Method for improving liquid-state fluidity of TiAl-Nb alloy

A tial-nb and fluidity technology, which is applied in the field of improving the liquid fluidity of TiAl-Nb alloys, can solve the problems of niobium-aluminum segregation and uneven as-cast microstructure of the alloy, and achieves the reduction of aluminum segregation, shrinkage cavities, and uniform alloy composition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Select high-purity Ti, Al and Nb raw materials with a purity of 99.99%, and the proportioning composition is Ti 50 al 40 Nb 10 alloy.

[0019] (1) Use water-cooled copper crucible for electromagnetic induction levitation melting, first place niobium on the bottom of the copper crucible, place titanium along the inner wall of the copper crucible, place aluminum on the niobium and avoid contact with the copper crucible, adjust the power to 10kw to start melting, Keep it for 20s, then adjust it to 15kw until the metal is completely melted and suspended, then adjust the power to 20kw and keep it for 180s, and the ingot is smelted repeatedly for 4~5 times. Among them, the copper crucible adopts a copper crucible with a conical bottom;

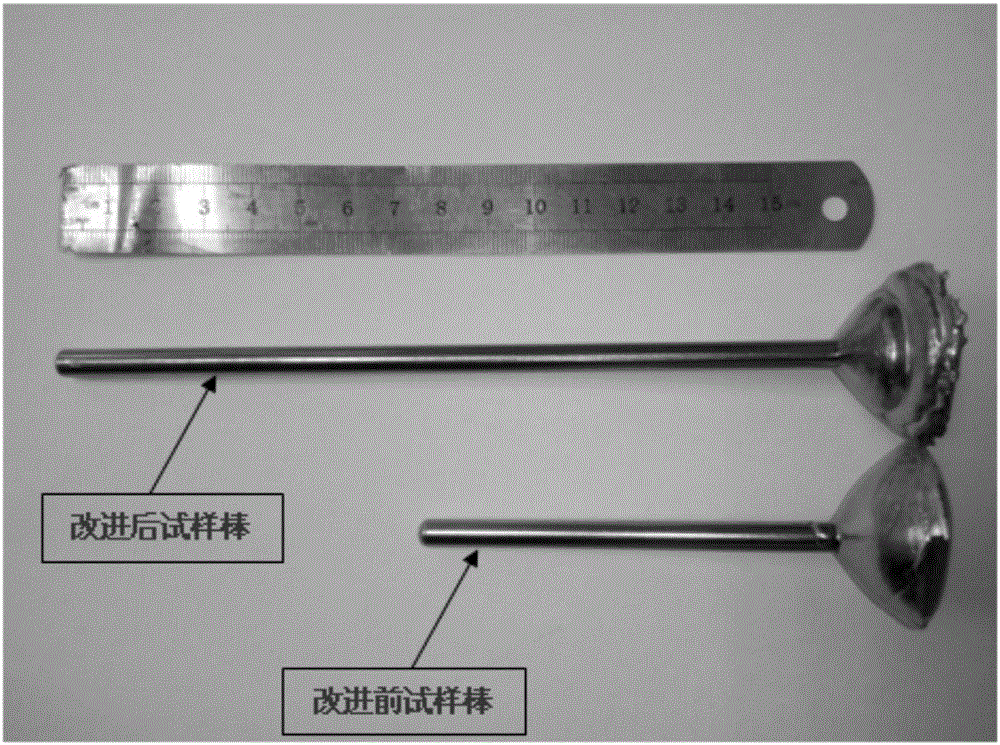

[0020] (2) Gravity casting of master alloy ingots in a vacuum non-consumable arc melting furnace: vacuumize to 10 -3 Below Pa, feed argon gas to 0.3MPa; turn on the power supply to start the arc, place the tungsten rod in the center of the...

Embodiment 2

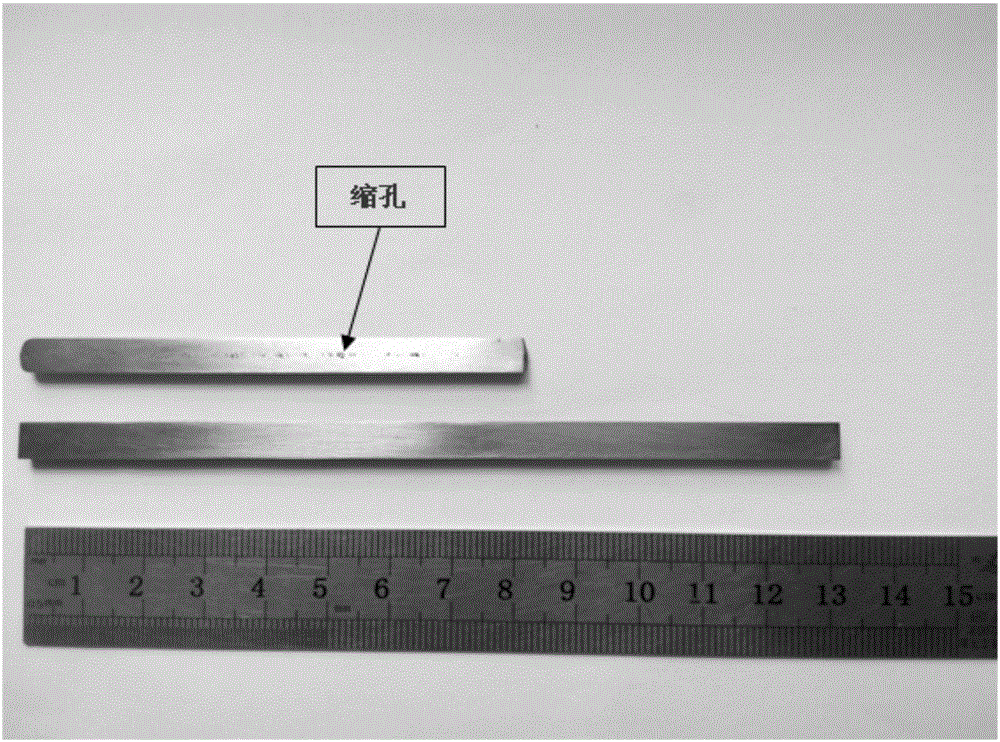

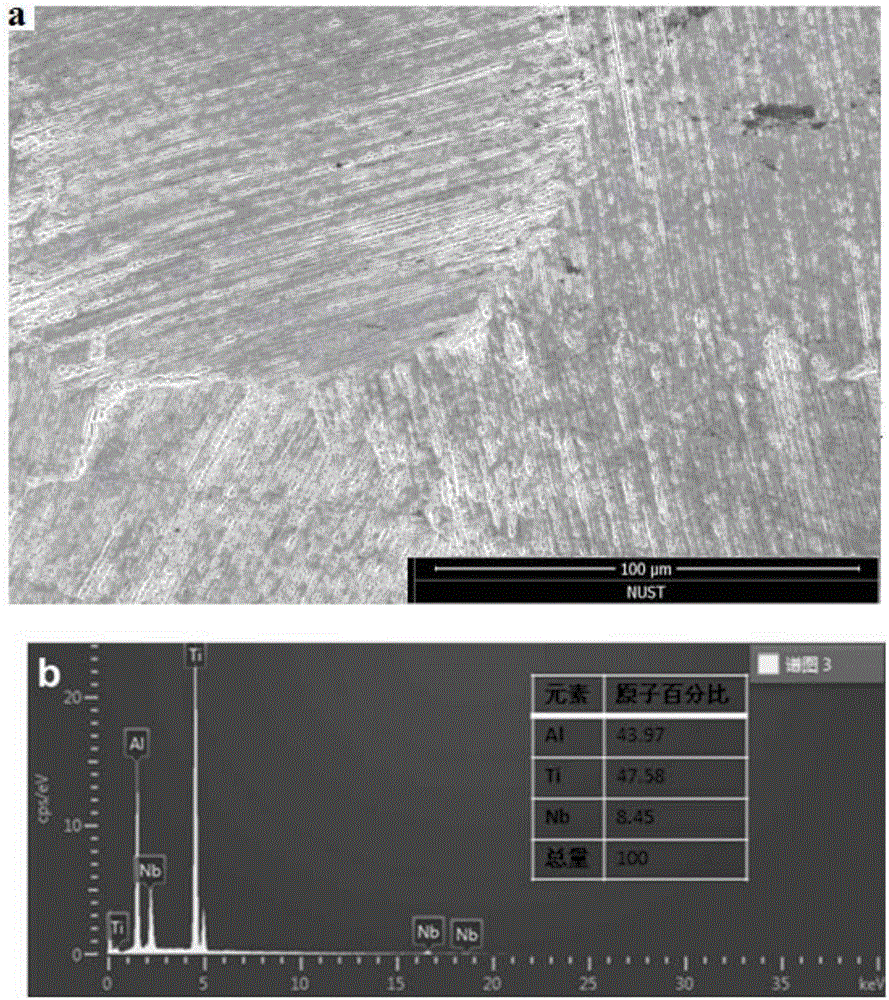

[0022] The composition is Ti 47 al 45 Nb 8 alloy. Other conditions are the same as embodiment 1, still can obtain the sample bar that does not have shrinkage cavity shrinkage defect, and the uniform length of composition reaches 15cm, as image 3 , Cut the sample bar in half to observe the microstructure and scan the surface, the actual composition of the alloy is accurately controlled within the error range.

Embodiment 3

[0024] The composition is Ti 45 al 50 Nb 5 alloy. Other conditions are the same as in Example 1, and a sample bar with no shrinkage cavity and porosity defects and a uniform length of 15 cm can still be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com