Permanent radiation-proof anti-bacterial and anti-static worsted cashmere fabric and production method

A technology for worsted fabrics and cashmere, which is applied in textiles, textiles, papermaking, fabrics, etc., can solve the problems of non-permanent antibacterial, anti-radiation, high static electricity and low cohesion of worsted fabrics, so as to reduce the impact on the human body. The harm of suede, the effect of full suede and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

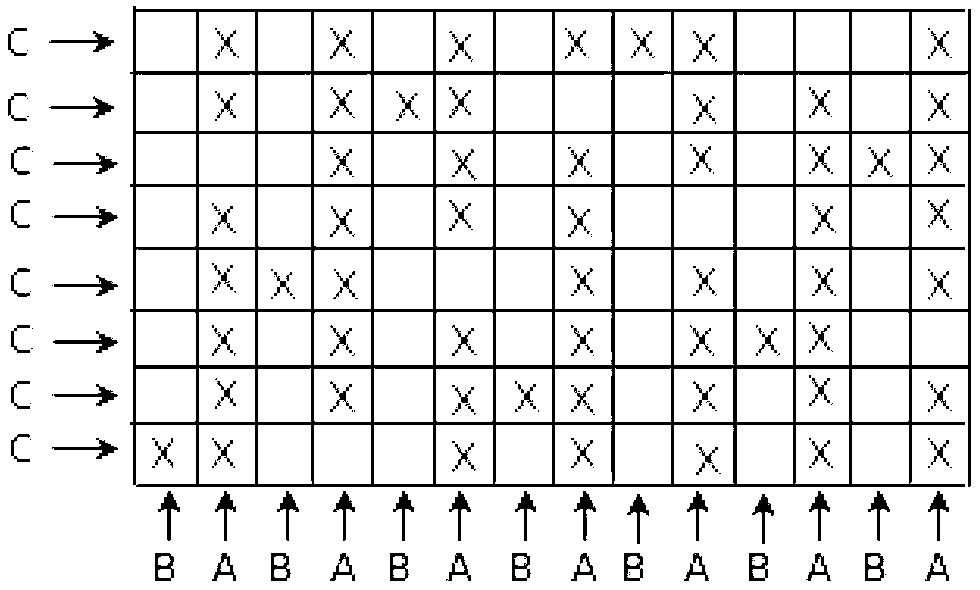

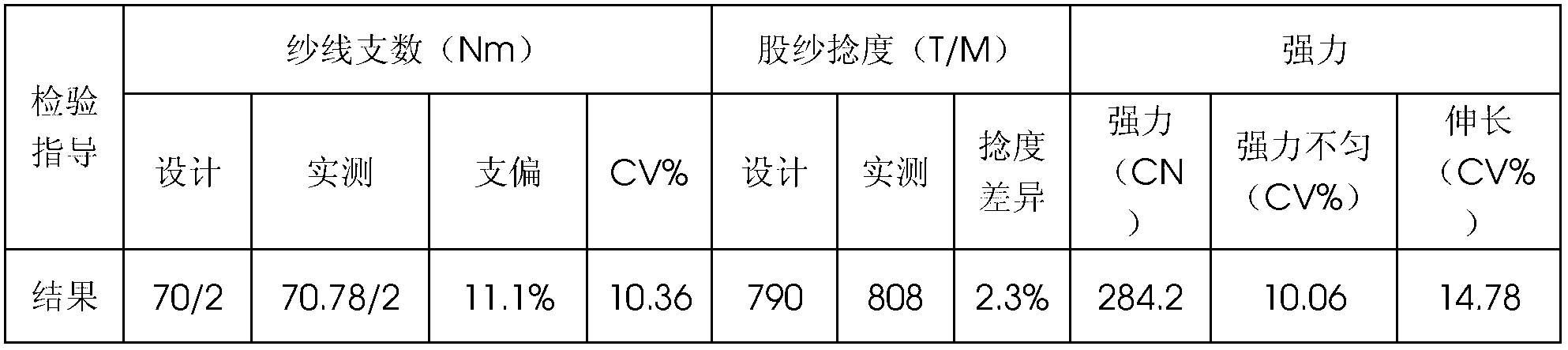

[0020] 1. The equipment and selection of raw materials: (1) The length of Conlon and conductive fiber is 38-40mm; (2) The length of cashmere is 38-45mm; (3) The specification of silver-plated filament is 22dtex / 3f; (4) Goat Cashmere content is 30%-35%, Conlon fiber content is 55-59%; (5) Silver-plated fiber content is 8%; (6) Conductive fiber is 2%, and the fabric is worsted fabric; (7) The structure is double-layer fabric .

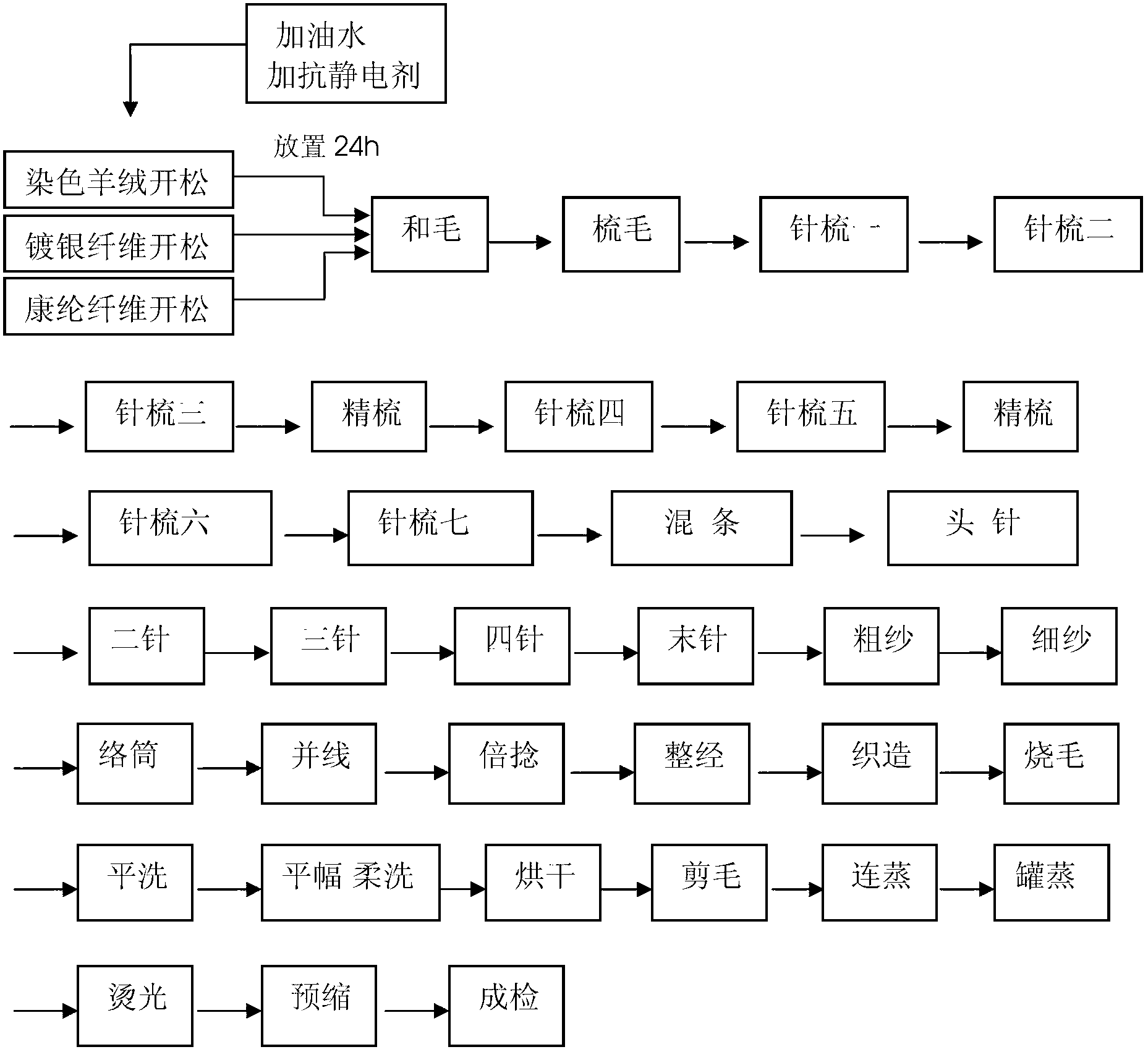

[0021] 2. Technological process

[0022] See figure 1 .

[0023] 3. Specific technology

[0024] (1) Open the cashmere and put oil and water evenly for 24 hours to ensure that the oil content of the cashmere is in the range of 1.2-1.5%, the moisture regain is in the range of 19.5-21.5%, and the moisture content is even;

[0025] (2) Loosen the 38mm of Conlon fiber and silver-plated fiber respectively;

[0026] (3) The above-mentioned three kinds of fibers and the imported antistatic agent are mixed according to the proportion required by the process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com