Low-compression ratio super-strength steel plate for ocean engineering and manufacturing method thereof

An ultra-high-strength, marine engineering technology, applied in the field of metallurgy, can solve the problems of low strength and achieve the effects of increased tensile strength, strong operability, and excellent low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

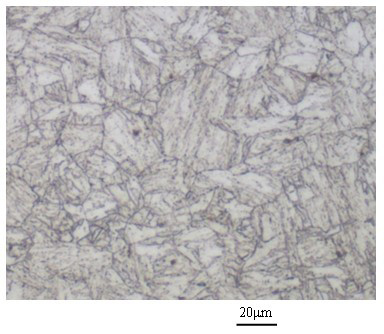

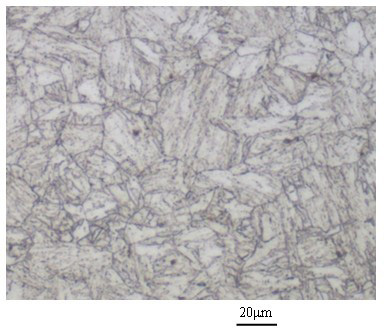

Image

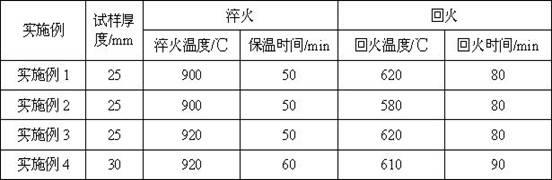

Examples

Embodiment Construction

[0033] A low-compression ratio ultra-high-strength steel plate for marine engineering according to the present invention, the chemical composition of the steel in the steel plate is calculated by weight percentage, C: 0.04-0.07%, Si: 0.10-0.30%, Mn: 1.60-1.80% , P: ≤0.010%, S: ≤0.0080%, Nb: 0.030~0.050%, V: 0.020~0.060%, Ti: 0.006~0.015%, Ni: 0.90~1.30%, Cr: 0.30~0.60%, Cu: 0.20-0.40%, Mo: 0.40-0.60%, the balance is Fe and unavoidable impurities.

[0034] According to the production process of the present invention, the actual chemical composition of the smelting and rolling steel of the present invention is shown in Table 1.

[0035] Table 1 Chemical composition (wt%) of the embodiment of the present invention

[0036] Example C Si mn P S Nb Ti Ni Cr Cu Mo V Example 1 0.065 0.22 1.76 0.0078 0.0075 0.040 0.012 1.00 0.31 0.31 0.49 0.032 Example 2 0.055 0.25 1.69 0.0080 0.0069 0.036 0.011 1.20 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com