Patents

Literature

66results about How to "Short hardening time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymethylmethacrylate waterproof paint and preparation method thereof

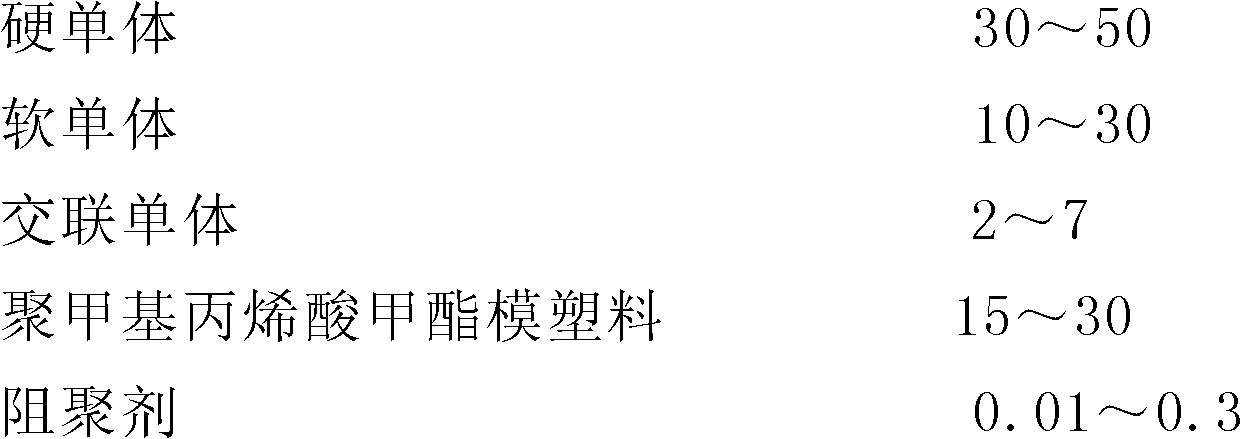

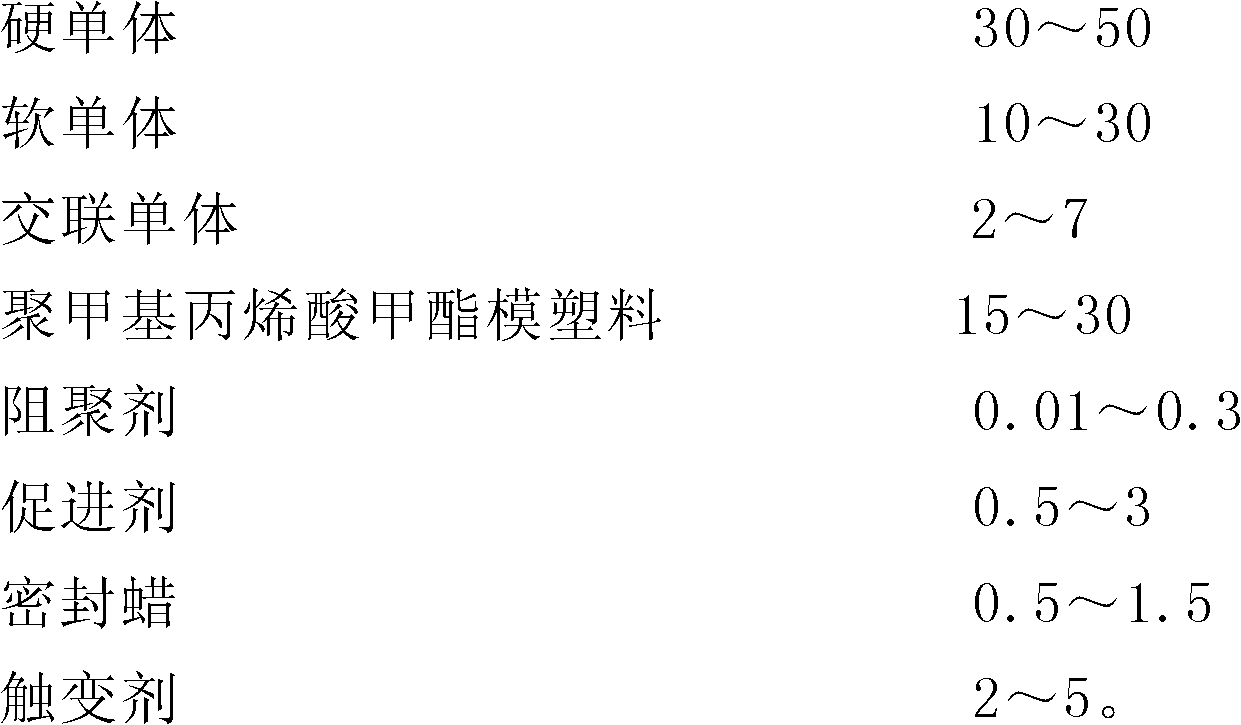

The invention relates to a polymethylmethacrylate waterproof paint and a preparation method thereof. The waterproof paint consists of components A and B, wherein the component A is a methacrylic acid resin liquid generated by reaction based on methyl methacrylate (MMA) utilized as a main composition, and the component B is an initiator. When the component A is prepared, a hard monomer, a soft monomer and a cross-linking monomer are put in a reaction kettle and evenly stirred, and then heating is carried out; polymethylmethacrylate moulding plastic is put, and then reaction is carried out for 1-6 hours at the temperature of 70-90 DEG C; cooling is carried out until the temperature is 50-65 DEG C, a polymerization inhibitor, an accelerator, sealing wax and a thixotropic agent are added and evenly stirred; and cooling is carried out until the temperature is 30-45 DEG C, and filtration and packaging are carried out so as to prepare the component A resin liquid. The components A and B are evenly stirred and mixed in a proper proportion, then coated, and finally solidified into a film. The waterproof paint has the characteristics of good strength, good elasticity, low temperature hardness, excellent weather resistance and the like, is simple and convenient for construction, can be solidified rapidly, and can be used for waterproof work of rapid transit railway bridge surfaces and super highway subgrades.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Manufacturing method of resin diamond wire

InactiveCN102658606AStable production processAdvanced technologyMetal sawing toolsFine working devicesMetal coatingOrganosolv

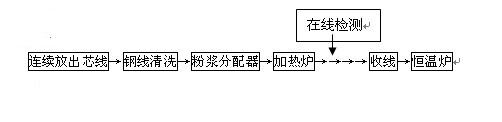

The invention discloses a manufacturing method of a resin diamond wire, relating to the field of photovoltaic technology. The manufacturing method of a resin diamond wire adopts viscose, carborundum and core wire and sequentially comprises the following steps of: preparing carborundum resin liquid including carborundum coated with metal, resin adhesive, organic solvent and SiC sand grain auxiliary, wherein the resin adhesive is soluble phenolic resin; mixing with a mixer until the phenolic resin is dissolved in the paste in dimethylformamide, and then injecting into a mould; in the mould, smearing the resin liquid on the steel wire; processing the steel wire with the resin liquid by a heating furnace to obtain a semi-hardened resin diamond wire; and collecting the wire to obtain a finished product of the resin diamond wire. The method disclosed by the invention has stable technology, short semi-hardening time and high production efficiency; and the production equipment can also be miniaturized.

Owner:HONGKONG YACHENG INT

Method for cultivating and planting organic dendrobium candidum

InactiveCN104855262AGuaranteed qualityFast multiplicationCultivating equipmentsPlant tissue cultureAdditive ingredientWater quality

The invention discloses a method for cultivating and planting organic dendrobium candidum. Illumination is conducted on dendrobium candidum tissue culture seedlings through LED red and blue hybrid light, and control and adjustment are conducted on factors such as an illumination period and a light intensity environment of the tissue culture seedlings at different stages, so that the speed of expanding propagation of the tissue culture seedlings is fast, and the yield is high; the cultivation time of the dendrobium candidum from seeds to finished rooting seedlings is about 160 days, high quality seedlings account for over 90% of total amount of the seedlings, the time for seedling hardening is about two weeks, the survival rate of seedbed planting in a greenhouse can reach over 98%, the time for seedling hardening for the tissue culture seedlings is short, the survival rate of transplanting is high, plant diseases and insect pests are few, the acidic water quality is adopted, fertilizer is not needed, and the growing environment of the dendrobium candidum is closer to the natural environment, so that the quality of the dendrobium candidum is guaranteed, nutritional ingredients of the dendrobium candidum is close to those of wild dendrobium candidum, and the medicinal value is high.

Owner:HANGZHOU ZHENGDE AGRI DEV CO LTD

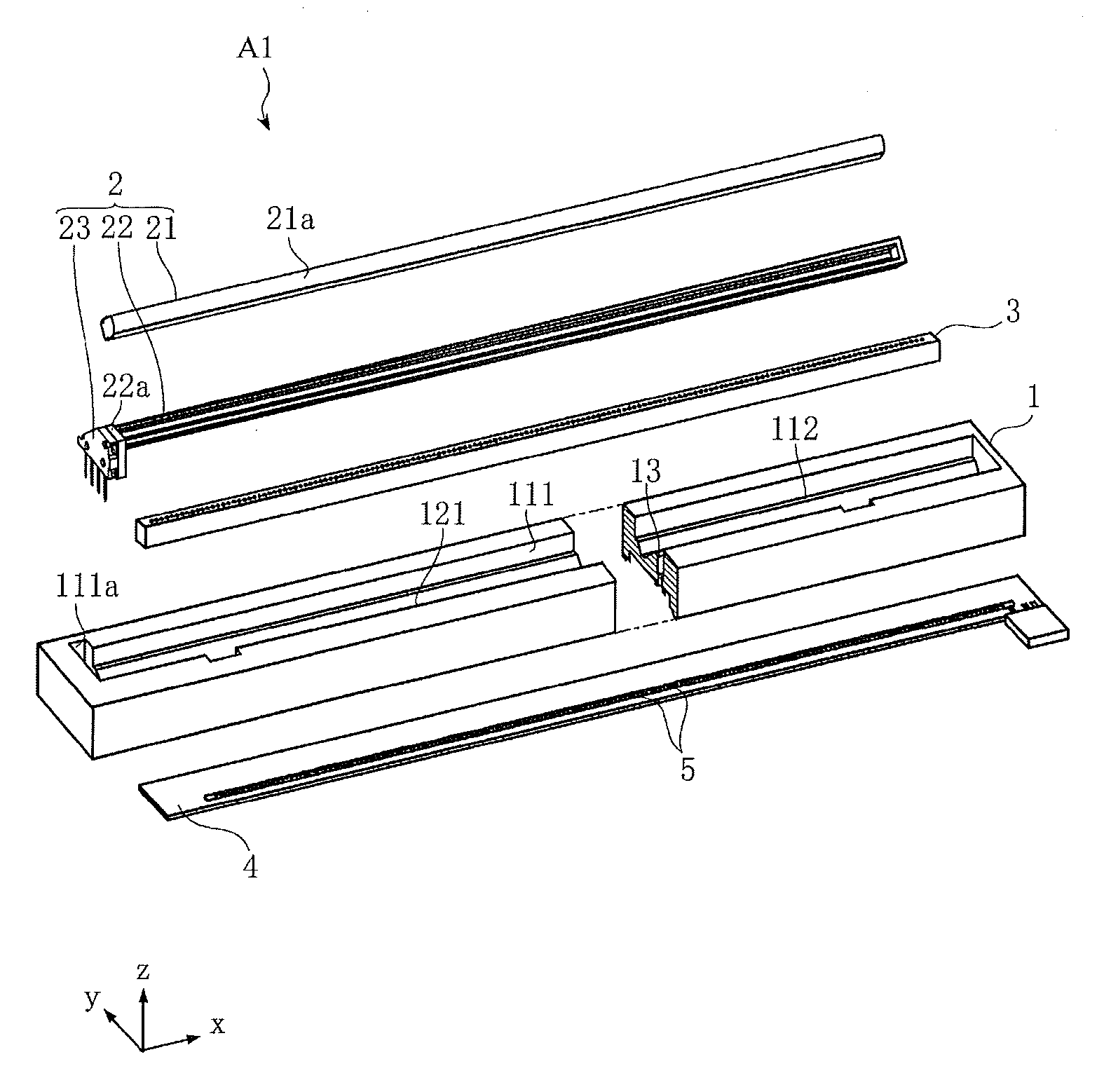

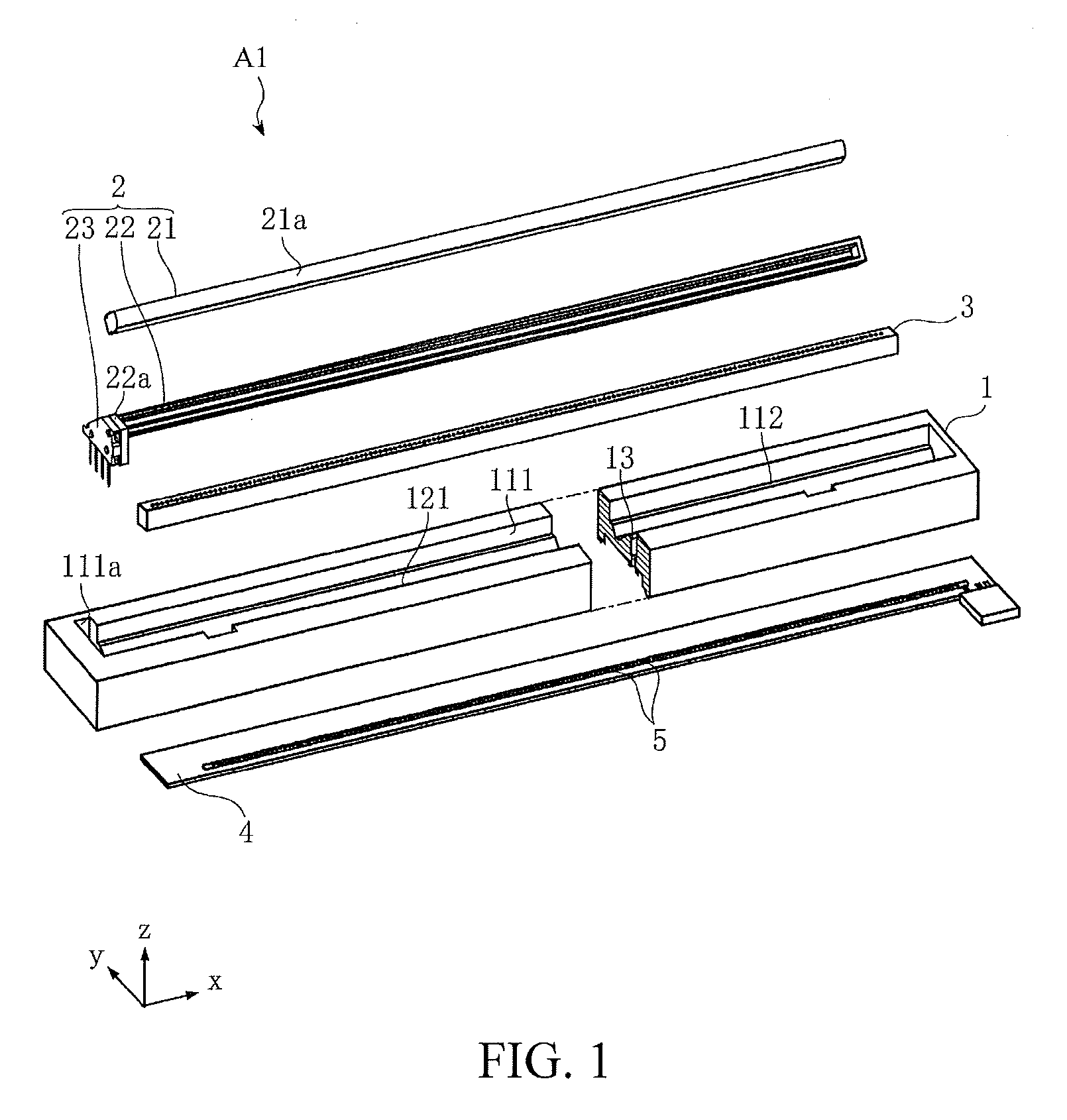

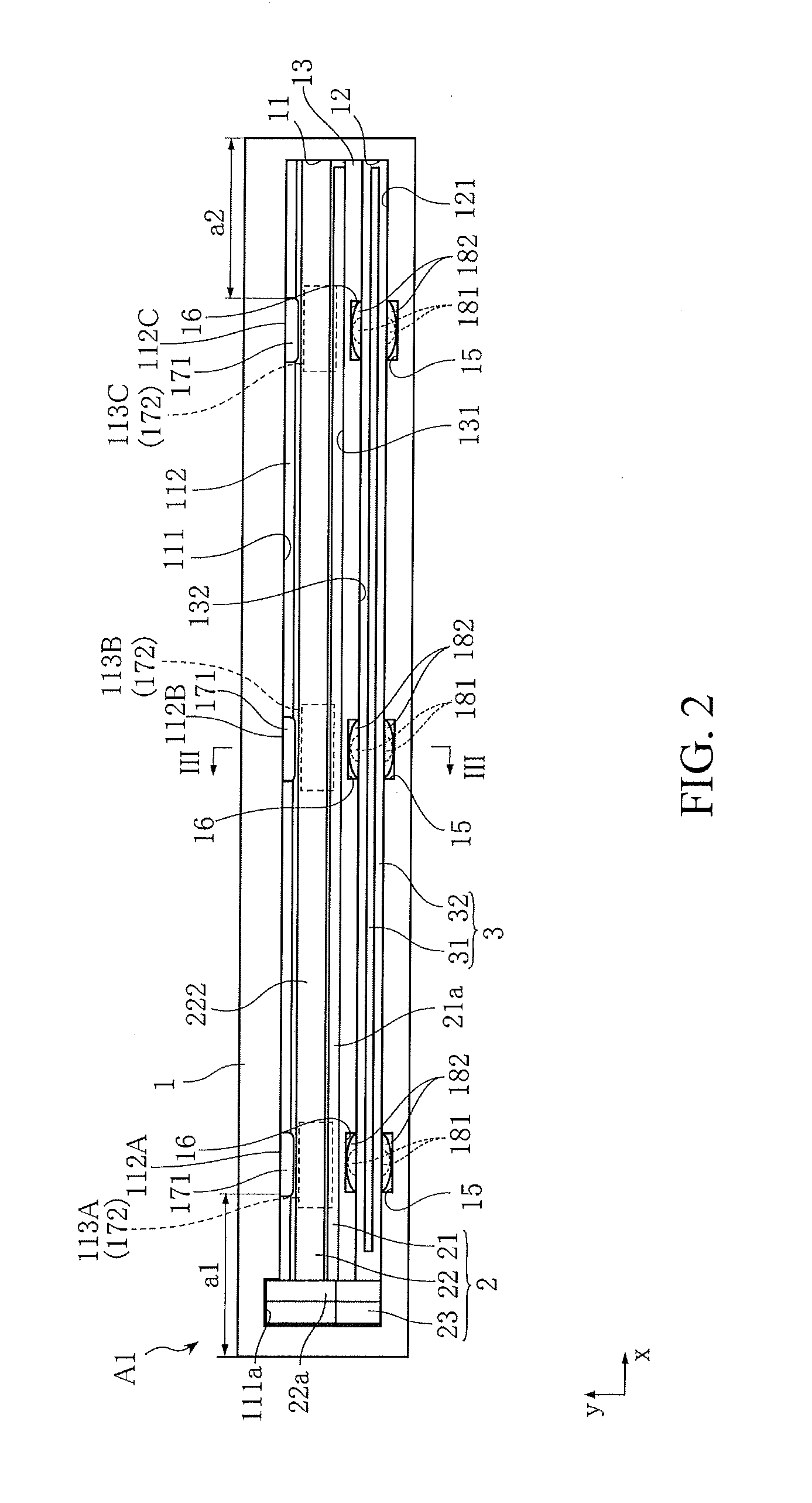

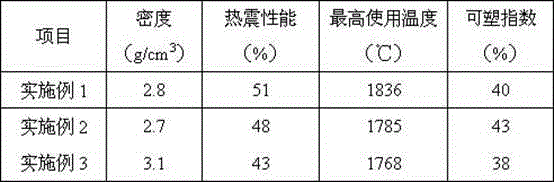

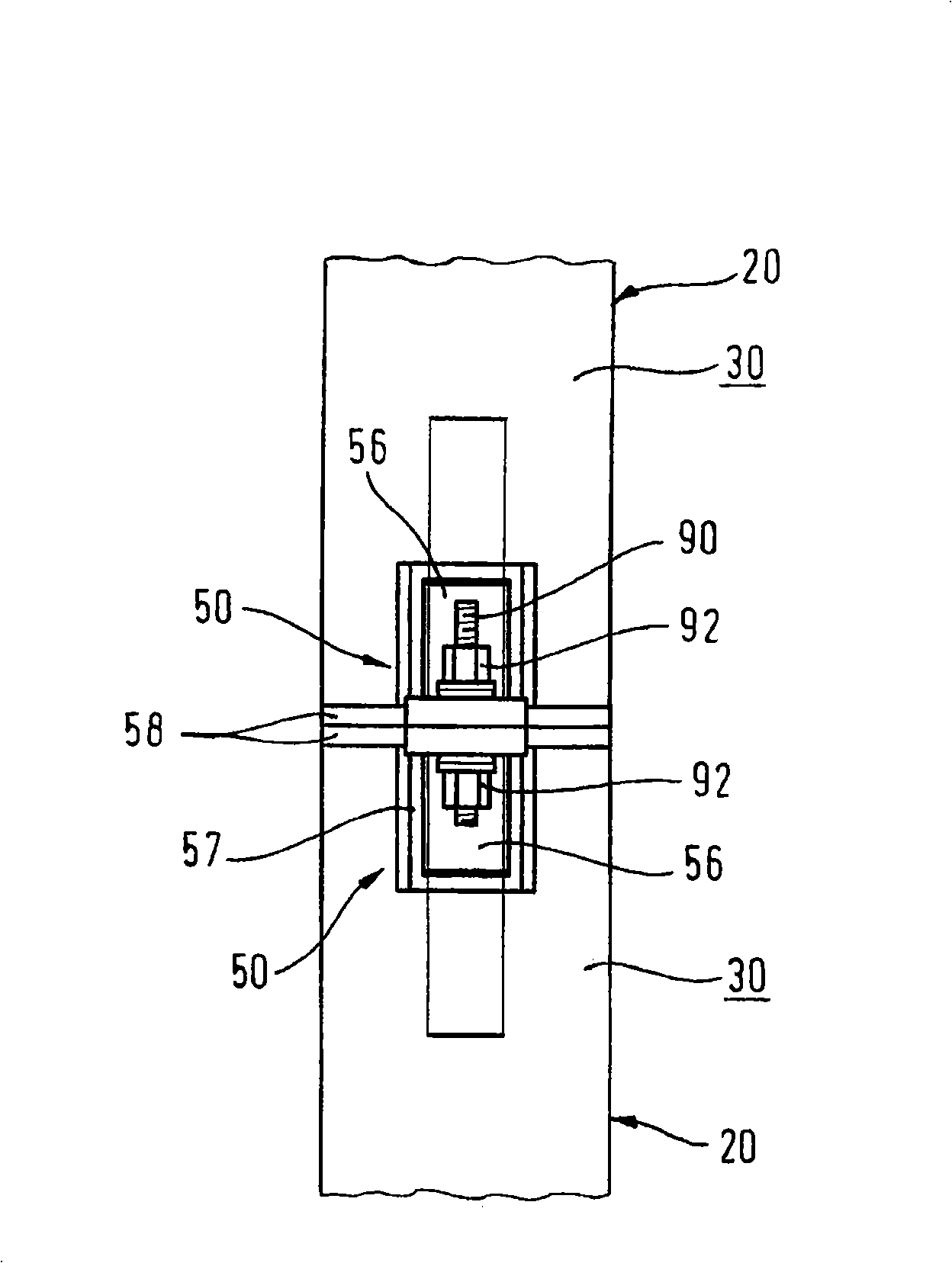

Image reading device and method for manufacturing the same

ActiveUS20120194878A1Efficient assemblyShort hardening timeLamination ancillary operationsFilm/foil adhesivesAdhesiveEngineering

An image reading device and a method for manufacturing the same are provided, where the image reading device is capable of being assembled more efficiently. The image reading device includes: an optical part, extending long in a direction; a case, having an accommodating portion for accommodating the optical part; and a light receiving component, accommodated in the case. The optical part is fixed in the accommodating portion through a first adhesive and a second adhesive with hardening time longer than that of the first adhesive.

Owner:ROHM CO LTD

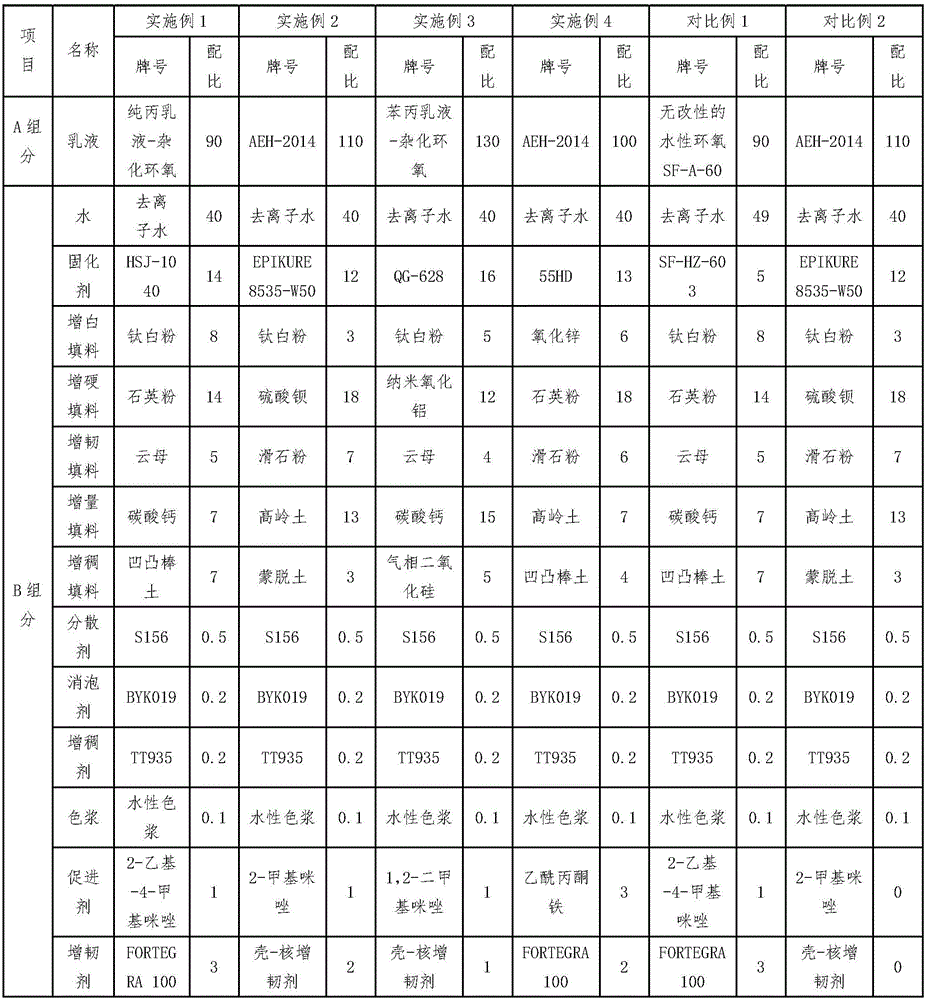

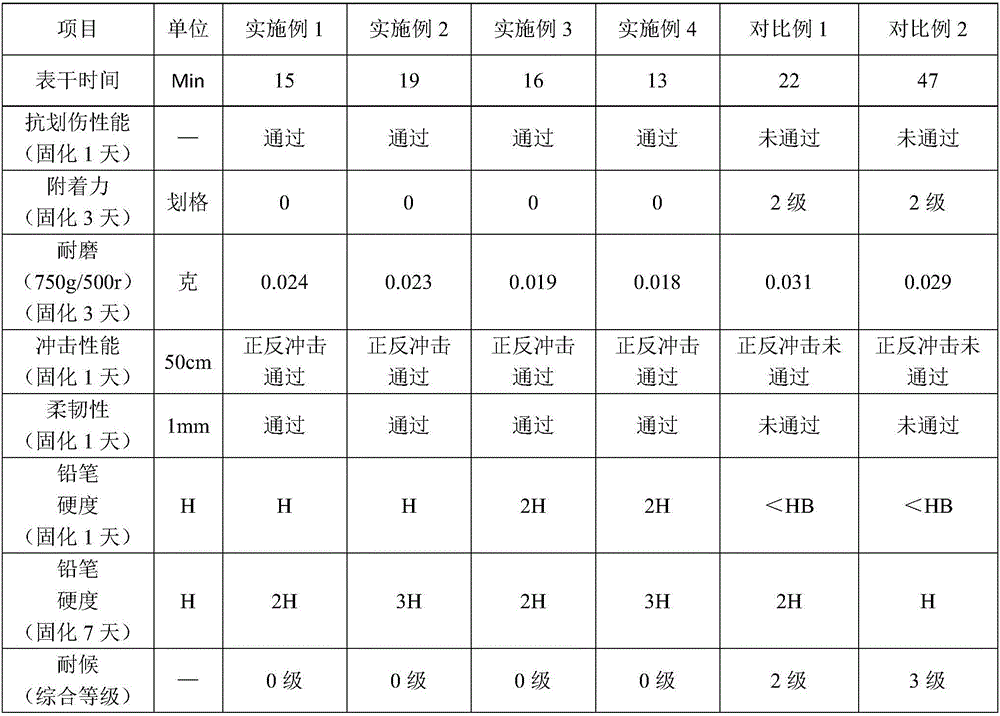

Water-based epoxy floor paint composition capable of being used outdoors, and preparation method thereof

ActiveCN106811006AOvercoming weather resistanceOvercome the shortcomings of intolerance to yellowingEpoxy resin coatingsEpoxyWater based

The invention discloses a water-based epoxy floor paint composition capable of being used outdoors. The water-based epoxy floor paint composition comprises a component A and a component B, wherein according to the mass proportion, the ratio of A to B is (80-150):100; the component A is acrylic resin hybrid modified water-based epoxy resin; the epoxy equivalent of the acrylic resin hybrid modified water-based epoxy resin is 800 to 1500. The water-based epoxy floor paint provided by the invention belongs to a water-based system, the whole system does not contain VOC, and the water-based epoxy floor paint is environmentally-friendly water-based epoxy floor paint; moreover, hybrid modification is conducted by the acrylic resin, so that the defects that the traditional water-based epoxy floor paint has low weather resistance and does not resist yellowing are overcome, and the water-based epoxy floor paint composition is high in ultraviolet resistance and excellent weather resistance and can be completely used outdoors.

Owner:JIANGSU AKST NEW MATERIALS CO LTD

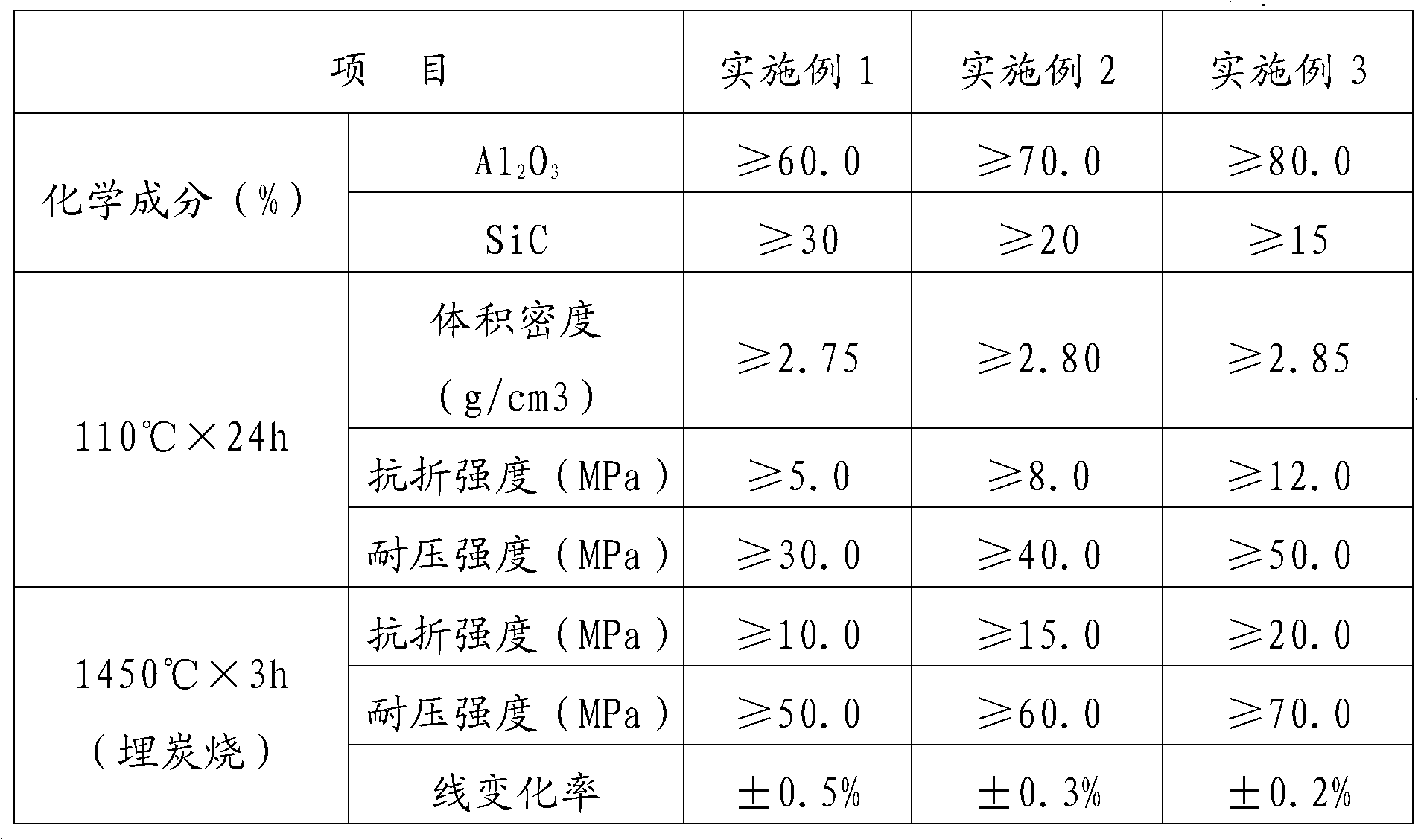

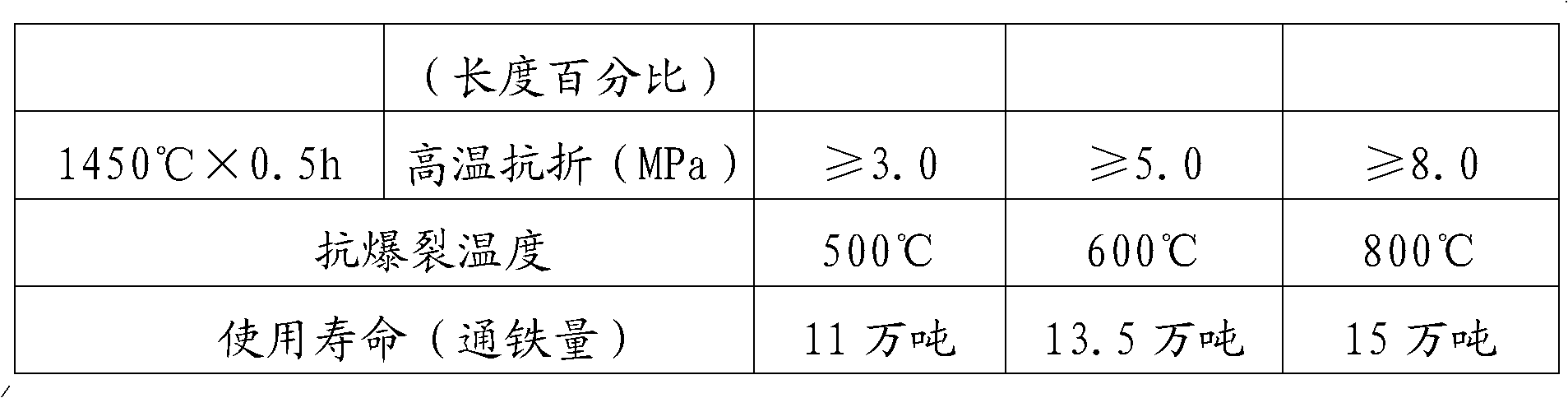

Main ditch self-flowing anti-blowout pour material of main channel and construction method thereof

The invention relates to a main ditch self-flowing anti-blowout pour material and a construction method thereof, which solve the problems that an existing main ditch pour material is long in maintaining and baking time and incapable of performing quick baking after pouring so as to cause blowout, reduce material strength and shorten service life. The technical scheme is that the main ditch self-flowing anti-blowout pour material comprises, by weight, 60-80 parts of electric smelting low-carbon brown fused alumina, 15-30 parts of silicon carbide, 1-3 parts of binding agent, 2-7 parts of ultramicro powder, 0.2-2.2 parts of antioxidant, 0.1-1.55 parts of anti-blowout agent and 0.1-0.25 part of water reducing agent. The main ditch self-flowing anti-blowout pour material is low in cost, simplein ingredients and construction method, short in baking time, high in material strength and long in service life.

Owner:WUGANG REFRACTORY CO LTD

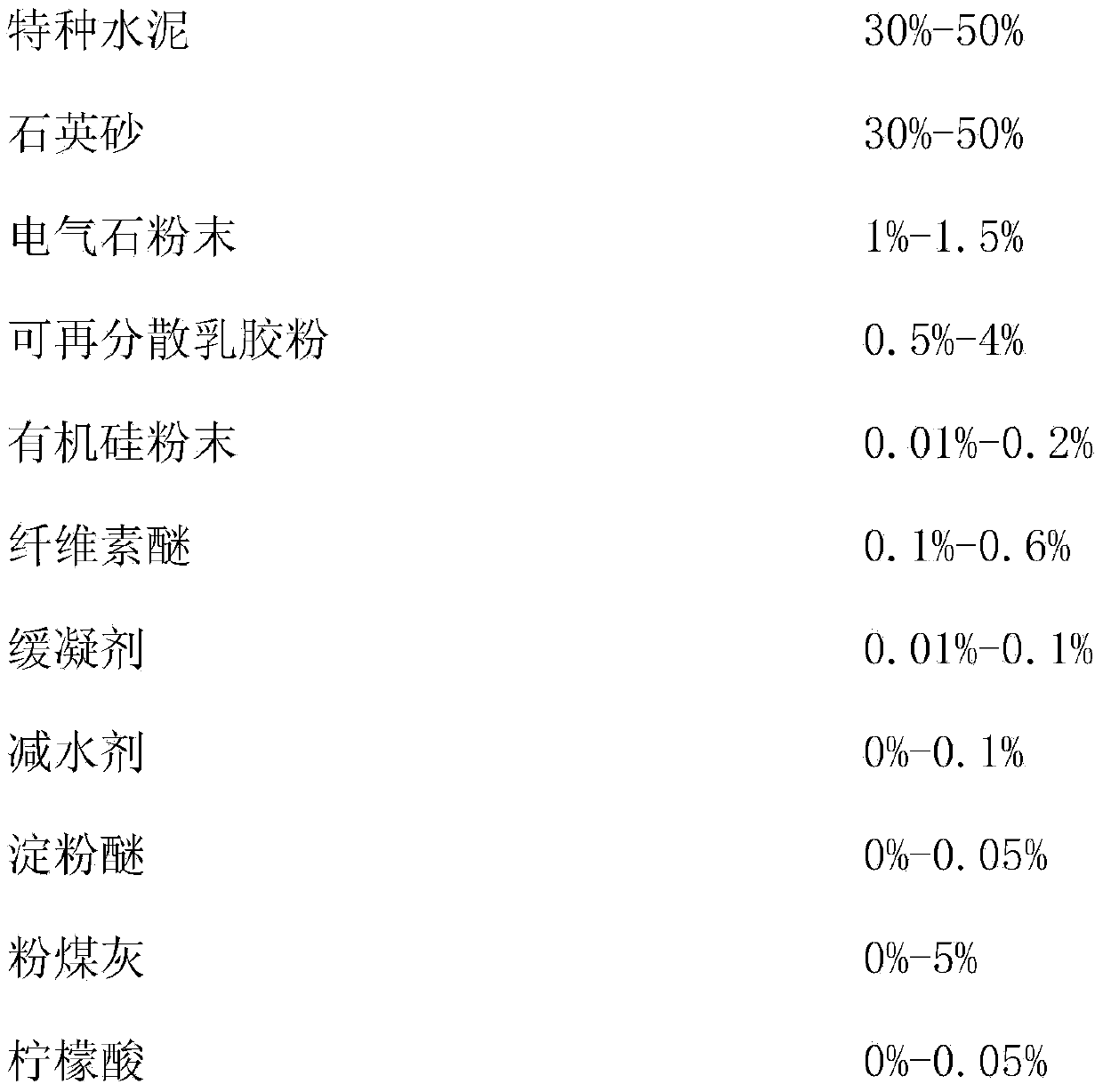

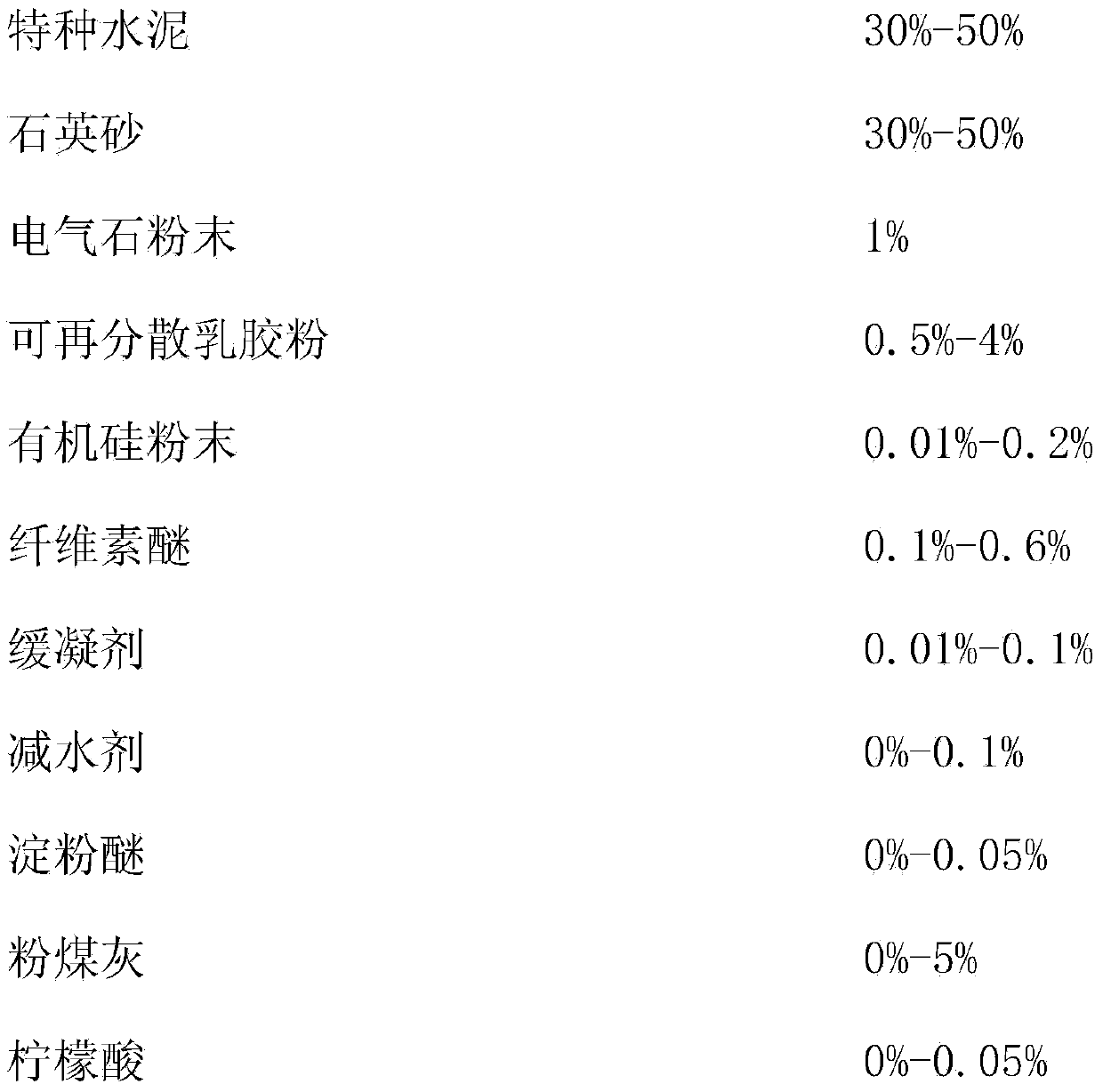

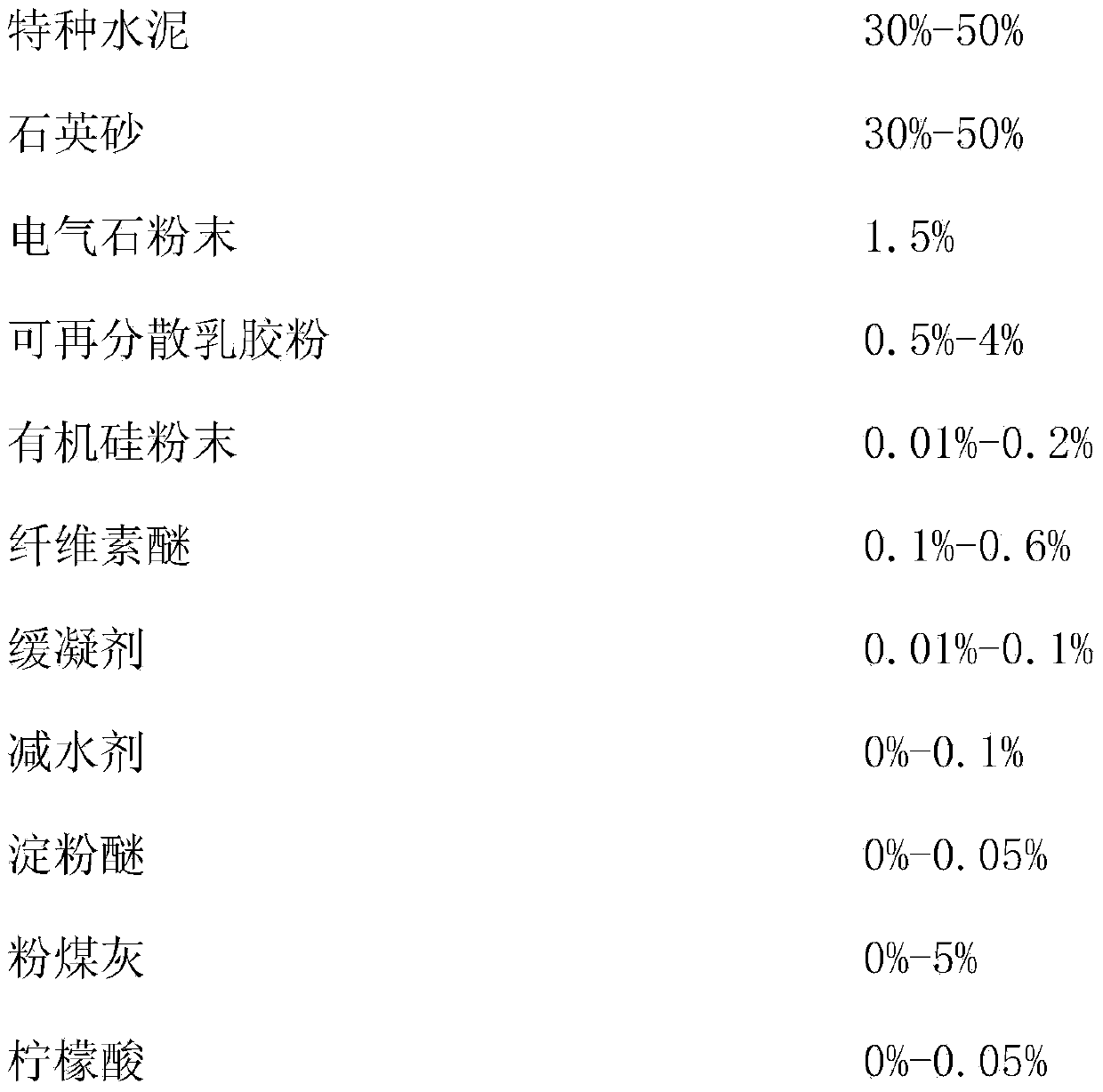

Improved low-alkaline ceramic tile adhesive

The invention discloses an improved low-alkaline ceramic tile adhesive which is prepared by adding tourmaline powder, redispersible emulsion powder, organosilicone powder, cellulose ether, a retarder, a water reducer, starch ether, coal ash, citric acid and the like by using special cement (low-alkaline sulphate aluminum cement) and quartz sands as raw materials. The adhesive disclosed by the invention is good in water-resisting, freeze thawing-resisting and aging-resisting performances, has excellent flexible performance, is high in adhesive strength and short in hardening time, and can be used for effectively avoiding saltpetering of a tapestry brick.

Owner:DEQING YANGTAI BUILDING MATERIAL

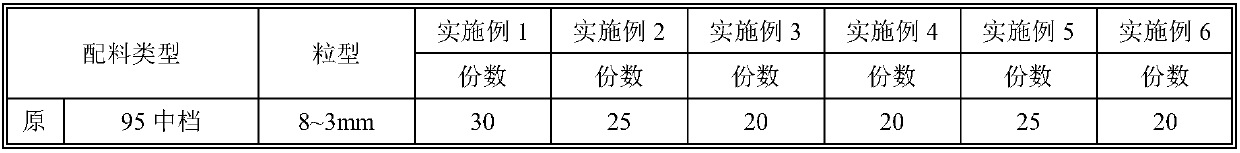

Fettling material for converter as well as preparation and using methods thereof

InactiveCN107793163AResolution timeSolve the pollution of the environmentManufacturing convertersThermal stateEconomic benefits

The invention provides a fettling material for a converter as well as preparation and using methods thereof. The fettling material is prepared from the following raw materials in parts by weight: 60 to 95 parts of magnesia, 10 to 20 parts of a binding agent, 2 to 5 parts of additives and 6 to 10 parts of wetting agents, wherein the binding agent is a mixture of asphalt and silica fume. Compared with the prior art, the fettling material for the converter has the beneficial effects that the fettling material for the converter as well as the preparation and using methods thereof disclosed by theinvention have good self-flow property, thermal-state strength, erosion resistance and thermal shock property; the hardening time of the fettling material is short, the maintenance time of furnace shutdown of the converter can be effectively reduced, the operation efficiency is improved, and the binding of the fettling material and a working lining of the converter is good so as to prevent stripping of the fettling material in a using process, and environmental pollution is reduced. The fettling material for the converter as well as the preparation and using methods of the fettling material disclosed by the invention have significant meanings on energy conservation and consumption reduction, environmental protection and increment of economic benefits.

Owner:海城利尔麦格西塔材料有限公司 +1

Method of utilizing well-drilling solid waste soil to prepare concrete or concrete blocks

Owner:CHINA PETROLEUM & CHEM CORP +1

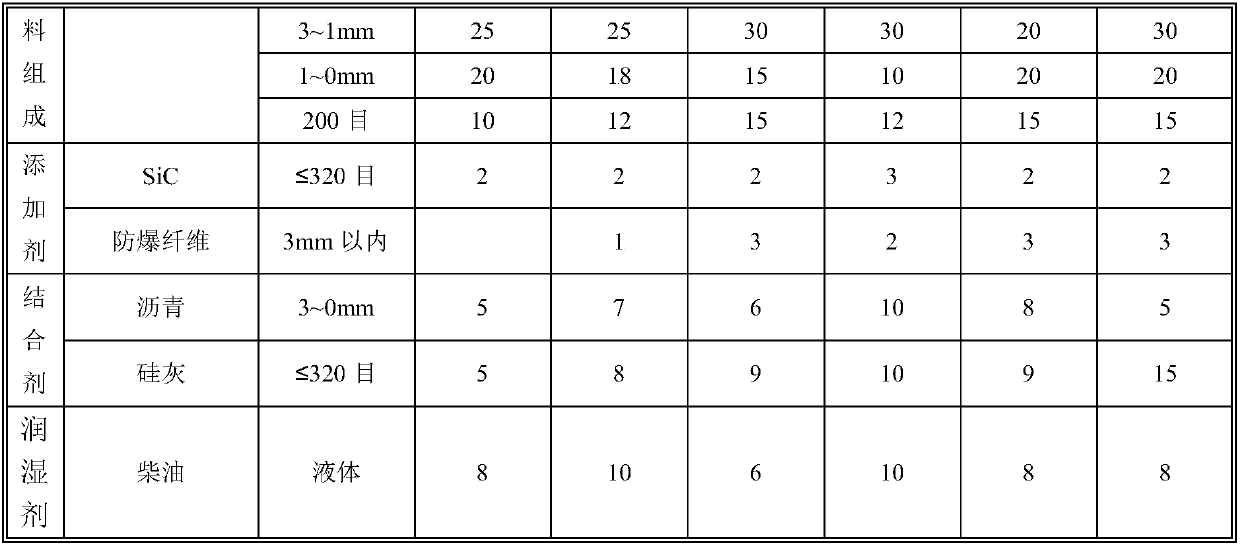

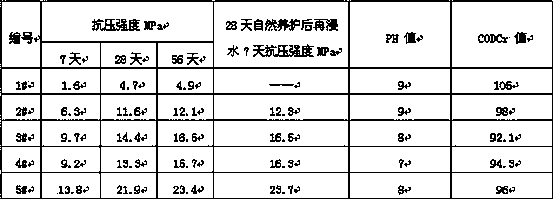

Pit patching material for converter

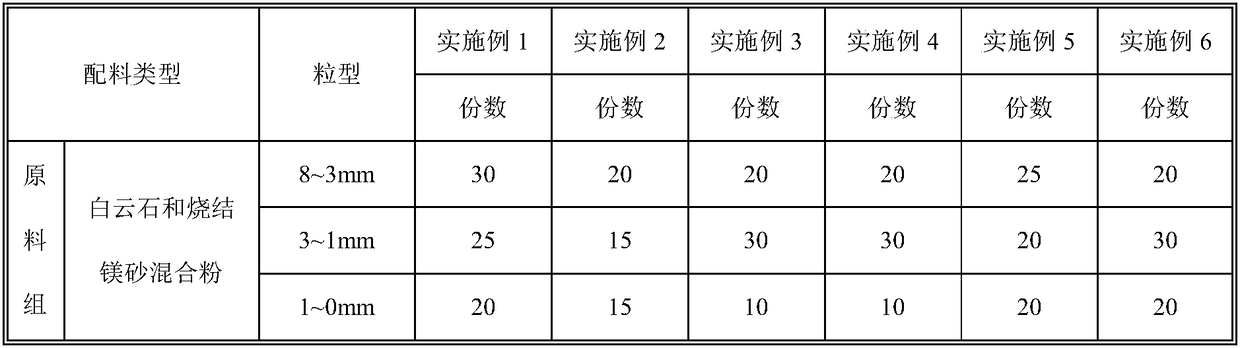

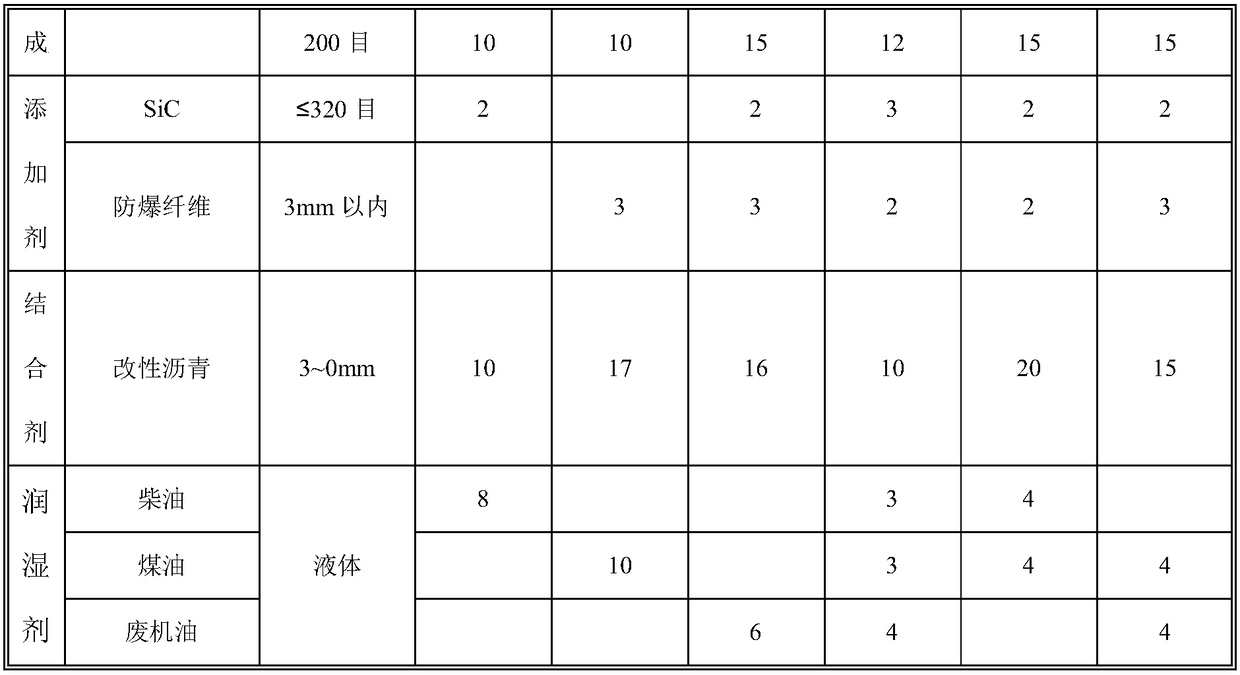

The invention relates to a pit patching material for a converter, wherein the pit patching material comprises the following raw materials by weight: 60-85 parts of the mixed powder of dolomite and sintered magnesia, 10-20 parts of modified asphalt, 2-5 parts of an additive, and 6-10 parts of a wetting agent, and a ratio of the dolomite to the sintered magnesia in the mixed powder is 1:(1-2). According to the present invention, the pit patching material has advantages of good self-flowing property, hot strength, corrosion resistance, thermal shock resistance and short hardening time so as to reduce the blowing-out maintenance time of the converter and improve the working efficiency; and the pit patching material and the converter working line are well adhered so as to prevent the pit patching material from peeling off during the use.

Owner:海城利尔麦格西塔材料有限公司

Quick-drying water-borne coating

InactiveCN105238180AStrong adhesionGood dispersionPolyester coatingsEnvironmental resistanceAcrylic resin

The invention belongs to the field of a water-borne coating technology, and concretely relates to a quick-drying water-borne coating. The quick-drying water-borne coating comprises the following components in parts by weight: 28-43 parts of acrylic resin, 70-90 parts of pure water, 20-25 parts of an aqueous alkyd resin, 15-20 parts of glycerin, 10-15 parts of hexenyl bis-stearamide, 2-5 parts of a dispersant, and 1-3 parts of a surface control agent. The quick-drying water-borne coating has the advantages of safety, environmental protection, good adhesive force, good dispersion performance and good film forming performance. The quick-drying water-borne coating is hard to crack, and almost does not contain volatile solvents; the quick-drying water-borne coating has short drying time and hardening time, and substantially reduced spray painting time.

Owner:桂林瑞丰环保微生物应用研究所

High-temperature corrosive-proof plastic material and preparation method thereof

The invention relates to a high temperature resistant material and a preparation method thereof and in particular relates to a high-temperature corrosive-proof plastic material and a preparation method thereof. The high-temperature corrosive-proof plastic material is prepared from the following raw materials: activated aluminum oxide micro powder, special high aluminum powder, silicon carbide powder, a binding agent and an additive. The high-temperature corrosive-proof plastic material provided by the invention is short in hardening time, high-temperature-resistant, high in strength, wear-resistant, convenient in construction, rapid in repair, good in thermal shock performance, crack-free, high in peel strength and high in sealing property and can be widely applied to repair of severely worn and eroded parts of boilers and heating furnaces or overall masonry of the boilers and heating furnaces, a baking oven is not needed, the natural curing time is short, the furnace shut-down loss is reduced, and the influence on the production is alleviated.

Owner:YIXING GUOQIANG FURNACE IND

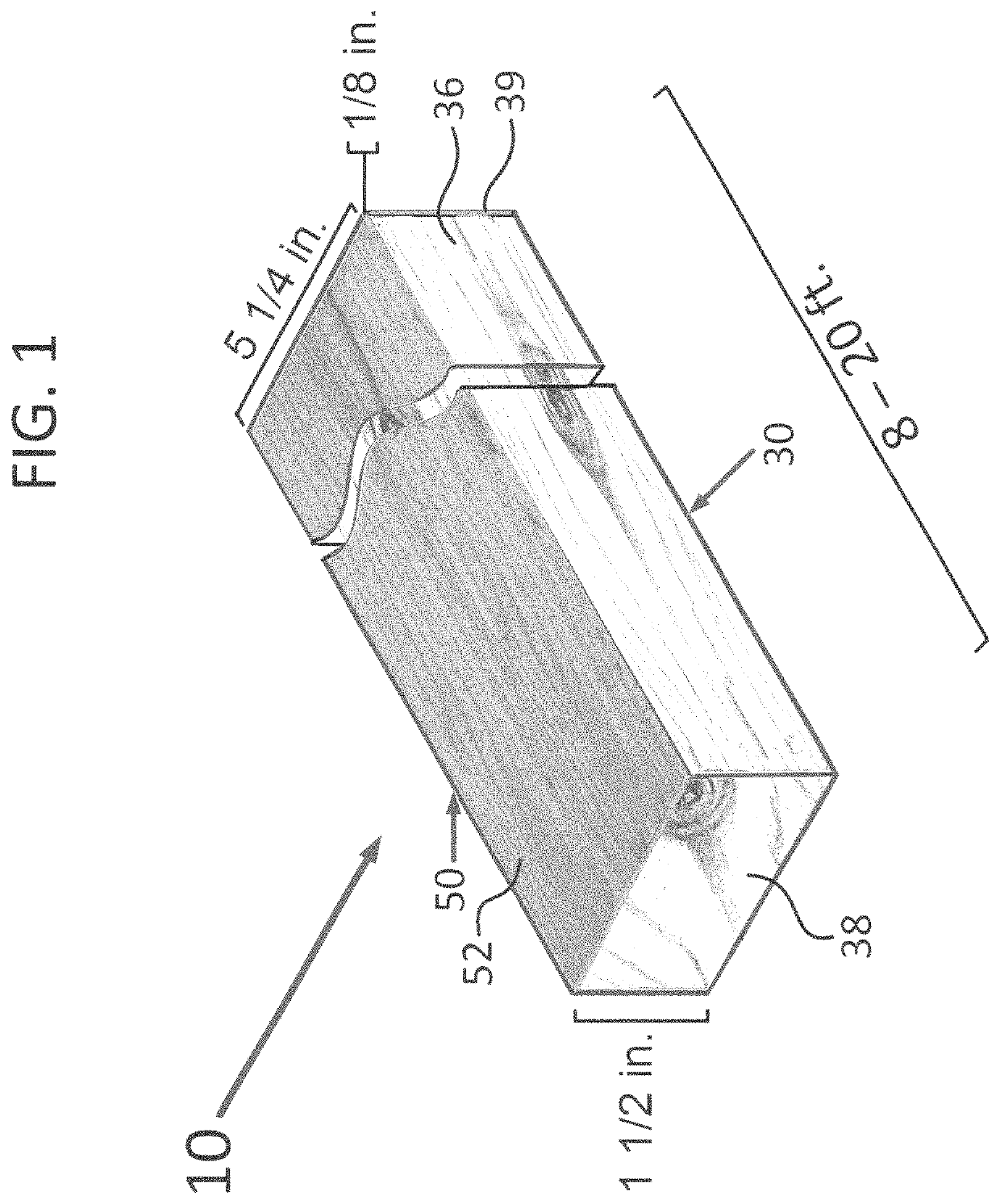

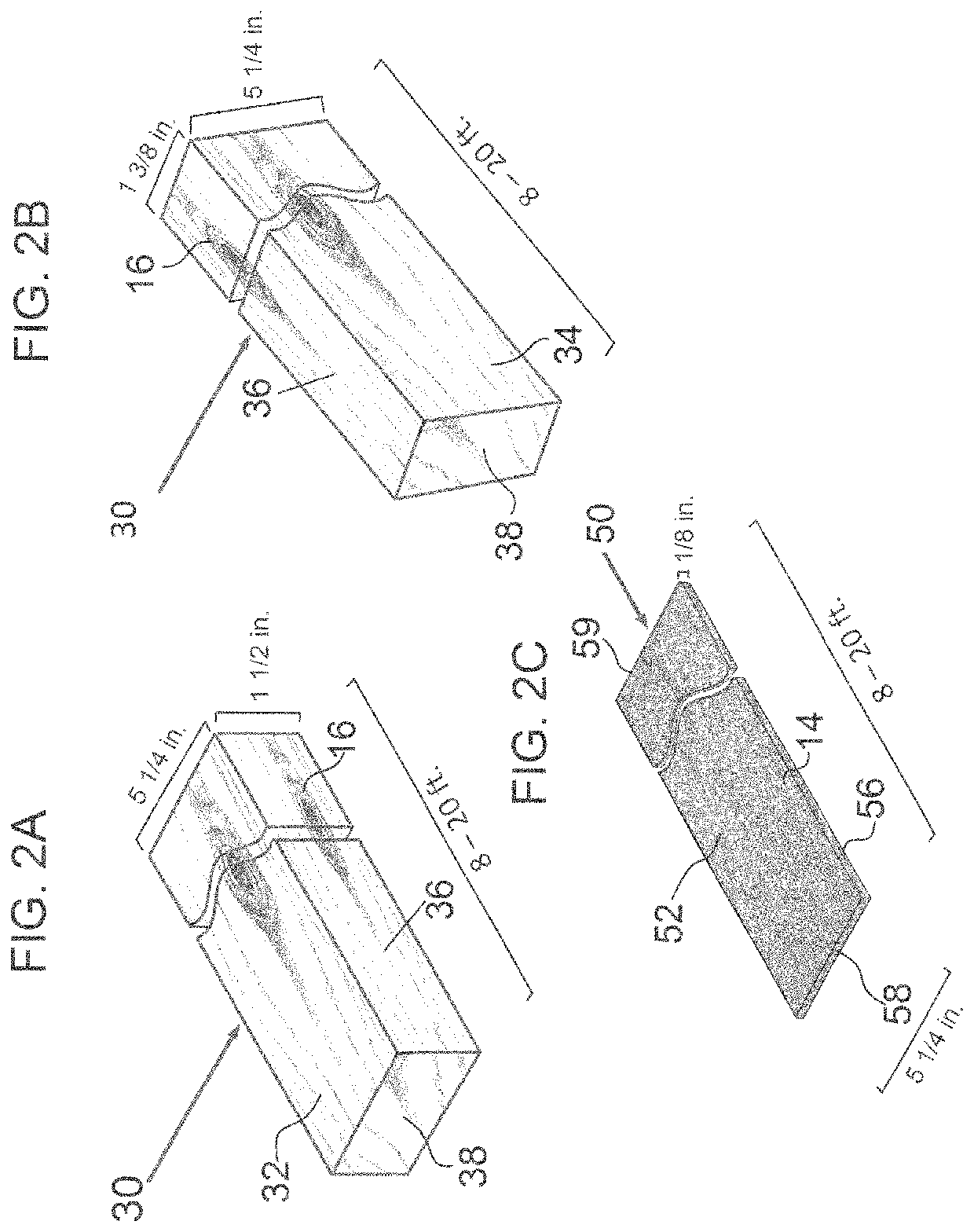

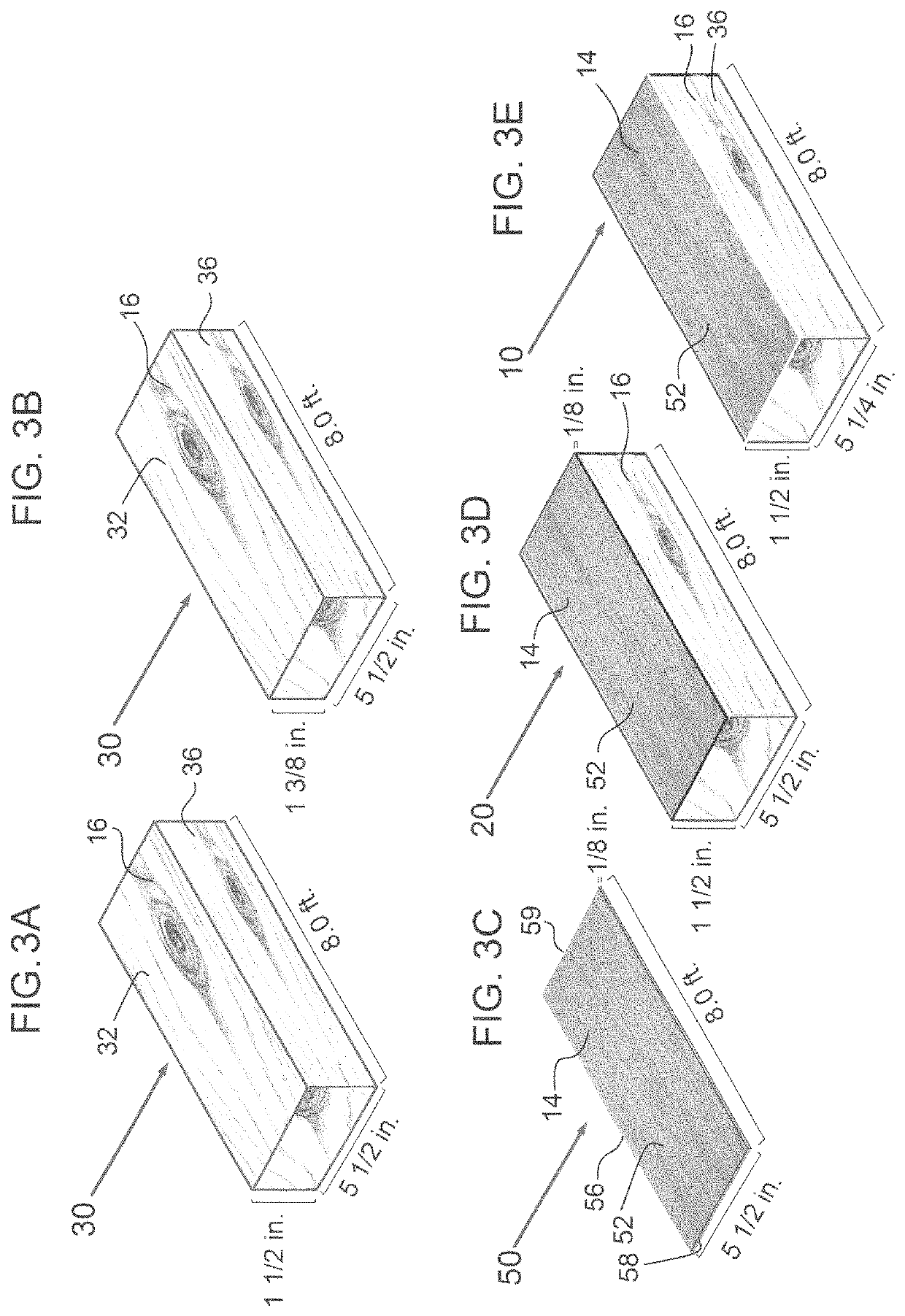

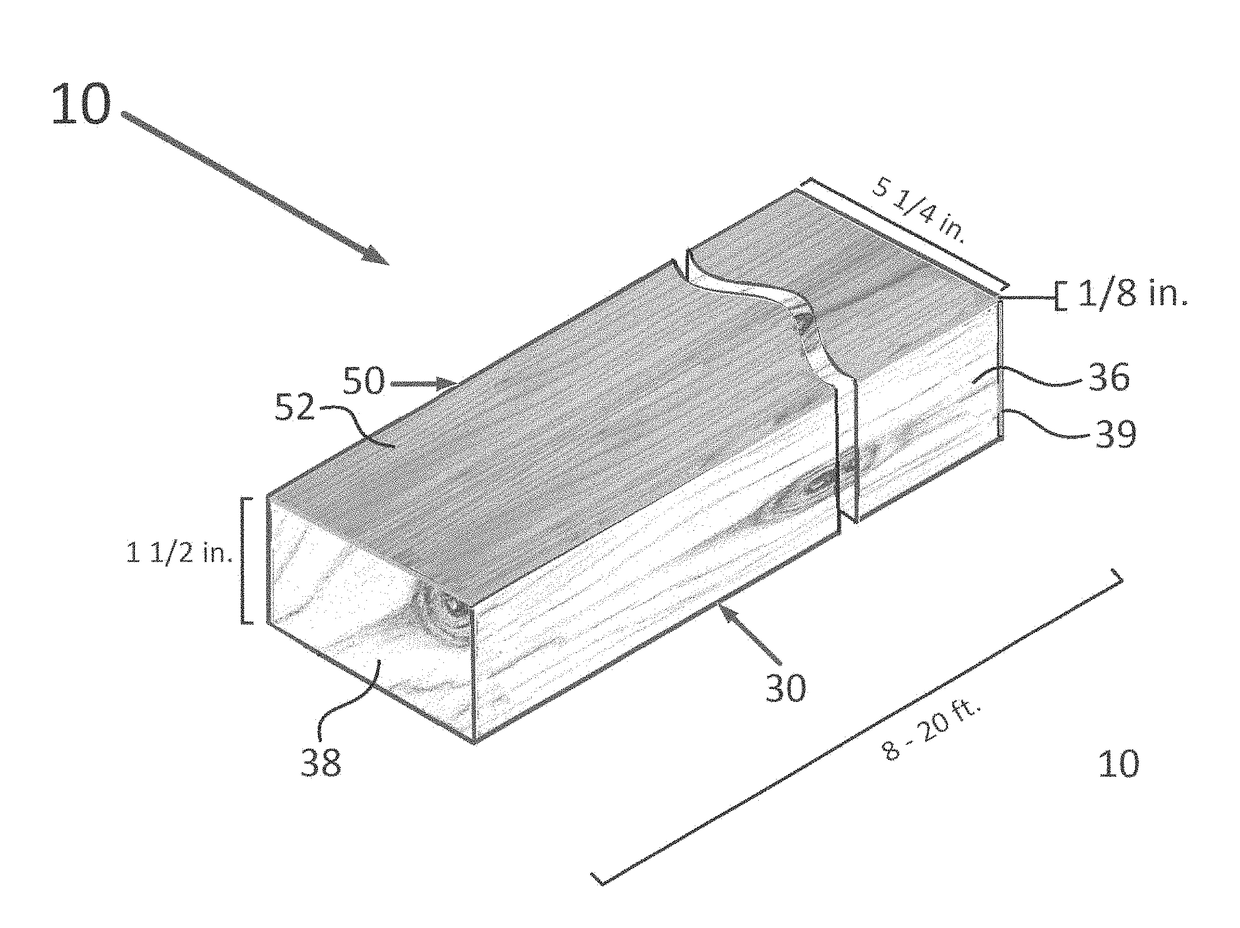

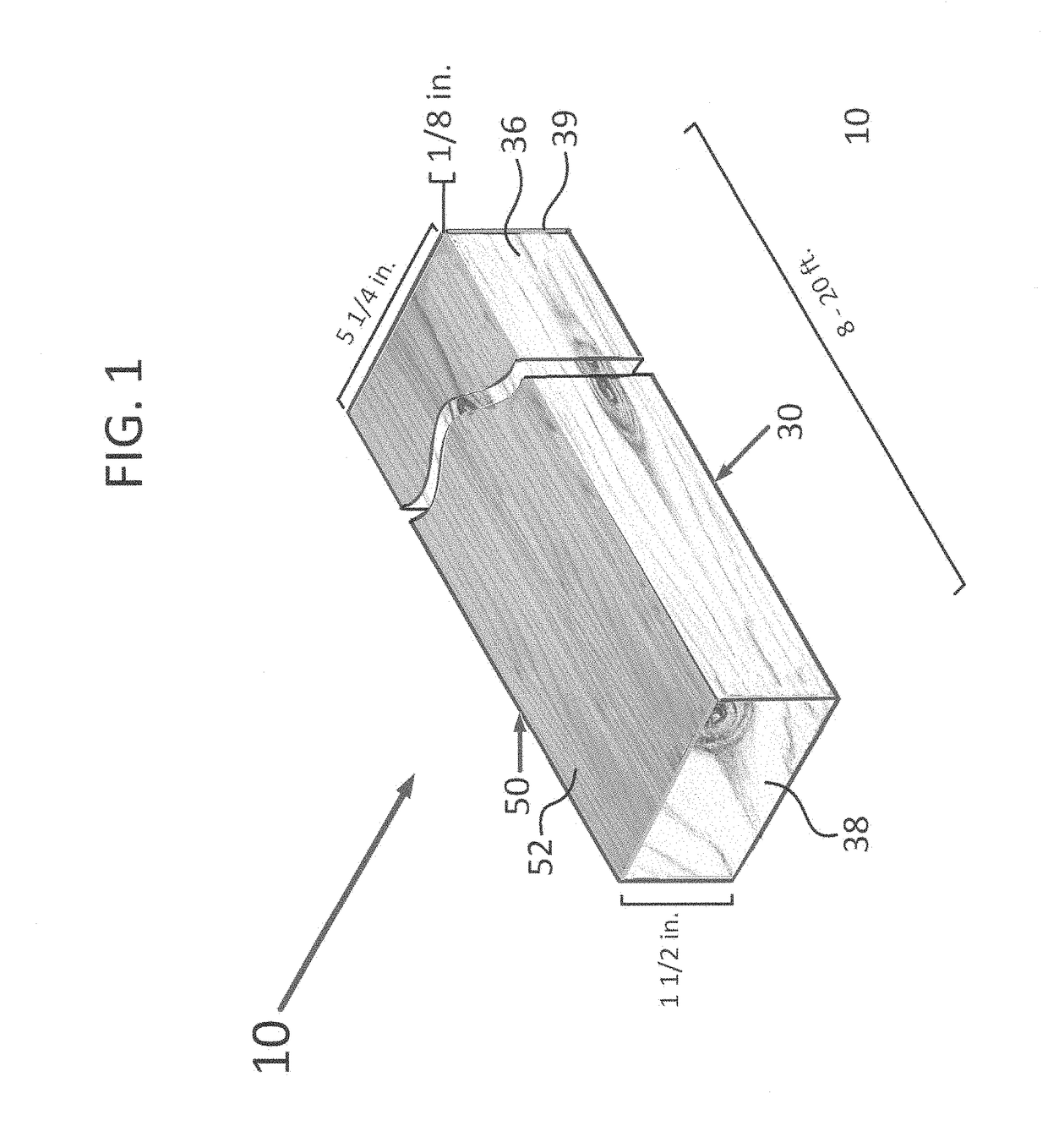

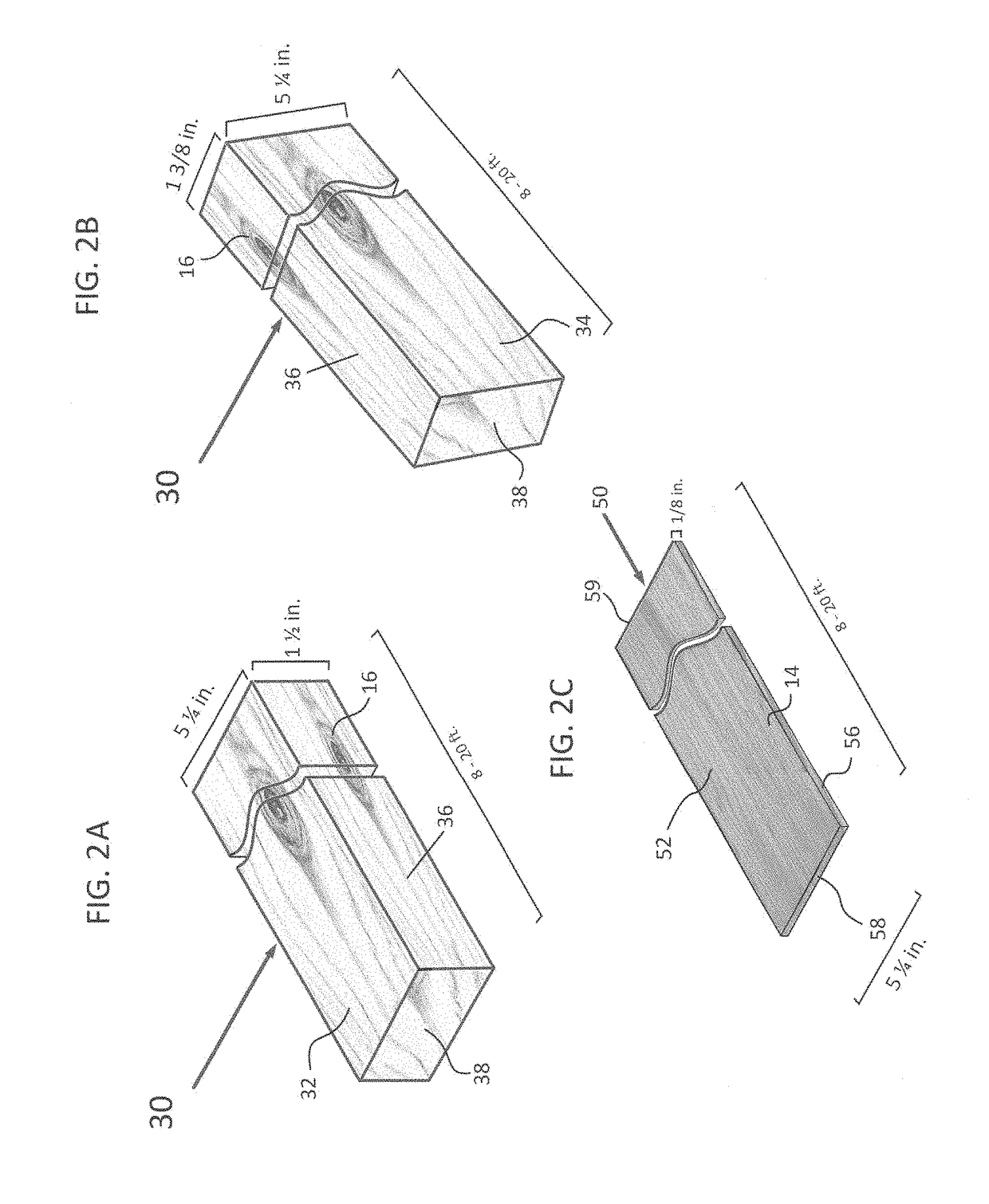

Outdoor wood decking board

An outdoor wood decking board for use in construction of an outdoor deck floor, the outdoor decking board including a wood core formed from a first wood species of common grade wood species as a three-dimensional solid rigid body. A facing wood veneer formed from a second wood species of superior grade wood species as a three-dimensional solid rigid wood finishing layer permanently directly seamlessly attached via an adhesive to a first wood face of the wood core thereby the wood core having an appearance of the second wood species. In another embodiment, the facing wood veneer is formed from a third wood species, exotic hardwood species. A two-part emulsion polymer isocyanate adhesive is used to bond the wood core against the facing wood veneer; to bond two wood cores together. In another embodiment, the adhesive is a two-part polyurethane emulsion polymer.

Owner:TEBB TERRY ALLEN +1

High-strength abrasion-resistant refractory plastic mass

The invention relates to a high-temperature resisting material, in particular to high-strength abrasion-resistant refractory plastic mass. The high-strength abrasion-resistant refractory plastic mass is prepared from, by weight, 16-26 parts of active vitriol with the particle size ranging from 0.010 mm to 0.015 mm, 7-10 parts of cooked high-aluminum powder with the particle size ranging from 0.6 mm to 1 mm, 7-13 parts of cooked high-aluminum powder with the particle size ranging from 2 mm to 3 mm, 12-25 parts of cooked high-aluminum powder with the particle size ranging from 3 mm to 5 mm, 5-16 parts of cooked high-aluminum powder with the particle size ranging from 5 mm to 8 mm, 7-10 parts of silicon carbide powder with the particle size ranging from 0.1 mm to 0.3 mm, 15-20 parts of silicon carbide powder with the particle size ranging from 0.5 mm to 1 mm, 8-16 parts of magnesium oxide, 25-30 parts of aluminum sulfate and 13-20 parts of calcium phosphate. The high-strength abrasion-resistant refractory plastic mass is short in hardening time, resistant to high temperatures and abrasion and capable of facilitating construction, and is used for repairing parts, seriously abraded and scoured, in a furnace.

Owner:YIXING JICHUANG NEW MATERIAL TECH CO LTD

High-alumina refractory plastics

The invention relates to a high temperature resistant material, specifically to high-strength refractory plastics, which is composed of the following raw materials (by weight): 15-25 parts of high-alumina bauxite with particle size being 0.02-0.03 mm, 7-10 parts of aluminium oxide with particle size being 0.3-0.71 mm, 7-13 parts of aluminium oxide with particle size being 2-3 mm, 12-25 parts of aluminium oxide with particle size being 3-5 mm, 5-15 parts of aluminium oxide with particle size being 5-8 mm, 7-10 parts of silica micropowder with particle size being 0.05-0.15 mm, 15-20 parts of silica micropowder with particle size being 0.5-1 mm, 8-15 parts of magnesia, 25-30 parts of mullite and 13-20 parts of aluminium dihydrogen phosphate. The high-strength refractory plastics provided by the invention has short hardening time, is convenient for construction, and is used for repairing parts inside a furnace which are severely worn and scoured.

Owner:YIXING JICHUANG NEW MATERIAL TECH CO LTD

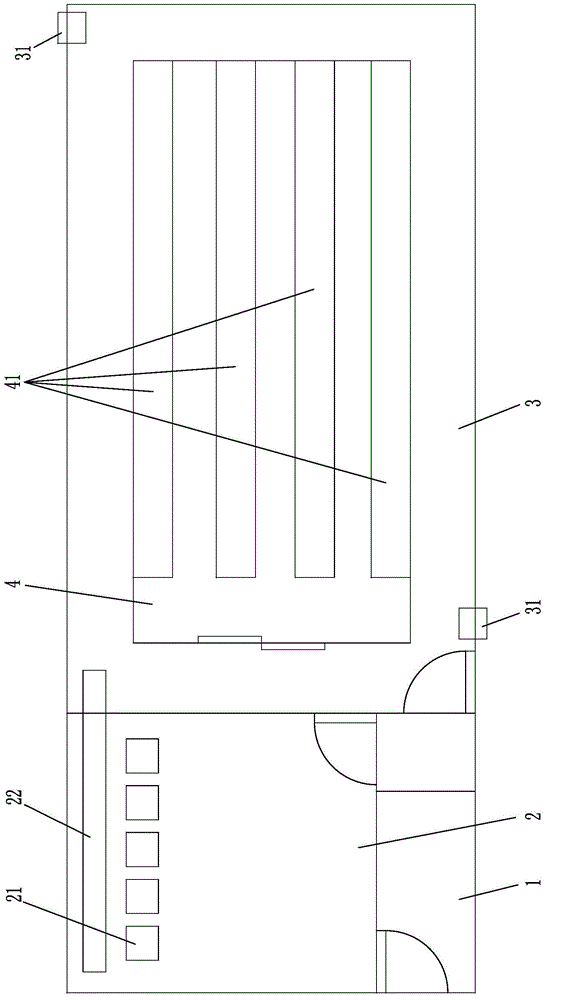

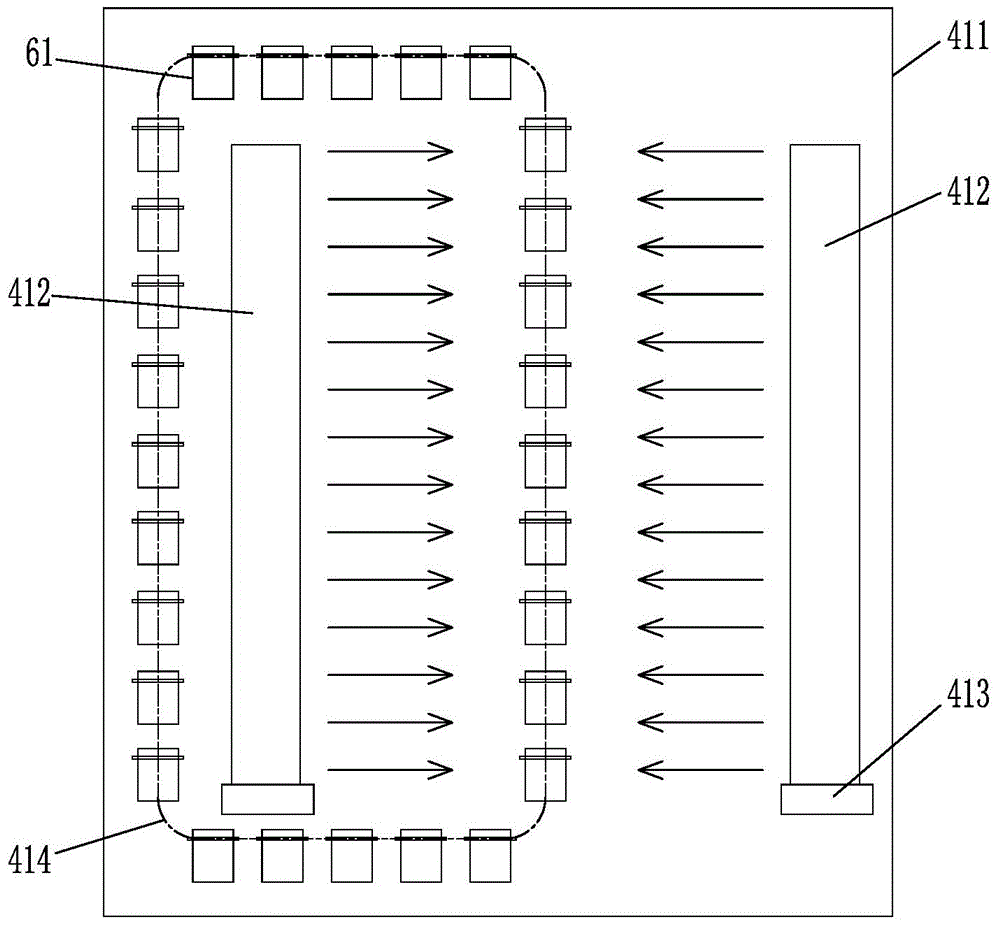

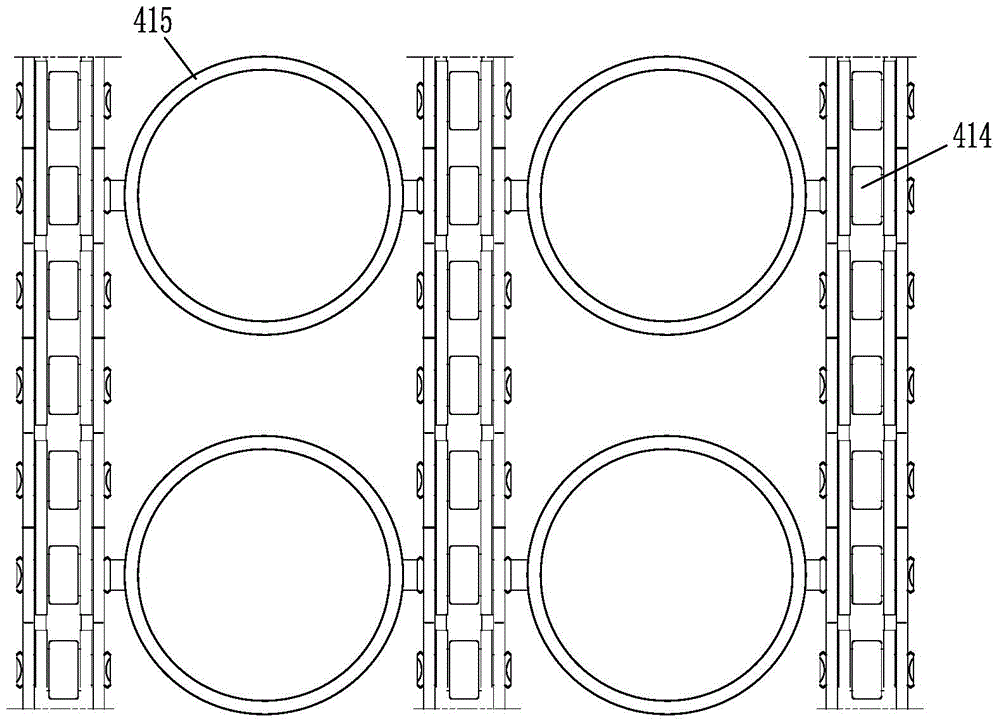

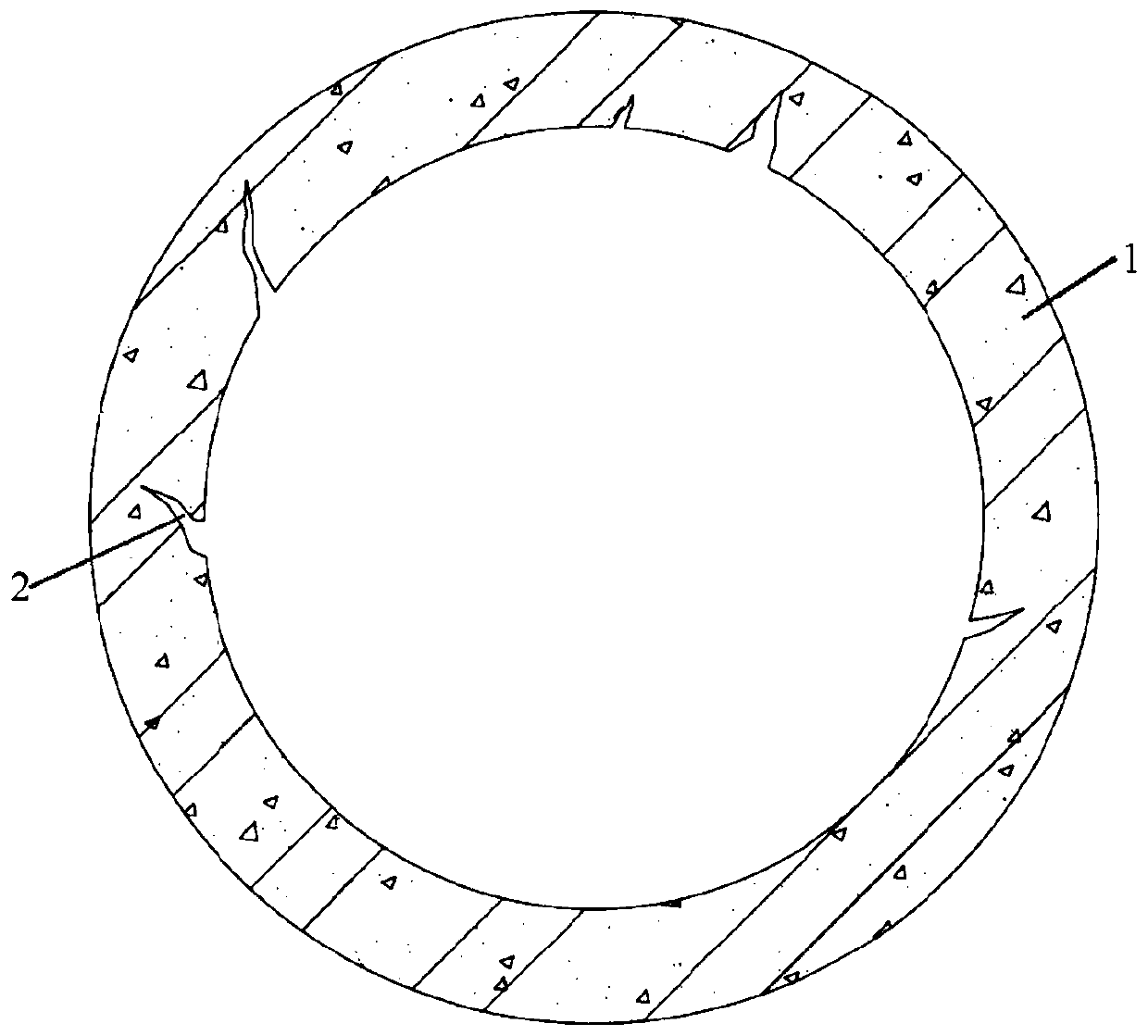

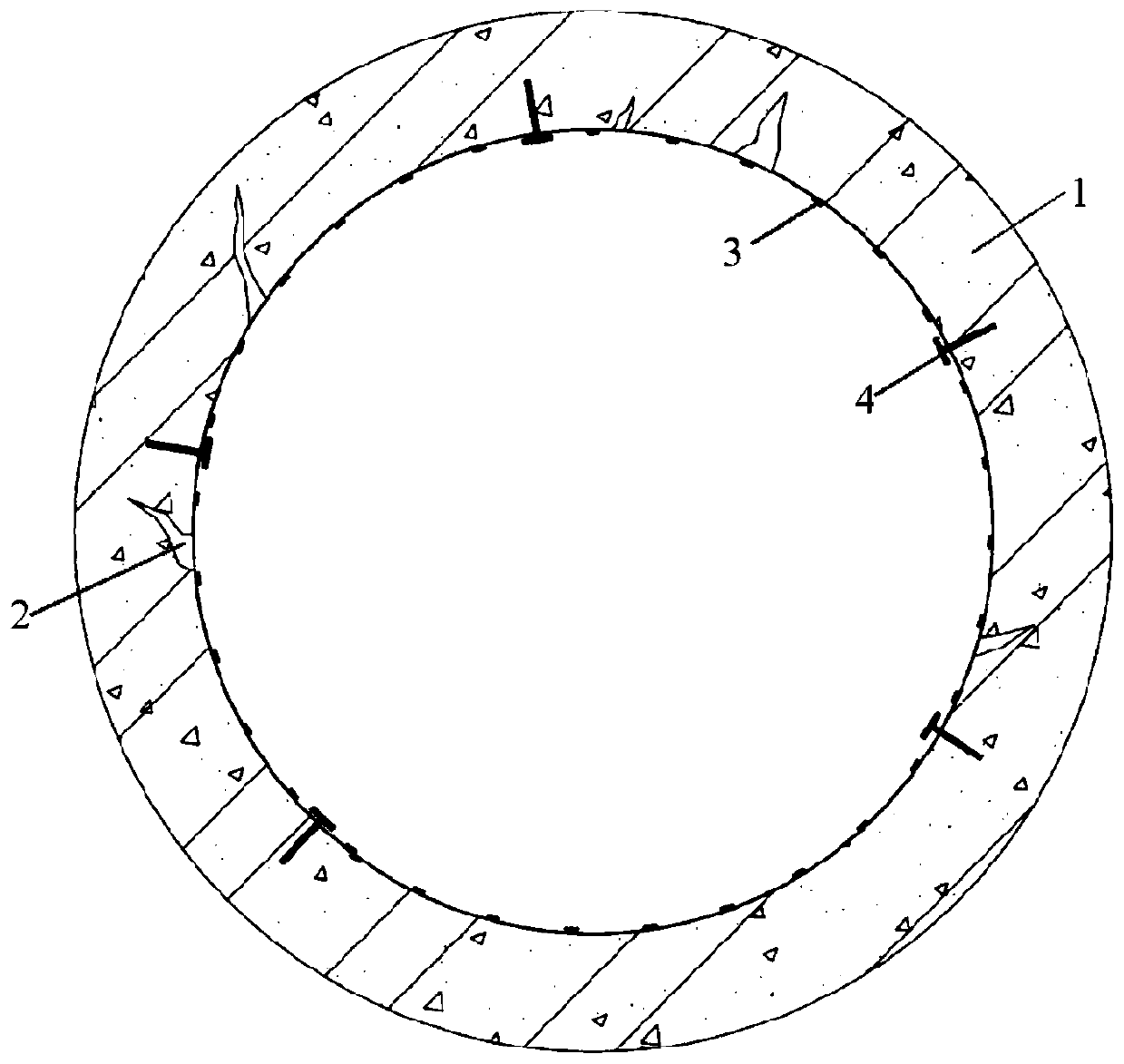

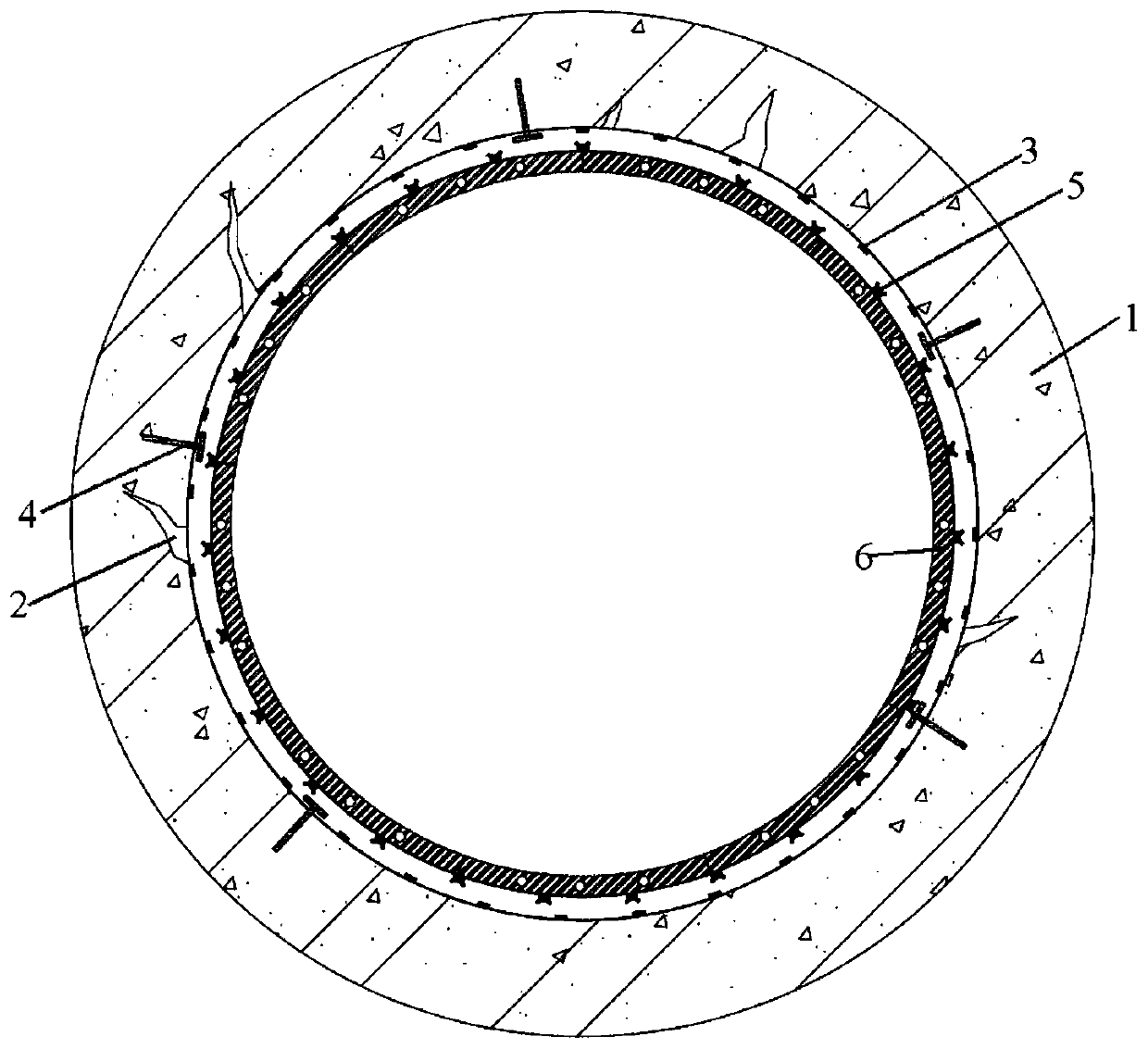

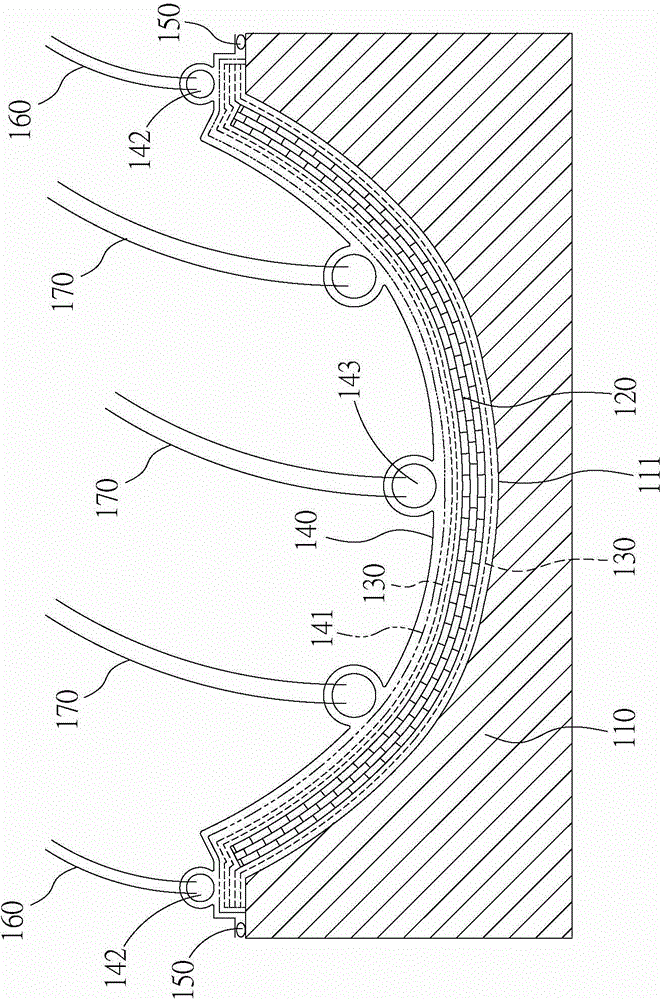

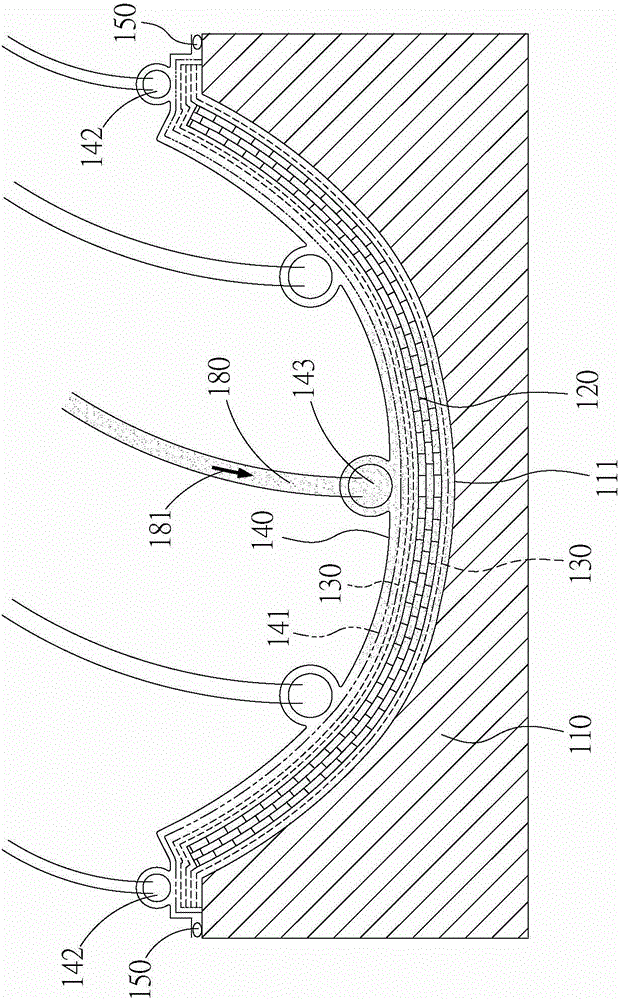

Grouting consolidation method for large-diameter concrete pipeline lining fiber grid

ActiveCN111536362AImprove bearing capacityImprove transportation capacityGround-workPipe elementsFiberMesh grid

The invention discloses a grouting consolidation method for a large-diameter concrete pipeline lining fiber grid. The grouting consolidation method comprises the following steps: clearing the inner surface of a to-be-consolidated concrete pipeline; mounting a fiber grid on the inner surface of the processed pipeline, and temporarily fixing the fiber grid by the device; mounting a waterproof surface layer at the outer side of the mounted fiber grid, and using the device to temporarily fix the waterproof surface layer; grouting mortar into a gap between the paved fiber grid and the waterproof surface layer; and after mortar curing is accomplished, dismounting a waterproof surface layer fixing device, and welding a jointing seam exposed by the surface layer. The effect of the fiber grid, themortar and the waterproof surface layer is sufficiently brought into play. The method disclosed by the invention can be adopted to remarkably improve structure bearing ability, also can form an effective waterproof layer on the surface of the structure, does not need excavation, is quick in construction, and is small in influences on production and life.

Owner:江苏绿材谷新材料科技发展有限公司

PMMA prepolymer and its preparation method and application

The invention discloses a PMMA prepolymer and its preparation method and application and belongs to the field of material synthesis. The PMMA prepolymer is prepared from 130 to 180 parts by weight of methyl methacrylate, 150 to 200 parts by weight of a diluent, 0.05 to 0.2 parts by weight of an initiator, 0.1 to 0.8 parts by weight of paraffin, and 0.1 to 0.8 parts by weight of a tertiary amine accelerator. The invention provides the PMMA prepolymer and its preparation method and application. The prepared PMMA prepolymer material can be stably stored for one year or more at a normal temperature in a dark place. In the temperature range of -35 to 35 DEG C, the PMMA prepolymer has short hardening time and excellent performances and can be used in fields of polymer concrete, concrete structure gap fillers, bridge water resistance, color pavement and anti-corrosion concrete floors.

Owner:北京华腾东光科技发展有限公司

Macromolecular moistureproof blocking agent

InactiveCN109266295ALow initial viscosityImprove permeabilityPolyureas/polyurethane adhesivesLiquid productSurface-active agents

The invention discloses a macromolecular moistureproof blocking agent. The moistureproof blocking agent is a double-liquid product prepared from two components of a main agent A and an auxiliary agentB, the ratio in parts by weight of the main agent A to the auxiliary agent B is 1 to 1, the component A is prepared from the elements in parts by weight: 60-70 parts of macromolecular polyether, 3.5-5 parts of chain extender, 0.7-1.0 part of self-made catalyst, 0.7-0.9 part of organic silicon surface active agent, 0-0.2 part of foaming agent, 10-15 parts of TCPP, 4-6 parts of flame retarding agent, 1-3 parts of anti-static agent, 4-6 parts of rutile titanium dioxide, 4-6 parts of aluminum hydroxide, 4-6 parts of light calcium carbonate, 2-4 parts of light magnesium carbonate, 0.01-0.05 part of anti-UV agent and 0.1-0.2 part of organic tin. The component B is various kinds of isocyanate, in particular DG-1521 material or PAPI. The initial viscosity of the reactive mixture of the macromolecular moistureproof blocking agent is very low, the macromolecular moistureproof blocking agent can be convenient to permeate and level, meanwhile, time is adjustable, the hardening time is short, theblocking agent is elastic, has the high binding strength, is flame retarding and antistatic, can block and fill under the existence of water and waterproof environment, and is applicable to various kinds of severe environments.

Owner:HUAINAN HONGYANG IND & TRADE

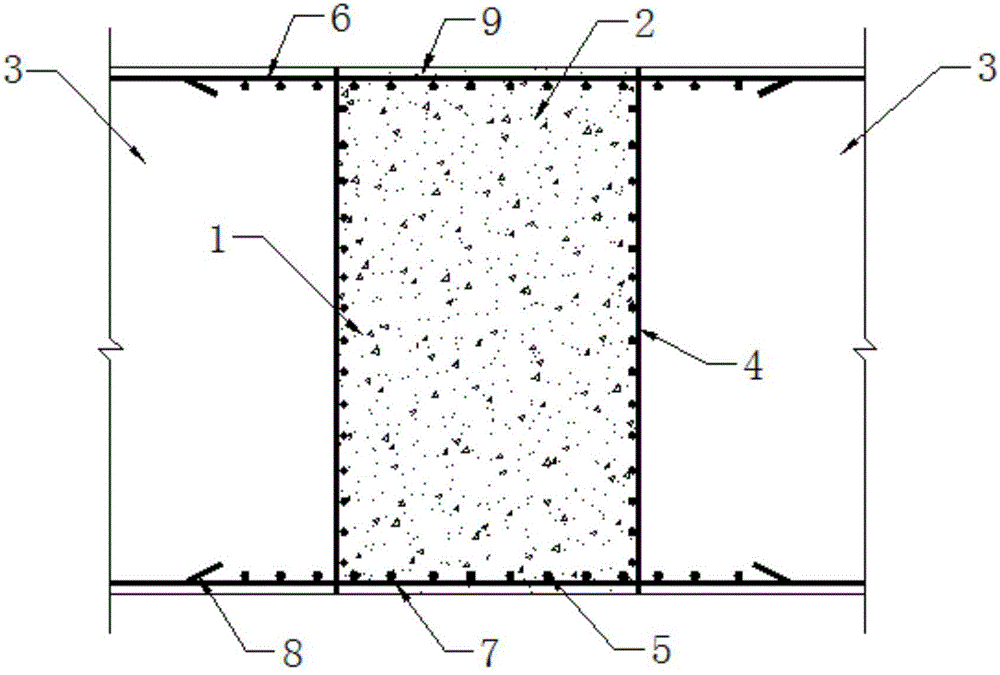

Jointless construction structure combining SCC (self-compacting concrete) and common concrete

InactiveCN106337443AShort hardening timeImprove self-waterproof performanceArtificial islandsUnderwater structuresRebarBuilding construction

The invention discloses a jointless construction structure combining SCC (self-compacting concrete) and common concrete. The jointless construction structure comprises a reinforced band, the high-performance SCC, two non-reinforced bands, close-drilling steel wire meshes; horizontal temperature reinforcement bars, upper reinforcement bars, lower reinforcement bars, vertical reinforcement bars and concrete protecting layers, wherein the high-performance SCC is uniformly arranged in the reinforced band; the close-drilling steel wire meshes are arranged between the high-performance SCC and the two non-reinforced bands; the upper ends of the vertical reinforcement ribs are connected with the upper reinforcement ribs; and the lower ends of the vertical reinforcement ribs are connected with the lower reinforcement ribs. The jointless construction structure disclosed by the invention achieves the beneficial effects that protecting and waterproof measures for a post-cast strip, the post-cast strip cleaning work, and a reinforcement part of the post-cast strip are eliminated; the construction period is shortened, the engineering cost is reduced, the construction is simplified, the engineering quality is improved, the homogeneity and the stability are high, and the concrete hardening period is short; the construction structure is simple and convenient, and no complex process is adopted, thereby saving the manpower and shortening the construction period; and the concrete self-waterproof effect is improved.

Owner:CHINA MCC17 GRP

Outdoor wood decking board

ActiveUS20180223529A1Improve stabilityReduce foam generationFloorsWood working apparatusIsocyanateWood finishing

An outdoor wood decking board for use in construction of an outdoor deck floor, the outdoor decking board including a wood core formed from a first wood species of common grade wood species as a three-dimensional solid rigid body. A facing wood veneer formed from a second wood species of superior grade wood species as a three-dimensional solid rigid wood finishing layer permanently seamlessly attached via an adhesive to a first wood face of the wood core thereby the wood core having an appearance of the second wood species. In another embodiment, the facing wood veneer is formed from a third wood species, exotic hardwood species. A two-part emulsion polymer isocyanate adhesive is used to bond the wood core against the facing wood veneer; to bond two wood cores together. In another embodiment, the adhesive is a two-part polyurethane emulsion polymer.

Owner:TEBB TERRY ALLEN +1

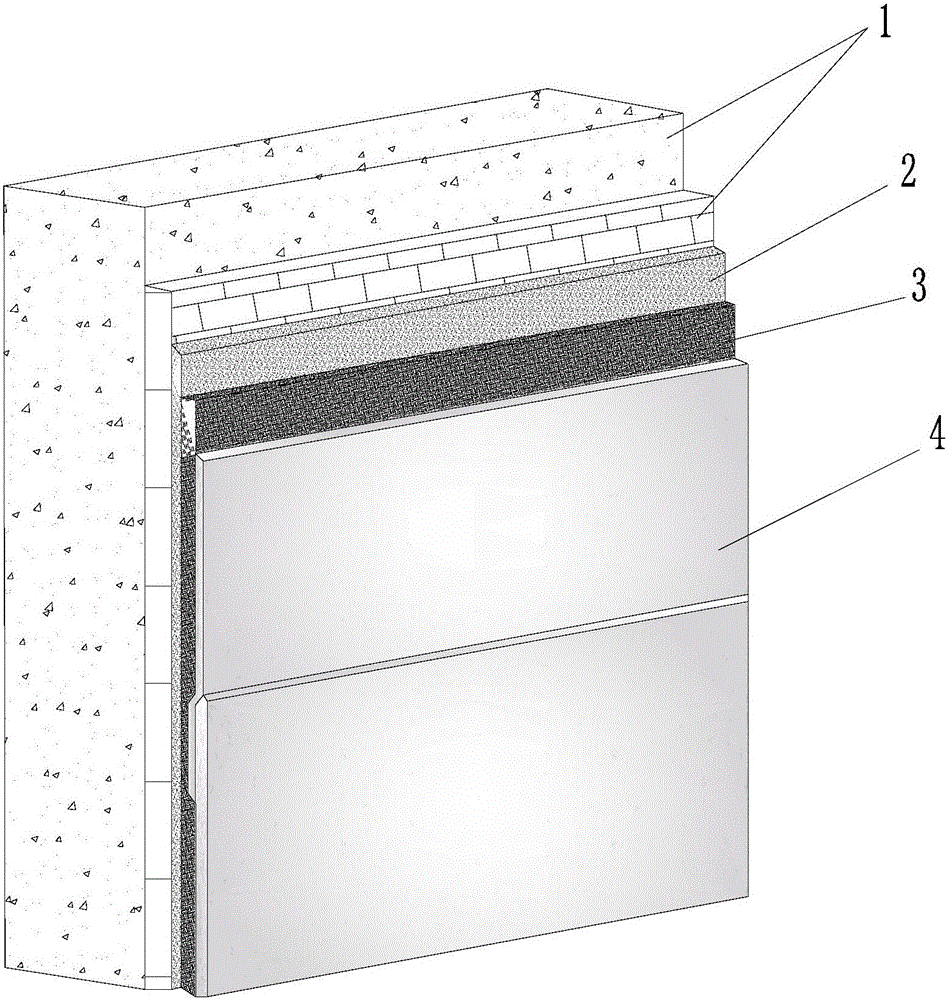

Anti-corrosion structure for chimney and construction method thereof

ActiveCN104989167AAvoid spot weldingAvoid Weld Quality IssuesTowersBuilding insulationsAdhesiveTitanium plate

The invention discloses an anti-corrosion structure for a chimney. The anti-corrosion structure comprises a first coat (2), an adhesive layer (3) and a titanium plate layer (4) which are arranged in sequence, wherein a chimney base (1) is coated with the first coat (2), and the titanium plate layer (4) adheres to the first coat (2) through the adhesive layer (3). The invention further discloses a construction method of the anti-corrosion structure for the chimney. The method comprises the steps of cleaning the chimney base, coating the cleaned chimney base with the first coat material, applying adhesive and sticking a titanium plate after the first coat material on the chimney base is solidified, and conducting inspection and repair. According to the method, the lapped titanium plate is directly stuck onto the structural layer of a chimney by means of the titanium plate adhesive. The method has the advantages that construction period is short, the requirement for the site construction environment is low, and the problem that titanium plate welding quality is poor due to poor construction site welding environment is solved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

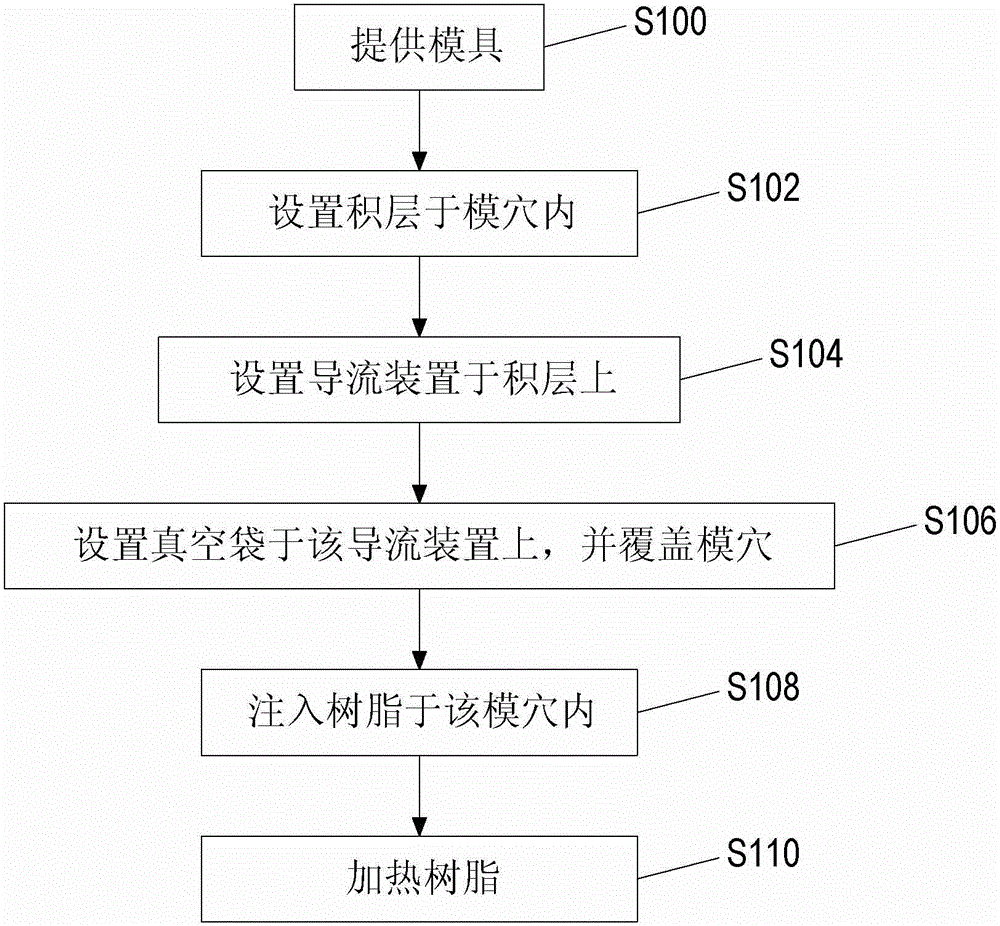

Fiberglass reinforced plastic and manufacturing method thereof

The invention discloses a fiberglass reinforced plastic and the manufacturing method thereof. The manufacturing method includes providing a die including a die cavity, providing a depositing layer in the die cavity, providing a diverting device on the depositing layer, providing a vacuum bag on the diverting device and covering the die cavity to seal the diverting device and the depositing layer between the vacuum bag and the die, injecting resin in the die cavity and heating the resin. The fiberglass reinforced plastic prepared with the method is excellent in surface flatness. The resin is long in curing time, short in hardening time, low in dispersed heat, high in glassfiber conversion temperature and low in contraction. The fiberglass and carbon fiber are excellent in immersion performance.

Owner:ATECH COMPOSITES +1

Manufacturing method of light building board

The invention discloses a manufacturing method of a light building board. The manufacturing method comprises the following steps: adding a balanced amount of starch expanded material in foamed rapid hardening cement mixed slurry to be stirred uniformly, injecting the rapid hardening cement mixed slurry containing the starch expanded material into a forming mould for hardening forming. Since the hardening time of the rapid hardening cement is short, and the starch expanded material has certain water resistance, during the cement hardening process, the rapid hardening cement has been prehardened before the starch expanded material scatters and is dissolved, but the interior of the rapid hardening cement has no flowability, and the starch expanded material can be poured into a foamed space to reduce the volume weight of the product to enable the product to be lighter. Meanwhile, during the process of foamed magnesium cement hardening, most of the starch expanded material forms starch glue through micro-grinding and high-temperature gelatinization, and the starch expanded material is diffused toward the surrounding space in a starch glue form at the later period of hardening, so that the flexural and compressive strength of the product is improved greatly.

Owner:王铁石

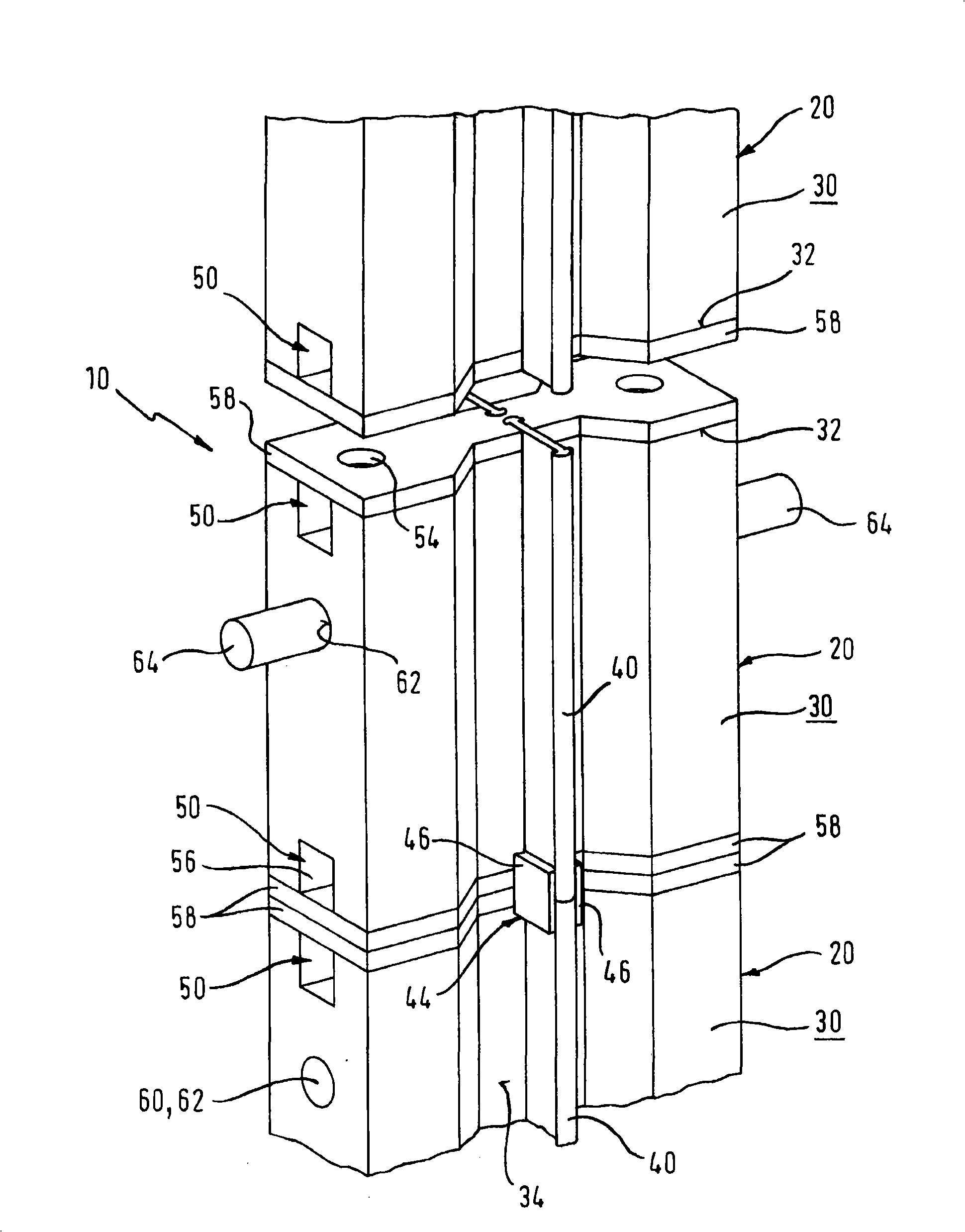

Formwork for limiting a diaphragm wall section, formwork element and method for manufacturing a diaphragm wall in the ground

InactiveCN101289854AShort hardening timeGuaranteed not to deformForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksEngineeringMechanical engineering

Owner:BAUER MASCH GMBH

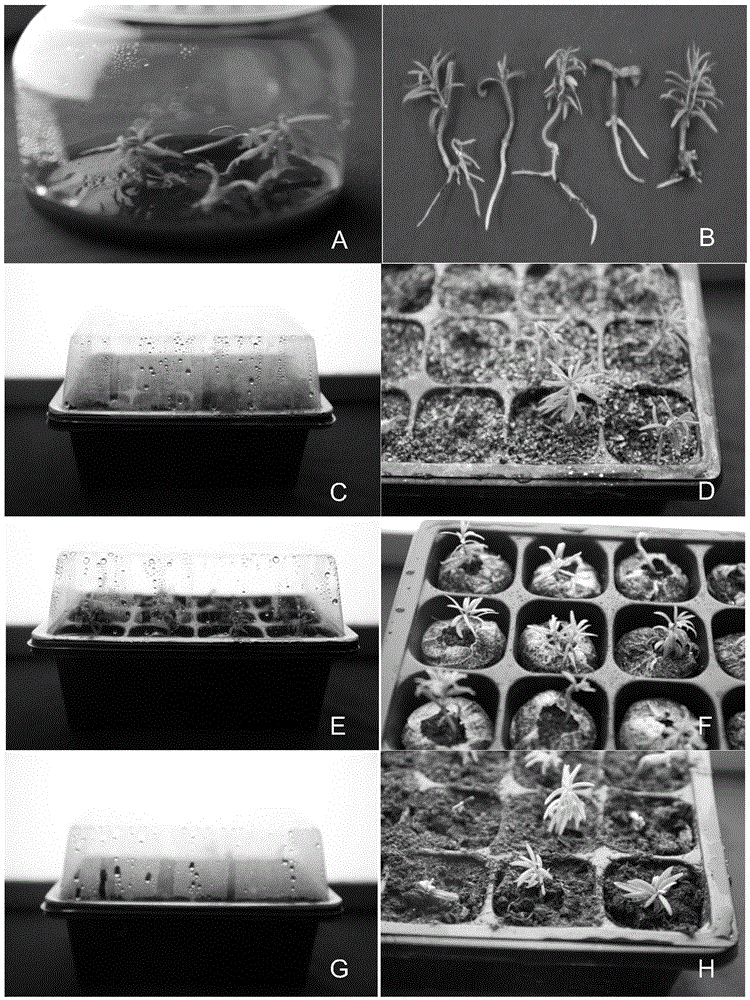

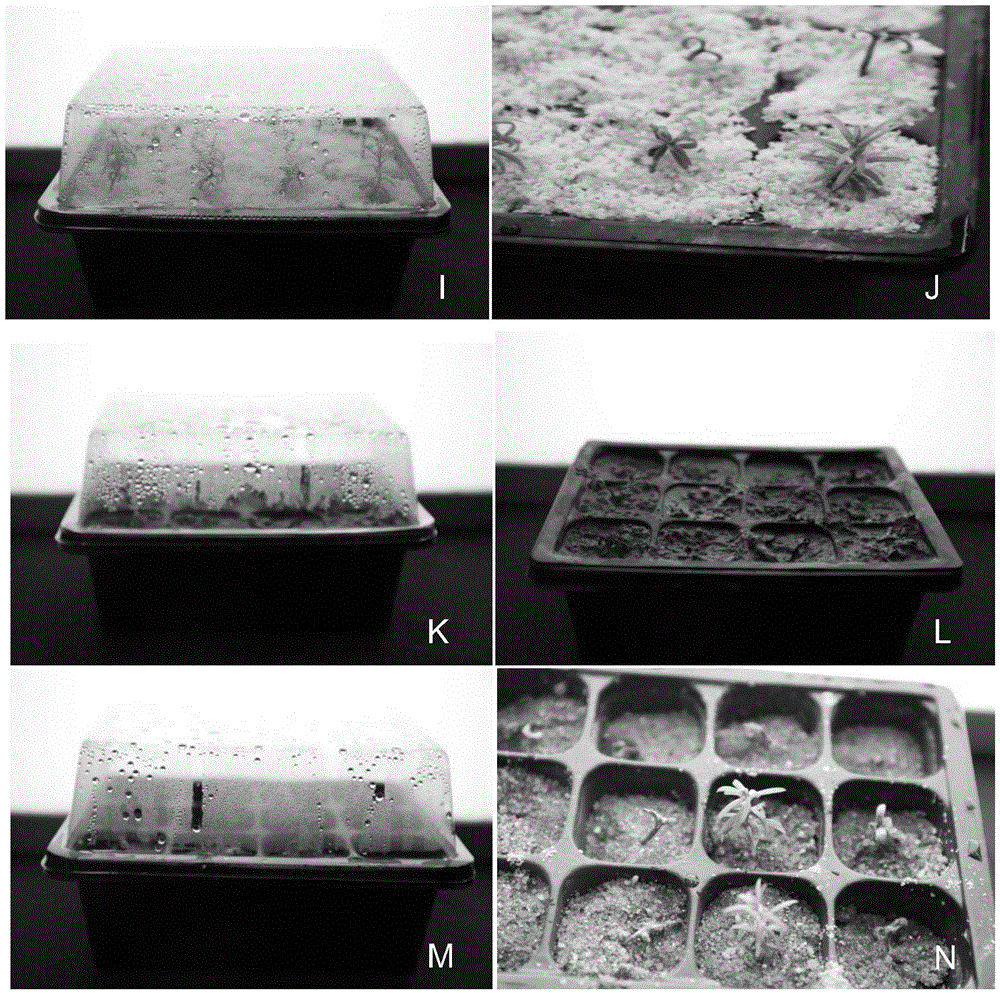

Method for domesticating and transplanting taxus chinensis var mairei tissue culture seedling

ActiveCN105638462AImprove survival rateShort hardening timeGrowth substratesCulture mediaRoot systemTaxus chinensis var. mairei

The invention discloses a method for domesticating and transplanting a taxus chinensis var mairei tissue culture seedling. The method comprises the following steps of (1) selecting the tissue culture seedling by means of selecting the taxus chinensis var mairei tissue culture seedling with a well-grown root system and more than one true leaf; (2) preliminarily domesticating the tissue culture seedling by means of putting a tissue culture container with the tissue culture seedling into a greenhouse for 3 to 5 days; (3) preparing a transplanting container and a culture substrate by means of selecting a seedling culturing box, and filling vermiculite, turf or nonwoven-fabric wrapped fresh coconut chaff in holes of the seeding culturing box; (4) transplanting and hardening seedling by means of planting the tissue culture seedling in the middle of the culture substrate obtained in the step (3), watering sufficiently, closing a seedling culturing box cover, putting the box into the greenhouse with 50 percent of sunshield screen, culturing at an environmental temperature of not more than 35 DEG C, and opening the seedling culturing box cover and performing a conventional seedling management mode after two weeks, wherein the survival rate of transplanted tissue culture seedlings reaches 100 percent at most. The method disclosed by the invention has the advantages that the disadvantages in the prior art are overcome, and the effects of simplicity in operation, low cost, high efficiency, stability and reusability of the seedling culturing box are achieved.

Owner:HUNAN AGRICULTURAL UNIV

A polymer-loaded coagulant and its preparation method and cement slurry

ActiveCN107987813BPromote hydrationShort hardening timeDrilling compositionCompressive resistanceWell cementing

The invention relates to a polymer supported coagulant, a preparation method thereof and cement paste containing the polymer supported coagulant in the field of petroleum drilling and production. Thepolymer supported coagulant is prepared from a polymer supported organic component and inorganic matter in the weight ratio being 1:(0.1-100), preferably 1:(0.5-10). The polymer supported coagulant can be used as a cement coagulant for oil well cementation, particularly in a low-temperature environment. The polymer supported coagulant has good adaptability in the temperature range of 5-10 DEG C, has good dosage linearity, is compatible with multiple additive systems, has good compatibility, has the compressive strength larger than 3.5 MPa within 24 h for set cement and has no effects on comprehensive performance of the cement paste.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sodium silicate molding sand and sand casting method based on sand removal through water jet

ActiveCN107175311AGood formabilityShort hardening timeFoundry mouldsFoundry coresSodium BentoniteGraphite

The invention relates to sodium silicate molding sand and a sand casting method based on sand removal through a water jet. The casting method comprises steps of molding sand preparation, molding, core making, mold assembling and pouring. The sodium silicate molding sand used during molding sand preparation is prepared from raw material components in parts by weight as follows: 92-96 parts of quartz sand, 3-6 parts of sodium silicate and 1-2 parts of a molding sand breakdown agent. The molding sand breakdown agent is prepared from raw materials as follows: bentonite, graphite, starch and dextrin. After the pouring step is completed, water is jetted to the molding sand for quick cooling when the temperature of poured melt is reduced to be in the range of 650 DEG C-700 DEG C. The sodium silicate molding sand has the good collapsibility, the purposes of grain refinement and directional exhaust can be achieved through water jetting and quick cooling, and the performance of a casting is improved; loose sand after collapsing can be recycled, the cost is low, and the sand is pollution-free, clean and environment-friendly.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Self hardening glass carbomer composition

InactiveCN1809329AHigh hardnessReduce sensitivityImpression capsSurgical adhesivesFluorosilicate saltAcid water

The present invention relates to a self hardening glass carbomer composition obtainable by treating a fluorosilicate glass powder with: (a) a poly(dialkylsiloxane) having terminal hydroxyl groups, wherein the alkyl groups contain 1 to 4 carbon atoms, (b) an aqueous acid solution, and (c) separating the treated fluorosilicate glass powder from the aqueous acid solution. The glass carbomer compositions according to the invention have for example good toughness and strength and excellent fluoride release, In addition, the glass carbomer compositions according to the invention do not show shrinkage or expansion, an essential property for providing fillings for cavities having high strength and long durability. Moreover, the glass carbomer composition according to the present invention has a lower sensitivity towards abrasion and wear, a greater stiffness, a smoother surface, a better colourfastness, a better adherence to e.g. bone tissue and a lower water sensitivity.

Owner:健康玻璃基金会

High-intensity fire-resistant plastic material

The invention relates to a high-temperature-resistant material, in particular to a high-intensity fire-resistant plastic material. The high-intensity fire-resistant plastic material is prepared from the following raw materials in parts by weight: 16 to 26 parts of high-aluminum clinkers with the particle diameter being 0.02 to 0.03mm, 7 to 10 parts of corundum with the particle diameter being 0.6 to 1mm, 7 to 13 parts of corundum with the particle diameter being 2 to 3mm, 12 to 25 parts of corundum with the particle diameter being 3 to 5mm, 5 to 16 parts of corundum with the particle diameter being 5 to 8mm, 7 to 10 parts of silicon carbide powder with the particle diameter being 0.1 to 0.3mm, 15 to 20 parts of silicon carbide powder with the particle diameter being 0.5 to 1mm, 8 to 16 parts of magnesium oxide, 25 to 30 parts of mullite and 13 to 20 parts of calcium phosphate. The high-intensity fire-resistant plastic material provided by the invention has the advantages that the hardening time is short; the construction is convenient; the high-intensity fire-resistant plastic material is used for repairing parts, with serious abrasion erosion, in a furnace.

Owner:YIXING JICHUANG NEW MATERIAL TECH CO LTD

Cement-based spraying material and preparation method and application thereof

The invention discloses a cement-based spraying material and a preparation method and application thereof. The cement-based spraying material comprises the following components in parts by weight: 60-80 parts of cement, 20-50 parts of an organic monomer, 1-5 parts of a cross-linking agent, 1-5 parts of an initiator, 1-5 parts of a coagulation accelerator, 1-3 parts of a water reducing agent and 60-100 parts of water, the organic monomer is one or more of acrylamide, acrylic acid, butyl acrylate and ethylene glycol; and the cross-linking agent is one or more of N, N-dimethyl diacrylamide, triethylene diammonium, ethylene glycol dimethacrylate, carbodiimide and an aziridine cross-linking agent. During preparation, the cement, the water reducing agent, the initiator and the coagulant are uniformly mixed to obtain powder, the organic monomer, the cross-linking agent and the water are uniformly mixed to obtain a liquid, and during use, the powder and the liquid are uniformly mixed to obtainthe cement-based spraying material so that the hardening time is short, and the deformation resistance is high.

Owner:SHAANXI COAL & CHEM TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com