Samarium and cobalt sintered permanent magnet material and preparation method thereof

A permanent magnet, samarium cobalt technology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the anisotropy and particle size distribution of easily damaged magnetic powder, increase equipment, energy consumption and production costs, affect the growth of columnar crystals, etc. problems, achieve the same and uniform grain size, improve various performances, and reduce the effect of element composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

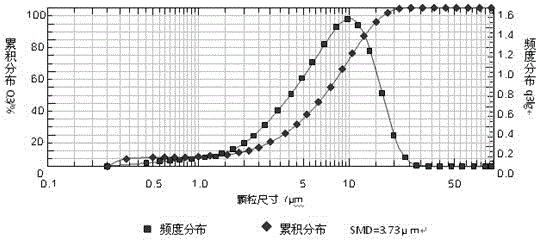

Embodiment 1

[0021] The raw materials were weighed according to the following weight fractions: samarium: 23.5%; cobalt: 51%; copper: 5%; zirconium: 3%; iron: 17.5%.

[0022] (1) Melting: Put the metal elements with the purity of Sm≥99.5%, Co≥99.6%, Cu≥99.7%, Zr≥99%, Fe≥99.8% in the crucible of the vacuum induction melting furnace, and evacuate to 5× 10 -2 Pa, filled with argon to 5×10 -2 Mpa, increase the power to gradually increase the melting temperature to 1500 ° C ~ 1600 ° C, refining under the protection of argon to obtain a uniform alloy melt;

[0023] (2) Ingot casting: After the smelting is complete, reduce the power of the smelting furnace, thereby reducing the temperature of the alloy solution to 1300-1400°C, and keep it for 2 minutes, then pour cooling water at 10°C-15°C into the cooling chamber of the ingot mold wall, Then the alloy melt is poured into an ingot cavity with a cavity thickness of 15 mm;

[0024] (3) Hydrogen absorption: 4.5 minutes after casting, at this time...

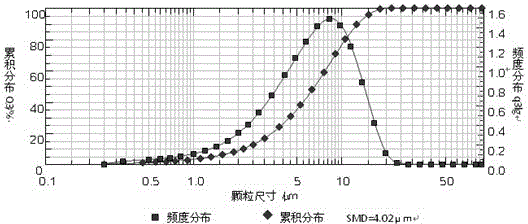

Embodiment 2

[0034] The raw materials were weighed according to the following weight fractions: samarium: 23.5%; cobalt: 51%; copper: 5.5%; zirconium: 3.2%; iron: 16.8%.

[0035] (1) Melting: Put the metal elements with the purity of Sm≥99.5%, Co≥99.6%, Cu≥99.7%, Zr≥99%, Fe≥99.8% in the crucible of the vacuum induction melting furnace, and evacuate to 5 ×10 -2 Pa, filled with argon to 5×10 -2 Mpa, increase the power to gradually increase the melting temperature to 1500 ° C ~ 1600 ° C, refining under the protection of argon to obtain a uniform alloy melt;

[0036] (2) Ingot casting: After the smelting is complete, reduce the temperature of the alloy solution in the melting furnace to 1300-1400°C and keep it for 2 minutes, then pour cooling water at 10°C-15°C into the cooling chamber of the ingot mold wall, and then put the alloy The melt is poured into an ingot cavity with a cavity thickness of 15mm;

[0037] (3) Hydrogen absorption: 5 minutes after casting, at this time, the alloy tempe...

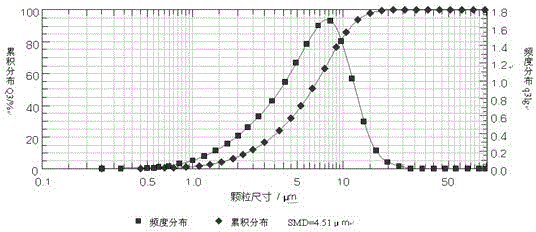

Embodiment 3

[0047] The raw materials were weighed according to the following weight fractions: samarium: 23.5%; cobalt: 51%; copper: 5%; zirconium: 3.5%; iron: 17%.

[0048] (1) Melting: Put the metal elements with the purity of Sm≥99.5%, Co≥99.6%, Cu≥99.7%, Zr≥99%, Fe≥99.8% in the crucible of the vacuum induction melting furnace, and evacuate to 5× 10 -2 When it is below Pa, fill it with argon to 5×10 -2 Mpa, increase the power to gradually increase the melting temperature to 1500 ° C ~ 1600 ° C, refining under the protection of argon to obtain a uniform alloy melt;

[0049] (2) Ingot casting: After the smelting is complete, reduce the power of the smelting furnace, thereby reducing the temperature of the alloy solution to 1300-1400°C, and keep it for 2 minutes, then pour cooling water at 10°C-15°C into the cooling chamber of the ingot mold wall, Then the alloy melt is poured into an ingot cavity with a cavity thickness of 15mm;

[0050] (3) Hydrogen absorption: 4.5 minutes after cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com