Ammonium salt antibacterial polyethylene material and preparation method thereof

A polyethylene and hydroxypolyethylene technology, applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of loss of antibacterial properties, difficulty in ensuring compatibility, and achieve good antibacterial properties. Active, permanent antibacterial properties, antibacterial enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

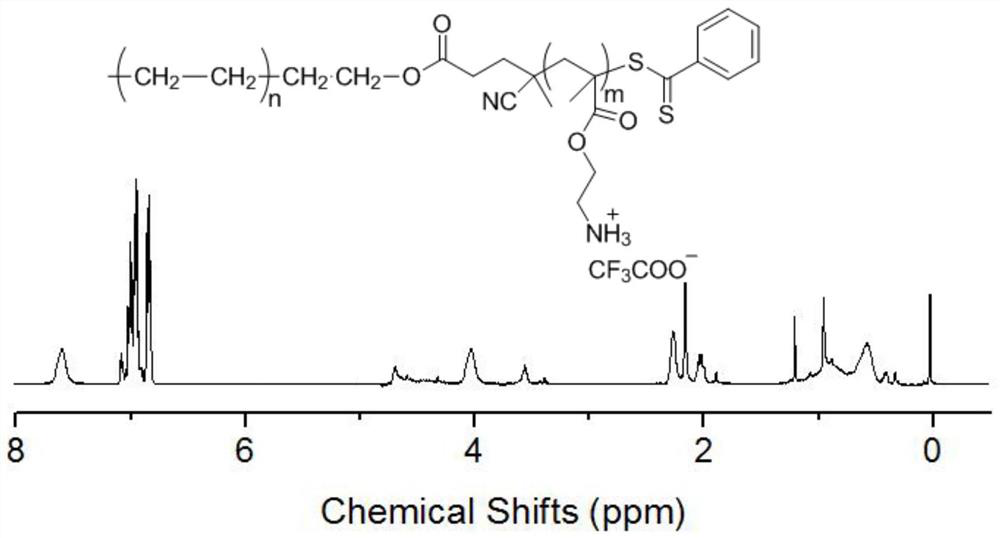

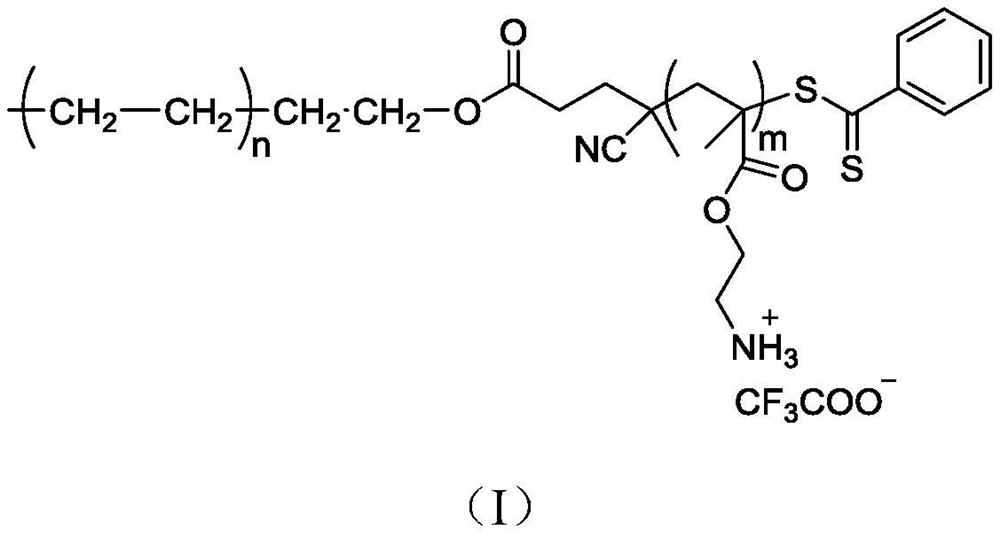

[0029] Preparation of polyethylene macromolecular chain transfer agent.

[0030] Add 4-cyano-4-(thiobenzoic acid) valeric acid (5.0mmol) and 20ml of anhydrous tetrahydrofuran THF into a 50mL branched-necked flask, place the branched-necked flask on a heating reactor, raise the temperature to 80°C, Slowly add SOCl dropwise 2 (5.0mmol), the dropwise addition was completed, and after continuing the reaction for 1.5h, the reaction temperature was cooled to room temperature, and the SOCl was removed by distillation under reduced pressure. 2 and THF to give 4-cyano-4-(thiobenzoic acid)pentanoyl chloride.

[0031] Add the single-end hydroxyl polyethylene PE-OH (1.0mmol) into the 50ml Schlenk bottle, place the Schlenk bottle on the heating reactor, and pump nitrogen three times, N 2 Under protection, add 30ml of anhydrous toluene, raise the temperature to 80°C, add 1ml of pyridine after the PE-OH is completely dissolved, and after stirring for 30min, add the above-mentioned 4-cyano-...

Embodiment 2

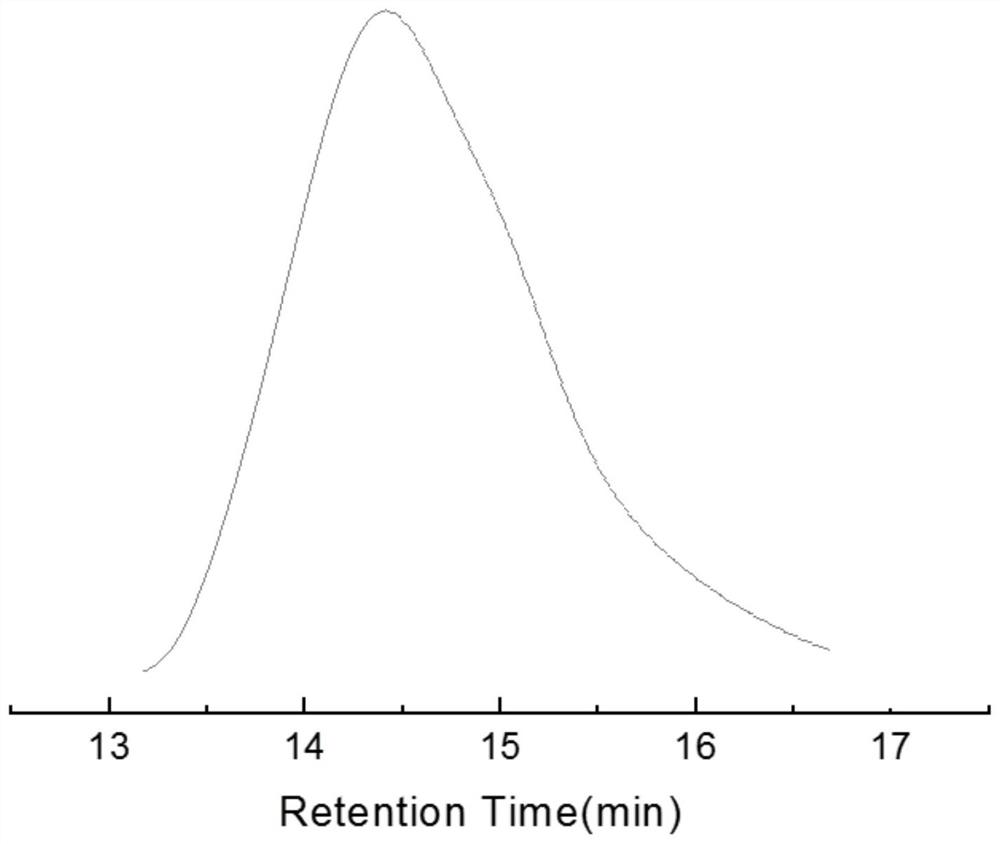

[0033] Preparation of ammonium salt antibacterial polyethylene material.

[0034] Add ammonium salt (5.0mmol), polyethylene macromolecular chain transfer agent (0.08mmol), and azobisisobutyronitrile (0.01mmol) into a 25ml Schlenk bottle, place the Schlenk bottle on the heating reactor, and pump and charge it three times After nitrogen, N 2 Under protection, add 7.5mL N,N-dimethylformamide DMF, react in an 80°C oil bath for 1.5h, put the product into liquid nitrogen to quench, add the product dropwise to methanol / water to precipitate, and continuously dissolve the precipitate After 3 times, filter, wash with methanol, and dry under vacuum at 45°C to constant weight to obtain an ammonium salt antibacterial polyethylene material.

Embodiment 3

[0036] Preparation of polyammonium salts.

[0037] Add ammonium salt (5.0mmol), 4-cyano-4-(thiobenzoic acid) valeric acid (0.08mmol), azobisisobutyronitrile (0.01mmol) into a 25ml Schlenk bottle, place the Schlenk bottle on heating On the reactor, after pumping nitrogen three times, N 2 Under protection, add 7.5mL N,N-dimethylformamide DMF, react in an oil bath at 80°C for 0.5h, put the product into liquid nitrogen to quench, add the product dropwise to methanol / water to precipitate, and continuously dissolve the precipitate After 3 times, filter, wash with methanol, and dry under vacuum at 45°C to constant weight to obtain polyammonium salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com