Patents

Literature

797results about How to "Stable production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of super strength interference pearlylustre pigment

The invention relates to a production process for ultra-strong interferential golden pearl pigment of a multi-coating two-dimensional structural slice base object, which is obtained by coating mica with four layers. The golden pearl pigment product prepared by the production process of the invention has the effect of 24K gold, low price, and extremely-large economic value.

Owner:河北欧克新型材料股份有限公司

Process for manufacturing low-silicon low-carbon deep punching/drawing steel

ActiveCN101343677ARelaxation of sulfur content requirementsReduce manufacturing costManufacturing convertersProcess efficiency improvementExtensibilitySlag

The invention discloses a production method of low-silicon and low-carbon deep punching / drawing steel, bottom-blowing argon is performed in the whole process of converter smelting, and a single slag / double slag technique is adopted to pour out the dephosphorized slag, high-basicity slag is produced in later period, the dualistic basicity of final slag R is more than 3.5, the terminal temperature of molten steel is 1620 DEG C to 1650 DEG C, and tapping ( P ) is less than 0.012 percent. The molten steel is refined by adopting low-silicon and low-carbon high-basicity reductive slag in a LF furnace refining station, thus to manufacture reductive slag for desulphurisation, and the ( Al ) in the molten steel is less than 0.005 percent. The molten steel refined by the LF furnace is vacuum-treated by a RH vacuum furnace, the carbon and the silicon in the molten steel is circularly removed, the molten steel is continuously casted into a casting blank through a CSP sheet bar conticaster, the casting blank is sent into CSP sheet bar heat continuous rolling mill and rolled into a coiled sheet after being heated in a roller hearth soaking furnace, a hot rolled coiled sheet is coldrolled into cold rolled coiled sheet through a cold tandem mill or a single mill after being acidwashed, and leveled through a leveling machine after being annealed by a cover furnace, and a leveling divided coil is stretched and divided. The production method has the advantages that the production cost of the working procedure is saved, the consumption of the refractory consumption of the converter is reduced, the equipment investment is saved, the process of the production technique is steady and smooth, the n value of the cold rolled plate is bigger than 0.23, the r value thereof is bigger than 2.1, and the deep punching performance and the extensibility are good.

Owner:湖南华菱涟钢特种新材料有限公司 +1

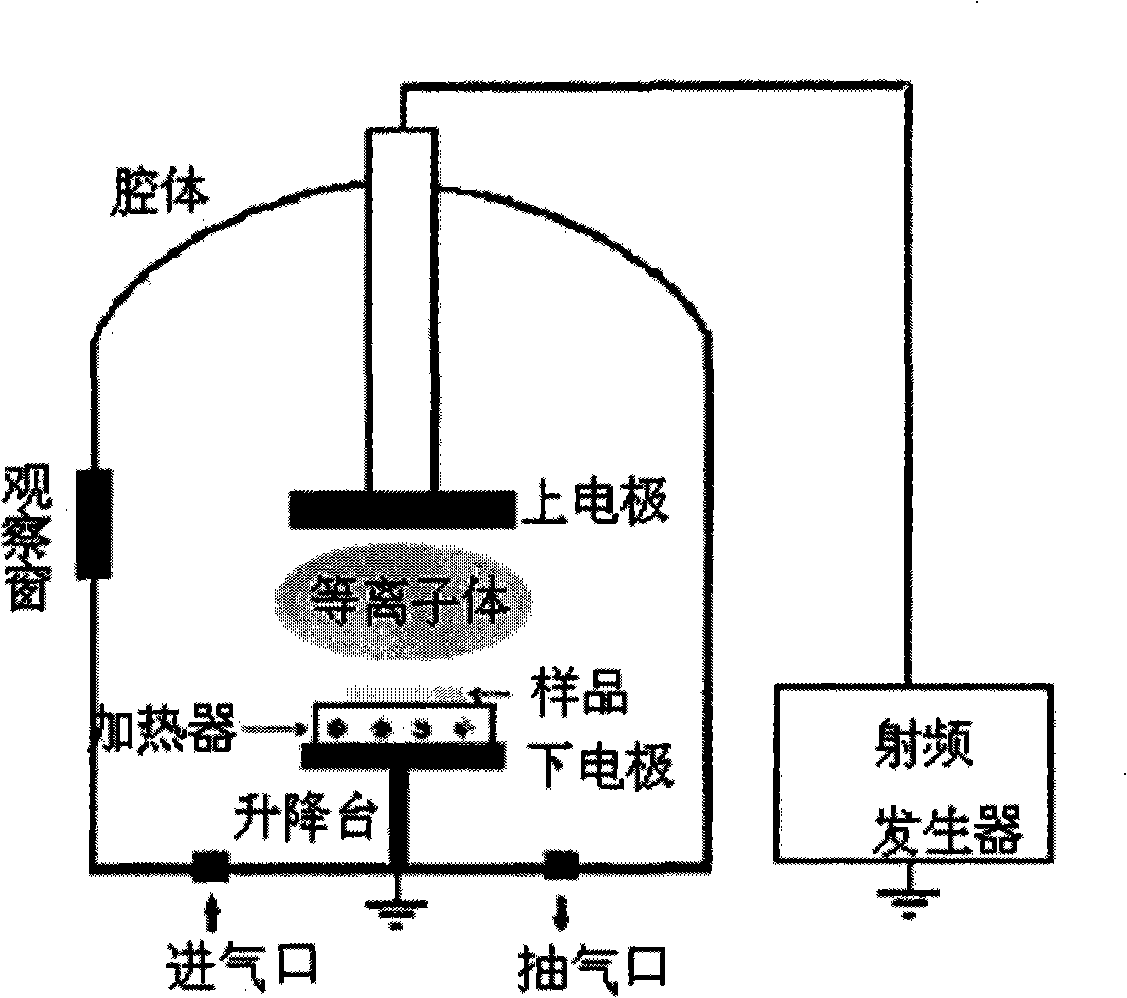

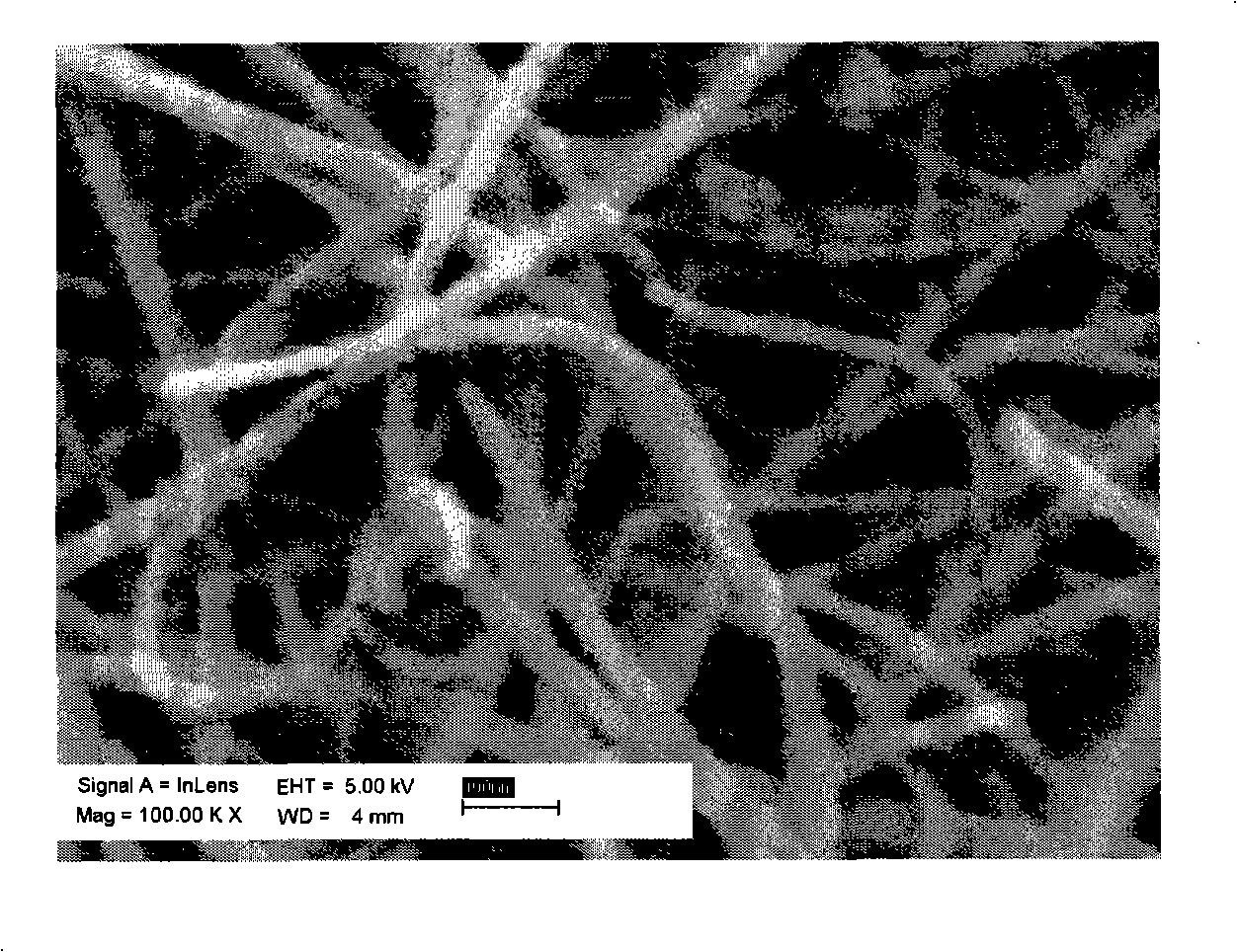

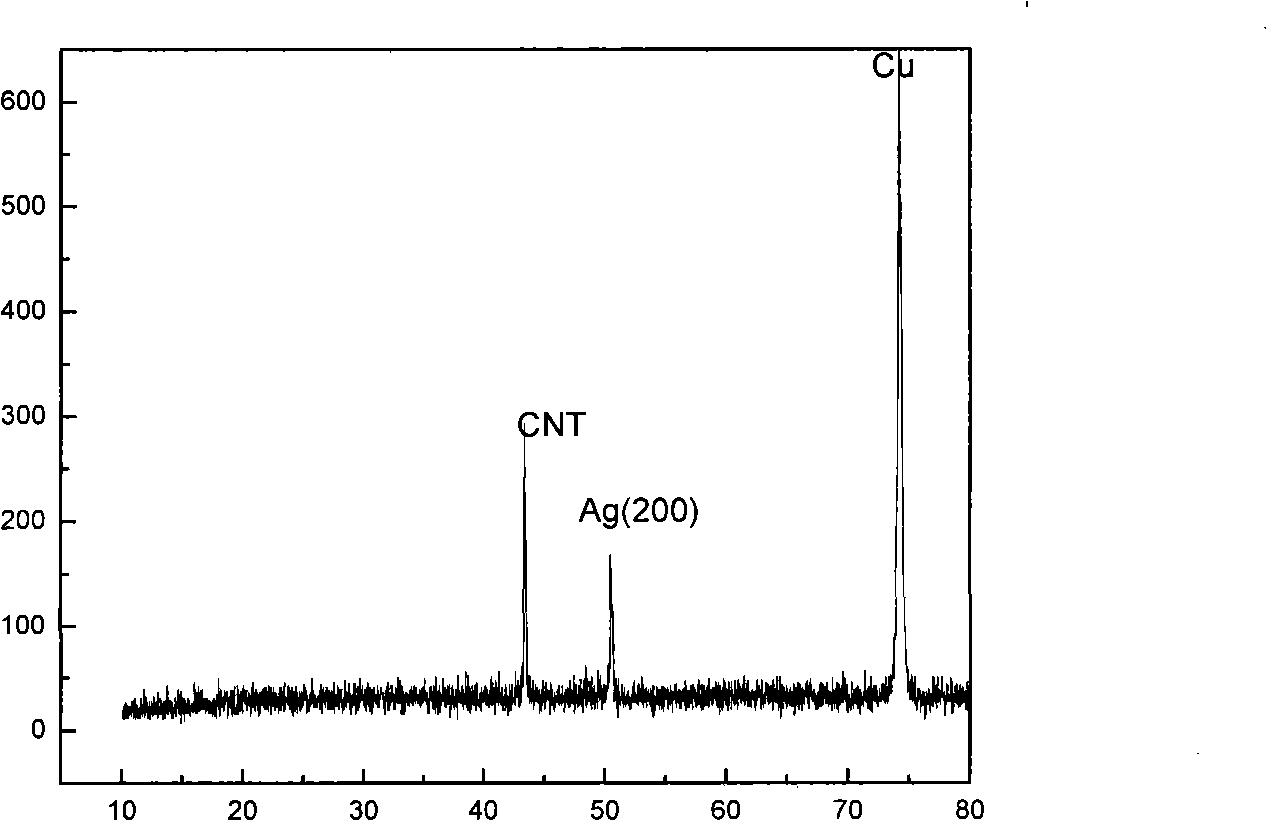

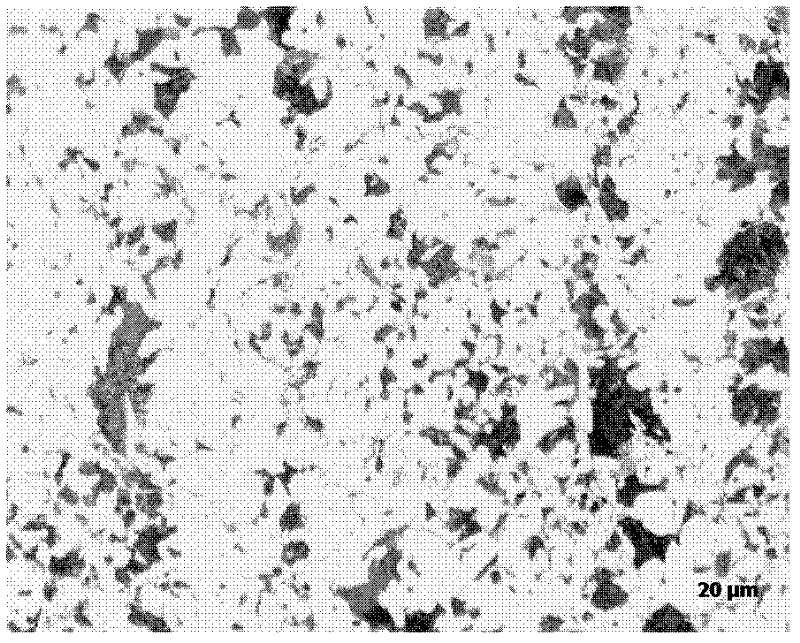

Method for preparing nano metal or metal oxide/carbon nano-tube composite material

InactiveCN101255544AShort processStable production processFrom normal temperature solutionsAfter-treatment detailsEvaporationCarbon nanotube

The invention relates to a simple practical preparation for metal or metal oxide / carbon nano-tube nano-composite, characterized in: with carbon nano-tube as the matrix, Fe, Co, Ni, Si, Ag, Au, Ti, Zn, Al, Mg, Ta, Pd, Mo, Sn and Pt as well as oxide nano-materials thereof are prepared by any method of radio frequency sputtering deposition, pulsed laser deposition, spraying schizolysis, hot evaporation or hydrothermal method, metal or metal oxide nano-grain or nano-film is formed on the surface of a carbon nano-tube. By this method, carbon nano-tube matrix composite material having multiple forms can be prepared, the process is simple, the cost is low, the carbon nana-tube matrix composite material has special optical property, electrical property, and magnetic property, thus having wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Steel plate with thickness of 80mm and low compression ratio for ocean engineering and manufacturing method thereof

ActiveCN102392192ASuitable for productionWide applicabilityTemperature control deviceFurnace typesLaminar coolingCooling temperature

The invention relates to steel for ocean engineering and a manufacturing method thereof, in particular to a steel plate with a thickness of 80mm and a low compression ratio for ocean engineering and a manufacturing method thereof. The steel plate comprises the chemical components with the weight percentages as follows: 0.12 to 0.16 percent of C, 0.20 to 0.40 percent of Si, 1.20 to 1.60 percent ofMn, smaller than or equal to 0.010 percent of P, smaller than or equal to 0.003 percent of S, 0.025 to 0.050 percent of Nb, 0.030 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than or equal to 0.20 percent of Cr, 0.10 to 0.40 percent of Ni, smaller than or equal to 0.20 percent of Cu, smaller than or equal to 0.08 percent of Mo, 0.0250 to 0.050 percent of Al, smaller than or equal to 20ppm of O, smaller than or equal to 40ppm of N, smaller than or equal to 3ppm of H, and the remaining amount of Fe and inevitable impurities. A controlled rolling and cooling technology is adopted, the heating temperature before rolling is 1180 DEG C to 1250 DEG C, the rough rolling temperature is 1000 to 1100 DEG C, and the finish rolling starting temperature is 850 to 880 DEG C; laminar cooling is conducted after the rolling, the final cooling temperature is 640 to 680 DEG C, and the cooling rate is 5 to 15 DEG C / s; and normalizing treatment is conducted, the normalizing temperature is 890 to 910 DEG C, the heating rate is 1.4min / mm, and the heat preservation time is 50 to 90min. The obtained steel has the characteristics of high strength, good Z-direction lamellar tearing resistant performance, high plasticity, and the like.

Owner:NANJING IRON & STEEL CO LTD

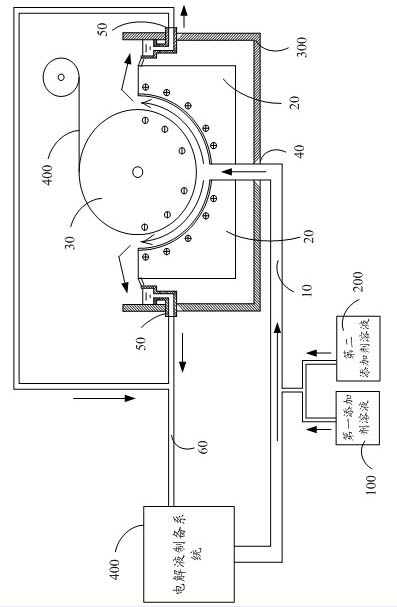

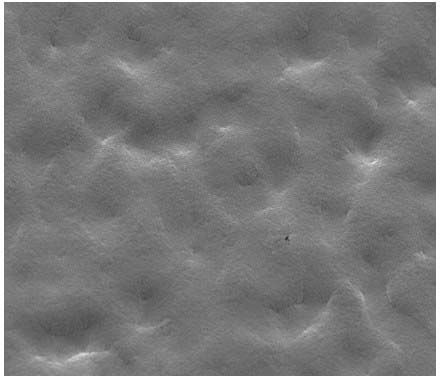

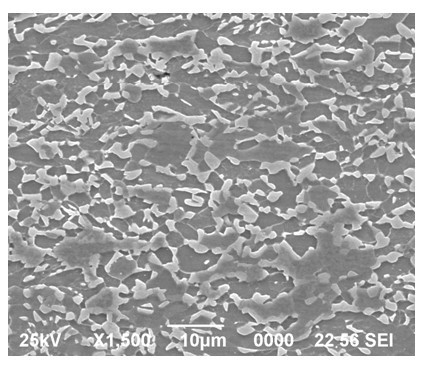

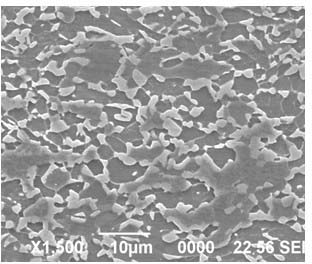

Preparation of Double-sided Photoelectrolytic Copper Foil for Special Lithium Batteries

ActiveCN102277597AStable production processHigh quality and efficient material selectionElectroforming processesElectrochemical responseCopper foil

The invention relates to the preparation of a double-sided photoelectrolytic copper foil for a special lithium battery, which comprises the following steps: preparing solution of a first additive, solution of a second additive, and copper sulfate electrolyte, wherein the copper ion concentration in the copper sulfate electrolyte is 70 to 100g / L, the sulfuric acid concentration is 100 to 170g / L and the chlorine ion concentration is 0.01 to 0.04g / L, and the temperature of the copper sulfate electrolyte is 40 to 60 DEG C; adding 60 to 200 milliliters of solution of the first additive and 35 to 100 milliliters of solution of the second additive into each cubic meter of electrolyte each hour, wherein the electrolyte formed by uniformly stirring enters an electrolytic cell and the electrolysis current density of the electrolyte in the electrolytic cell is 5,000 to 6,000A / m<2>; and after electrochemical reactions are accomplished, obtaining the double-sided electrolytic copper foil for a photic lithium battery. The preparation of the double-sided photoelectrolytic copper foil for the special lithium battery has the advantages that: the unit area weight of the prepared photoelectrolytic copper foil is 87 to 89g / m<2>, the tensile strength is more than 45Kgf / m<2>, the elongation rate is more than 5 percent, the surface roughness R2 is less than 1.5 mu m, and the uniform thickness of thecopper foil is 8.6 to 9.3 mu m according to actual measurement.

Owner:合肥铜冠电子铜箔有限公司

Pipeline steel plate with low yield ratio, fine grains and high strength and production method thereof

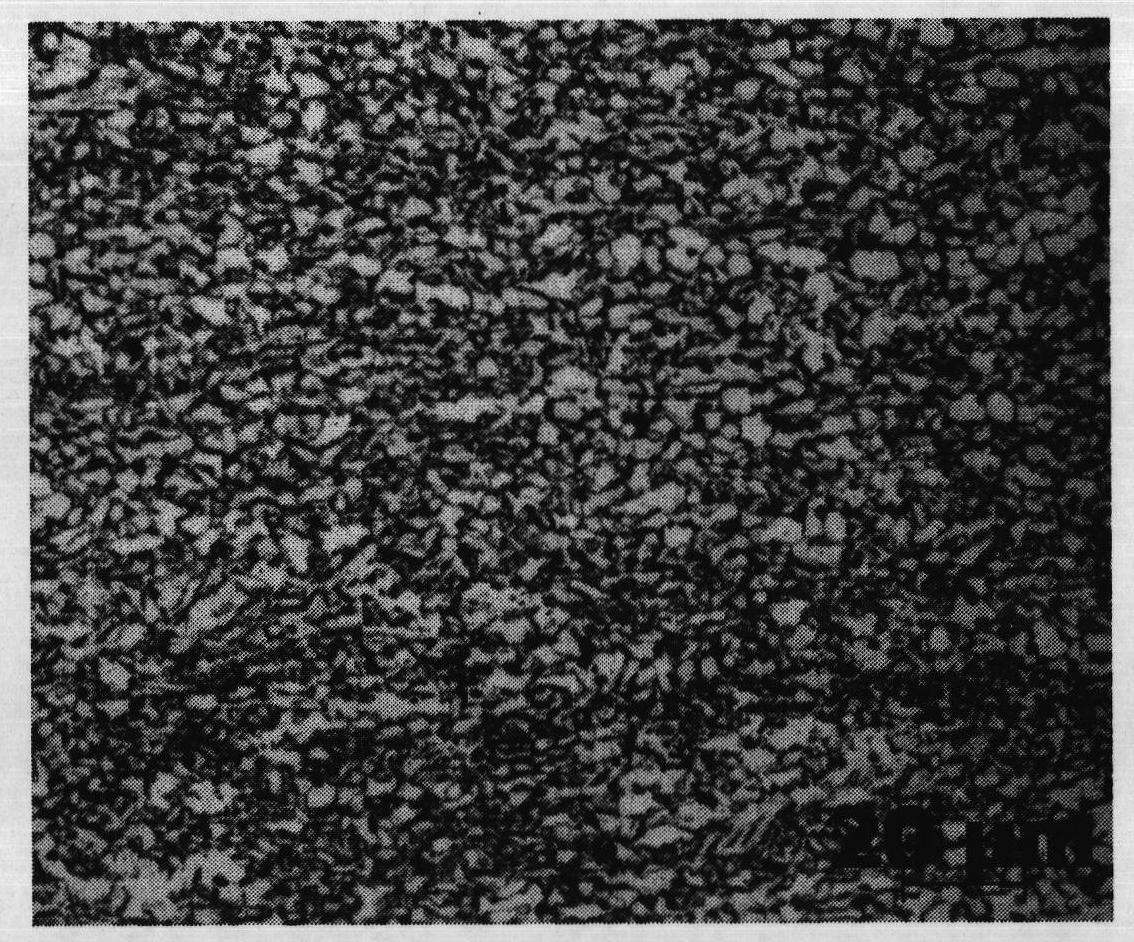

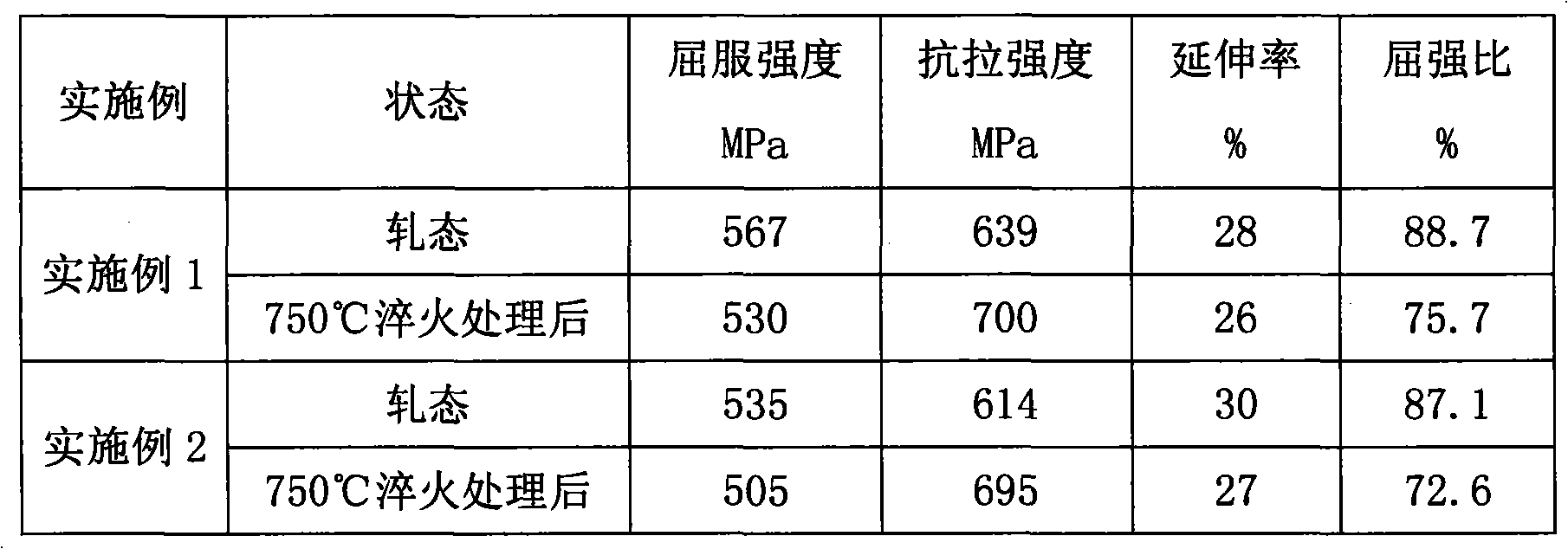

The invention discloses a pipeline steel plate with low yield ratio, fine grains and high strength and a manufacturing method thereof, and steel in the pipeline steel plate comprises the following chemical components by weight percent: 0.03-0.10% of C, 0.10-0.30% of Si, 1.20-1.80% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.040-0.060% of Nb, 0.006-0.020% of Ti, 0.10-0.40% of Cr, 0.10-0.30% of Ni, 0.010-0.050% of Al and the balance of Fe and inevitable impurities. The manufacturing method adopts a converter for smelting, adopts the TMCP (thermo mechanical control process) and the two-phase region subthermal quenching treatment at 720-750 DEG C, thereby obtaining the pipeline steel plate with low yield ratio, fine grains and high strength; and the manufacturing method has stable production process, strong operability, low cost and high performances.

Owner:NANJING IRON & STEEL CO LTD

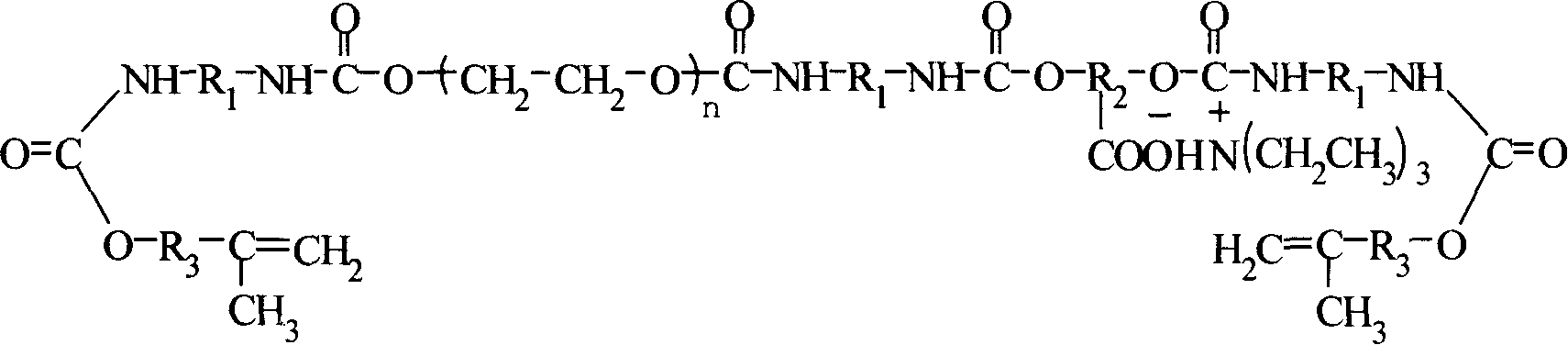

Ultraviolet light solidfication water polyurethane acrylate paint resin and its preparation method

InactiveCN1869139AThe molecular structure is well controlledImprove performancePolyurea/polyurethane coatingsSolubility(Hydroxyethyl)methacrylate

The invention relates to an ultraviolet light solidified water urethane acrylate coating resin. It is mainly made up of aromatic diisocyanate, polyethylene glycol, polyhydroxy-carboxylic acid, dihydric alcohol, hydroxyethyl methacrylate ethyl ester, and tri-ethylamine. It is prepared by adding the above materials orderly. It has the advantages of good water solubility, pliability, and stability.

Owner:SHANTOU UNIV +1

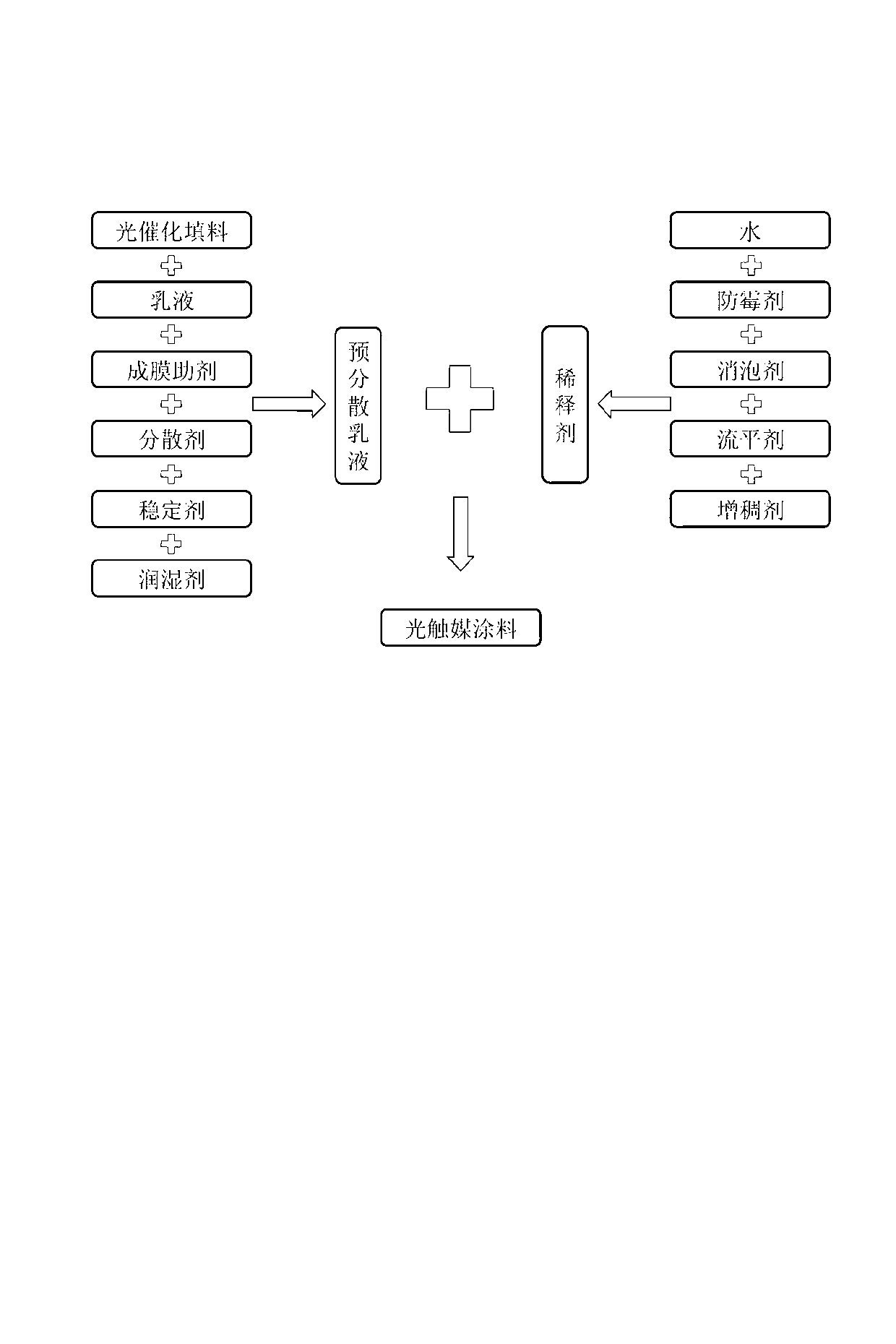

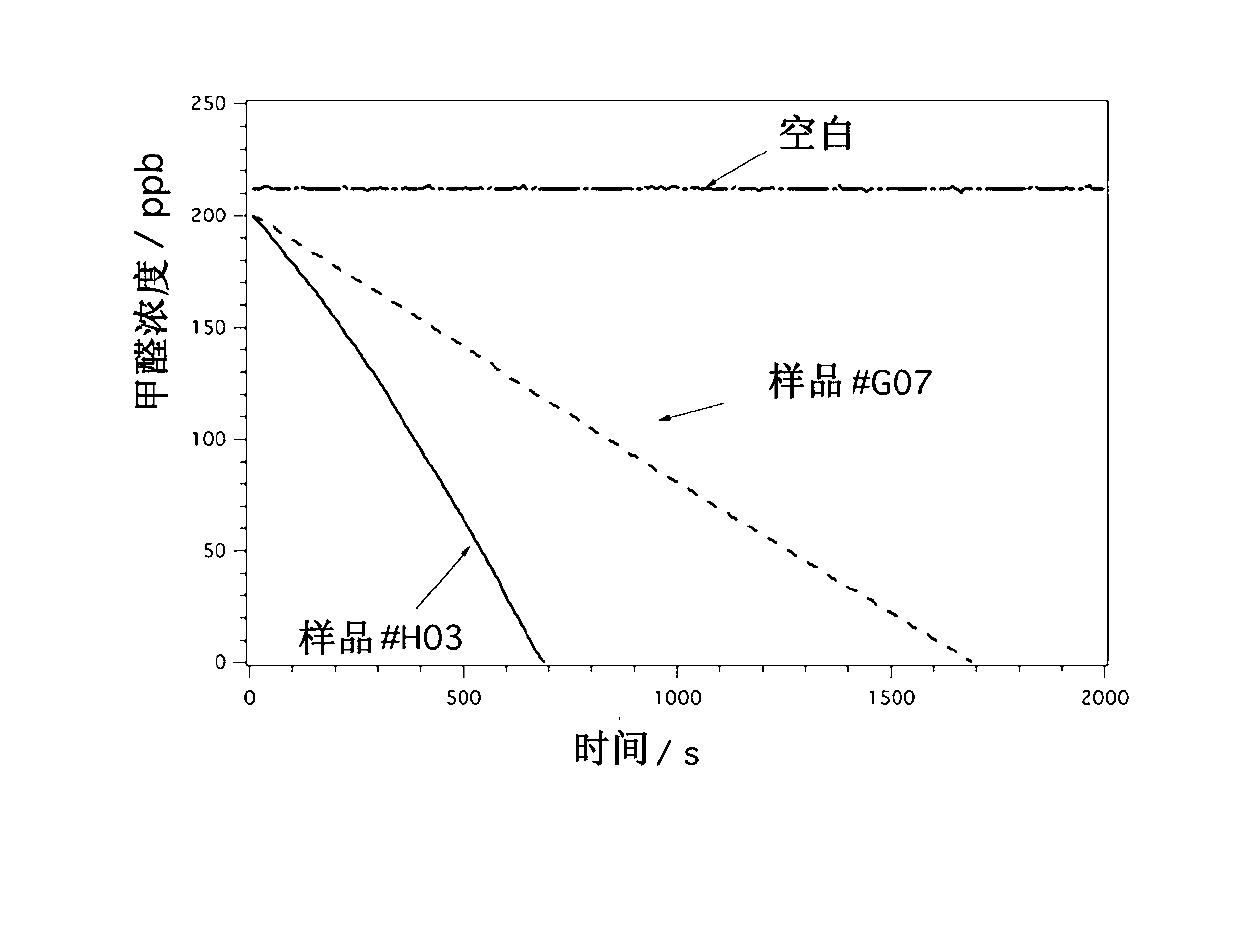

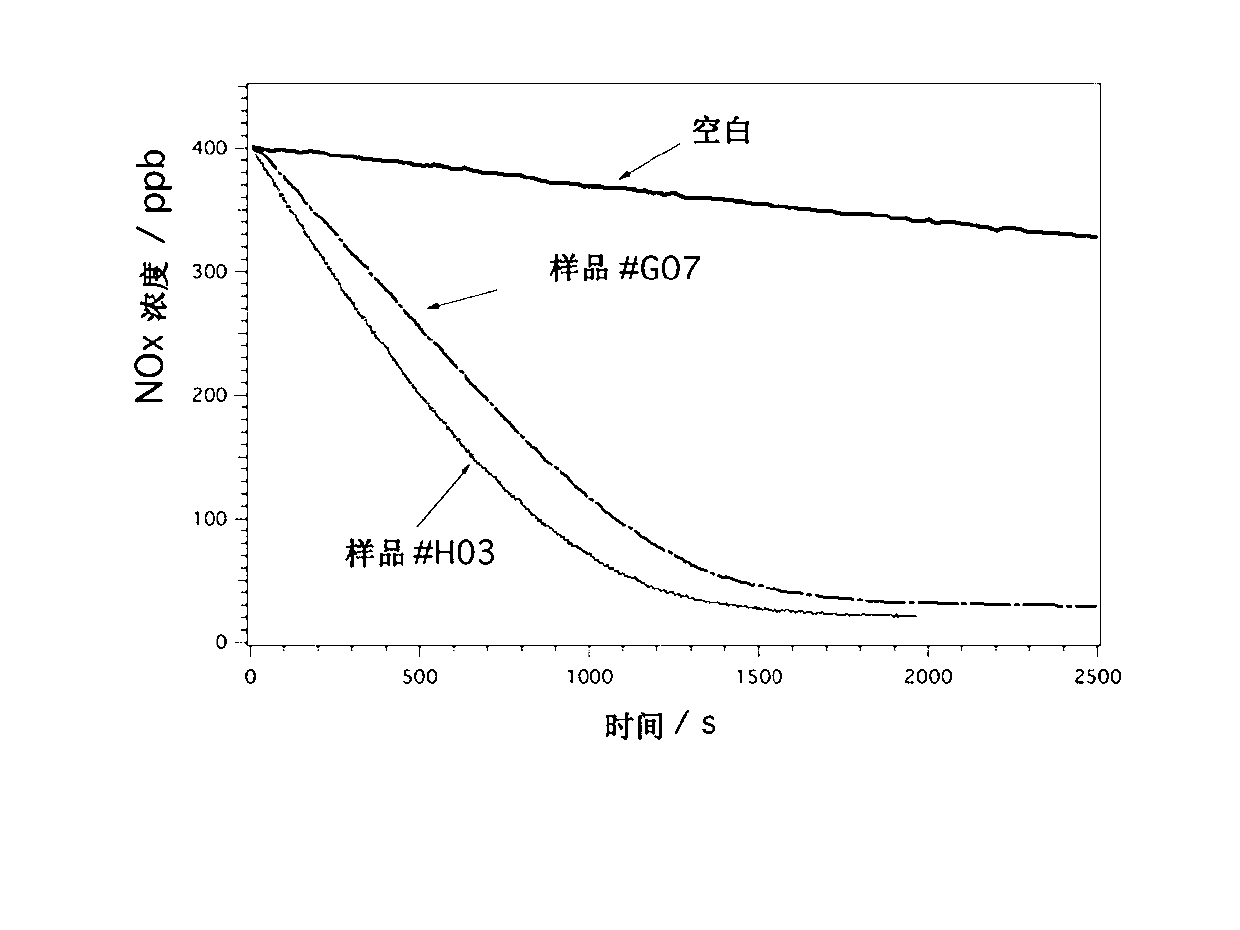

Compound type photocatalyst air purification waterborne interior wall coating and preparation method thereof

ActiveCN103131313ABroaden the photoresponse wavelengthImprove photocatalytic abilityAntifouling/underwater paintsPaints with biocidesChemistryPhoto catalysis

Provided are a compound type photocatalyst air purification waterborne interior wall coating and a preparation method thereof. The compound type photocatalyst air purification waterborne interior wall coating comprises, by weight, the following materials of 5.5-22.3% of photocatalysis packing, 25-65% of polyurethane emulsion, 1-6% of propylene glycol phenylate, 2-6% of dispersing agents, 2-4% of stabilizing agents, 1-2% of wetting agents, 20-60% of water, 1.5-4% of mildewproof agents, 1-2% of antifoaming agents, 0.5-2% of flatting agents, and 0.5-1% of thickening agents. The photocatalysis packing is formed by complexation of nanoanatase type titanium dioxide and nano-zinc oxide or nano stannic oxide according to a weight ratio of 5-9:1-5. The coating has good air purifying capacity, and can effectively degrade harmful gases in the air and kill bacterial viruses under excitation of ultraviolet light. As an interior decorative material, the coating has good covering power and adhesive power and excellent stability. The coating and the production method are simple in production process, suitable for various coating methods, and easy to popularize and apply.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

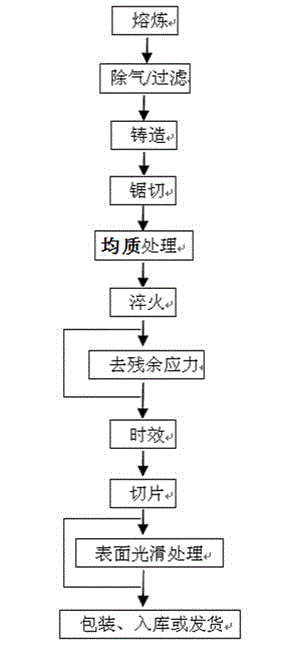

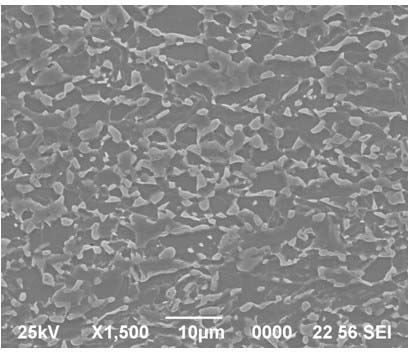

Processing method for aluminium alloy middle thick plate

The invention discloses a processing method for an aluminium alloy middle thick plate. The processing method comprises the following steps of smelting, degassing and filtering, casting, sawing, homogenizing, quenching, removing residual stress, carrying out aging treatment, cutting into slices and performing surface treatment to obtain the aluminium alloy middle thick plate. The aluminium alloy middle thick plate is uniform in structure, low in internal stress, high in size precision, high in strength and low in production cost, and has relatively good economic benefits and social benefits.

Owner:广西南南铝加工有限公司

Industrial production method of hydrolyzed wheat protein for feeding

InactiveCN101627793AConfiguration highAdvanced configurationAnimal feeding stuffAccessory food factorsHydrolysateCombined treatment

The invention discloses an industrial production method of hydrolyzed wheat protein for feeding, belonging to the technical field of feed additive production. In the method, through the method of synergy of multiple enzymes and combined treatment of multiple steps, the hydrolyzed wheat protein for feeding is prepared by taking wheat gluten meal and water with weight ratio of 1:10-1:2 and adding compound enzyme, ensuring the mass percent concentration of the compound enzyme in the solution is 0.2-1.4%, hydrolyzing the mixture for 1-13h under the conditions that the temperature is 30-70 DEG C and pH value is 5.0-10.0, then carrying out such processes as filtering, decoloring and drying, etc. Compared with the traditional methods, the method of the invention features mild hydrolysis conditions, sanitation and safety and maintains the original nutritive composition of amino acid free of loss; the hydrolysate is low in salt content, mellow in mouth feel and high in yield which is up to 98%. The tests that the hydrolyzed wheat protein is added in the feed for suckling pigs, chicks, calves, aquaculture and the like to be used show that the hydrolyzed wheat protein has the advantages and evident effects of improving daily feed intake, reducing diarrhea rate, enhancing immunity, slowing weanling stress, improving growth performance and the like.

Owner:郑州新威营养技术有限公司

Tundish dry ribration material for continuous casting and its preparation method

InactiveCN1651352ANo irritating smellEasy constructionMelt-holding vesselsPolyvinyl alcoholRefractory

A lining material of tundish for conticasting is prepared from 6 primary raw materials including sintered magnesium sand, electrosmelted magnesium sand, forsterite, light forsterite, etc and 9 secondary raw materials including water glass, sodium tripolyphosphate, dextrin, starch, etc through proportionally mixing, stirring, loading in mould, vibrating, baking at 150-400 deg.C and demoulding.

Owner:WUHAN UNIV OF SCI & TECH

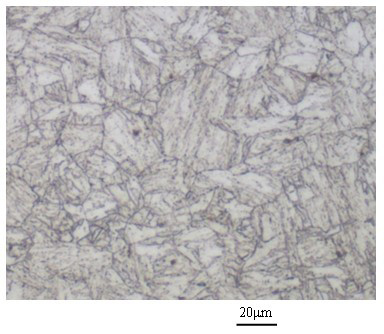

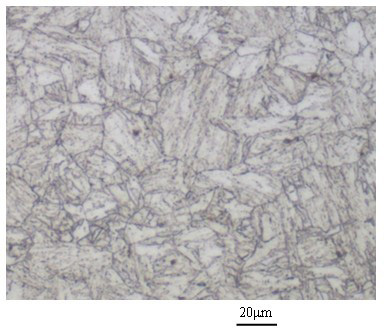

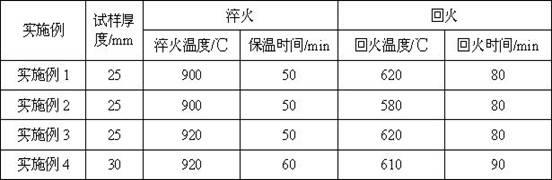

A kind of low yield ratio high plastic ultrafine grain high strength steel and its manufacturing method

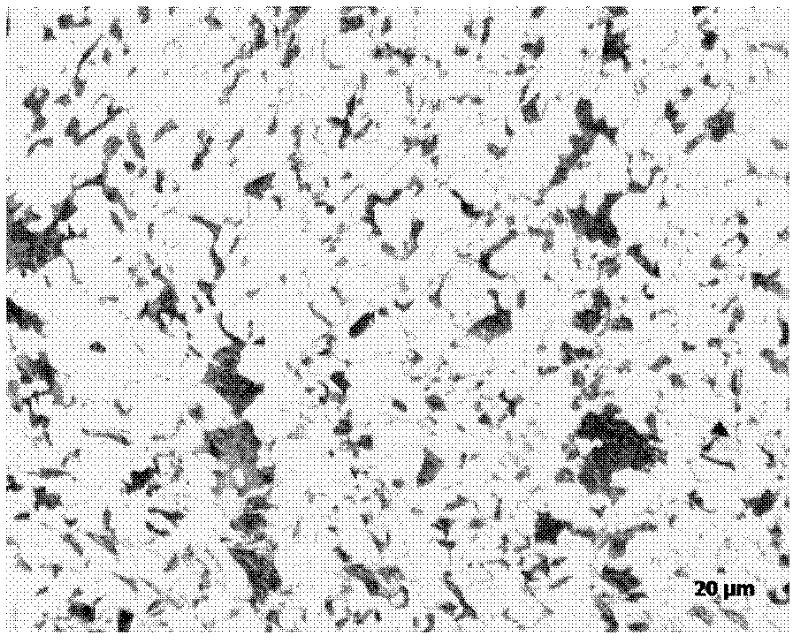

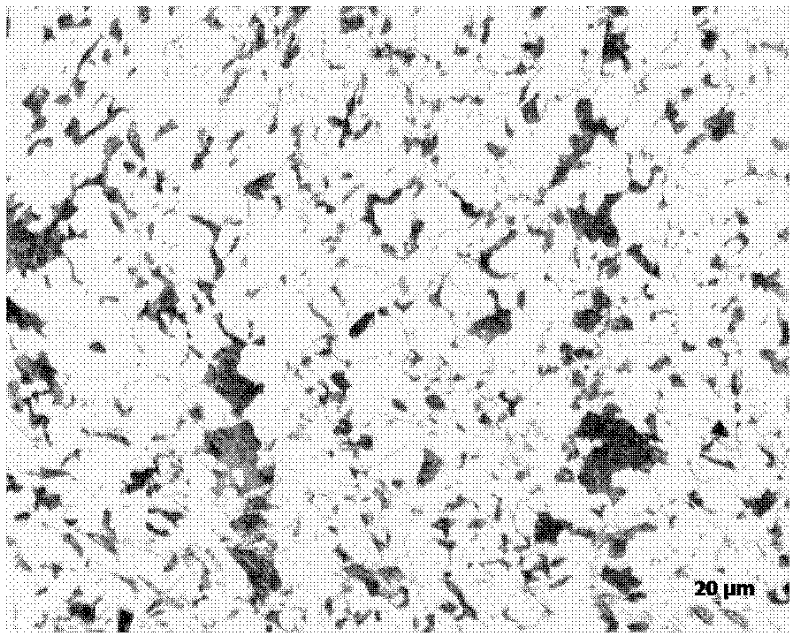

InactiveCN102277539AHigh yield strengthHigh tensile strengthRoll mill control devicesMetal rolling arrangementsChemical compositionGrain structure

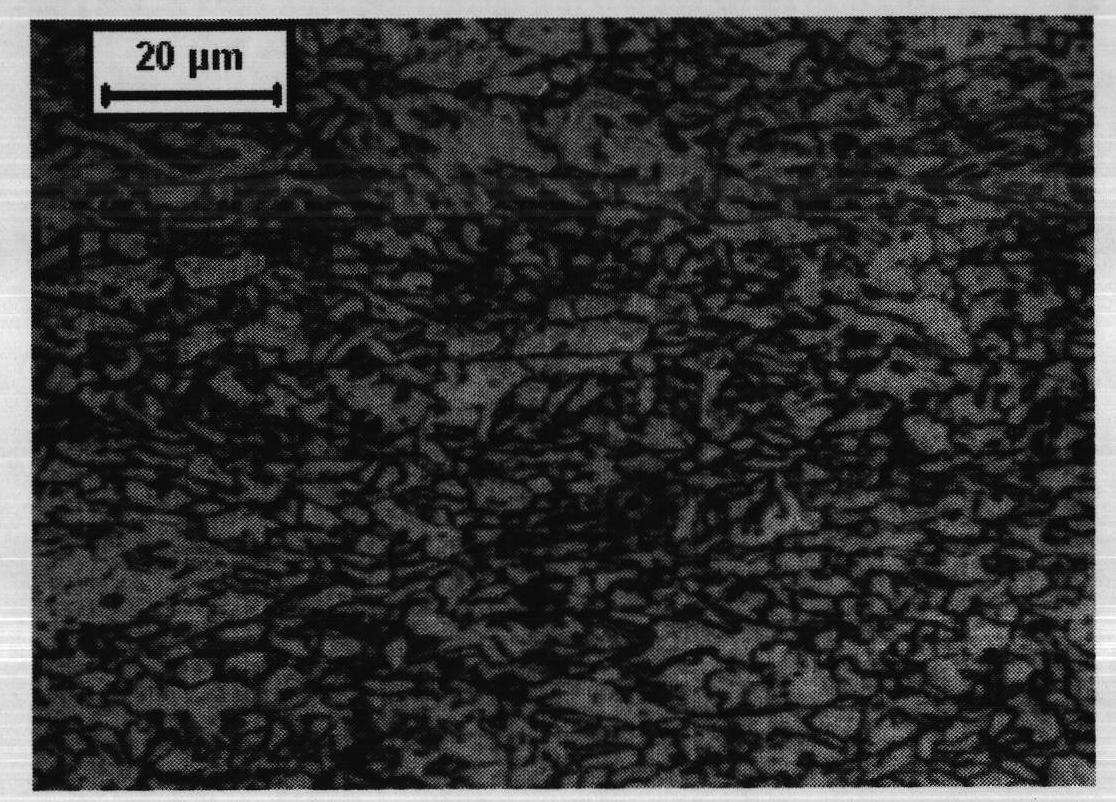

The invention discloses a high-strength steel with low yield ratio, high plasticity and ultra-fine grain and a manufacturing method. The chemical composition weight percentage of steel is: C: 0.06~0.09%, Si: 0.15~0.25%, Mn: 1.20~1.50%, P: ≤0.015%, S: ≤0.005%, Nb: 0.020~0.040%, V: 0.010~0.030%, Ti: 0.008~0.015%, Cr: 0.10~0.30%, Ni: 0.10~0.30%, Cu: 0.10~0.30%, Al: 0.010~0.050%, and the balance is Fe and unavoidable impurities. The invention obtains the bainite structure by adopting the controlled rolling and controlled cooling process. Through the heat treatment process, an ultra-fine grain structure with bimodal distribution is obtained, which makes the material have characteristics such as low yield ratio, superplasticity, and high strength. The production process is stable, the operability is strong, the cost is low, and the comprehensive performance of the obtained material is excellent.

Owner:NANJING IRON & STEEL CO LTD

Method for laser hardening gear part

ActiveCN102021568AImprove wear resistanceImprove anti-corrosion performanceMetallic material coating processesLaser beam welding apparatusWear resistantLaser scanning

The invention discloses a method for laser hardening gear part, which comprises the following steps: 1) machining a gear part according to the prior art, wherein the thickness of the gear is required to be 1.5 mm less than the design value; 2) laser scanning the gear part by a laser hardening equipment with a laser output power of 5 kw, a scanning speed of 480 mm / min, and a powder feed rate of 18 g / min, performing the powder feeding and the laser cladding simultaneously in one work step, and cladding the gear surface with metal powder containing wear resistant materials to form a laser hardening layer with a cladding thickness of 3 mm and with polishing allowance reserved, wherein the laser beam is a broadband rectangular spot of 15X2.5; the metal powder material comprises, by weight: 48.4% of Fe, 0.077% of C, 0.85% of Si, 0.368% of Mn, 17.02% of Cr, 24.4% of Ni, and 2.68% of Mo; 3) processing the laser-clad mating surface to achieve a design size. The laser-clad gear of the present invention has an average micro-hardness of HV800, a Rockwell hardness of HRC65, and the wear resistance of the gear surface is enhanced.

Owner:SHANDONG ENERGY HEAVY EQUIP GRP DAZU REMANUFACTURING CO LTD +1

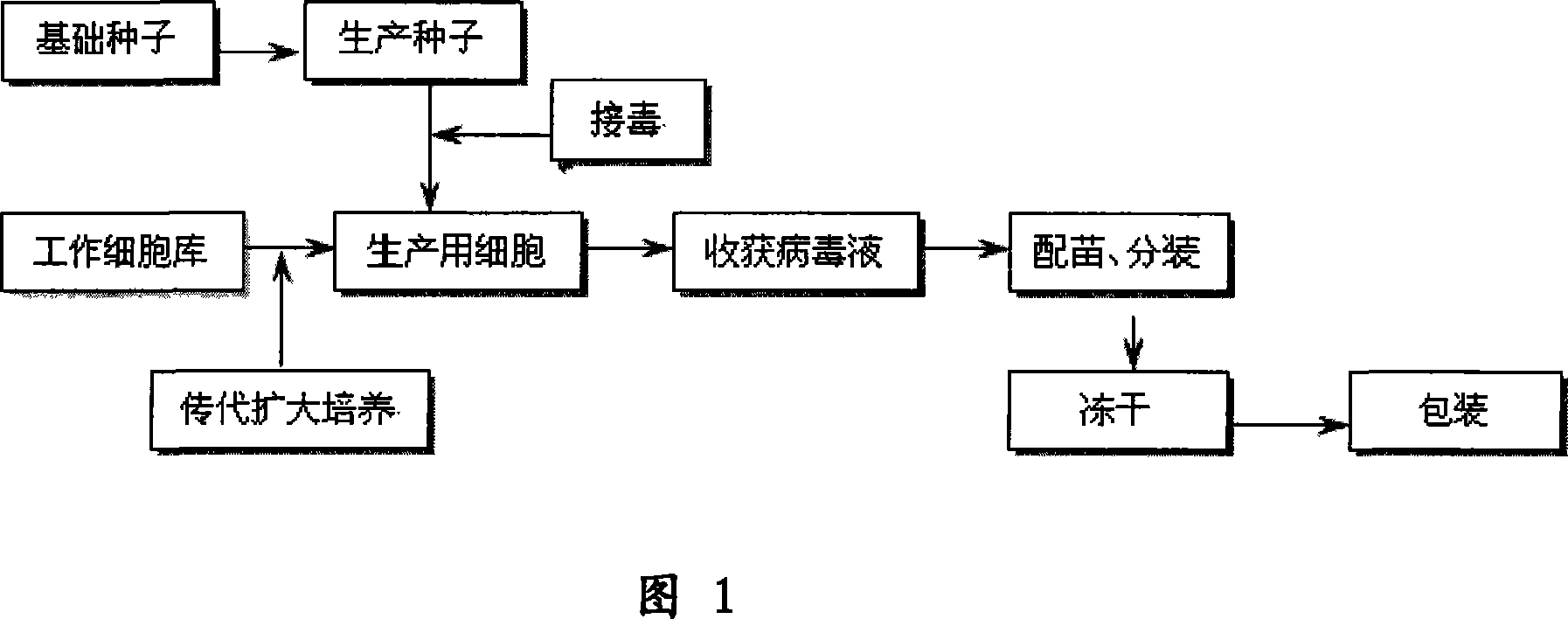

Method for producing swine fever live vaccine with cell line

ActiveCN101181637AGuaranteed to be pureEnsure safetyAntiviralsAntibody medical ingredientsQuality controlSeedling

The invention discloses a method for producing a live swine fever vaccine by using a cell line. The present invention comprises the following technical steps: (1) selecting a cell line as the cells for making seedlings; (2) subculture and cultivation of cells for making seedlings; (3) breeding of cytotoxic species; (4) breeding of venom for making seedlings; 5) Mixing seedlings, subpackaging and freeze-drying. The invention has the advantages of simple and stable production process, easy operation, high virus content, small difference between batches, easy quality control, and can significantly improve the yield and quality of vaccines. The live swine fever vaccine produced by the invention has good safety and high immune efficacy, and has complete immune protection against the virulent attack of swine fever.

Owner:CHINA INST OF VETERINARY DRUG CONTROL +1

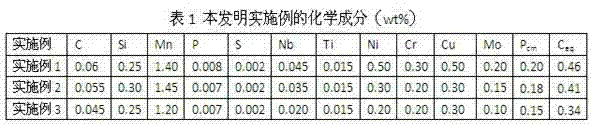

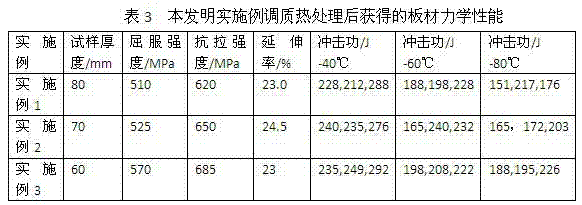

460MPa-grade low-compression-ratio and high-toughness steel plate for ocean engineering, and its production method

InactiveCN103938108AAchieve recrystallization refinementGuaranteed low temperature impact performanceAustenite grainChemical composition

The invention relates to the field of steels material, and concretely relates to a 460MPa-grade low-compression-ratio and high-toughness ocean steel plate and its production method. The steel plate comprises 0.04-0.07wt% of C, 0.2-0.4wt% of Si, 1.0-1.5wt% of Mn, 0.010wt% or less of P, 0.003wt% or less S, 0.2-0.5wt% of Ni, 0.2-0.5wt% of Cu, 0.2-0.4wt% of Cr, 0.1-0.3wt% of Mo, 0.02-0.05wt% of Nb, 0.01-0.025wt% of Ti, and the balance Fe and unavoidable impurities. The C content, the P content and the S content are controlled in a range of 0.04-0.07%, in a range of not greater than 0.010% and in a range of not greater than 0.003% respectively. Even though compression ratio is low, the heating temperature and the rolling temperature are reduced to realize the recrystallization refinement of austenite grains and ensure the low-temperature impact performance, and tempering after rolling further improves the toughness and the microstructure uniformity. The steel plate produced by the above scheme has a tensile strength of 620- 685MPa, a yield strength of 500-570MPa and a fracture elongation of 20-25%, has (horizontal) Charpy impact energy at -60DEG C reaching 240J, has a -80DEG C low temperature impact of not lower than 150J, has a Pcm value of not greater than 0.22 and a Ceq value of not greater than 0.47, and has the characteristics of easy welding, stable production process, strong operability and the like.

Owner:JIGANG GRP

Manufacturing method of resin diamond wire

InactiveCN102658606AStable production processAdvanced technologyMetal sawing toolsFine working devicesMetal coatingOrganosolv

The invention discloses a manufacturing method of a resin diamond wire, relating to the field of photovoltaic technology. The manufacturing method of a resin diamond wire adopts viscose, carborundum and core wire and sequentially comprises the following steps of: preparing carborundum resin liquid including carborundum coated with metal, resin adhesive, organic solvent and SiC sand grain auxiliary, wherein the resin adhesive is soluble phenolic resin; mixing with a mixer until the phenolic resin is dissolved in the paste in dimethylformamide, and then injecting into a mould; in the mould, smearing the resin liquid on the steel wire; processing the steel wire with the resin liquid by a heating furnace to obtain a semi-hardened resin diamond wire; and collecting the wire to obtain a finished product of the resin diamond wire. The method disclosed by the invention has stable technology, short semi-hardening time and high production efficiency; and the production equipment can also be miniaturized.

Owner:HONGKONG YACHENG INT

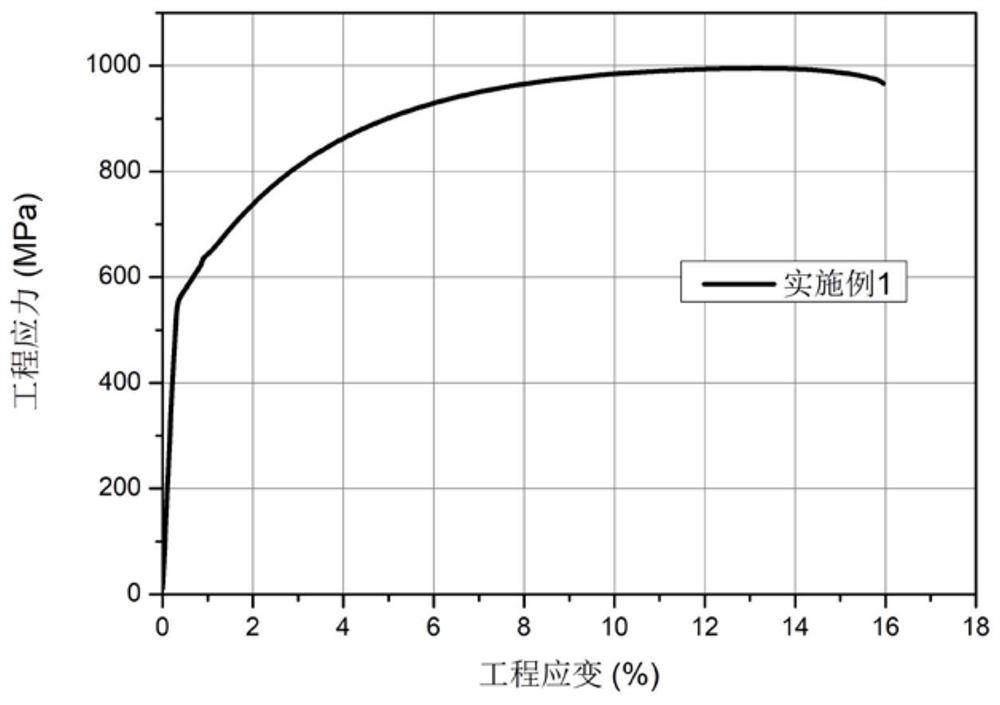

980 MPa-grade high-formability cold-rolled DH steel and preparation method thereof

The invention discloses 980 MPa-grade high-formability cold-rolled DH steel and a preparation method thereof. The steel comprises 0.16 %-0.23 % of C, 1.8 %-2.8 % of Mn, 0.3 %-1.5 % of Si, 0.02 %-1.2 %of Al, 0.02 %-0.50 % of Mo, 0.02 %-0.70 % of Cr, less than or equal to 0.01 % of P, less than or equal to 0.01 % of S, less than or equal to 0.05 % of Nb, less than or equal to 0.04 % of Ti and the balance iron and inevitable impurities. The heating temperature of a continuous casting blank is 1150-1300 DEG C, the initial rolling temperature is 1000-1150 DEG C, the final rolling temperature is greater than or equal to 880 DEG C, and the coiling temperature is 500-700 DEG C; the cold rolling reduction rate is 40 %-80 %; the annealing temperature is 760-880 DEG C, the annealing time is 10-600 s, the slow cooling outlet temperature is 660-760 DEG C, the rapid cooling rate is larger than 20 DEG C / s, the overaging temperature is 350-450 DEG C, and the overaging time is 30-3600 s; and the finishing elongation rate is 0.3 %-0.7 %. According to the steel and the method, the tensile strength of a steel sheet is 980-1100 MPa, the A <80> is 16 %-20 %, and the reaming performance is excellent.

Owner:ANGANG STEEL CO LTD

Method for extracting xylose from viscoce chemical fiber squeezed alkali liquor

InactiveCN104099431ASave resourcesReduce pollutionArtificial filament recoveryTextile/flexible product manufactureFiberHydrolysate

The invention relates to a method for extracting xylose from viscoce chemical fiber squeezed alkali liquor. According to the technical scheme, the method comprises the following steps: pre-filtering to obtain pre-concentrated liquor; filtering the pre-concentrated liquor through a nanofiltration membrane to obtain concentrated liquor; adding hydrochloric acid to the concentrated liquor to obtain hydrolysate; adding hydrolysate to NaOH until being neutral; decolorizing; regulating the concentration of NaCl; cooling at constant speed until reaching room temperature; enabling glucose in hydrolysate to cocrystallize with NaCl to remove glucose; treating filtrate through ion exchange columns to obtain purified liquor; crystallizing and purifying the purified liquor for the second time to obtain coarse xylose; refining the coarse xylose to obtain final xylose. With the adoption of the method, the resource is saved, the economic benefit is brought to enterprises, and the environment is protected.

Owner:沈阳新华环保技术有限公司

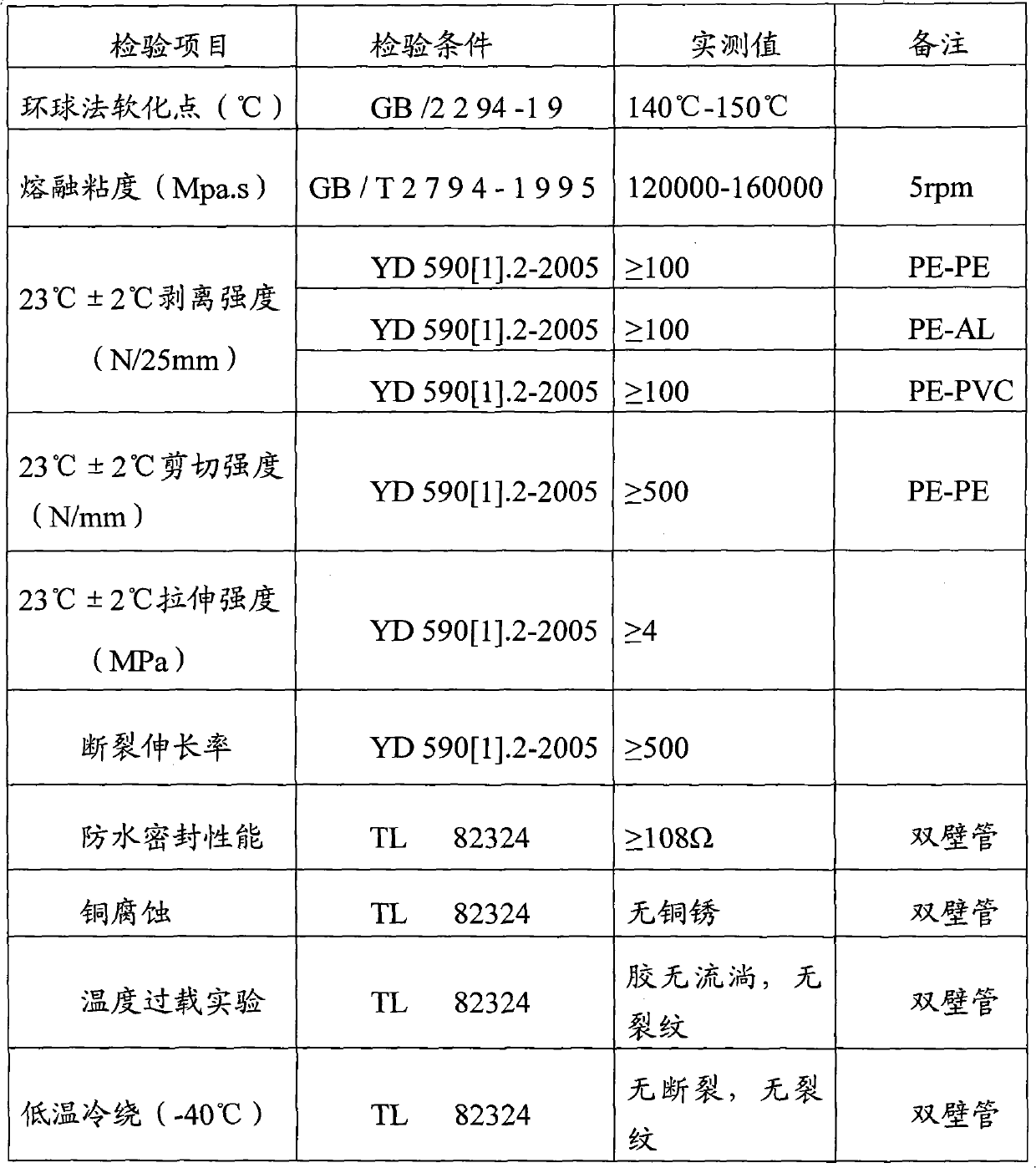

High temperature resistant hot melt adhesive and processing process thereof

The invention provides a formula of a high temperature resistant hot melt adhesive and a processing process of the hot melt adhesive. The formula comprises the following components: polyamide, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, a tackifier, an antioxidant and a modifier. The high temperature resistant hot melt adhesive is high in bonding strength, resistant to high temperature, excellent in insulating and sealing performance, resistant to a low temperature, environment-friendly, non-toxic, simple in production process and good in repeatability.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

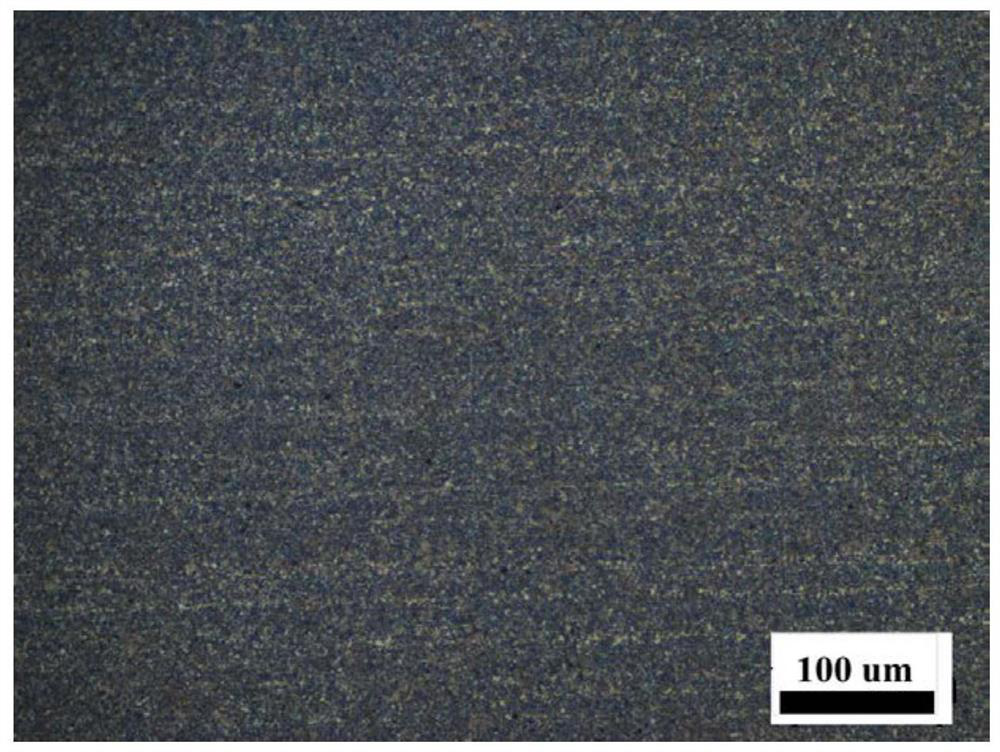

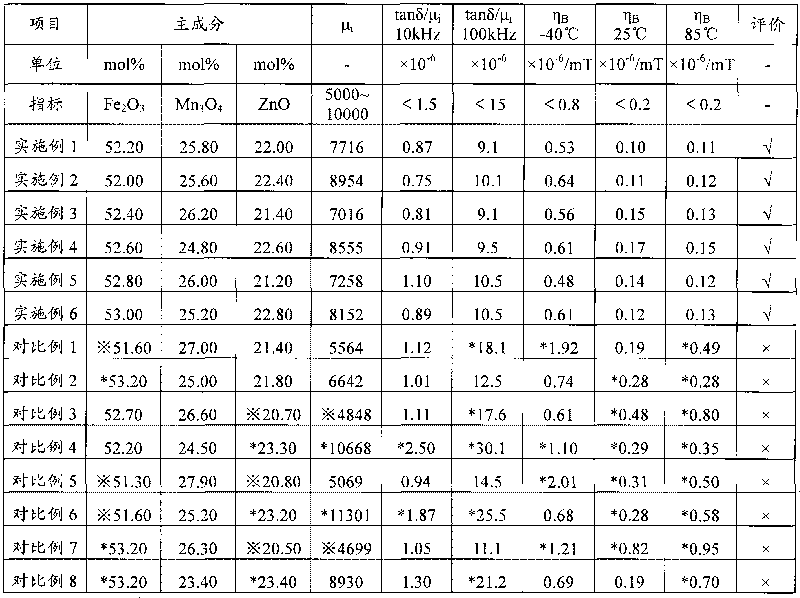

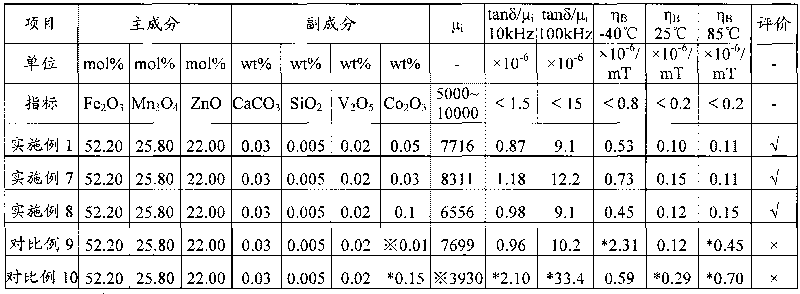

Wide-temperature low-distortion mangan zinc ferrite and preparation method thereof

ActiveCN101728048AReduce production energy consumptionBurn-in lowInorganic material magnetismLow distortionTransformer

The invention relates to a wide-temperature low-distortion mangan zinc ferrite applicable to a broadband network transformer and a preparation method thereof. The mangan zinc ferrite mainly comprises the following components: 52.0 to 53.0 mol percent of iron oxide computed by Fe2O3, 21.0 to 23.0 mol percent of zinc oxide computed by ZnO, and the balance of trimanganese tetroxide, and also comprises the following auxiliary components in percentage by weight (wt %) computed by respective standard substance CaCO3, SiO2, V2O5 and Co2O3: 0.03 to 0.04 of CaCO3, 0.005 to 0.01 of SiO2, 0.01 to 0.03 of V2O5 and 0.03 to 0.1 of Co2O3. The mangan zinc ferrite is prepared by an oxide method and sintered under the condition of bell-type furnace densification. A product has higher initial magnetic permeability mu i, low relative loss factor tan delta / mu i, and wide-temperature low-magnetic hysteresis coefficient eta B (-40 to 85 DEG C), is capable of reducing waveform distortion, reducing transmission errors and prolonging transmission distance in the process of transmitting signals, and meets the requirement of the application in outdoor severe environment.

Owner:TDG HLDG CO LTD

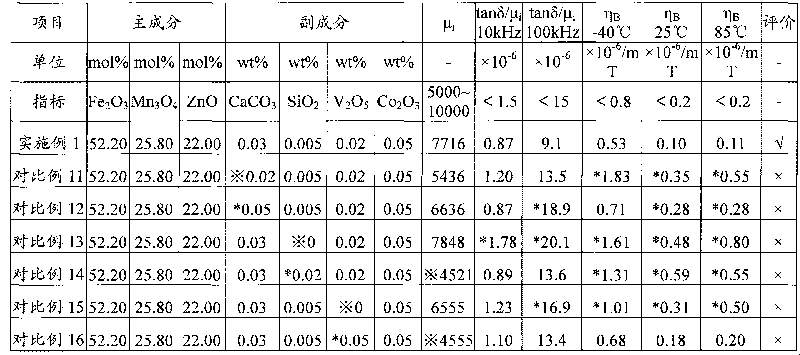

Recovering process of valent metal from crude bismuth

ActiveCN1800421AStable production processStrong raw material adaptabilityProcess efficiency improvementQuenchingSlag

The invention relates to a crude bismuth metal recovery technology which adopts wet process and pyrogenic process craft to recover the mental. It first dose water quenching, ball milling, extracting, scouring and filtering to the crude bismuth alloy to obtain the antimony lead skim and leaching solution; the antimony lead skim returns to the pyrogenic process system and then to the lead smelt system; it uses spongy copper to displace the Au and Ag of the leaching solution to produce the gold silver earth which returns to the noble metal smelting system; the liquid after displacing the gold silver earth dose hydrolytic precipitation bismuth and uses limestone and water to inactive it to pH=3-3.5, it filters the solution to obtain the bismuth oxide chloride and obtains the crude bismuth by smelting and then obtains the purified bismuth; it uses iron slag to displace the Cu to produce the spongy copper; adding limestone in the liquid after depositing Cu to inactive it and discharges it.

Owner:HENAN YUGUANG GOLD & LEAD

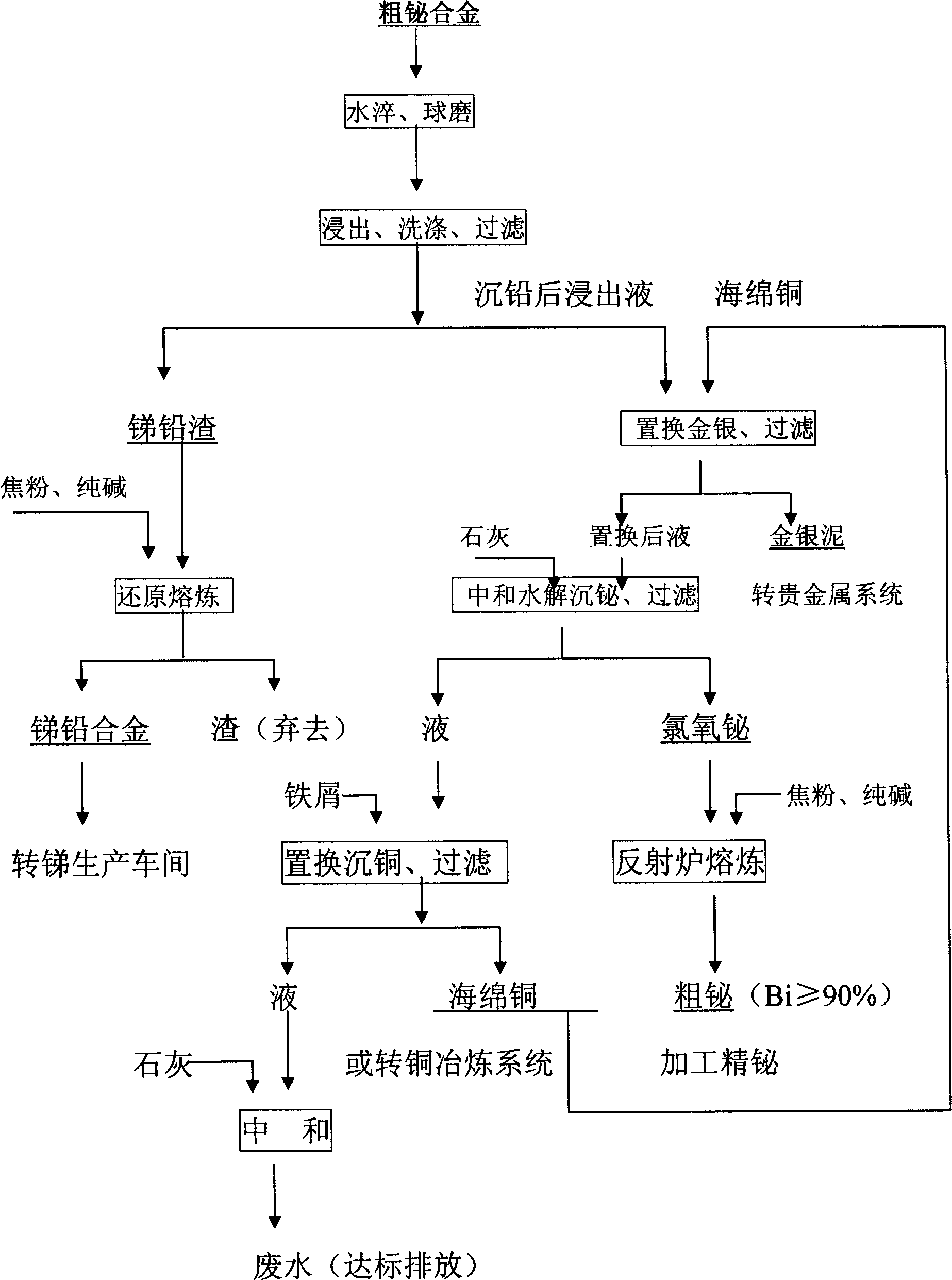

Samarium and cobalt sintered permanent magnet material and preparation method thereof

ActiveCN104637642ASpeed up coolingIntegrity guaranteedInorganic material magnetismCobaltCritical magnetic field

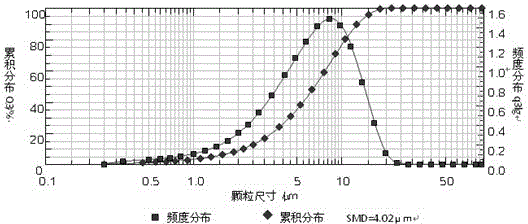

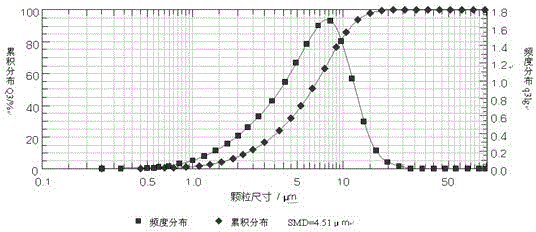

A samarium and cobalt sintered permanent magnet material comprises, in weight percent, 25-27%wt of samarium, 49-51%wt of cobalt, 5-6.5%wt of copper, 3-3.5%wt of zirconium and 15-18%wt of iron. A preparation method includes the steps: smelting; casting an ingot; absorbing hydrogen for the cast ingot; making powder; performing orientation forming and sintering. In the smelting process, the thickness of a casting mould cavity is decreased, cooling water is filled into the wall of the mould cavity, cooling of the cast ingot is accelerated, element composition segregation is decreased, the production process is stabilized, a dendrite crystal is restrained by adding a zirconium element, hydrogen absorbing is performed for the cast ingot in the smelting process, production steps are saved, and energy consumption is reduced. In the subsequent milling process, the cast ingot absorbed hydrogen is crystallized into particles, the particles fracture along crystal boundaries in the milling process of airflow, the integrality of crystal particles is ensured, the anisotropy of the crystal particles is improved, magnetic powder particles are obtained, particle size distribution is concentrated with the range of 3.5-4.5 micrometers, the sintering temperature needed by the magnetic powder particle of each point of a blank is the same in the later sintering process, the sizes of the sintered crystal particles are the same and uniform, and the performances, particularly, such as residual magnetism Br, maximum magnetic energy product (BH) max and critical magnetic field Hk of a sintered permanent magnet are improved.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS

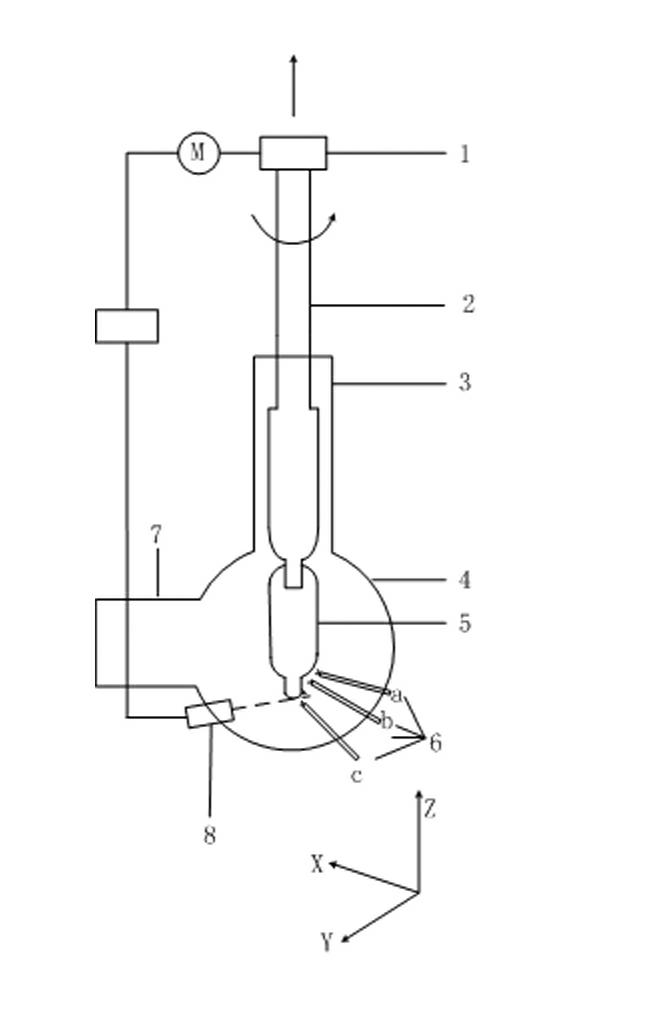

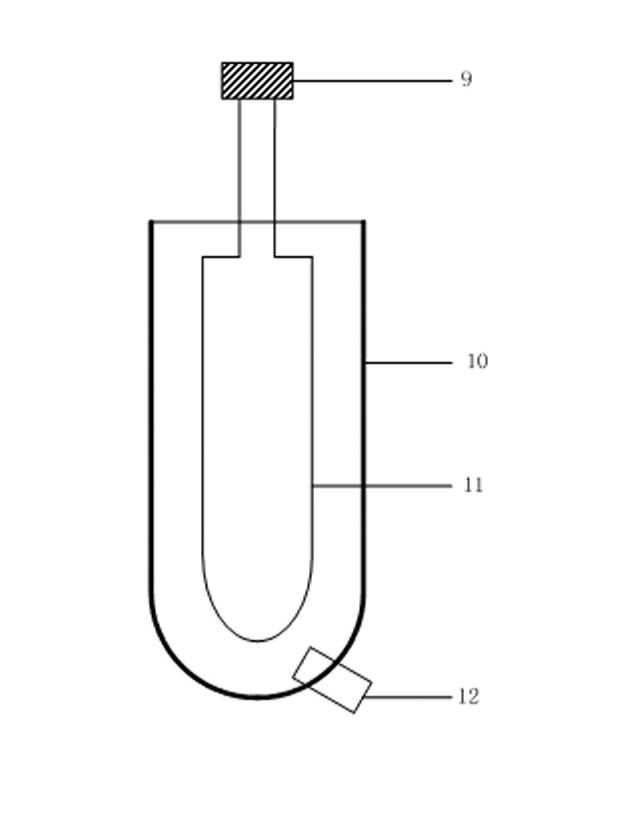

Method and equipment for manufacturing fully-synthesized oversize ultralow water peak optical fiber preform

ActiveCN102173572ASmall sizeLow water peakGlass deposition burnersGlass productionVitrificationFiber

The invention relates to a method and equipment for manufacturing a fully-synthesized oversize ultralow water peak fiber preform, in particular to a method for manufacturing an oversize ultralow water peak fiber preform. The method comprises the following steps of: firstly, adjusting the flow and the position of a blow lamp group so as to increase the core diameter under the condition that the diameter of a core raw material is unchanged; and then, respectively carrying out deuterium gas treatment before the vitrification process of a core powder rod and a porous glass preform. The equipment comprises a deposition device for the core raw material of the fiber preform and a sintering device for the core raw material of the fiber preform and the porous glass preform, wherein the deposition device for the core raw material of the fiber preform comprises a gas supply part, a rotary lifting part and a control part, and the rotary lifting part comprises a servo motor, a drive screw rod, a screw rod nut and a deposition boom; and the sintering device for the core raw material of the fiber preform and the porous glass preform comprises a sintering gas supply part, a preform rotary liftingpart and a sintering furnace.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD

Polyvinyl formal sponge material with uniform abscesses and rapid imbibition and preparation method thereof

ActiveCN102020816ASolution can not be reusedSolve the shortcomings of high closed cell rate and slow water absorption rate of the productPharmaceutical non-active ingredientsAbsorbent padsCross-linkLiquid waste

The invention discloses a polyvinyl formal sponge material with uniform abscesses and rapid imbibition and a preparation method thereof. The material comprises polyvinyl alcohol, a cross-linking agent, a catalyst and a pore-forming agent, wherein the cross-linking agent is formaldehyde or paraformaldehyde or formaldehyde solution. The preparation method comprises the following steps of: stirring 2-9 parts of polyvinyl alcohol in 100-200 parts of water of which the temperature is 60-98 DEG C to obtain solution, and adding 0.05-8 parts of pore-forming agent to the solution; fully emulsifying the pore-forming agent to form evenly dispersed continuous solution phase; then adding 1-26 parts of catalyst and 1-15 parts of cross-linking agent or 5-50 parts of recovered liquid waste, 1-8 parts of catalyst and 1-15 parts of cross-linking agent, and mixing; pouring the mixture into a mould after 1-60 min for cross-linking reaction for 0.1-2 hours to form the abscesses under the action of the pore-forming agent; and continuing to heat and cure for 2-18 hours to prepare the polyvinyl formal sponge material. The invention has the advantages of good hydrophily, high compression strength, high dry wetting rate, high imbibition ratio and the like.

Owner:克林纳奇(荆州)高分子科技有限公司

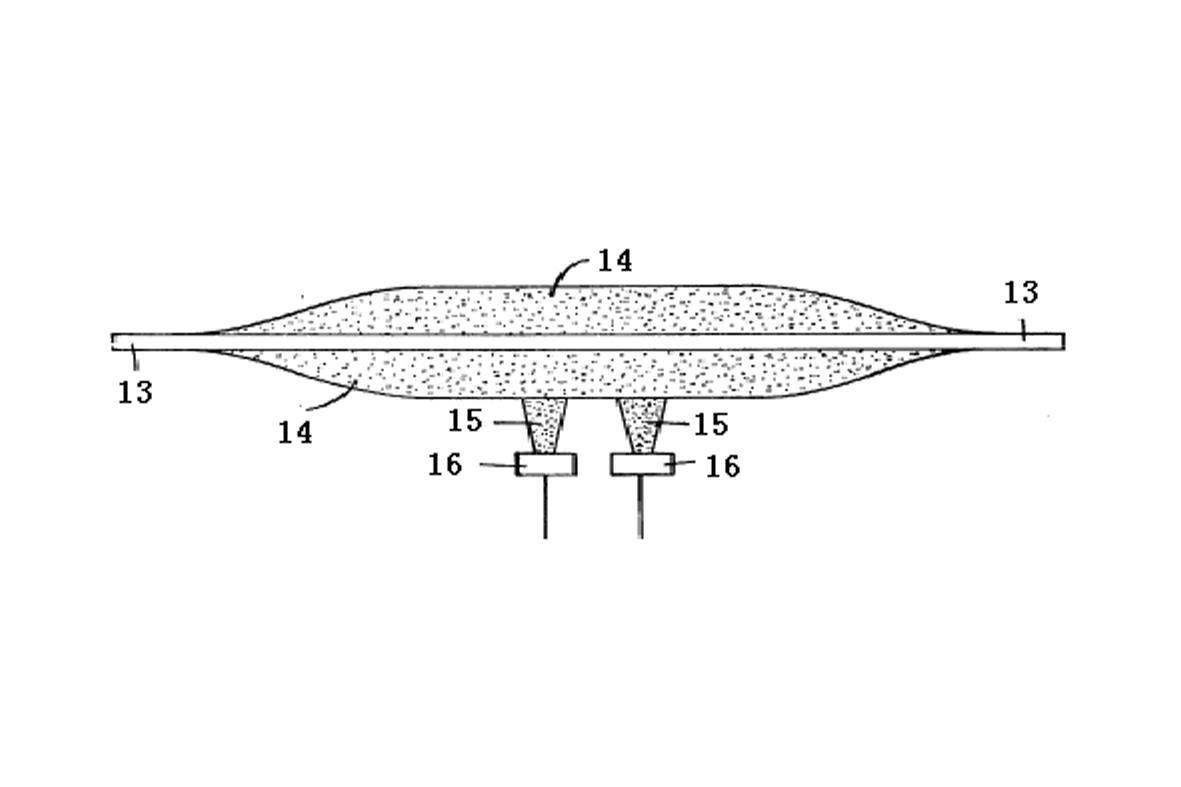

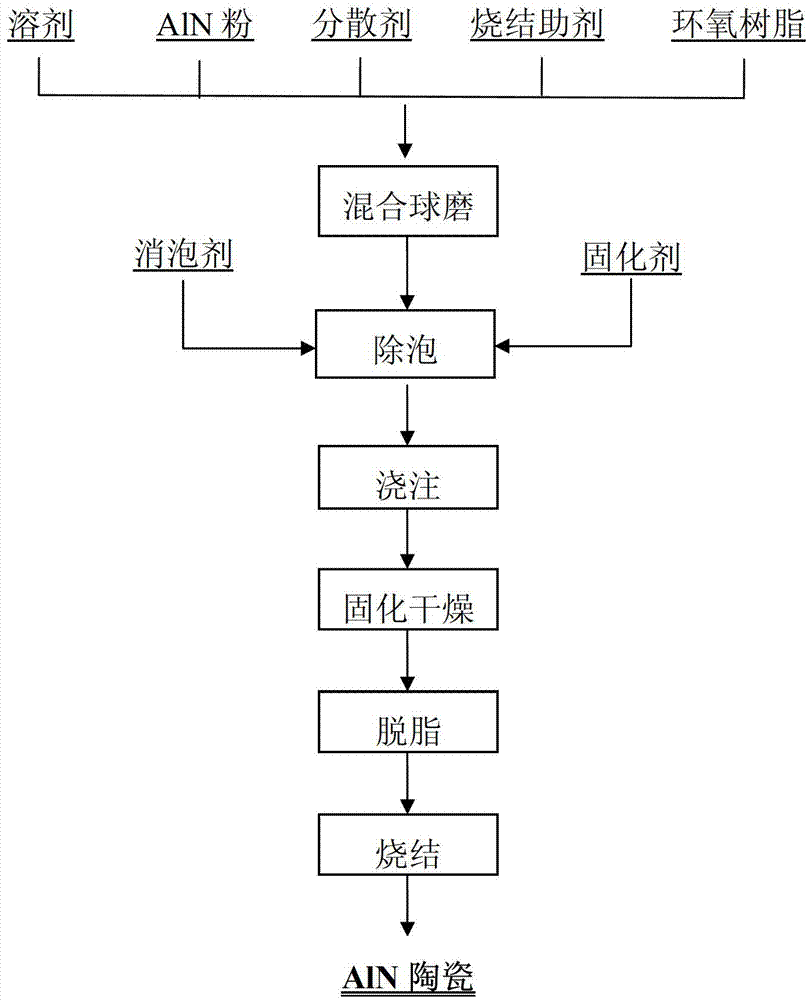

Preparation method of high-heat-conduction aluminum nitride ceramic shaped part

The invention discloses a preparation method of a high-heat-conduction aluminum nitride (AlN) ceramic shaped part. The preparation method is characterized in that aluminum nitride powder is used as a basic raw material, ethanol, propyl alcohol, butanol or other mixture is used as organic solvent, the basic raw material and the organic solvent are mixed with epoxy resin and dispersion agent to form pre-mixed solution, the pre-mixed solution is mixed and spherically ground into sizing agent, the sizing agent is uniformly mixed with solidifier after being vacuum degasified, and then shaped ceramic blank with large strength is formed through technique flows such as pouring molding, solidification, demolding, drying and the like; and an aluminum nitride ceramic shaped component with relative density being more than 97 percent, heat conductivity being more than 160W / m.K and tensile strength being more than 300Mpa is formed through degreasing, sintering and compacting. The method has advantages of simpleness in process, low production cost, good product performance and the like, and different aluminum nitride ceramic parts in different complicated shapes with high heat conduction performance can be prepared.

Owner:CENT SOUTH UNIV

Method for preparing live vaccines of hog cholera and product thereof

InactiveCN101879311ASmall batch-to-batch quality varianceStable production processInactivation/attenuationAntiviralsVaccine ProductionFreeze-drying

The invention discloses a method for preparing live vaccines of hog cholera and a product thereof. The preparation method comprises the following steps of: (1) culturing porcine passage cell lines; (2) inoculating the porcine passage cell lines with live vaccine production seed viruses of the hog cholera to obtain attenuated vaccine strains of the hog cholera; (3) performing virus multiplication on the attenuated vaccine strains of the hog cholera; (4) measuring the virus titer of multiplication virus suspension by adopting an immunofluorescence method; and (5) adding a freeze-drying protective agent and antibiotics into the virus suspension which is detected to be qualified for vaccine matching and freeze-drying. The preparation method has the advantages of producing the live vaccines of the hog cholera by using the cell lines so as to achieve small quality differences among batches and the characteristics of simple and stable process, easy operation, high yield, low cost, the feasibility and extendibility of industrial production and the like, and measuring the virus titer of the multiplication virus suspension by adopting the immunofluorescence method so as to achieve sensitive, fast, specific and accurate detection, high repeatability and reliable results. The live vaccines of the hog cholera prepared by the method can completely protect pigs from the attacks of violent hog cholera viruses.

Owner:武华

Low-compression ratio super-strength steel plate for ocean engineering and manufacturing method thereof

InactiveCN102691018AHigh strengthImprove plasticityHeat treatment process controlSolderabilityUltimate tensile strength

The invention discloses a low-compression ratio super-strength steel plate for ocean engineering and a manufacturing method thereof. The super-strength steel plate for ocean engineering comprises the following chemical components in percentage by weight: 0.04-0.07% of C, 0.10-0.30% of Si, 1.60-1.80% of Mn, less than or equal to 0.010% of P, less than or equal to 0.0080% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.90-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.40% of Cu, 0.40-0.60% of Mo, and the balance of Fe and inevitable impurities. The laboratory smelting, trial rolling on a rolling mill, TMCP (thermal mechanical control processing) technology and thermal refining are sequentially performed, thus the super strength, high toughness, weldability and manufacturability of the super-strength steel plate for ocean engineering are realized.

Owner:NANJING IRON & STEEL CO LTD

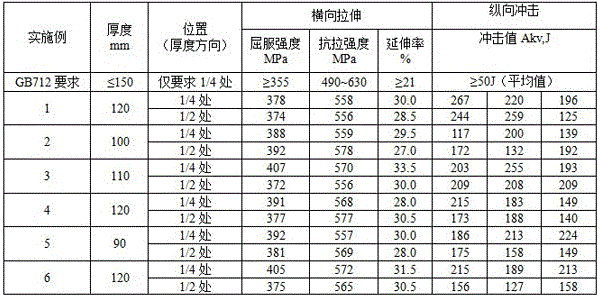

Super-thick EH36 steel for offshore wind power pipe pile and preparation method thereof

The invention relates to super-thick EH36 steel for an offshore wind power pipe pile. The super-thick EH36 steel for the offshore wind power pipe pile comprises the following chemical components in percentage by mass: .015 to 0.18 percent of C, 0.15 to 0.30 percent of Si, 1.40 to 1.60 percent of Mn, less than or equal to 0.0070 percent of P, less than or equal to 0.0030 percent of S, 0.050 to 0.070 percent of Nb, 0.015 to 0.030 percent of V, 0.08 to 0.020 percent of Ti, 0.030 to 0.050 percent of Al, 0.15 to 0.40 percent of Ni, 0.10 to 0.20 percent of Cr, and the balance of Fe. A production process flow comprises the following steps: performing converter operation, performing LF refining, performing vacuum degasifying, performing Ca treatment, performing continuous casting, dehydrogenizing, rolling, performing air cooling, performing high-temperature hot straightening, and normalizing. According to the production process flow, the super-thick EH36 steel of 90 to 120 mm for the offshore wind power pipe pile, which is high in unit weight, high in strength, high in impact toughness, small in thickness tolerance and high in straightness and does not have a surface defect is obtained.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

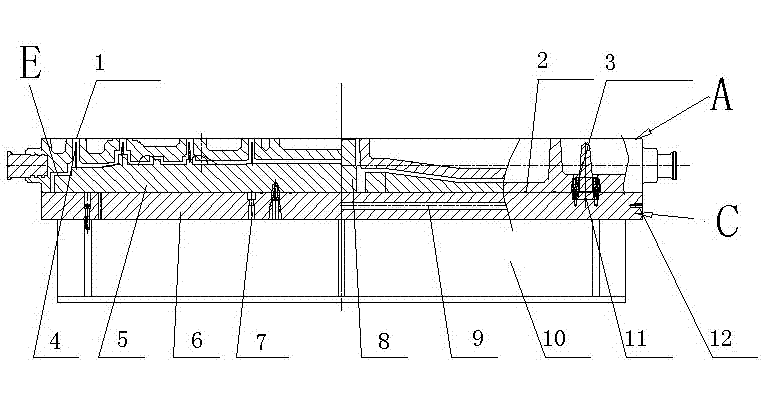

Device and production method for manufacturing automobile rear axle cast through metal mold with sand lining

ActiveCN102380586AHigh dimensional accuracyImprove surface qualityFoundry mouldsMoulding machinesTemperature controlMetallurgy

The invention discloses device and production method for manufacturing an automobile rear axle cast through the sand lining process of a metal mold. The device is characterized in that a mud core component is arranged in a mold cavity formed after an upper iron mold and a lower iron mold are assembled, positions of sand shooting holes of the upper iron mold and the lower iron mold are in one-to-one correspondence, gas needles are arranged on an upper mold plate, the gas needles and the sand shooting holes of the upper iron mold are in one-to-one correspondence, a plurality of heating pipes are respectively and uniformly distributed in mold plates of the upper mold plate and a lower mold plate, a temperature control meter of the heating pipes is connected with a temperature sensor, a plurality of exhaust bosses are further uniformly distributed on the peripheries of the mold plates of the upper mold plate and the lower mold plate, water-cooling bases are respectively arranged on the upper mold plate and the lower mold plate, and a plurality of exhaust grooves are arranged on the parting surface of the upper iron mold and the parting surface of the lower mold plate. The automobile rear axle cast manufactured by adopting the device and the method is good in quality, high in size precision, high in process yield, low in production cost, good in a working environment and low in energy consumption.

Owner:浙江省机电设计研究院有限公司

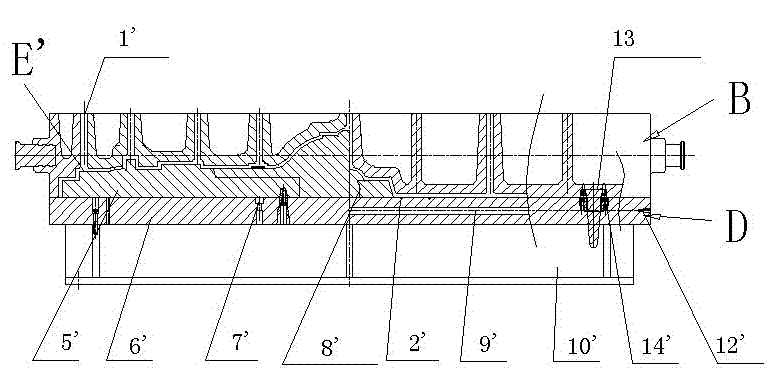

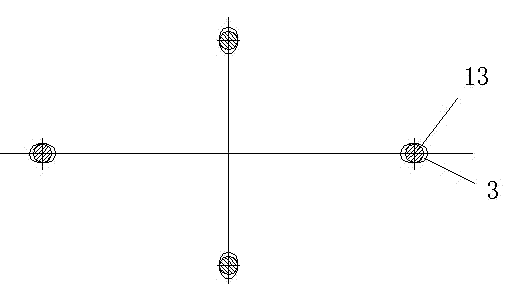

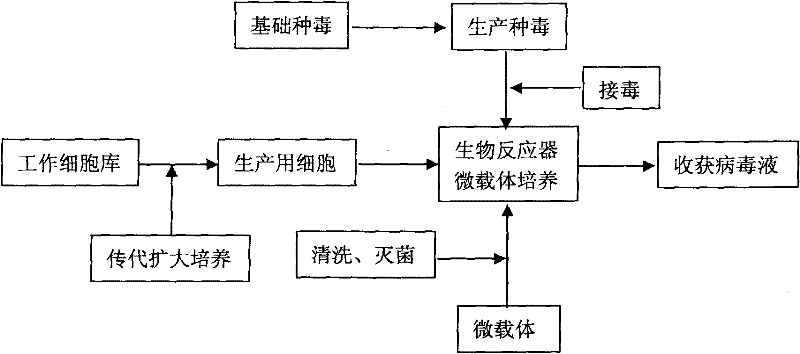

Method for production of porcine epidemic diarrhea virus

The invention discloses a technology for the production of porcine epidemic diarrhea virus by means of the microcarrier culture of VREO cells using a bioreactor, and comprises the technology for the production of different porcine epidemic diarrhea virus strains. The technology comprises the following technical steps: (1) selection of VERO cells as cell line for vaccine; (2) passage and culture of cells for vaccine; (3) propagation of seed culture of the porcine epidemic diarrhea virus; (4) microcarrier suspension culture of the VERO cells in the bioreactor; (5) propagation of porcine epidemic diarrhea virus antigen; and (6) treatment of acquired virus antigen liquid. The production method can remarkably lower production cost and enhance output-input ratio by 5 to 10 times, and has the advantages of short production period, small occupied space, great easiness for enlarging production scale rapidly, little environmental pollution, easy processing, high automation degree, a small number of staff, easy implementation of even and stable quality, obviously lowered production cost and enhanced yield and quality of vaccine.

Owner:成都史纪生物制药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com