Permanent antibacterial polymer composite material and preparation method thereof

A composite material and polymer technology, applied in the direction of single-component synthetic polymer rayon, hollow filament manufacturing, fiber chemical characteristics, etc., can solve the problems of reducing the antibacterial performance of materials, prone to precipitation, and loss of antibacterial agents, etc., to achieve Good electrochemical and thermal stability, low vapor pressure, good bactericidal and bacteriostatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

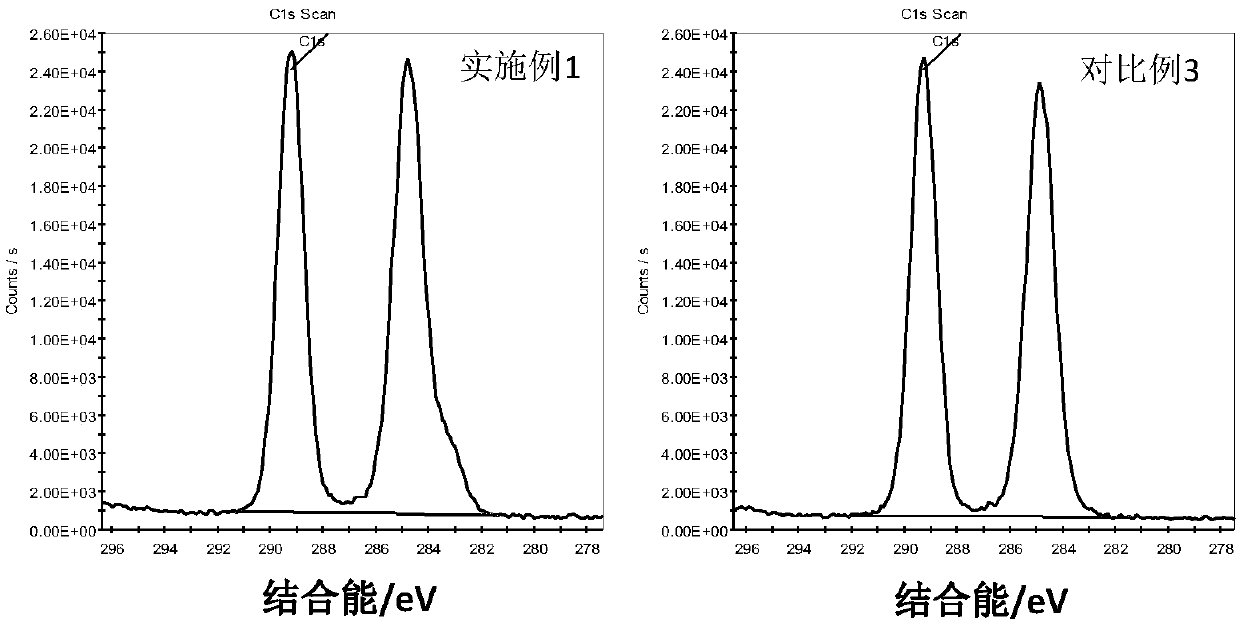

Embodiment 1

[0053] Step (1) First, 100g of PVDF and 0.001g of 1-vinyl-3-propylimidazolium bromide are added to the melt blending equipment (specific equipment), the temperature is 200°C, and when the rotation speed is 20rpm / min, kneading The mixing time is 1 min; when the rotating speed is 60 rpm, the mixing time is 5 min. Then discharge, obtain the blend of PVDF and IL, be denoted as PVDF / IL (100 / 0.001) blend.

[0054] Step (2) Put the above-mentioned PVDF / IL (100 / 0.001) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 20 kGy.

[0055] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite membrane, the molding temperature is 200° C., the pressure is 15 MPa, the pressure is maintained for 2 minutes, and the thickness is 300 microns.

Embodiment 2

[0057] Step (1) First, 100g of PVDF and 0.002g of 1-vinyl-3-propylimidazolium bromide are added to the melt blending equipment (specific equipment), the temperature is 200°C, and when the rotation speed is 25rpm / min, kneading The mixing time is 1 min; when the rotating speed is 50 rpm, the mixing time is 6 min. Then discharge, obtain the blend of PVDF and IL, be denoted as PVDF / IL (100 / 0.002) blend.

[0058] Step (2) Put the above-mentioned PVDF / IL (100 / 0.002) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 25 kGy.

[0059] Step (3) directly press-molding the graft blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite film, the molding temperature is 190° C., the pressure is 15 MPa, the pressure is maintained for 2 minutes, and the thickness is 300 microns.

Embodiment 3

[0061] Step (1) First, 100g PVDF and 0.04g 1-vinyl-3-propylimidazolium bromide are added to the melt blending equipment (specific equipment), the temperature is 190°C, and the rotation speed is 20rpm / min, mixing The time is 1min; when the rotation speed is 60rpm, the mixing time is 5min. Then discharge, obtain the blend of PVDF and IL, be denoted as PVDF / IL (100 / 0.04) blend.

[0062] Step (2) Put the above-mentioned PVDF / IL (100 / 0.04) film into a polyethylene ziplock bag. In electron beam irradiation, irradiation at normal temperature was performed at an irradiation dose of 50 kGy.

[0063] Step (3) directly press-molding the grafted blend obtained by the above-mentioned irradiation to obtain an antibacterial polymer composite membrane at a molding temperature of 195° C., a pressure of 10 MPa, a pressure hold of 2 minutes, and a thickness of 300 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com