Antibacterial fibroin protein fiber and preparation method thereof

A protein fiber and antibacterial silk technology, applied in fiber treatment, animal fiber, biochemical fiber treatment, etc., can solve the problems of poor bonding fastness, low adhesion, and limited application and promotion, and achieve permanent antibacterial properties and low biological toxicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

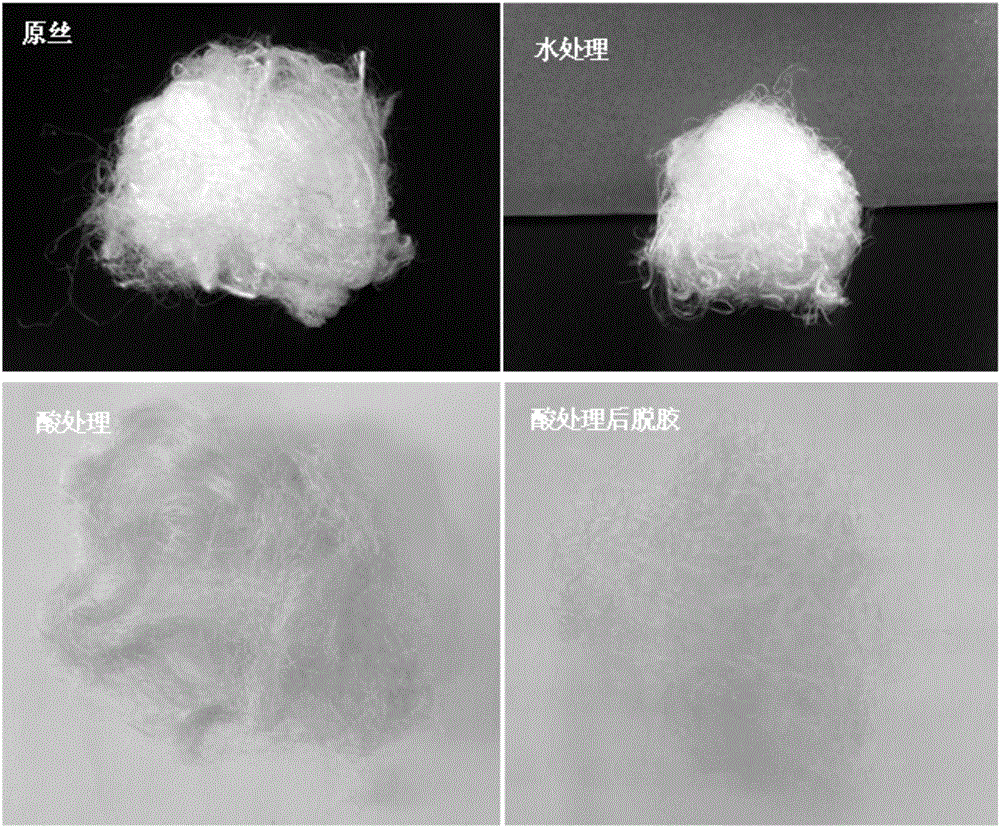

[0036] Prepare an aqueous solution of formic acid with a mass fraction of 90%, and then add silver nitrate to the formic acid solution, with a mass fraction of silver nitrate of 0.001%, and dissolve it under magnetic stirring in the dark for 5 minutes; immerse the undegummed natural mulberry silk raw silk in the formic acid solution, and keep it in the dark for 1 hour. 4°C; the obtained raw silk is fully washed with water, and after natural drying, the silk fiber containing nano-silver is obtained; the silver nitrate aqueous solution is used as a control treatment, and the silk fiber containing nano-silver is also obtained;

[0037]Degumming silk fibers containing nano-silver with 0.05% sodium carbonate aqueous solution, the bath ratio of silk and sodium carbonate solution is 1:50, repeat degumming three times, wash with deionized water, and dry naturally to obtain antibacterial silk fibroin fibers; The tensile strength of the raw silk before treatment is 410MPa, and after trea...

Embodiment 2

[0041] Configure an aqueous solution of formic acid with a mass fraction of 98%, and then add silver nitrate to the formic acid solution, with a mass fraction of silver nitrate of 0.01%, and dissolve with magnetic stirring in the dark for 15 minutes; immerse the undegummed natural mulberry cocoon silk in the formic acid solution, and keep it in the dark for 5 hours. 20°C; then fully washed with water, and after natural drying to obtain antibacterial silkworm cocoons; degumming the antibacterial silk with 0.25% sodium bicarbonate aqueous solution, the bath ratio of silk and sodium bicarbonate solution is 1:40, and repeat the degumming three times , washed with deionized water, and dried naturally to obtain antibacterial silk fibroin fibers.

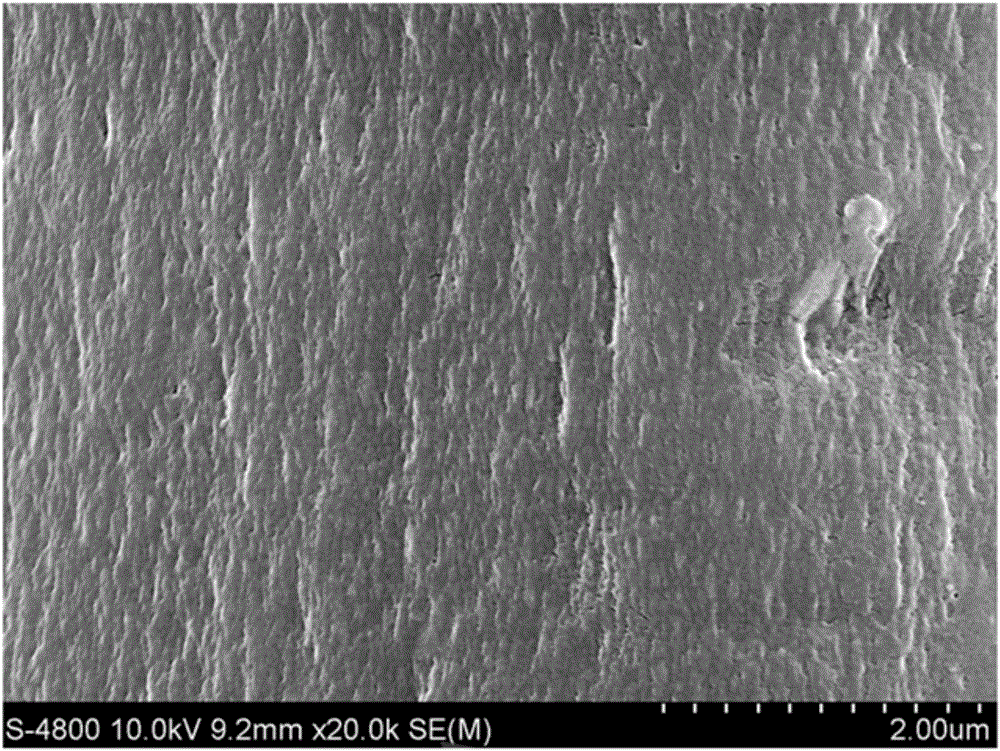

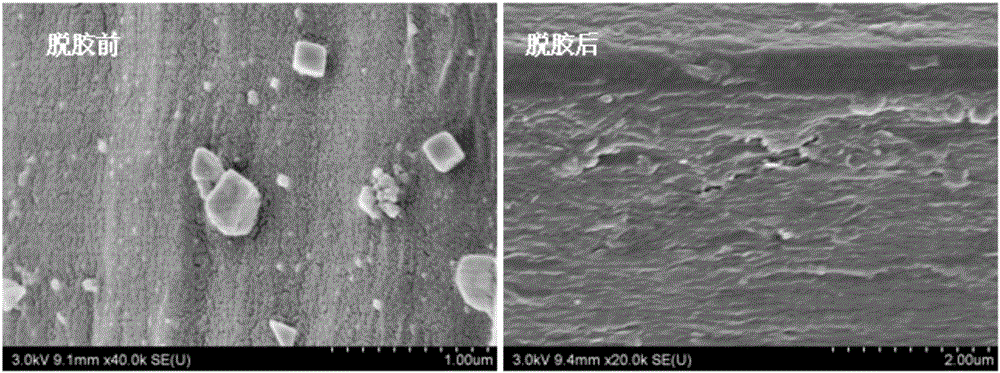

[0042] like image 3 Shown are scanning electron microscope pictures of silver-containing silk before and after degumming. It can be seen from the figure that before degumming, the surface of silk fiber contains many impurities and many na...

Embodiment 3

[0048] Prepare a formic acid ethanol solution with a mass fraction of 85%, then add silver fluoride to the formic acid solution, the silver fluoride mass fraction is 0.1%, and stir for 30 minutes in the dark to dissolve; immerse the undegummed natural tussah silk in the formic acid solution, and keep it in the dark for 2 hours , temperature 14°C; the obtained natural tussah silk was fully washed, and after natural drying, the tussah silk fiber containing nano-silver was obtained; finally, the tussah silk was degummed with 0.5% sodium carbonate aqueous solution, and the bath ratio of silk and sodium carbonate solution was 1 : 50, repeated degumming three times, washed with deionized water, and dried naturally to obtain antibacterial tussah silk fibroin protein fibers; the inhibition rate of E. After sub-standard washing, the antibacterial silk still retains more than 85% of the antibacterial effect, indicating that the antibacterial fastness is high.

[0049] like Figure 4 Sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com