Device and production method for manufacturing automobile rear axle cast through metal mold with sand lining

A technology for metal mold sand coating and automobile rear axle, which is applied in the direction of manufacturing tools, metal processing equipment, casting molds, etc. problems, to achieve the effect of fast solidification and cooling, less cleaning and grinding workload, and good production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

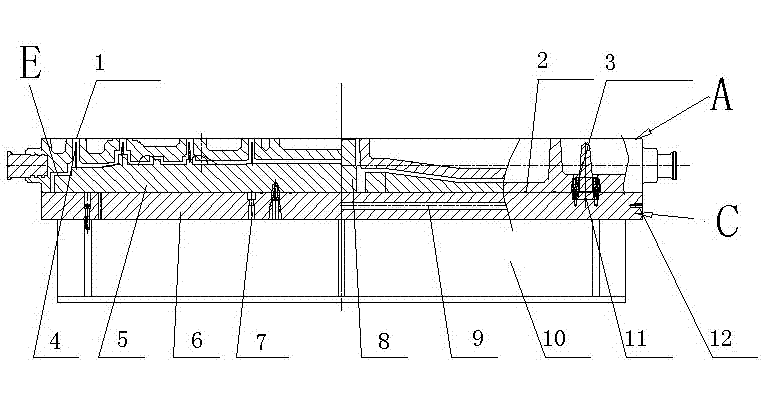

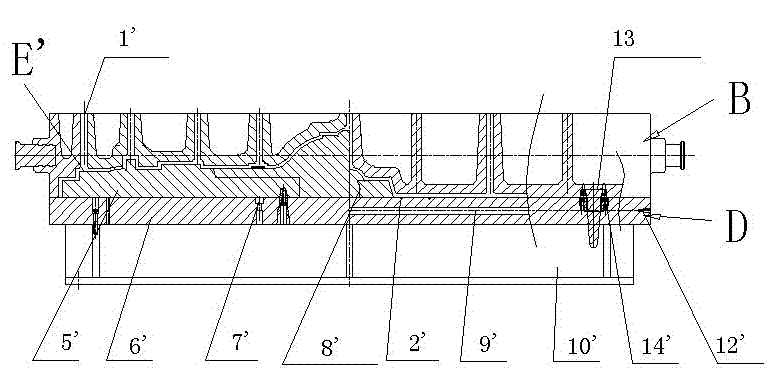

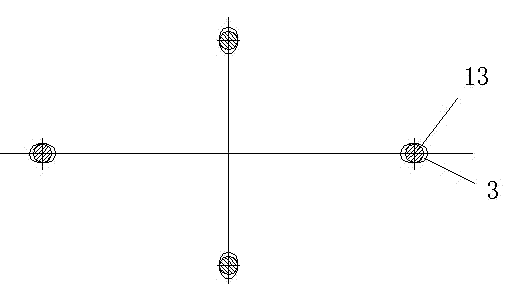

[0023] Sand-covered casting of metal molds for automotive rear axle castings mainly depends on cooling rate, solidification feeding and exhaust technology. These three technical elements all depend on the rationality of tooling design such as molds and iron molds and the correct production process control methods. The following problems are the main problems to be solved in the process design and actual production of the iron mold sand-coated casting process when producing the axle housing: 1. The wall thickness of the iron mold and the thickness of the sand-coated layer and the combination of the two to meet different wall thicknesses and different materials Different requirements for solidification and cooling of castings; 2. Determination of process parameters, such as pouring system, sand injection system, exhaust system, etc.; 3. Realization of mass production, such as design and finalization of production line and sand-coated main and auxiliary machines; 4 , The formulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com