Preparation method of self-fragrance natural antibacterial and deodorizing fiber and application thereof

A natural antibacterial and fragrant technology, applied in the preparation of microspheres, fiber treatment, microcapsule preparations, etc., can solve the problems of affecting the application of silver ion antibacterial agents, silver ions turning black, poor anti-discoloration ability, etc., to ensure washing resistance. and antibacterial and deodorizing effect, and the effect of uniform fragrance release and long fragrance lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the preparation of self-aromatic natural antibacterial and deodorizing fibers includes the preparation of aromatic sustained-release bodies, the preparation of natural antibacterial and deodorizing compositions, the preparation of self-aromatic natural antibacterial and deodorizing masterbatch, and the preparation of self-aromatic natural antibacterial and deodorizing fibers. The specific preparation process and steps are as follows:

[0046] 1) Preparation of aromatic sustained-release body: In this process, the aromatic sustained-release body adopts spray drying microcapsule technology, the polymer of the capsule wall adopts gum arabic, and the fragrance type of the aromatic essential oil in the capsule core chooses jasmine essential oil, which is calculated according to the mass percentage. , Arabic gum: Jasmine essential oil is 40%:60%, the emulsifier is Span-80, and its mass accounts for 0.5% of the jasmine essential oil. The preparation process inc...

Embodiment 2

[0067] In this embodiment, the specific preparation process and steps of the self-aromatic natural antibacterial and deodorizing fiber are as follows:

[0068] 1) Preparation of aromatic sustained-release body: In this process, the aromatic sustained-release body adopts spray drying microcapsule technology, the wall polymer adopts urea-formaldehyde resin prepolymer, and the fragrance type of the aromatic essential oil in the capsule core chooses lemon essential oil. According to the calculation, the ratio of ethylene-vinyl acetate copolymer: lemon essential oil is 60%:40%, the emulsifier is sodium dodecylbenzene sulfonate, and its mass proportion is 0.8% of the lemon essential oil. The preparation process includes the following step:

[0069] Step 1: Weigh 40 parts of lemon essential oil, add the emulsifier sodium dodecylbenzene sulfonate to the essential oil, stir to dissolve and form an oil phase.

[0070] Step 2: Weigh a solution of 60 parts of urea-formaldehyde resin prepolymer ...

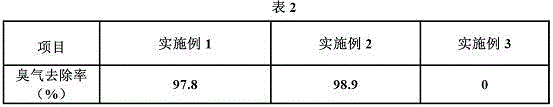

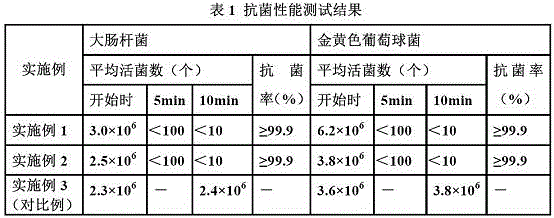

Embodiment 3

[0090] This example is a comparative example, that is, this example does not add aromatic sustained-release body and natural antibacterial composition, but uses polyethylene terephthalate and polyethylene to directly melt extrude and spin to obtain the core The structure of the bicomponent fiber, specifically, the fiber preparation process of this embodiment is the same as that of embodiment 2, that is, it includes the following steps:

[0091] Step 1: Take 30 parts of polyethylene and set its spinning temperature to 190-220°C.

[0092] Step 2: Take 100 parts of polyethylene terephthalate into the screw extruder, and enter the compound spinning box through the twin-screw extruder.

[0093] Step 3: Set the spinning temperature to 280°C, set the spinning temperature to 285-295°C, the spinning winding speed to 950-120m / min, the cooling air temperature to 16-20°C, and the wind speed to 4-6m / s , The screw length to diameter ratio L / D is 20-28, and the compression ratio is 3.5-3.7.

[0094...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com