Method for casting rotary axis casts of aerogenerators

A technology of wind power generators and rotating shafts, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of increasing the production cost of casting products, increasing shrinkage cavities, shrinkage porosity, and slag inclusions, etc., and achieve reduction The effect of production cost, improvement of yield rate, and good slag blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

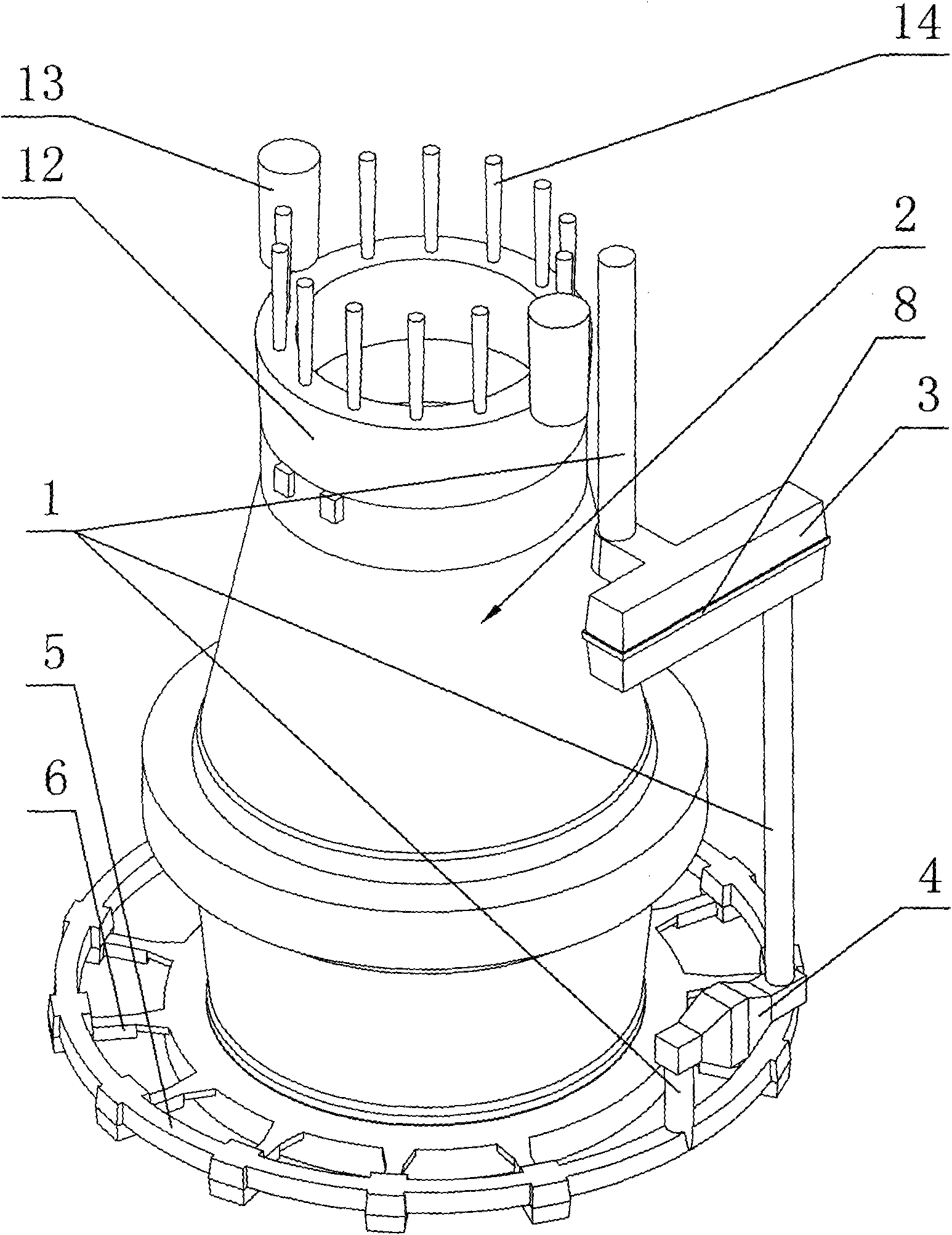

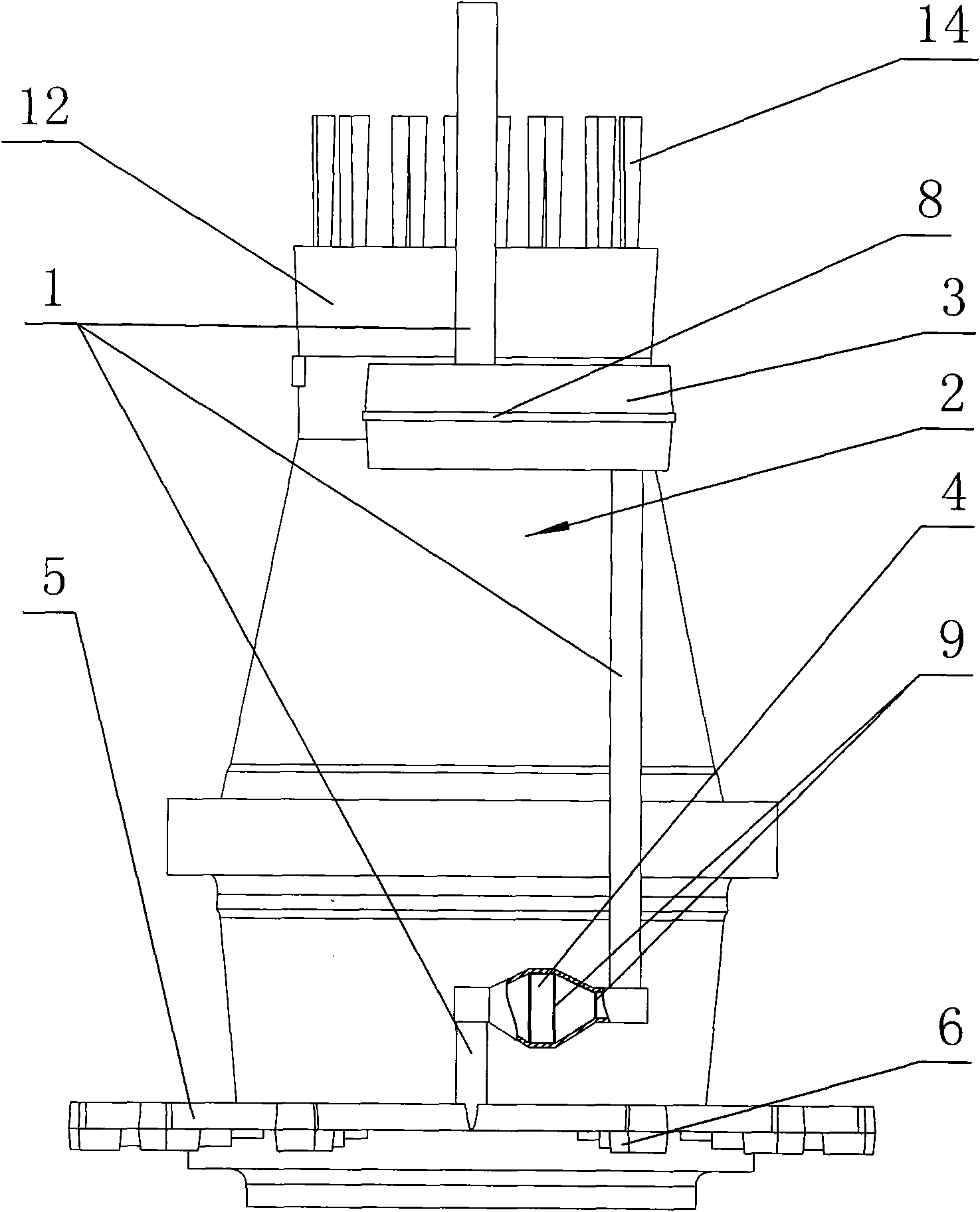

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the casting method of wind power generator rotating shaft casting of the present invention, it comprises the following steps: a, mold manufacture; b, sand mold manufacture; c, casting molding;

[0025] During the manufacturing of the sand mold in step b, the sprue 1 with the highest position is used as the molten iron inlet, the sprue 1 and the runner are alternately connected, the runner with the lowest position is connected with the ingate, and the ingate The channel communicates with the casting cavity.

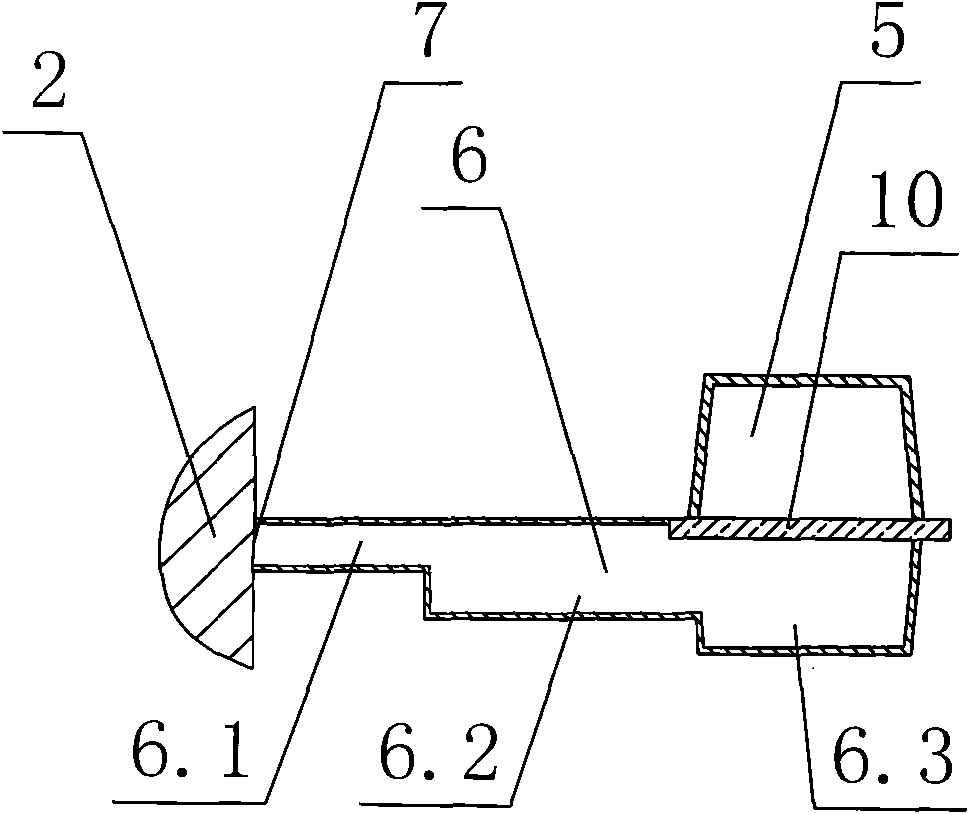

[0026] The runner is designed as the first runner 3 with the highest position, the second runner 4 in the middle and the annular runner 5 with the lowest position. The inner runners are designed as a plurality of radial runners 6 that are radially distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com