Grouting consolidation method for large-diameter concrete pipeline lining fiber grid

A technology of fiber mesh and concrete, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of low efficiency of pipe strength and rigidity improvement, difficulty in guaranteeing long-term performance, and high requirements for pasting technology, so as to avoid the phenomenon of hollow drums in reinforcement, Improve pipeline transportation capacity and eliminate the effect of waterproofing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Embodiment: A fiber grid grouting reinforcement method for the lining of large-diameter concrete pipes.

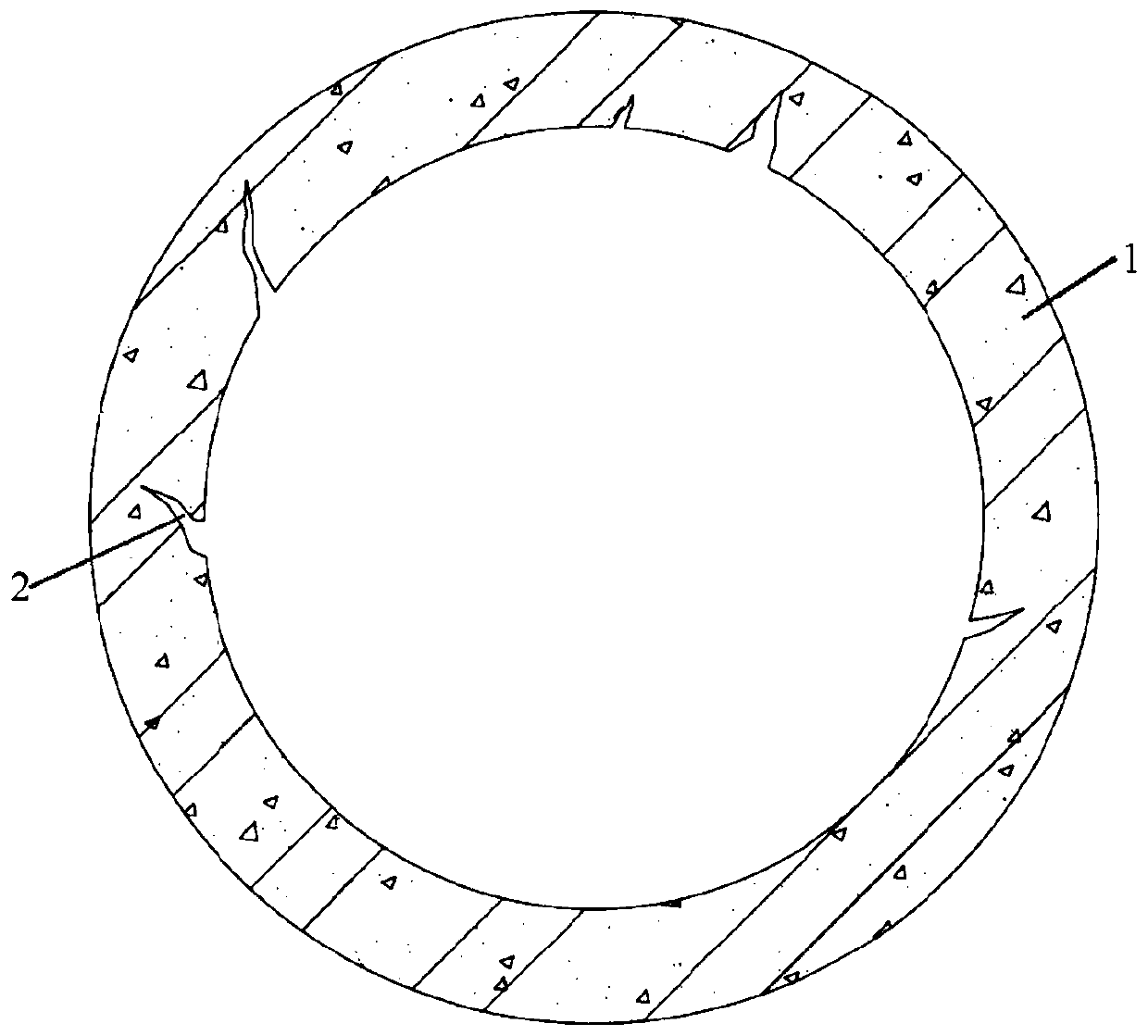

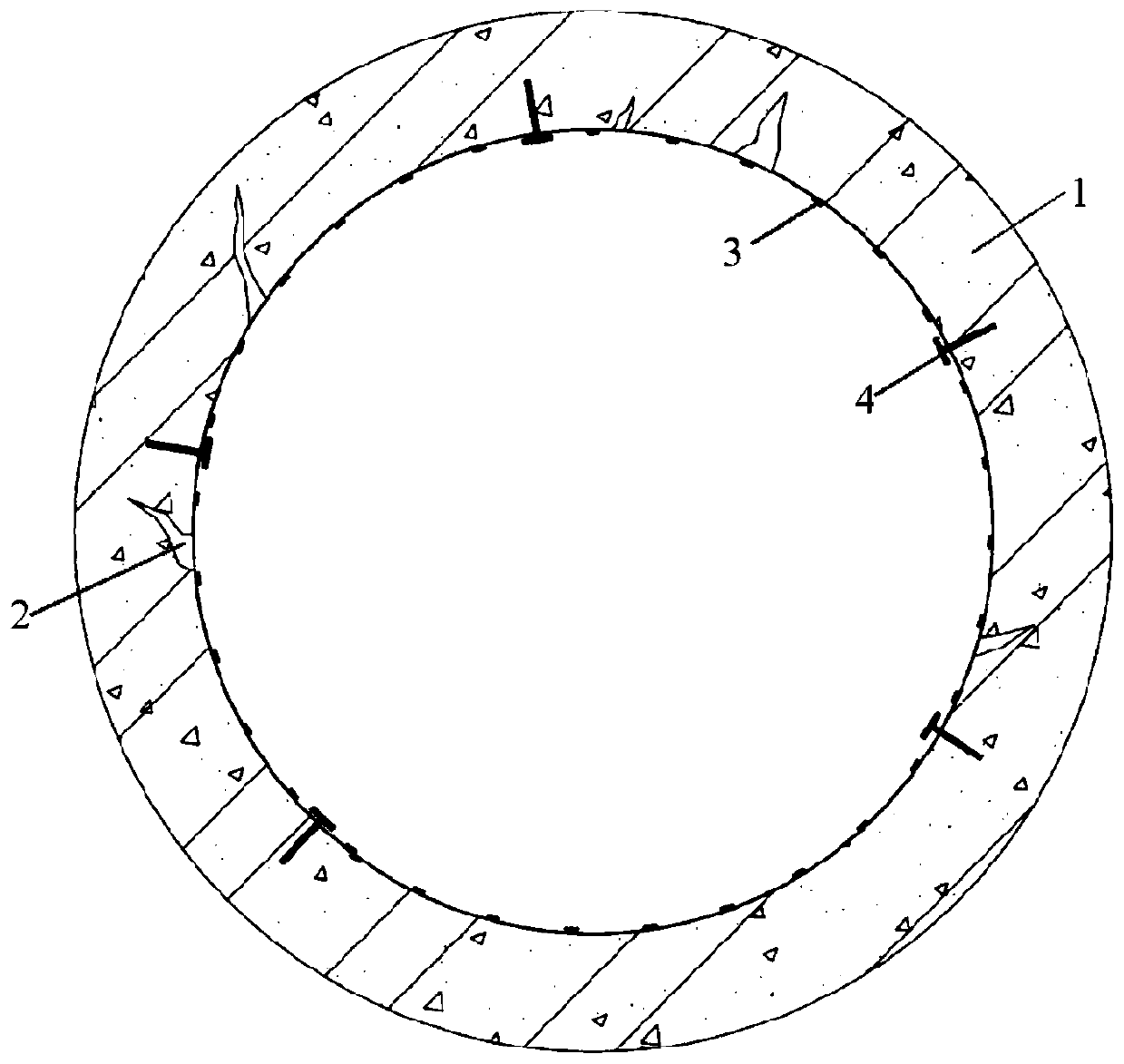

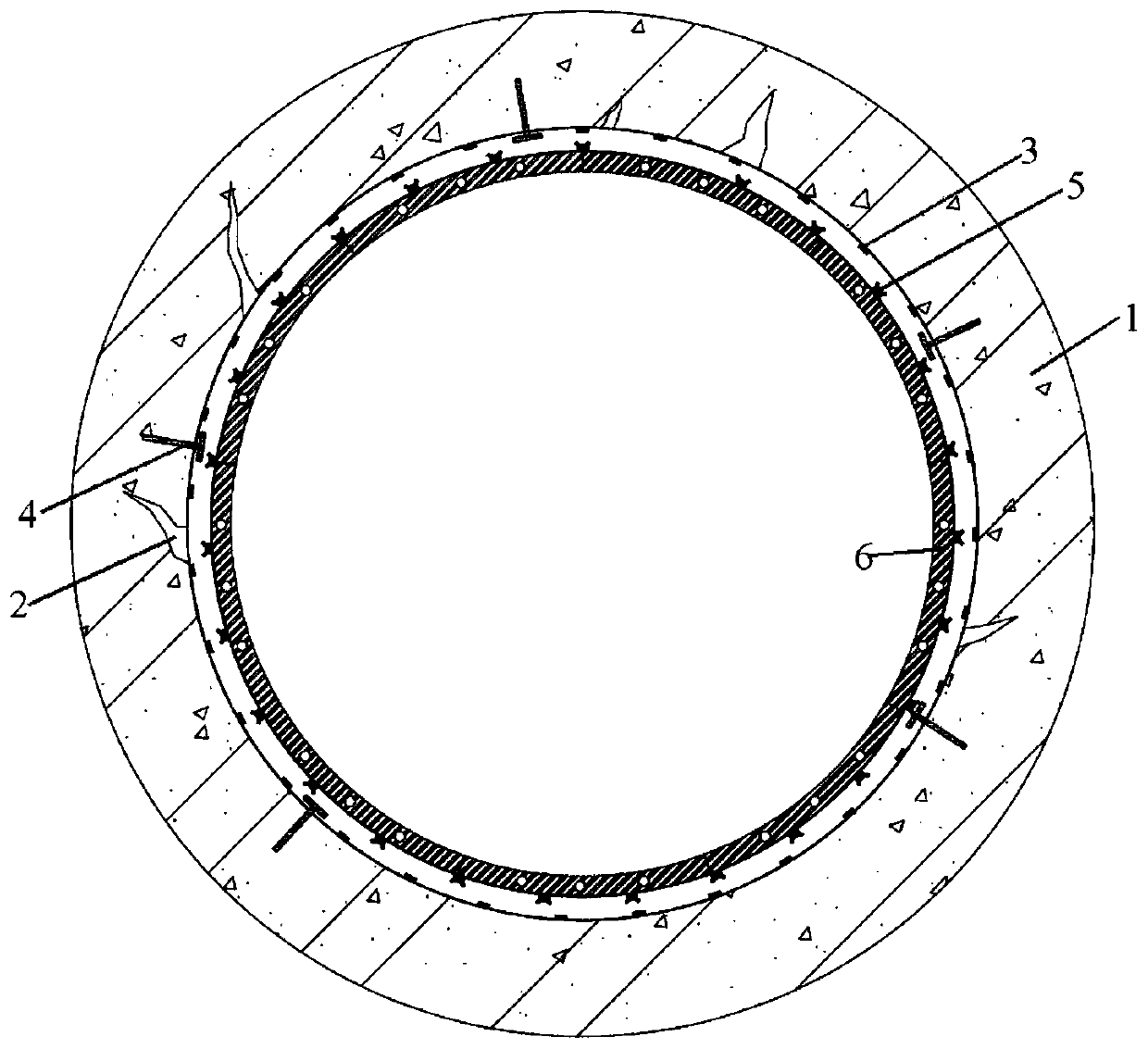

[0036] Pipeline 1 is a concrete circular pipe with a diameter of more than 1m that can enter people, or a pipe with a height of more than 1m and a width of more than 0.9m that can enter people. The long-term use of the pipeline will lead to the cracking and damage of the pipeline concrete, forming structural cracks2.

[0037] The specific reinforcement method includes the following steps:

[0038] (1) Firstly, manually survey the inside of the pipeline 1, remove foreign matter and garbage in the pipeline, and chisel out the deteriorated part of the concrete on the pipe wall; then use a high-pressure water gun to clean the surface of the inner wall of the pipeline 1 and keep it dry;

[0039] (2) Put the fiber mesh 3 cut according to the designed size into the pipeline 1 through the manhole; When bolting, the edge of the gasket should be aligned with the edge of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com