Preparation method of acrylate graft-modification waterborne polyurethane resin

A technology of water-based polyurethane and graft modification, applied in the direction of coating, etc., can solve the problems of poor water resistance, solvent resistance, chemical resistance, mechanical strength, poor resistance to organic solvents, and low softening point, and achieve molecular structure Good control, stable resin performance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

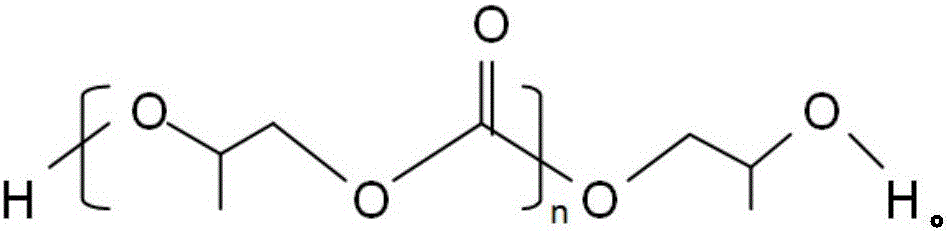

Image

Examples

Embodiment 1

[0031] Prepare acrylate grafting modified waterborne polyurethane resin according to the following steps:

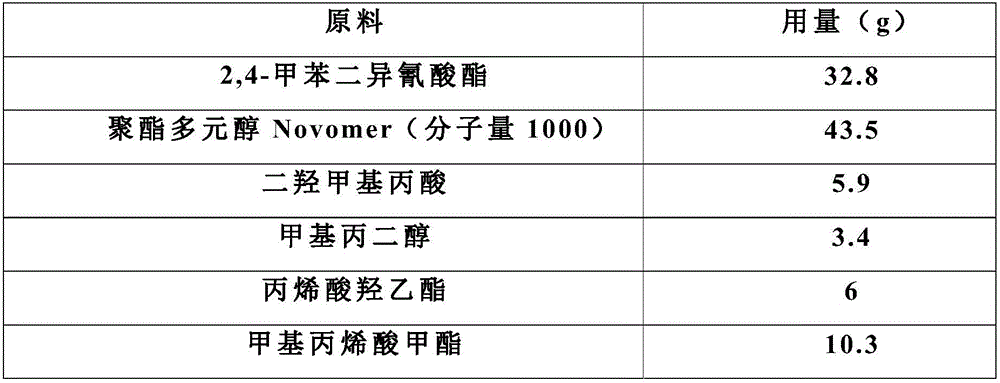

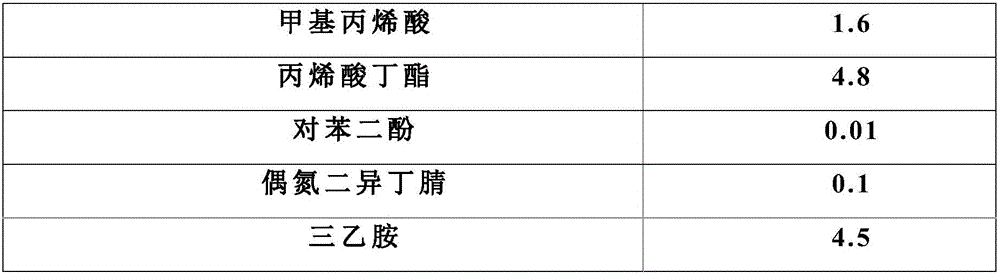

[0032] Equipped with raw materials:

[0033]

[0034]

[0035] Also equipped with appropriate amount of deionized water, acetone (diluent), N-methylpyrrolidone;

[0036] The molecular weight of polyester polyol Novomer is about 1000, the content of carboxyl group is about 5%, the content of hydroxyethyl acrylate is about 5.2%, the content of hydroquinone is about 0.001%, and the content of acrylic acid monomer is about 21%. The molar ratio is as follows : 2,4-Toluene diisocyanate: Polyester polyol Novomer: Dimethylolpropionic acid: Methylpropylene glycol: Hydroxyethyl acrylate: Triethylamine is about 3.8:1.0:1.0:0.6:1.2:1.0.

[0037] The appearance of the prepared resin is a milky white emulsion with blue light, the solid content is about 36%, the emulsion has good stability, the hardness is >3H, the adhesion is 0 grade, water resistance and aging resistance.

Embodiment 2

[0039] Prepare acrylate grafting modified waterborne polyurethane resin according to the following steps:

[0040] Equipped with raw materials:

[0041] raw material

Dosage (g)

Isophorone diisocyanate

33.6

Polyester polyol Novomer (molecular weight 1000)

43.5

5.2

5.5

0.1

2.6

8.7

3.3

0.9

Quinol

0.01

0.1

4.5

[0042] Also equipped with appropriate amount of deionized water, acetone (diluent), N-methylpyrrolidone;

[0043] The molecular weight of polyester polyol Novomer is about 1000, the content of carboxyl group is about 4.2%, the content of hydroxyethyl methacrylate is about 2.5%, the content of hydroquinone is about 0.001%, and the content of dibutyltin dilau...

Embodiment 3

[0047] Prepare acrylate grafting modified waterborne polyurethane resin according to the following steps:

[0048] Equipped with raw materials:

[0049] Also equipped with appropriate amount of deionized water, acetone (diluent), N-methylpyrrolidone;

[0050] The molecular weight of polyester polyol Novomer is about 2000, the content of carboxyl group is about 6%, the content of hydroxypropyl methacrylate is about 2.5%, the content of hydroquinone is about 0.001%, and the content of dibutyltin dilaurate is about 0.01%. The content of acrylic acid monomer is about 17%, and the molar ratio is as follows: Isophorone diisocyanate: Polyester polyol Novomer: Dimethylol propionic acid: 1,4-Butanediol: Hydroxypropyl methacrylate: Tri Ethylamine is about 3.8:1.0:1.0:0.6:1.2:1.0.

[0051] The appearance of the prepared resin is a milky white emulsion with blue light, the solid content is about 40%, the emulsion has good stability, the hardness is >3H, the adhesion is 0 grade, water re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com