High temperature resistant hot melt adhesive and processing process thereof

A technology of warming and melting glue, applied in the direction of adhesives, etc., can solve problems such as complex production process, achieve the effects of simple production process, avoid product purification, and good prospects for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

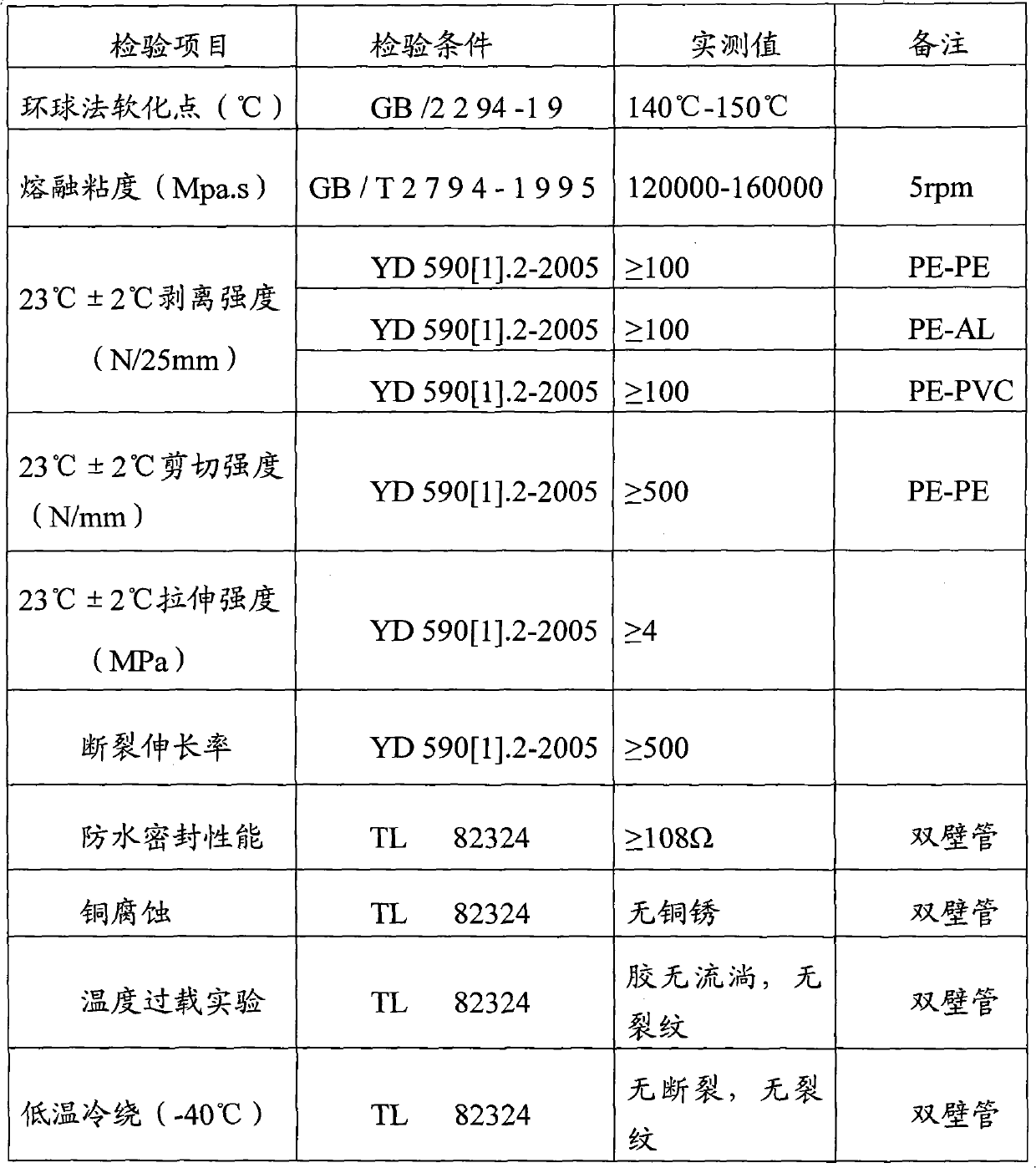

[0049]Example 1: High melting point dimer acid type polyamide resin (softening point 156°C) 40g, ethylene vinyl acetate (EVA210) 20g, ethylene vinyl acetate (EVA150) 10g, ethylene vinyl acetate (EVA930) 10g, terpene Resin, antioxidant 10101g, antioxidant 10981g, antioxidant 8020.5g, polyethylene wax 0.5g, add to twin-screw extruder for mixing, mixing temperature is 120°C, mixing twice, using circulating water The high-melting point polyamide hot-melt adhesive product was obtained by cooling hob dicing. The softening point of this product was 142°C and the viscosity was 144000mpa.s.

Embodiment 2

[0050] Embodiment two: high melting point dimer acid type polyamide resin (softening point 156 ℃) 35g, ethylene ethyl acrylate (EEA) 15g, ethylene vinyl acetate (EVA930) 10g, terpene resin 30g, ethylene vinyl acetate (EVA210 ) 7g, antioxidant 10101g, antioxidant 10981g, antioxidant 8020.5g, polyethylene wax 0.5g, PA150 and EEA897 were first mixed in the internal mixer, and then all materials were added to the twin-screw extruder for Mixing, the mixing temperature is 120 °C, mixing twice, using circulating water to cool the hob and pelletizing to obtain a high melting point polyamide hot melt adhesive product, the softening point of this product is 145 °C, and the viscosity is 154000mpa.s.

Embodiment 3

[0051] Example 3: 50 g of high melting point dimer acid type polyamide resin (softening point 146° C.), 20 g of ethylene vinyl acetate (trade name EVA220, purchased from Mitsui Corporation, Japan), 10 g of ethylene vinyl acetate (EVA150,), terpene 17g of resin, 10101g of antioxidant, 10981g of antioxidant, 8020.5g of antioxidant, and 0.5g of polyethylene wax were added to the twin-screw extruder for mixing. The mixing temperature was 120°C. The high-melting point polyamide hot-melt adhesive product is obtained by water-cooling hob cutting pelletization. The softening point of this product is 149°C and the viscosity is 156000mpa.s.

[0052] The embodiment of the present invention also provides a processing technology of high temperature resistant hot melt adhesive, which includes the steps of:

[0053] A, the preparation step of material: according to the formula described in above-mentioned each embodiment, weigh the material of each component;

[0054] B. Premixing step: for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com