Water cooling jacket for titanium alloy tube ring seam by tungsten argon arc welding and seam following cooling welding method

A technology of argon tungsten arc welding and titanium alloy tube, applied in welding accessories and other directions, can solve the problems of poor protection effect and slow overall heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

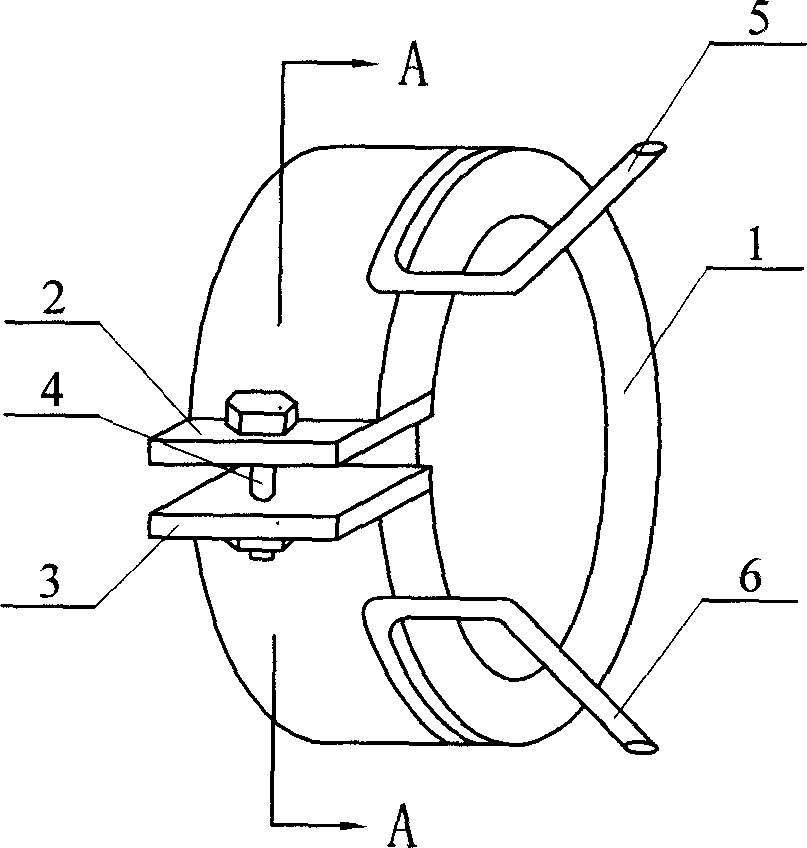

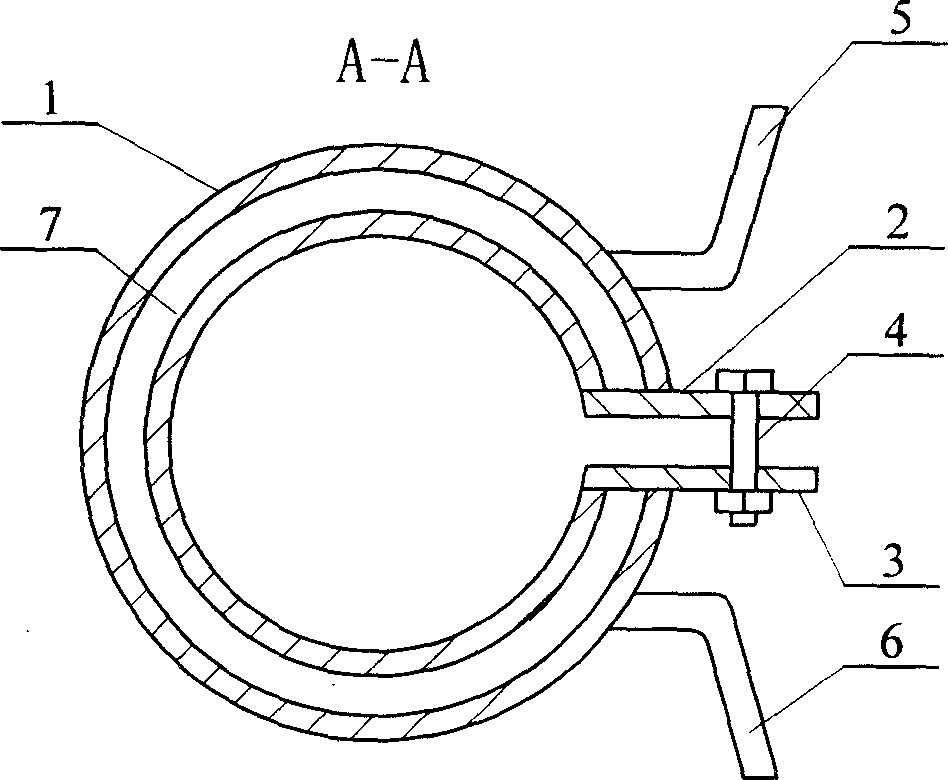

[0005] Specific implementation mode one: (see figure 1 , figure 2 ) The water cooling jacket used for titanium alloy pipe annular seam tungsten arc welding in this embodiment is composed of C-shaped sleeve 1, upper connecting plate 2, lower connecting plate 3, connecting bolt 4, water inlet pipe 5 and water outlet pipe 6; the upper connection One side plane of plate 2 is sealingly connected with the upper end of C-shaped sleeve 1, one side plane of lower connecting plate 3 is sealingly connected with the lower end of C-shaped sleeve 1, and the other side plane of upper connecting plate 2 is connected with lower connecting plate 3 The other side of the plane is provided with a connecting bolt 4, the water inlet pipe 5 is fixed on the upper end of the C-shaped sleeve 1, the outlet pipe 6 is fixed on the lower end of the C-shaped sleeve 1, and the water inlet pipe 5 and the water outlet pipe 6 are connected with the C-shaped sleeve respectively. The inner cavity 7 of the cartri...

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, the material of the C-shaped sleeve 1 is red copper. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

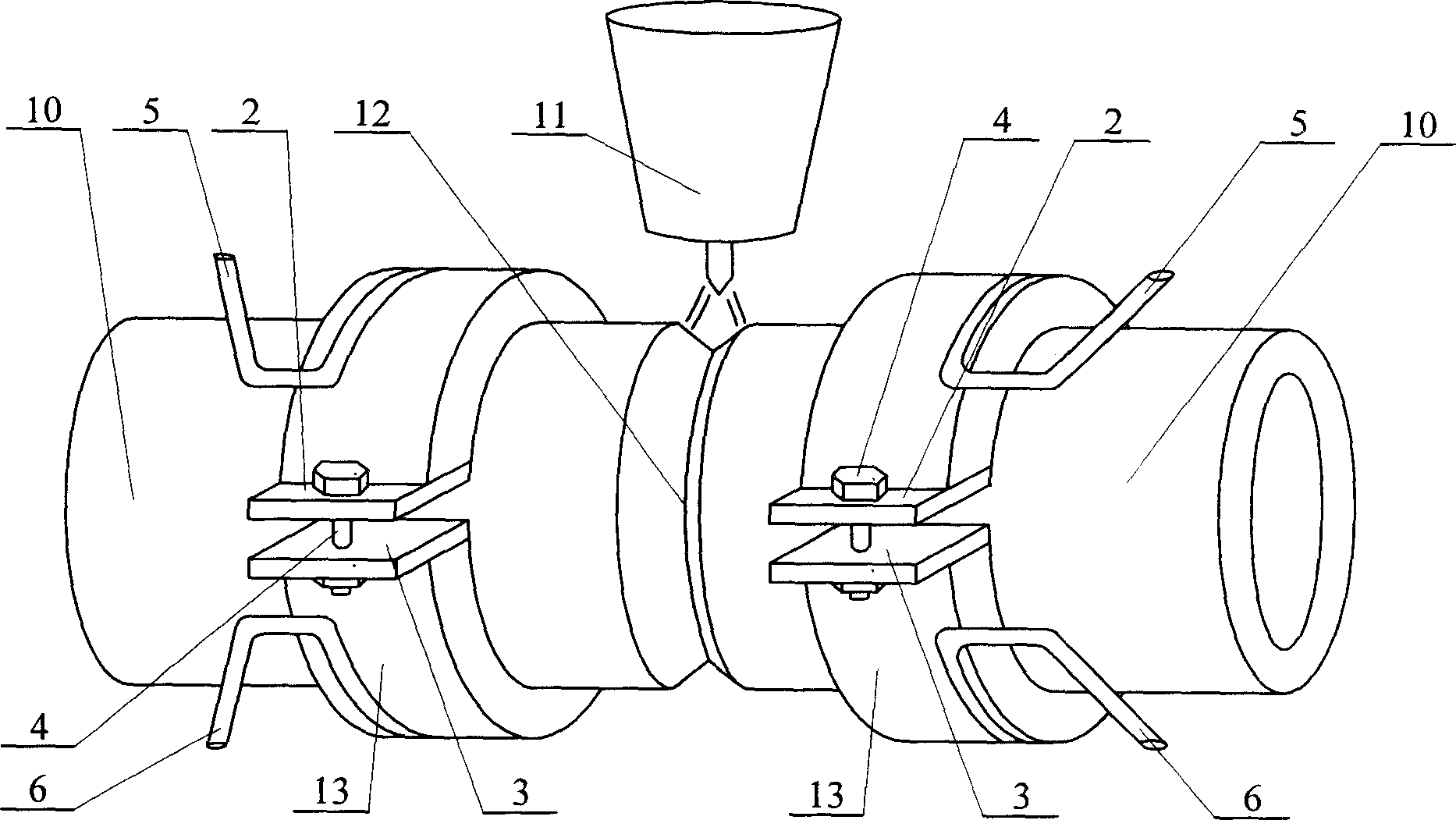

[0007] Specific implementation mode three: (see image 3 ) The cooling welding method of this embodiment is achieved in this way: first, put water-cooling jackets on two titanium alloy pipes respectively, fasten the water-cooling jackets to the titanium alloy pipes with connecting bolts, and then make the two titanium alloy pipes One end of the groove is butted with each other so that it can form a circular weld and can be welded. The distance between the two water cooling jackets is 10-50mm, the temperature of the circulating cooling water is equal to or lower than 30°C, the welding speed is 10-400mm / min, and the argon gas flow rate is 5-50L / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com