Patents

Literature

36results about How to "Permanent antibacterial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

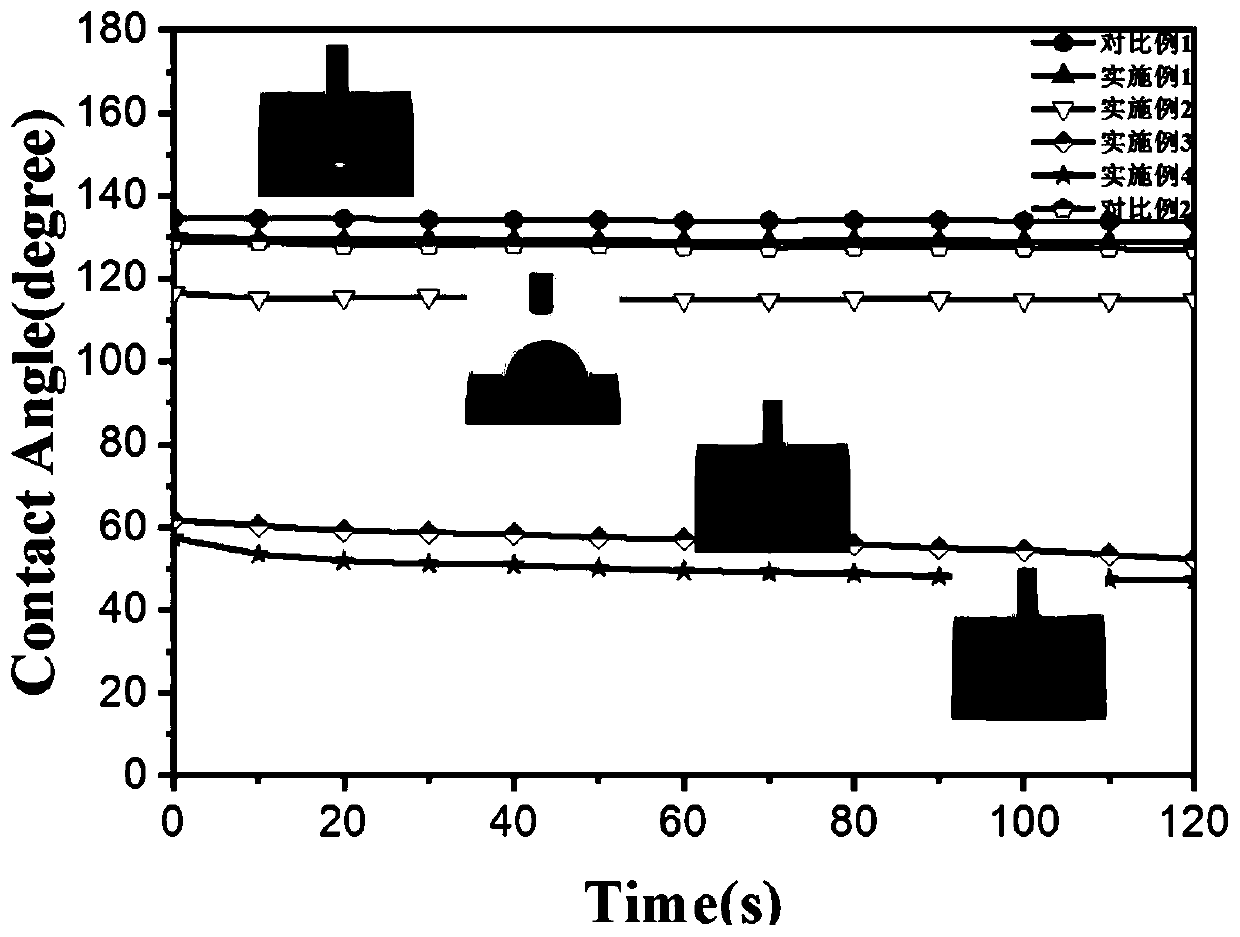

Permanent antibacterial polymer composite material and preparation method thereof

ActiveCN107903561AImprove antibacterial propertiesImprove electrochemical stabilityHollow filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceNonwoven fabric

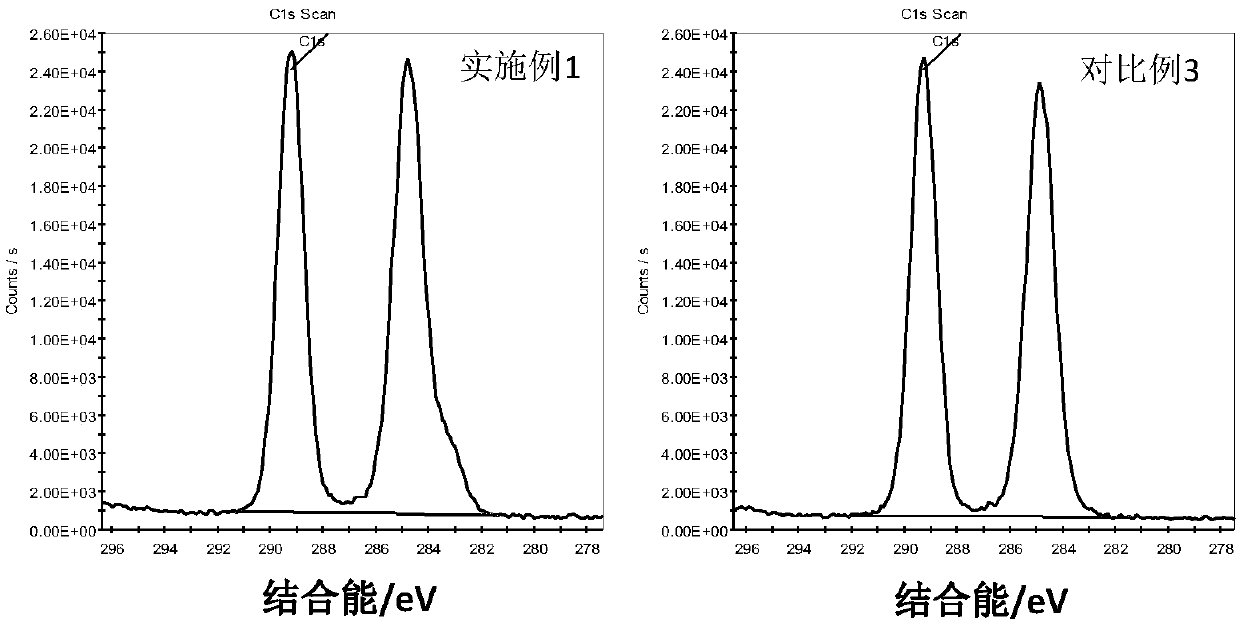

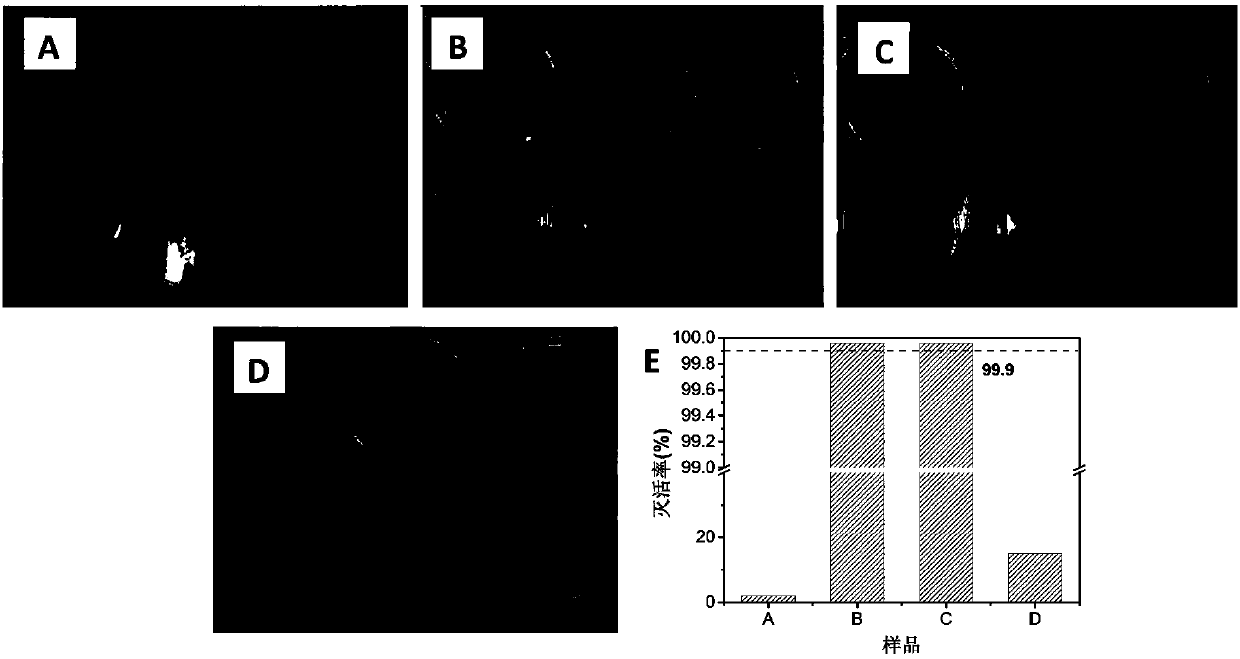

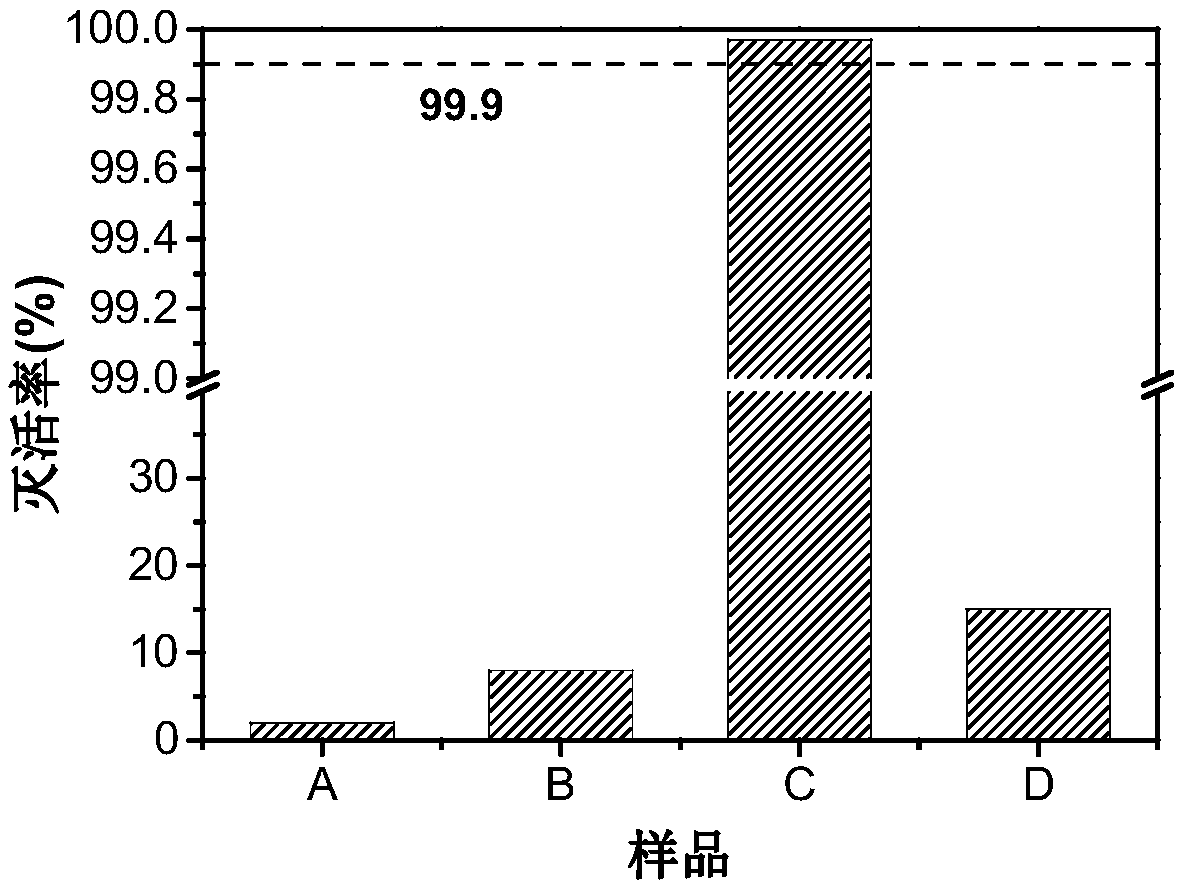

The invention discloses a permanent antibacterial polymer composite material and a preparation method thereof. According to the present invention, various materials such as polymer films, fibers, non-woven fabrics and the like are prepared by selecting different polymer molding technologies while an ion liquid is uniformly distributed and chemically bonded on the material surface, such that the material has good antibacterial effect; and the ion liquid and the polymer molecule are linked through the chemical bond, such that the loss of the ion liquid (antibacterial agent) due to migration andother causes during the long-term use can be avoided so as to maintain the permanent antibacterial performance.

Owner:HANGZHOU NORMAL UNIVERSITY

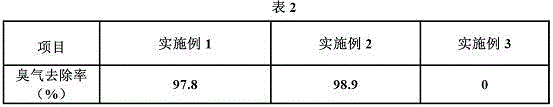

Preparation method of self-fragrance natural antibacterial and deodorizing fiber and application thereof

InactiveCN106637498APermanent antibacterialOutstanding antibacterial propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsHigh absorptionIrritation

The invention relates to a preparation method of self-fragrance natural antibacterial and deodorizing fiber. The preparation method comprises the following steps of (1) preparing a fragrance slow release body; (2) preparing a natural antibacterial composition; (3) preparing fragrance natural antibacterial and deodorizing master batches; (4) preparing self-fragrance natural deodorizing fiber, wherein the prepared self-fragrance natural antibacterial and deodorizing fiber is of a skin-core structure including a core layer and a skin layer; the core layer is a high-melting-point polymer; the skin layer is a low-melting-point polymer; a high-molting point polymer body of the core layer comprises the fragrance slow-release bodies and the natural antibacterial compositions. The fiber provided by the invention has no irritation on the human body skin, has the permanent antibacterial performance, can inhibit the bacterium invasion and breeding, and has high absorption rate on ammonia and very excellent antibacterial mouldproof and deodorization effects; the characteristics of uniform fragrance release and long fragrance maintaining time are realized; the product added value is high; the application market prospects are wide.

Owner:漳州市鼎鑫电子科技有限公司

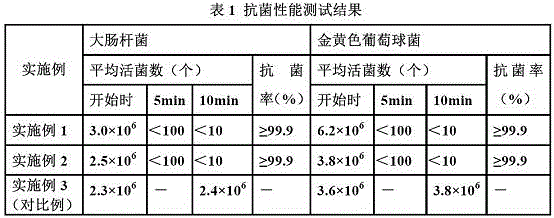

Antibacterial and antistatic polyester resin slice

ActiveCN103351585AHas antibacterial propertiesAntistaticElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentPlasticizerPolyethylene glycol

The invention relates to an antibacterial and antistatic polyester resin slice which comprises the following raw materials in parts by weight: 75-85 parts of a PET (polyethylene glycol terephthalate) slice, 5-15 parts of an antibacterial additive, 0.5-5 parts of an antistatic additive and 5-10 parts of a plasticizer, wherein the molecular weight of the PET slice is 25,000-50,000 and the plasticizer is one of dibutyl-o-phthalate, diisopropyl-o-phthalate and diamyl-o-phthalate. Due to the application of the technical scheme, the antibacterial antistatic polyester resin slice has the following advantages: the antibacterial additive and the antistatic additive in the raw materials of the polyester resin slice are added at the same time, so that the polyester resin slice has antibacterial and antistatic performances at the same times; a textile prepared by the polyester resin slice is endowed with permanent antibacterial and antistatic performances; and the increasing requirement of people on the textile can be met.

Owner:CHANGSHU HULIAN PRINTING & DYEING

Antibacterial fiber and machining process thereof

InactiveCN102586937AHas antibacterial effectStay attractiveMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterMicroparticle

The invention discloses antibacterial fiber and a machining process thereof. The antibacterial fiber is mainly composed of nanometer-scale zinc oxide microparticle, polyester chips, zinc stearate, titanate coupling agent and a liquid paraffin component, wherein the average diameter of the nanometer-scale zinc oxide microparticle is 20-100nm. The realization method comprises the steps of: uniformly mixing the nanometer-scale zinc oxide microparticle, the polyester chips, the zinc stearate, the titanate coupling agent and the liquid paraffin according to a mass ratio of 10: (28-32): (0.7-0.9): ( 0.15-0.17): (1.1-1.3) to form a mixture, granulating the mixture through a granulator to form mixture master batch, uniformly mixing the mixture master batch with the polyester chips according to a mass ratio of 1: (0.9-1.1) to form mixture particles, carrying out melting spinning on the mixture particles at a temperature of 255-263 DEG C to form cellosilk and drafting the cellosilk to form fiber filament. The antibacterial fiber and the machining process thereof, disclosed by the invention have the advantages that antibacterial agent is uniformly dispersed in the fiber and the antibacterial effect is long-lasting.

Owner:KUNSHAN HUAYANG NEW MATERIAL

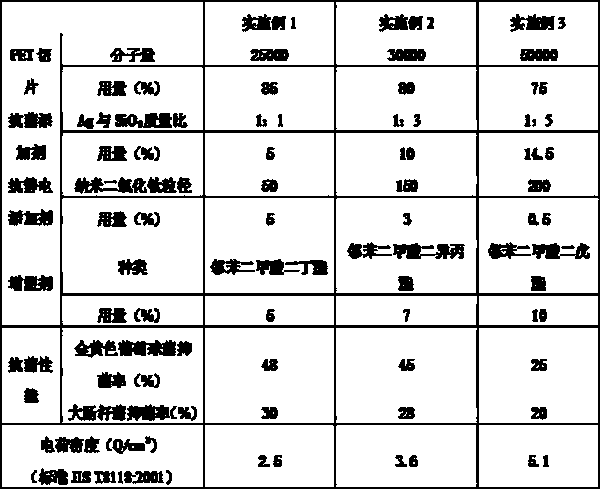

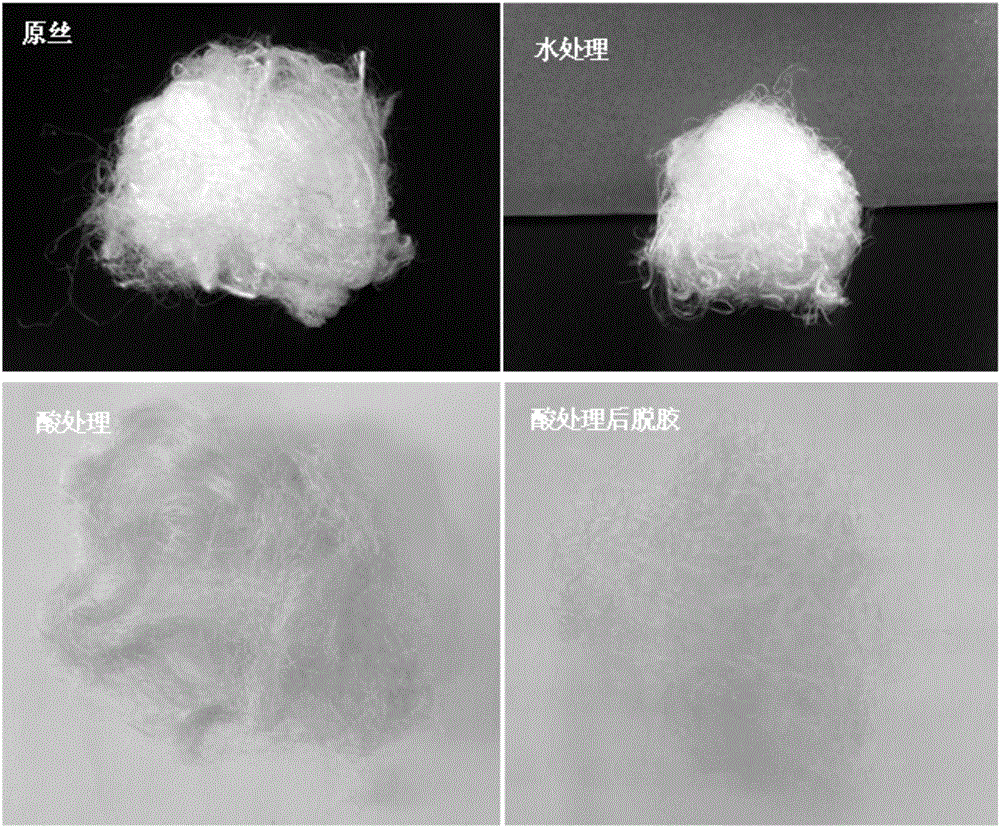

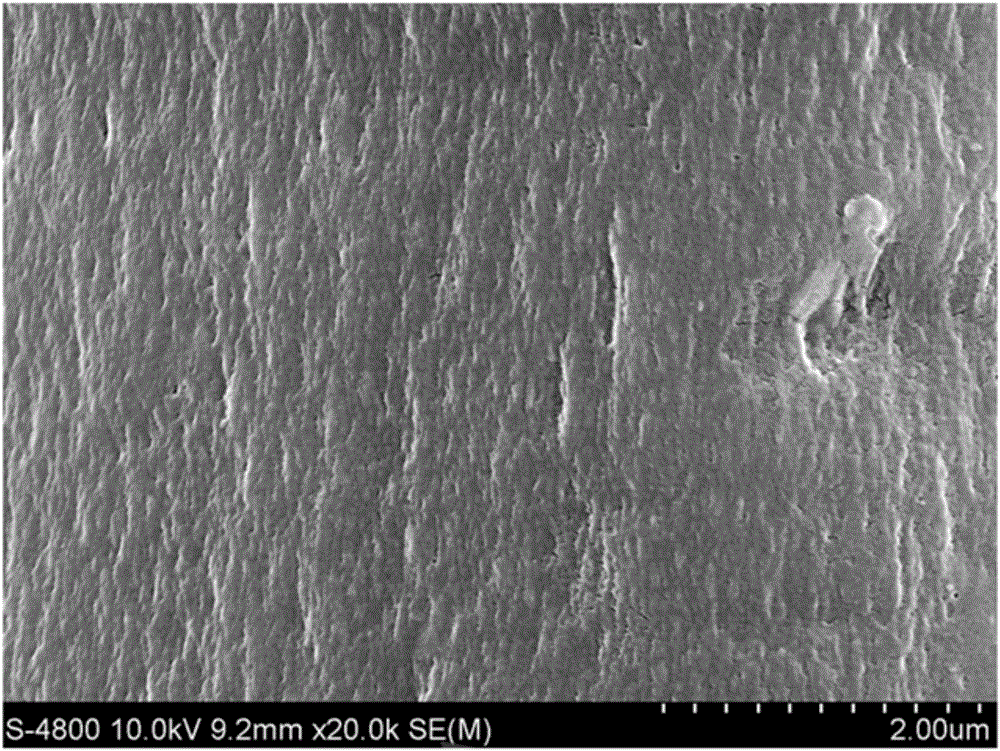

Antibacterial fibroin protein fiber and preparation method thereof

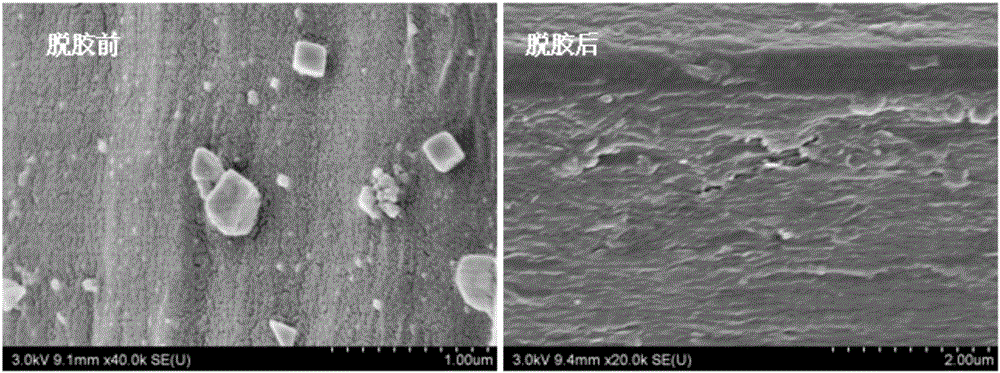

ActiveCN106835688AEvenly dispersedAvoid uneven loadBiochemical fibre treatmentDe-gumming silkBiocompatibility TestingAntibacterial agent

The invention provides antibacterial fibroin protein fiber and a preparation method thereof. The preparation method comprises the following steps: preparing a formic acid solution, adding silver salt into the formic acid solution, and stirring and dissolving; soaking a silk fiber which is not degummed or is partially degummed into the formic acid solution containing the silver salt, and performing lucifugal reaction for a period of time; completely washing the silk fiber product after the reaction, and drying to obtain a silver-containing silk fiber product; and performing degumming treatment on the silver-containing silk fiber product to obtain the antibacterial fibroin protein fiber. The preparation method provided by the invention is simple and easy in batched production; and in the prepared antibacterial fibroin protein fiber, the antibacterial agent nano-silver is mainly distributed in the fiber, so that excellent biocompatibility of the fibroin protein can be maintained, the biological toxicity exposed by the nano-silver is avoided, broad-spectrum antibacterial property is given to the fibroin protein fiber product, the antibacterial property is durable, and the antibacterial fibroin protein fiber is very suitable for people sensitive to the antibacterial agent and can serve as biological products such as antibacterial dressing and antibacterial suture lines.

Owner:杭州季盛新材料有限公司

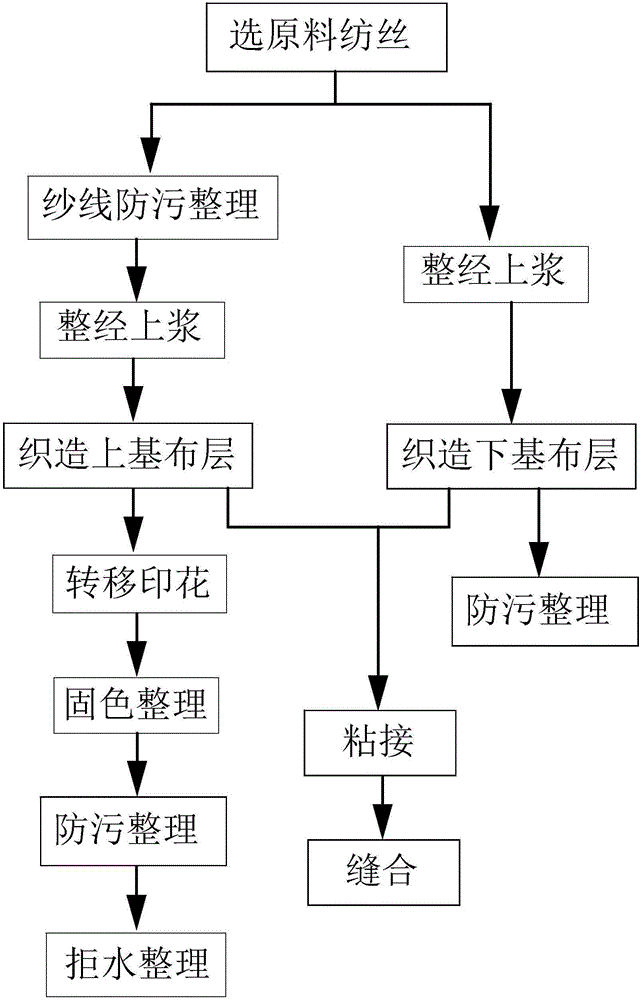

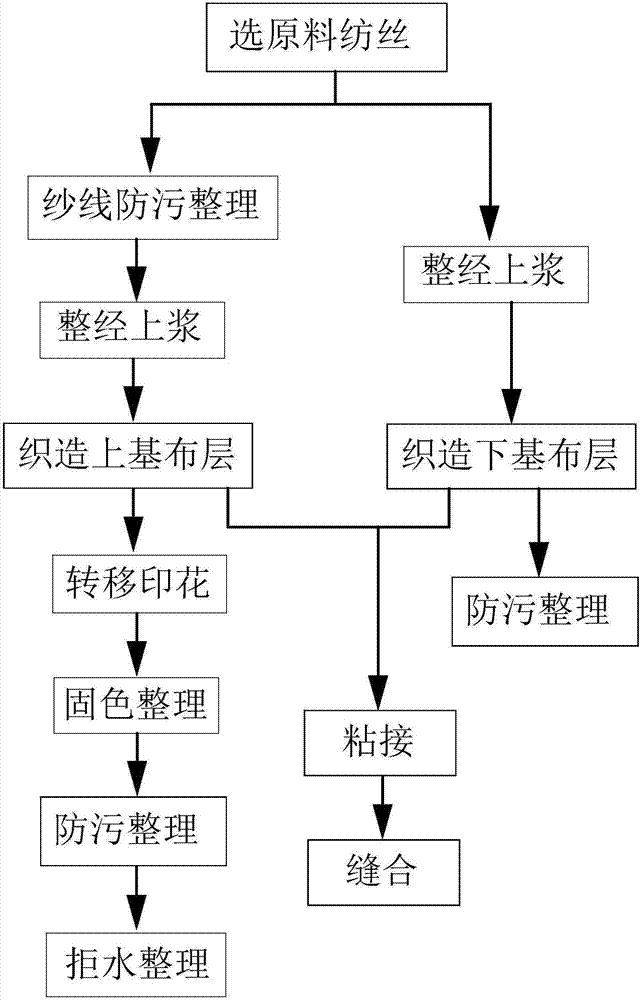

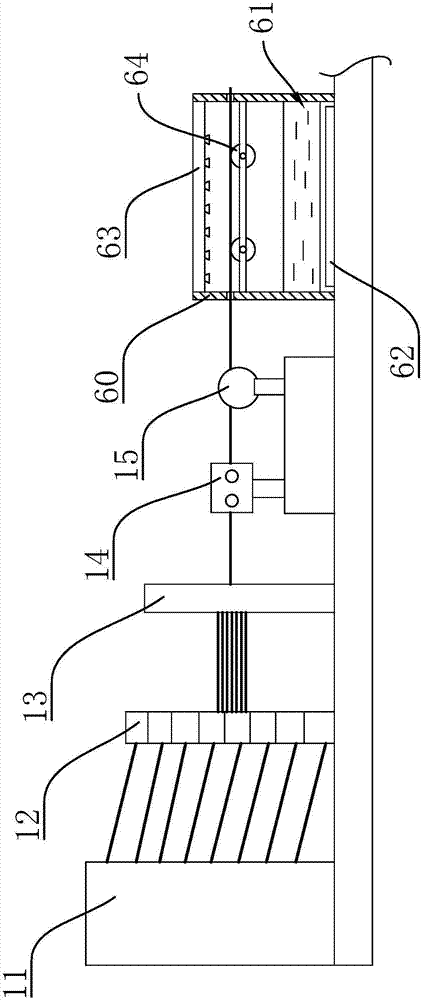

Production method of antifouling sofa fabric

ActiveCN106283340AIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnAdhesive

The invention provides a production method of an antifouling sofa fabric, belonging to the technical field of home textiles. The production method comprises the following steps: (1) selecting raw materials and spinning; (2) performing anti-pollution finishing of yarns; (3) warping and sizing; (4) weaving: weaving an upper base cloth layer and a lower base cloth layer; (5) transferring and printing; (6) fixing color and finishing; (7) performing anti-pollution finishing; (8) conducting water repellent finishing; (9) adhering: coating adhesives on the upper side and the lower side of a sponge respectively, applying pressure to the upper base cloth layer, the sponge and the lower base cloth layer which are superposed vertically, so as to enable the three to be adhered as a whole; and (10) sewing. The yarns treated by a warping and sizing machine are high in sizing rate, and fewer in feathers, so that static electricity generated due to friction among yarns can be reduced, the static electricity of the fabric can be effectively reduced, and the woven fabric is difficult to generate static electricity, thus being relatively difficult to adsorb dust; and the sofa fabric produced by utilizing the method has multiple antifouling capabilities, and has obvious antifouling effect.

Owner:海宁宝祥布业有限公司

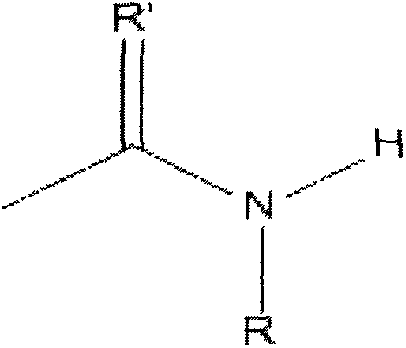

Preparation method of non-dissolution type durable antibacterial regenerated cellulose fibers

InactiveCN103526319ASolve the spinning processSolve problems that affect fiber performanceArtificial filaments from viscoseSpinning solutions preparationPolymer scienceSide chain

The invention discloses a preparation method of non-dissolution type durable antibacterial regenerated cellulose fibers. The method comprises the steps as follows: firstly, cellulose sizy dregs are prepared into a spinning viscose solution, and a reactive antibacterial agent is added in the process or after the process ends; and then processing steps of spinning, post-processing and drying are performed sequentially, so that the durable antibacterial regenerated cellulose fibers are prepared. Therefore, the antibacterial agent provided with reactive groups is adopted and added into the spinning solution; the agent and hydroxide radicals on macromolecular side chains of the cellulose fibers form covalent bond combination; and the cellulose fibers with antibacterial performance are prepared with the wet spinning method. The fibers have permanent antibacterial performance; and the fibers have reactions with the cellulose macromolecular side chains, so that no damage is caused to the basic performance of the cellulose fibers.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

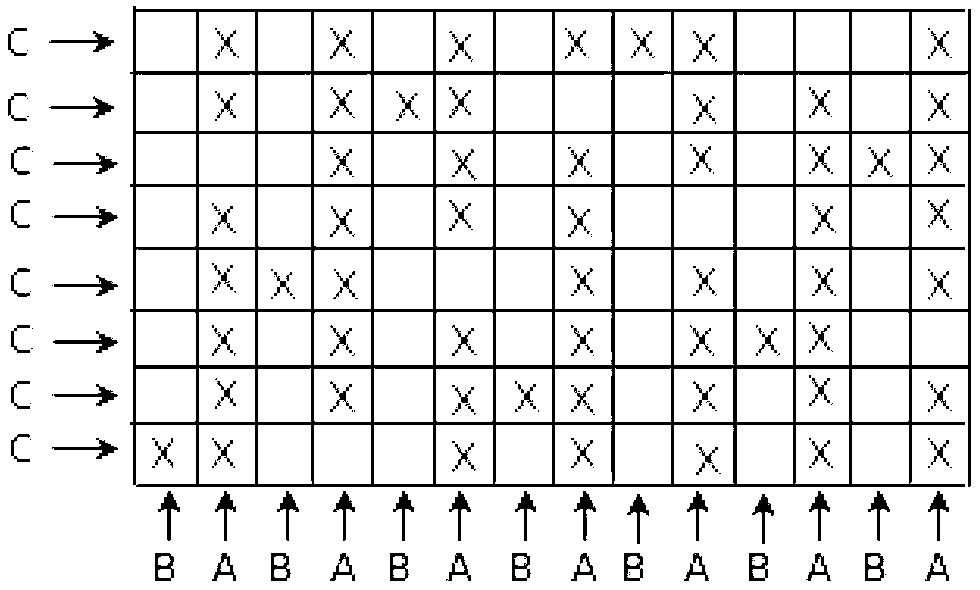

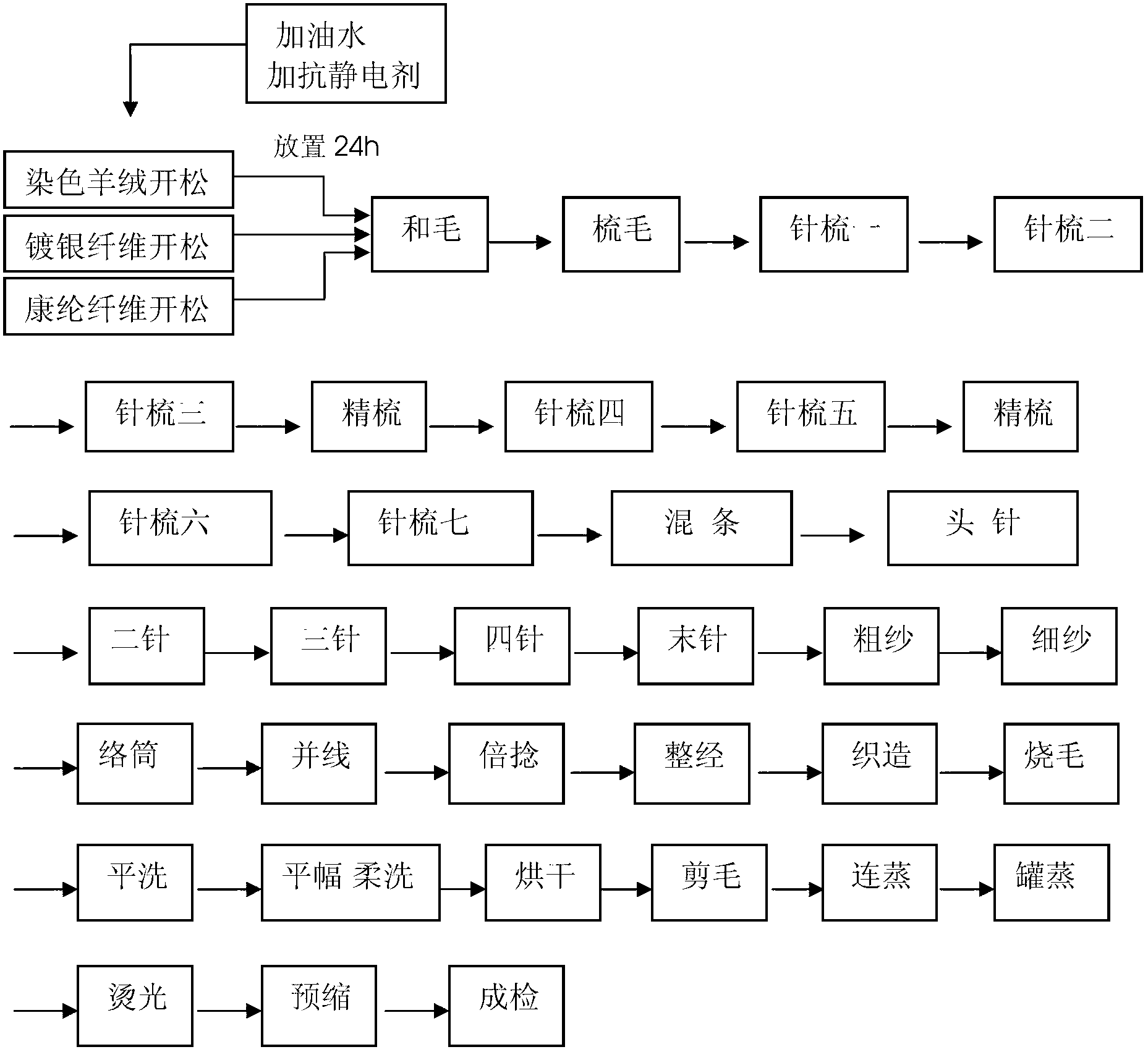

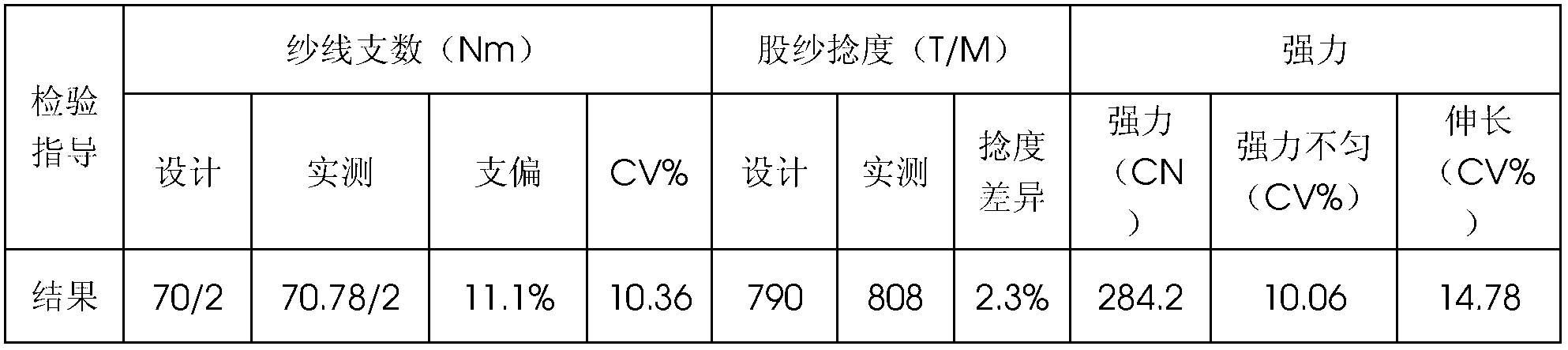

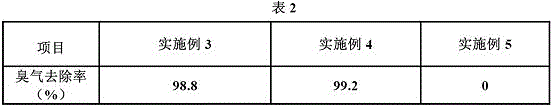

Permanent radiation-proof anti-bacterial and anti-static worsted cashmere fabric and production method

InactiveCN102704141ASuede plumpWith high-end productsWoven fabricsYarnElectromagnetic radiationAnti bacterial

The invention relates to interlaced fabric of permanent radiation-proof anti-bacterial and anti-static worsted cashmere fabric, wherein the worsted fabric adopts a duplex fabric structure; the worsted fabric includes compositions by weight as follows: the content of cashmere ranges from 30 to 35 percent, the content of cleancool ranges from 55 to 59 percent, the content of silvered fibers is 8 percent, and the content of electro-conductive fibers is 2 percent, wherein the denier of cleancool is 1.67dtex, and the length of cleancool ranges from 38 to 40mm; the specification of the electro-conductive fibers is 3.3dtex / 38mm, and the electrical conductivity ranges from 105 to 6; the fineness ratio of cashmere ranges from 15.2 to 15.6 micrometers, and the length ranges from 38 to 45mm; in addition, the specification of silvered filaments is 2.2dtex / 3f. The worsted fabric has the characteristics of cashmere and silk sheen, is permanently antibacterial, achieves the anti-static index that reaches the national standard of GB / T20944.1-2007, achieves the radiation-proof ratio that reaches the standard of ASTMD4935-99 (American Society of Testing Materials4935-99), can resist bacteria permanently and can also reduce the damage to a human body caused by electromagnetic radiation.

Owner:DEHONG INTERNATIONAL CASHMERE CO LTD

Self-aromatic natural antibacterial deodorization non-woven cloth and application thereof

ActiveCN106400308APermanent antibacterialOutstanding antibacterial propertiesConjugated synthetic polymer artificial filamentsNon-woven fabricsAbsorption rateEngineering

The invention relates to a piece of self-aromatic natural antibacterial deodorization non-woven cloth which comprises double-component fiber. The self-aromatic natural antibacterial deodorization non-woven cloth comprises double-component fiber, self-aromatic fiber and natural antibacterial deodorization fiber, and is made of the double-component fiber, the self-aromatic fiber and the natural antibacterial deodorization fiber which are randomly arranged in the longitudinal direction and the transverse direction after the fibers are weighed and combed so as to form a mixed fiber net after being longitudinally and transversely interwoven, tangled, embraced and paved, and the mixed fiber net is treated in a heat setting compounding manner. The self-aromatic natural antibacterial deodorization non-woven cloth is free of irritation on human skin, is capable of inhibiting invasion and generation of bacteria, is high in amino absorption rate, very outstanding in antibacterial anti-molding deodorization effect and high in product additional value, and has the characteristics of being uniform in aroma release and long in aroma retention time.

Owner:漳州市鼎鑫电子科技有限公司

Silver-containing nylon 6-based composite resin material and preparation method thereof

ActiveCN102702509AImprove antibacterial propertiesPermanent antibacterialIn situ polymerizationResin-Based Composite

The invention discloses a silver-containing nylon 6-based composite resin material and a preparation method thereof. The silver-containing nylon 6-based composite resin material is prepared by caprolactam, soluble silver salt, polyvinylpyrrolidone, ascorbic acid aqueous solution, ammonia, a alkaline catalyst and solvent as raw materials by using an in situ polymerization method. The amount of each component is as below : the soluble silver salt is 0.3-3 wt% of the weight of caprolactam, the polyvinylpyrrolidone is 0.3-1.0 wt% of the weight of caprolactam, the weight ratio of the ascorbic acid and the soluble silver salt is 1.2-1.5:1, the weight ratio of the soluble silver salt and the ammonia is 1-3:1. The nylon 6 / Ag composite resin material provided by the invention not only maintains the mechanical property of the original nylon 6, but also has excellent antibacterial property and permanent antimicrobial property. The preparation method provided by the invention has the advantages of simple process, short preparation period, low cost, and no pollution, and is suitable for large-scale industrial production.

Owner:上海仕天工程塑料有限公司

Multi-component antibacterial non-woven fabric

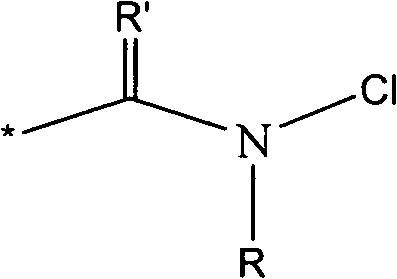

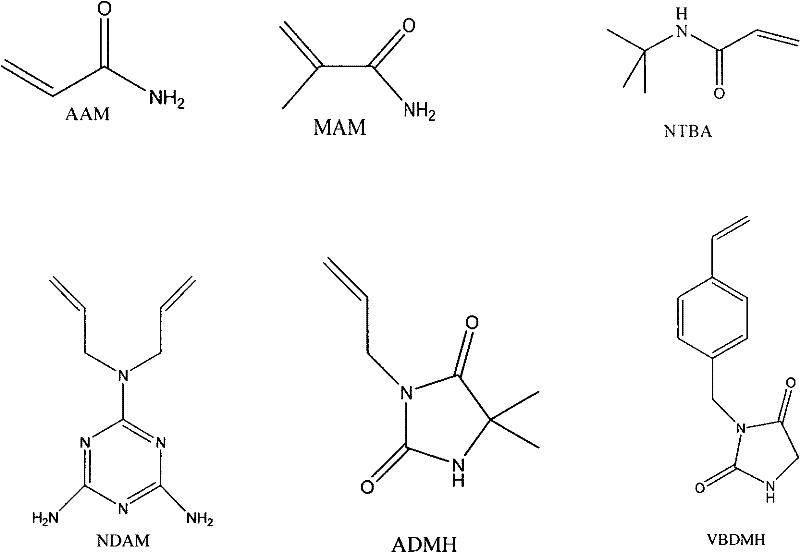

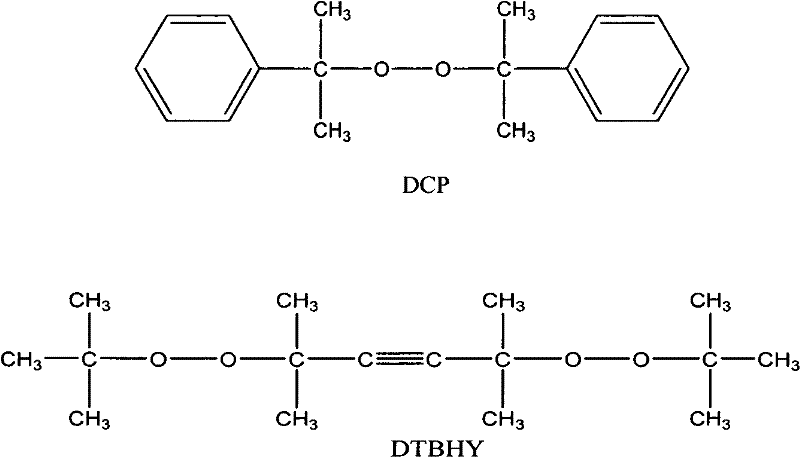

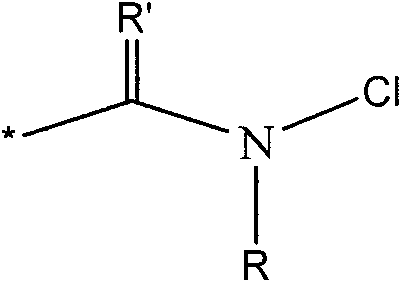

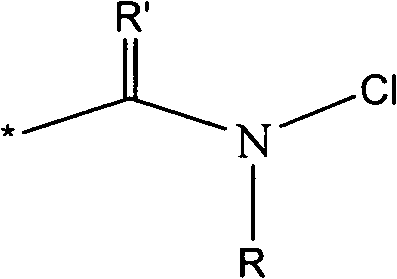

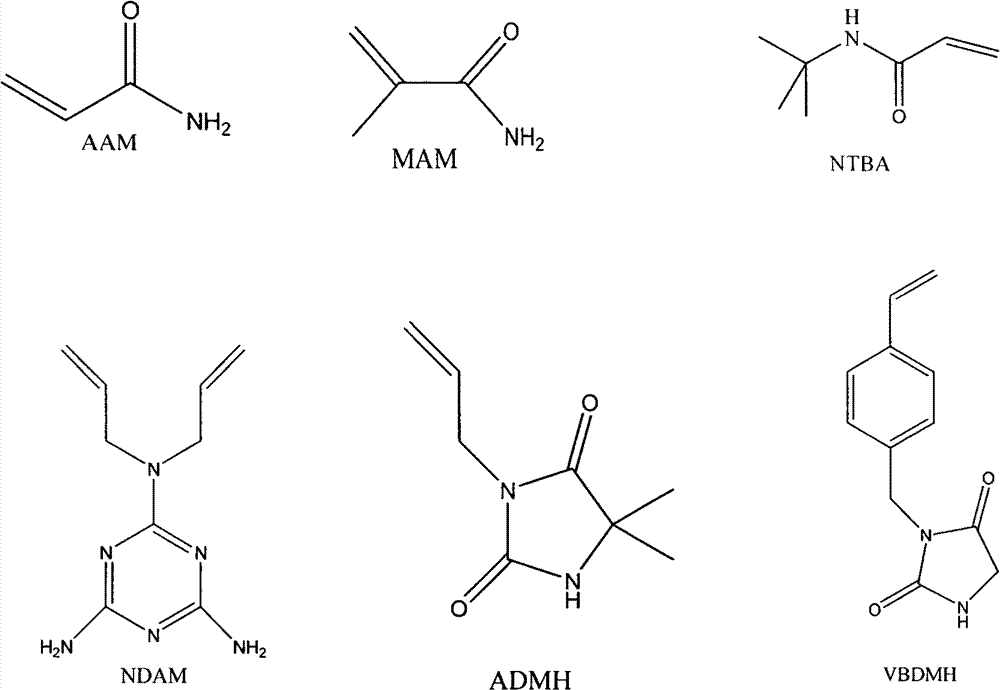

ActiveCN102677394AHas antibacterial propertiesOvercome mechanical propertiesConjugated synthetic polymer artificial filamentsNon-woven fabricsChloramine BPolyester

The invention discloses a multi-component antibacterial non-woven fabric. The antibacterial non-woven fabric is formed by mixing 80%-20% by mass of modified polyamide and 20%-80% by mass of modified polyester, and preparing and molding through a spunbond spunlace process; and the surface of non-woven fabric fibre member is provided with a chloramine structure connected by covalent bond. The multi-component antibacterial non-woven fabric disclosed by the invention has the characteristics of strong sterilizing effect, ultrafine fibre, comfortable touch feeling and good mechanical property, and overcomes the defects of a post-treatment method using a finishing agent during traditional preparation of the antibacterial fabric; and the non-woven fabric disclosed by the invention is subjected to simple chloration so as to recycle the sterilizing effect of the non-woven fabric.

Owner:HUBEI SANYANG NEW TECH CO LTD

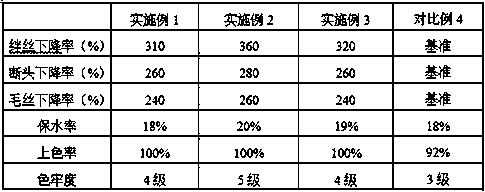

Chitin polyester fiber

PendingCN109735956AImprove skinPermanent antibacterialConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterFiber

The invention provides a chitin polyester fiber. Raw materials for preparing the fiber include polyester chips, chitosan, a modifier and a regulator; and the mass ratio of the polyester chips to chitosan to the modifier to the regulator is (75-85):(3-5):(4-5.5):(1.5-2.3). The polyester chips has the water content of less than or equal to 0.2%, the acetaldehyde content of less than or equal to 1%,the acid value of max.35 Meq / kg and the inherent viscosity of 0.865+ / -0.015 dl / g; the chitin polyester fiber provided by the invention has the water retention rate of 18-20% and the dyeing degree of 92-95%; and the chitin polyester fiber has functions of permanent skin affinity, antibacterial property and mildew prevention. No spinder webs are generated in a process of preparing the chitin polyester fiber, so that the winding performance of a bobbin is improved, the web breaking and filament breaking caused in subsequent processing due to the addition of chitin fiber are avoided, and the quality of the fiber is improved.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Antibacterial and ozone-resistant modified calcium carbonate and preparation method thereof

The invention discloses antibacterial and ozone-resistant modified calcium carbonate. Antibacterial and ozone-resistant modified calcium carbonate is prepared from the following raw materials in parts by weight: 0.5-0.7 part of cadmium stearate, 2-3 parts of glycerin, 1-2 parts of activated carbon, 0.4-0.6 part of lanthanium stearate, 2-3 parts of nano attapulgite, 1-1.5 parts of oxidized polyethlene wax, 3-4 parts of barium hydroxide, 2-3 parts of tetrabutyl titanate, 1-2 parts of disproportionated potassium abietate, 2-2.5 parts of eleostearic acid, 4-6 parts of chlorinated polyethylene, 0.8-1.1 parts of nano silver, 0.1-0.2 part of sodium hydroxide, 80-85 parts of light calcium carbonate, 13-16 parts of an auxiliary agent and 120-140 parts of water. According to antibacterial and ozone-resistant modified calcium carbonate disclosed by the invention, the nano silver is added into a filling material to ensure that PVC (polyvinyl chloride) has permanent antibacterial performance; chlorinated polyethylene is added to ensure that the weather resistance, ozone resistance, chemical medicine resistance and aging resistance of the PVC can be increased, and good oil resistance, flame-retardant performance and coloring performance can be provided; by virtue of surface treatment, calcium carbonate disclosed by the invention has good compatibility with PVC, and can be used for improving the mechanical performance of PVC.

Owner:QINGYANG COUNTY YONGCHENG CALCIUM IND

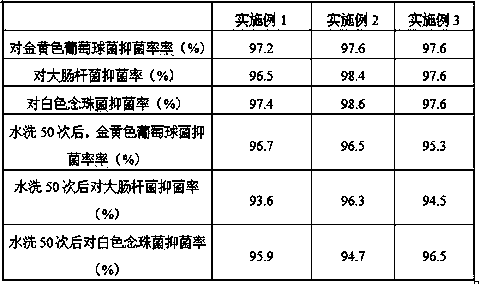

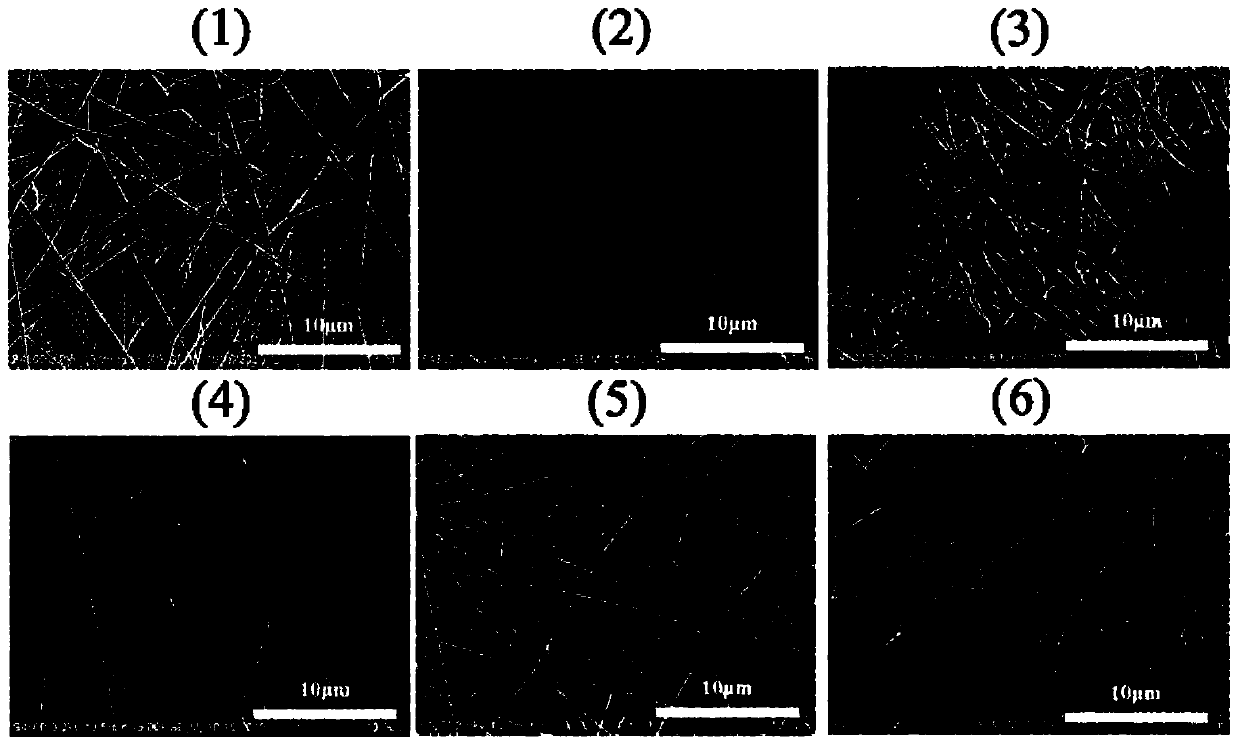

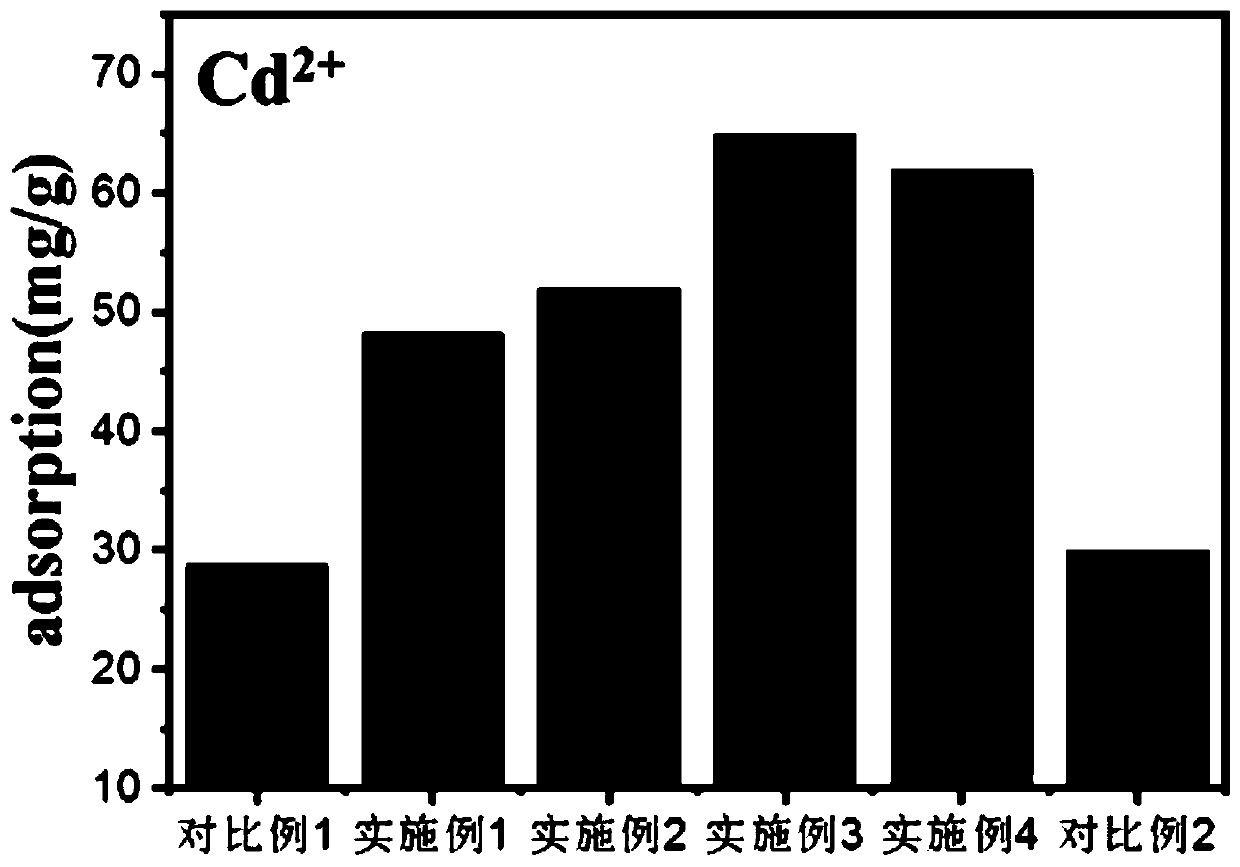

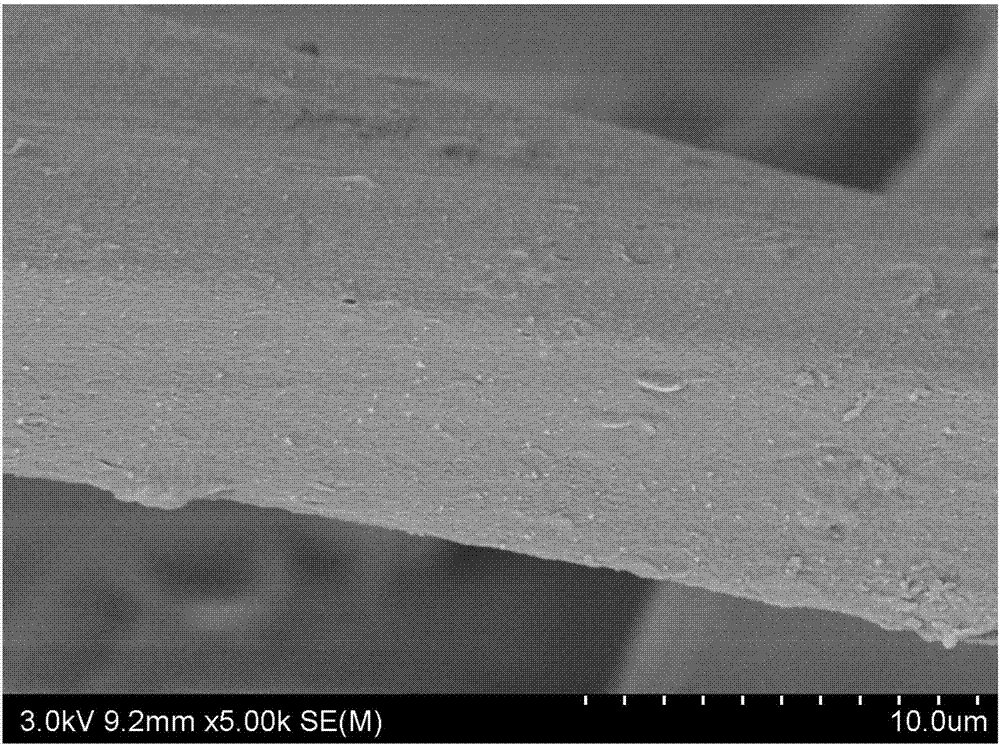

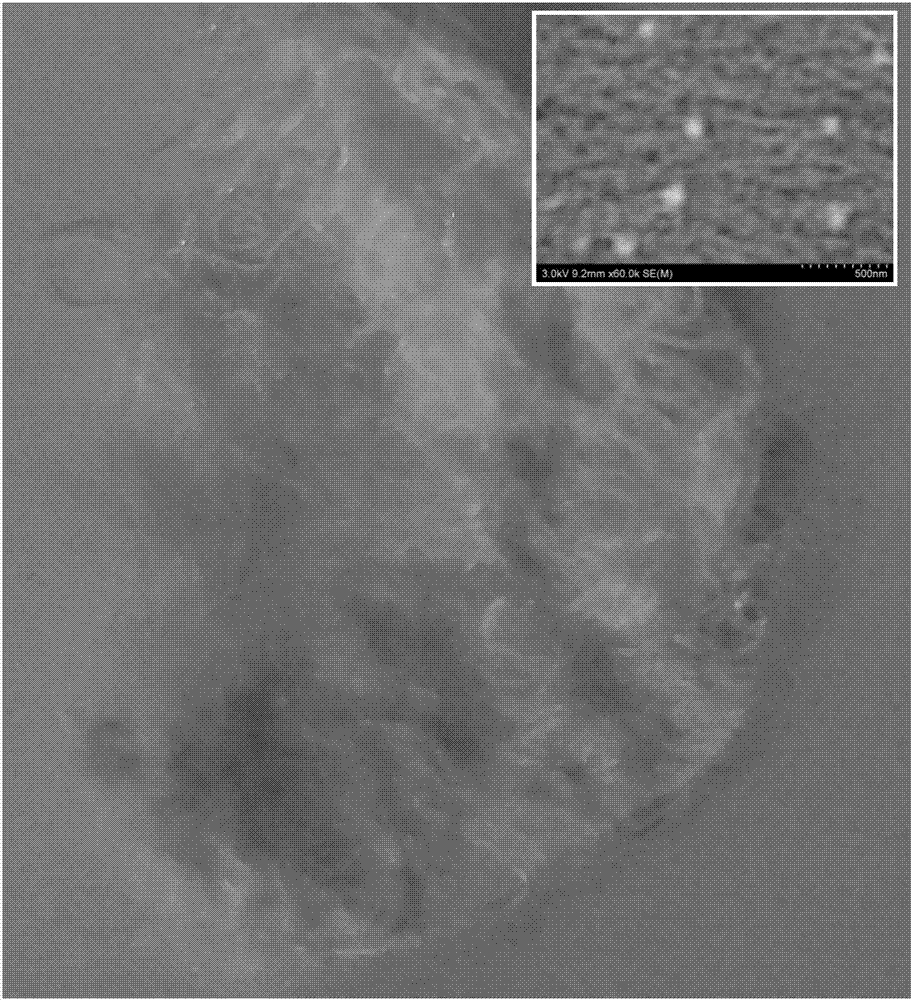

High-efficiency heavy metal adsorption and antibacterial nanofiber membrane and preparation method thereof

InactiveCN110878441AImprove antibacterial propertiesImprove adsorption capacityElectro-spinningMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention discloses a high-efficiency heavy metal adsorption and antibacterial nanofiber membrane and a preparation method thereof. Chemically bonded ionic liquid containing unsaturated bonds is uniformly distributed on the surface of polyether sulfone through Co-gamma radiation grafting chemical modification, and an electrostatic spinning method is carried out to prepare the membrane; a massratio of the ionic liquid to the polyether sulfone is (2-11):100. The polymeric nanofiber membrane according to the invention has excellent antibacterial and heavy metal adsorption properties.

Owner:HANGZHOU NORMAL UNIVERSITY

Antibacterial silk product with nano-copper and preparation method of antibacterial silk product with nano-copper

ActiveCN108004762AUniform penetrationUniform fixationBiochemical treatment with enzymes/microorganismsAnimal fibresReduction treatmentPollution

The invention discloses an antibacterial silk product with nano-copper and a preparation method of the antibacterial silk product with nano-copper. The preparation method comprises the following steps: immersing a silk product in a buffer solution containing monascus, then adding a copper hydrochloride solution for soaking the immersed silk product, then performing reduction treatment with a reducing agent, and finally, performing cleaning and drying to obtain the antibacterial silk product with nano-copper. The antibacterial silk product with nano-copper and the preparation method thereof have the advantages that the broad-spectrum antibacterial property of silk fibers and fabrics thereof can be improved, furthermore, harm to human bodies can be avoided, and pollution to the environment also can be avoided; the preparation method is simple and easy to realize batch production; and the prepared antibacterial silk fiber product has excellent and lasting antibacterial property.

Owner:湖州金裕丝绸科技有限公司

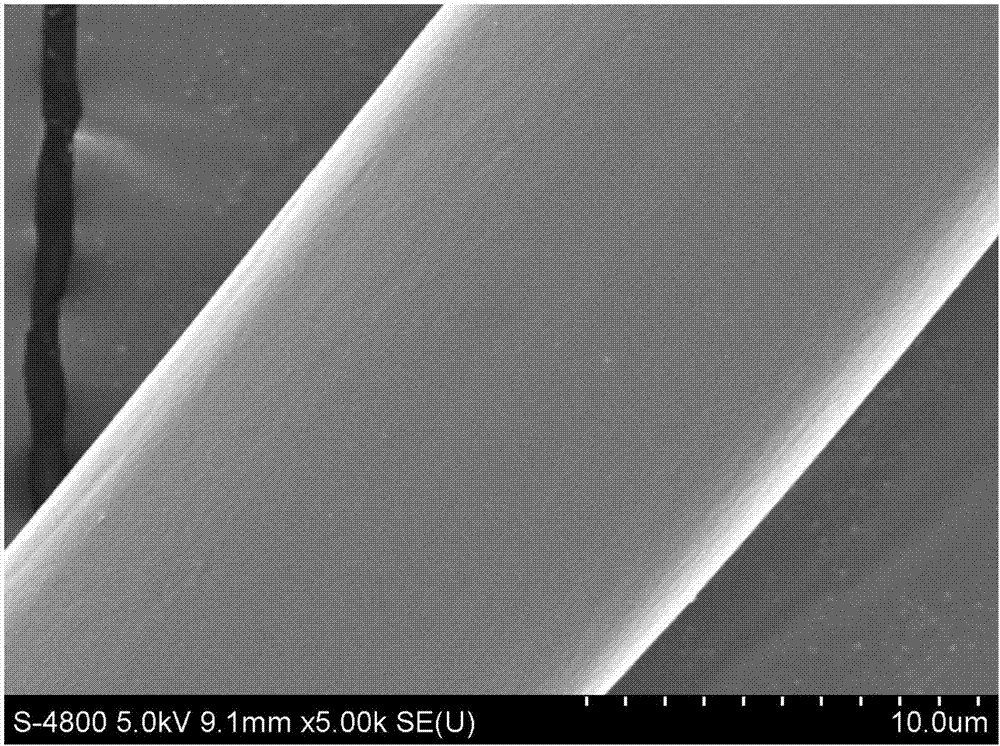

An antibacterial natural silk fiber product and a preparing method thereof

ActiveCN106917266AAvoid uneven loadUniform dispersionBiochemical fibre treatmentAnimal fibresFormic acidSilk fiber

An antibacterial natural silk fiber product and a preparing method thereof are disclosed. The method includes steps of preparing a formic acid solution, then adding a silver salt to the solution, stirring the solution to dissolve the silver salt, soaking a natural silk fiber product in the solution comprising the silver salt, performing a reaction for certain time, fully washing the reacted natural silk fiber product, and drying the natural silk fiber product to obtain the antibacterial natural silk fiber product. Wide-spectrum antibacterial performance of silk fibers and textiles thereof are improved, harm to human bodies is avoided, and environment pollution is avoided. The method is simple and prone to bulk production. The obtained antibacterial natural silk fiber product has good antibacterial performance, and the antibacterial performance is durable.

Owner:湖北福临花纺织有限公司

Preparation method for polyolefin film with anti-bacterial function

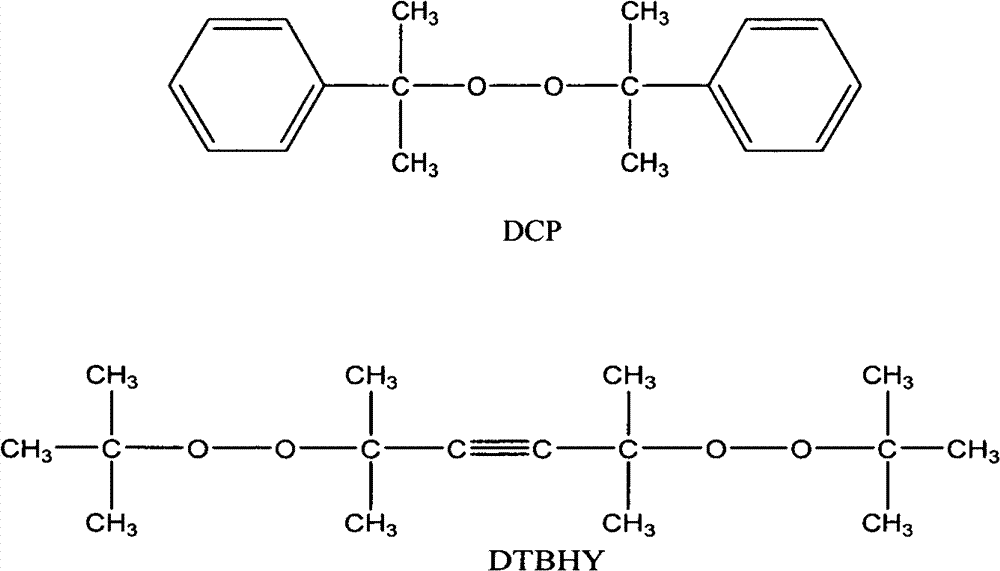

The invention discloses a polyolefin film with an anti-bacterial function. The sterilizing polyolefin film comprises the following raw materials by weight percentage of: 100 % of polyolefin, 1%-10% of a functional monomer containing double bonds and an amine structure, and 0.1%-4% of a radical initiator, the raw materials are subjected to reactive extrusion through a double-screw extruder so as to prepare modified polyolefin raw granules, the modified polyolefin raw granules are subjected to a blow molding and casting film forming process, and a functionality film the surface of which is provided with a chloramine structure is prepared. The polyolefin film with the anti-bacterial function, provided by the invention, has the advantages of strong sterilizing function, good mechanical property and the like, and the abuse that the conventional anti-bacterial film utilizes a rear processing method of a finishing agent is overcome. The polyolefin film with the sterilizing function, provided by the invention, can kill bacteria for one time, and a functional group containing the amine structure is changed into a functional group with a chloramine antibiosis structure through the amine chloration, so that a film material has a circulating anti-bacterial function.

Owner:ZHENDE MEDICAL CO LTD +1

Antibacterial and antiviral express packaging bag special material and preparation method thereof

The invention belongs to the field of antibacterial and antiviral polyolefin packaging bag special materials, and particularly relates to an antibacterial and antiviral express packaging bag special material and a preparation method thereof. The preparation method comprises the following steps: mixing polyolefin powder, an antioxidant, an auxiliary antioxidant, a halogen absorbent and an antibacterial agent in a high-speed stirrer for 2-3 minutes to obtain a mixture, and extruding and granulating the mixture by a double-screw extruder to obtain the antibacterial and antiviral express packaging bag special material. Polyolefin materials such as polypropylene and polyethylene have permanent antibacterial, mildew-proof and antiviral properties, and an express packaging bag produced by using the special material also has permanent antibacterial, mildew-proof and antiviral properties, so that the diffusion of pathogens is effectively prevented.

Owner:NORTH HUAJIN CHEM IND CO LTD

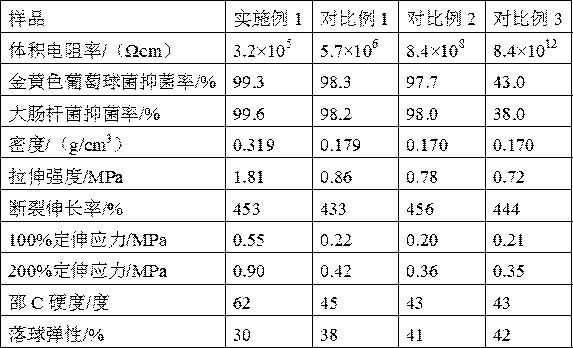

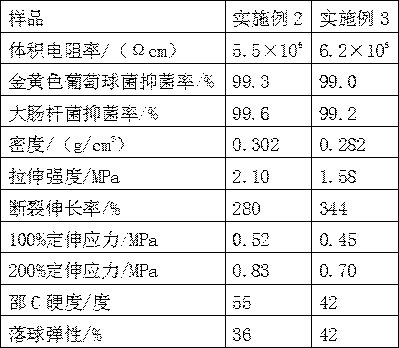

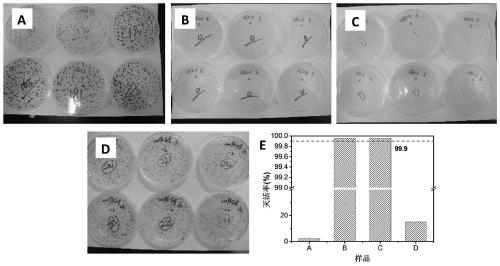

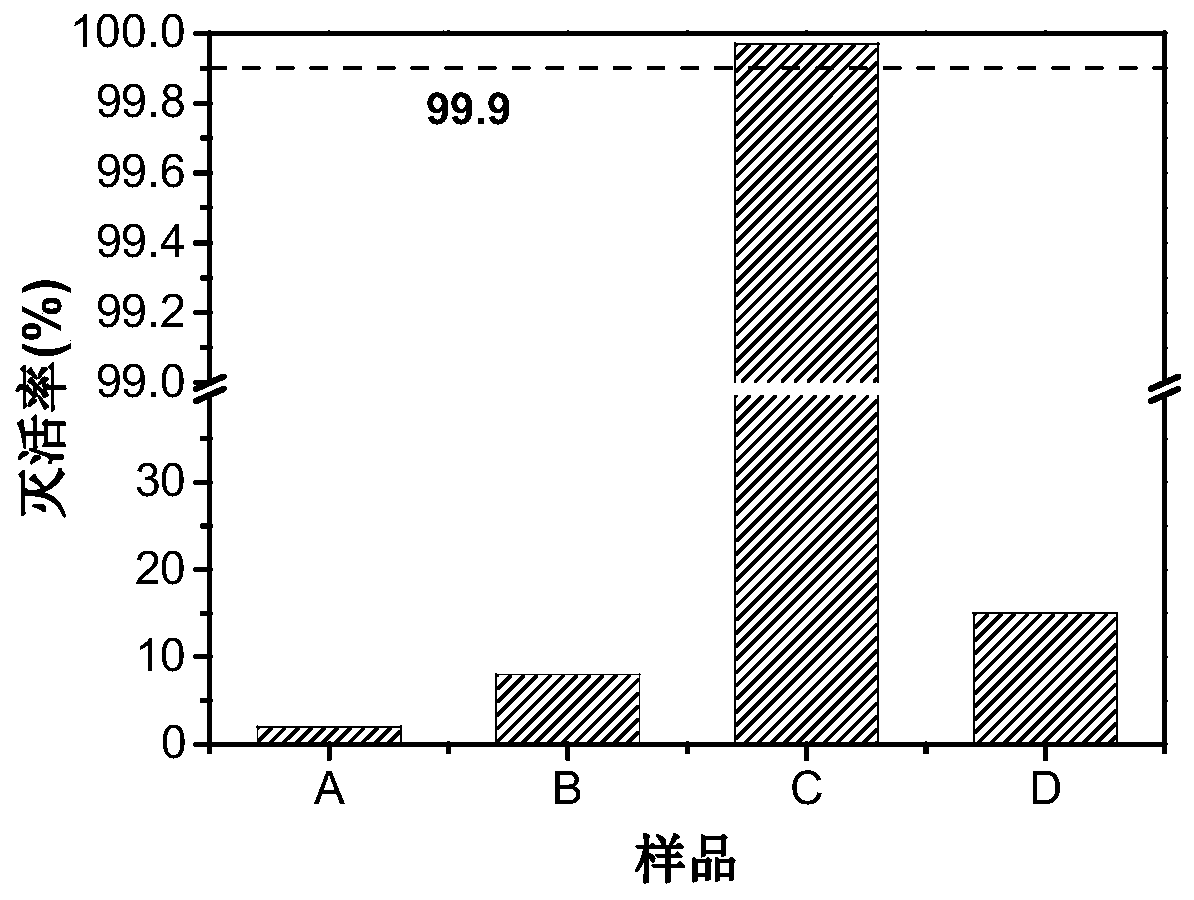

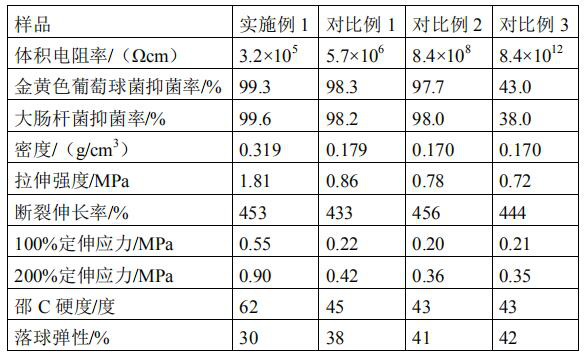

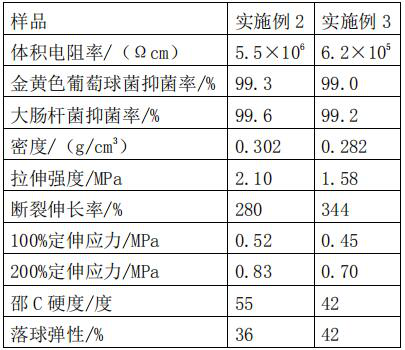

Antibacterial antistatic foamed elastomer material and preparation method thereof

ActiveCN111138749AHas antistatic propertiesImprove antibacterial propertiesElastomerAntimicrobial action

The invention provides an antibacterial antistatic foamed elastomer material and a preparation method thereof, and belongs to the technical field of foamed elastic materials. The preparation method comprises the following steps: placing tin antimony oxide particles in a quaternary phosphonium salt solution until adsorbing saturation, washing the particles, and drying and grinding and the particlesto obtain quaternary phosphonium salt modified tin antimony oxide; modifying the quaternary phosphonium salt modified tin antimony oxide with a coupling agent, and uniformly mixing with a modified polymer blend, a foaming agent, a cross-linking agent and a modified compounding agent to obtain a rubber compound; and carrying out foaming cross-linking shaping on the rubber compound to obtain the antibacterial antistatic foamed elastomer material. The foamed elastomer prepared by the preparation method not only has an antistatic property, but also has an excellent antibacterial effect, and can effectively destroy bacteria in an EVA use environment; and after being modified with the coupling agent, the quaternary phosphonium salt doped tin antimony oxide can be uniformly dispersed in the EVAmatrix, has permanent antibacterial and antistatic effects, and can be used as a packaging material, a shoe material and other products.

Owner:QINGDAO UNIV OF SCI & TECH

Stretch-resistant and aging-resistant plastic film

The invention discloses a stretch-resistant and aging-resistant plastic film. The stretch-resistant and aging-resistant plastic film comprises, by weight, 50-60 parts of PVC (polyvinyl chloride) resin, 20-25 parts of polystyrene, 10-15 parts of disulfide carbamic acid ester, 10-15 parts of elastomers, 10-15 parts of bamboo charcoal powder, 3-7 parts of plasticizers, 5-9 parts of sodium alginate, 10-14 parts of carbon fibers, 5-10 parts of glass fibers, 3-5 parts of 2-hydroxypropyl-beta-cyclodextrin, 3-5 parts of nanometer titanium dioxide powder, 2-4 parts of nanometer tin antimony oxide powder, 1-3 parts of light stabilizers, 2-4 parts of natural antibacterial agents and 2-4 parts of plant oil. The stretch-resistant and aging-resistant plastic film has the advantages that the stretch-resistant and aging-resistant plastic film is economical, environmentally friendly, antistatic, stretch-resistant, aging-resistant, fog-resistant, safe and reliable and is wide in application, and the physiochemical properties of the stretch-resistant and aging-resistant plastic film can be effectively controlled while high light permeability of the stretch-resistant and aging-resistant plastic film is guaranteed; excellent antibacterial, weather-resistant, stable, heat-insulation, anti-ultraviolet and self-cleaning effects can be realized by the stretch-resistant and aging-resistant plastic film, and the like.

Owner:安徽省天乐塑业有限公司

Antibacterial air-conditioning quilt

InactiveCN102342698AImprove antibacterial propertiesImprove breathabilityBed-coversCombingEngineering

The invention discloses an antibacterial air-conditioning quilt, which comprises a quilt cover and a quilt inner, wherein the quilt cover is made of combed pure cotton printed fabric; and the quilt inner is made by filling antibacterial cotton and silk fibers, wherein the antibacterial cotton accounts for 80 to 90 percent of the weight of the quilt inner, and the silk fibers account for 10 to 20 percent of the weight of the quilt inner. The antibacterial air-conditioning quilt overcomes the defects that a common air-conditioning quilt is not breathable and is easy to propagate bacteria and the like, and has antibacterial, mite-proof, moisture-absorbing and breathable properties and the like.

Owner:NANTONG XIYUN TRADE

A multi-component antibacterial non-woven fabric

ActiveCN102677394BHas antibacterial propertiesIncrease contact areaConjugated synthetic polymer artificial filamentsNon-woven fabricsChloramine BPolyester

The invention discloses a multi-component antibacterial non-woven fabric. The antibacterial non-woven fabric is formed by mixing 80%-20% by mass of modified polyamide and 20%-80% by mass of modified polyester, and preparing and molding through a spunbond spunlace process; and the surface of non-woven fabric fibre member is provided with a chloramine structure connected by covalent bond. The multi-component antibacterial non-woven fabric disclosed by the invention has the characteristics of strong sterilizing effect, ultrafine fibre, comfortable touch feeling and good mechanical property, and overcomes the defects of a post-treatment method using a finishing agent during traditional preparation of the antibacterial fabric; and the non-woven fabric disclosed by the invention is subjected to simple chloration so as to recycle the sterilizing effect of the non-woven fabric.

Owner:HUBEI SANYANG NEW TECH CO LTD

Environment-friendly ceramic glaze, and thermal-shock-resistant environment-friendly ceramic product prepared from same and preparation method thereof

PendingCN111559864APermanent antibacterialImprove antibacterial propertiesBiocideDisinfectantsKaolin clayAnti bacteria

The invention relates to an environment-friendly ceramic glaze, a thermal-shock-resistant environment-friendly ceramic product prepared from the environment-friendly ceramic glaze and a preparation method of the thermal-shock-resistant environment-friendly ceramic product, belonging to the technical field of domestic ceramics. The environment-friendly ceramic glaze disclosed in the invention comprises the following components in parts by mass: 100-130 parts of potassium feldspar, 5-15 parts of quartz, 1-3 parts of aluminum oxide, 2-4 parts of zinc oxide, 5-10 parts of an antibacterial base material, 5-12 parts of kaolin, 1-2 parts of molybdenum trioxide, 6-15 parts of diatomite, 10.5-15 parts of calcium carbonate, 1-2 parts of titanium diboride and 10-15 parts of waste ceramic particles. According to the invention, the ceramic glaze with permanent antibacterial property is prepared based on research on the antibacterial base material of the ceramic, and the ceramic product is endowed with excellent permanent antibacterial property and self-cleaning stain resistance after glazing and sintering; and the glaze surface of the ceramic product is smooth and not easy to stain, has excellent mechanical properties and acid and alkali resistance, and meets the requirements of domestic ceramics on the glaze surface.

Owner:福建德化瓷国文化股份有限公司

Manufacturing method of antifouling sofa fabric

ActiveCN106283340BIncrease sizing rateLess hairyTransfer printing processWarping machinesYarnTextile printer

The invention provides a method for making an antifouling sofa fabric, which belongs to the technical field of home textiles and comprises the following steps: (1) selecting raw materials for spinning; (2) yarn antifouling finishing; (3) warping and sizing; (4) weaving (5) transfer printing; (6) solid color finishing; (7) antifouling finishing; (8) water repellent finishing; (9) bonding: on the upper and lower sides of the sponge The adhesive is applied on the sides respectively, and pressure is applied to the upper base cloth layer, sponge and lower base cloth layer stacked up and down, so that the three are bonded into one; (10) sewing; the yarn processed by the warping and sizing machine The sizing rate on the line is high and the hairiness is small, which can reduce the static electricity generated by the friction between the yarns, effectively reducing the static electricity of the fabric itself, so the woven fabric is not easy to generate static electricity, and relatively difficult to absorb dust. The sofa fabric produced has multiple anti-fouling capabilities, and the anti-fouling effect is remarkable.

Owner:海宁宝祥布业有限公司

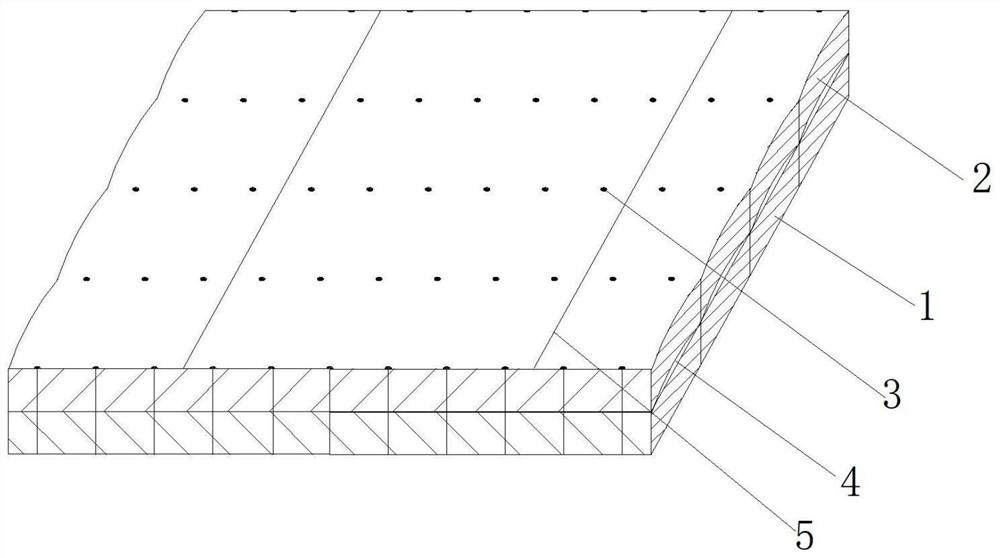

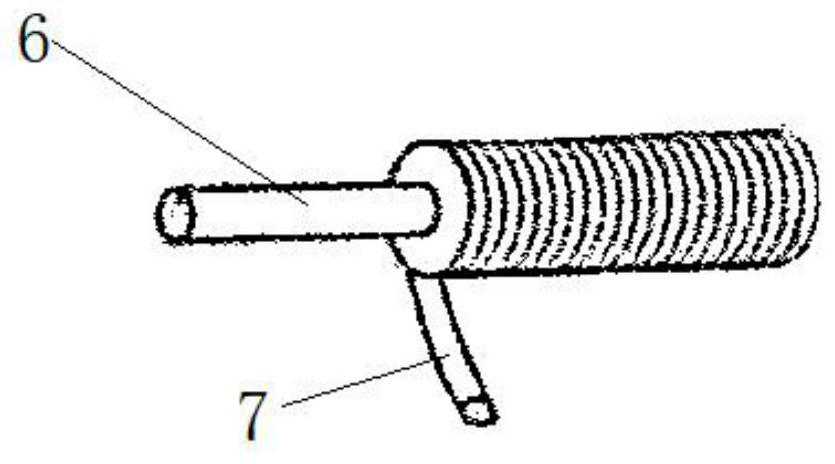

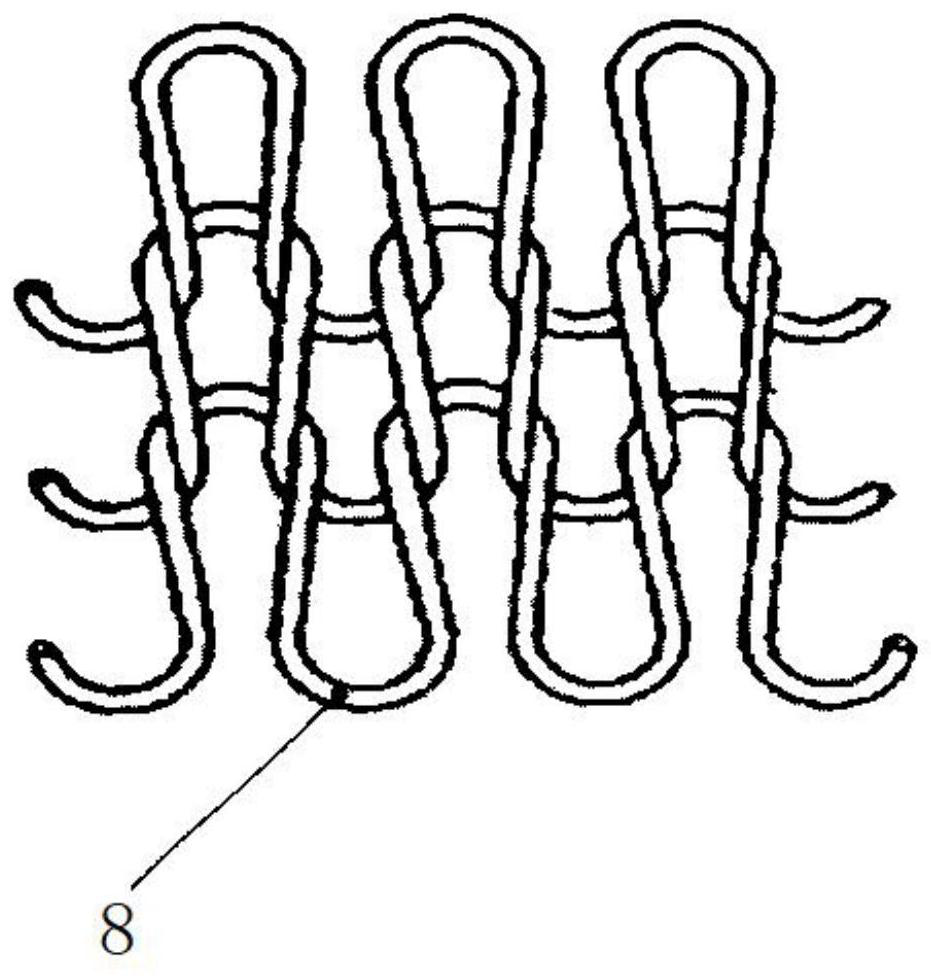

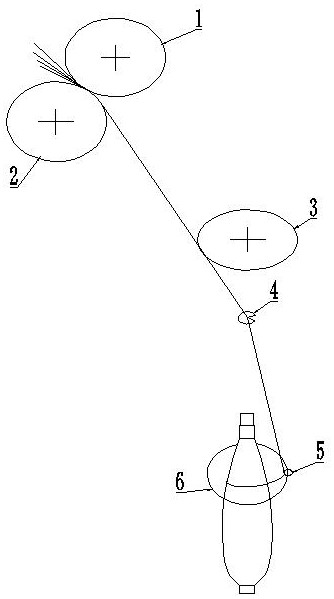

Easy-to-clean knitted fabric

ActiveCN113322569AEasy to spreadReduce contaminationWeft knittingLiquid/gas/vapor yarns/filaments treatmentPolyesterAnti bacterial

The invention provides a easy-to-clean knitted fabric. The easy-to-clean knitted fabric is a weft-knitted double-sided knitted fabric formed by connecting a front fabric 1 and a back fabric 2 through a connecting point 3. According to the invention, while the fabric is finished with a easy-to-clean auxiliary agent FC-226 and yarn is treated with a waterproof and oil-resistant auxiliary agent NB-NH, an easy-to-clean knitted fabric structure is designed. According to a yarn structure, wrap yarn is adopted, and the outer layer wrap yarn mainly needing to be cleaned is relatively easy to clean; and according to the fabric structure, the double-sided fabric structure is adopted, two layers are not tightly connected, a certain gap is reserved, and drop needle wales are arranged, so that washing water flow can easily pass through the space between the two layers of fabric, and cleaning is easy. According to the easy-to-clean knitted fabric, the easy-to-clean structure is configured according to the use mode of clothes; the inner side face of the fabric is more easily polluted by human bacteria, so that antibacterial polyester fibers are configured; and the outer side face of the fabric is more easily polluted by the environment, so that anti-pollution Sorona fibers are configured.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

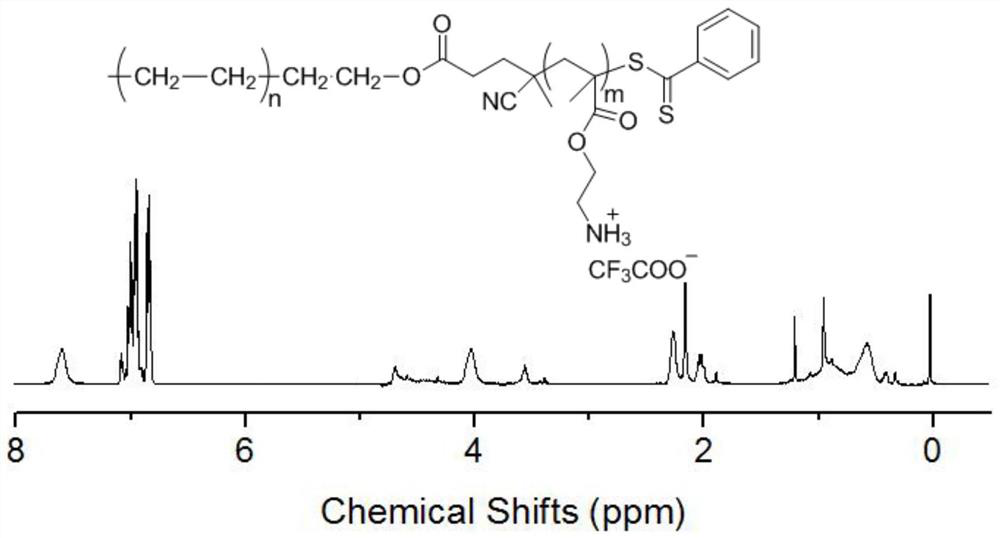

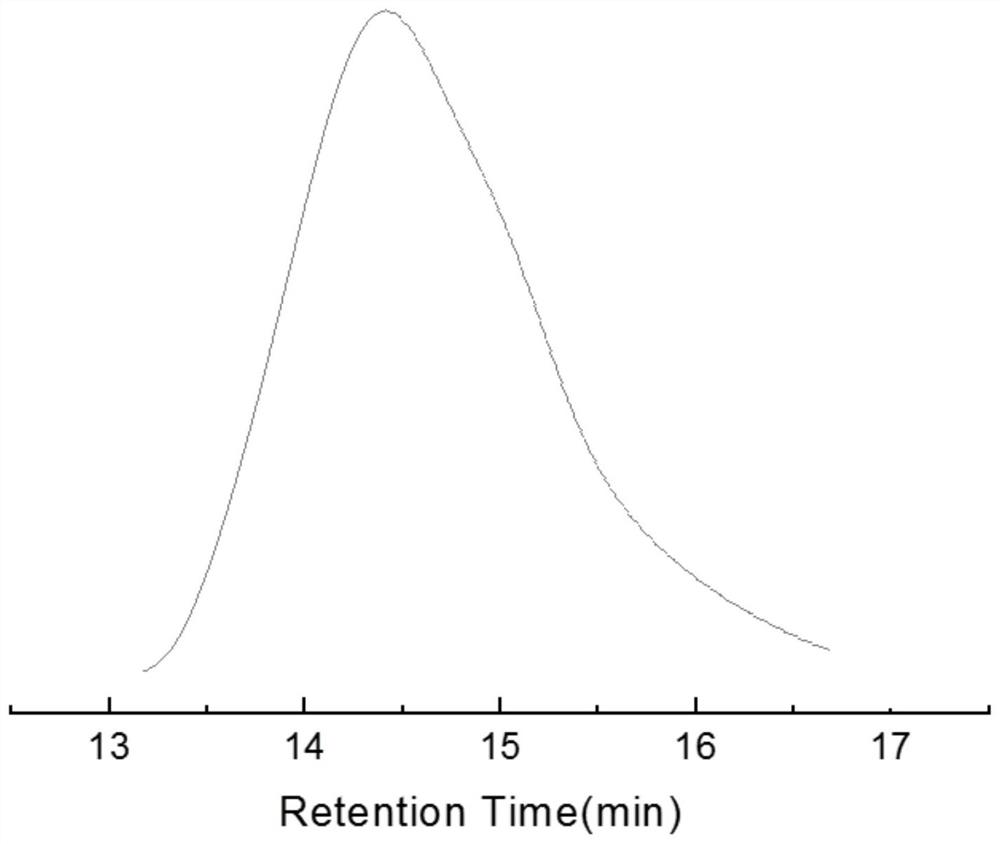

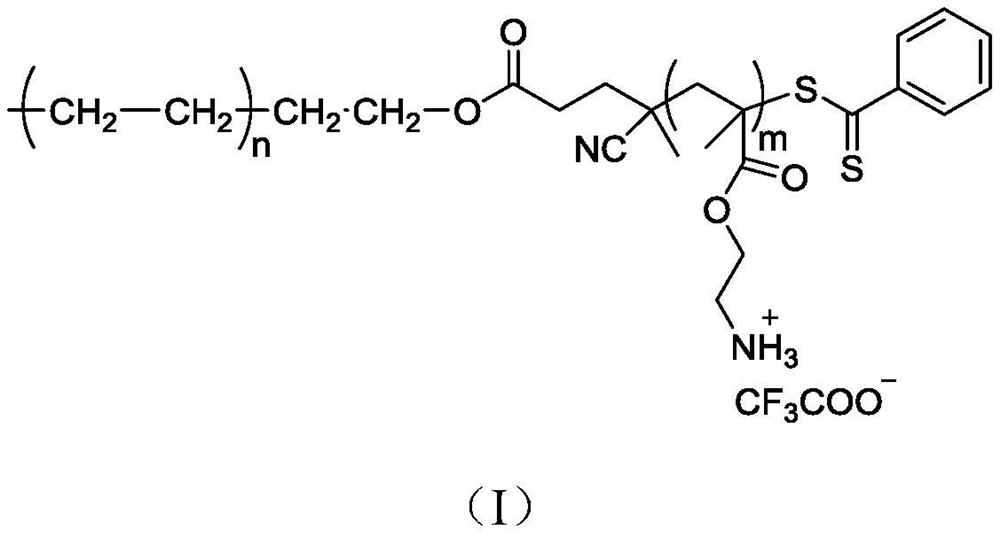

Ammonium salt antibacterial polyethylene material and preparation method thereof

InactiveCN112142931AImprove antibacterial propertiesPermanent antibacterialBiocideDisinfectantsEscherichia coliPseudomonas chlororaphis subsp. aureofaciens

The invention discloses an ammonium salt antibacterial polyethylene material and a preparation method thereof. The preparation method comprises the following steps: taking single-terminal hydroxyl polyethylene as a raw material, reacting with a chain transfer agent to obtain a polyethylene macromolecular chain transfer agent, and initiating ammonium salt polymerization by utilizing the polyethylene macromolecular chain transfer agent to obtain an ammonium salt antibacterial polyethylene material; the preparation process of the ammonium salt antibacterial polyethylene material is simple and non-toxic, and the obtained antibacterial material is safe and has lasting antibacterial property; good antibacterial activity is realized on proteus, pseudomonas aeruginosa, staphylococcus aureus and escherichia coli.

Owner:邓天生

A three-component supersoft antibacterial yarn of fine denier polyester, antibacterial polyester and cotton and its manufacturing method

The invention discloses a three-component supersoft antibacterial yarn of fine denier polyester, antibacterial polyester and cotton. According to weight percentage, fine denier polyester fiber accounts for 30%, antibacterial polyester fiber accounts for 20%, and cotton fiber accounts for 50%. The fiber is made into 14.8tex blended yarn through a blending process; its manufacturing method includes the following steps: S1, raw material selection; S2, raw material pretreatment; S3, cleaning and carding process; S4, drawing process; S5, roving process; S6, Spinning process: After the roving is drafted, the roving is output from the nip formed by the front rubber roller and the front roller, and then passes through the single-disc runner section with a matching speed, and then passes through the yarn-guiding ceramics, steel wire coil and steel collar run to form a low-twist yarn; the antibacterial yarn made by the present invention has the characteristics of evenness, high strength, softness, fluffy, and long-lasting antibacterial performance; The antibacterial effect is obvious, and the bacteriostatic rate reaches 99%.

Owner:潍坊迅纺新材料科技有限公司

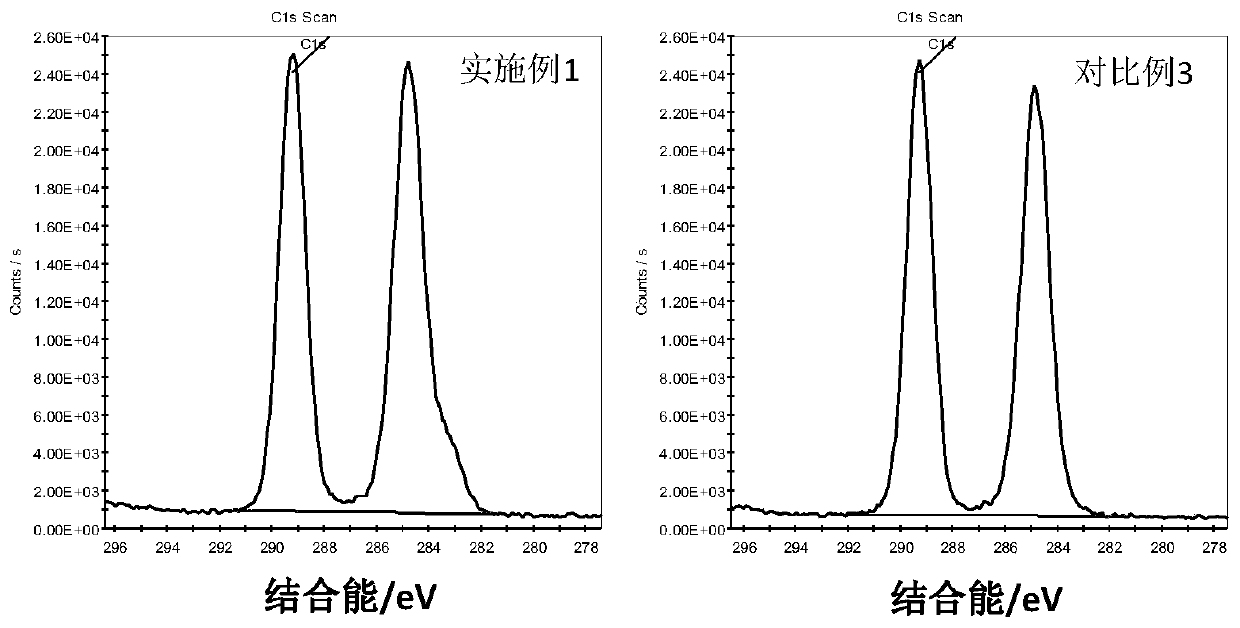

A kind of permanent antibacterial polymer composite material and preparation method thereof

ActiveCN107903561BImprove antibacterial propertiesImprove electrochemical stabilityHollow filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceNonwoven fabric

The invention discloses a permanent antibacterial polymer composite material and a preparation method thereof. According to the present invention, various materials such as polymer films, fibers, non-woven fabrics and the like are prepared by selecting different polymer molding technologies while an ion liquid is uniformly distributed and chemically bonded on the material surface, such that the material has good antibacterial effect; and the ion liquid and the polymer molecule are linked through the chemical bond, such that the loss of the ion liquid (antibacterial agent) due to migration andother causes during the long-term use can be avoided so as to maintain the permanent antibacterial performance.

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of antibacterial and antistatic foamed elastomer material and preparation method thereof

ActiveCN111138749BHas antistatic propertiesImprove antibacterial propertiesAntimicrobial actionElastomer

The invention provides an antibacterial and antistatic foamed elastomer material and a preparation method thereof, belonging to the technical field of foamed elastic materials. The preparation method comprises: placing tin antimony oxide particles in a quaternary phosphonium salt solution to absorb to saturation, drying and grinding after washing to obtain quaternary phosphonium salt modified tin antimony oxide; The coupling agent is modified, and then mixed with the modified polymer blend, foaming agent, cross-linking agent and modified compounding agent to obtain a rubber compound; the above-mentioned rubber compound is foamed, cross-linked and shaped to obtain an antibacterial Antistatic foam elastomer material. The foamed elastomer prepared by the present invention not only has antistatic properties, but also has excellent antibacterial effect, and can effectively destroy bacteria in the environment where EVA is used; secondly, the quaternary phosphonium salt doped tin antimony oxide is modified by a coupling agent, It can be evenly dispersed in the EVA matrix, has permanent antibacterial and antistatic effects, and can be used as packaging materials, shoe materials and other products.

Owner:QINGDAO UNIV OF SCI & TECH

Fine denier polyester, antibacterial polyester and cotton three-component super-soft antibacterial yarn and manufacturing method thereof

The invention discloses a fine denier polyester, antibacterial polyester and cotton three-component super-soft antibacterial yarn. The antibacterial yarn is prepared from the following components in percentage by weight: 30% of fine denier polyester fibers, 20% of antibacterial polyester fibers and 50% of cotton fibers, and 14.8 tex blended yarn is prepared from the fibers through a blending process; a manufacturing method of the antibacterial yarn comprises the following steps: S1, selecting raw materials; S2, pretreating the raw materials; S3, conducting a blowing and carding procedure; S4, conducting a drawing procedure; S5, conducting a roving procedure; and S6, conducting a spinning procedure, specifically, drawing the rough yarn, outputting the rough yarn through a jaw formed by a front rubber roller and a front roller, cutting the rough yarn through a single-wheel-disc rotating wheel with a set matching speed, and running through yarn guide ceramic, a steel wire coil and a steel collar to form low-twist yarn. The prepared antibacterial yarn has the characteristics of being uniform in evenness, high in strength, soft, fluffy, lasting in antibacterial performance and the like; and the antibacterial effect on three strains including escherichia coli bacteriostasis rate, glucococcus and candida albicans is obvious, and the bacteriostasis rate reaches 99%.

Owner:潍坊迅纺新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com