Improved low-alkaline ceramic tile adhesive

A ceramic tile adhesive and alkaline technology, applied in the field of improved tile adhesive preparation, can solve the problems of easily causing skin diseases and respiratory diseases, abnormal structural expansion cracks, affecting the appearance of buildings, etc., so as to prolong the time of hydration and hardening. , Fast hardening time, reducing the effect of mixing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

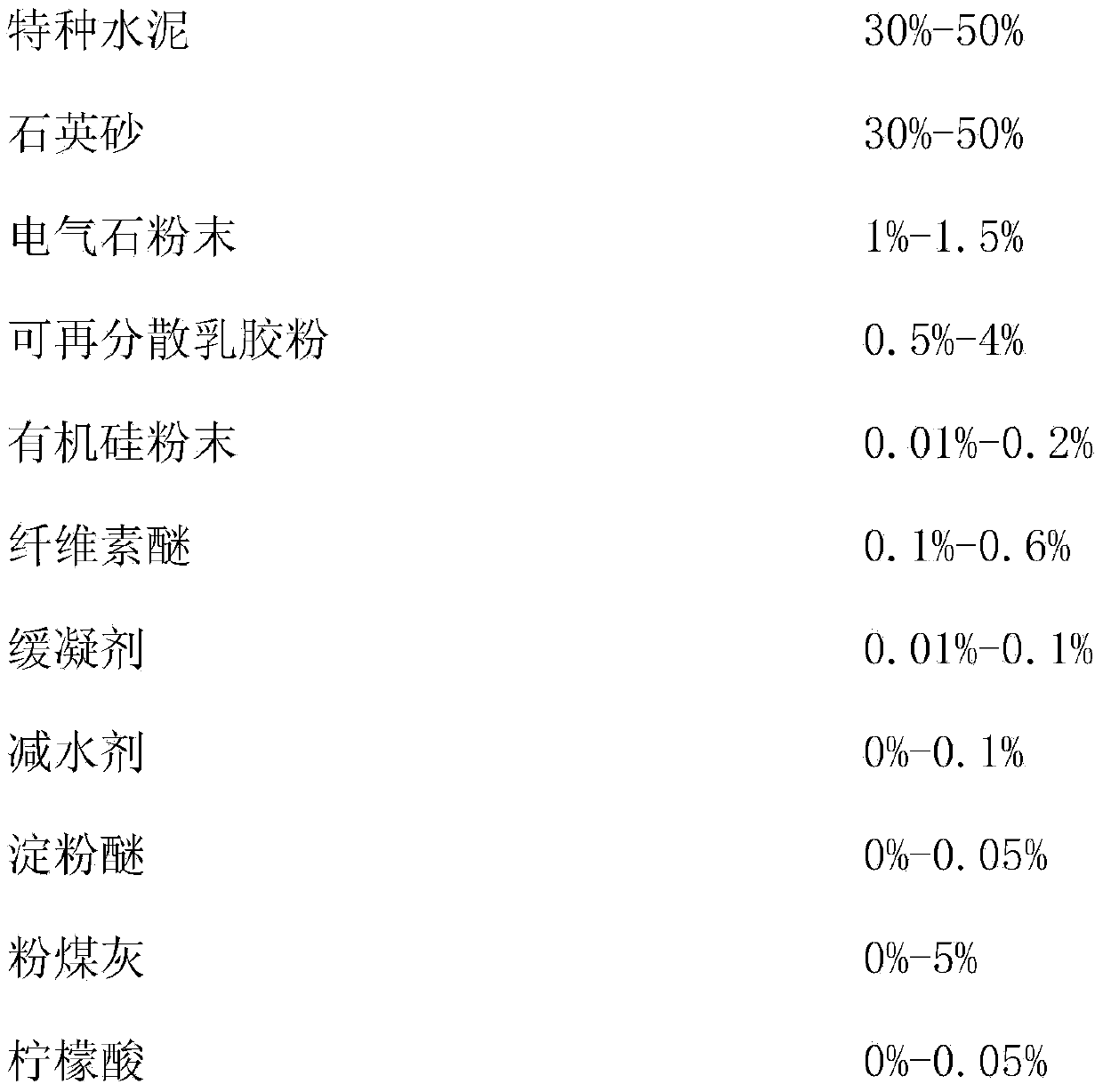

[0021] A low-alkaline tile adhesive, the material is made of special sulfoaluminate cement as the cementitious material, with graded quartz sand aggregate, active mineral admixture and high molecular polymer and other additives. become. The specific formula is as follows:

[0022]

[0023] Said percentages are all mass percentages.

[0024] The special cement is low alkalinity sulphoaluminate cement.

[0025] The quartz sand is sand with a particle size of 40-70 mesh.

[0026] The particle size of the tourmaline powder is 0.8 μm

[0027] The redispersible latex powder is vinyl acetate and ethylene copolymer powder.

[0028] The cellulose ether is methyl hydroxyethyl cellulose ether or methyl hydroxypropyl cellulose ether.

[0029] The retarder is a carboxylate-based organic substance.

[0030] The order of feeding raw materials is to mix additives in the order of redispersible latex powder-organic silicon powder-cellulose ether-retarder-water reducer-starch ether-tour...

Embodiment 2

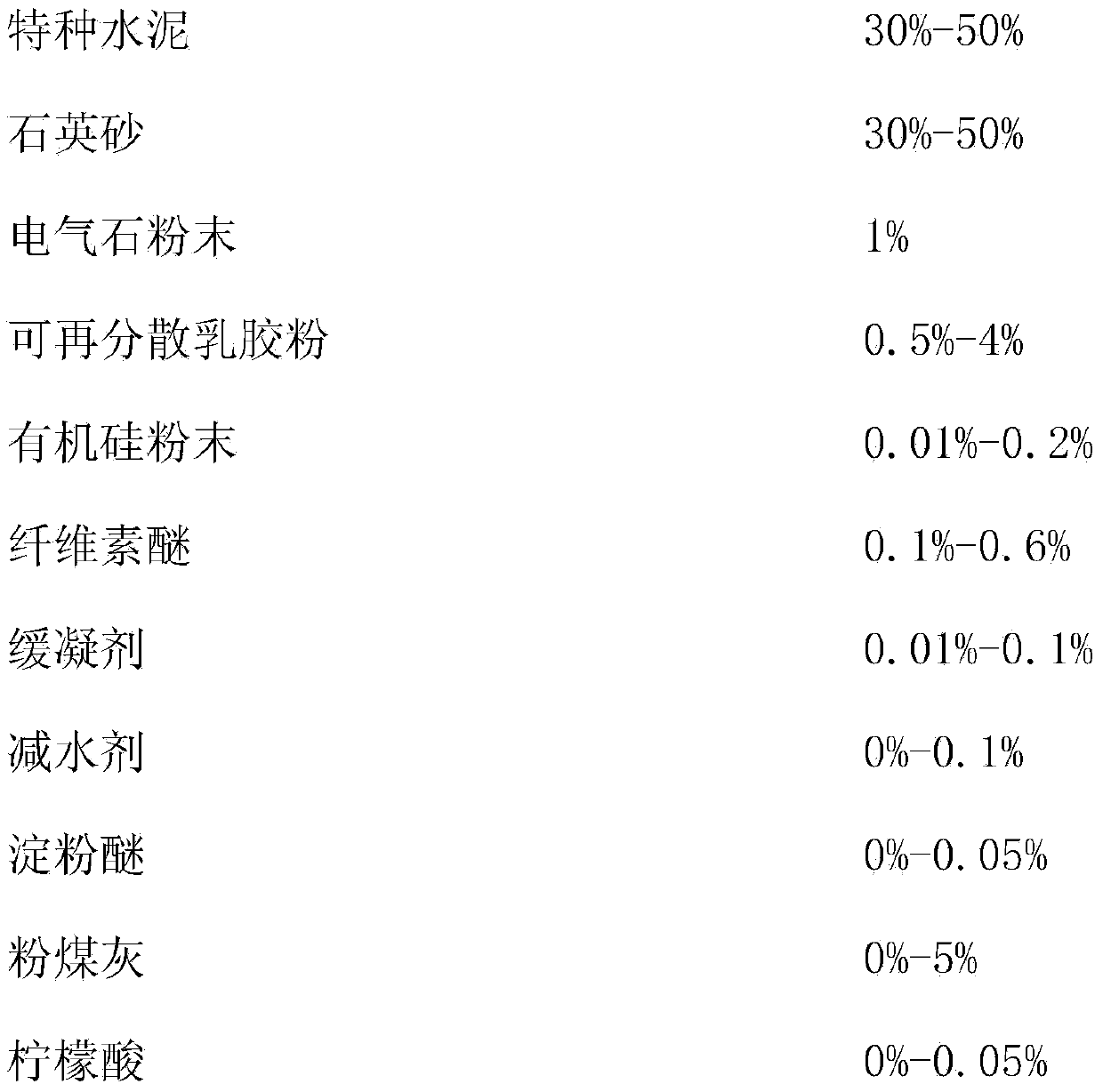

[0032] A low-alkaline tile adhesive, the material is made of special sulfoaluminate cement as the cementitious material, with graded quartz sand aggregate, active mineral admixture and high molecular polymer and other additives. become. The specific formula is as follows:

[0033]

[0034] Said percentages are all mass percentages.

[0035] The special cement is low alkalinity sulphoaluminate cement.

[0036] The quartz sand is sand with a particle size of 40-70 mesh.

[0037] The particle size of the tourmaline powder is 1 μm

[0038] The redispersible latex powder is vinyl acetate and ethylene copolymer powder.

[0039] The cellulose ether is methyl hydroxyethyl cellulose ether or methyl hydroxypropyl cellulose ether.

[0040] The retarder is a carboxylate-based organic substance.

[0041] The order of feeding raw materials is to mix additives in the order of redispersible latex powder-organic silicon powder-cellulose ether-retarder-water reducer-starch ether-tourma...

Embodiment 3

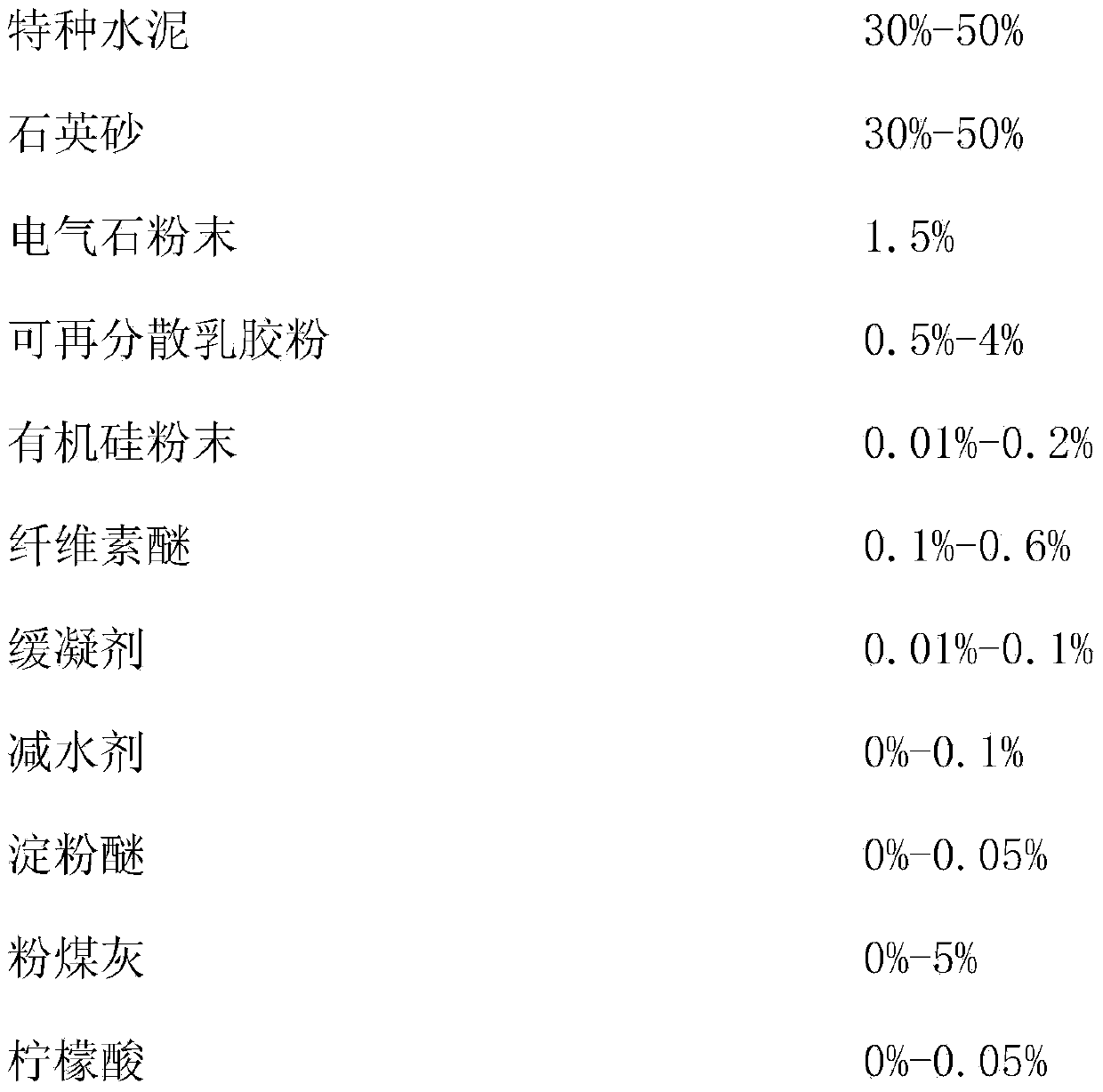

[0043] A low-alkaline tile adhesive, the material is made of special sulfoaluminate cement as the cementitious material, with graded quartz sand aggregate, active mineral admixture and high molecular polymer and other additives. become. The specific formula is as follows:

[0044]

[0045] Said percentages are all mass percentages.

[0046] The special cement is low alkalinity sulphoaluminate cement.

[0047] The quartz sand is sand with a particle size of 40-70 mesh.

[0048] The particle size of the tourmaline powder is 0.6 μm

[0049] The redispersible latex powder is vinyl acetate and ethylene copolymer powder.

[0050] The cellulose ether is methyl hydroxyethyl cellulose ether or methyl hydroxypropyl cellulose ether.

[0051] The retarder is a carboxylate-based organic substance.

[0052] The order of feeding raw materials is to mix additives in the order of redispersible latex powder-organic silicon powder-cellulose ether-retarder-water reducer-starch ether-tour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com