Processing method for aluminium alloy middle thick plate

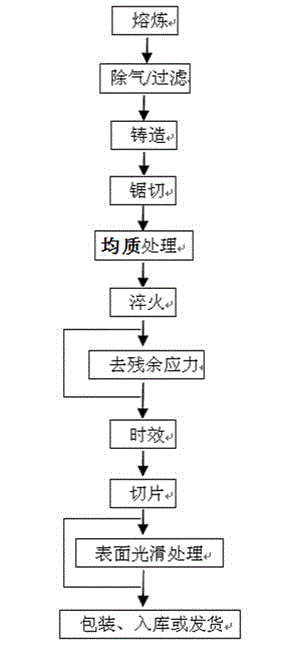

A processing method and technology of aluminum alloy, applied in the field of aluminum alloy medium and thick plate, can solve the problems such as the surface deformation of the rolled plate is larger than that of the core, the uneven structure of the plate in the height direction, and the size of the tool and die are unstable, and the preparation process can be achieved. The effect of reduction, uniformity and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] According to Si 0.2 Kg; Mg 0.5 Kg; Cu 1.0 Kg; Cr 0.22 Kg; Fe 0.1kg; Zn 0.3Kg; , then heat the material to 600-1000 ° C, keep the material in a molten state for 1-10 hours, filter to remove the insoluble matter in the aluminum melt, cool to room temperature, and obtain an aluminum alloy ingot, and saw the aluminum alloy ingot into 6mm thickness plate; keep the plate at 480°C for 4 hours, and then immediately quench the plate by spraying, and control the cooling rate of the plate to about 10°C / s; pre-stretch the quenched plate, and then heat it at 130°C The plate is subjected to aging treatment for 20 hours, and the aged plate is cut into a certain thickness, and then the surface is smoothed by milling and grinding methods to obtain aluminum alloy medium and thick plates, which are packaged and put into storage.

[0040] In the smelting, argon gas is introduced for refining, and electromagnetic stirring is applied.

Embodiment 2

[0042] According to Si 0.6 Kg; Mg 0.9 Kg; Cu 0.8 Kg; Cr 0.09 Kg; Mn 0.1kg; Zn 0.05Kg; Ti 0.05 Kg; V 0.02 Kg; , then heat the material to 600-1000 ° C, keep the material in a molten state for 1-10 hours, filter to remove the insoluble matter in the aluminum melt, cool to room temperature, and obtain an aluminum alloy ingot, and saw the aluminum alloy ingot to a thickness of 20mm plate; keep the plate at 520°C for 3 hours, and then immediately quench the plate by spraying, and control the cooling rate of the plate to be about 8°C / s; pre-stretch the quenched plate, and then The plate is subjected to aging treatment for 15 hours, and the aged plate is cut into a certain thickness, and then the surface is smoothed by milling and grinding methods to obtain aluminum alloy medium and thick plates, which are packaged and put into storage.

[0043] In the smelting, argon gas is introduced for refining, and electromagnetic stirring is applied.

Embodiment 3

[0045] According to Si 0.8 Kg; Mg 1.2 Kg; Cu 0.6 Kg; Cr 0.02 Kg; Mn 1.0kg; Fe 0.3Kg; Ti 0.12 Kg; to 600-1000°C, keep the material in a molten state for 1-10 hours, filter to remove the insoluble matter in the aluminum melt, cool to room temperature, and obtain an aluminum alloy ingot, and saw the aluminum alloy ingot into a plate with a thickness of 50mm; The plate is kept at 550°C for 2 hours, and then the plate is immediately quenched by spraying, and the cooling rate of the plate is controlled to be about 6°C / s; the quenched plate is pre-stretched, and then the plate is subjected to 3 hours at 220°C After the aging treatment, the aging-treated plate is cut into a certain thickness, and then the surface is smoothed by milling and grinding methods to obtain aluminum alloy medium and thick plates, which are packaged and put into storage.

[0046] In the smelting, argon gas is introduced for refining, and electromagnetic stirring is applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com