Preparation of Double-sided Photoelectrolytic Copper Foil for Special Lithium Batteries

A lithium battery and photoelectrolysis technology, applied in the field of copper foil manufacturing, can solve the problems affecting the quality and reliability of downstream products, large fluctuations in product quality parameters, and unstable production processes, etc., to achieve simple and stable production processes and small fluctuations in quality parameters , The effect of reducing the internal resistance of lithium batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

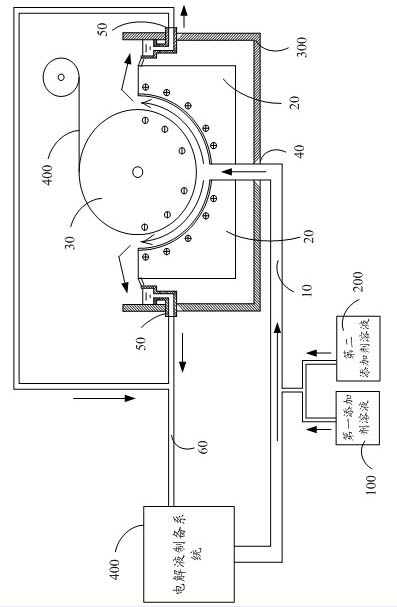

[0018] see figure 1 , the preparation of the special double-sided photoelectrolytic copper foil for lithium batteries provided by the first embodiment of the present invention, that is, the manufacturing method of ultra-thin double-sided photoelectrolytic copper foil for lithium-ion secondary batteries, which includes the following steps.

[0019] The prepared first additive solution 100 and second additive solution 200 are injected into the liquid inlet pipe 10 of the electrolytic cell 300 through a metering pump (not shown) at a rate of 2:1 at a flow rate of 7.5 L / h. During the process, fully mix with the electrolyte in the electrolyte preparation system 400 and then enter the electrolytic cell 300;

[0020] The flow rate of the electrolyte is 55-65 cubic meters per hour. After the mixed solution of the first additive solution 100, the second additive solution 200 and the electrolyte enters the electrolytic cell 300, the flow rate is 5000-6000A / m 2 (6000A / m in this embodime...

Embodiment 2

[0027] Referring to the production method of Example 1, the copper foil product was prepared. The temperature of the electrolyte was 50-55°C, and the concentrations of the components were: copper ion concentration 85g / L, sulfuric acid concentration 170g / L, and chloride ion concentration 0.03g / L, the flow rate of the electrolyte is 60-70 cubic meters per hour; the first additive solution and the second additive solution are added at a ratio of 7 liters per hour in a ratio of 2:1. The first additive solution is made according to the raw materials of following ratio: 2.0g / L of sodium 3-mercapto 1-propanesulfonate, 0.020g / L of polyethylene glycol, 0.0020g / L of ethylene thiourea; Raw material ratio is: gelatin 2.5g / L, hydroxyethyl cellulose 0.25g / L.

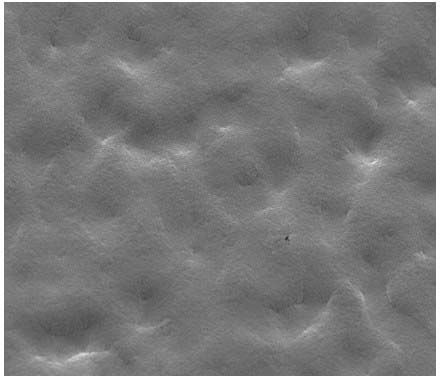

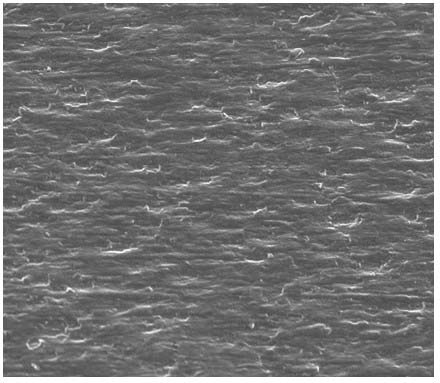

[0028] The rough surface of the electrolytic copper foil prepared in this example is mirror-like like the smooth surface, and the crystal grains are in a layered structure. The thickness of the copper foil is 8.9-9.1um. After testing...

Embodiment 3

[0030] Referring to the production method of Example 1, the copper foil product was prepared. The temperature of the electrolyte was 50-55°C, and the concentrations of the components were: copper ion concentration 75g / L, sulfuric acid concentration 165g / L, and chloride ion concentration 0.03g / L, the electrolyte flow rate is 60-70 cubic meters per hour; the first additive solution and the second additive solution are added at a ratio of 7.5 liters per hour in a ratio of 2:1. The first additive solution is made by the raw material of following ratio: 3-mercapto 1-propanesulfonate sodium 2.5g / L, polyethylene glycol 0.030g / L, ethylene thiourea 0.0025g / L; The second additive solution Raw material ratio is: gelatin 2.0g / L, hydroxyethyl cellulose 0.20g / L.

[0031] The rough surface of the electrolytic copper foil prepared in this example is mirror-like like the smooth surface, and the crystal grains are in a layered structure. The thickness of the copper foil is 9.0-9.2um. After tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com