Ultraviolet light solidfication water polyurethane acrylate paint resin and its preparation method

A technology of polyurethane acrylate and ultraviolet light, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor water solubility, short storage stability period, and slow photocuring speed, and achieve good stability and good molecular structure control , Mature and stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

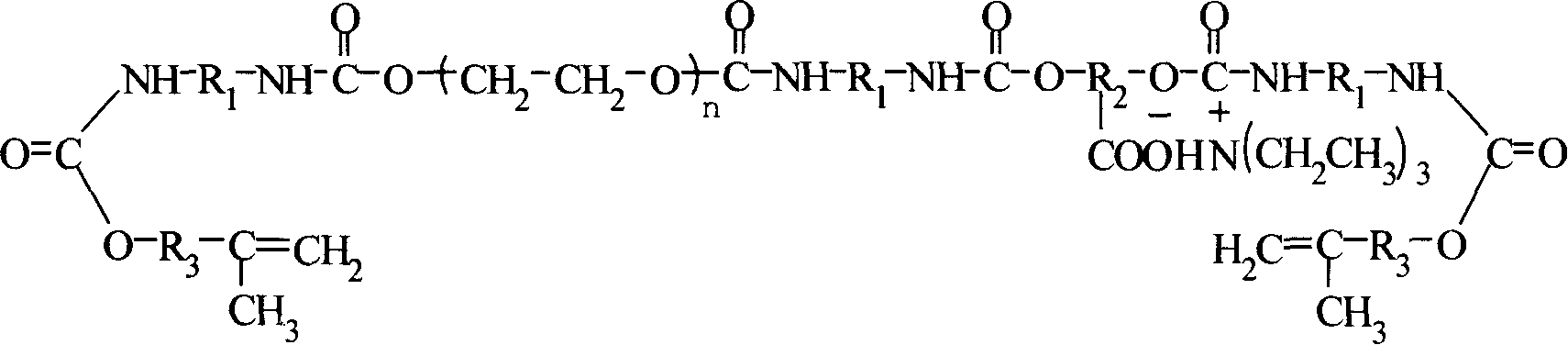

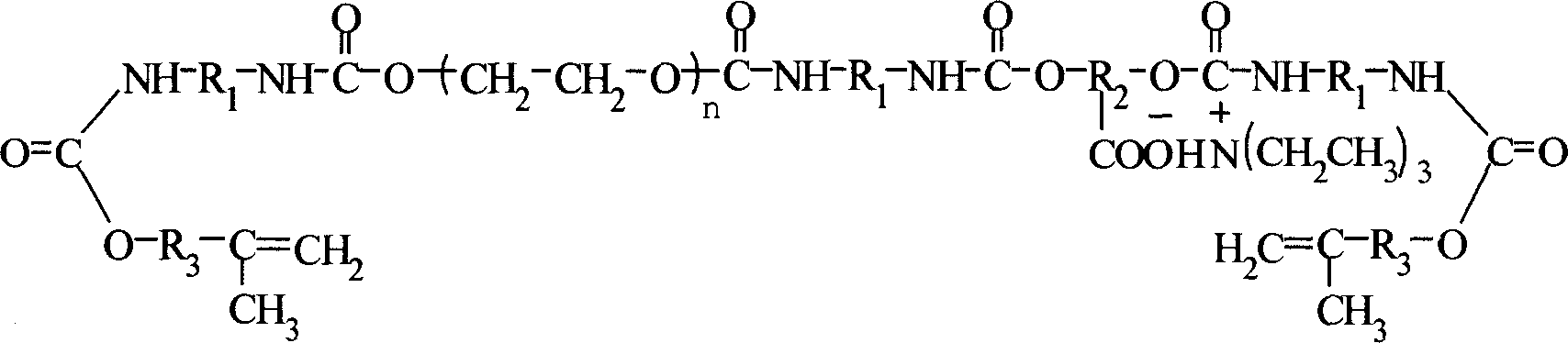

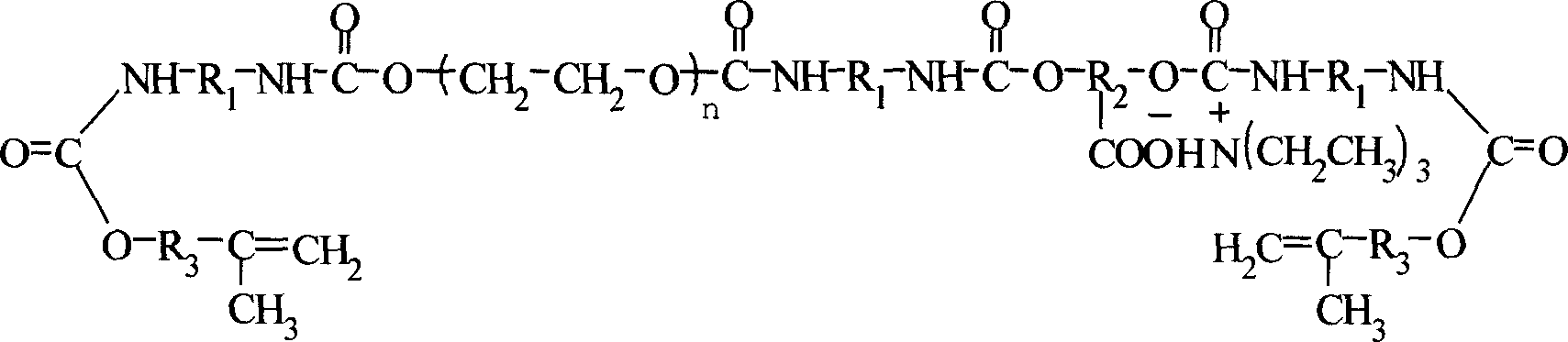

Image

Examples

Embodiment 1

[0032] Prepare UV-curable waterborne polyurethane acrylate coating resin as follows:

[0033] raw material

Dosage (% by weight)

2,4-Toluene diisocyanate

Polyethylene glycol (molecular weight 400)

1,4-Butanediol

41.0

24.8

14.2

4.4

4.9

10.7

[0034] The polymerization inhibitor (2,2,6,6-tetramethylpiperidinol-1-nitroxyl radical) is 0.001% of the total weight of the above raw materials, and an appropriate amount of acetone, water and dimethylformamide are also provided;

[0035]The molecular weight of polyethylene glycol is about 400, the carboxyl content is about 5%, and the double bond content is about 1%. The molar ratio is as follows: 2,4-toluene diisocyanate: polyethylene glycol: dimethylol propionic acid: 1 , 4-butanediol: hydroxyethyl methacrylate: triethylamine is about 3.6: 1.0: 1.7: 0.8: 0.6: 1.7;

...

Embodiment 2

[0045] Raw materials were prepared according to the following proportions, and then the UV-curable water-based polyurethane acrylate coating resin was prepared according to the same steps as in Example 1.

[0046] raw material

Dosage (% by weight)

Toluene diisocyanate (80 / 20)

Polyethylene glycol (molecular weight 600)

1,3-Butanediol

38.4

34.9

7.8

7.6

5.4

5.9

[0047] The polymerization inhibitor (2,2,6,6-tetramethylpiperidinol-1-nitroxyl radical) is 0.001% of the total weight of the above raw materials, and an appropriate amount of acetone, water and dimethylformamide are also provided;

[0048] The molecular weight of polyethylene glycol is about 600, the carboxyl content is about 3%, and the double bond content is about 1%. The molar ratio is as follows: toluene diisocyanate (80 / 20): polyethylene glycol: dimethy...

Embodiment 3

[0054] Raw materials were prepared according to the following proportions, and then the UV-curable water-based polyurethane acrylate coating resin was prepared according to the same steps as in Example 1.

[0055] raw material

Dosage (% by weight)

2,4-Toluene diisocyanate

28.9

Polyethylene glycol (molecular weight 1000)

1,4-Butanediol

43.8

5.9

2.0

14.9

4.5

[0056] The polymerization inhibitor (2,2,6,6-tetramethylpiperidinol-1-nitroxyl radical) is 0.002% of the total weight of the above raw materials, and an appropriate amount of acetone, water and dimethylformamide are also provided;

[0057] The molecular weight of polyethylene glycol is about 1000, the carboxyl content is about 3%, and the double bond content is about 3%. The molar ratio is as follows: 2,4-toluene diisocyanate: polyethylene glycol: dime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com