Patents

Literature

98results about How to "Guaranteed long-term" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antistatic automobile glass cleaning agent

InactiveCN101798550AReduce resorptionGuaranteed long-termOrganic detergent compounding agentsSurface-active detergent compositionsCleansing AgentsToxicity

The invention relates to an antistatic automobile glass cleaning agent. On the basis of maintaining and enhancing the basis cleaning capability, a functional component is added, therefore, the invention enables the glass surface to have the properties of recontamination resistance, fast dryness, fog resistance, hydrophilicity, no trace after cleaning, and the like, and has the advantages of no toxicity, environment protection, corrosion resistance and the like.

Owner:HEBEI AGRICULTURAL UNIV.

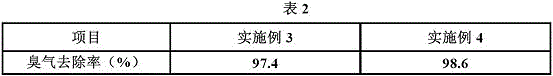

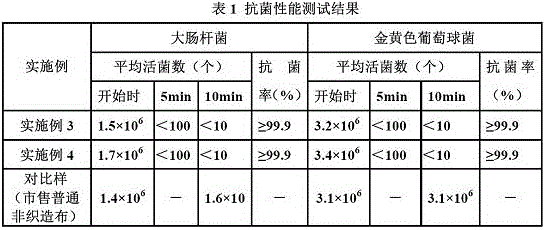

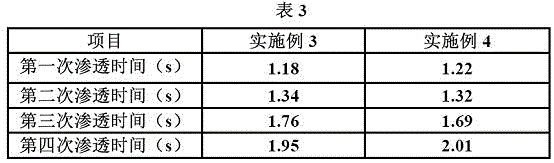

Antibacterial fiber, preparation method and antibacterial non-woven cloth used for surface layer of disposable moisture-absorption product

InactiveCN107938021AInhibitionAvoid breedingFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPorous graphene

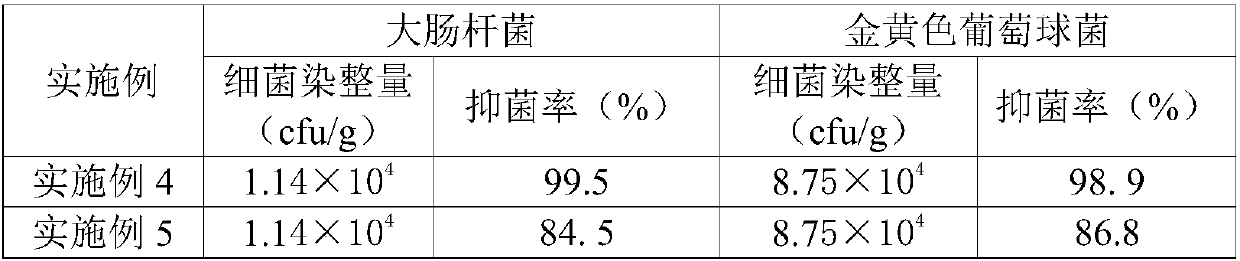

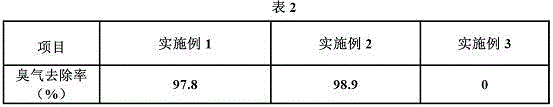

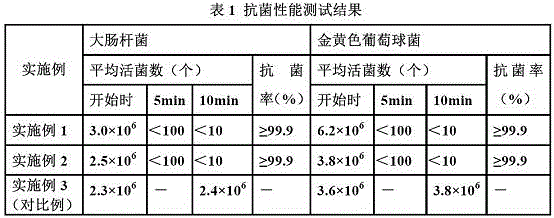

The invention relates to antibacterial fiber having a core-skin structure, wherein a skin layer is a low-melting point polymer, a core layer is a high-melting point polymer, the core layer and the skin layer are composited through a two-component spinneret assembly, the low melting point polymer body of the skin layer contains a graphene antibacterial composition, the graphene antibacterial composition takes modified porous graphene as a skeletal material, the graphene antibacterial composition is loaded at an aperture or in a surface layer of the modified porous graphene, the graphene antibacterial composition comprises the following components in parts by mass: 20-70% of the modified porous graphene, 20-80% of an antibacterial plant extract, and 1-5% of organic rare earth salt. The antibacterial fiber is subjected to metering, carding and thermoforming composite to form an antibacterial non-woven cloth used for a surface layer of a disposable moisture-absorption product. The antibacterial fiber and the antibacterial non-woven cloth has no stimulation on skin of human body, and have excellent antibacterial property, the antibacterial property is slowly released and stable, and thepersistence of washing resistance and effects of bacteriostasis and deodorizing can be guaranteed.

Owner:FUJIAN HENGAN HYGIENE MATERIAL +3

Water retention method of back fill course

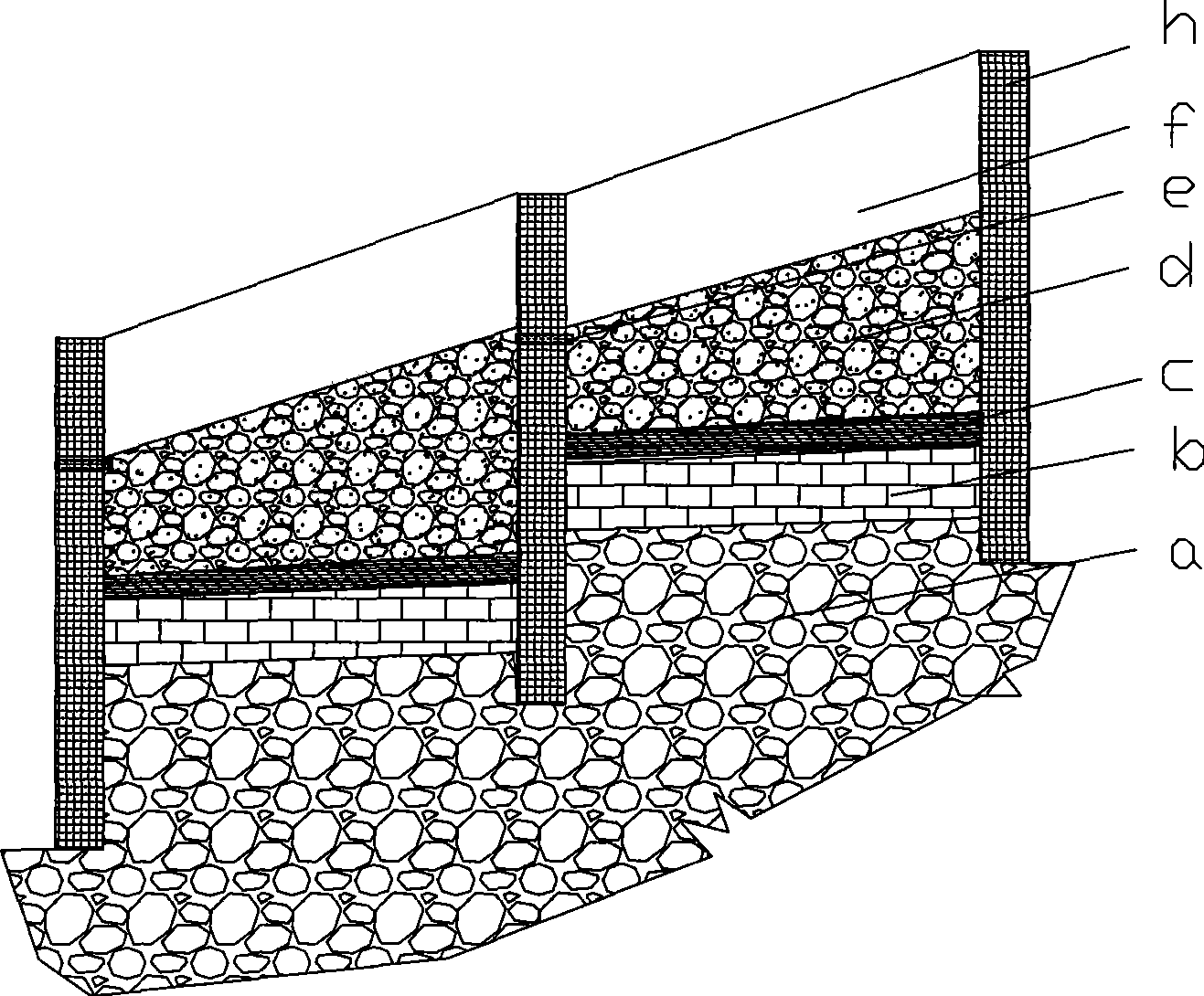

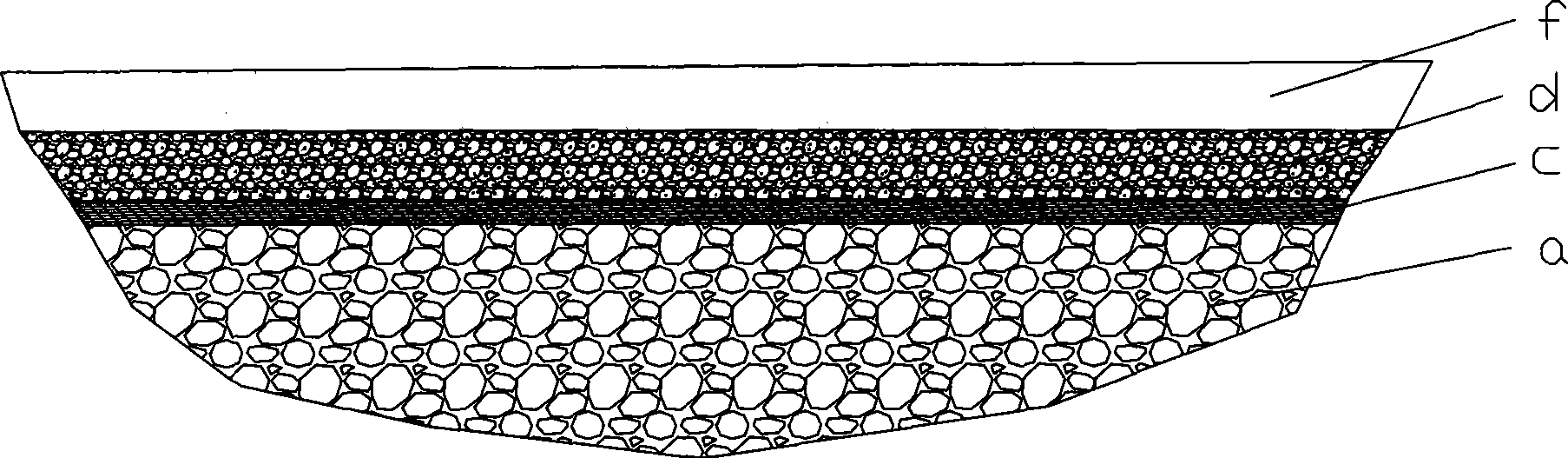

The invention discloses a water-keeping method for a backfill soil layer used in recovering green for a waste mine or a re-cultivating filling type land. The method comprises: determining bottom elevation of a seepage-proof layer according to the terrain of the areas to be recovered green in the waste mine, determining top elevation of a planting layer according to requirement of terrain design, and determining thicknesses of the planting layer and a water-keeping layer according to types of vegetation to be planted; and filling a solid waste foundation, a rigid seepage-proof layer, a plastic seepage-proof layer, the water-keeping layer and a planting soil layer from top down in turn. As the design of the water-keeping layer is adopted, after survival of the vegetation, only less water even no water is needed to meet the demand of moisture by the vegetation, so the method ensures long-term effect of biological recovery and is suitable for recovering green of waste mines in arid regions and semi-arid areas. Whether the solid waste foundation is filled stably or not does not influence the effect of water keeping so as to save time for the construction. The water-keeping method is simple and easy to construct, can increase water keeping space and effect, and can greatly reduce use of soil for planting.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of self-fragrance natural antibacterial and deodorizing fiber and application thereof

InactiveCN106637498APermanent antibacterialOutstanding antibacterial propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsHigh absorptionIrritation

The invention relates to a preparation method of self-fragrance natural antibacterial and deodorizing fiber. The preparation method comprises the following steps of (1) preparing a fragrance slow release body; (2) preparing a natural antibacterial composition; (3) preparing fragrance natural antibacterial and deodorizing master batches; (4) preparing self-fragrance natural deodorizing fiber, wherein the prepared self-fragrance natural antibacterial and deodorizing fiber is of a skin-core structure including a core layer and a skin layer; the core layer is a high-melting-point polymer; the skin layer is a low-melting-point polymer; a high-molting point polymer body of the core layer comprises the fragrance slow-release bodies and the natural antibacterial compositions. The fiber provided by the invention has no irritation on the human body skin, has the permanent antibacterial performance, can inhibit the bacterium invasion and breeding, and has high absorption rate on ammonia and very excellent antibacterial mouldproof and deodorization effects; the characteristics of uniform fragrance release and long fragrance maintaining time are realized; the product added value is high; the application market prospects are wide.

Owner:漳州市鼎鑫电子科技有限公司

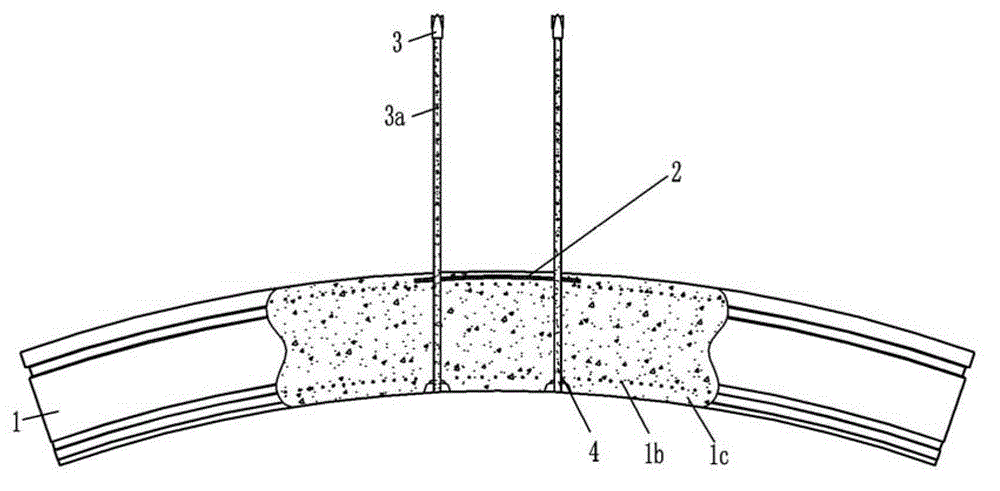

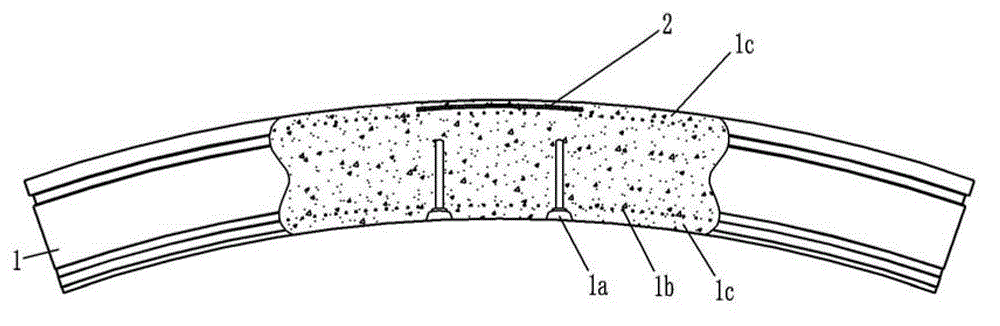

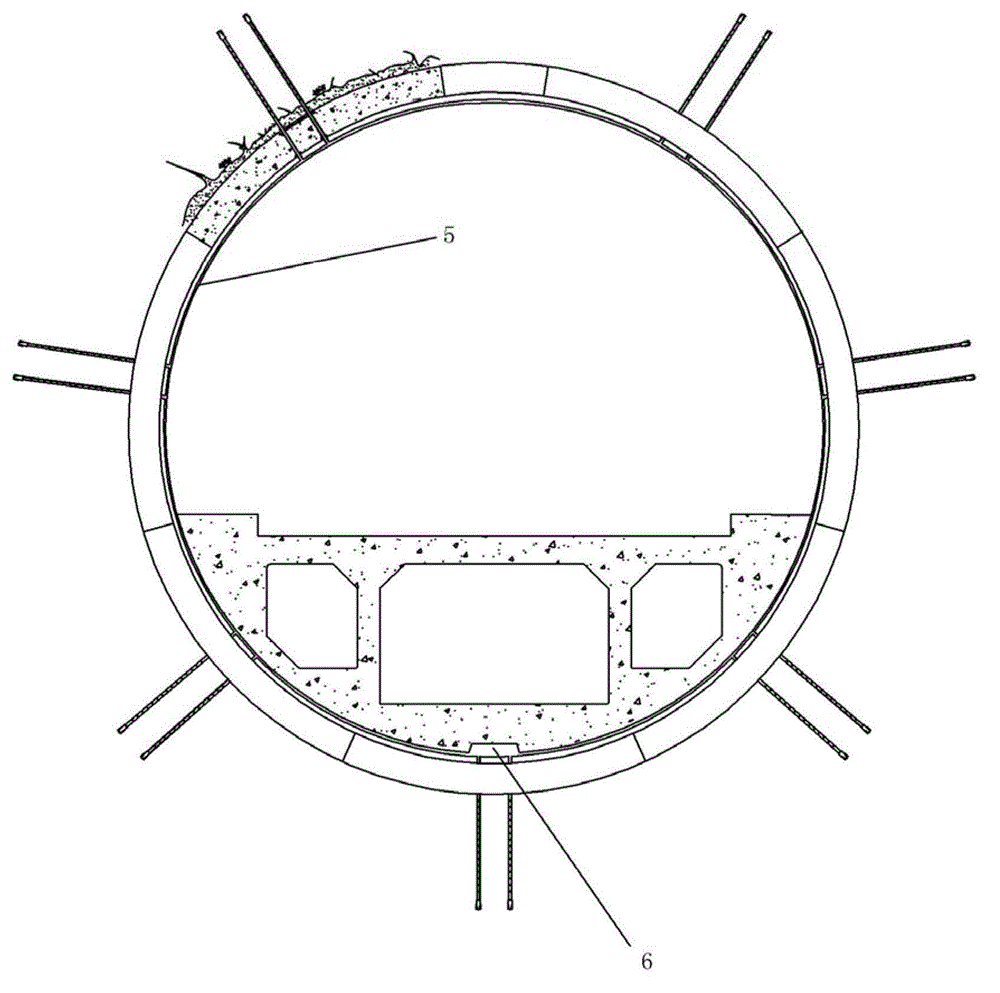

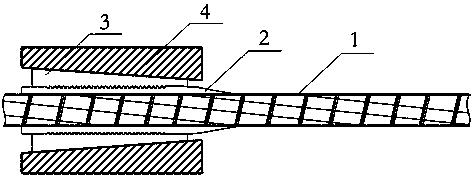

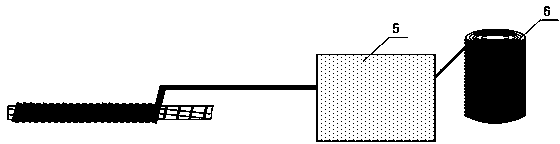

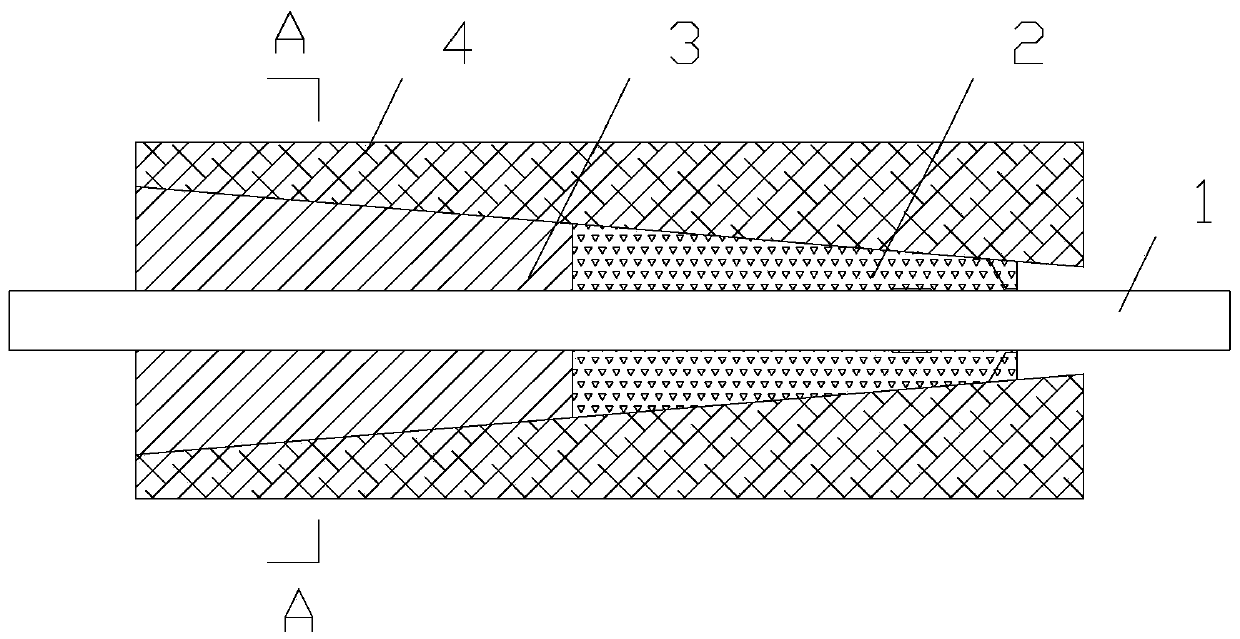

Drain-type pipe piece for tunnel lining

ActiveCN102979535ANo need to increase intensityEnsure safetyUnderground chambersDrainageReinforced concreteSlurry

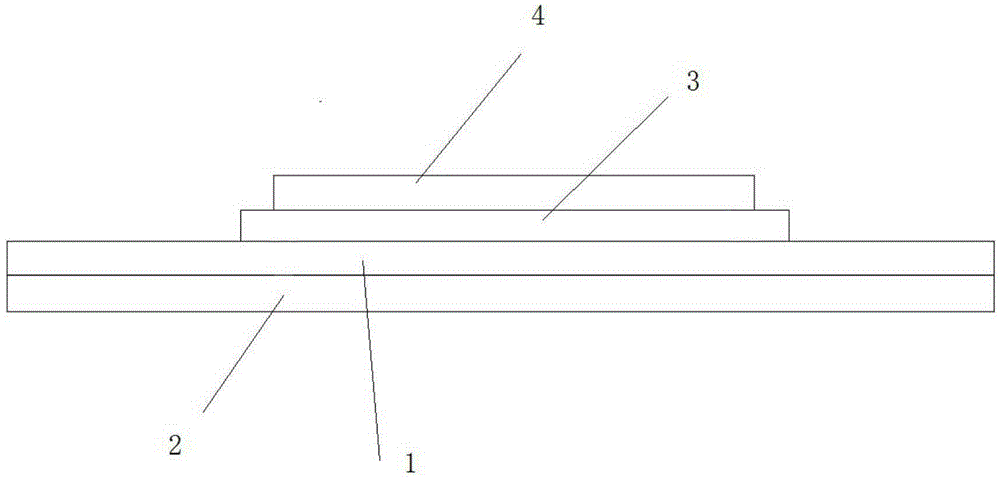

The invention discloses a drain-type pipe piece for tunnel lining. The drain-type pipe piece comprises a reinforced concrete pipe piece (1), a slurry injection hole (or a hoist hole) (1a) in the pipe piece (1), a load bearing steel bar (1b), and a concrete protective layer (1c) on the outer side; a water stop rubber block (2) capable of being expanded when being in contact with water is preburied in the concrete protective layer (1c) right opposite to one or two slurry injection holes (1a) of the pipe piece (1); a self-advancing type hollow anchor rod (3) is inserted in the slurry injection holes (or the hoist hole) (1a) of the pipe piece (1), then penetrates the water stop rubber block (2), and shoots out of the concrete protective layer (1c); and drain holes (3a) are formed in the rod wall of the outer end of the self-advancing type hollow anchor rod (3), and a filter column (4) used for filtering sand is plugged in the inner cavity of the self-advancing type hollow anchor rod (3). Lining built with the pipe pieces has a reliable drain function, and can reduce water pressure around the structure to ensure tunnel safety; and construction is convenient, small damage is caused to the pipe piece lining structure, and construction cost of the pipe piece lining is low.

Owner:SOUTHWEST JIAOTONG UNIV

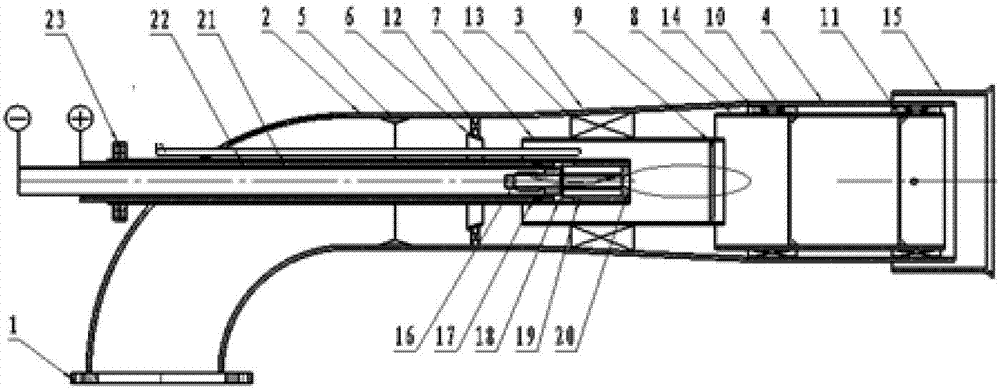

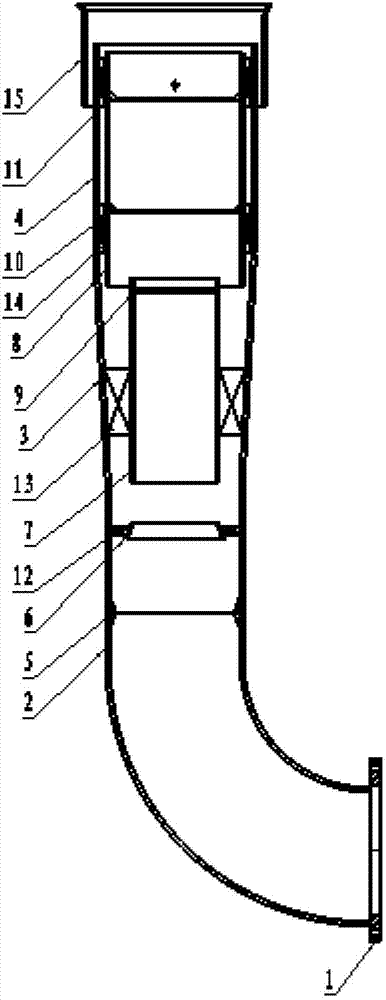

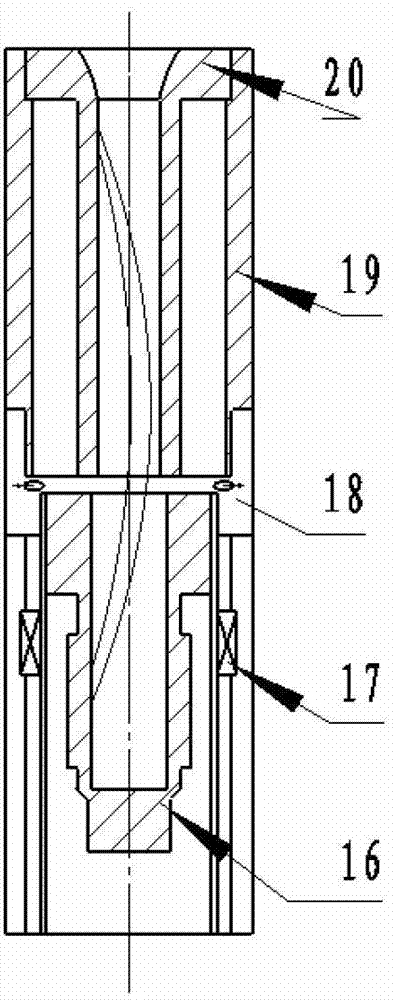

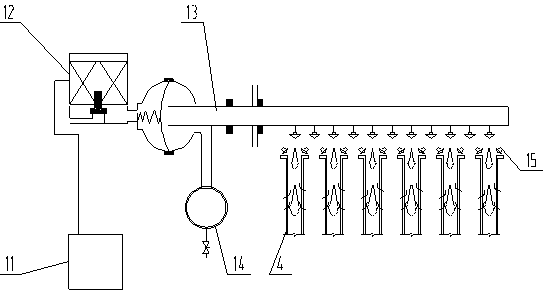

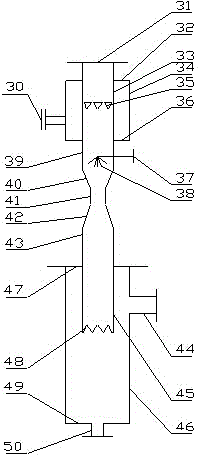

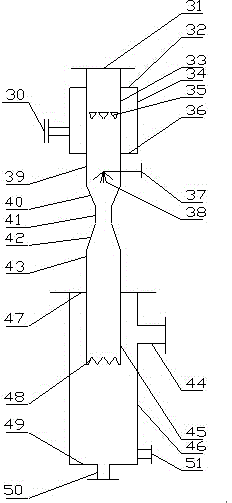

Plasma ignition and combustion stabilization device for IGBT (insulated gate bipolar transistor) rectification power supply

ActiveCN103486579AIncrease arc voltageImprove efficiencyPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionCombustion chamberEngineering

The invention discloses a plasma ignition and combustion stabilization device for IGBT (insulated gate bipolar transistor) rectification power supply. The plasma ignition and combustion stabilization device for the IGBT rectification power supply comprises a collision type pulverized coal concentration fractional combustion pulverized coal burner and a plasma spray gun, wherein the plasma spray gun generates high-temperature flame at the temperature of about 4000DEG C to ignite pulverized coal in an inner-layer combustion chamber of the pulverized coal burner; heat released from the burning of the pulverized coal in the inner-layer combustion chamber then ignites pulverized coal in an outer-layer combustion chamber to realize the stable combustion of pulverized coal flame; the collision type pulverized coal concentration fractional combustion pulverized coal burner comprises a primary air dust inlet, a straight pipe section, a taper pipe section, an outer nozzle, a collision concentration block, a collision concentration ring, the inner-layer combustion chamber, the outer-layer combustion chamber, an inner-layer combustion chamber disturbance block, an outer-layer combustion chamber rear disturbance block and an outer-layer combustion chamber front disturbance block; and the plasma spray gun comprises a cathode, a magnetic field coil, a spiral air chamber, an anode, a nozzle and a gun body. The plasma ignition and combustion stabilization device for the IGBT rectification power supply is applied to the starting ignition and the combustion stabilization stage of a pulverized coal fired boiler to replace the traditional big oil gun ignition and combustion stabilization mode, coal is used for replacing oil, and therefore the purpose of saving cost is achieved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

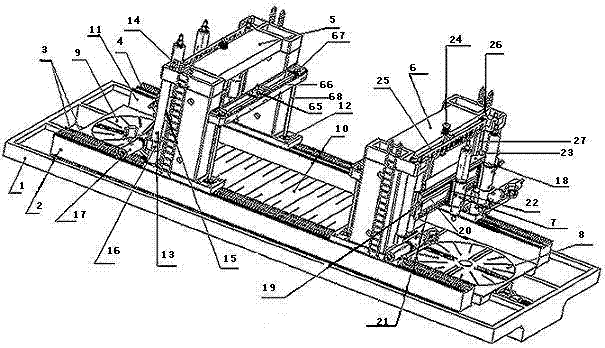

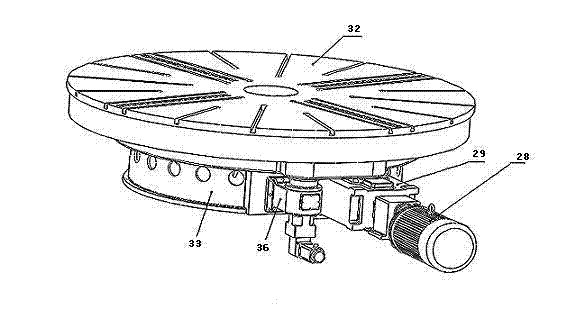

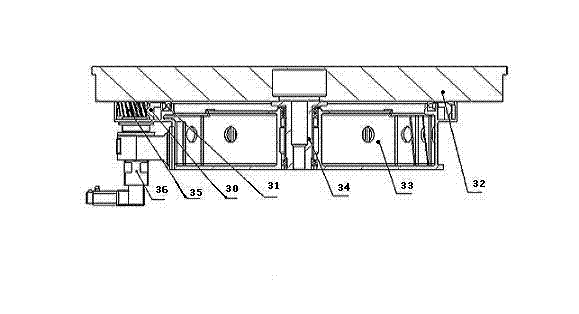

Gantry-movable drilling, boring and milling compound machine tool

InactiveCN102862053AGuaranteed lubrication effectGuaranteed long-termOther manufacturing equipments/toolsLarge fixed membersNumerical controlThick wall

A gantry-movable drilling, boring and milling compound machine tool is guided by matching of typical cylinders and cylindrical sliding sleeves and adopts a stepless variable frequency speed regulation mechanism and a numerical control mode. Large-scale swing bearings are adopted for support and rotation of workbenches. In the material aspect, vertical column guide rails and cylindrical movable cutters are manufactured by structural alloy steel thick-walled seamless pipes and are subjected to grinding and hard chromium plating, and the workbenches are casted by ductile cast iron. The gantry movable drilling, boring and milling compound machine tool has the advantages that the machine tool can be used for drilling and boring and has functions of excircle, inner bore, section and curved surface turning, flat surface, inclined surface, curved surface and groove milling, thread tapping and the like, lubrication, dust prevention and durability of the guide rails are guaranteed, and long-term precision is maintained. Double gantries are movable, work efficiency can be improved by machining long and large pieces by the juxtaposed double gantries together, the large-scale rotating workbenches additionally arranged at two ends can be used as two numerical control lathes, equipment utilization rate is increased, and the gantry-movable drilling, boring and milling compound machine tool is simple in structure and can meet customer machining requirements particularly when parts are large in machining face and machining length.

Owner:SHANDONG YIXIN HEAVY MACHINERY MFG

Anchoring method applicable to large-tonnage FRP inhaul cable

ActiveCN103669208AGood bonding performanceIncrease stress transferBridge structural detailsBuilding reinforcementsShearing deformationEngineering

The invention discloses an anchoring method applicable to a large-tonnage (larger than 50 tones) FRP inhaul cable. The FRP inhaul cable is anchored with a clamping piece type anchorage device, a protection transition layer with the length no smaller than the length of an anchoring area of the clamping piece type anchorage device is formed at the anchoring end of the FRP inhaul cable, the protection transition layer and the FRP inhaul cable are integrated, and the clamping piece type anchorage device is anchored to the protection transition layer. After the FRP inhaul cable and the protecting layer are pressed into a whole, while the shearing strength of the FRP inhaul cable and a protecting layer interface is increased, the phenomenon that the FRP inhaul cable weak in transverse strength makes direct contact with load transmitting mediums large in rigidity in the anchoring area can be avoided, a stressed buffering layer is formed, and the FRP inhaul cable can be indirectly protected. The anchoring method used for anchoring the FRP inhaul cable has the advantages of facilitating construction and being high in anchoring efficiency and the like, long-term performance of an anchoring system can be guaranteed, the method can also be used for tensile tests on the FRP inhaul cable, samples can be prepared easily and conveniently, and compared with an adhesive type anchoring method, test errors caused by overlarge shearing deformation of resin can be avoided.

Owner:SOUTHEAST UNIV +1

Essential oil patch and manufacturing method thereof

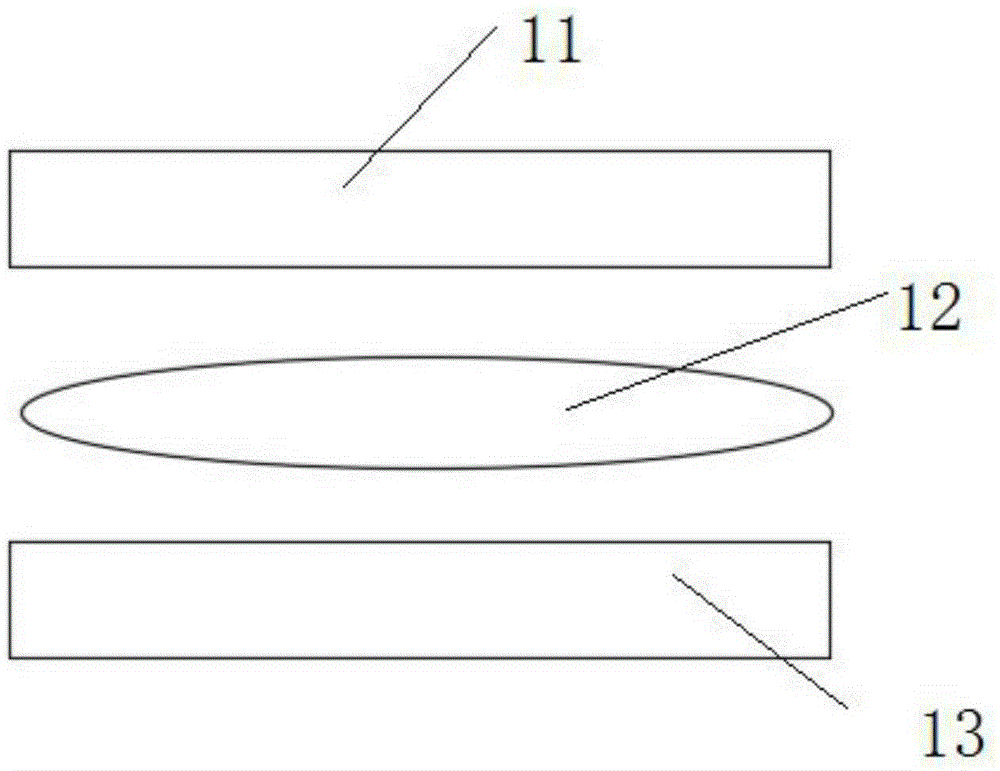

InactiveCN105310819AEasy to fixAchieve quantitative releaseMedical devicesTherapeutic coolingSilicone oilPetroleum engineering

The invention relates to an essential oil patch and a manufacturing method thereof. The essential oil patch sequentially comprises a silicon oil paper layer, an essential oil storage layer, a binding layer and a self-heating layer, wherein the essential oil storage layer is used for storing essential oil in a quantitative mode; the binding layer is used for binding; and the self-heating layer is used for taking a heat-insulation effect. The essential oil patch disclosed by the invention can achieve the quantitative release of the essential oil and can keep a lasting effect; and the essential oil patch is conductive to the implementation of various self-help moxibustion therapies, SPA and the like.

Owner:SUZHOU QIUSHIAIKANG MEDICAL APP TECH CO LTD

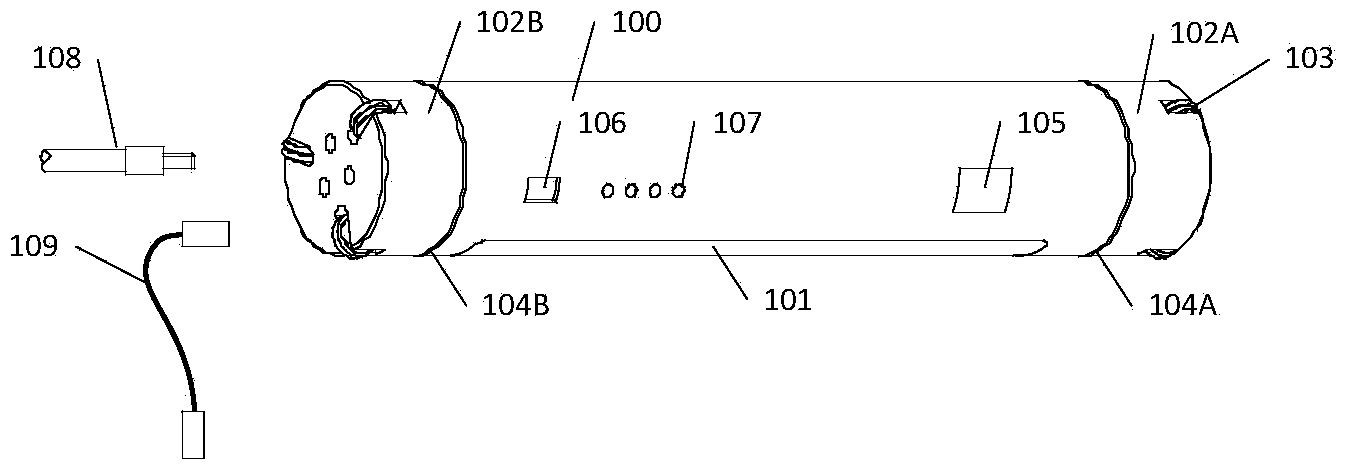

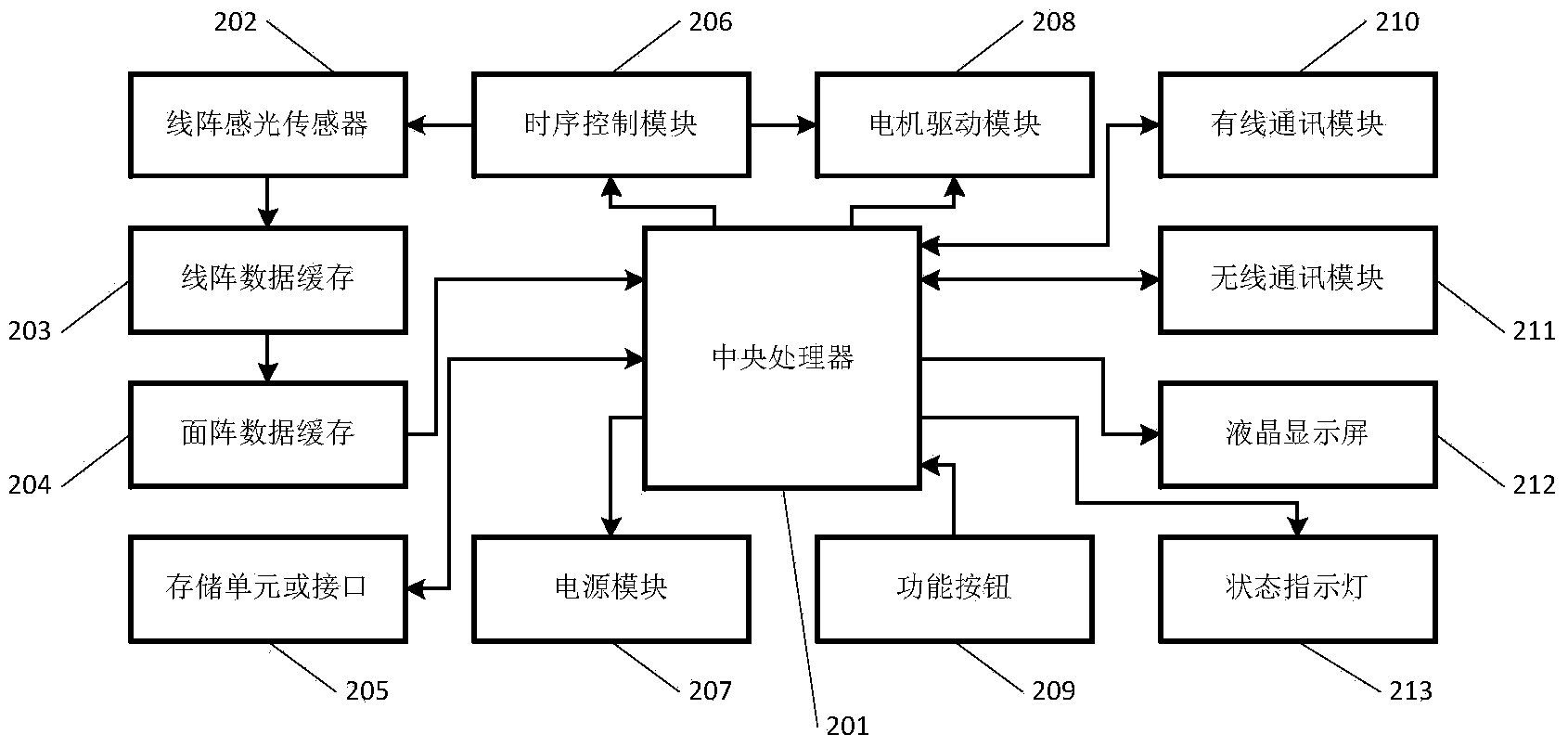

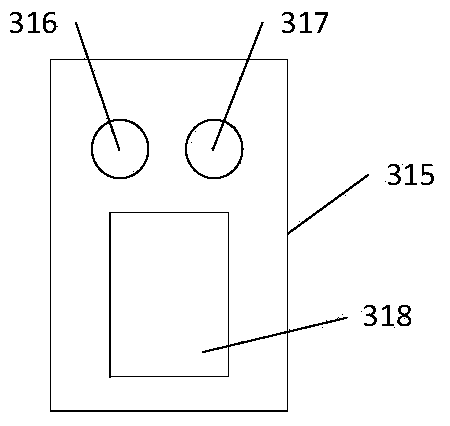

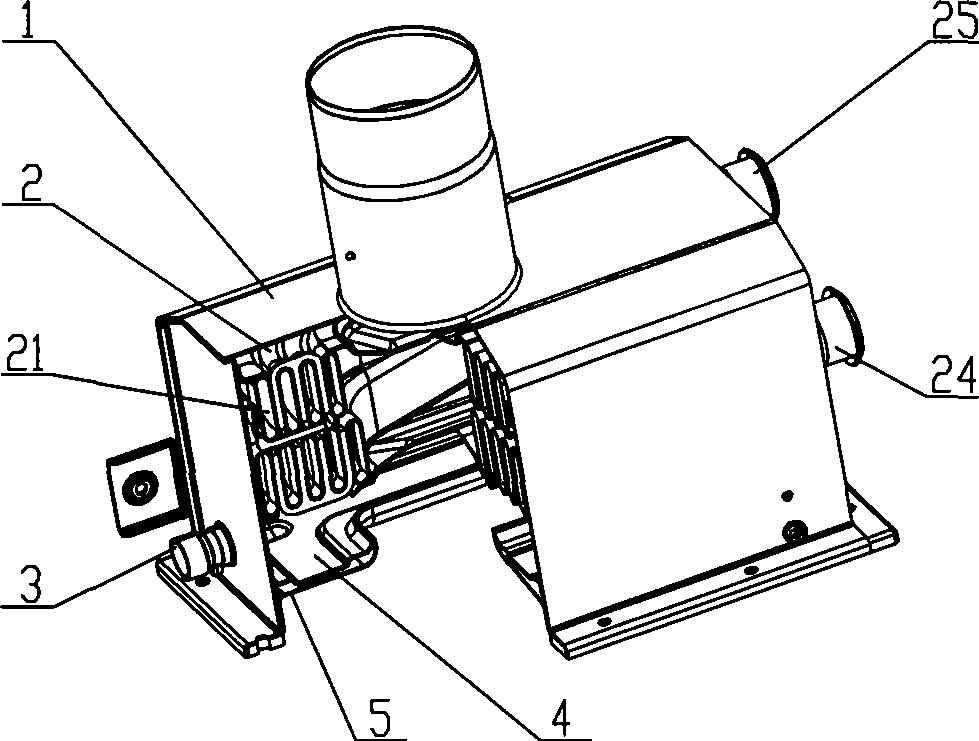

In-situ scanning device

InactiveCN103454279AEasy to replaceLighten travel loadMaterial analysis by optical meansIn situ soil foundationMotor driveImage resolution

The invention discloses an in-situ scanning device. The in-situ scanning device comprises a scanning device body and a connecting rod, wherein the scanning device body comprises a guide part and a scanning part. The in-situ scanning device also comprises a control system which is arranged in the in-situ scanning device body, wherein the control system comprises a central processing unit and a motor driving module; the central processing unit is used for data processing in the control system and control of each component; the motor driving module is used for driving a motor in a rotation speed corresponding to a required resolution. Moreover the control system also comprises a linear array sensitive sensor, linear array data cache, area array data catch, and a time sequence control module. According to the in-situ scanning device, pattern data of cylindrical inner walls of various objects to be measured can be continuously acquired, is subjected to primary processing and storage and is subjected to data exchange with other terminals, so that in-situ scanning measurement for a plant root system in soil under a field environment is realized; the in-situ scanning device can also be used for researching mire, rock, soil, geology and the like.

Owner:毕昆

High fly ash and coal gangue dry mixed guniting material for underground anchor net support

Belonging to the technical field of building materials, the invention provides a high fly ash and coal gangue dry mixed guniting material for underground anchor net support to solve the problems of difficult control of proportion, great operation arbitrariness, high rebound rate, poor cohesiveness, large dust pollution and the like in existing guniting material on-site blending. The high fly ash and coal gangue dry mixed guniting material is composed of the following raw materials: 800-1800 parts of fly ash, 800-1800 parts of coal gangue, 50-200 parts of cement, 50-150 parts of slag powder, 5-10 parts of silica, 30-100 parts of silica fume, 5-10 parts of a naphthalene water reducer, and 0.1-0.3 part of polypropylene fiber. The guniting material provided by the invention solves the problems of waste of resources and environmental pollution, reduces the production cost and protects environment. The number of underground operation workers and mixing equipment are reduced, the labor intensity is reduced, and the safety factor is enhanced. The material has strong adhesive force, few rebound material, high cohesiveness, and high support strength, avoids waste of a large number of floor materials, improves the benefits, saves manpower, and achieves a storage life of 2-3 years without deterioration.

Owner:SHANXI SHANGYITONG BUILDING MATERIAL TECH CO LTD

Cellular foam thermal-insulation material for fireproof walls

InactiveCN102531532ALow apparent densityLow thermal conductivitySolid waste managementThermal insulationAbsorption rate

The invention discloses a cellular foam thermal-insulation material for fireproof walls, which comprises components, by weight ratio, 30 to 80 of sulphur aluminum cement, 15 to 30 of coal ash, 35 to 55 of water, 2 to 8 of hydrogen peroxide, 0.2 to 0.91 of stearin hard calcium, 0.1 to 1.39 of calcium powder and 0.5 to 2 of low-alkali glass fiber. The thermal-insulation material is an inorganic thermal-insulation material, thereby being small in appearance density and low in heat conductivity coefficient and having the advantages of being thermal-insulation, noncombustible, low in waste absorption rate and the like. Industrial waste is converted into benefits, so that the thermal-insulation material is a novel wall body material with high social benefits and economic benefits.

Owner:丹东市兄弟建材有限公司

High-speed wire finish-rolling process

InactiveCN101564734ASimple production processLow failure rateGuiding/positioning/aligning arrangementsRoll mill control devicesFailure rateWire rod

The invention discloses a high-speed wire finish-rolling process. Rolling is performed on 28 passes finishing mill 1-17 passes use the pass-free rolling way and the rolling piece is rolled between the two pass-free rollers and the height of the roll gap is the height of the rolling piece and the width of the rolling piece is the breadth of the freely spread rolling piece without gripping and deforming action of the pass sidewall. During rolling, it is only necessary to change the roll gap to adjust the section size of the rolling piece and the rolling adaptability is very strong, thereby optimizing the production process of the wire tandem mill, reducing the guide loss, reducing the oil gas lubrication consume, reducing the failure rate of the roller, increasing the use frequency of the roller and reducing the roller loss, improving the bite of the rolling piece, reducing the roll-changing number during rolling, in order to increase the productivity, save the energy, reduce the consume, ensure the production operate for long period. The high-speed wire finish-rolling process can be used in the same or similar rolling mill in civil with very wide application foreground.

Owner:CHONGQING IRON & STEEL CO LTD

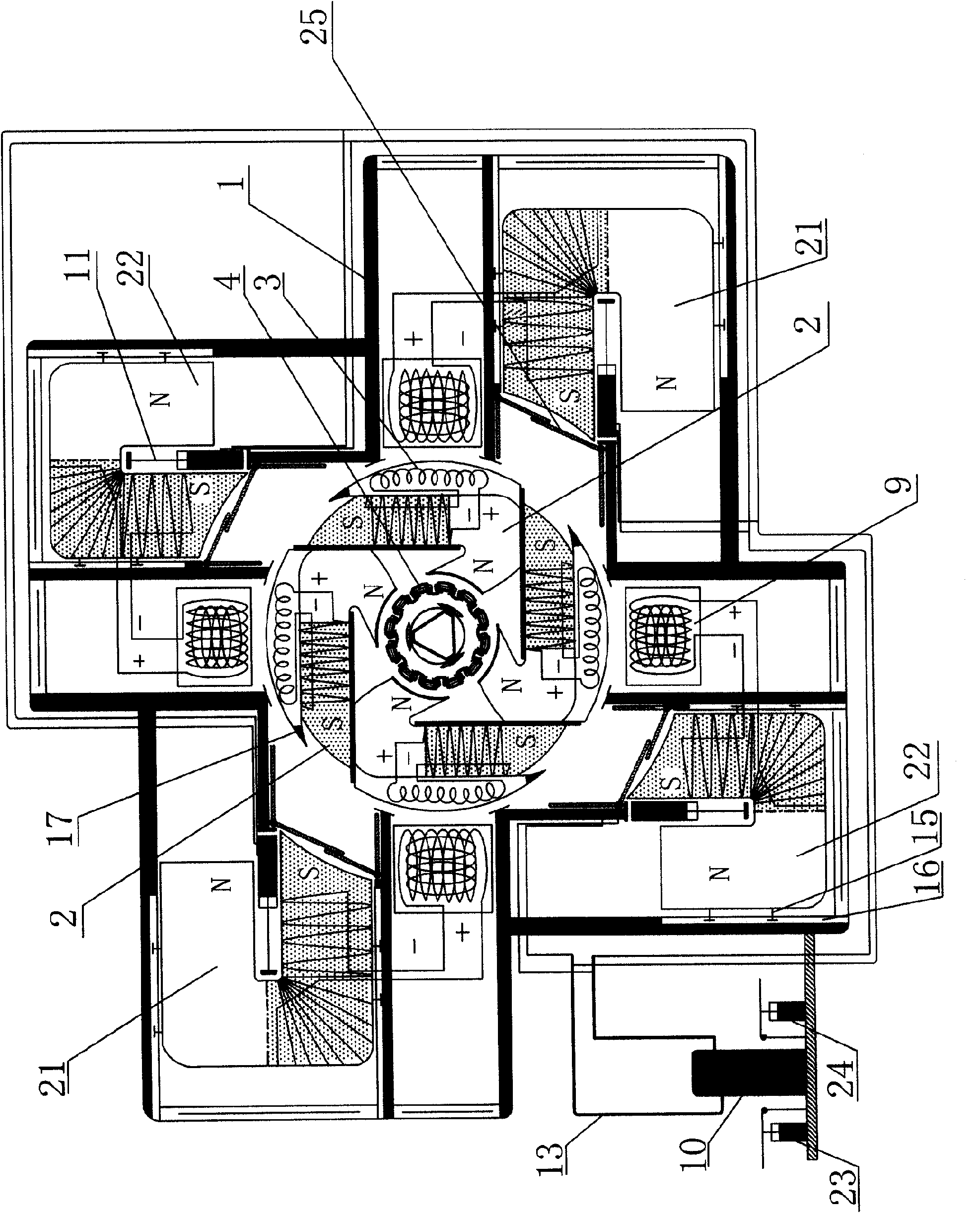

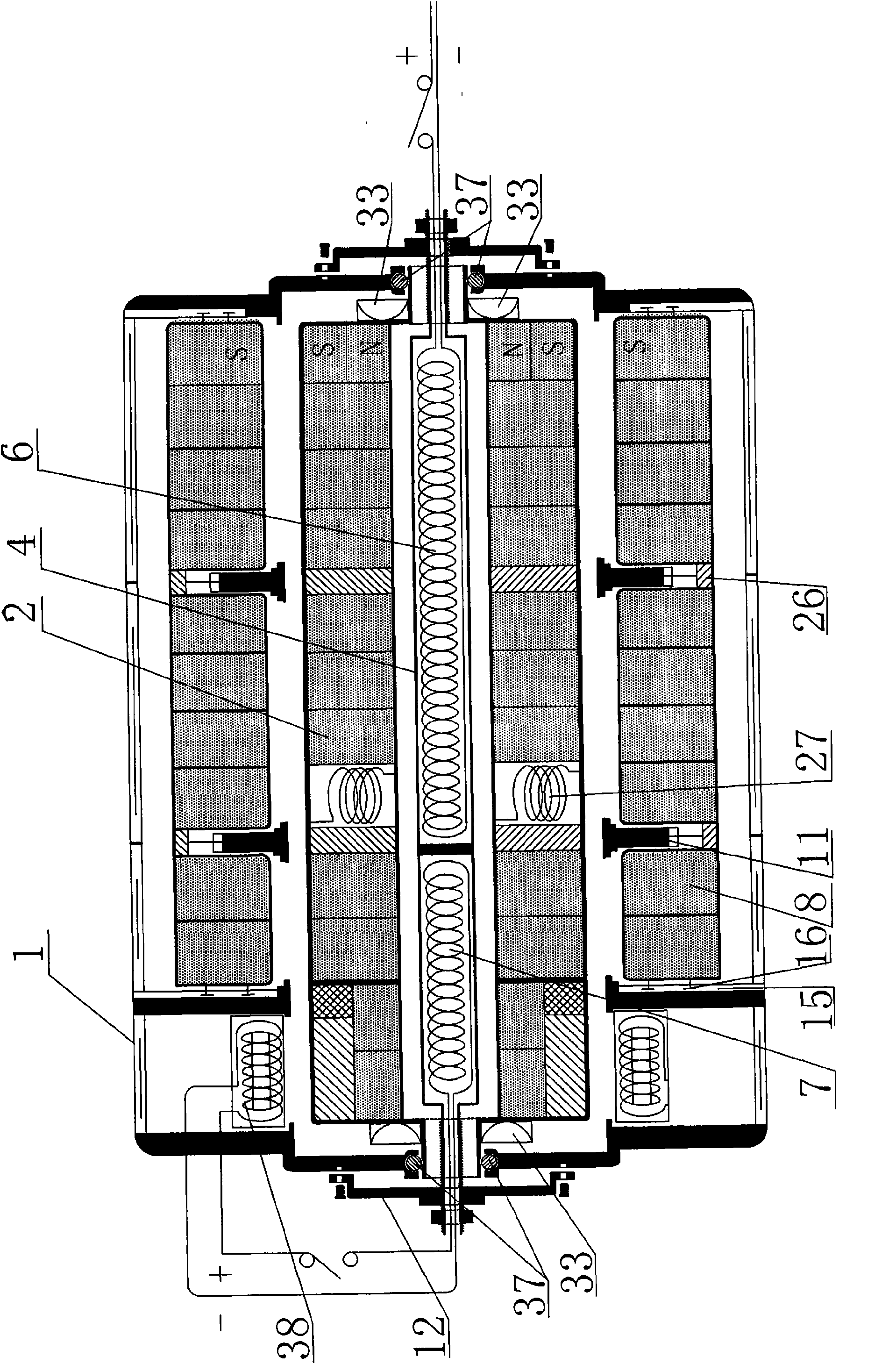

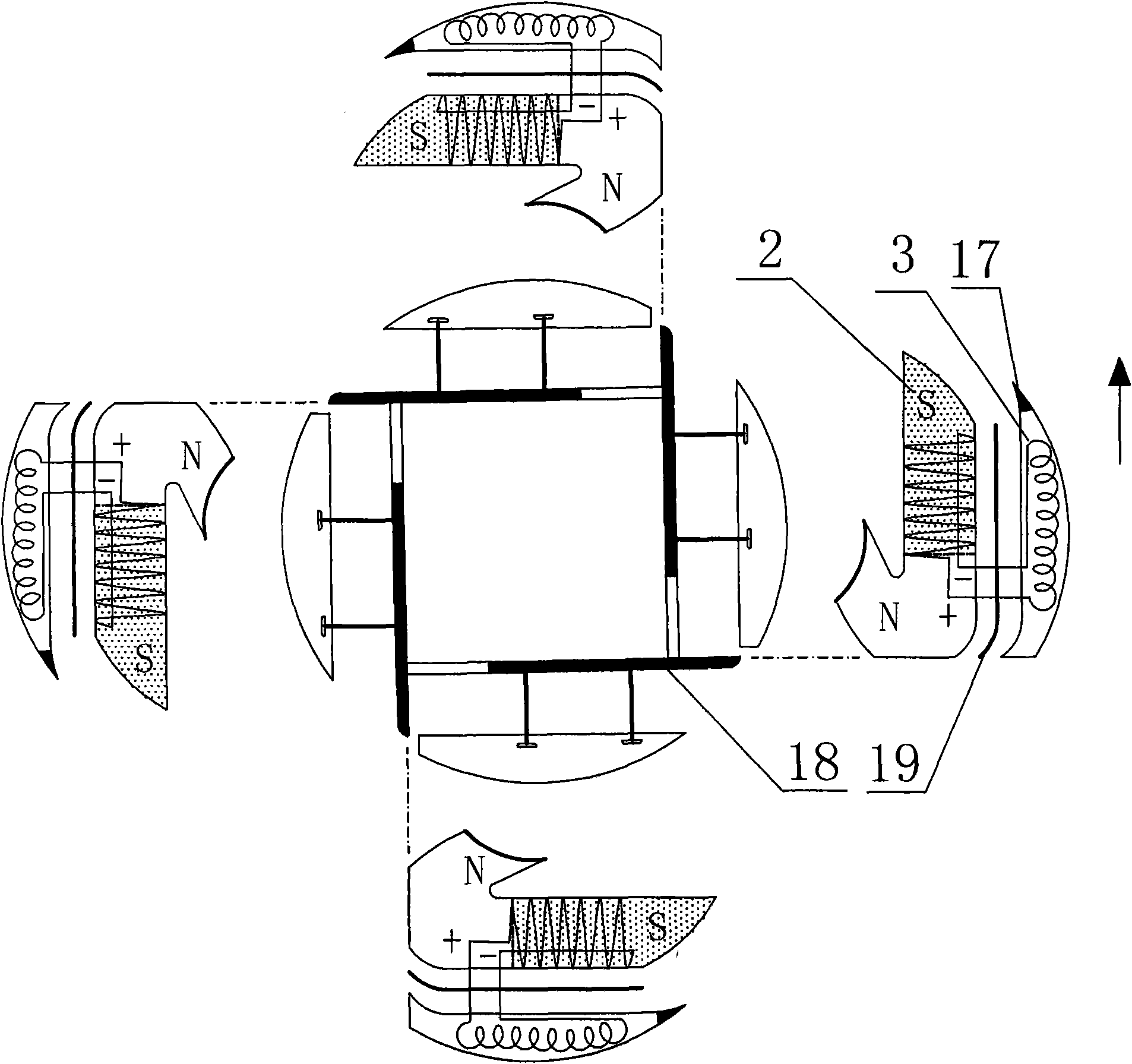

Permanent magnetic independent generator

InactiveCN101577478ATo achieve the purpose of long-term workNot easy to lose magnetismSynchronous machine detailsRotor magnetsHydraulic pump

A permanent magnetic independent generator comprises a shell, a rotor and a stator, wherein the stator is arranged at the center of the permanent magnetic independent generator; the rotor is arranged at the periphery of the stator, the periphery of the rotor is provided with an active cell, the active cell is formed by a plurality of active cell magnets and active cell fixing magnetic coils, and the rotor is formed by a plurality of rotor magnets and rotor fixing magnetic coils; the inner wall of the shell is provided with an active cell magnet sliding chute, the active cell magnet is sleeved into an active cell magnet fixing sleeve, the outer side of the active cell magnet fixing sleeve is provided with a sliding pin which is connected with the active cell magnet sliding chute in a sliding way, a groove of the active cell magnet is internally connected with a hydraulic jack through a connecting piece, the hydraulic jack is connected with a hydraulic total pump, a hydraulic starting device and a hydraulic arresting device through a hydraulic pipeline, and the position on the inner lateral wall of the shell, near the front end of the S pole of the active cell magnet, is provided with an elastic magnet isolating subassembly. The invention converts the repulsive force of same magnetic poles into rotary force so that the rotor rotates and then a stator coil generates current, thereby the purpose of power generation is achieved; in addition, the invention has the advantages of energy saving and good effect.

Owner:张成华

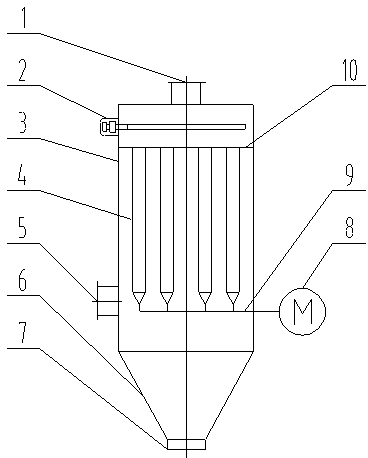

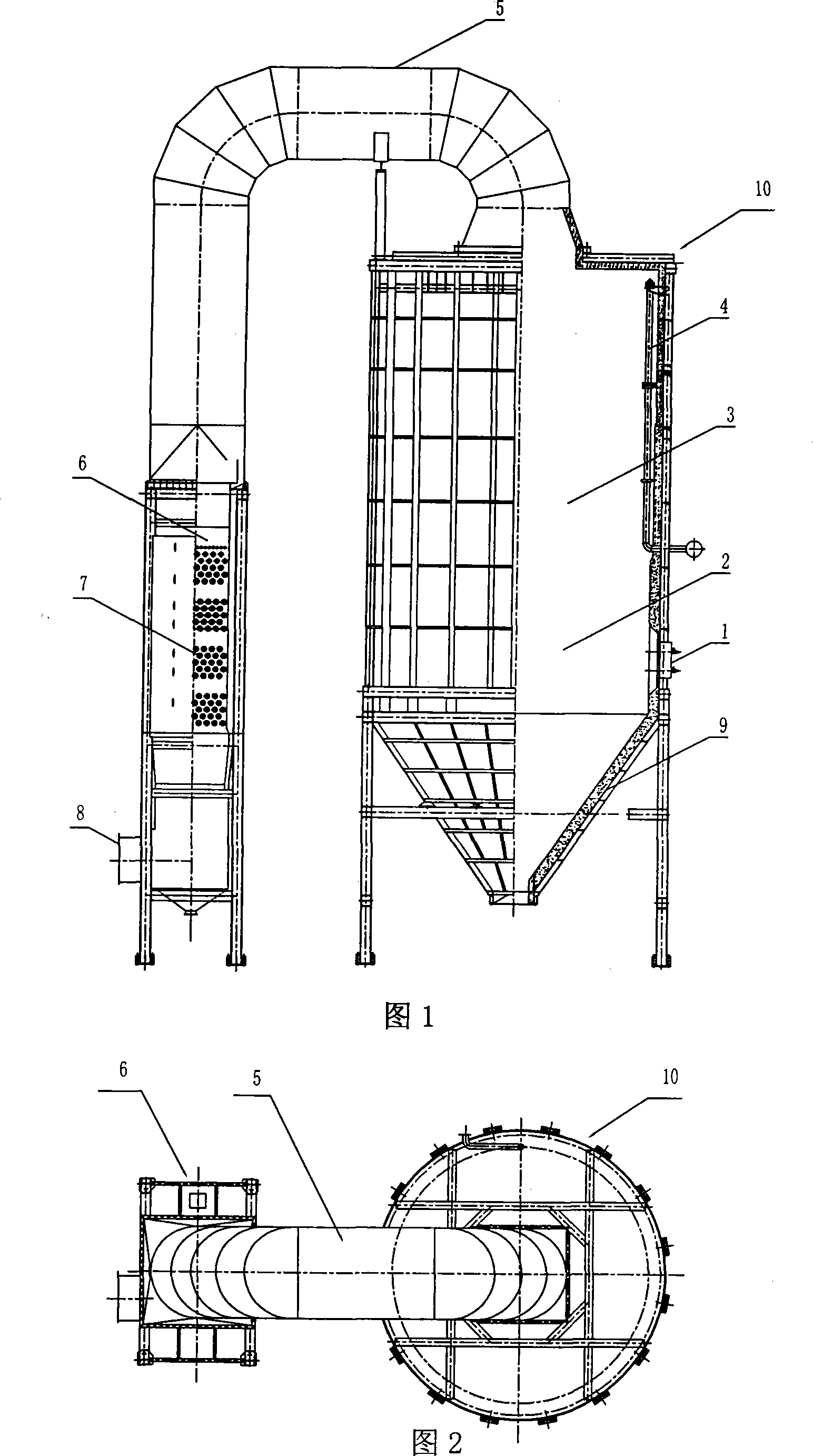

Vibrating and backflushing integrated bag type dust remover

InactiveCN103212252ASmall operating resistanceIncrease production capacityDispersed particle filtrationPulse controlBaghouse

The invention relates to the field of dust removers, provides a vibrating and backflushing integrated bag type dust remover, and aims to reduce dust attachment and enable equipment to operate for a long time. The vibrating and backflushing integrated bag type dust remover comprises a shell, a filter bag, a mechanical vibrating device and a gas distribution structure, wherein a dust-containing gas inlet is formed in the lower part of the shell; a purified gas outlet is formed in the upper part of the shell; a pulse backflushing device is also arranged in the shell; a backflushing pipe of the pulse backflushing device corresponds to the purified gas outlet; the pulse backflushing device comprises a pulse controller, an electromagnetic valve, the backflushing pipe and a gas pocket; the pulse controller is connected with the electromagnetic valve; the backflushing pipe is connected with the gas pocket; and the electromagnetic valve is arranged on a connection pipeline between the backflushing pipe and the gas pocket. By the vibrating and backflushing integrated bag type dust remover, mechanical vibrating and pulse backflushing is integrated, so that accumulated dust on the surface of the filter bag can be cleared away, the operation resistance of the equipment is reduced, and the production capacity of the equipment is improved.

Owner:NANJING TIANHUA CHEM ENG

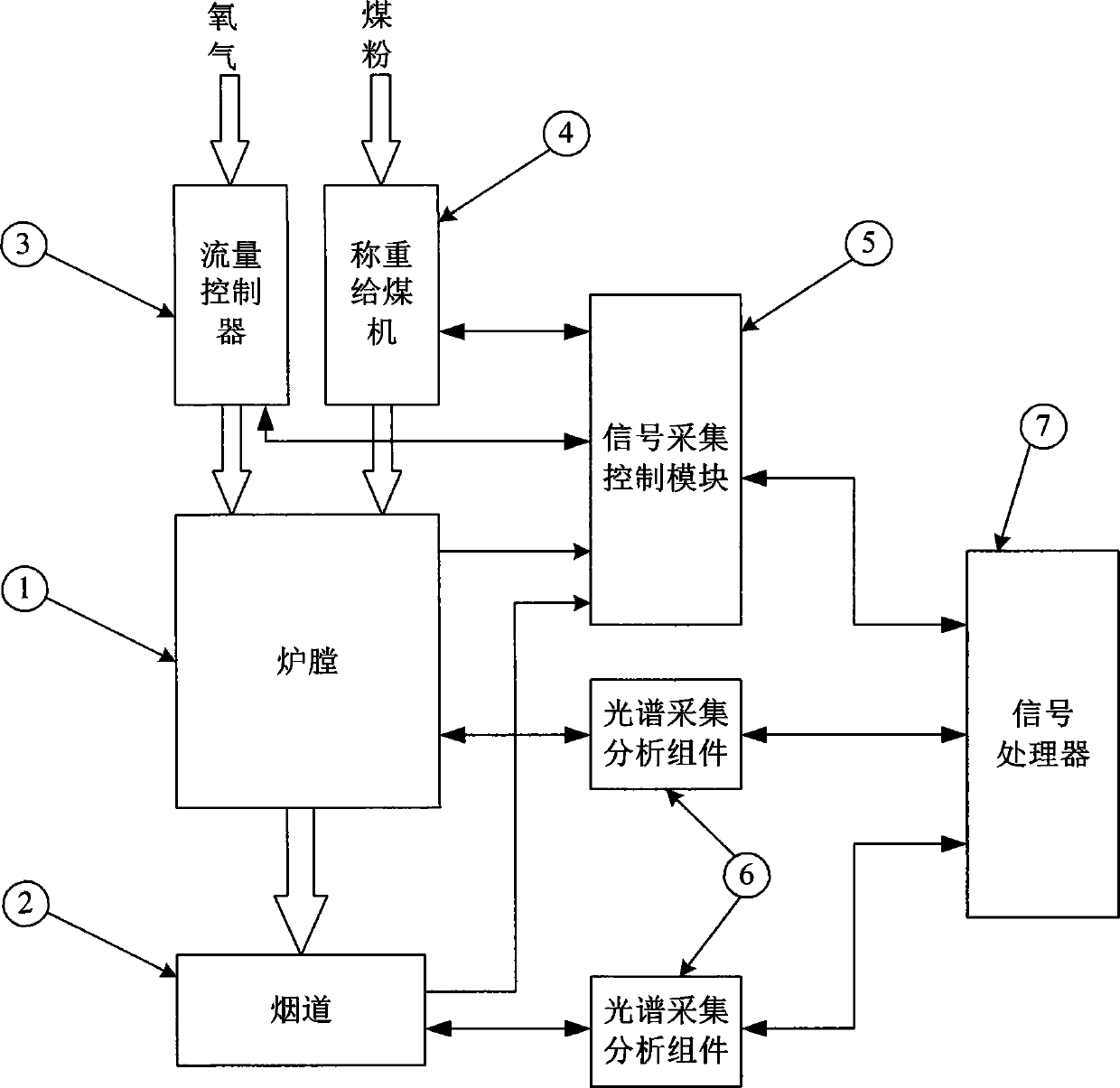

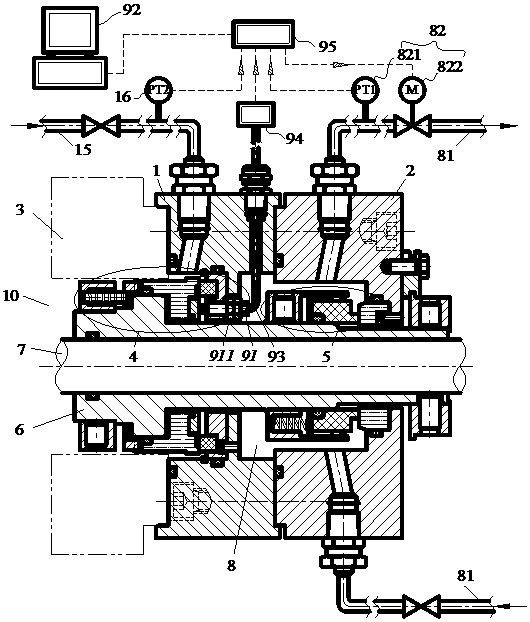

Method and system for on-line analysis of coal quality

InactiveCN103278653AGuaranteed uptimeGuaranteed long-termMaterial analysisCombustion chamberWater vapor

The invention discloses a method for on-line analysis of coal quality. The method comprises: spraying coal fines to be measured into oxygen flow for combustion; by a spectroscopic analysis method and combining the remainder oxygen content and the water vapor content in flue gas, analyzing and calculating the calorific value, the volatile compound content, the carbon content, the sulfur content, the phosphor content and the like of the coal fines. A system for the on-line analysis of the coal quality comprises a combustion chamber, a flue, a flow controller, a coal weighing feeder, a signal acquisition control module, a spectrum acquisition analysis assembly, and a signal processor; the combustion chamber, the flue, the flow controller and the coal weighing feeder are connected with the signal acquisition control module, the combustion chamber and the flue are connected with the spectrum acquisition analysis assembly, and the signal acquisition control module and the spectrum acquisition analysis assembly are connected with the signal processor. The method and the system have the beneficial effects that: problems that laboratory measurements cannot be carried out continuously and rapidly are solved, the devices can run with long term stability in a live environment, and chronicity and stability of the measurements can be ensured.

Owner:太原海通智慧信息技术有限公司

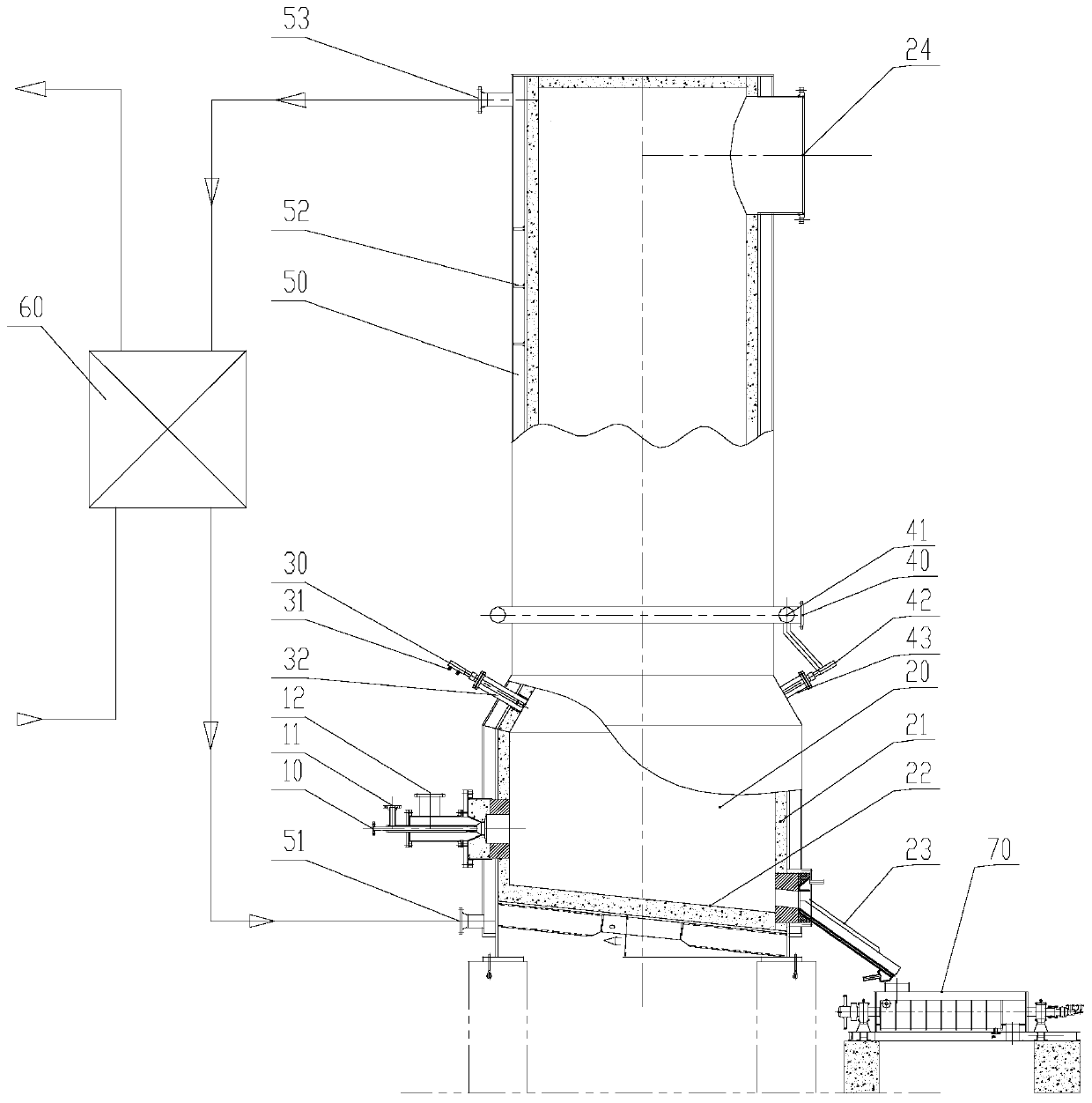

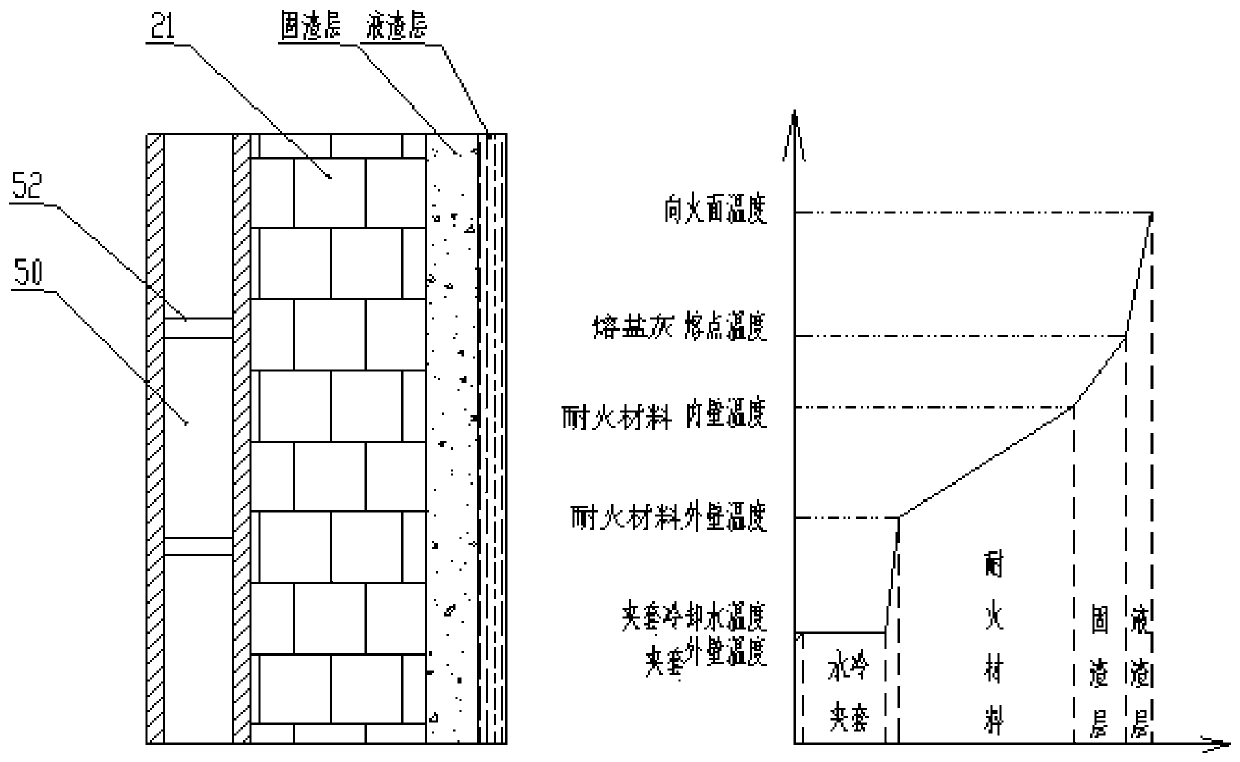

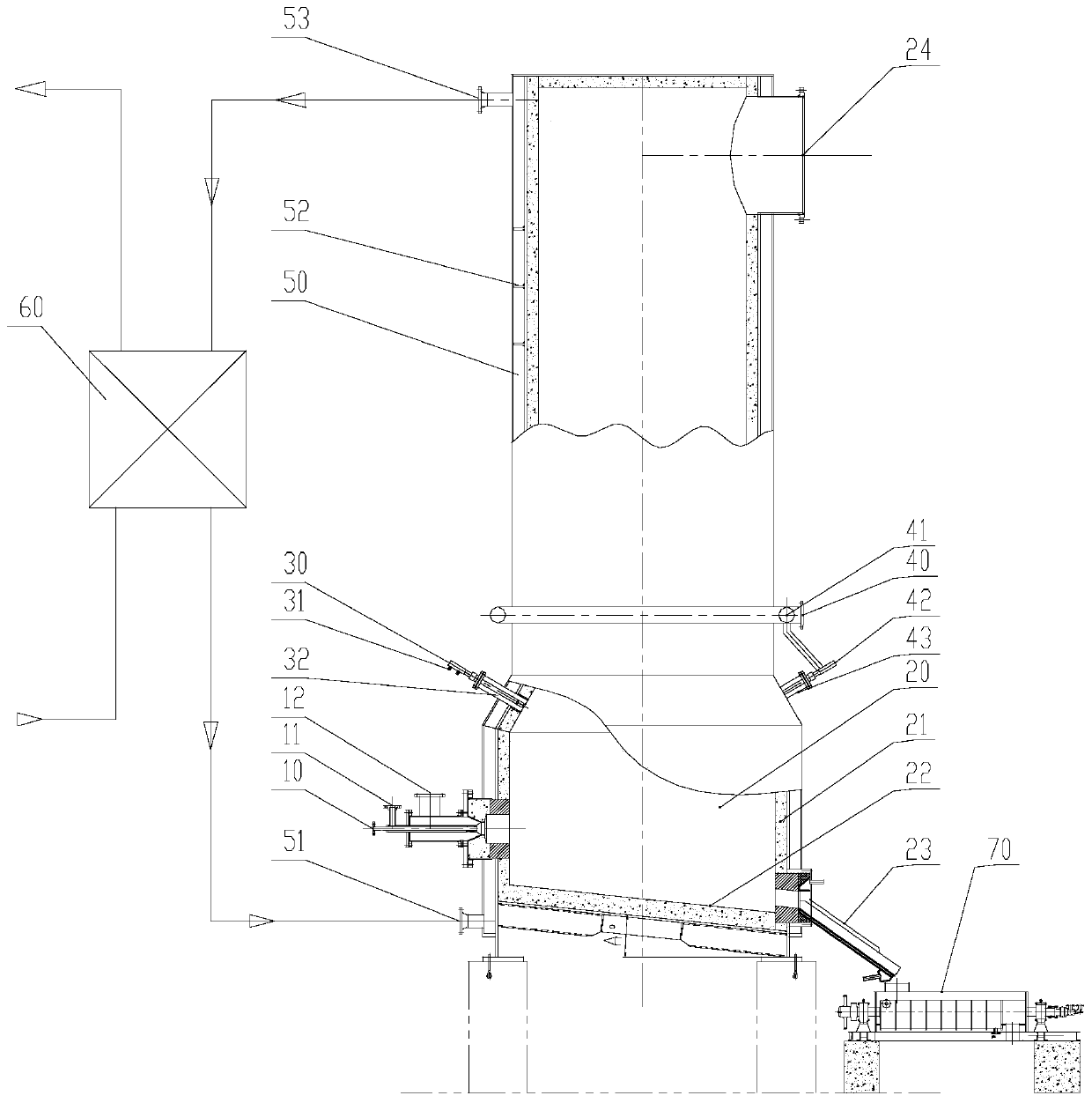

Water cooling jacket incineration device and method for processing salt-containing waste liquid and waste gas

PendingCN109838794AExtended service lifeGuaranteed long-termIncinerator apparatusDecompositionSafe operation

The invention discloses a water cooling jacket incineration device and method for processing salt-containing waste liquid and waste gas. The device comprises a combustion-supporting combustor (10), anincineration furnace (20), a waste liquid spraying device (30), a waste gas spraying device (40), a water cooling jacket device (50), a cooled water heat exchanger (60) and a double-shaft cooling slag discharging device (70); and a bottom incineration technology is adopted, high-temperature flame is generated at the bottom of the furnace to realize complete decomposition of waste, meanwhile, liquid state molten salt is smoothly discharged out of the incineration furnace (20) with lowest fuel consumption, the double-shaft cooling device (70) is used for enabling the molten salt phase to be solidified, and finally solid state slag discharging is realized. The incineration device synchronously adopts a water cooling jacket technology, a solid slag layer is formed on a furnace liner flame facing surface, and slag resistance with the slag is realized, under the condition that a chromium-containing liner is abandoned, the service life of the furnace liner is effectively prolonged, and long-period, low-cost, stable and safe operation of the incineration furnace is realized.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Sealant for photovoltaic module and preparation method of sealant

ActiveCN104178040AStable chemical propertiesStable and water resistantOther chemical processesOrganic non-macromolecular adhesivePolymer scienceOctanoic Acids

The invention belongs to the technical field of sealants and relates to a sealant for a photovoltaic module. The sealant is characterized by comprising the following raw materials in parts by weight: 100 parts of E-51 epoxy resin, 15-25 parts of 201 polysulfide rubber, 10-15 parts of m-phenylenediamine, 10-20 parts of dibutyl phthalate, 1-3 parts of diethylenetriamine, 30-50 parts of talc power, 10-15 parts of maleic anhydride, 15-20 parts of 651 low-molecular-weight polyamide, 4-6 parts of stannous octoate and 20-30 parts of epoxypropane phenyl ether or diglycidyl resorcinol ether or ethylene glycol diglycidyl ether. The invention also discloses a preparation method of the sealant. The sealant disclosed by the invention has the beneficial effects of convenience in operation, short curing time, good adhesion, low water vapor and gas permeability, good sealing property / weather resistance and UV resistance and wide application temperature range and the long-term performance is maintained.

Owner:特瓦特能源科技有限公司

Natural antibacterial and deodorizing finishing agent for non-woven fabrics and preparation method of finishing agent

InactiveCN106436323AInhibitionAvoid breedingBiochemical treatment with wool-protecting/anti-moth agentsPolyethylene glycolPOLYOXYETHYLENE ETHER

The invention relates to a natural antibacterial and deodorizing finishing agent for non-woven fabrics. The formula of the natural antibacterial and deodorizing finishing agent comprises the following components in percentage by weight: 5%-20% of polyoxyethylene sorbitan tristearate, 1%-10% of ester-base quaternary ammonium salt, 5%-20% of a natural antibacterial composition, 5%-9% of polyethylene glycol glyceryl ether, 3%-8% of a fragrant slow-released system and the balance of deionized water, wherein the natural antibacterial composition comprises chitosan, aloe oil, chitin, catechinic acid, tea polyphenol, tea-seed oil, tea saponin, a grape seed extract, citric acid, amino acid chelate, an amino acid derivative and an emulsifying agent. The natural antibacterial and deodorizing finishing agent has no stimulation to the skin of the human body, is capable of inhibiting the invasion and breeding of bacteria and high in ammonia absorptivity and further has outstanding antibacterial and deodorization effects. The natural antibacterial and deodorizing finishing agent has the characteristics that fragrance is uniformly released, the fragrance preservation time is long, and the added value of the product is high.

Owner:漳州市鼎鑫电子科技有限公司

Secondary heat exchanger of condensing gas water heater

ActiveCN101545679AAvoid influenceGuarantee long-termEnergy efficient heating/coolingAir heatersEngineeringWeld line

The invention relates to a secondary heat exchanger of a condensing gas water heater, mainly comprising a fume emission component, a secondary heat exchange component, a condensing water discharge pipe, a condensing water collecting disk and a thermal baffle. The secondary heat exchange component is welded with the fume emission component, the condensing water collecting disk is arranged below the secondary heat exchanger component and welded with the fume emission component, and the condensing water discharge pipe is welded on the fume emission component. The secondary heat exchanger of the condensing gas water heater is characterized in that the secondary heat exchanger component is provided with a double-layer coil heat exchanger, and the thermal baffle is fixed on the fume emission component by self-tapping screws. The invention can prevent condensing water from eroding welding lines on a waterway system, prevents the condensing water from being evaporated once again, improves the heat exchange efficiency, greatly prolongs the service life of the product and ensures the long-term validity of the heat exchange effect.

Owner:ARISTON THERMO CHINA

Antimicrobial nano silver additive for polymerizable dental materials

InactiveCN1893906AReduce concentrationGuaranteed long-termImpression capsMedical preparationsAdhesiveMicroparticle

Disclosed are polymerizable dental materials containing silver particles having a primary particle diameter < 40 nm as an antimicrobial additive. The inventive dental materials are suitable as filling composites, basic prosthetic materials, adhesives, coating composites for crowns and bridges, and materials for artificial teeth, for example.

Owner:HERAEUS KULZER

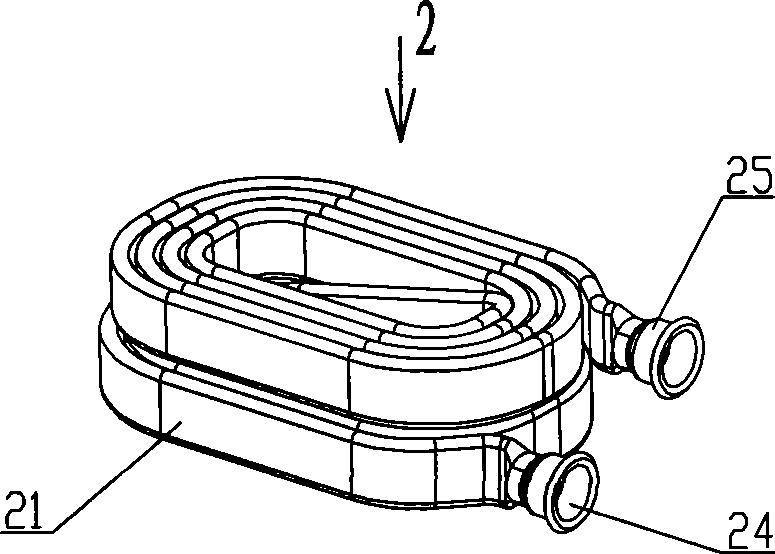

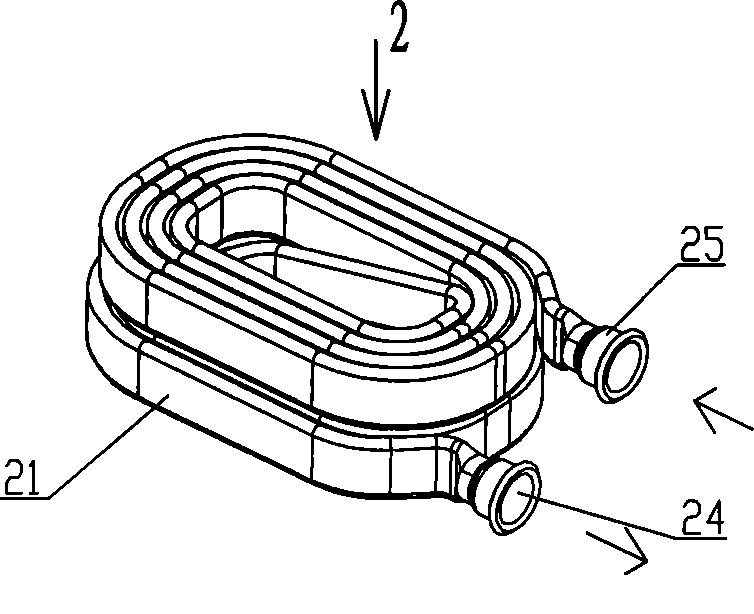

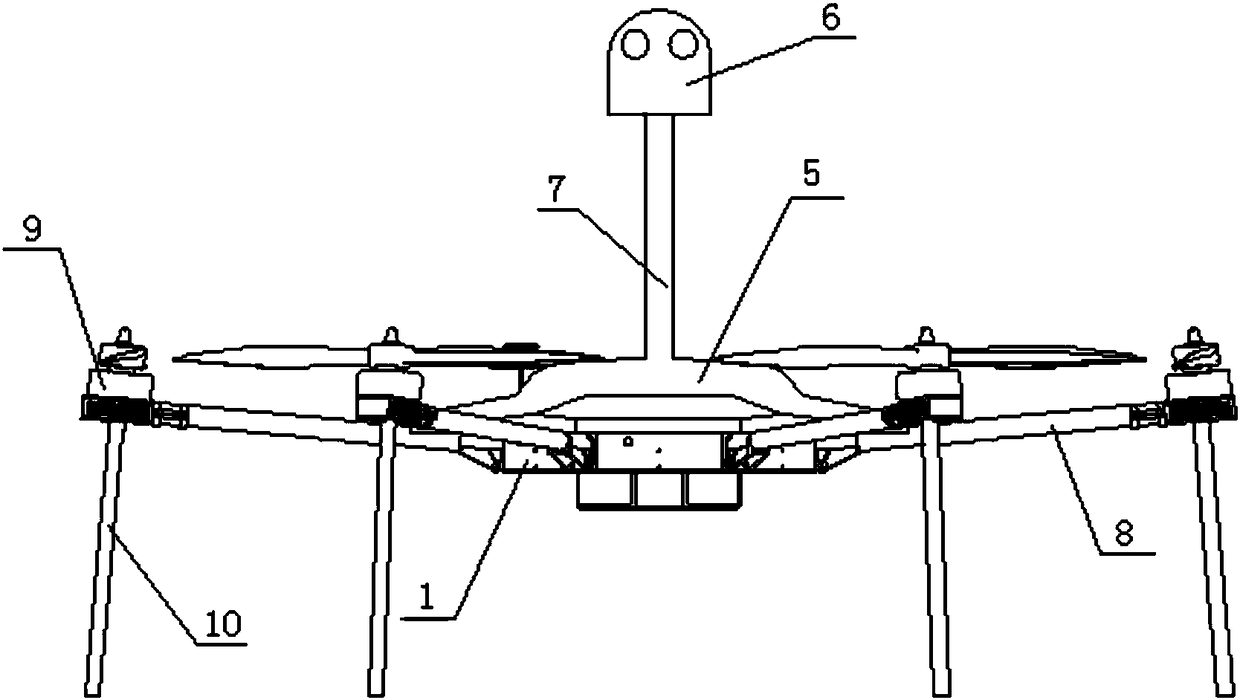

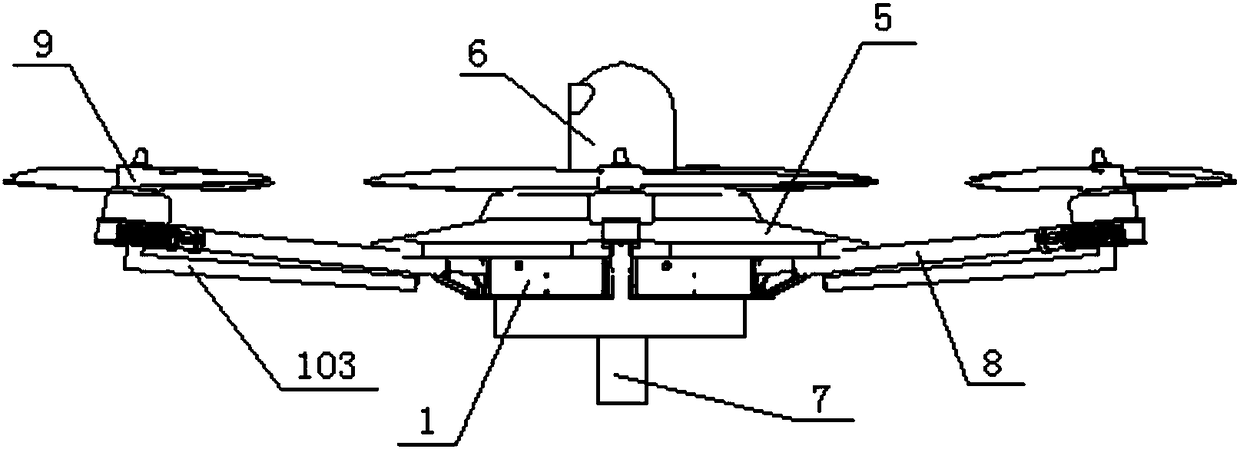

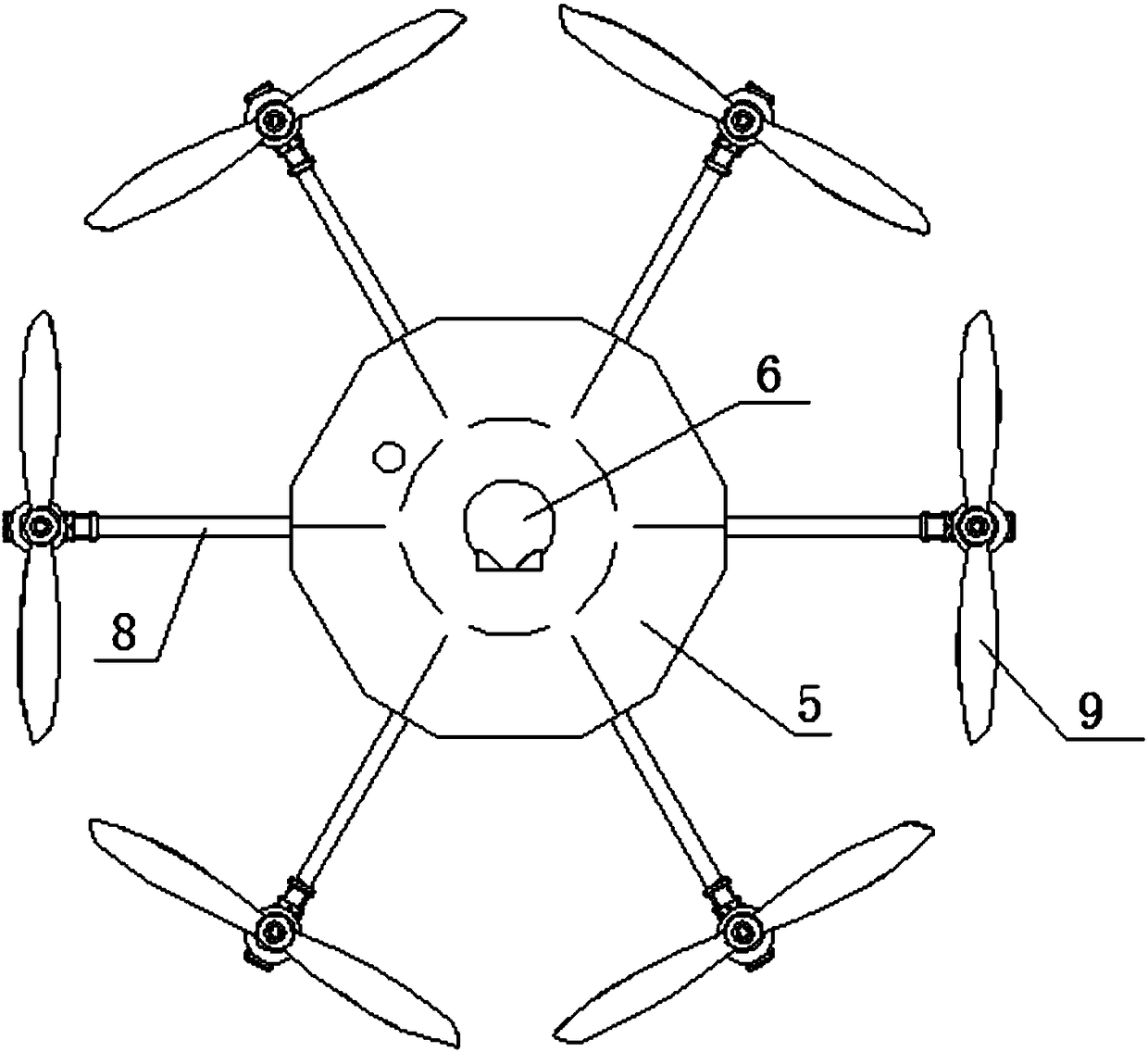

Reconnaissance and defense unmanned aerial vehicle for battlefields

PendingCN108341059AWide field of visionSurveillance range is wideSolar panel attachmentsRemote controlled aircraftControl systemUncrewed vehicle

The invention discloses a reconnaissance and defense unmanned aerial vehicle for battlefields. The reconnaissance and defense unmanned aerial vehicle for the battlefields comprises an unmanned aerialvehicle body, a navigation flight control system, an electrical system and an energy management system, a solar charging system, a mission payload, a lifting system, a plurality of frames and a plurality of groups of power systems and telescopic foldable landing gears, wherein the navigation flight control system, the electrical system and the energy management system are arranged in the unmannedaerial vehicle body; the solar charging system is arranged on the end surface of the top of the unmanned aerial vehicle body; the mission payload is right above the unmanned aerial vehicle body; the lifting system extends out of the unmanned aerial vehicle body and the top end of the lifting system is connected with the mission payload; the plurality of frames are uniformly fixed on the peripheryof the unmanned aerial vehicle body; and the plurality of groups of power systems and telescopic foldable landing gears are respectively connected to the outer ends of the corresponding frames. The reconnaissance and defense unmanned aerial vehicle for the battlefields has the advantages that the environmental suitability is stronger; the flying range is long; the reconnaissance and defense unmanned aerial vehicle can garrison the battlefields and execute reconnaissance and defense missions; the unmanned aerial vehicle hides in a designated area to perform reconnaissance and defense; the solarcharging device carried on the unmanned aerial vehicle can supply power to the mission payload for a long time; the telescopic foldable landing gears can guarantee that the unmanned aerial vehicle adapts to different landing sites; and by using a ground station system to remotely monitor the unmanned aerial vehicle and send a control instruction in real time, a purpose of remote reconnaissance and defense is achieved.

Owner:ANHUI YUNYI AVIATION TECH CO LTD

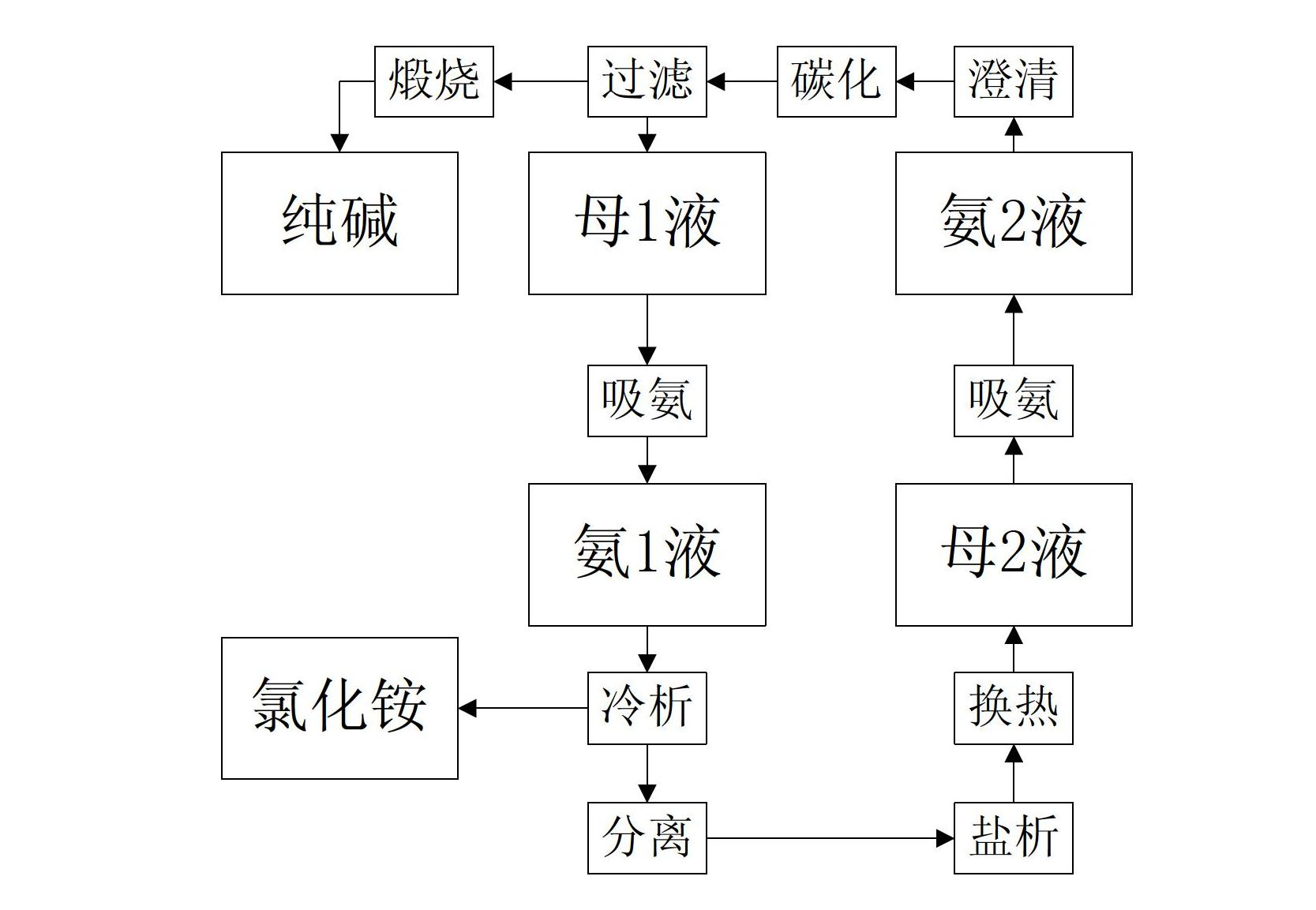

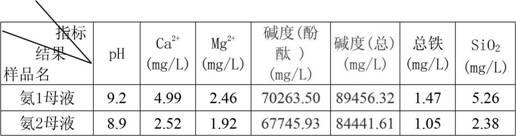

Scale inhibitor for soda ash mother liquid

ActiveCN102649605AGood scale inhibition and dispersibilityGood compatibilityScale removal and water softeningGluconic acidChemical cleaning

The invention discloses a scale inhibitor with soda ash mother liquor and belongs to the technical field of fine chemical products. The scale inhibitor comprises the following components in part by mass: 50 to 70 parts of HK-101 scale inhibitor, 5 to 15 parts of sodium gluconate, 10 to 20 parts of polyepoxysuccinic acid and 3 to 7 parts of pH regulator, wherein the HK-101 scale inhibitor is prepared through crylic acid, maleic acid, hydroxy-propyl acrylate, an initiator and a molecular weight regulator. The scale inhibitor applied to the soda ash mother liquid can prolong the scaling time of calcium ions and magnesium ions in the mother liquid, reduces the chemical cleaning frequency of a soda ash mother liquid production system from 2 to 4 times per year to 1 time per 2 to 3 years, guarantees long-period and stable operation of soda ash mother liquid production, greatly reduces damage to equipment caused by chemical cleaning and does not influence the quality of the soda ash product.

Owner:四川鸿康科技股份有限公司

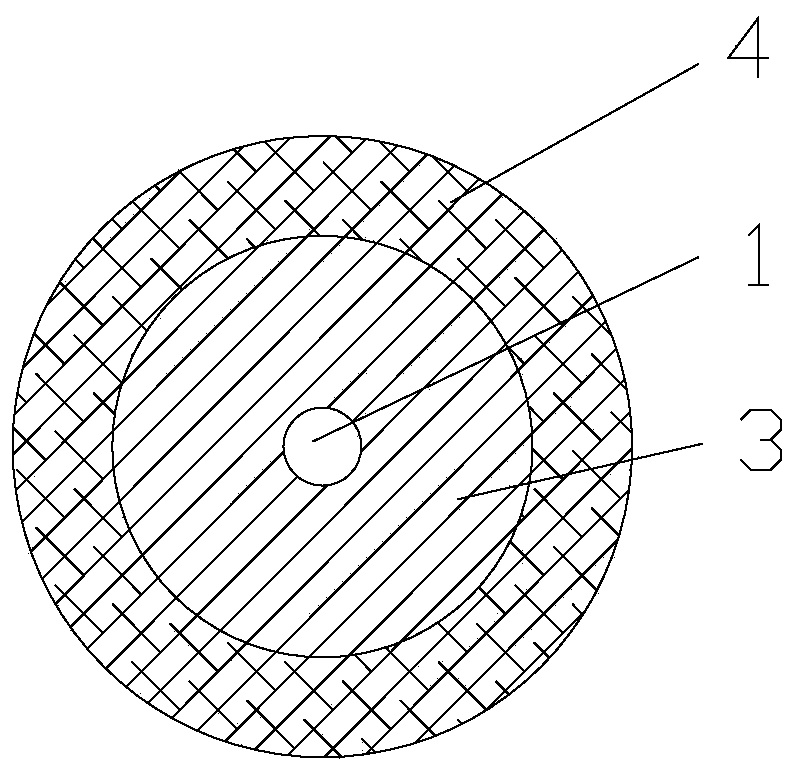

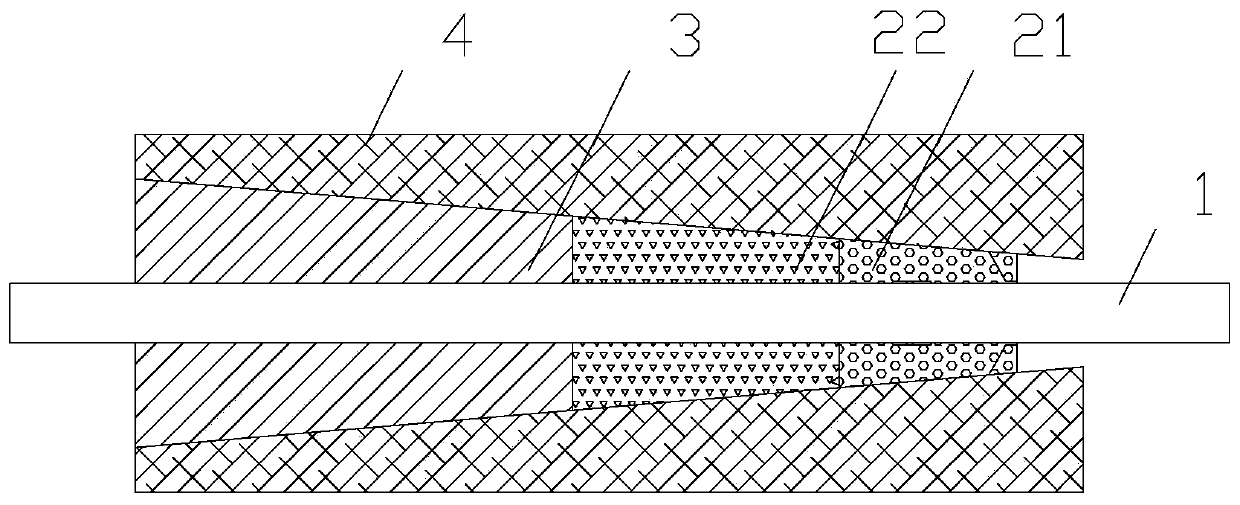

FRP (fiber reinforced polymer) rebar anchoring clamp piece, manufacturing method thereof and anchoring method thereof

ActiveCN109797910AReliable anchoringEasy constructionBuilding reinforcementsStress concentrationFiber

The invention discloses an FRP (fiber reinforced polymer) rebar anchoring clamp piece, a manufacturing method thereof and an anchoring method thereof. A circular arc groove for holding FRP rebars is formed in the sector-shaped FRP rebar anchoring clamp piece, the outer surface of the FRP rebar anchoring clamp piece is a circular conical surface, the FRP rebar anchoring clamp piece comprises a first medium segment for variable-stiffness load transfer and a second medium segment for variable-stiffness load transfer along the length direction, the stiffness of the FRP rebar anchoring clamp piecegradually increases from the loading end to the free end, and the first medium segment for variable-stiffness load transfer is formed by curing of resin-infiltrated fiber chopped yarn while the secondmedium segment for variable-stiffness load transfer is formed by curing of resin-infiltrated quartz sand. The FRP rebar anchoring clamp piece has the advantages that the content of fibers and the content of the quartz sand in the variable-stiffness load transfer media as well as lateral stiffness gradually increase from the loading end to the free end, so that the 'notch effect' at the loading ends of the FRP rebars can be relieved or eliminated, and the problem that lateral shear failure of the FRP rebars due to stress concentration is prior to tensile fracture is avoided.

Owner:SOUTHEAST UNIV

Chemical industry heating stove using water coal slurry as fuel

InactiveCN101109504ALower the altitudeFacilitate enhanced convective heat transferCombustion using gaseous and pulverulent fuelLiquid fuel feeder/distributionChemical industryCoal slurry

The invention discloses a heating furnace for the chemical industry taking water-coal slurry. The furnace is a radiation-convection vertical drum furnace with vertical pipes, the burners arranged in layers at sides are in tangent circle combustion way, the heat strength along the length direction in the vertical pipe in the radiation section can be controlled well, is good for enhancing the convection heat transmission in the radiation chamber, this can supplement the radiation heat transmission weakened at the pipes at upper part of the furnace. A compact structure form with parallelly arranged radiation section and convection section is employed, which is useful for reducing the height of the heating furnace, reducing the equipment cost and good for safety in manufacturing.

Owner:NANJING SHENGNUO HEAT PIPE

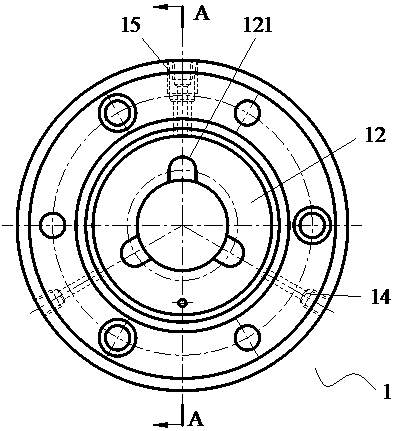

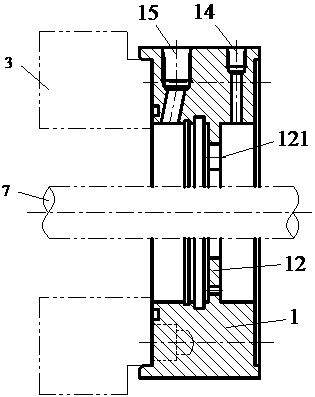

Monitorable shaft end sealing system and control method

ActiveCN108343747AImprove sealingGuaranteed long-termEngine sealsMechanical engineeringControl system

The invention provides a monitorable shaft end sealing system and a control method. The shaft end sealing system comprises a first-grade gap sealer and a second-grade contact sealer arranged in a serial connecting manner, a liquid auxiliary system and a control system; the first-grade gap sealer is a liquid film sealer; the liquid auxiliary system comprises an isolation cavity between the first-grade gap sealer and the second-grade contact sealer, and a conveying pipeline for conveying isolation liquid into the isolation cavity; and the control system comprises a first pressure adjusting device arranged on the conveying pipeline and capable of adjusting the pressure of the isolation liquid, a sensor for detecting the liquid film thickness of the first-grade gap sealer, and a main controller. Through arrangement of the first-grade gap sealer and the second-grade contact sealer in the serial connecting manner, the shaft end sealing tightness of fluid equipment is improved; and the control system is provided for guaranteeing maintenance of the liquid film thickness in a set numerical value range and guaranteeing operation of the first-grade gap sealer in an optimal working condition point always, so that safe and stable long-period operation of the shaft end sealing system is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

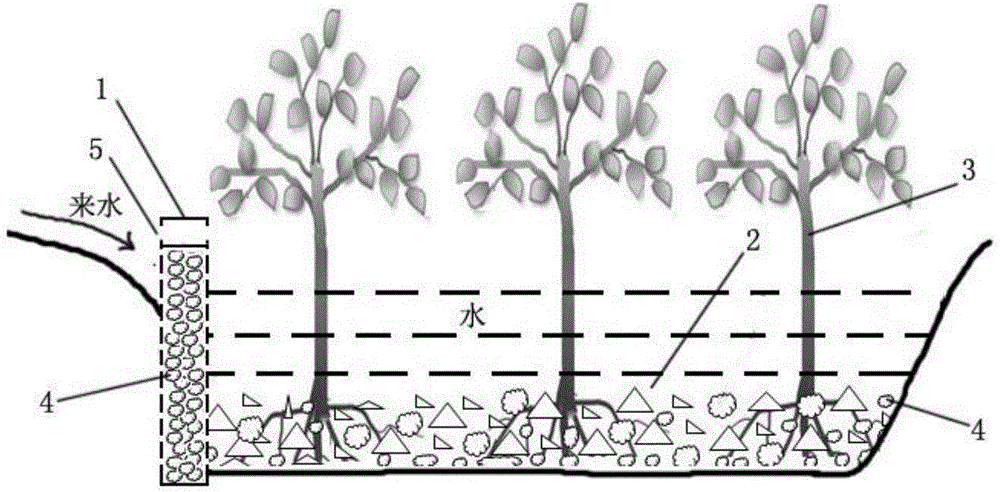

System for treating black stinking water

InactiveCN106315859AAvoid endogenous contaminationImprove adsorption capacityTreatment involving filtrationWater/sewage treatment by sorptionMass ratioEnvironmental engineering

The invention discloses a system for treating black stinking water. The system comprises an incoming water direction biological carbon filter, a water bottom substrate and aquatic plants, wherein the incoming water direction biological carbon filter is arranged in the incoming water direction of the system and is filled with activated biological carbon; the water bottom substrate is composed of water body bottom mud and activated charcoal; and the aquatic plants are planted on the water bottom substrate. The method for preparing the activated charcoal comprises the following steps: harvesting the mature aquatic plants, and sequentially drying and grinding; sequentially drying and grinding the water body bottom mud subjected to desilting; fully mixing the ground aquatic plants and water body bottom mud according to a mass ratio of (3-5):1, thereby obtaining a mixture; and performing high-temperature pyrolysis on the mixture under anoxic conditions so as to obtain the charcoal, and performing acid activation, thereby obtaining the activated charcoal.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

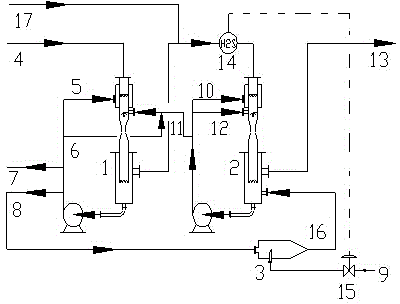

Acidic gas treatment process and system

ActiveCN105727715AAvoid thermal decompositionPrevent crystallizationDispersed particle separationChemical productsMixing tank

The invention provides an acidic gas treatment process and system. The process uses sodium hydroxide as an absorbent, and conducts two stages of gas-liquid reaction and one stage of liquid-liquid reaction process. The invention achieves up-to-standard emission of exhaust, and produces chemical product in line with national product quality standards. The acid gas treatment system includes a first processor, a second processor, a lye mixing tank, a process piping and a pump. The invention achieves dual goals of acidic gas purification and contaminant recycling.

Owner:CHINA PETROLEUM & CHEM CORP +1

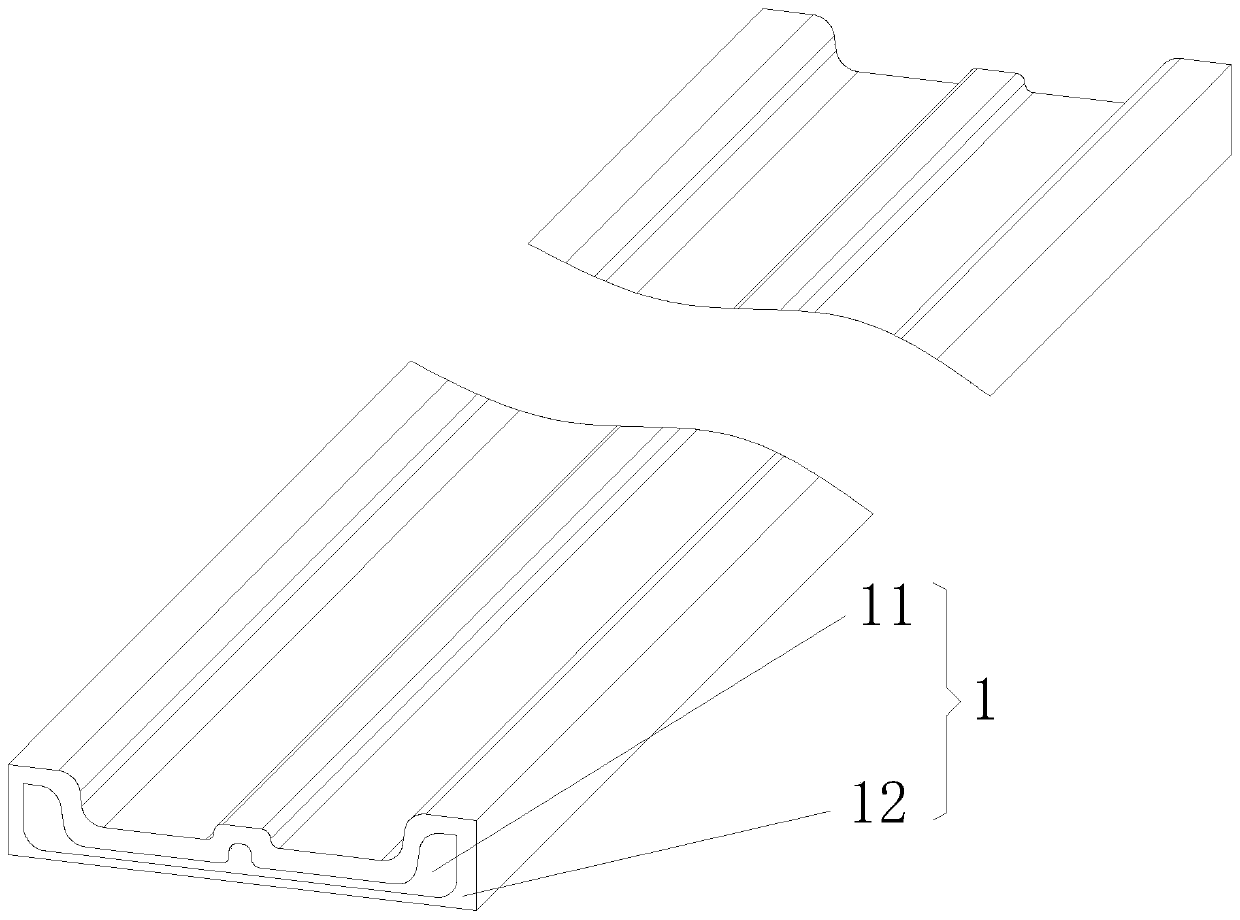

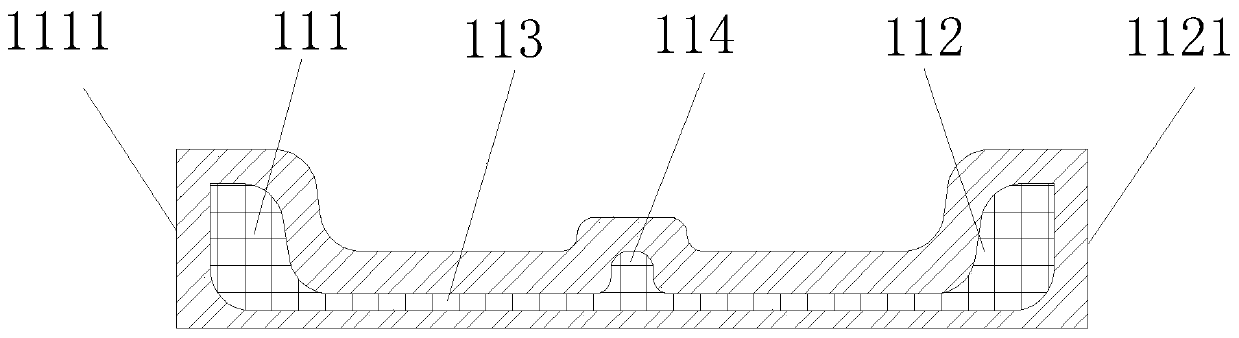

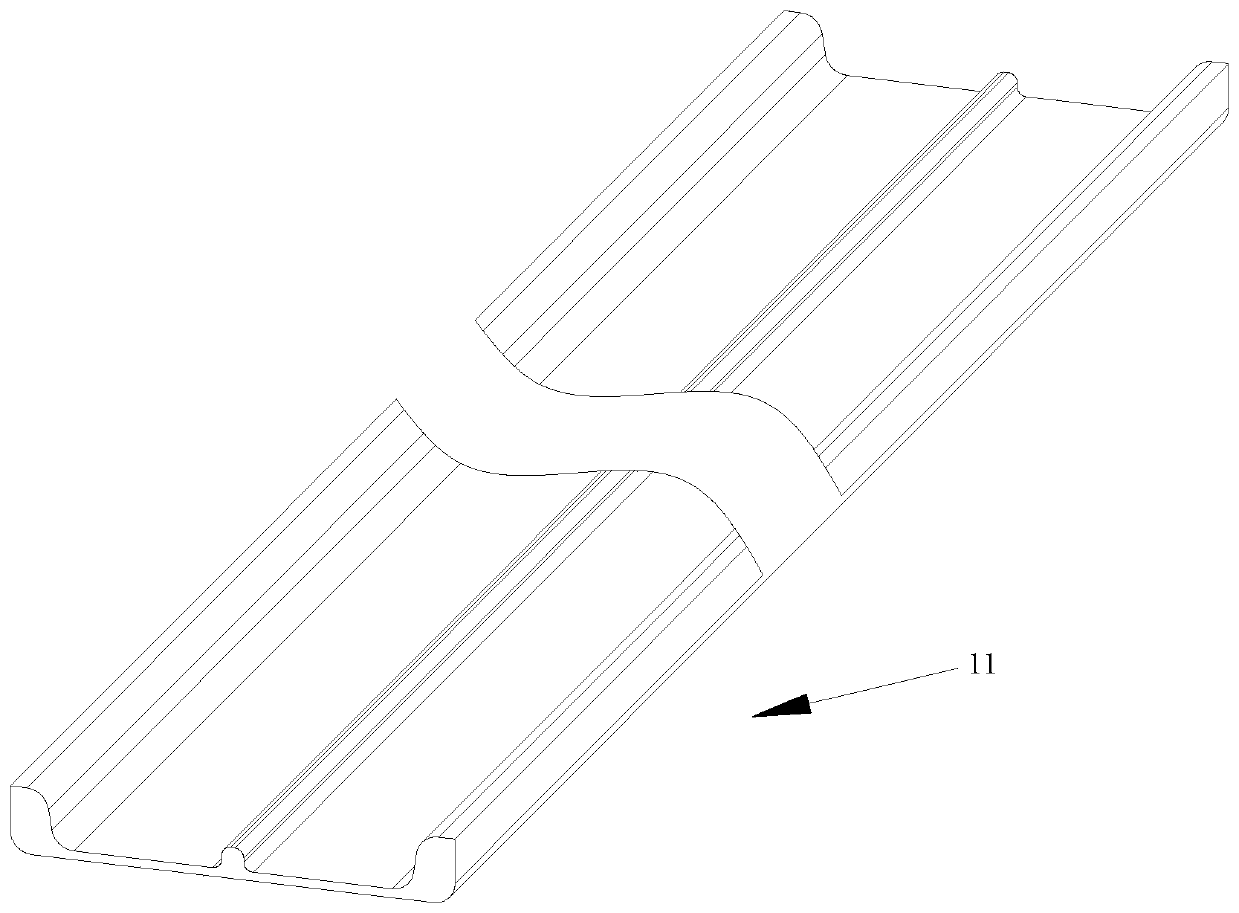

Hot winding solid corrugated pipe, sectional material thereof and manufacturing method thereof

PendingCN110588032AEasy to cool and formIncrease production speedRigid pipesTubular articlesSolid wallShock resistance

The invention relates to a hot winding solid corrugated pipe, and a sectional material and manufacturing method thereof. The sectional material of the hot winding solid corrugated pipe comprises a first sectional material and a second sectional material; the first sectional material comprises a supporting rib and a first hot coating layer; the first sectional material comprises a connecting strip,a first half wave crest strip and a second half wave crest strip; the second sectional material comprises a buckle plate and a second hot coating layer; a buckling groove is formed in the middle partof the second sectional material; and the shape and size of the buckling groove are matched with the shape and size of the outer wall of a small wave crest structure formed by splicing the first halfwave crest strip and the second half wave crest strip. The sectional material adopts the first sectional material and the second sectional material which are solid wall structures, and the sectionalmaterial can facilitate the cooling forming of a pipe, the production speed of the pipe is increased and the welding quality of the pipe can be improved. The solid corrugated pipe is of a solid wall structure, and is high in ring stiffness, good in impact resistance and destruction resistance, and excellent in ring flexibility. The manufacturing method of the corrugated pipe adopts hot winding tocompound all units together, the welding strength is high and the residual stress problem basically does not exist.

Owner:萍乡市大地新材料科技有限公司

Calcium carbide used as water phosphorus removal filter material and preparation method thereof

ActiveCN106219692ASolving Passivation ProblemsSolve the cost problemEnergy based wastewater treatmentWater/sewage treatment apparatusUranium carbideMixed materials

The invention relates to calcium carbide used as a water phosphorus removal filter material and a preparation method of the calcium carbide. The calcium carbide is prepared from, by volume, 0.5-30% of metal materials, 0.5-80% of binding agent, 1-40% of activating agent and 0.5-15% of catalyst. The preparation method of the filter material comprises the steps that the components of the filter material are subjected to micronization and nanocrystallization treatment, and the fineness of the components is not smaller than 300 mesh after micronization and nanocrystallization treatment; the components subjected to micronization and nanocrystallization treatment are mixed to be uniform; the evenly-mixed material is subjected to sintering-free extrusion (hydraulic) molding; the molded product is maintained, dried and packaged. Compared with the prior art, the problems of metal passivation, high cost and lack of timeliness in phosphorus removal methods are well solved.

Owner:上海润溪环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com