Manufacturing method of resin diamond wire

A technology of resin diamond wire and manufacturing method, which is applied in the direction of fine working devices, manufacturing tools, metal sawing equipment, etc., can solve the problem that it takes a long time for the adhesive to harden, and achieves short half-hardening time, advanced technology, The effect of stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

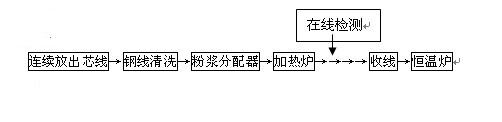

[0043] As shown in the figure, the process flow diagram of the present invention shows that the steps include continuous release of the core wire, cleaning of the steel wire, slurry distributor, semi-hardening treatment in the heating furnace, take-up of the qualified wire, and curing and setting in the constant temperature furnace.

[0044] The first step is to prepare emery resin liquid, including: emery after metal (Ni, Ti or Cu, etc.) Paste in methyl formamide, the components are calculated by weight percentage: 5-30 wt% of corundum with nickel coating (coating amount is 1-55 wt%), resin binder is resole phenolic resin (resole resin), (C 6 h 6 O??CH 2 O) x )5~30wt%, SiC5~20wt%, organic solvent N,N-dimethylformamide ((CH 3 )2NCHO) 5-25wt%, put each component into a container, stir with a mixer, dissolve the powdered resole phenolic resin in an organic solution, and mix emery and SIC to obtain a paste emery resin liquid, which is injected into the mold. The embodiment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com