Multi-component antibacterial non-woven fabric

A non-woven fabric, multi-component technology, applied in the direction of non-woven fabrics, textiles and papermaking, conjugated synthetic polymer artificial filaments, etc., can solve the problems of limited application range, large amount of waste water, poor washing resistance of fabrics, etc. , to enhance the bactericidal effect and increase the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation process steps of a multi-component antibacterial non-woven fabric are as follows:

[0031] 1 Preparation of modified polyamide and modified polyester

[0032] Mix polyamide, monomers containing double bonds and amine structures, and free radical initiator amine in a mass ratio of 100:1 to 10:0.1 to 0.4, dry for 2 hours, then mix evenly, and prepare by twin-screw reactive extrusion .

[0033] The modified polyamide is prepared by mixing polyamide, functional monomer containing amine structure, and free radical initiator at a mass ratio of 100:1-10:0.1-0.4, and then extruding through twin-screw reaction.

[0034] The melting point range of the polyamide is between 210°C and 270°C.

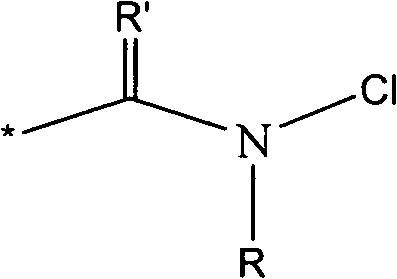

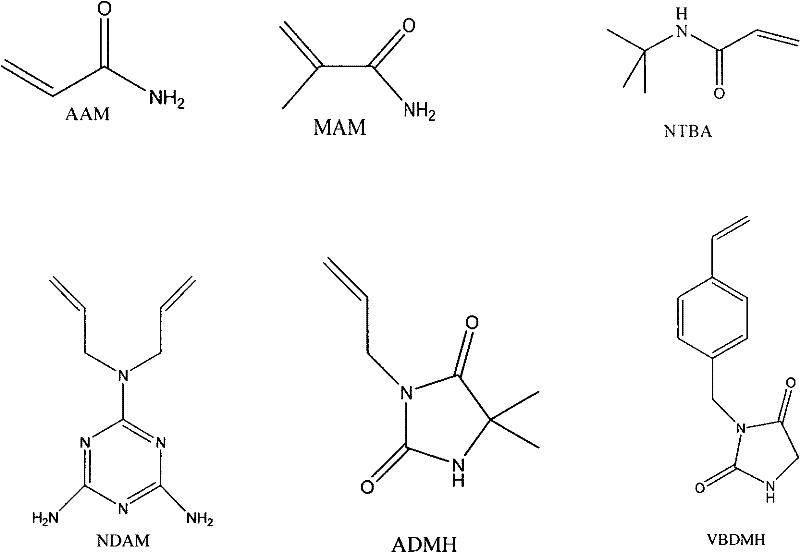

[0035] The functional monomers containing double bonds and amine structures are acrylamide (AAM), acrylamide (MAM), N-tert-butylacrylamide (NTBA), 2,4-diamino-6-diallyl Amino-1,3,5-triazine (NDAM) or 3-allyl-5,5-dimethylhydantoin (ADMH), 3-(4-vinylbenzyl)-hydantoin (VBDMH) ...

Embodiment 1

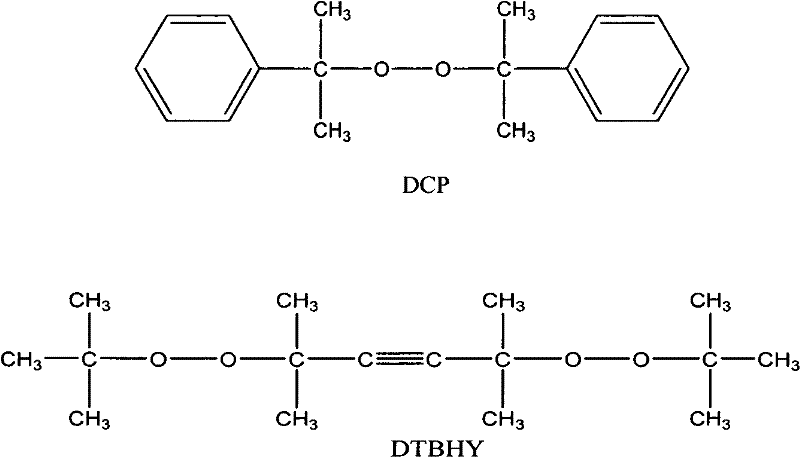

[0056] 1000 kg of polyethylene terephthalate (PET), 10 kg of AAM, and 1 kg of DCP were dried for 2 hours, then mixed uniformly, and nitrogen was introduced into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through melting reaction, and granulated into antibacterial particles. Among them, the temperature settings of each heating zone of the twin-screw extruder are: zone 1 temperature: 230°C; zone 2: 240°C; zone 3: 250°C; zone 4: 245°C; zone 5: 245°C; zone 6: 250; Zone 7: 250°C; machine head: 260°C; residence time: 2-3 minutes. The pressure is 15MPa. Modified PET chips.

[0057] Dry 1000 kg of polyhexamethylenediamine adipic acid (PA66), 10 kg of AAM, and 1 kg of DTBHY for 2 hours, then mix evenly, and blow nitrogen into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through me...

Embodiment 2

[0061] 1000 kg of polyethylene terephthalate (PET), 100 kg of MAM, and 4 kg of DCP were dried for 2 hours, then mixed uniformly, and nitrogen was introduced into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through melting reaction, and granulated into antibacterial particles. Among them, the temperature settings of each heating zone of the screw are: Zone 1: 230°C; Zone 2: 240°C; Zone 3: 250°C; Zone 4: 245°C; Zone 5: 245°C; Zone 6: 250; Zone 7: 250°C ; Head: 260 ° C; residence time 2 ~ 3min. The pressure is 15MPa. Obtain modified PET slices.

[0062] Dry 1000 kg of polyhexamethylenediamine adipic acid (PA66), 100 kg of MAM, and 4 kg of DCP for 2 hours, then mix well, and feed nitrogen into the container of the screw extruder for 5 minutes to remove oxygen. The mixed material is put into the hopper of the twin-screw extruder, extruded through melting reaction, and granulate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com