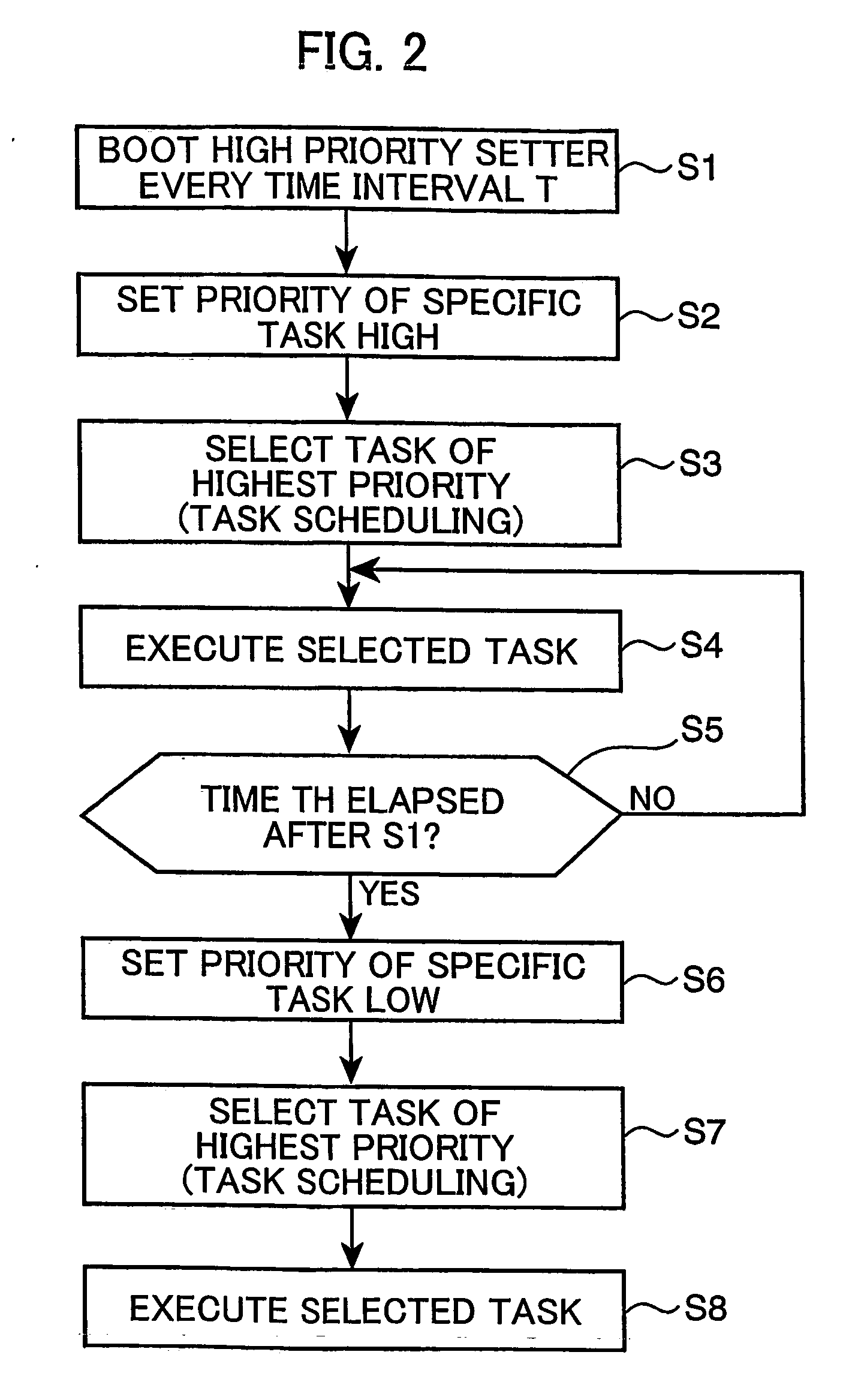

Task scheduling device, method, program, recording medium, and transmission medium for priority-driven periodic process scheduling

InactiveUS20060195847A1Efficient use ofLow priorityProgram initiation/switchingMemory systemsLower priorityTime duration

A high priority setter 102 writes the first priority (high priority) of a specific task #1 recorded in a specific task table 110 every time interval T, as the priority of the task #1 in a task priority table 111. Thereafter, when a time duration TH shorter than the time interval T elapsed, a low priority setter 103 writes the second priority (low priority) of the specific task #1 recorded in the specific task table 110, as the priority of the task #1 in the task priority table 111. The second priority is set lower than the first priority. A task selector 101 selects a task whose priority is set the highest among the tasks 10 recorded in the task priority table 111, as a specific task to be executed. Thus, the processing of the specific task #1 is securely executed during the time duration TH every time interval T, and the execution of the specific task #1 is allowed to continue if it is judged that there is no other task to be executed during the rest of the time interval T other than the time duration TH, by setting the first priority sufficiently high.

Owner:PANASONIC CORP

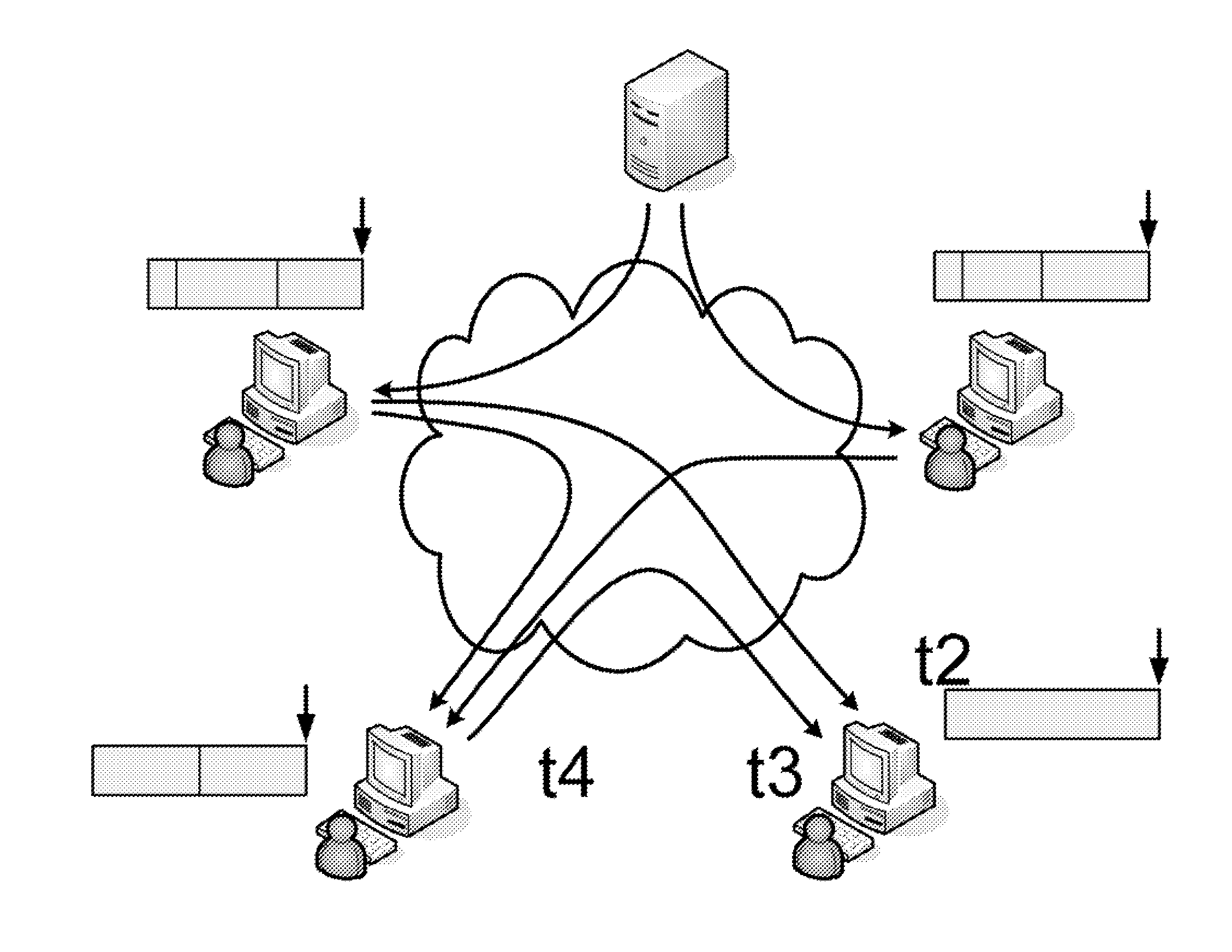

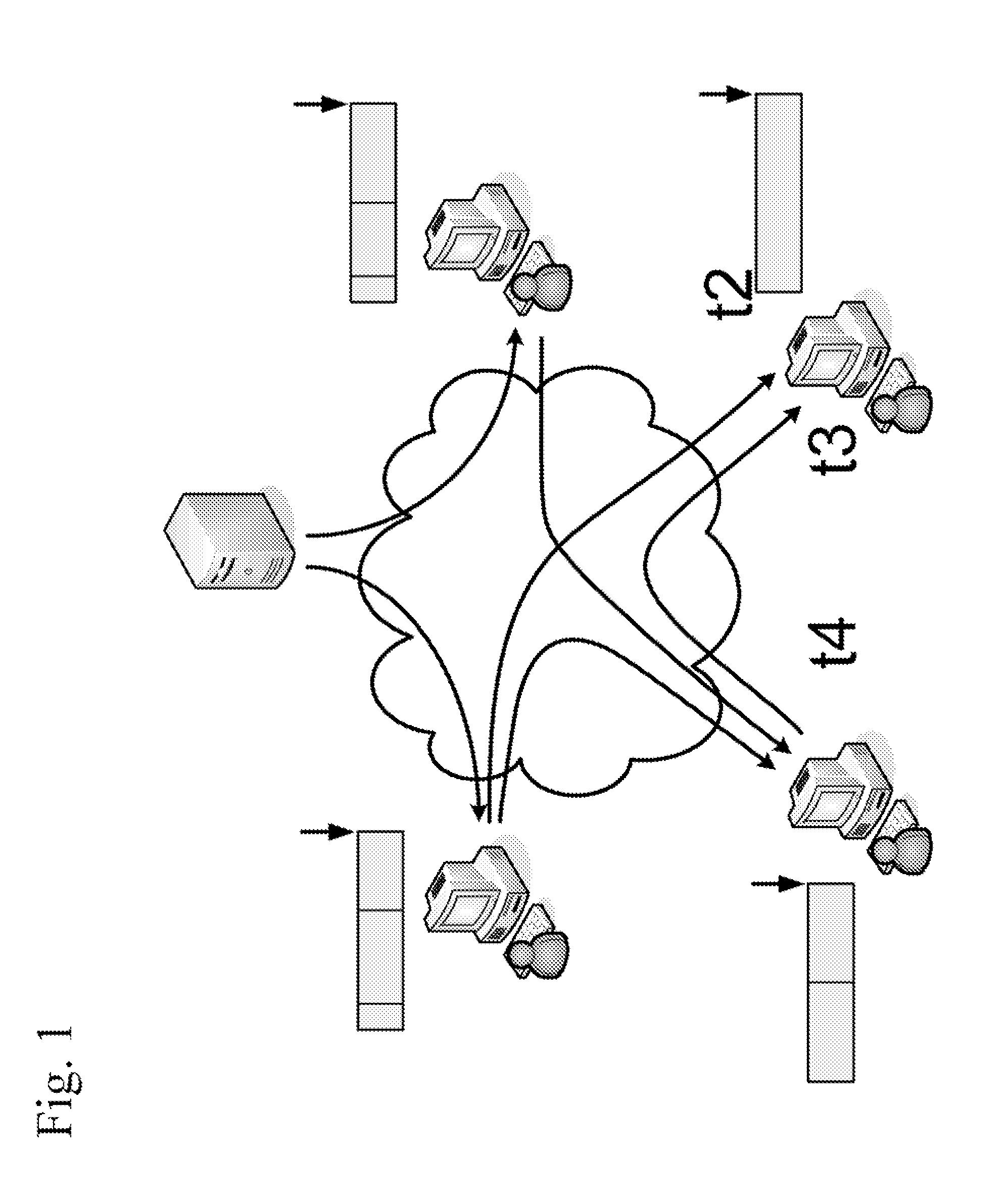

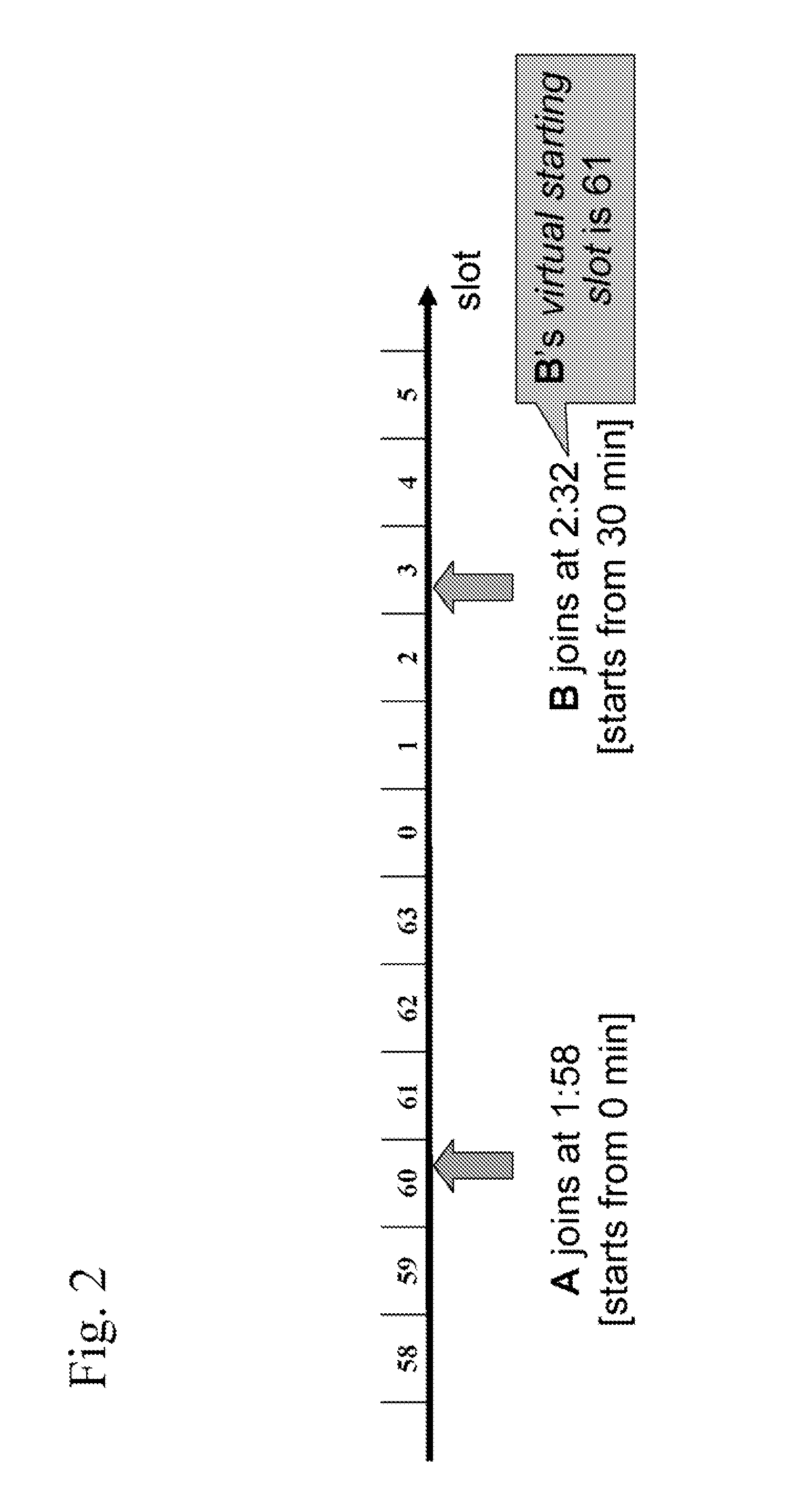

Peer-to-Peer Interactive Media-on-Demand

ActiveUS20080037527A1High probability of packet lossImproved scaling characteristicSelective content distributionNetwork connectionsThe InternetClient-side

A scalable Media-on-Demand (MoD) method to a large group of users in the Internet. This method makes use of peer buffering capabilities to collaborate in the distribution and downloading of media, facilitated by a central repository for the search of optimal peers as parent nodes to connect to and for the support of advanced features such as fast forward and backward plays. The method relieves the server load by shifting the media streaming functionality to the client side with high media receiving continuity and quality, leading to well-balanced and low network loads.

Owner:THE HONG KONG UNIV OF SCI & TECH

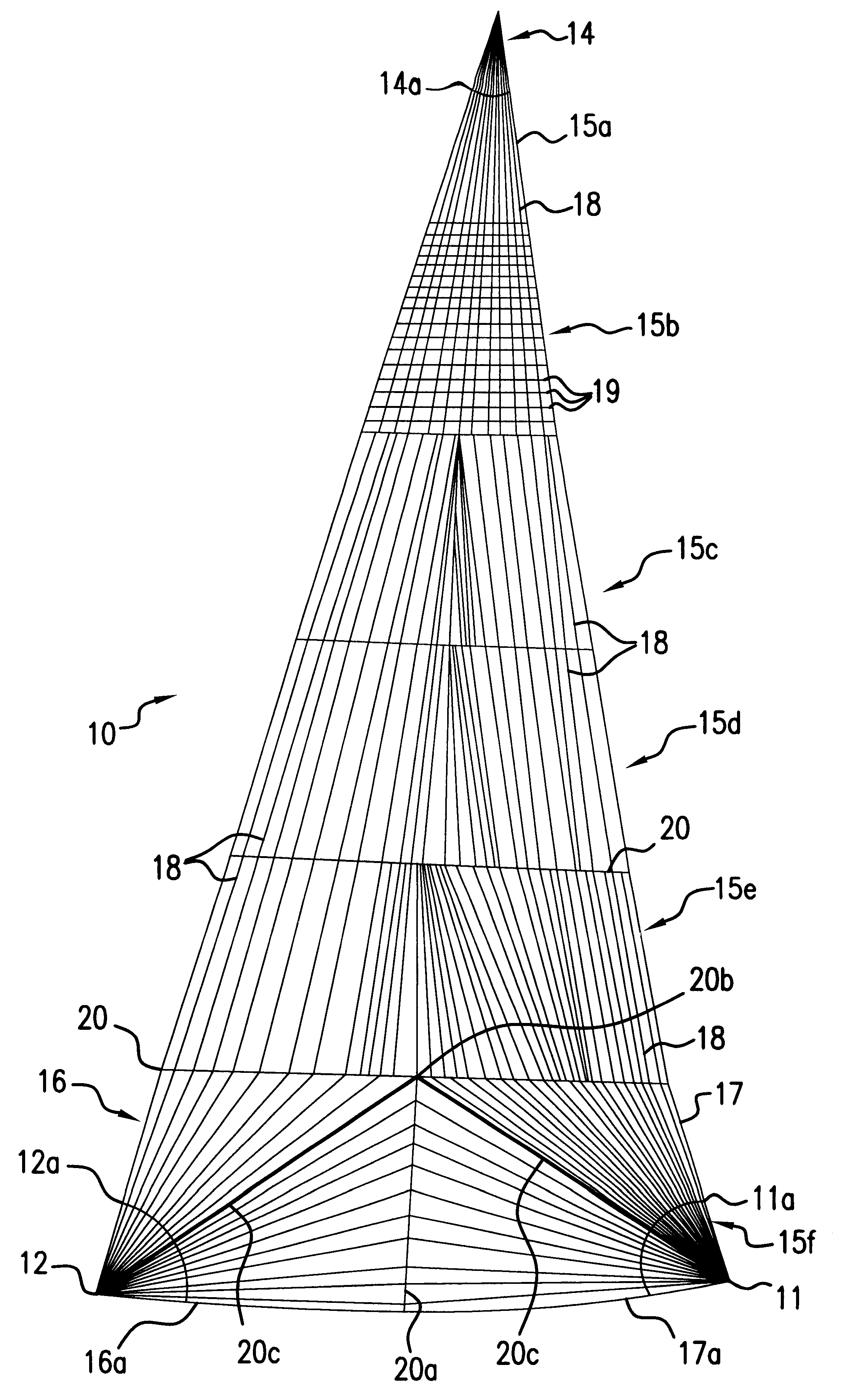

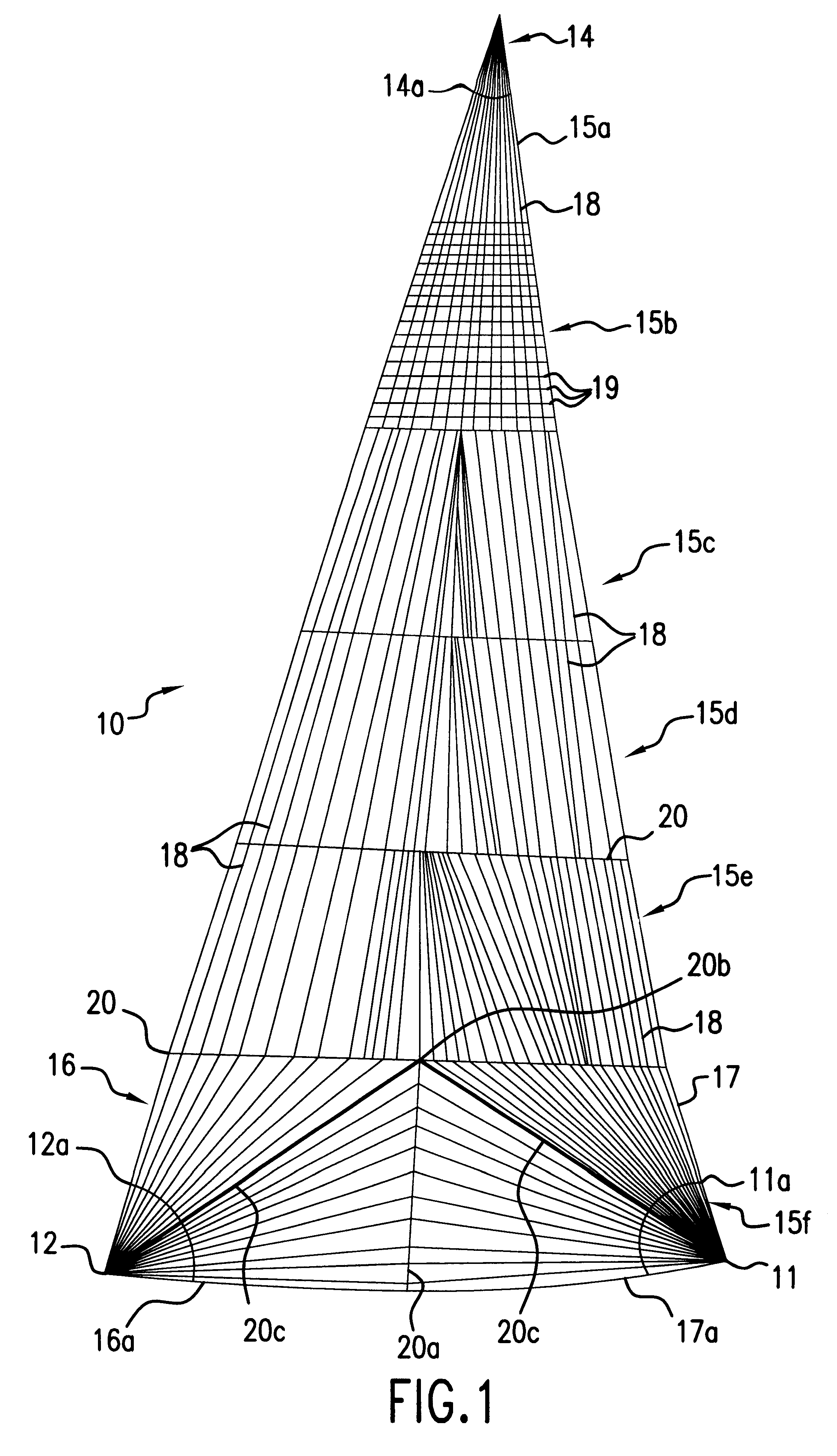

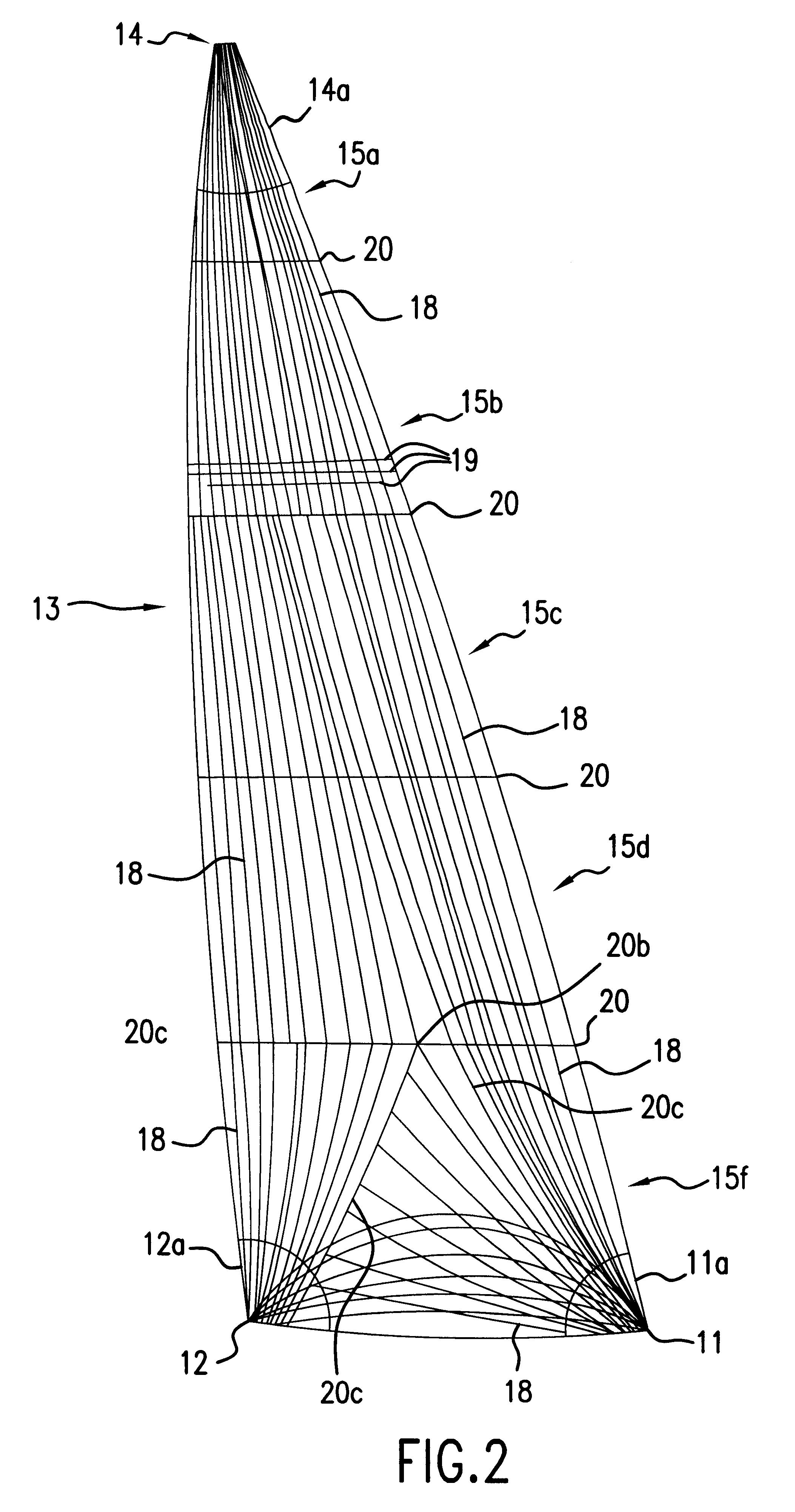

Woven fiber-oriented sails and sail material therefor

InactiveUS6311633B1Simple materialUniform processSynthetic resin layered productsWoven fabricsYarnFiber

Owner:KEIRE FRED AIVARS

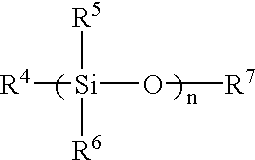

Silyl (METH) acrylate copolymers, processes for preparing the same, antifouling paint compositions containing the silyl (METH) acrylate copolymers, antifouling coating films formed from the antifouling paint compositions, antifouling methods using the antifouling paint compositions, and hulls or underwater structures coated with the antifouling coating films

InactiveUS6458878B1Improve antifouling performanceSuppressed hydrolysis rateAntifouling/underwater paintsPaints with biocidesMeth-Unsaturated monomer

Disclosed is a silyl (meth)acrylate copolymer which comprises 20 to 80% by weight of (a) silyl (meth)acrylate constituent units (I), 0.01 to 40% by weight of (b) acrylic unsaturated monomer constituent units (II) and 5 to 79.9% by weight of Ĉ unsaturated monomer constituent units other than the constituent units (a) and (b). Also disclosed is a process for preparing the silyl (meth)acrylate copolymer, an antifouling paint composition comprising the copolymer, a coating film formed from the paint composition, a hull with the coating film and an antifouling method using the paint composition.

Owner:CHUGOKU MARINE PAINTS

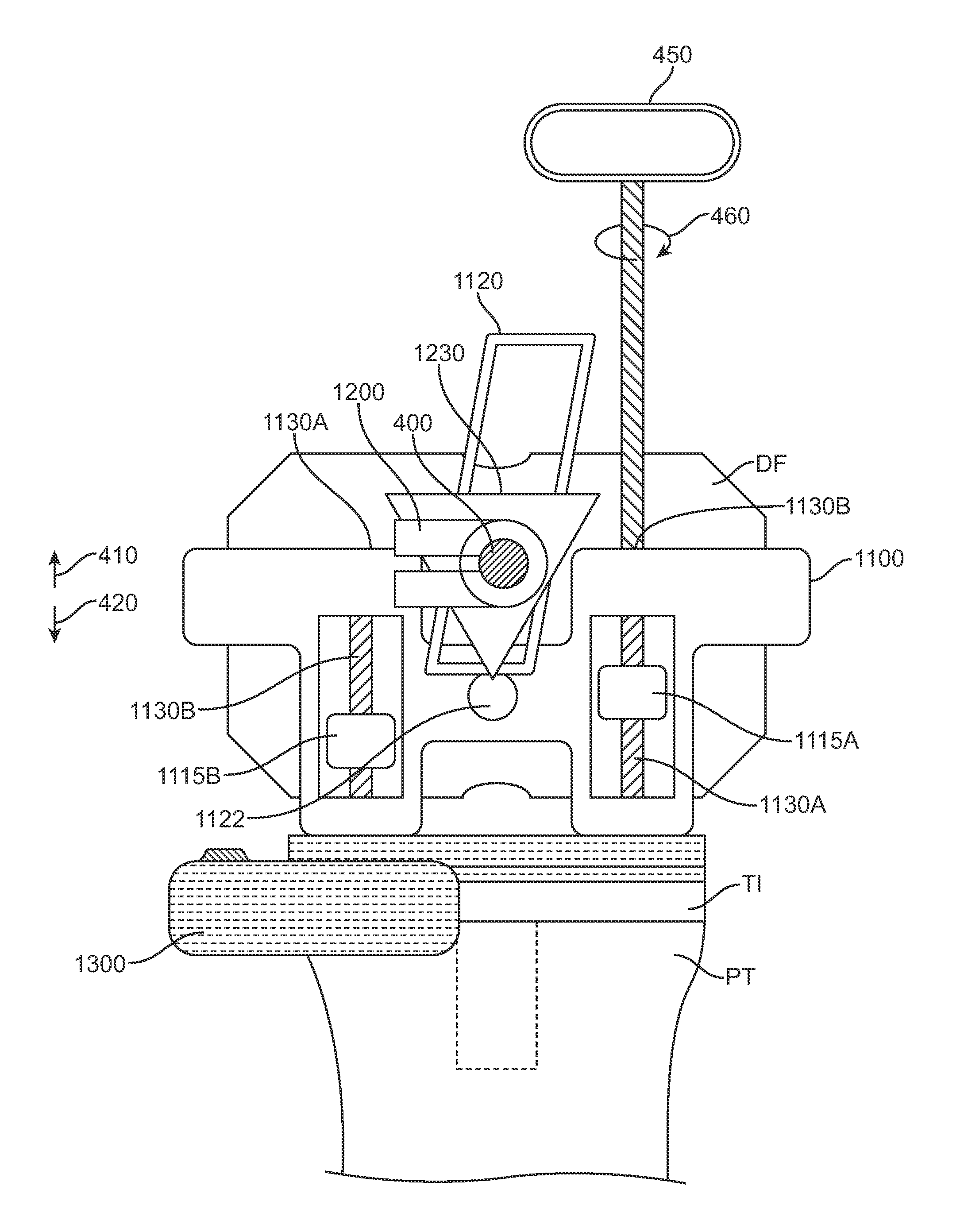

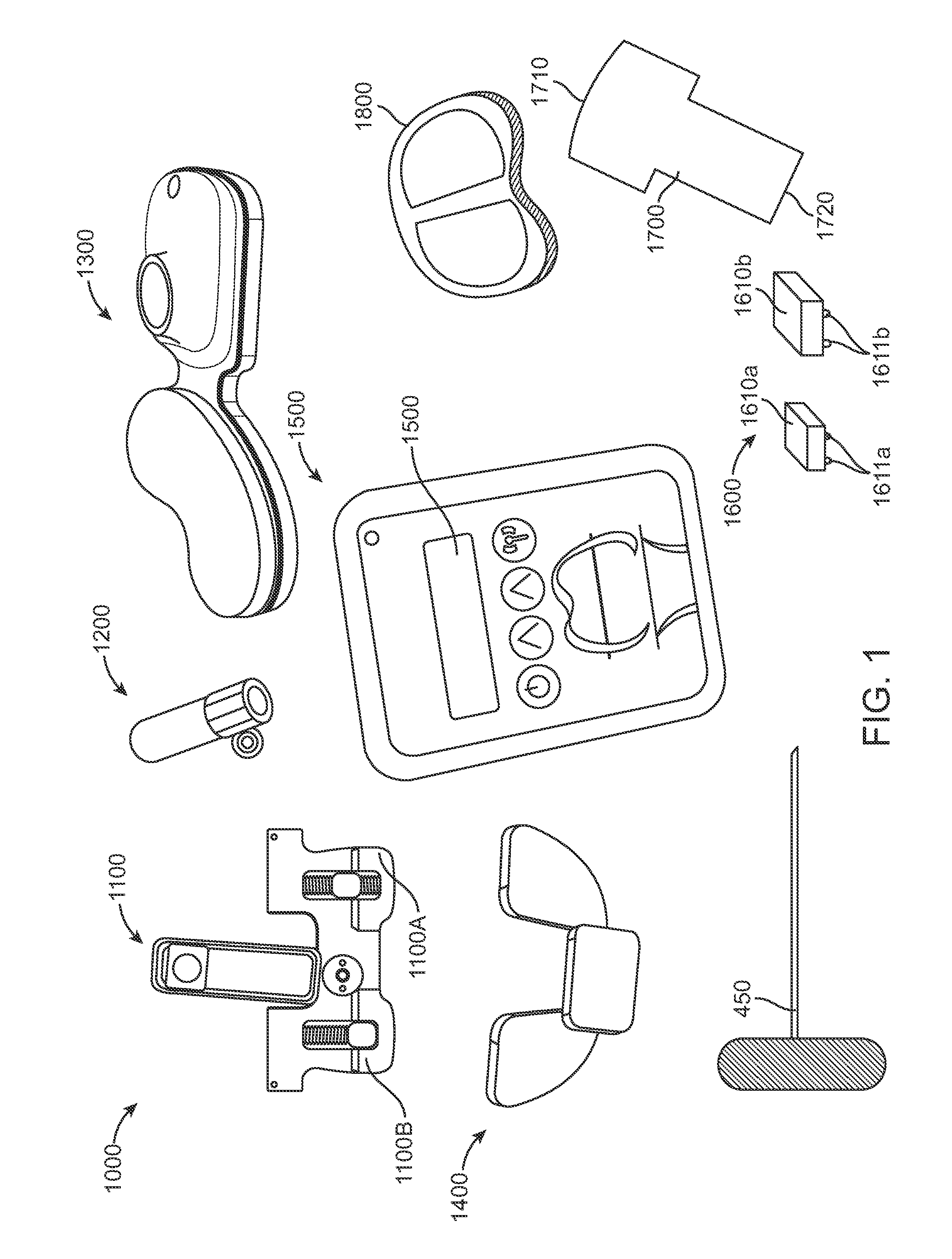

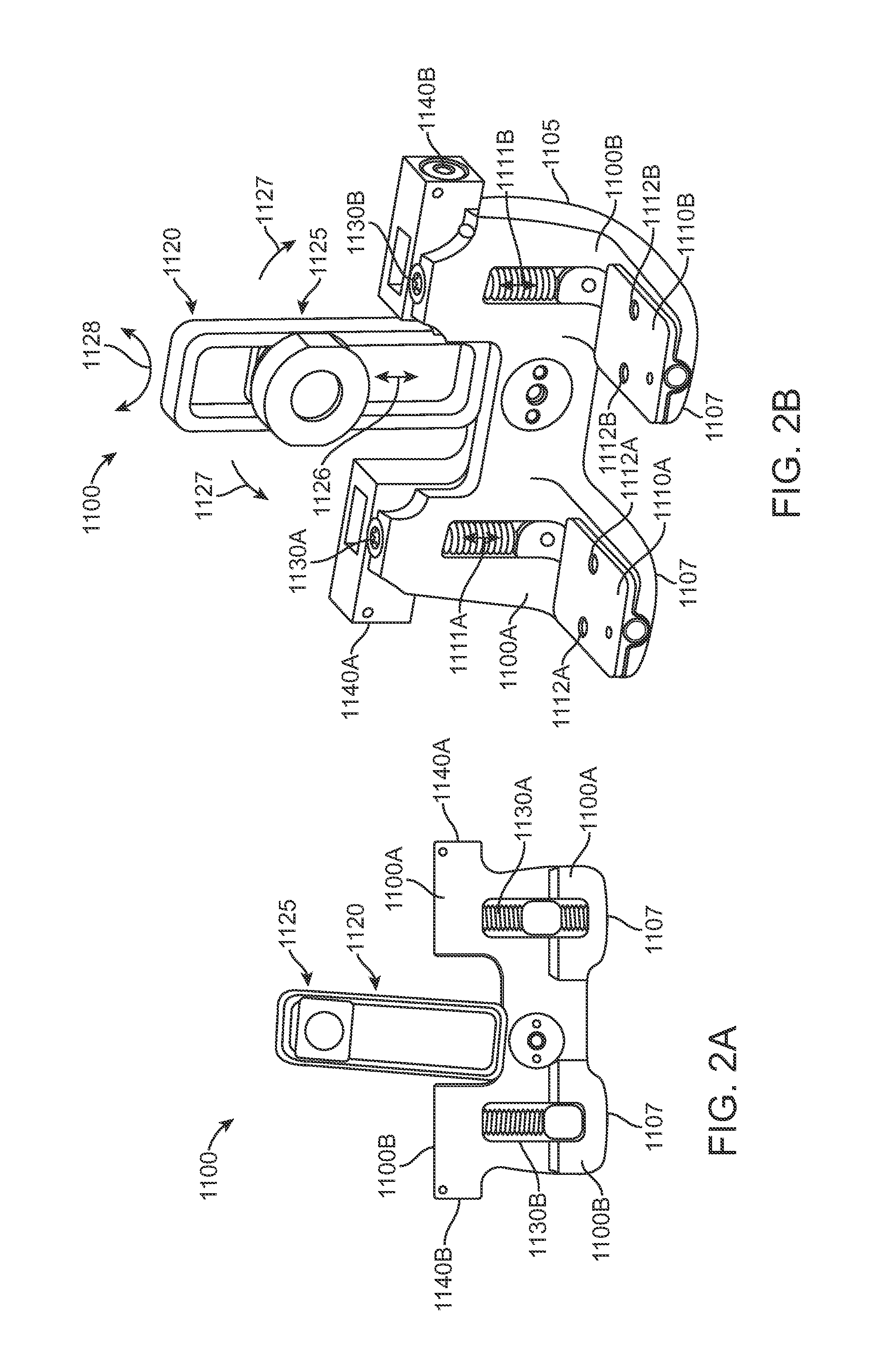

Knee balancing for revision procedures

ActiveUS20110093081A1Promote balance between supply and demandImprove balanceInternal osteosythesisJoint implantsTibial Collateral LigamentsTotal knee replacement

Methods, systems and devices are provided for facilitating a surgical procedure on a knee, particularly, a revision total knee replacement procedure. Prior femoral and tibial prostheses are removed. A cut end of a distal femur is engaged with a femoral adjustment member, which will typically center itself about an intermedullary rod placed into the femur. The lateral and medial forces exerted by lateral and medial sides of the femoral adjustment member and the cut tibial plateau against each other are measured. The femoral adjustment member is adjusted to apply and / or adjust tension to the lateral collateral ligament and / or the medial collateral ligament based on the measured forces, for example, such that the measured lateral force and the measured medial force are matched. Based on the position of the adjusted femoral member, guided clean-up cuts for placement of a new femoral prostheses are made on the cut end of the distal femur.

Owner:SYNVASIVE TECH

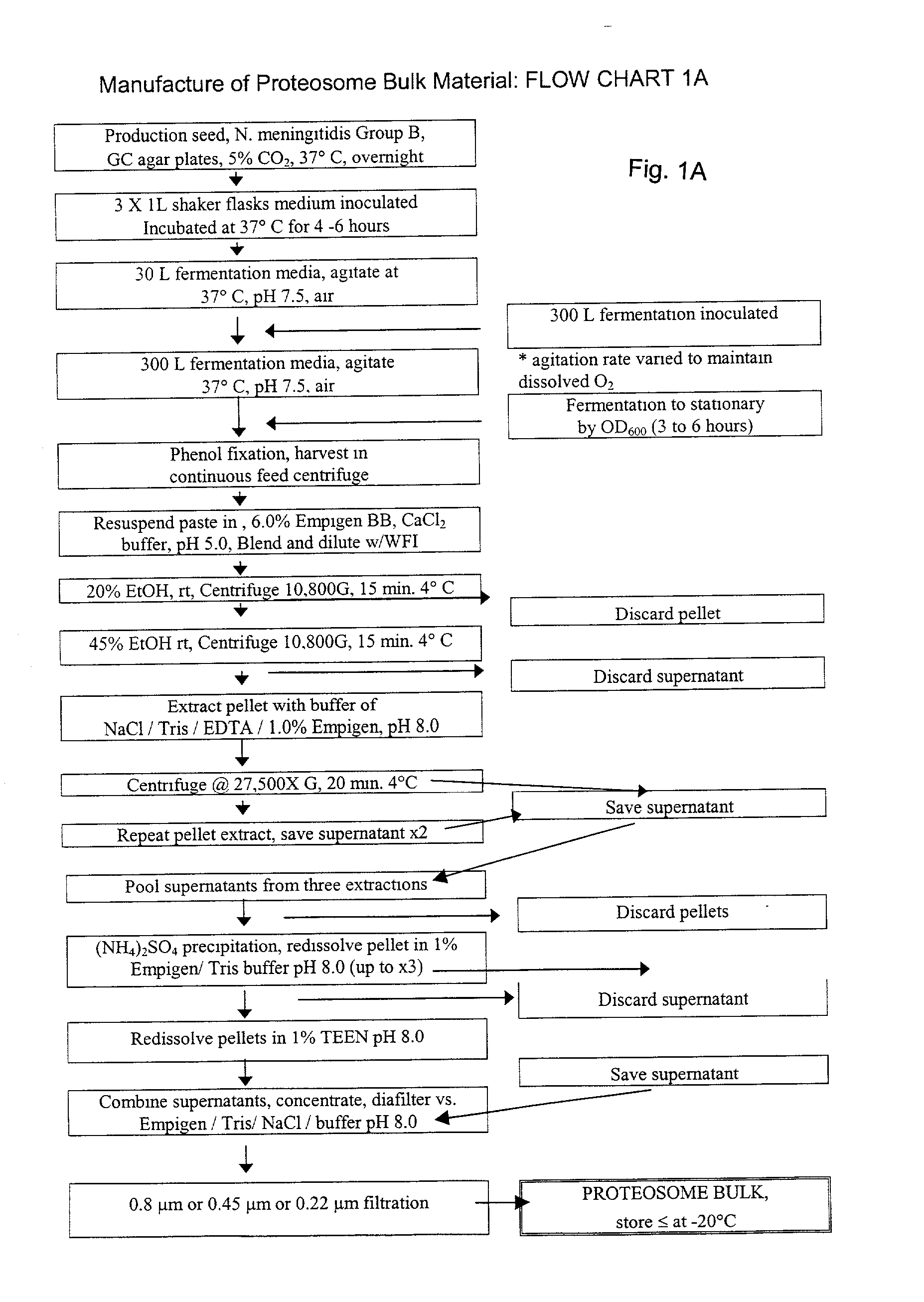

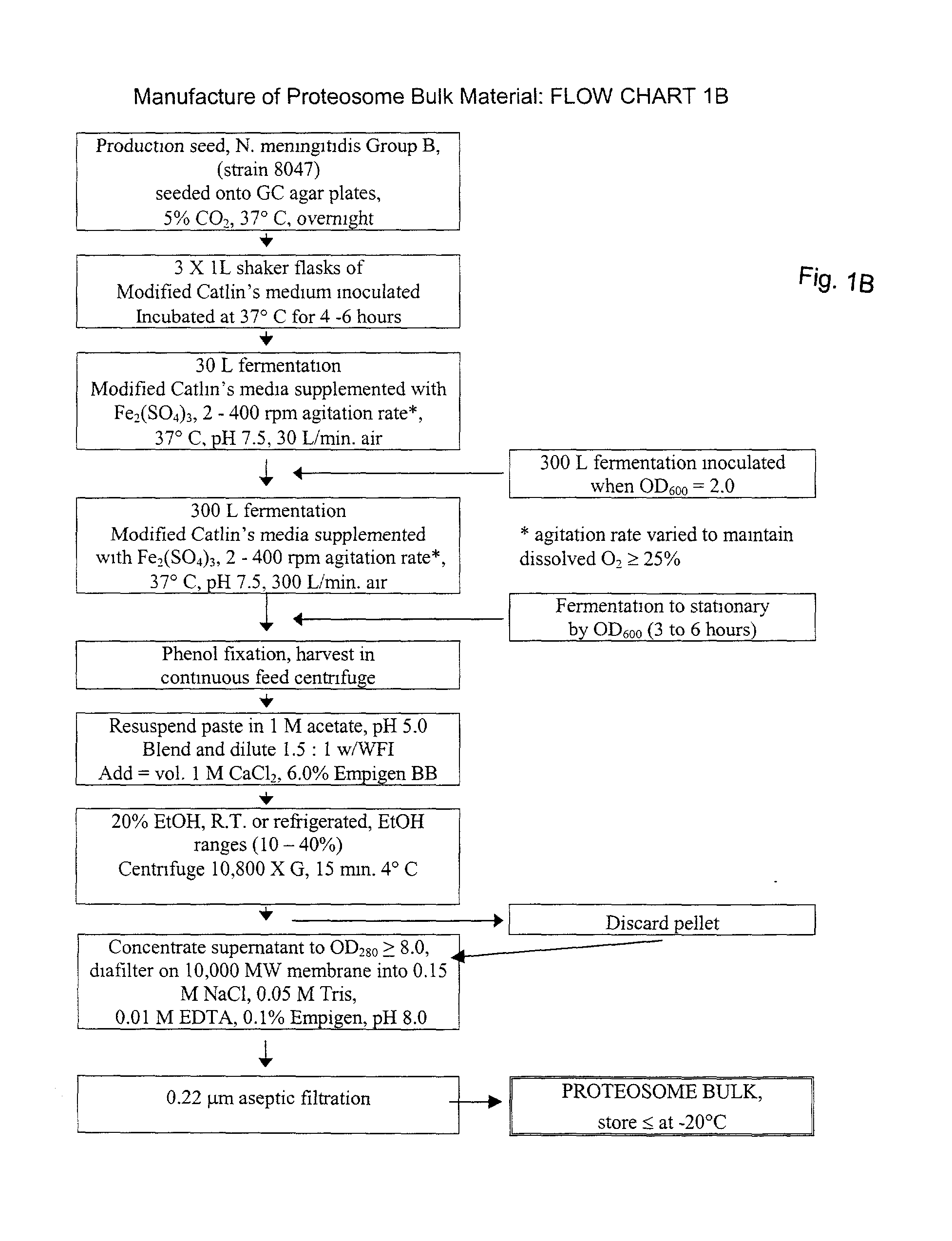

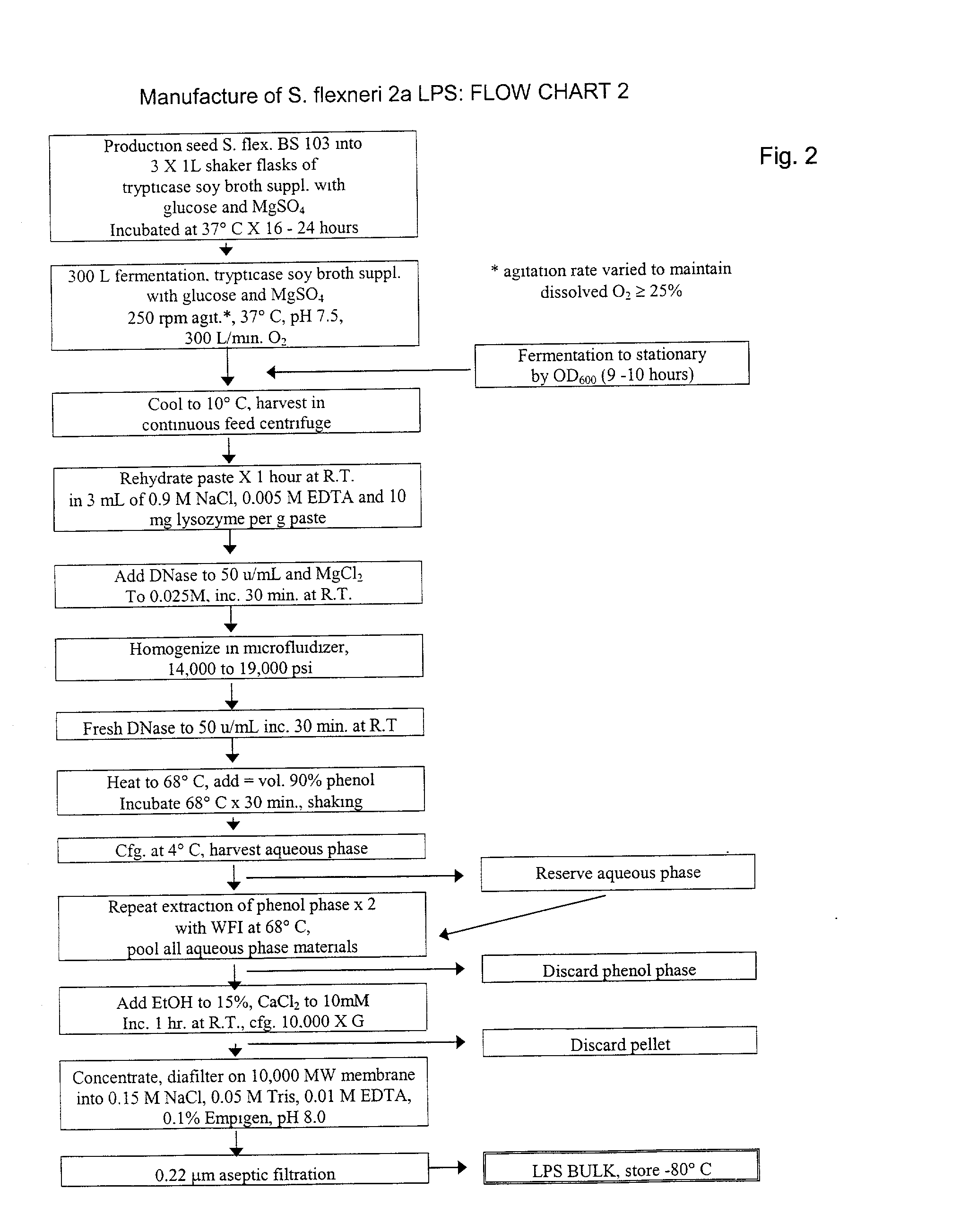

Novel proteosome-liposaccharide vaccine adjuvant

InactiveUS20030044425A1Increase secretionUniform processSsRNA viruses negative-senseBiocideImmunotherapeutic agentCytokine

An adjuvant complex composed of bacterial outer membrane protein proteosomes complexed to bacterial liposaccharide is prepared to contain the component parts under a variety of conditions. The complex can be formulated with antigenic material to form immunogenic compositions, vaccines and immunotherapeutics. An induced immune response includes protective antibodies and / or type 1 cytokines is shown for a variety of protocols.

Owner:ID BIOMEDICAL CORP LAVAL

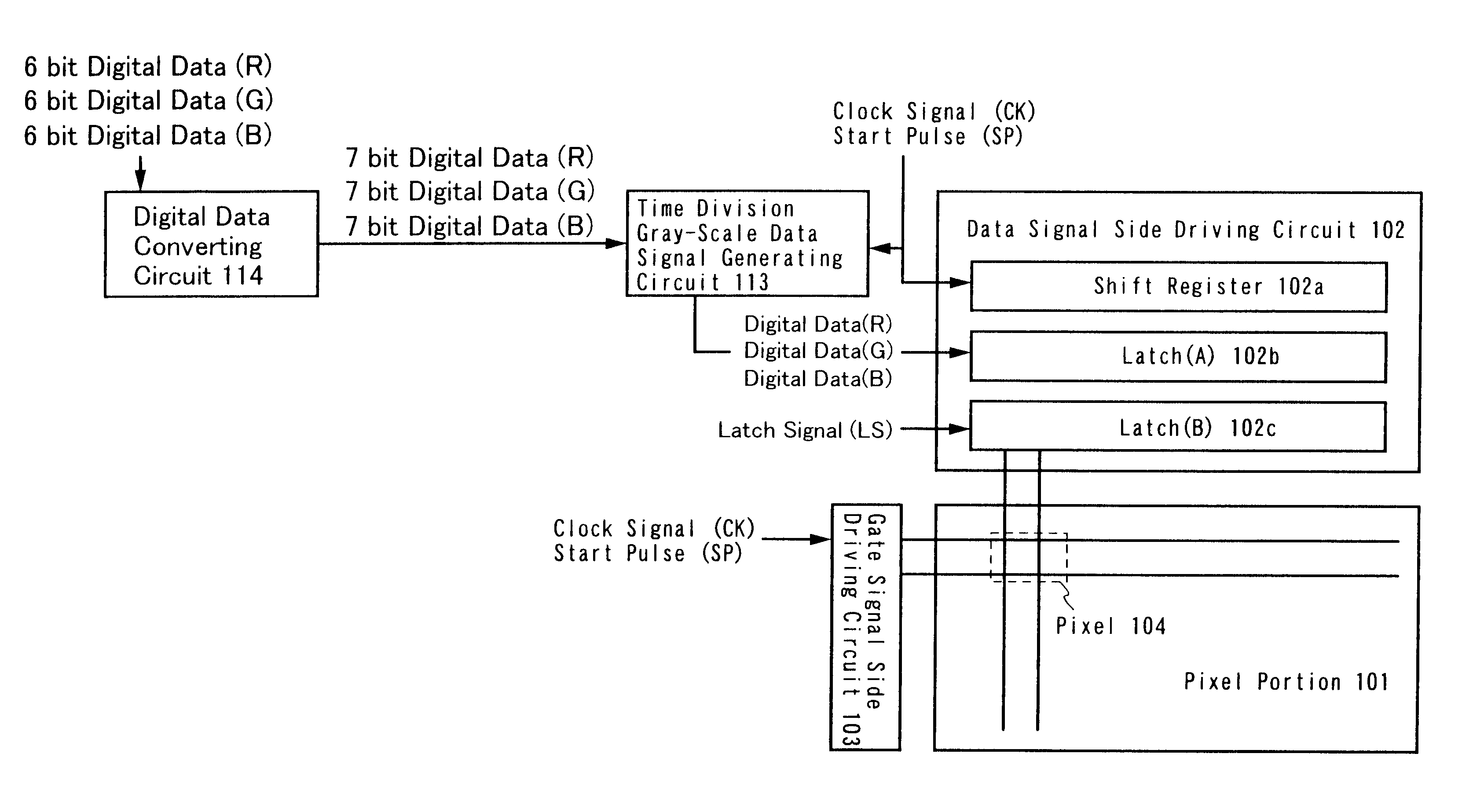

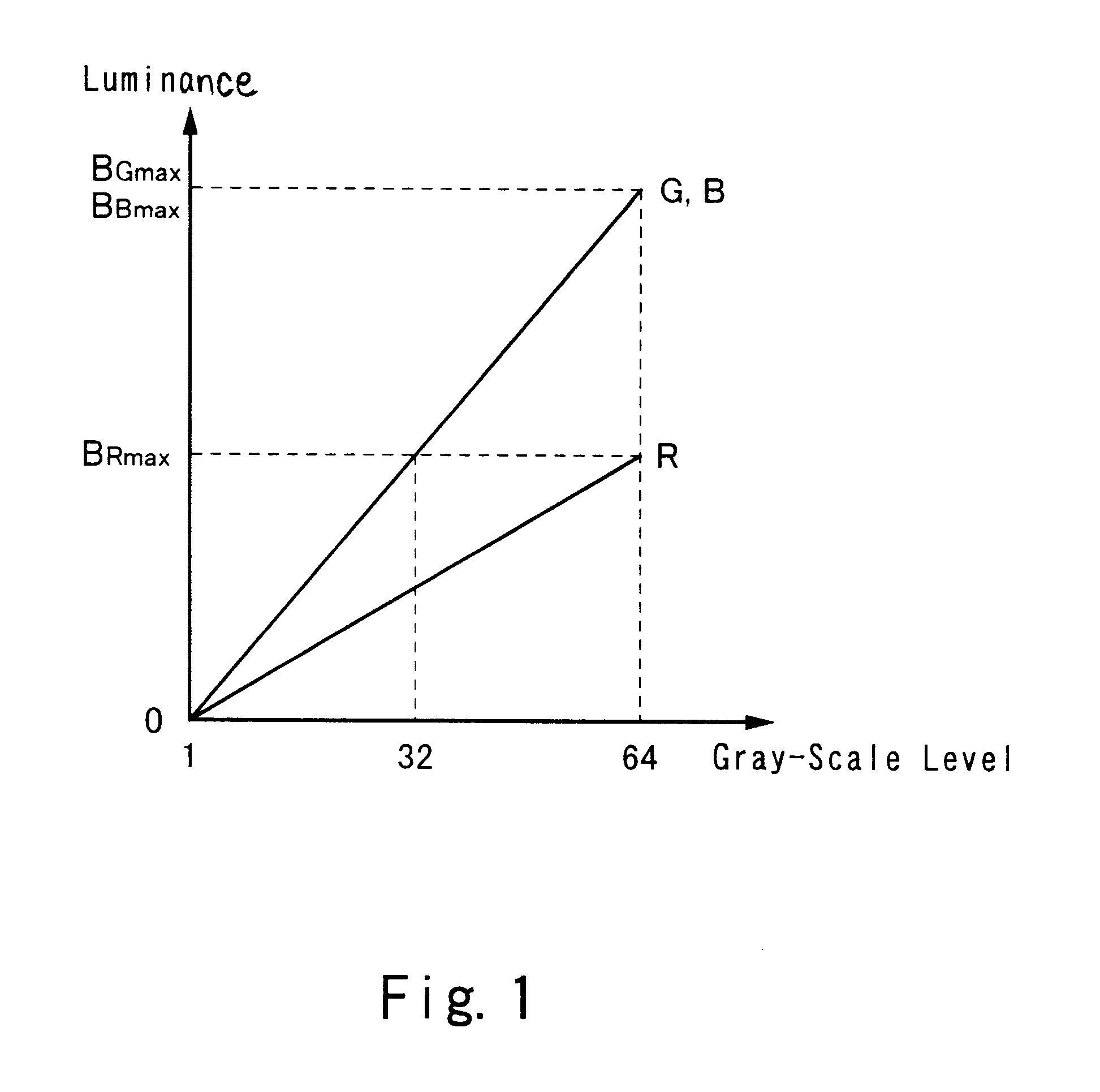

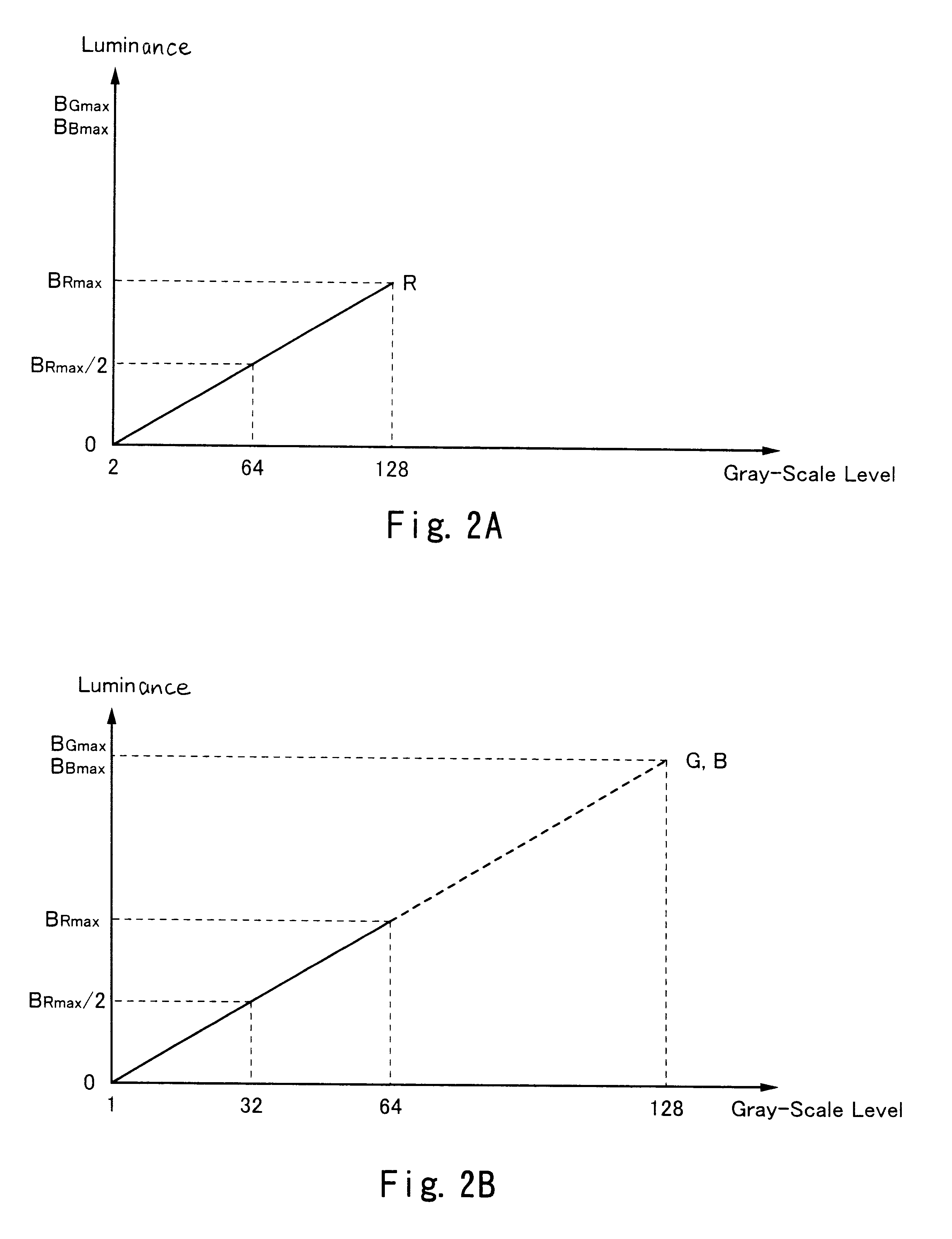

EL display device and driving method thereof

InactiveUS6351077B1Uniform processGood white balanceElectrical apparatusElectroluminescent light sourcesDigital dataComputer graphics (images)

The present invention is characterized by adding a bit having the value of one below the least significant bit of n bit digital data having red image information inputted from the external, adding a bit having the value of zero above the most significant bit of n bit digital data having green image information inputted from the external, and adding a bit having the value of zero above the most significant bit of n bit digital data having blue image information inputted from the external, whereby producing (n+1) bit digital data having red image information, (n+1) bit digital data having green image information, and (n+1) bit digital data having blue image information, respectively, for displaying an image.

Owner:SEMICON ENERGY LAB CO LTD

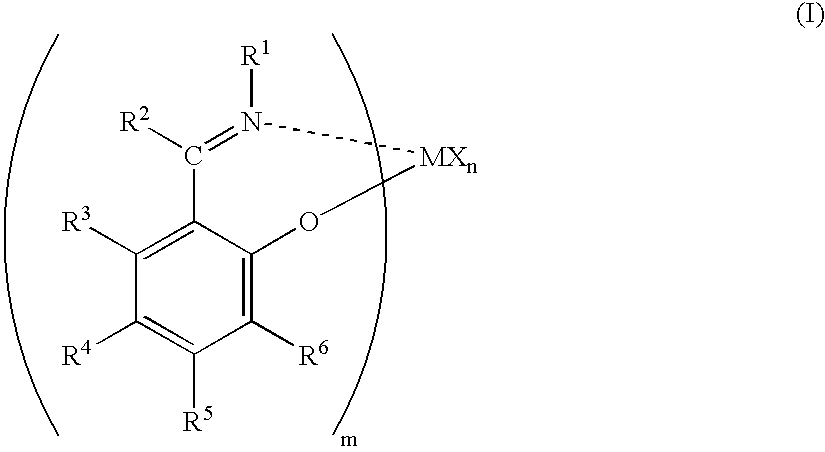

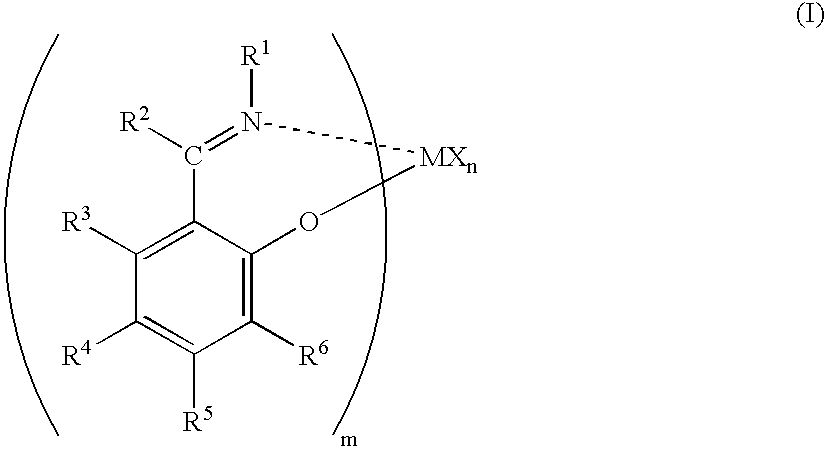

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

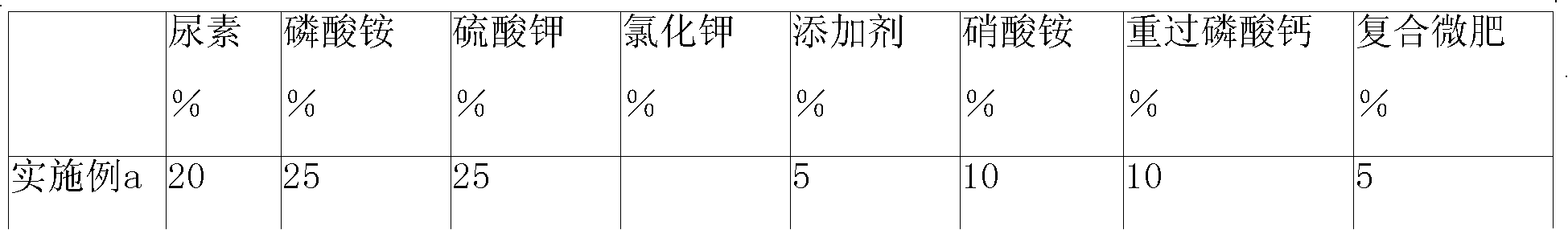

Long-acting special controlled release fertilizer for corn and preparation method thereof

InactiveCN101177365ALess hygroscopic expansion and contractionSimple preparation processFertilizer mixturesPotassiumNutrient

A special controlled-release fertilizer for long-acting corn and its preparation method. The fertilizer core accounts for 80-92% of the total weight of the fertilizer, wherein the weight sum of nitrogen fertilizer, phosphorus fertilizer and potassium fertilizer calculated by pure nitrogen, phosphorus pentoxide and potassium chloride is the fertilizer 25%-50% of the total weight, the weight ratio is: 2-4:1-2:1-3; the coating coating accounts for 8-20% of the total weight of the fertilizer, including: 69.5-93% sulfur, 530 % polyethylene wax, 0.5-2% leveling agent. Melt sulfur, add montmorillonite and stir evenly, then add leveling agent, stir evenly to form molten sulfur. The molten sulfur and polyethylene wax are simultaneously sprayed on the surface of the fertilizer core to form a slow-release coating layer. The process occupies less land, requires less investment in equipment, and consumes less energy. It has the characteristics that one fertilization can meet the nutrient needs of corn throughout the growth period. The fertilizer effect is long and safe, and fertilization is simple.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

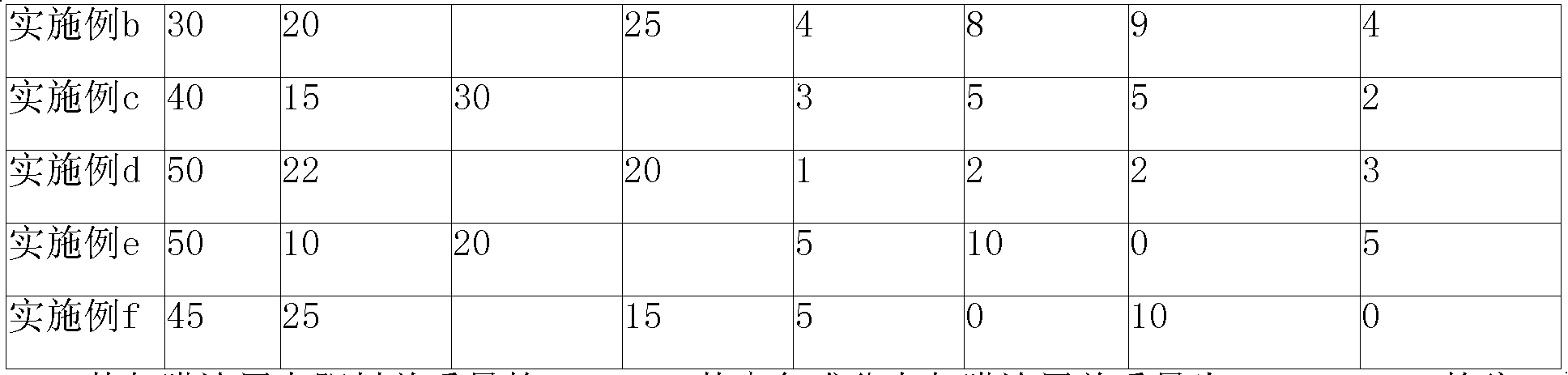

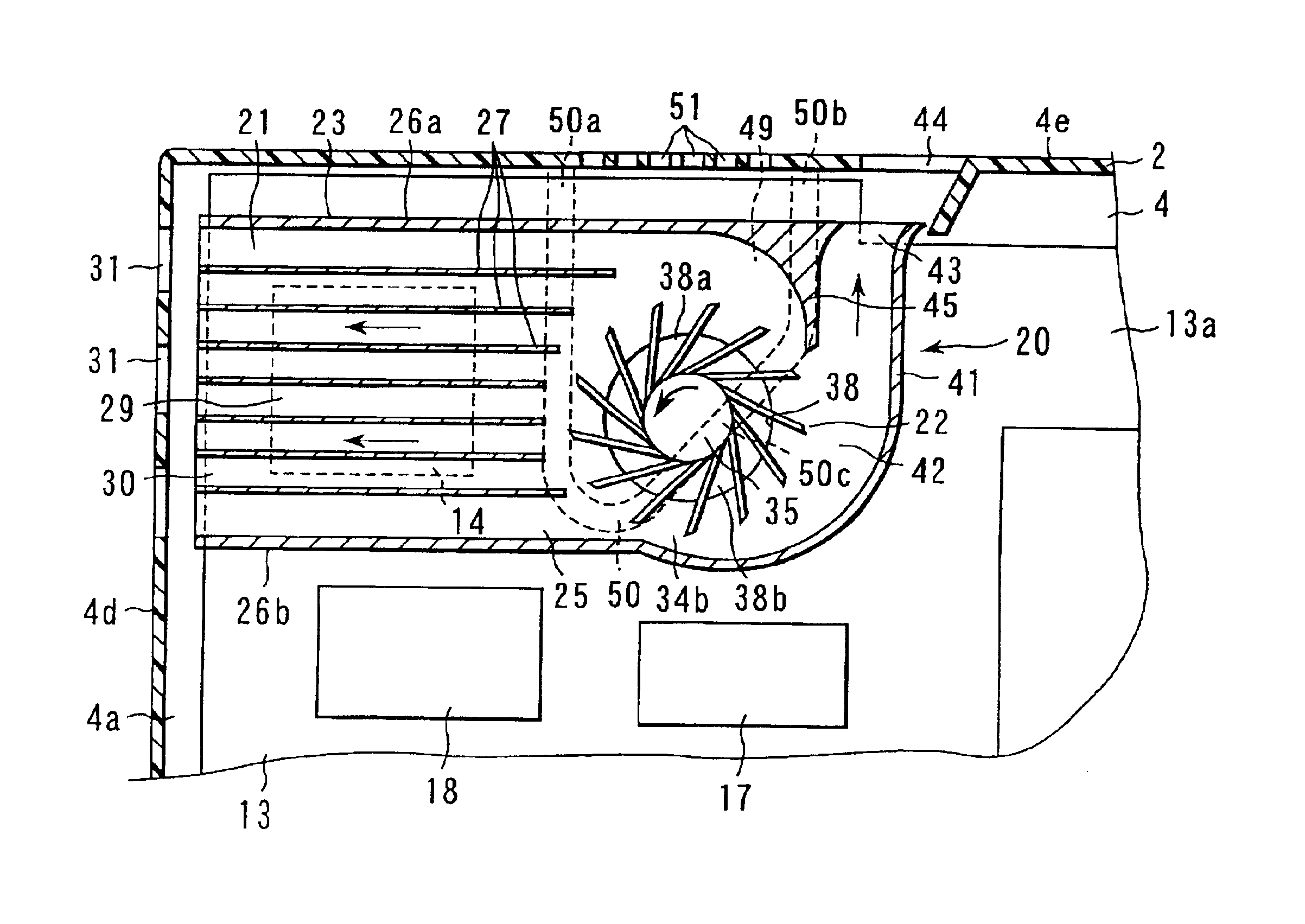

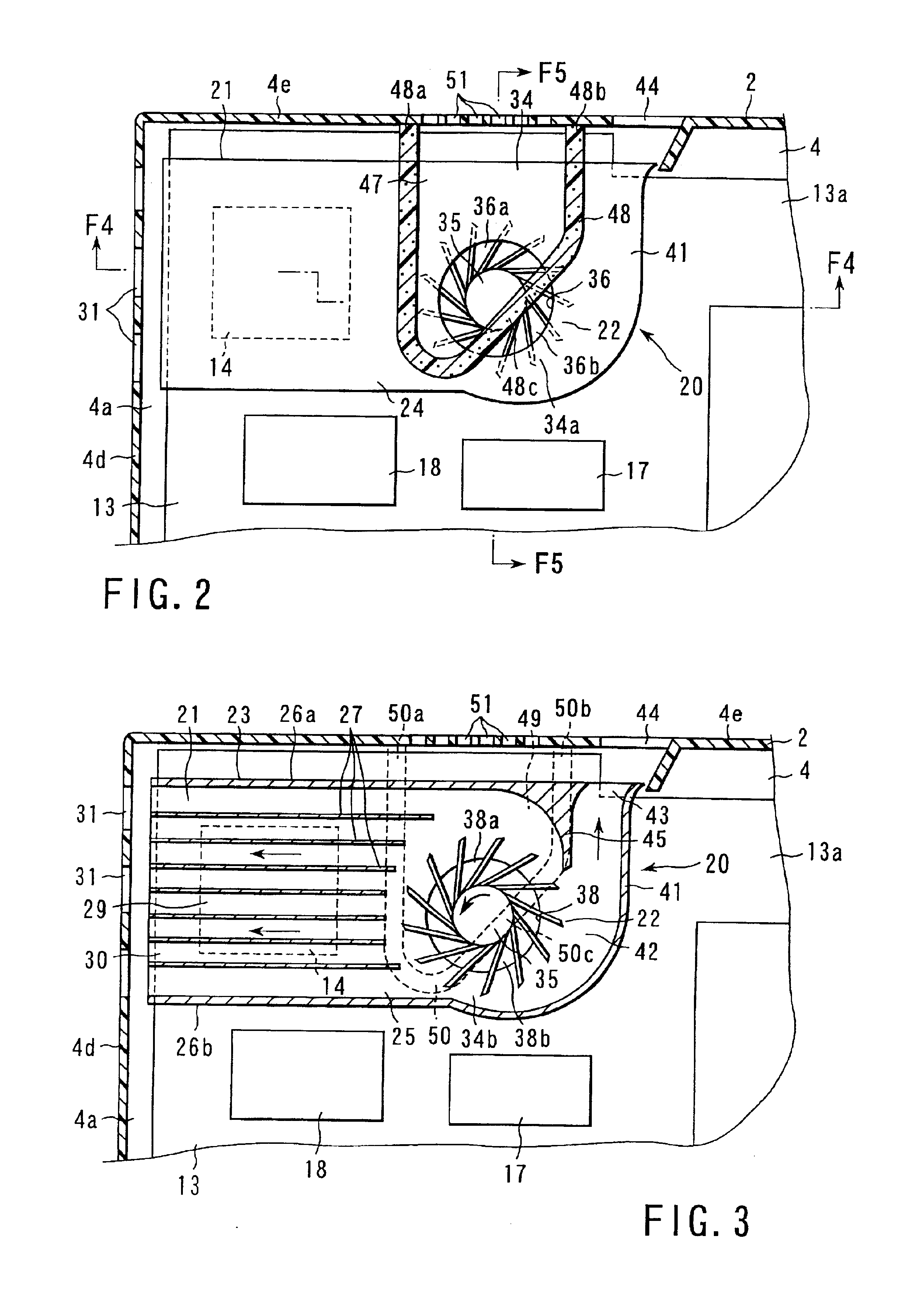

Electronic apparatus having cooling unit for cooling heat-generating component

InactiveUS6847524B2Improve cooling effectCool evenlyDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

An electronic apparatus comprises a housing containing a heat-generating component, and a cooling unit. The cooling unit includes a heat sink thermally connected to the heat-generating component, a first air passage for guiding air outside the housing to the heat sink and guiding air heated by heat exchange with the heat sink to the outside of the housing, and a second air passage for guiding air within the housing to the outside of the housing.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

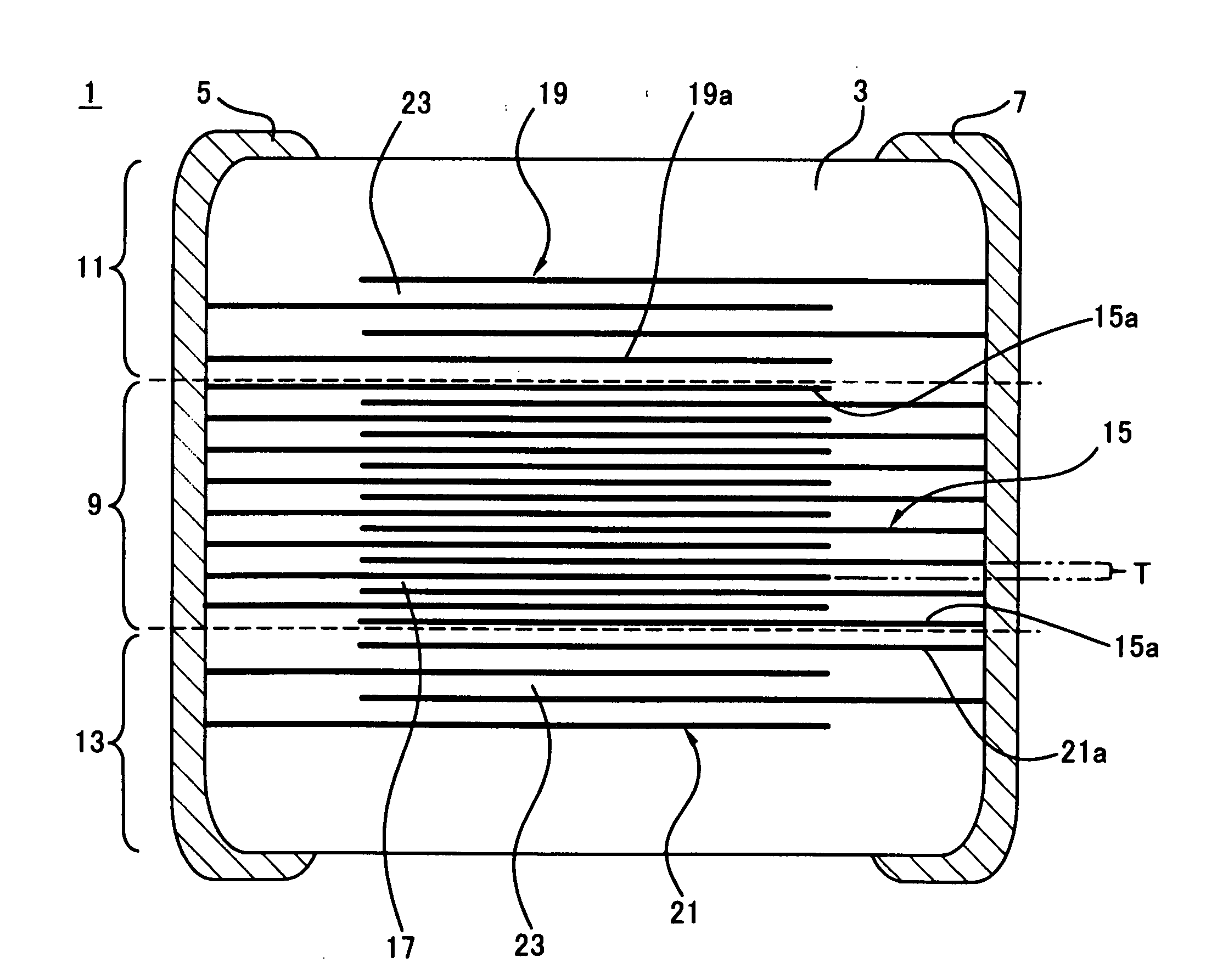

Laminated electronic component

ActiveUS20070025054A1Avoid it happening againInhibiting short-circuitFixed capacitor electrodesFixed capacitor dielectricElectronic componentBiomedical engineering

A laminated electronic component includes a ceramic body having an inner portion and a pair of outer portions disposed above and below the inner portion and a pair of external electrodes disposed on lateral sides of the ceramic body. A plurality of internal electrodes are embedded in the inner portion and alternately connected to the external electrodes. At least two layers of dummy electrodes are embedded in at least one of the outer portions and each connected to one of the external electrodes. An innermost one of the dummy electrodes has a same polarity as an adjacent outermost one of the internal electrodes. The dummy electrodes include at least one pair of adjacent dummy electrodes of opposite polarities.

Owner:TDK CORPARATION

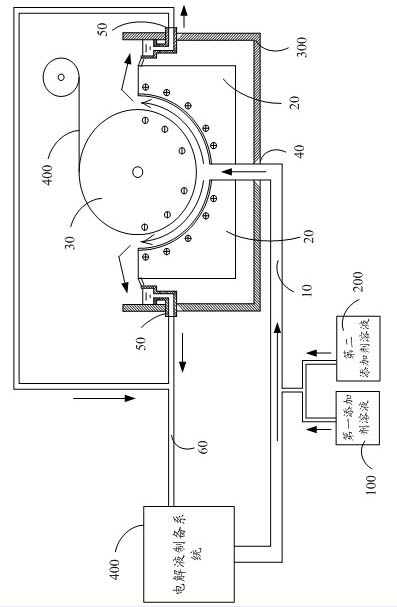

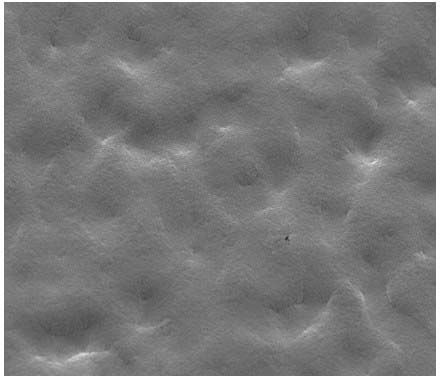

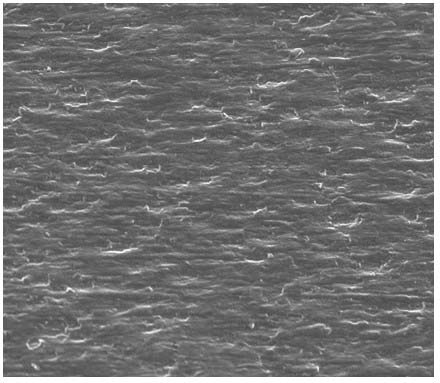

Preparation of Double-sided Photoelectrolytic Copper Foil for Special Lithium Batteries

ActiveCN102277597AStable production processHigh quality and efficient material selectionElectroforming processesElectrochemical responseCopper foil

The invention relates to the preparation of a double-sided photoelectrolytic copper foil for a special lithium battery, which comprises the following steps: preparing solution of a first additive, solution of a second additive, and copper sulfate electrolyte, wherein the copper ion concentration in the copper sulfate electrolyte is 70 to 100g / L, the sulfuric acid concentration is 100 to 170g / L and the chlorine ion concentration is 0.01 to 0.04g / L, and the temperature of the copper sulfate electrolyte is 40 to 60 DEG C; adding 60 to 200 milliliters of solution of the first additive and 35 to 100 milliliters of solution of the second additive into each cubic meter of electrolyte each hour, wherein the electrolyte formed by uniformly stirring enters an electrolytic cell and the electrolysis current density of the electrolyte in the electrolytic cell is 5,000 to 6,000A / m<2>; and after electrochemical reactions are accomplished, obtaining the double-sided electrolytic copper foil for a photic lithium battery. The preparation of the double-sided photoelectrolytic copper foil for the special lithium battery has the advantages that: the unit area weight of the prepared photoelectrolytic copper foil is 87 to 89g / m<2>, the tensile strength is more than 45Kgf / m<2>, the elongation rate is more than 5 percent, the surface roughness R2 is less than 1.5 mu m, and the uniform thickness of thecopper foil is 8.6 to 9.3 mu m according to actual measurement.

Owner:合肥铜冠电子铜箔有限公司

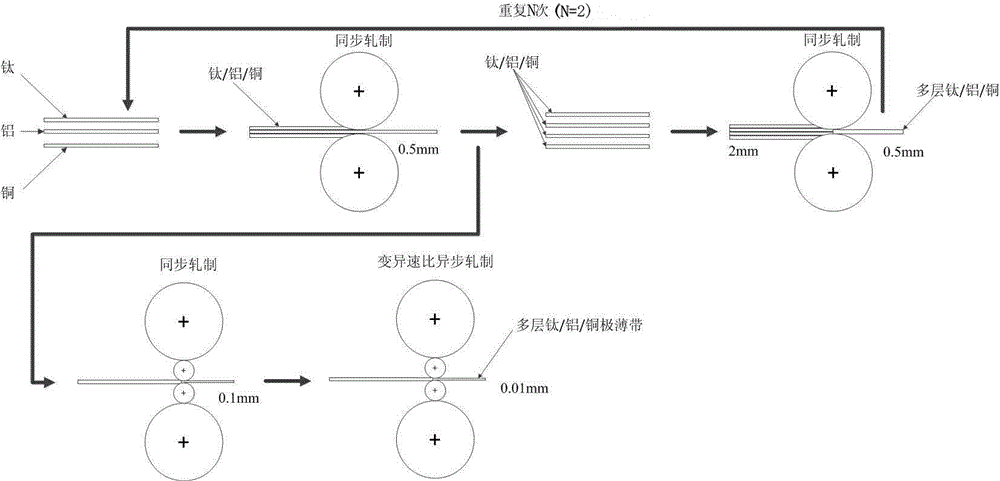

Preparation method for multilayer dissimilar metal composite ultra-thin strip

ActiveCN105170652AWide range of choicesEliminate intermediate heating processMetal rolling arrangementsRoll speed control deviceThinningMetal

The invention provides a preparation method for a multilayer dissimilar metal composite ultra-thin strip. The preparation method includes the process steps that (1) different metal materials are synchronously cold-rolled for first thinning; (2) metal thin strips are polished and cleaned; (3) the upper surfaces and lower surfaces of two or more metal thin strips are closely attached; (4) two-roll synchronous cold rolling is conducted on dissimilar metal combined strips; (5) the upper surfaces and lower surfaces of 2-10 dissimilar metal thin strips subjected to preliminary combination are closely attached and then the procedures of the step (1) to the step (4) are repeated 2-10 times; (6) reversible four-roll synchronous cold rolling is conducted on a multilayer dissimilar metal composite thin strip; and (7) reversible four-roll asynchronous cold rolling is conducted on the multilayer dissimilar metal composite thin strip, and the multilayer dissimilar metal composite ultra-thin strip with the thickness being 0.01 mm-0.02 mm is obtained. According to the method, the selection range of the metal materials is wide, the requirement for equipment capacity is low, and the surface quality of the ultra-thin strip can be improved remarkably; besides, production resources are saved, production cost is reduced, and the method is suitable for large-scale industrial production.

Owner:NORTHEASTERN UNIV

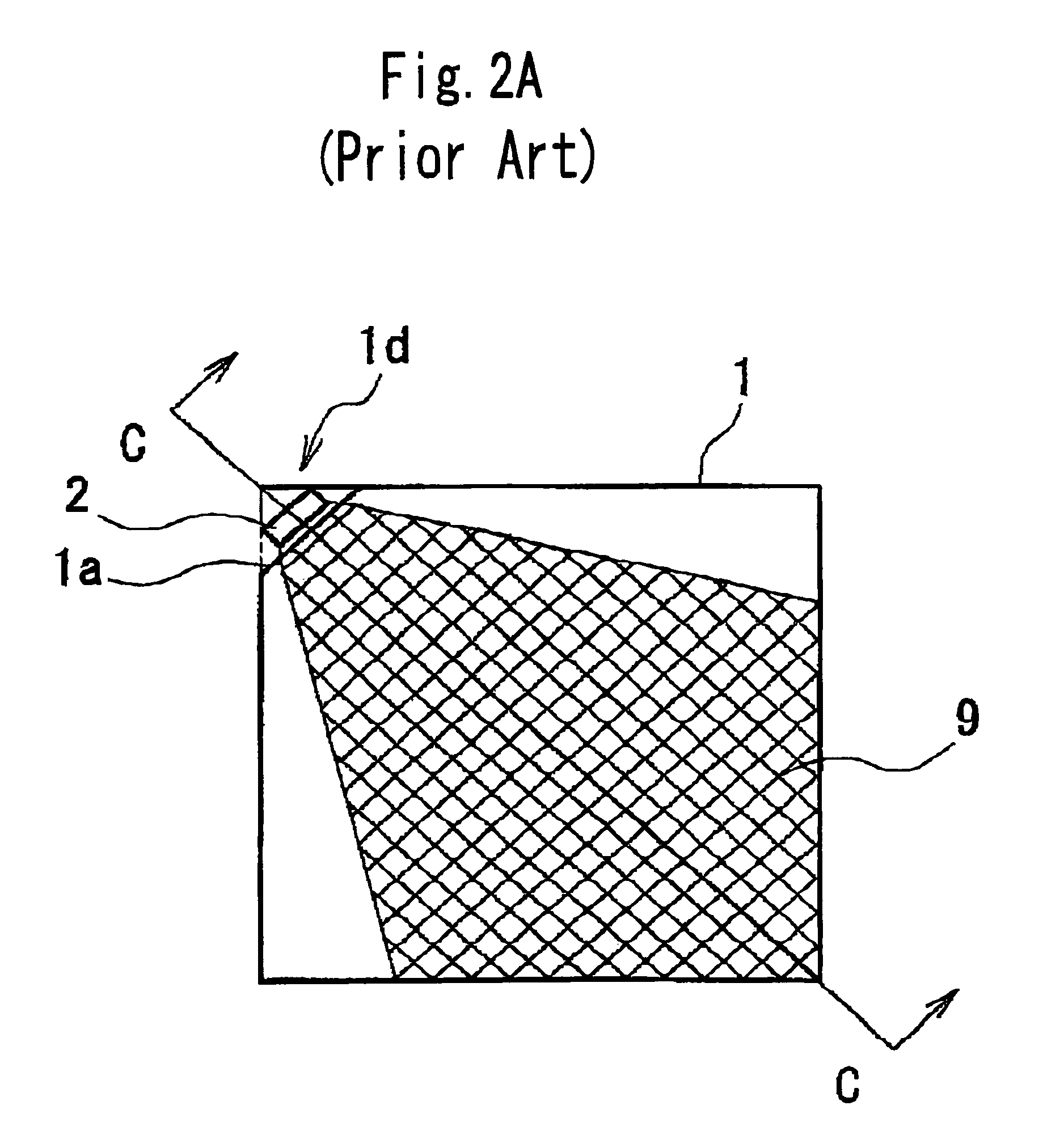

Light guide plate

ActiveUS7357557B2Improve display image qualityHigh quality imagingMechanical apparatusPlanar/plate-like light guidesEmberLight guide

Owner:CITIZEN ELECTRONICS CO LTD

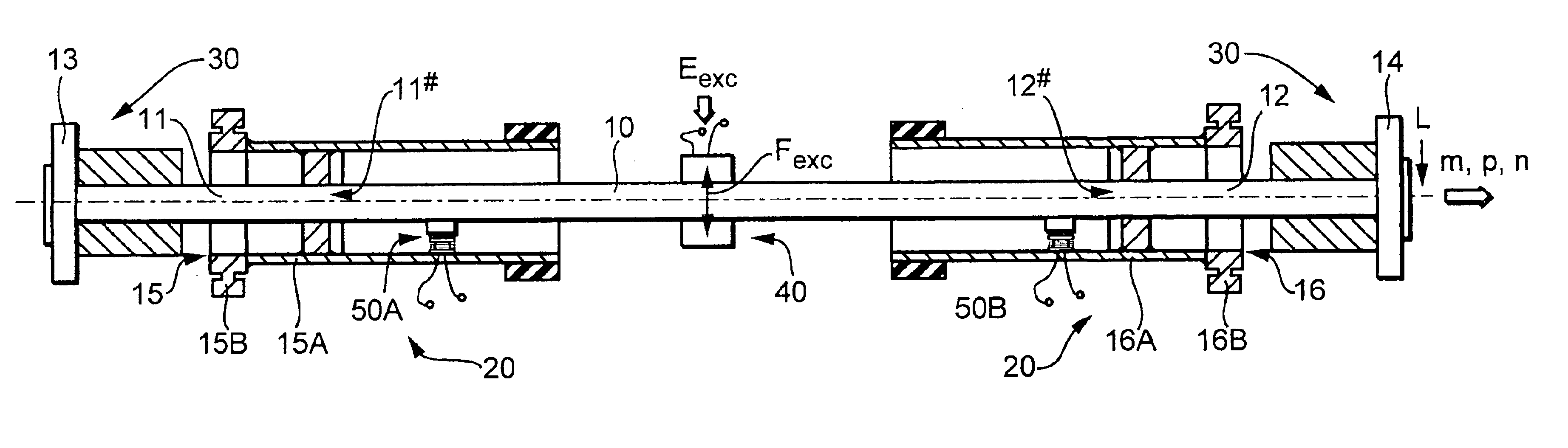

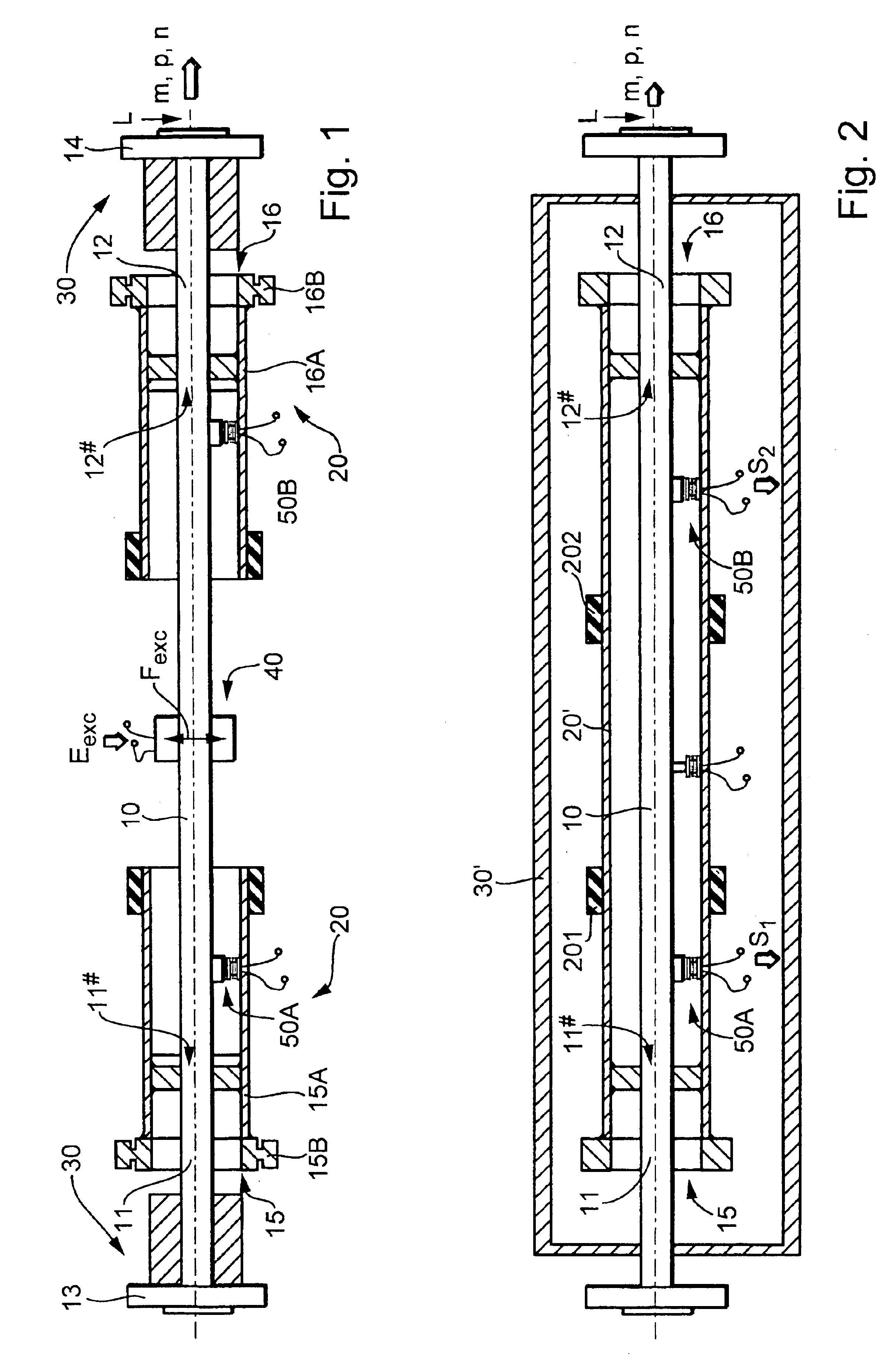

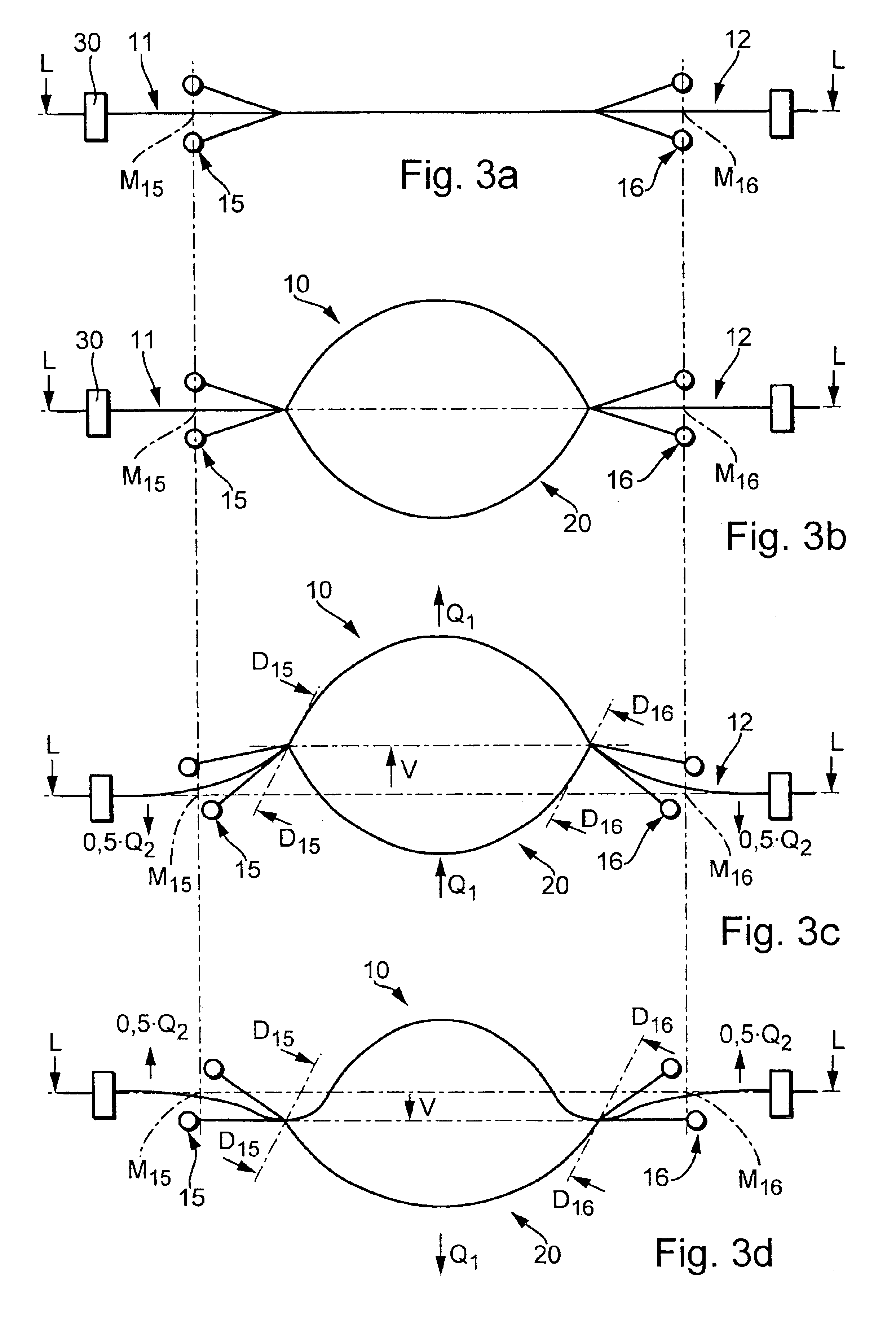

Vibratory transducer

InactiveUS6851323B2Improve balanceUniform processDirect mass flowmetersLateral displacementEngineering

To conduct a fluid, the transducer has a flow tube which in use is vibrated by an excitation system and whose inlet-side and outlet-side vibrations are detected by means of a sensor system. In response to transverse forces produced in the vibrating flow tube, the latter is, at least temporarily, laterally displaced from an assigned static rest position. To improve the dynamic balance of the transducer, a first cantilever and a second cantilever are rigidly fixed to an inlet-side tube section and an outlet-side tube section, respectively. By means of the cantilevers, the inlet-side and outlet-side tube sections are deformed as a result of lateral displacements of the flow tube. This produces counterforces which at least partially counterbalance the transverse forces produced in the vibrating flow tube. One advantage of the proposed transducer is that it is well balanced even during variations in fluid density.

Owner:ENDRESS HAUSER FLOWTEC AG

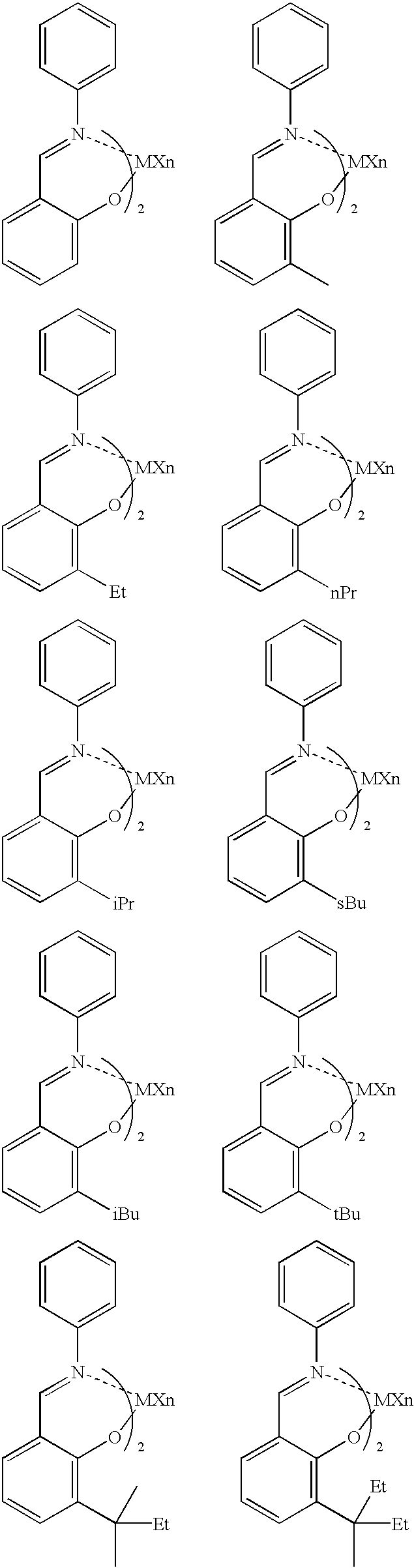

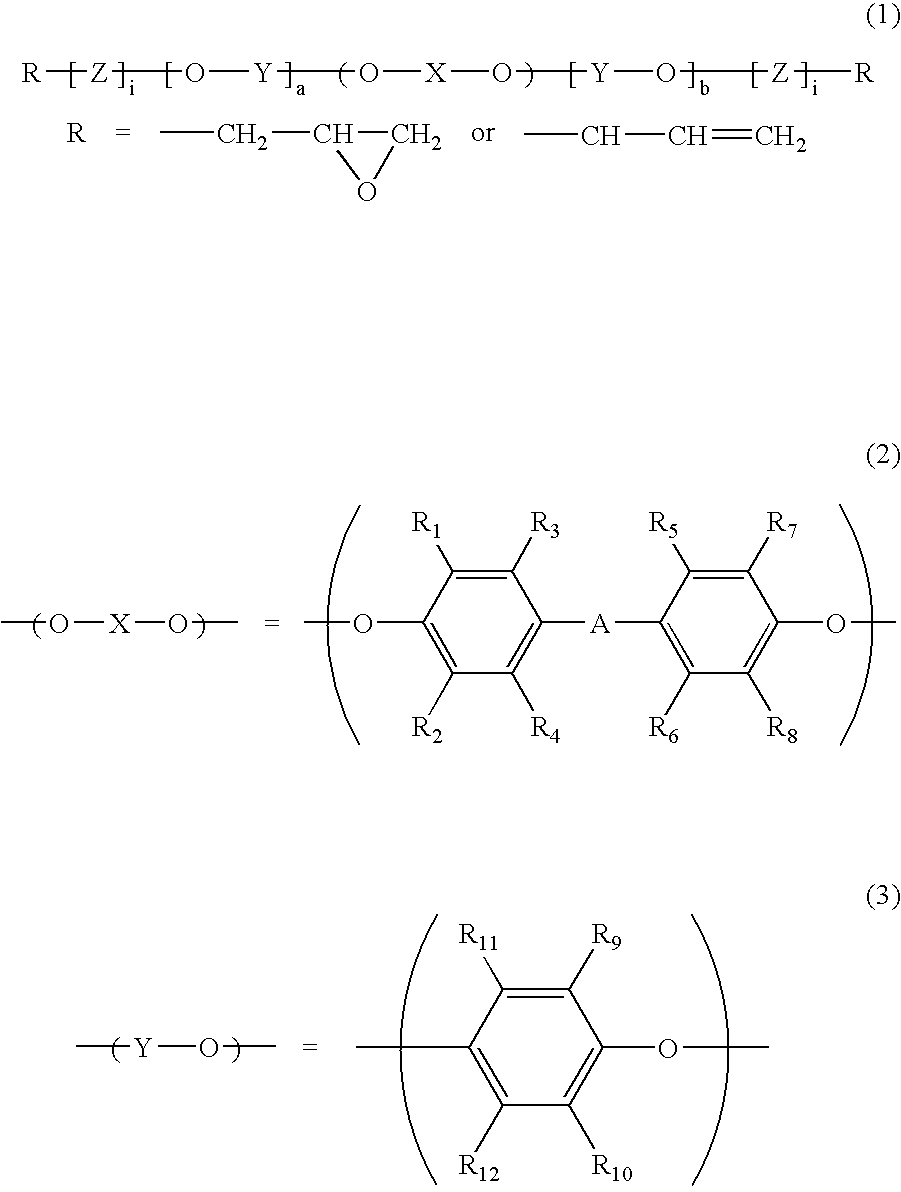

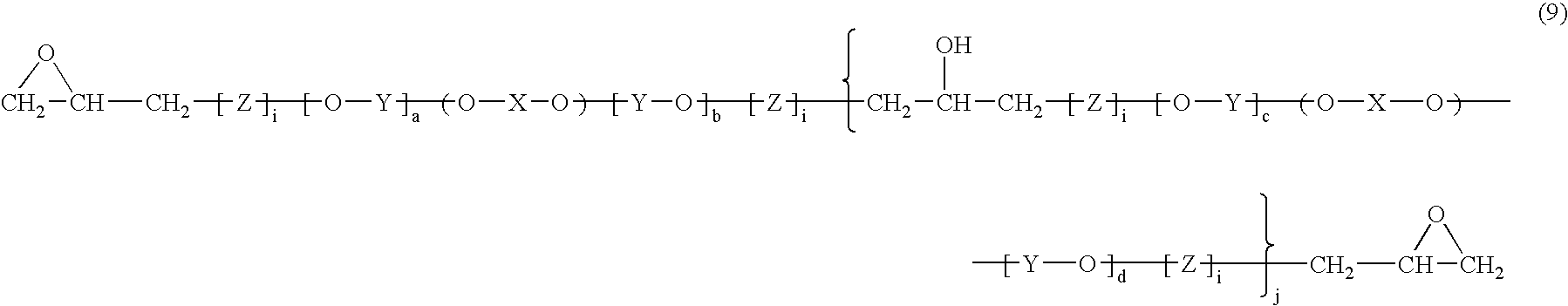

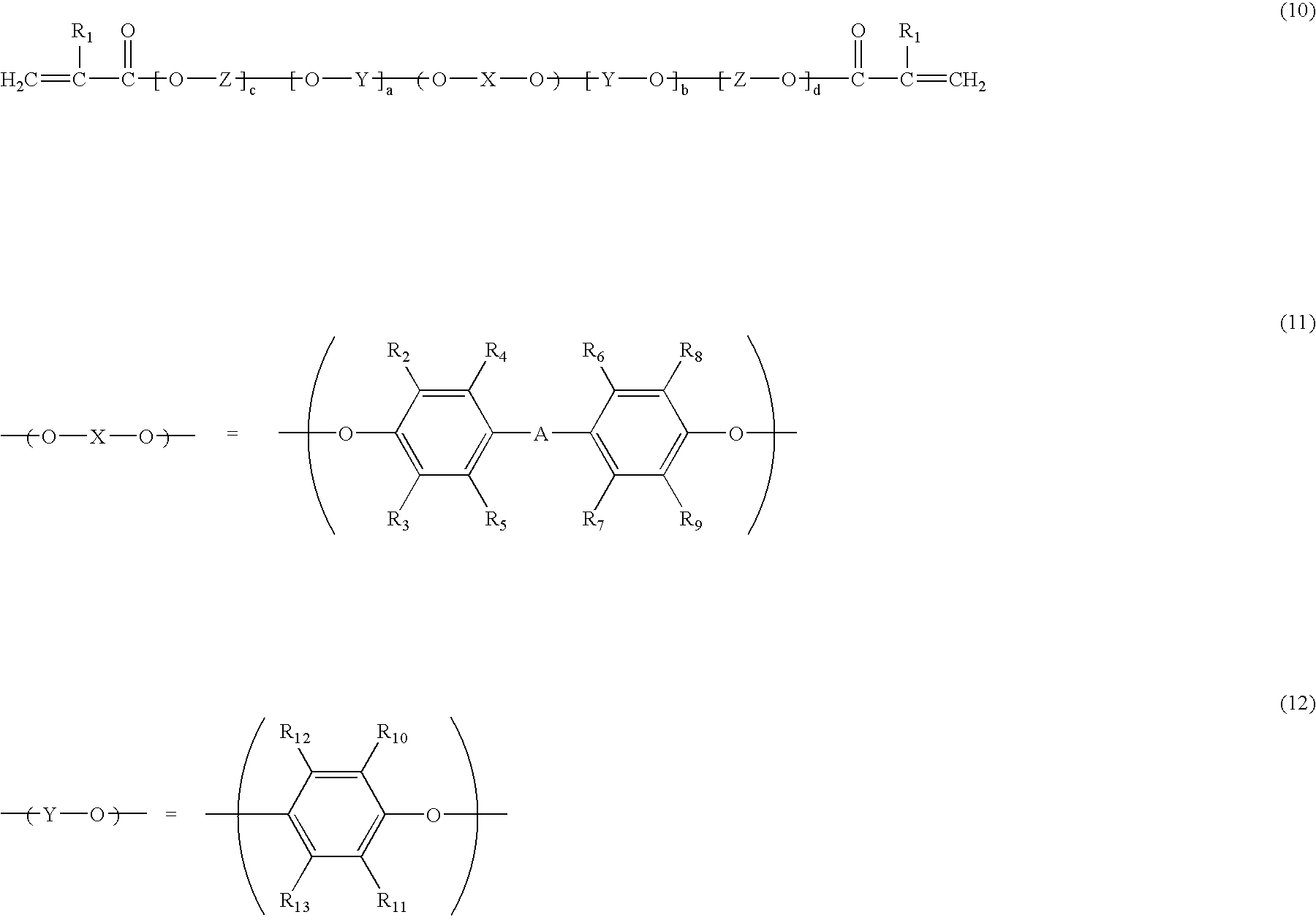

Polyphenylene ether oligomer compound, derivatives thereof and use thereof

InactiveUS20080033117A1Maintain good propertiesImprove compatibilityPrinted circuit aspectsPrinted circuit manufactureEpoxyOligomer

The present invention provides a bifunctional phenylene ether oligomer compound having a thermosetting functional group at each terminal, an epoxy resin containing the above oligomer compound and a use thereof. That is, it provides a sealing epoxy resin composition for sealing an electric part, an epoxy resin composition for laminates, a laminate, a printed wiring board, a curable resin composition and a photosensitive resin composition. The resins and resin compositions of the present invention are used in electronics fields in which a low dielectric constant, a low dielectric loss tangent and high toughness are required and also used for various uses such as coating, bonding and molding.

Owner:MITSUBISHI GAS CHEM CO INC

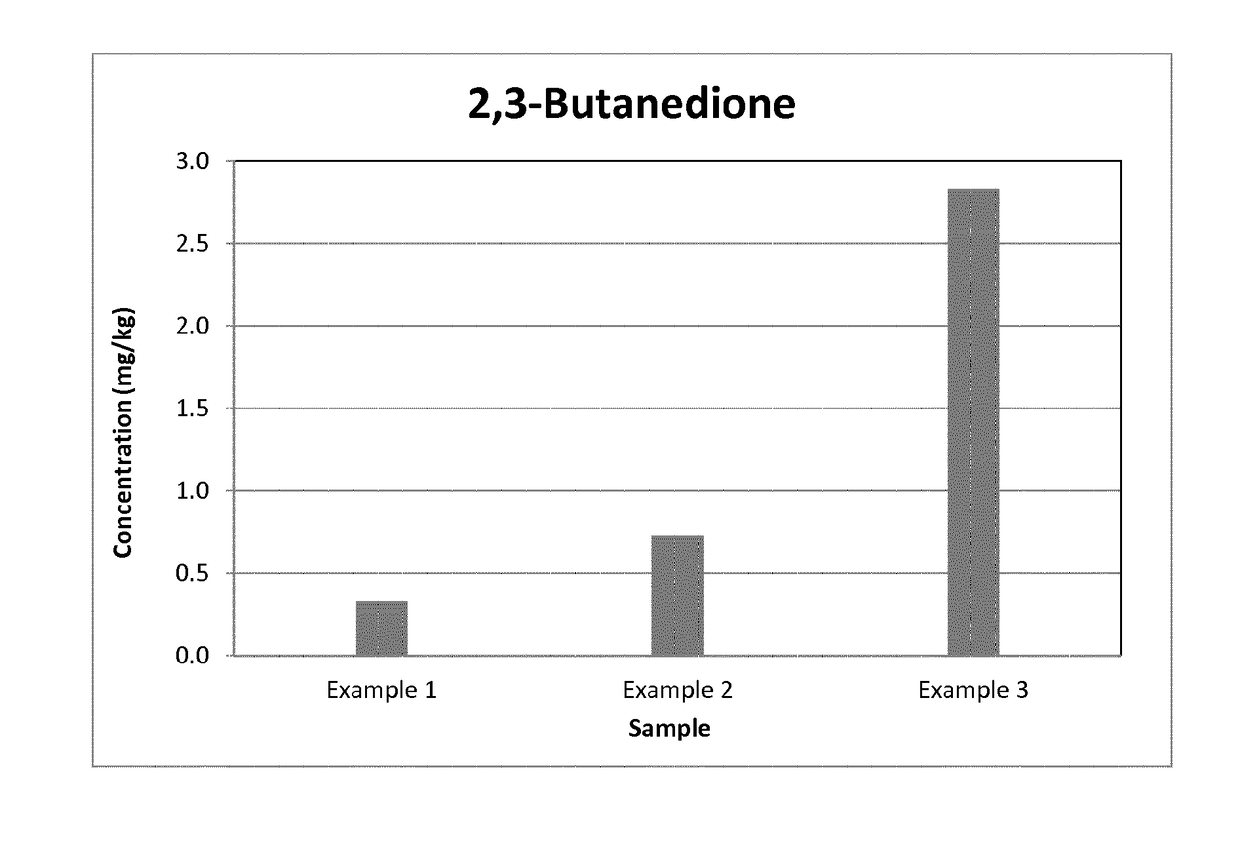

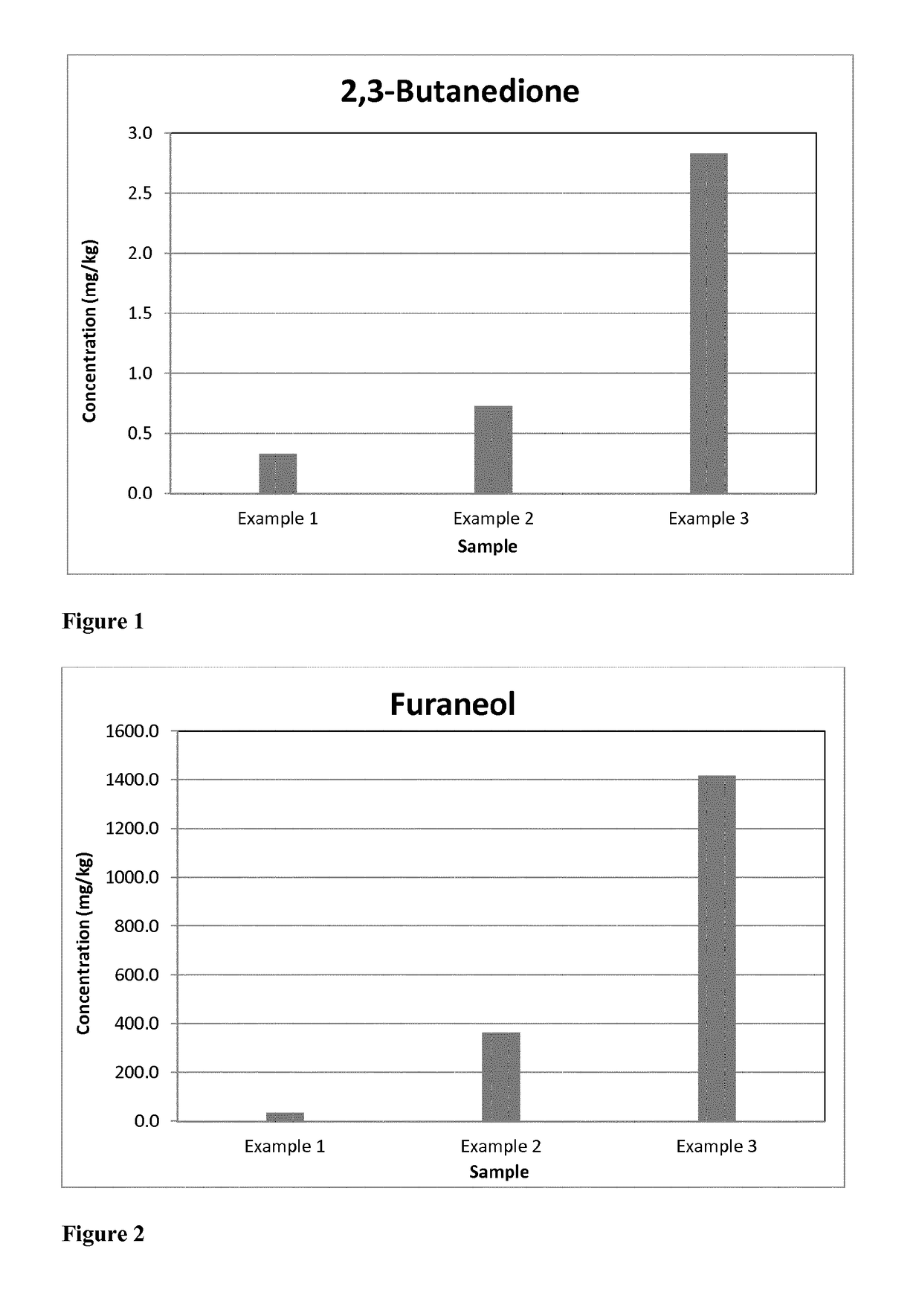

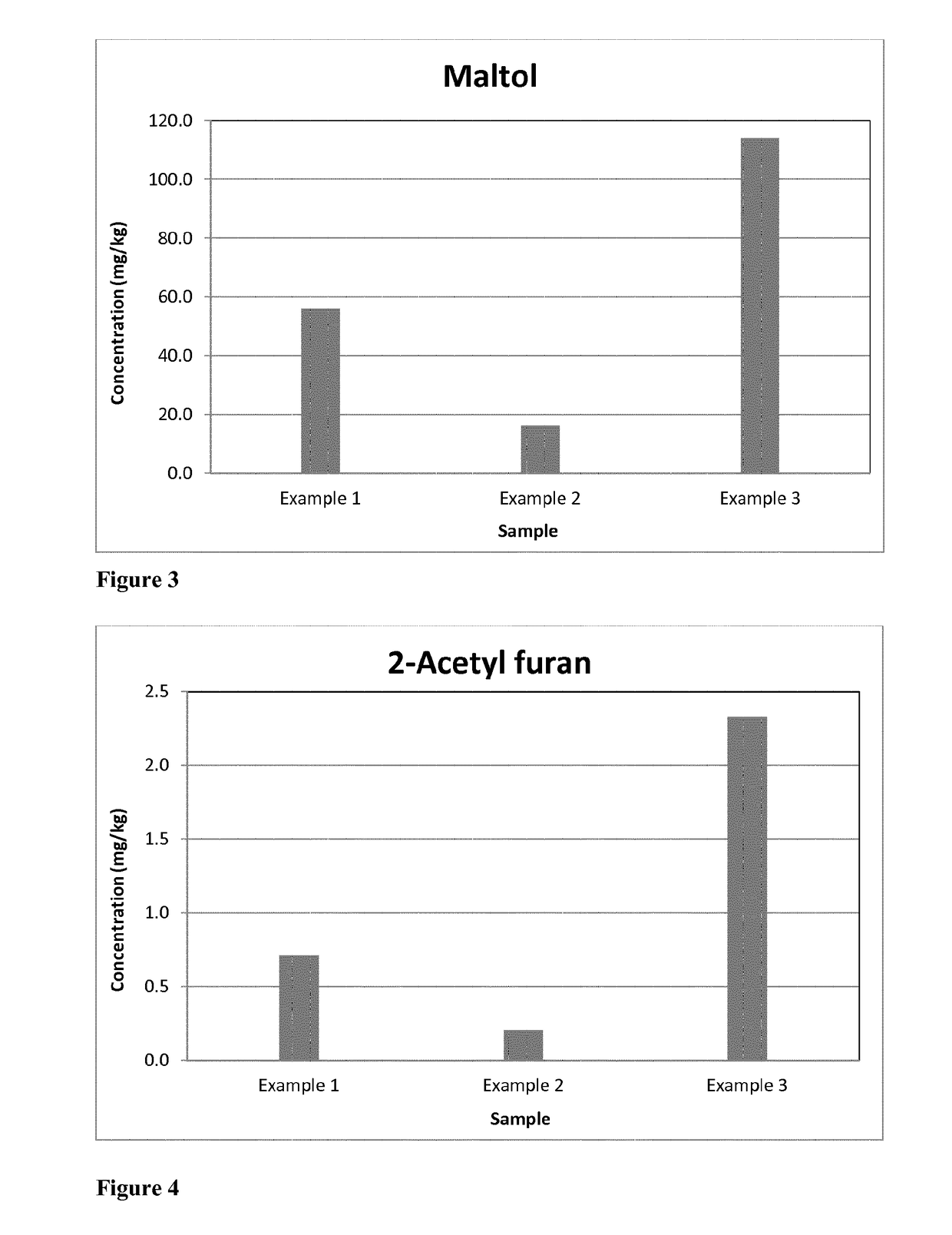

Fat-based flavour concentrates and process for producing same

InactiveUS20180042279A1Maintain roasty characterEnhance body (complexity, mouthfeelSugar food ingredientsFood ingredient as thickening agentPolyolAdditive ingredient

The present invention relates to a process for manufacturing a fat-based flavour concentrate obtained by a thermal reaction wherein the process comprises the step of providing a flavour precursor composition comprising at least one polyol and at least one amino compound comprising amino acids, amino acid derivatives and peptides with a dairy ingredient;followed by heating the flavour precursor composition with the dairy ingredient to generate a fat-based flavour concentrate; and cooling the fat-based flavour concentrate.

Owner:SOC DES PROD NESTLE SA

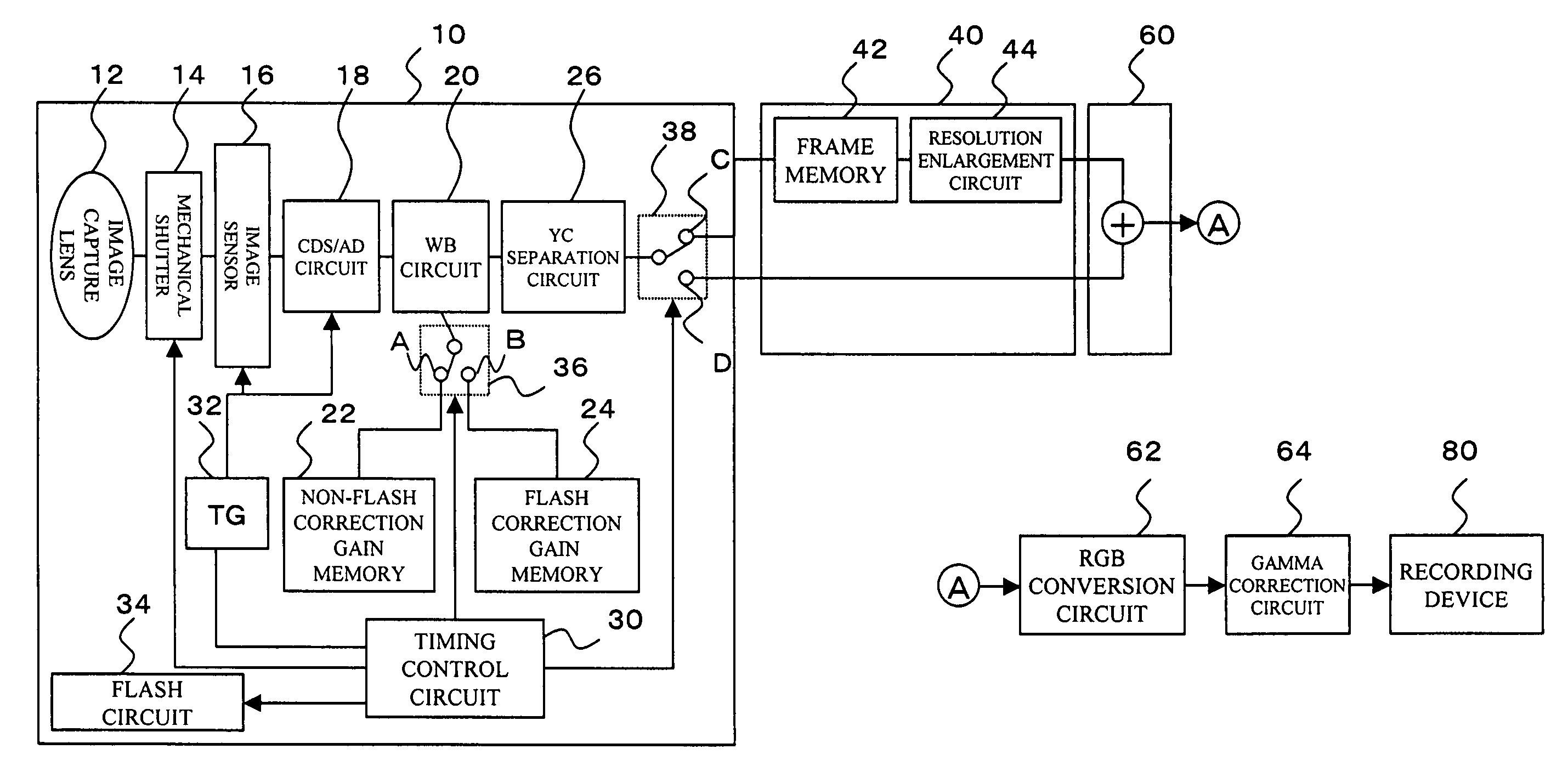

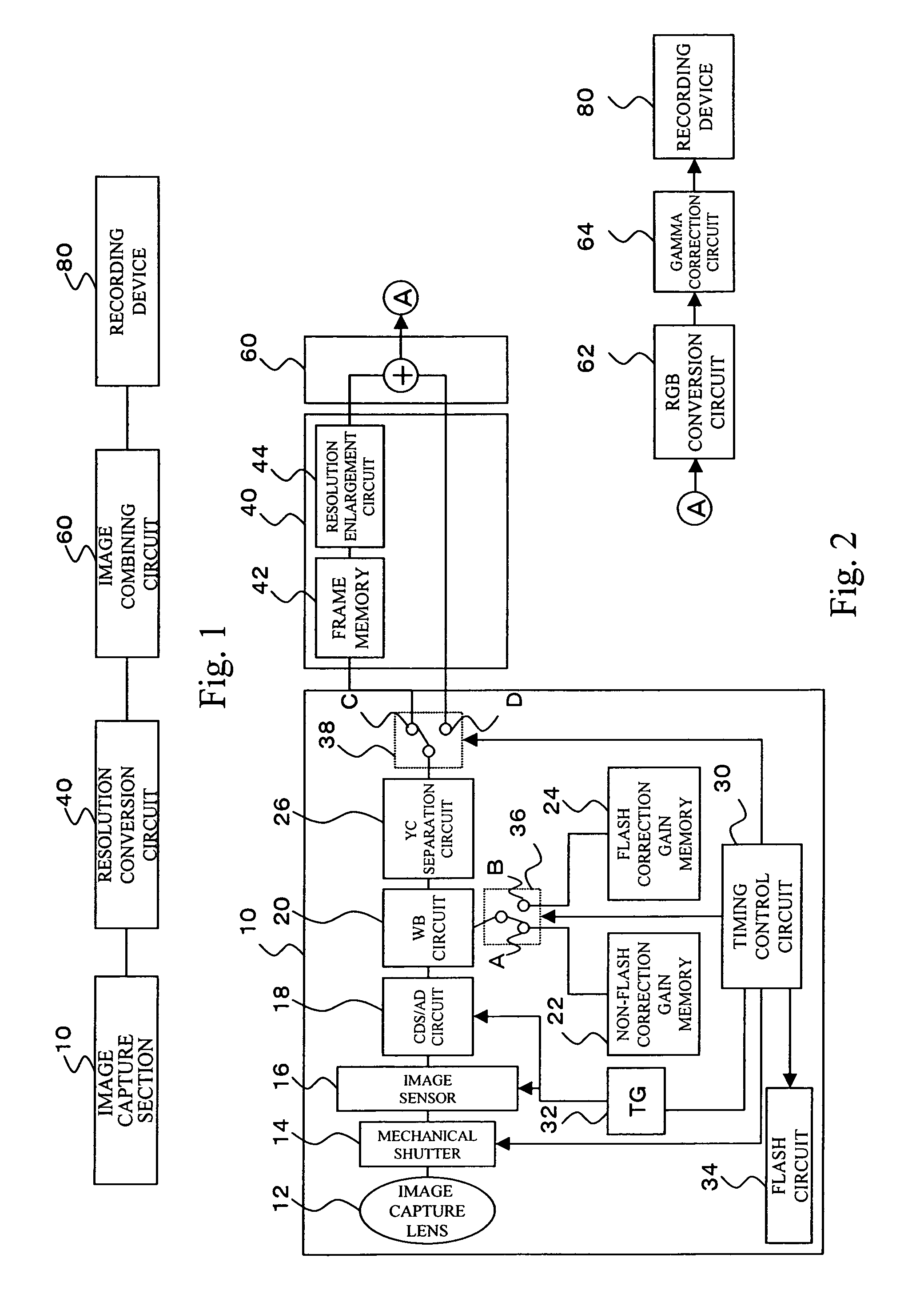

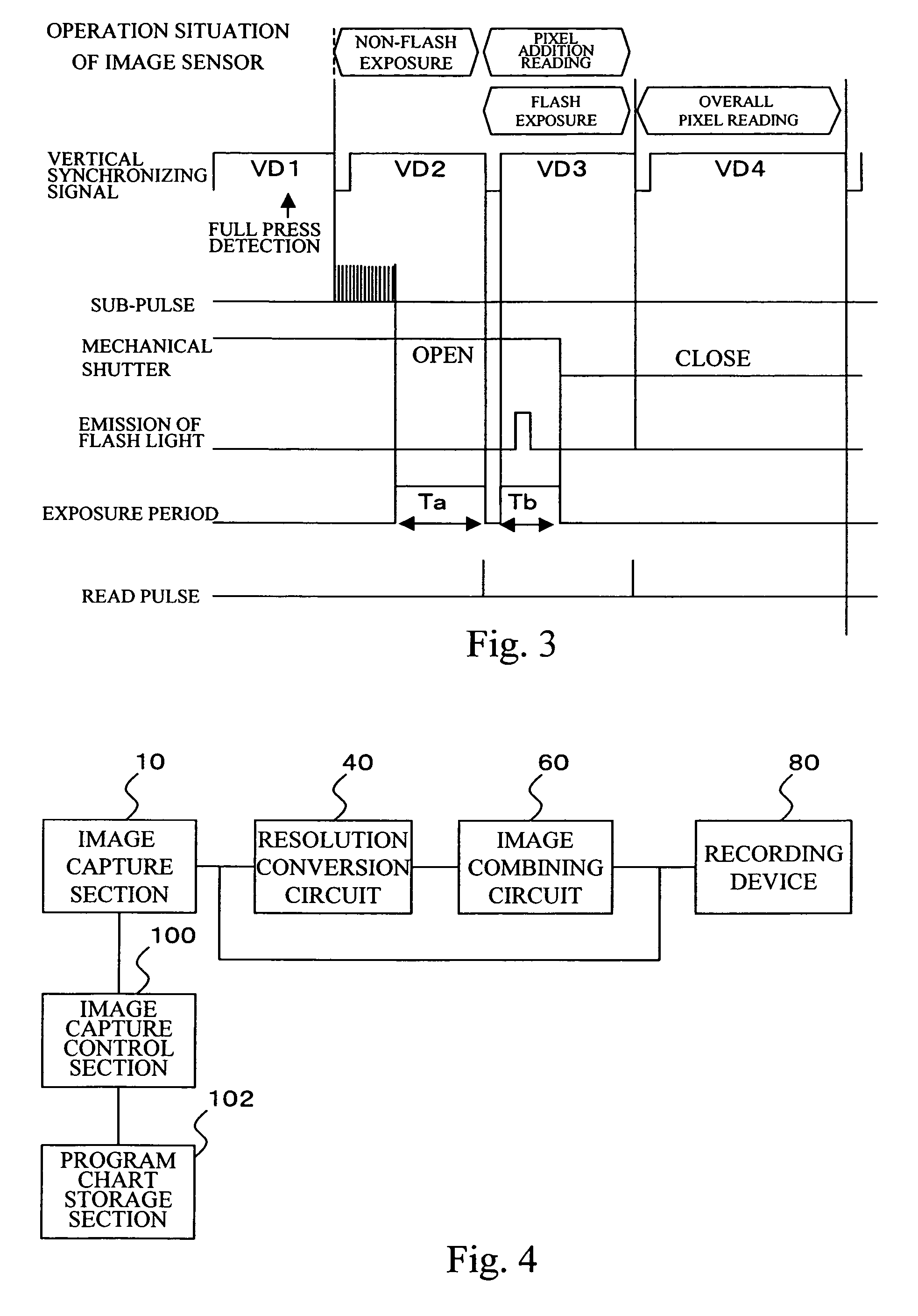

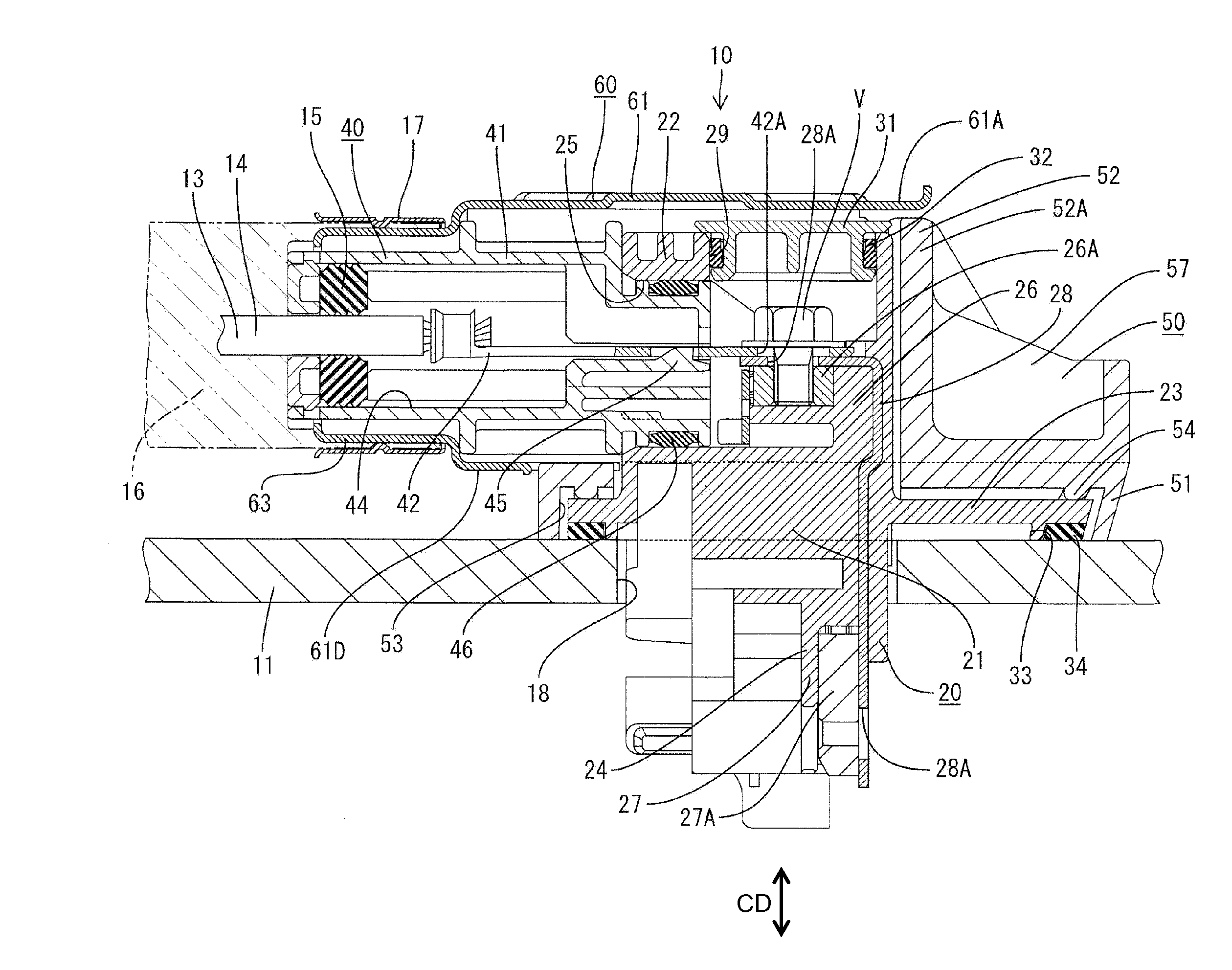

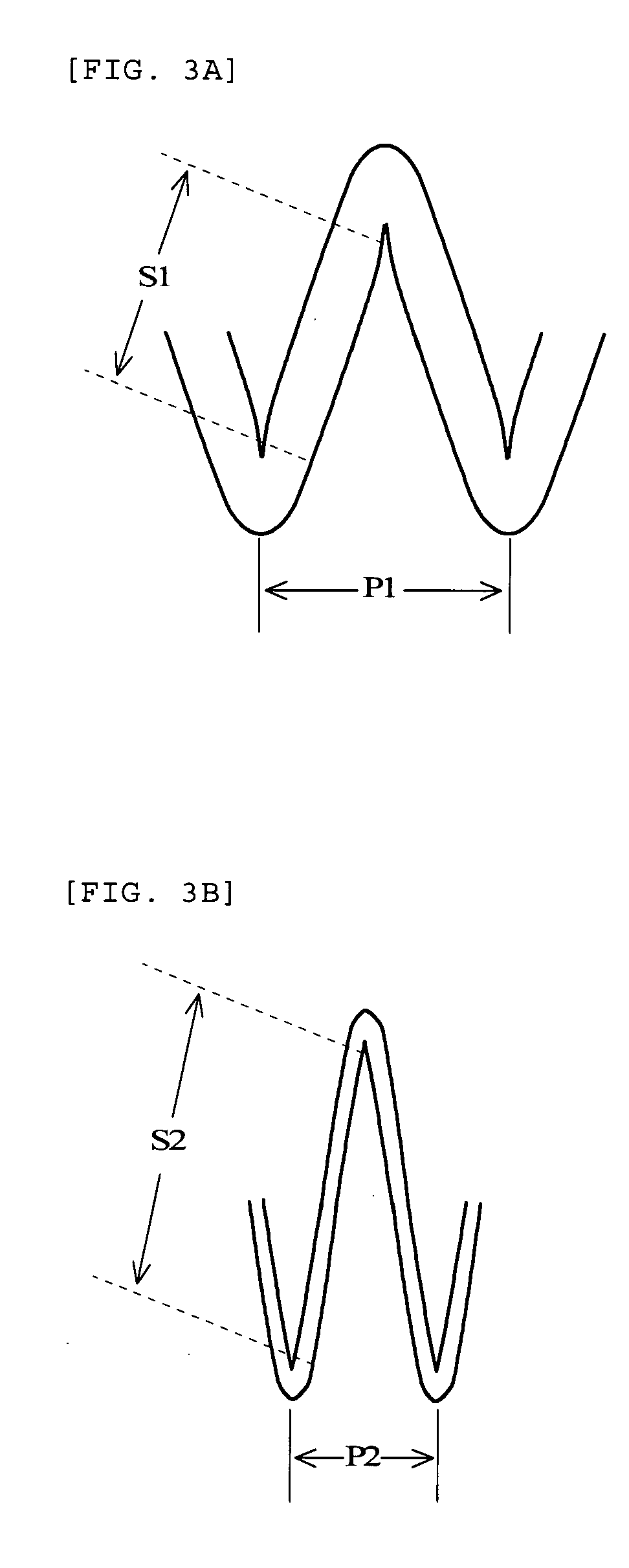

Digital camera, image capture method, and image capture control program

InactiveUS7509042B2Uniform processImage enhancementTelevision system detailsImage resolutionBrightness perception

The present invention provides a digital camera that is capable of capturing a picture in which the brightness between a main subject and a nighttime background are well balanced. When an image capture instruction is received while a night scene portrait mode is set, in a pixel addition output mode, an image sensor 16 is set to a high sensitivity state by performing pixel addition, and outputs low resolution non-flash image data. Further, in an overall pixel output mode, the image sensor 16 outputs high resolution flash image data in a low sensitivity state without performing pixel addition. Next, a resolution conversion circuit 40 converts a resolution of non-flash image data to be equivalent to a resolution of flash image data. Then, an image combining circuit 60 adds respective pixel values of corresponding pixels in the non-flash image data and the flash image data having the same resolution and combines both sets of image data to generate image data for recording.

Owner:APPLE INC

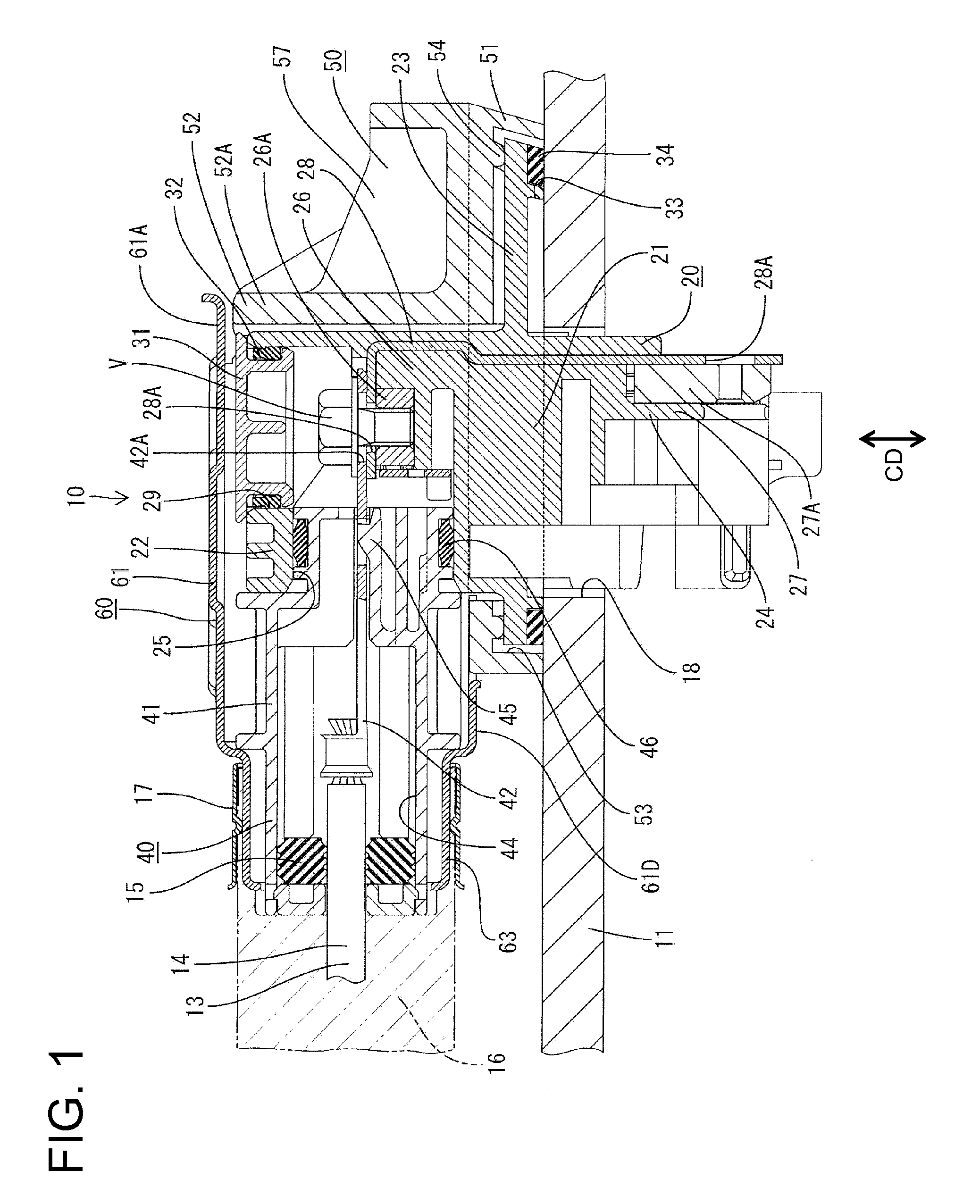

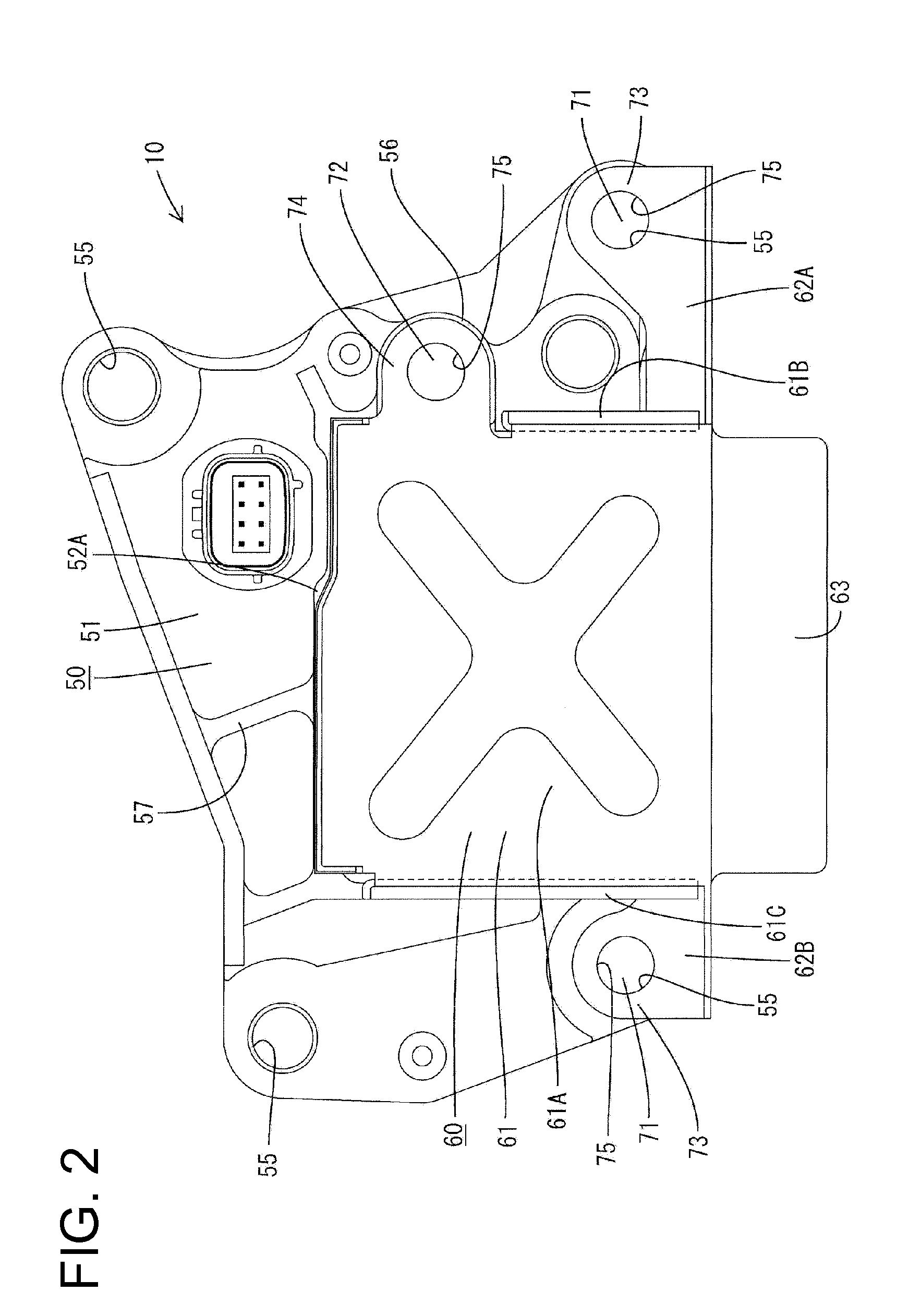

Connector device and connector assembly

ActiveUS20100216323A1Improve shielding effectUniform processSubstation/switching arrangement detailsCoupling parts mountingElectrical and Electronics engineeringEngineering

A connector device (10) has a connector (20) to be mounted on a metal case (11) that accommodates a device therein and is covered by a first shield shell (50) and a second shield shell (60). Connecting portions for connecting the first and second shield shells (50, 60) are provided at least at three positions and these connecting portions are arranged at positions displaced in a connecting direction of the connector (20) and a mating connector (40) and a direction orthogonal to the connecting direction. The connecting positions of the first and second shield shells (50, 60) are well-balanced to provide a good a shielding performance.

Owner:SUMITOMO WIRING SYST LTD

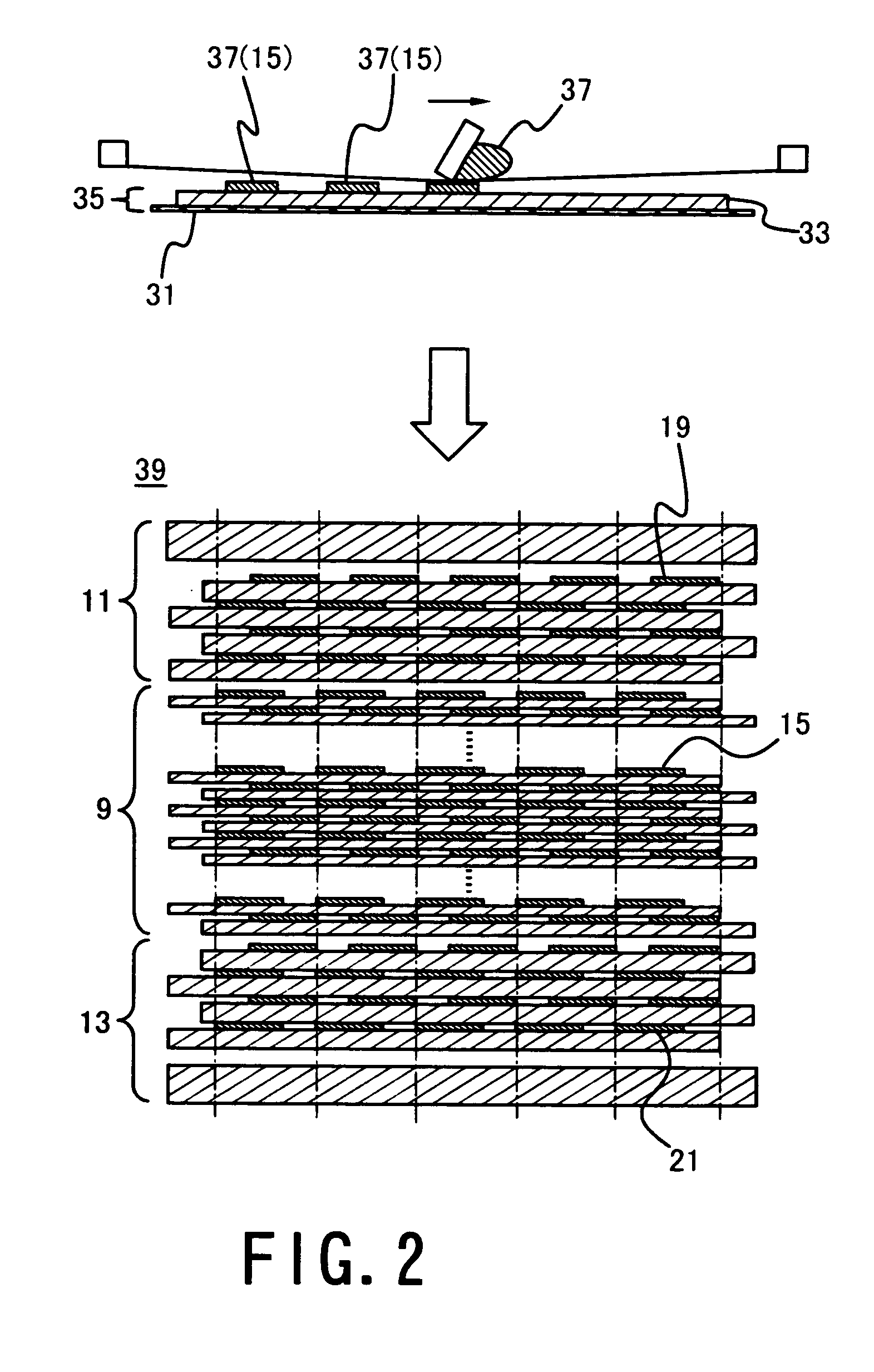

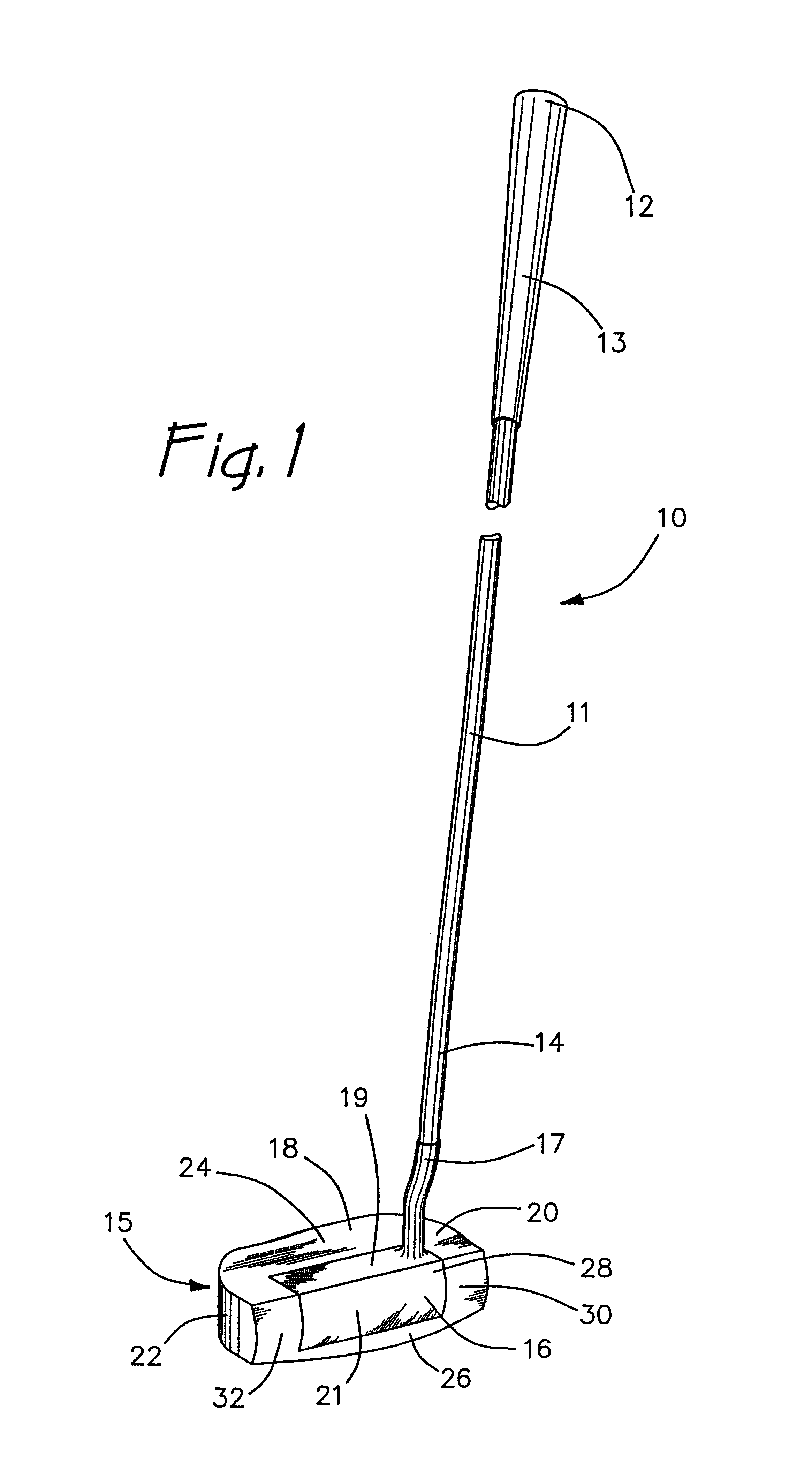

Portable radio communication apparatus provided with boom portion with through hole

ActiveUS20050075082A1Improve balanceUniform processAntenna supports/mountingsAntenna adaptation in movable bodiesEngineeringCantilever

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

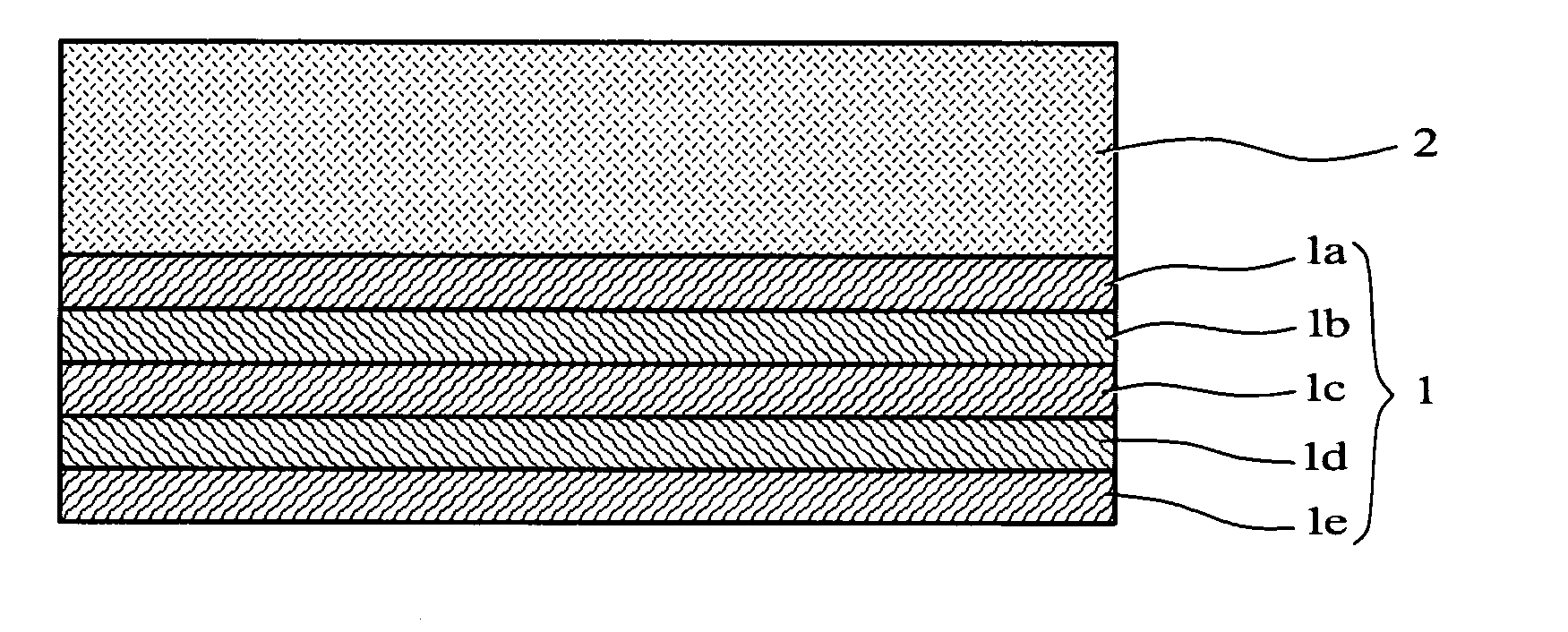

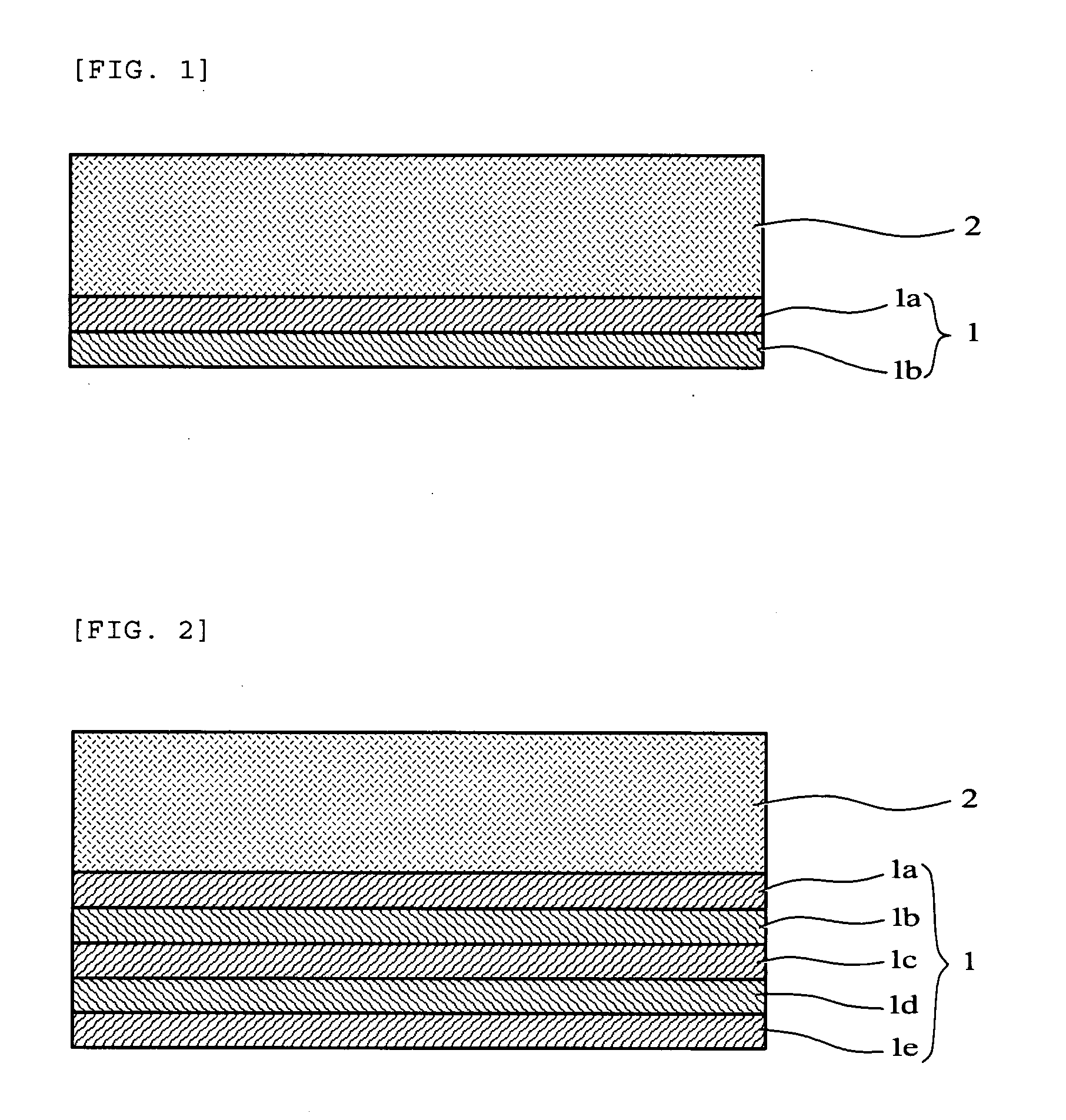

Air filter material

ActiveUS20080070022A1Small flow resistanceUniform processCombination devicesDispersed particle filtrationAir filtrationAir filter

An air filter material includes a laminate of an air inlet layer and an air outlet layer, and has a mean flow pore size of 20 μm to 40 μm, a minimum pore size of 2.4 μm to 3.8 μm, and a maximum pore size of 80 μm or less. The air inlet layer is a needle punched nonwoven fabric layer having an areal fiber weight of 55 g / m2 to 100 g / m2. The air outlet layer is a laminated spunlace nonwoven fabric made by laminating at least two or more spunlace nonwoven fabric layers having an areal fiber weight of 20 g / m2 to 60 g / m2, a mean flow pore size of 50 μm to 90 μm, a minimum pore size of 3.0 μm to 10.0 μm, and a maximum pore size of 180 μm or less.

Owner:DYNIC CORPORATION

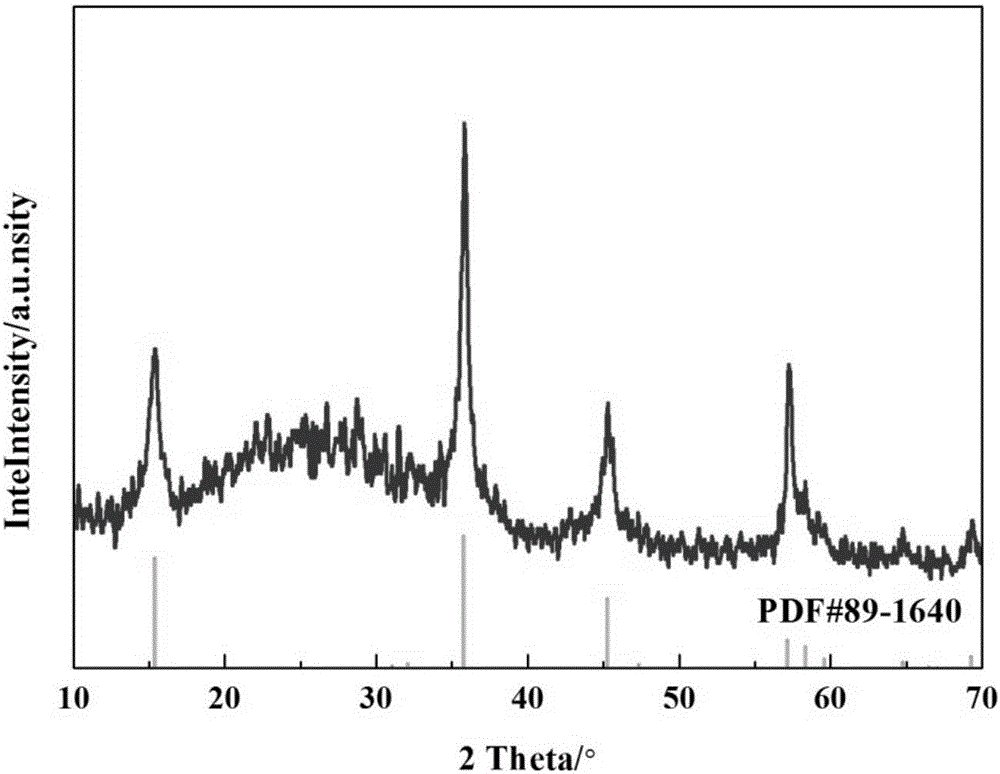

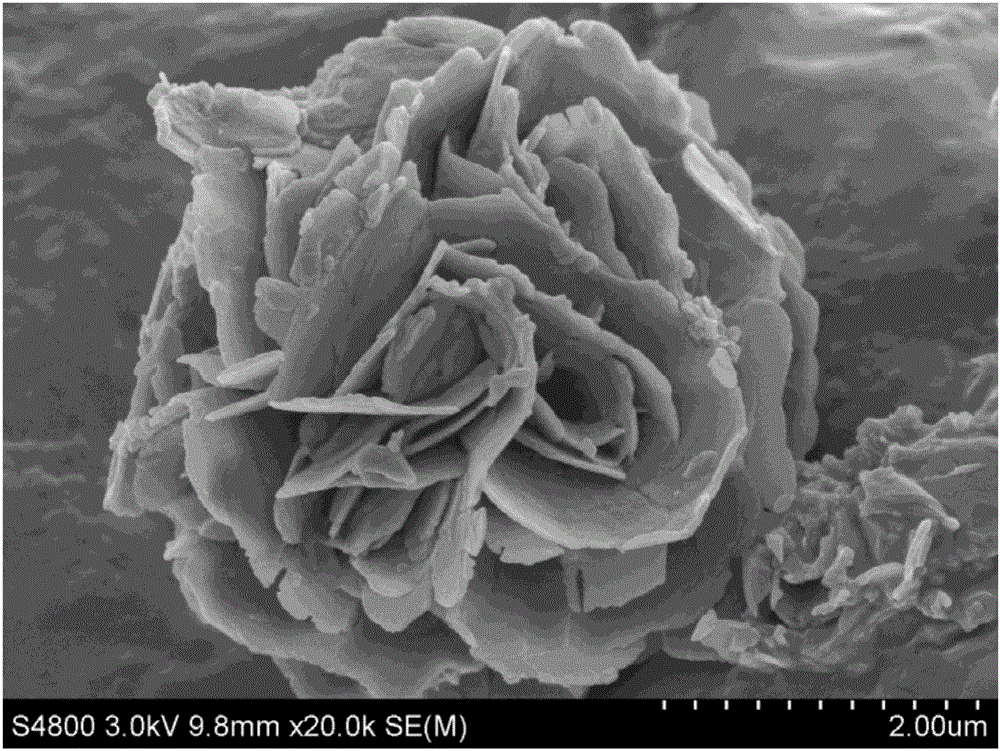

Preparation method and application of nanosheet self-assembled microflower-shaped VS2

ActiveCN105819507AOvercoming high temperatureRaw materials are cheap and easy to getCell electrodesNanotechnologyLithiumSodium hydroxide

The invention provides a preparation method and application of nanosheet self-assembled microflower-shaped VS2. The preparation method comprises the steps that firstly, the pH of a vanadium source solution and the pH of a sulfur source solution are regulated to be 11-14 under the magnetic stirring state through a sodium hydroxide solution; secondly, the solutions are poured into a reaction inner lining, the inner lining is contained in an outer kettle and fixed, and then the outer kettle is placed in a homogeneous reaction instrument; finally, a product obtained after a reaction is cooled, washed, collected and dried, and then the nanosheet self-assembled microflower-shaped VS2 can be obtained. The technology of the method is simple and easy to control, and the prepared nanosheet self-assembled microflower-shaped VS2 is uniform in chemical constitution and high in purity, has a specific self-assembled structure and shows the excellent electrochemical property when the nanosheet self-assembled microflower-shaped VS2 serves as a lithium-sodium ion battery electrode material. In addition, the method has the advantages that the defect that a traditional calcination method is high in temperature is overcome, large equipment and harsh reaction conditions are not needed, the raw materials are cheap and easy to obtain, the cost is low, the yield is high, aftertreatment is not needed, and the method is friendly to the environment and can be suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

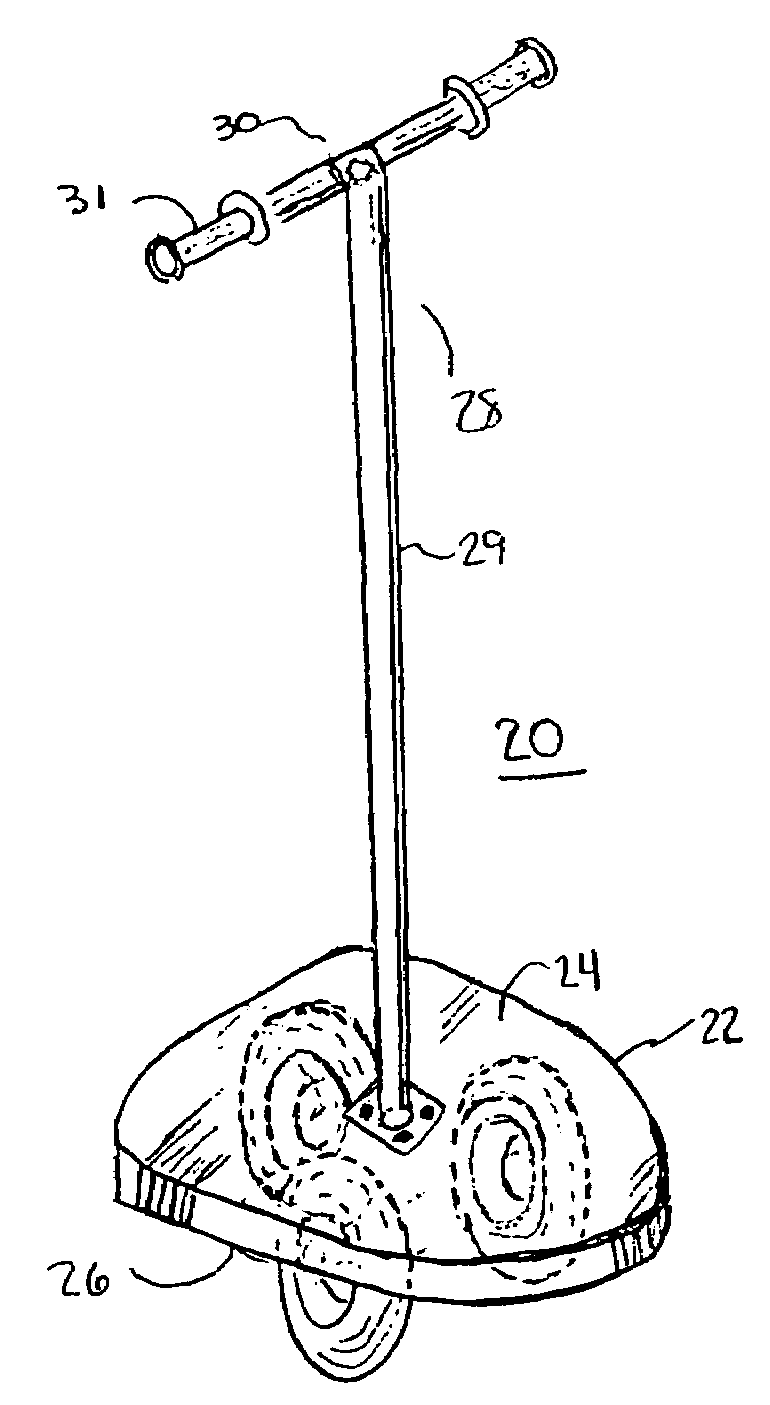

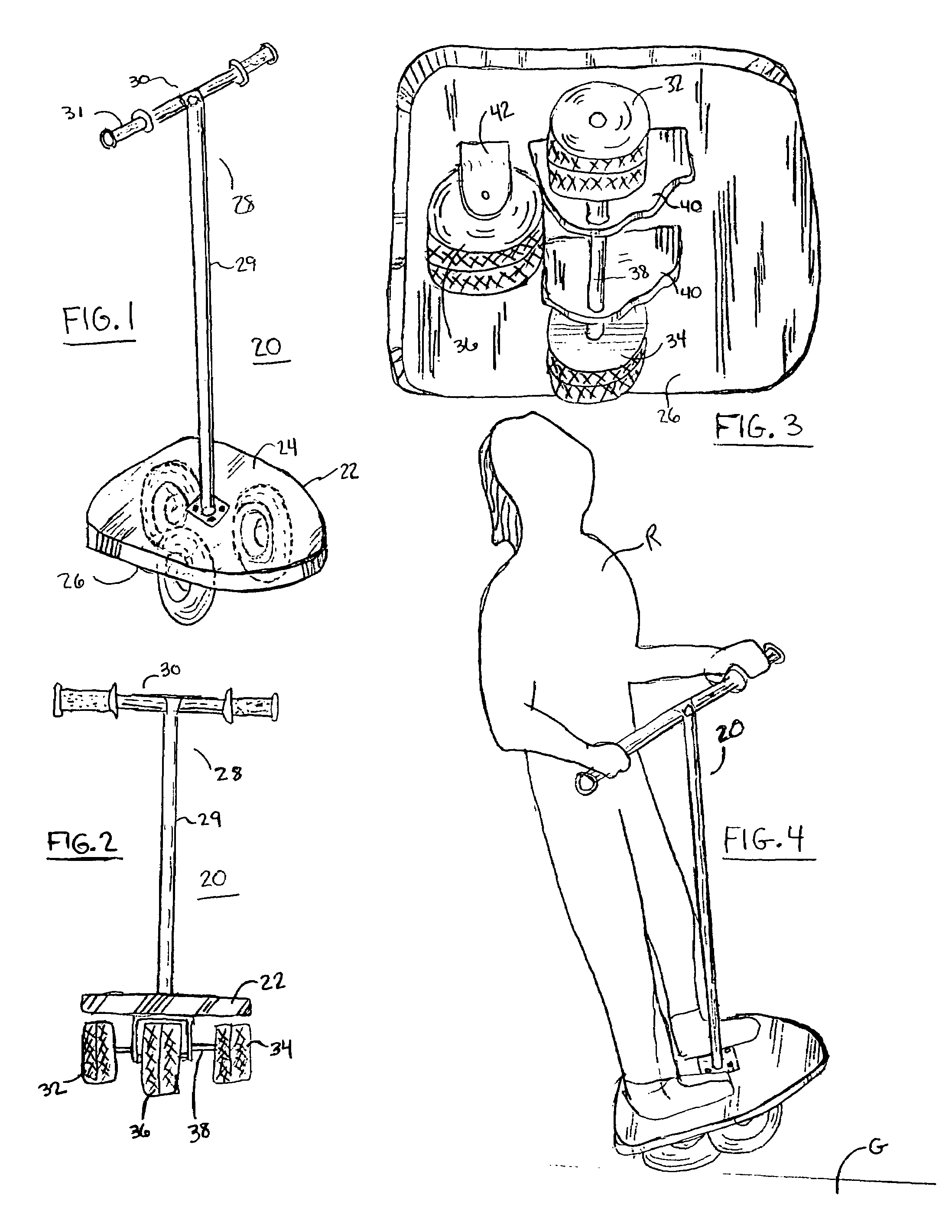

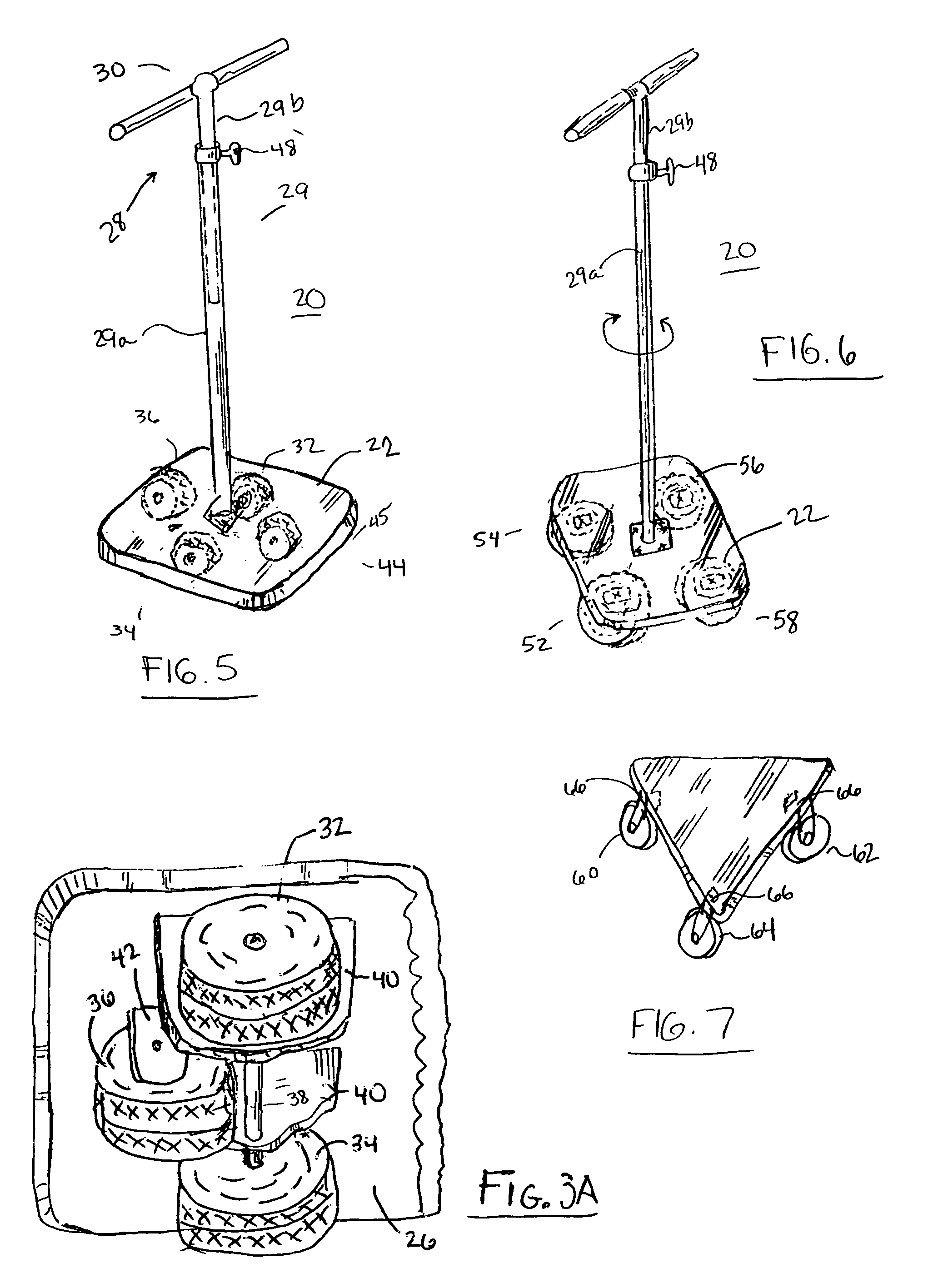

Recreational wheelie vehicle

ActiveUS7226062B1Improve securityOverall controllabilityWheel based transmissionFrictional rollers based transmissionEngineeringWheelie

An amusement-type vehicle is provided particularly for doing so-called wheelies having a short wheel base upon a platform-type base with at least two side by side wheels forwardly and one wheel rearwardly upon which wheelies are performed and having a central handle by which the vehicle may be controlled.

Owner:STEFANO NICK

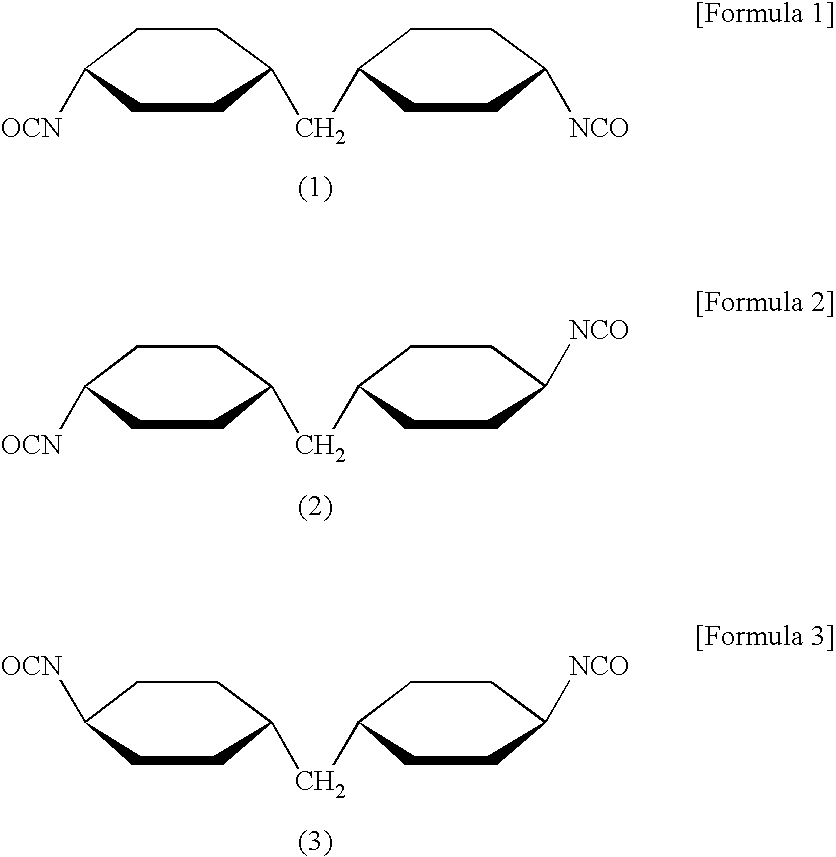

Golf ball

ActiveUS20090143169A1Excellent abrasion-resistanceImprove spin performanceSolid ballsEngineeringMethyl cyclohexane

A golf ball which has excellent abrasion-resistance and spin performance is provided. The golf ball of the present invention includes a core and a cover covering the core. The cover contains, as a resin component, polyurethane which is obtained using, as a polyisocyanate component constituting the polyurethane, 4,4′-dicyclohexylmethane diisocyanate having a mole ratio ((B) / (A)) of non-cis-structure molecule (B) to cis-structure molecule (A) in a range from 3 / 7 to 9 / 1.

Owner:SUMITOMO RUBBER IND LTD

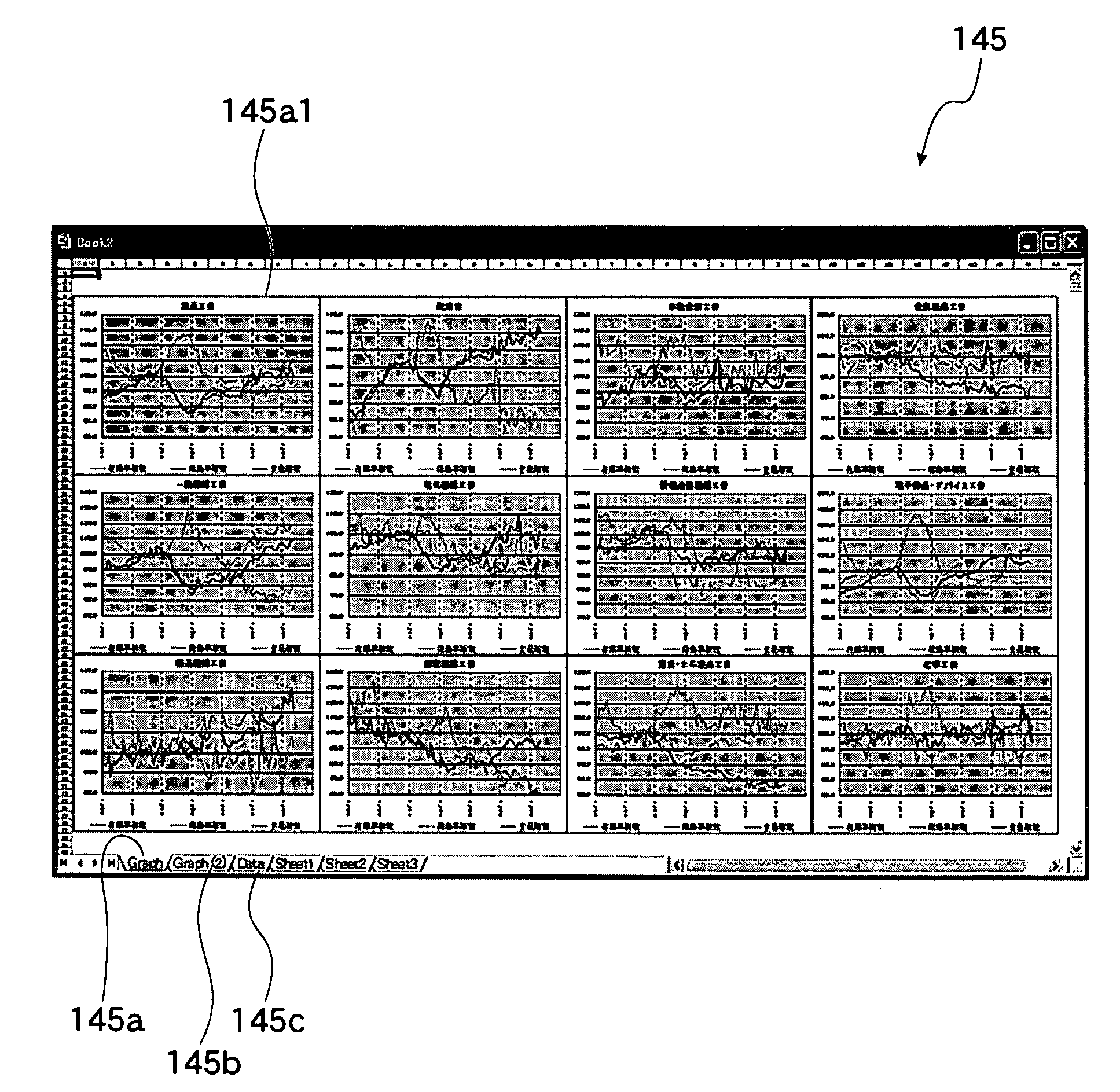

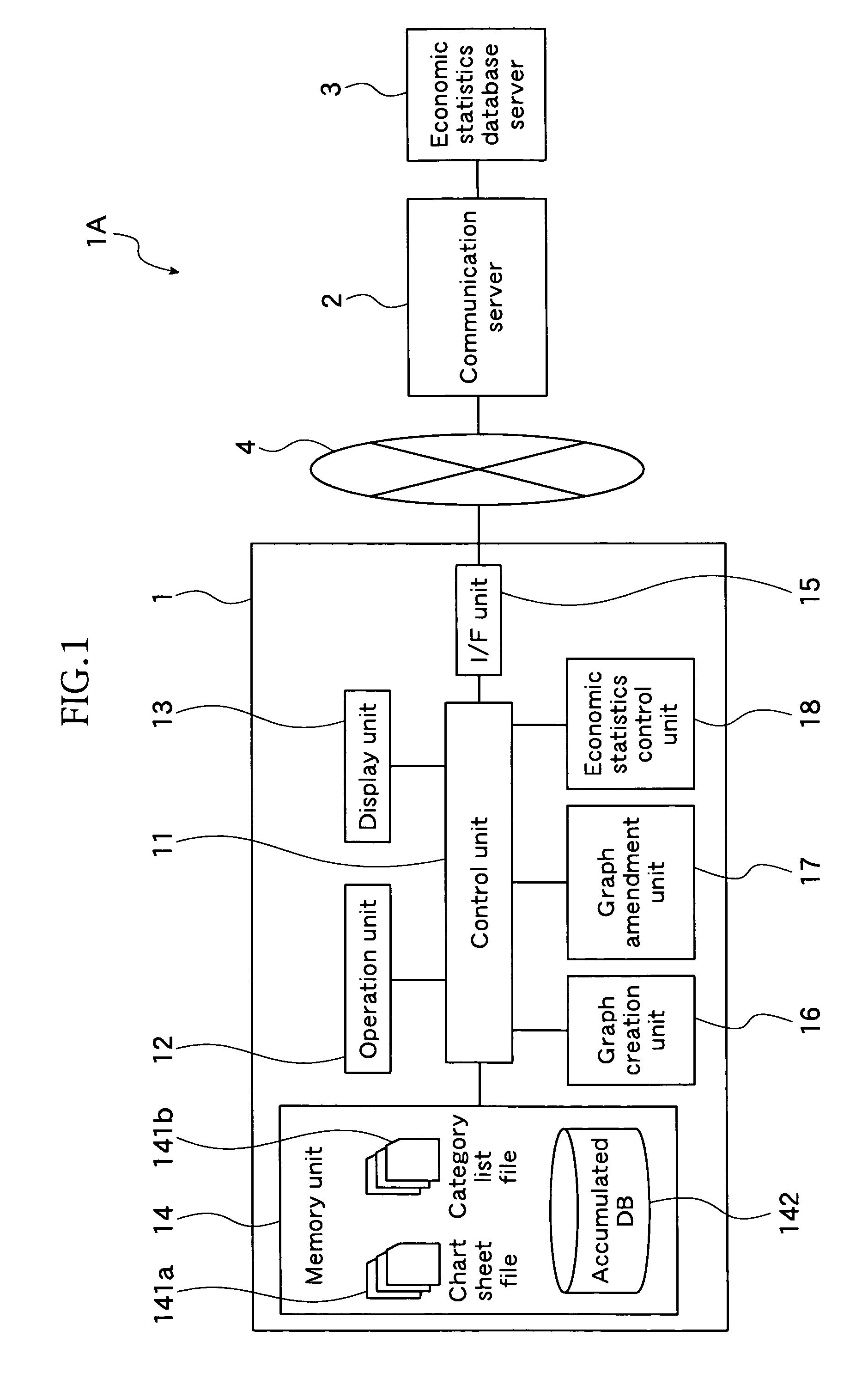

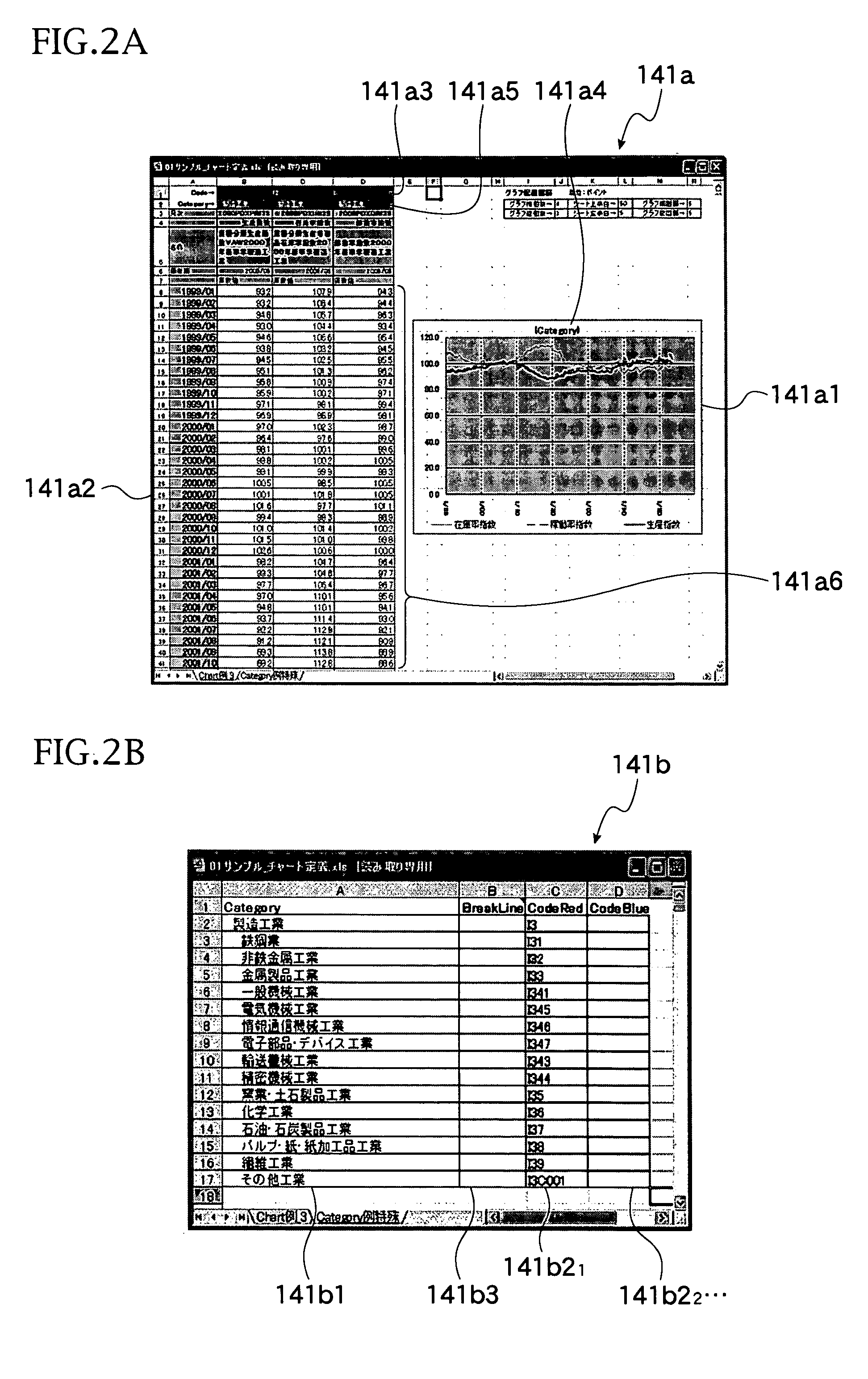

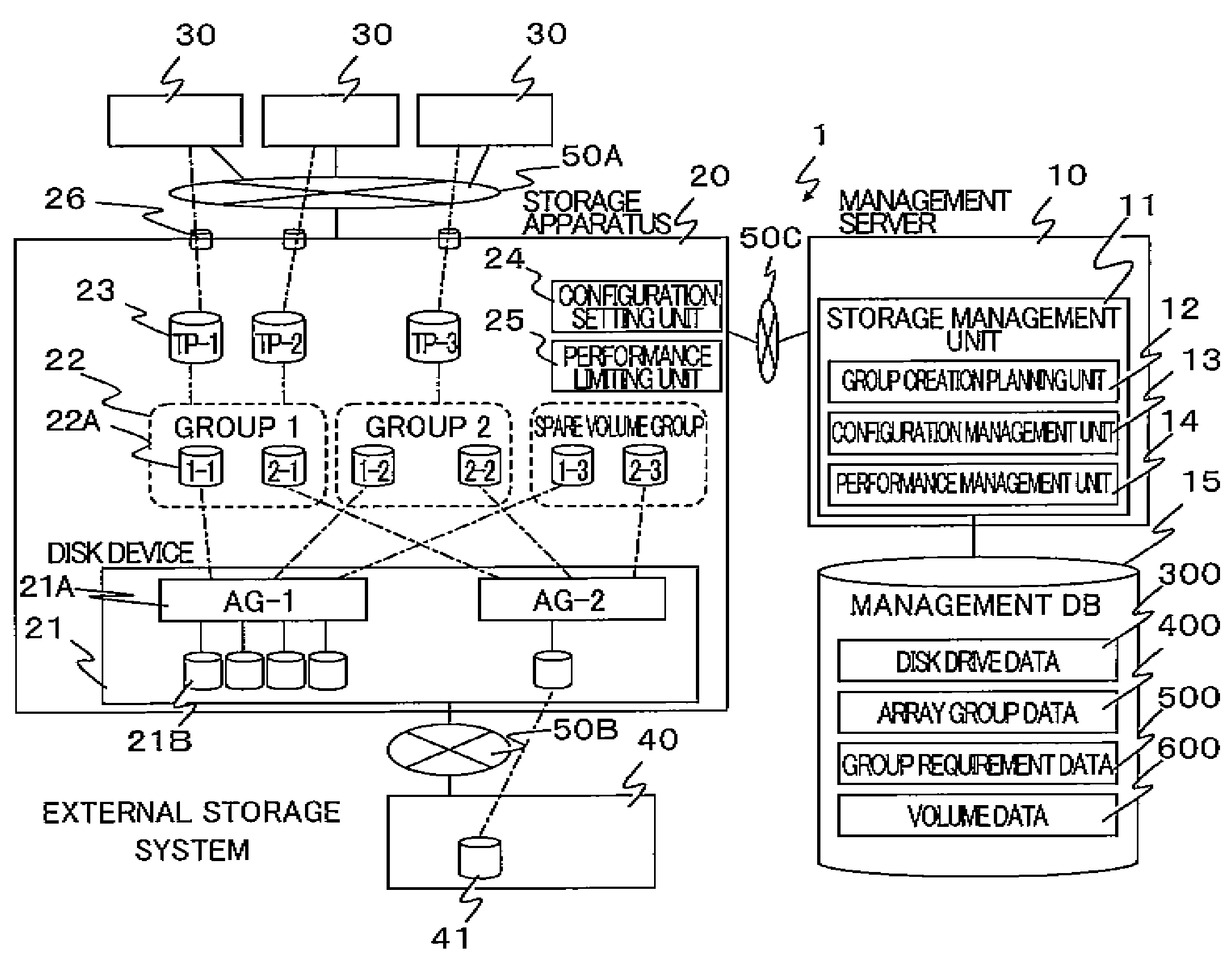

Chart display device and program for the same

InactiveUS7420562B2Saved from burdenEasy to adjustDrawing from basic elementsText processingGraphicsData control

A graph creation unit of a chart display device desplays a plurality of charts (graphs), which is created by applying one graph-model form to a plurality of categories in a category list file, onto one graph destination sheet, by aligning and arranging the charts in the one graph destination sheet. The graph creation unit makes an economic statistics data control unit obtain a predetermined numerical values corresponding to the chart displayed on the graph destination sheet from an accumulated database or an economic statistics database server, and displays the obtained numerical values on the graph destination sheet in the form of individual chart.

Owner:I N INFORMATION SYST

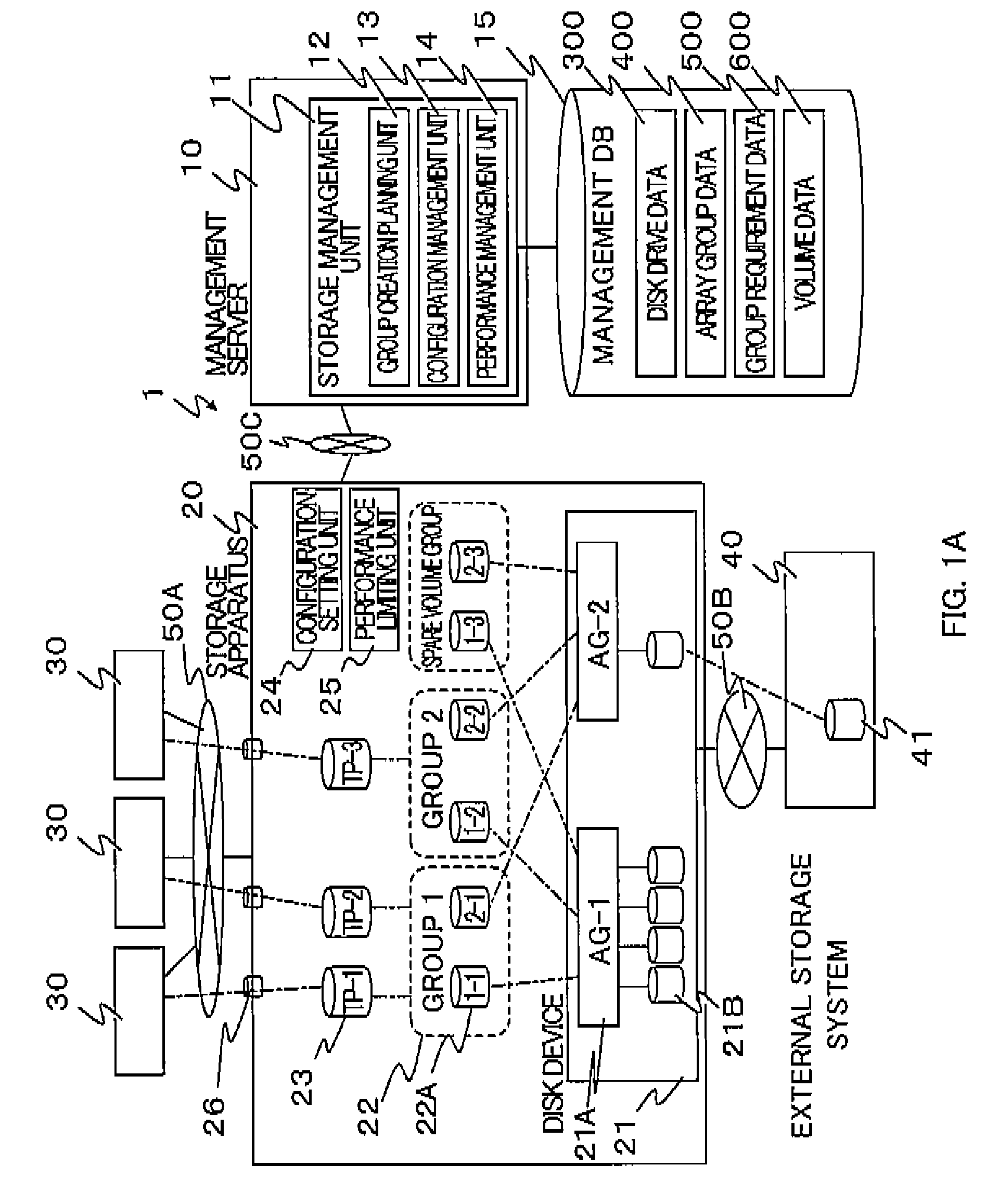

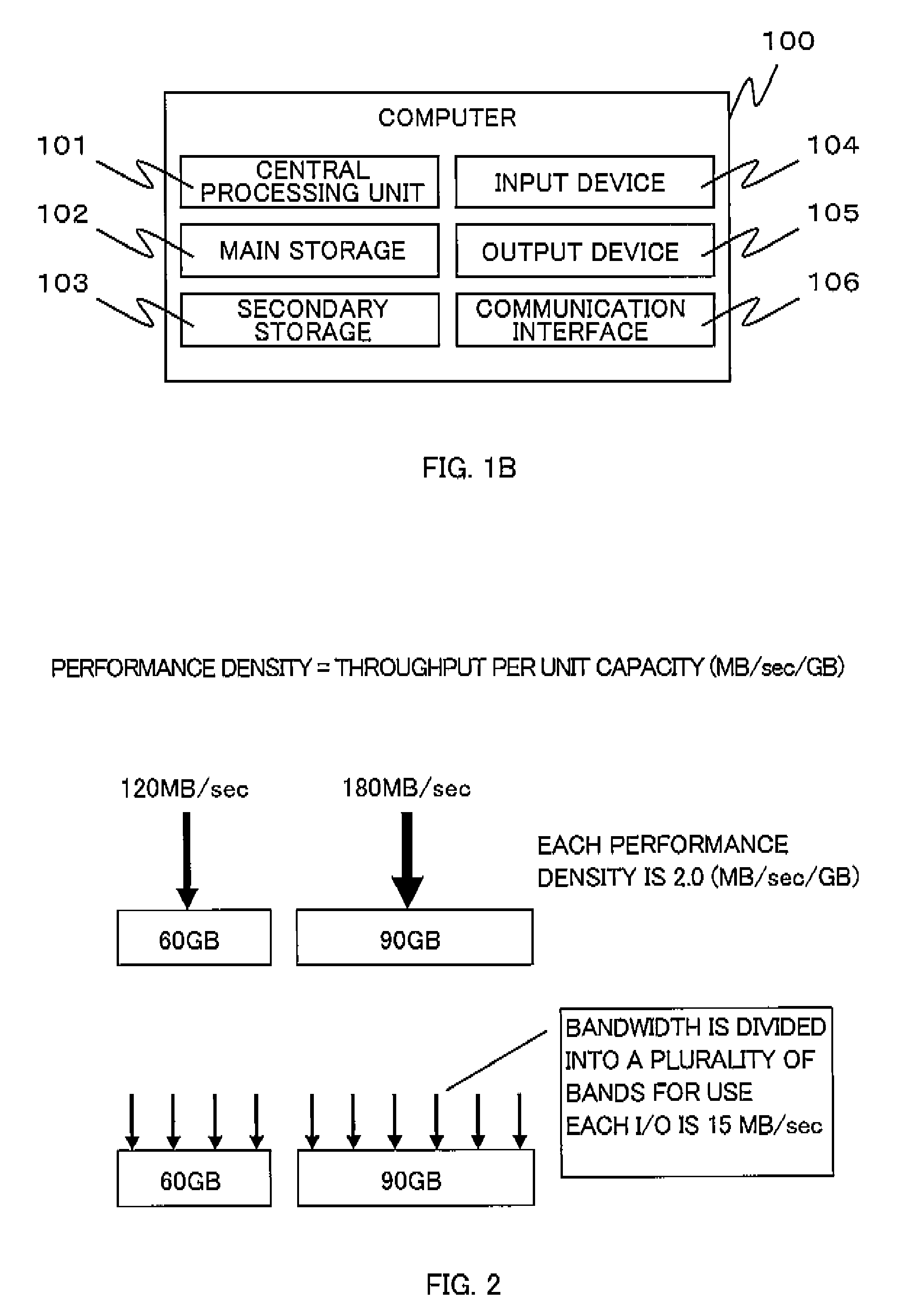

Storage System and Operation Method Thereof

InactiveUS20100125715A1Effective distributionUniform processMemory systemsInput/output processes for data processingStorage managementDisk array

To efficiently assign storage resources to storage areas in a well-balanced manner in terms of performance and capacity, provided is a storage system in which, for a storage apparatus including a disk array group providing a logical volume to be assigned to an application, a storage management unit holds the throughput, response time, and storage capacity of the array group; receives performance density being a ratio between a throughput and a storage capacity, and a requirement on a storage capacity required for the logical volume; and assigns the throughput to the logical volume on the basis of the received performance density and the capacity requirement with the throughput of the array group set as an upper limit, and assigns, to the logical volume, a storage area determined on the basis of the assigned throughput and the received capacity requirement.

Owner:HITACHI LTD

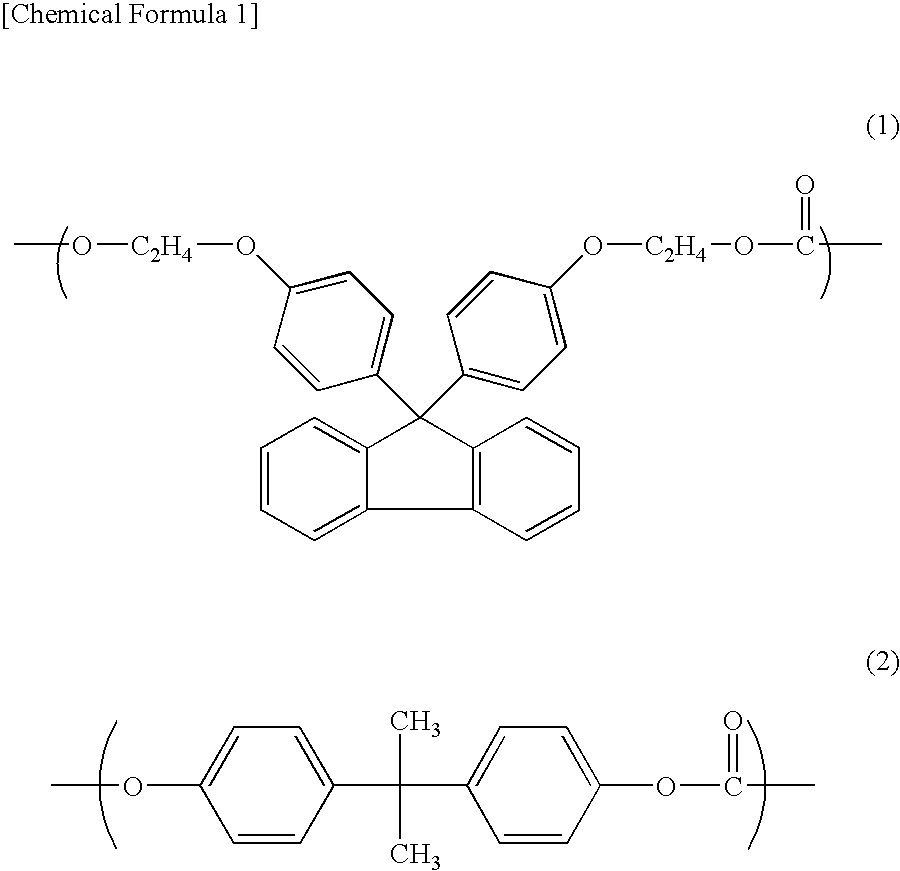

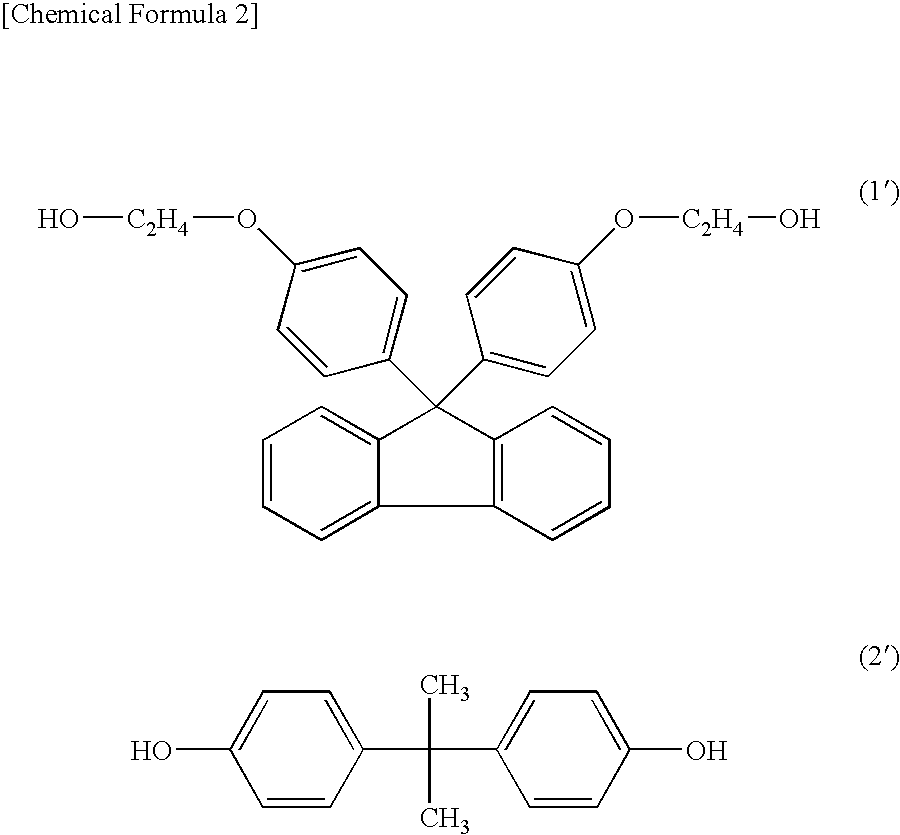

Optical Lens

ActiveUS20100048855A1Reduce light transmittanceHigh glass transition temperatureSynthetic resin layered productsMountingsCamera lensPolymer science

Disclosed is an optical lens which can be produced by injection molding on an industrial scale and which has a high refractive index, a low Abbe's number, a low birefringence index, a high transparency and a high glass transition temperature. The optical lens can be produced by injection molding of a polycarbonate resin (preferably having a reduced viscosity of 0.2 dl / g or higher and a glass transition temperature of 120 to 160° C.), wherein the polycarbonate resin is produced by reacting a diol component comprising 99 to 51 mol % of 9,9-bis(4-(2-hydroxyethoxy)phenyl)fluorene and 1 to 49 mol % of bisphenol A with a carbonate diester. It becomes possible to produce an optical lens preferably having a refractive index of 1.60 to 1.65, an Abbe's number of 30 or smaller, a birefringence index of 300 nm or lower and an all light transmittance of 85.0% or higher.

Owner:MITSUBISHI GAS CHEM CO INC

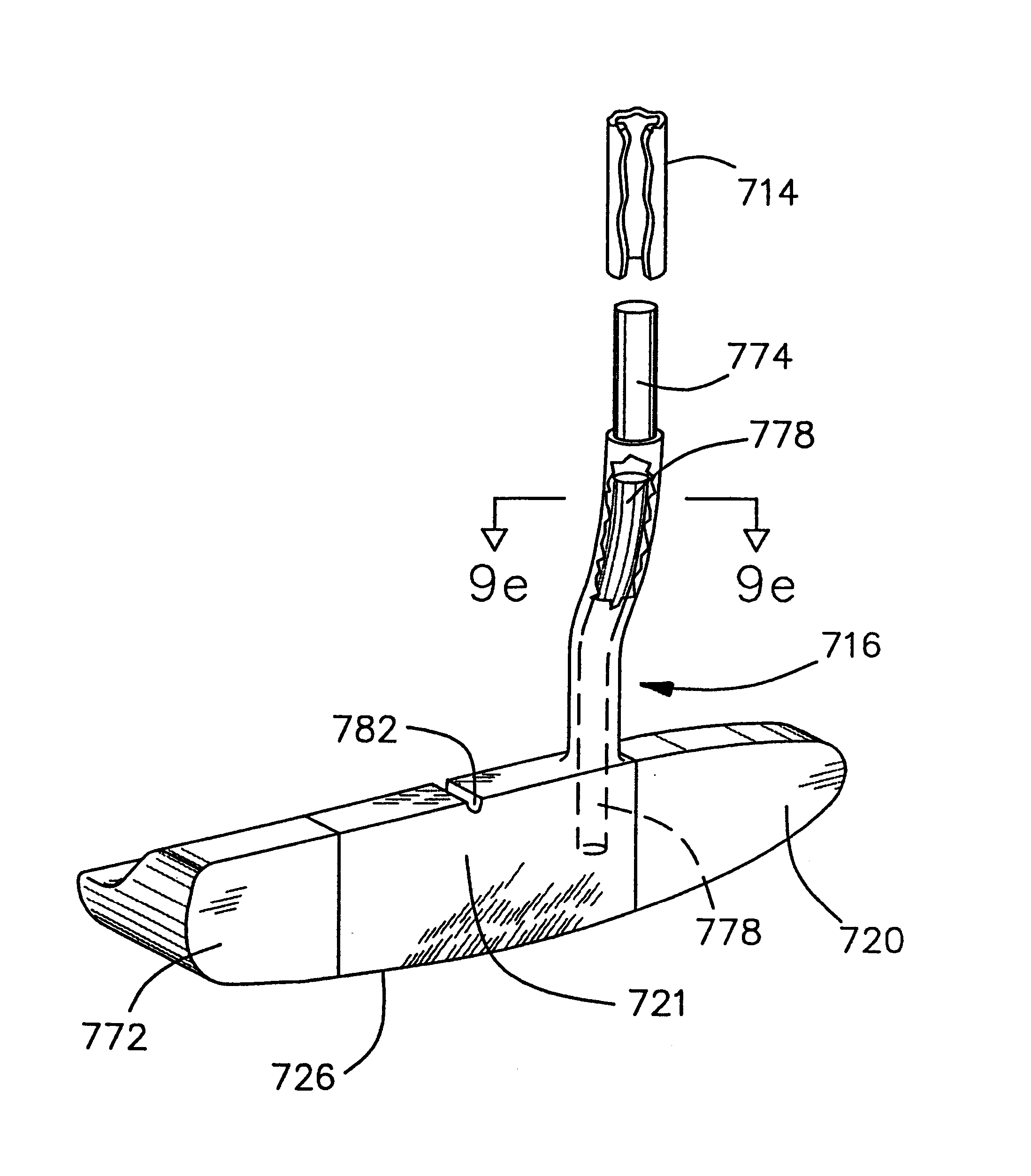

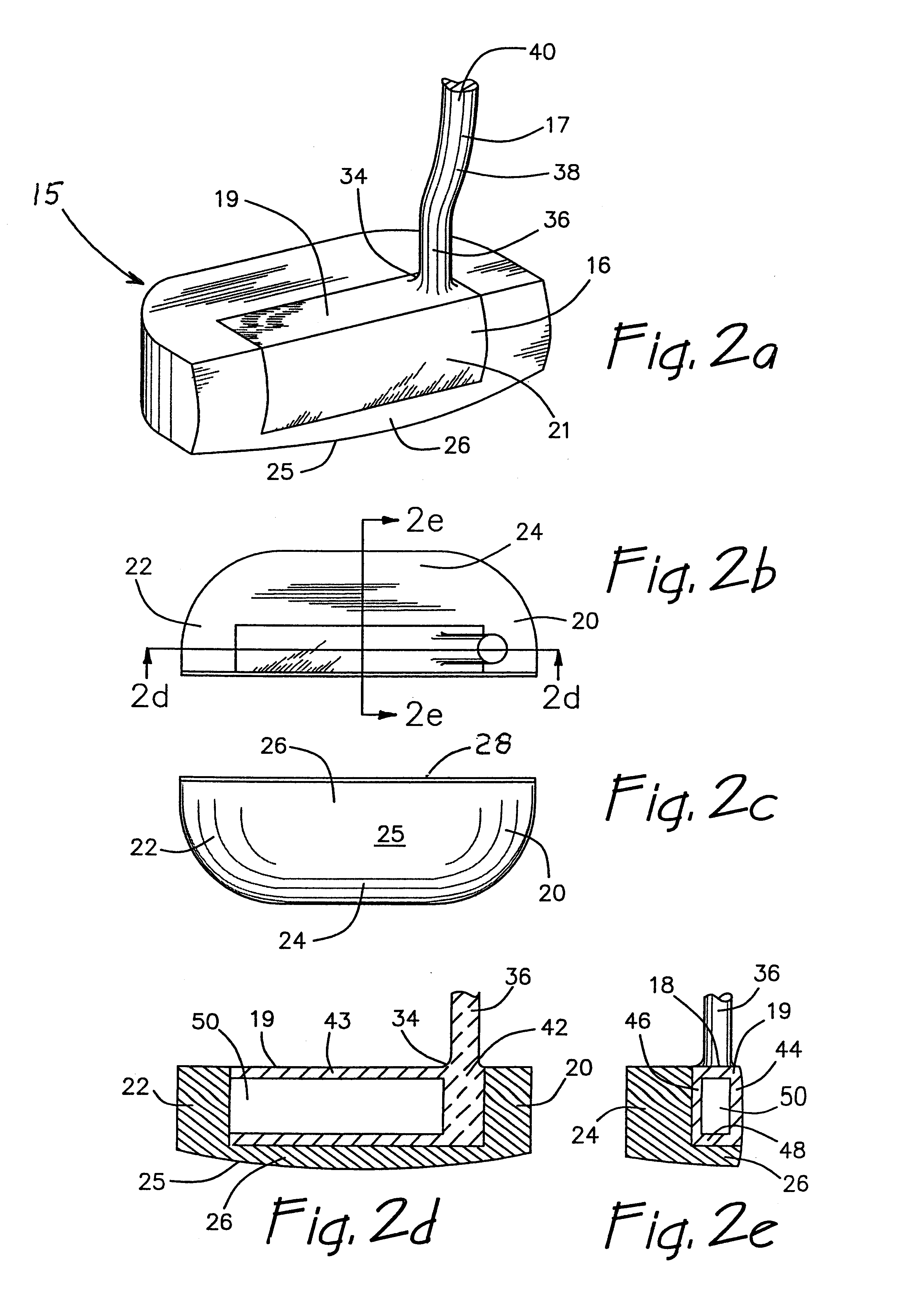

Golf club

InactiveUS7037211B1Improve balanceSensitive feedbackGolf clubsRacket sportsSensory FeedbacksGolf Ball

A golf club having superior balance and sensory feedback which includes a shaft connected to a clubhead comprising two basic elements, an integrated hosel and insert which defines a striking surface and a shell including a distal toe portion, and a heel portion uniquely integrated with the combined hosel and insert. In preferred embodiments the clubhead has a cylindrical striking surface, polar mass concentrations for optimum dynamic performance and a medial shell portion coupling the toe and heel portions to the insert. A cavity behind the striking surface of the insert enhances the sound of impact and a visible top surface of the insert integral with the hosel with sighting indicia enhances golfer alignment and stroking of the ball to provide resultant confidence and consistency.

Owner:CHAPEL GOLF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com